Drilling ink and application thereof

A technology for ink and drilling, which is applied in ink, applications, household appliances, etc., can solve the problems of easy generation of burrs or residues, and high production costs, so as to improve drilling efficiency and drilling accuracy, reduce production costs, and avoid The effect of debris wrapped around the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

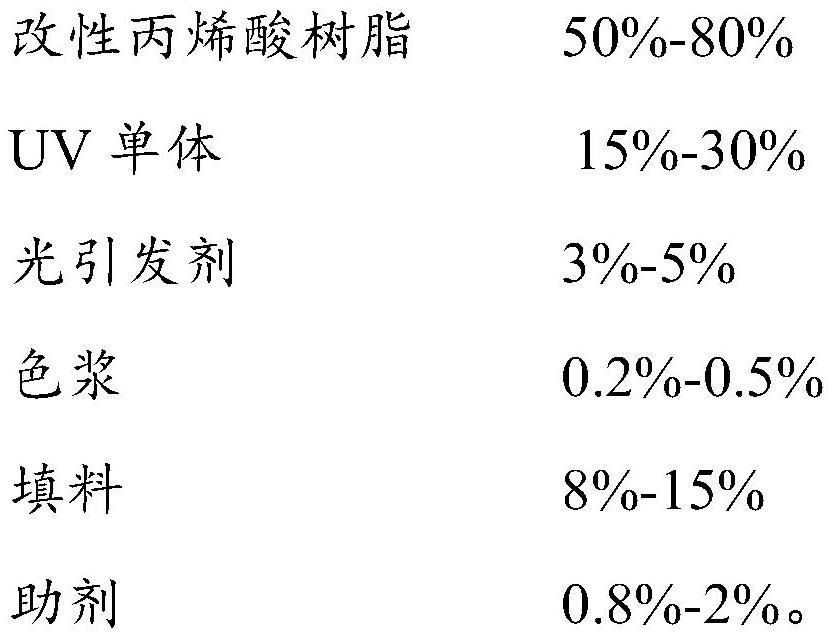

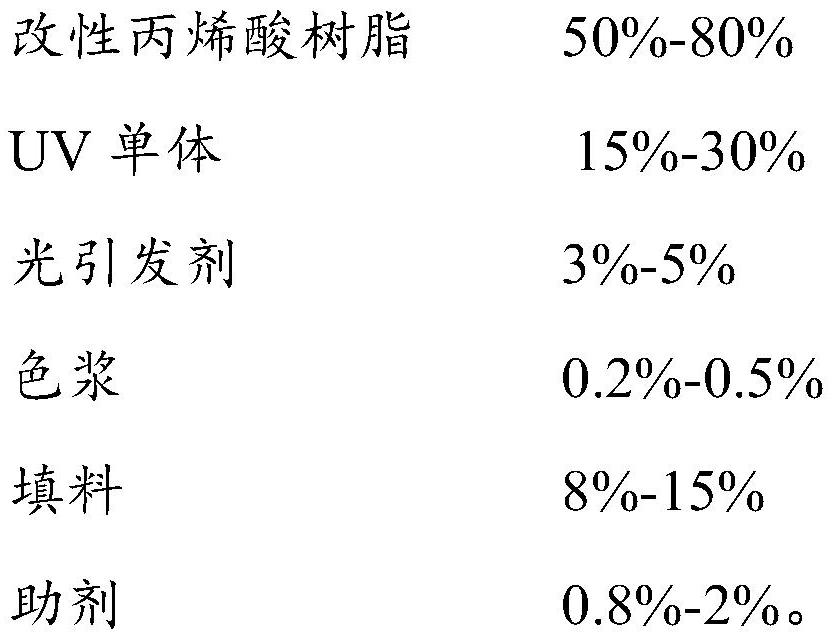

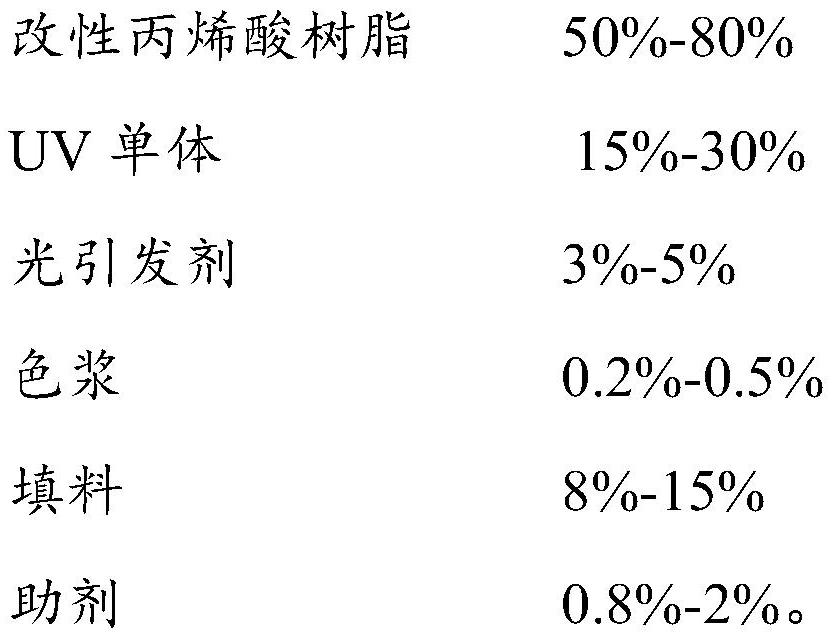

[0050] The embodiment of the present invention provides a preparation method of drilling ink, comprising the following steps:

[0051] S1. Provide modified acrylic resin, UV monomer, photoinitiator, color paste, filler, and auxiliary agent according to the above-mentioned drilling ink formula;

[0052] S2. Mix the modified acrylic resin, UV monomer, photoinitiator, color paste, filler and auxiliary agent to obtain the drilling ink.

[0053] Preferably, in the present invention, each component in S2 is added sequentially in the following order: photoinitiator, UV monomer, auxiliary agent, modified acrylic resin, filler, color paste; among the above components, each component should be added before adding Ensure that the aforementioned components are fully dispersed and evenly distributed. The dispersibility of the drilling ink obtained in this way is better, and it is easier to obtain a smooth and flat ink film when applied to the surface of the printed circuit board to be dri...

Embodiment 1

[0066] A kind of drilling ink, its preparation method comprises the steps:

[0067] (1) Stir and dissolve the photoinitiator in the UV monomer, and then evenly disperse the auxiliary agent in it;

[0068] (2) uniformly disperse the modified acrylic resin into the system obtained in step (1), and then add the filler to disperse evenly;

[0069] (3) Add color paste to the system obtained in step (2) and disperse evenly to obtain drilling ink.

[0070] The specific selection and content of each component in Example 1 are shown in Table 1. The resulting drilling ink was sampled for physical and chemical testing and performance testing for curing drilling applications, and the results are shown in Table 2.

[0071] Table 1 Embodiment 1 each component selection and content

[0072]

[0073]

[0074] The application and performance test result of the drilling ink of table 2 embodiment 1 gained

[0075] parameter Ink Consumption(g / m 2 )

Embodiment 2

[0077] A kind of drilling ink, its preparation method comprises the steps:

[0078] (1) Stir and dissolve the photoinitiator in the UV monomer, and then evenly disperse the auxiliary agent in it;

[0079] (2) uniformly disperse the modified acrylic resin into the system obtained in step (1), and then add the filler to disperse evenly;

[0080] (3) Add color paste to the system obtained in step (2) and disperse evenly to obtain drilling ink.

[0081]The specific selection and content of each component in Example 2 are shown in Table 3. The resulting drilling ink was sampled for physical and chemical testing and performance testing for curing drilling applications, and the results are shown in Table 4.

[0082] Each component selection and content of table 3 embodiment 2

[0083] Element Content (wt%) Trifunctional novolac epoxy acrylate UV1000 46.4 Difunctional epoxy acrylate 100 15 IBOA 8 TPGDA 11 DPHA 5 1173 0.5 907 0.1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com