Drilling and countersinking integrated dagger drill

An integrated, dagger technology, applied in drilling/drilling equipment, drill repair, drilling tool accessories, etc., can solve problems affecting product qualification rate, low work efficiency, troublesome processing, etc., achieve good edge finish, improve processing Efficiency, sharp knife effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

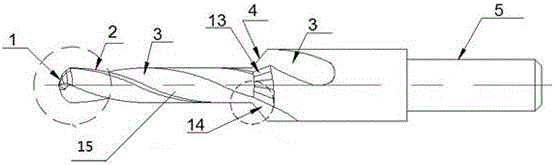

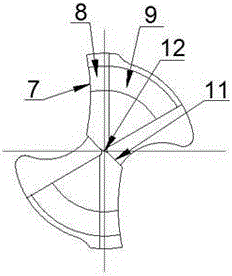

[0023] Embodiment 1, according to the attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , the present invention is a countersinking integrated dagger drill, which is characterized in that a countersinking integrated dagger drill includes a drill body 15, a drill tip 1 is provided at the front end of the drill body 15, and a drill tip 1 is arranged along the surface of the drill body 15. There is a helical cutting edge part 2, a chip flute 3, and a countersink part 4 is provided at the lower end of the drill body. Angular, the drill tip 1 includes a rake face 7, a first flank face 8, a second flank face 9, a backlash chip flute 10, a backlash entry angle 11, and a chisel edge angle 12. The chip removal The groove 3 extends helically from the drill tip to the handle portion 5 , and the countersinking portion includes a countersinking step angle and a tool undercut 6 .

Embodiment 2

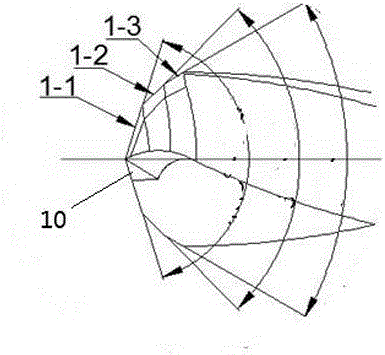

[0024] Embodiment 2, in the drill and countersink integrated dagger drill described in Embodiment 1, the three-vertex shape of the drill tip 1 includes a first corner 1-1, a second corner 1-2, and a third corner The apex angle 1-3, the first apex angle 1-1 is 140°~150°, the second apex angle 1-2 is 85°~95°, and the third apex angle 1-3 is 55° ~65°.

Embodiment 3

[0025] Embodiment 3, In the integrated countersinking dagger drill described in Embodiment 1, the countersinking portion includes a rake face 14 and a flank 13, and the countersinking step angle is 16°~18°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com