Method for manufacturing gradient composite of W-Cu system by aid of tape casting process

A composite material and technology of casting method, applied in the field of preparing W-Cu system gradient composite materials by casting method, can solve the problem of less metal system gradient composite materials, and achieve continuous controllable components, low cost and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

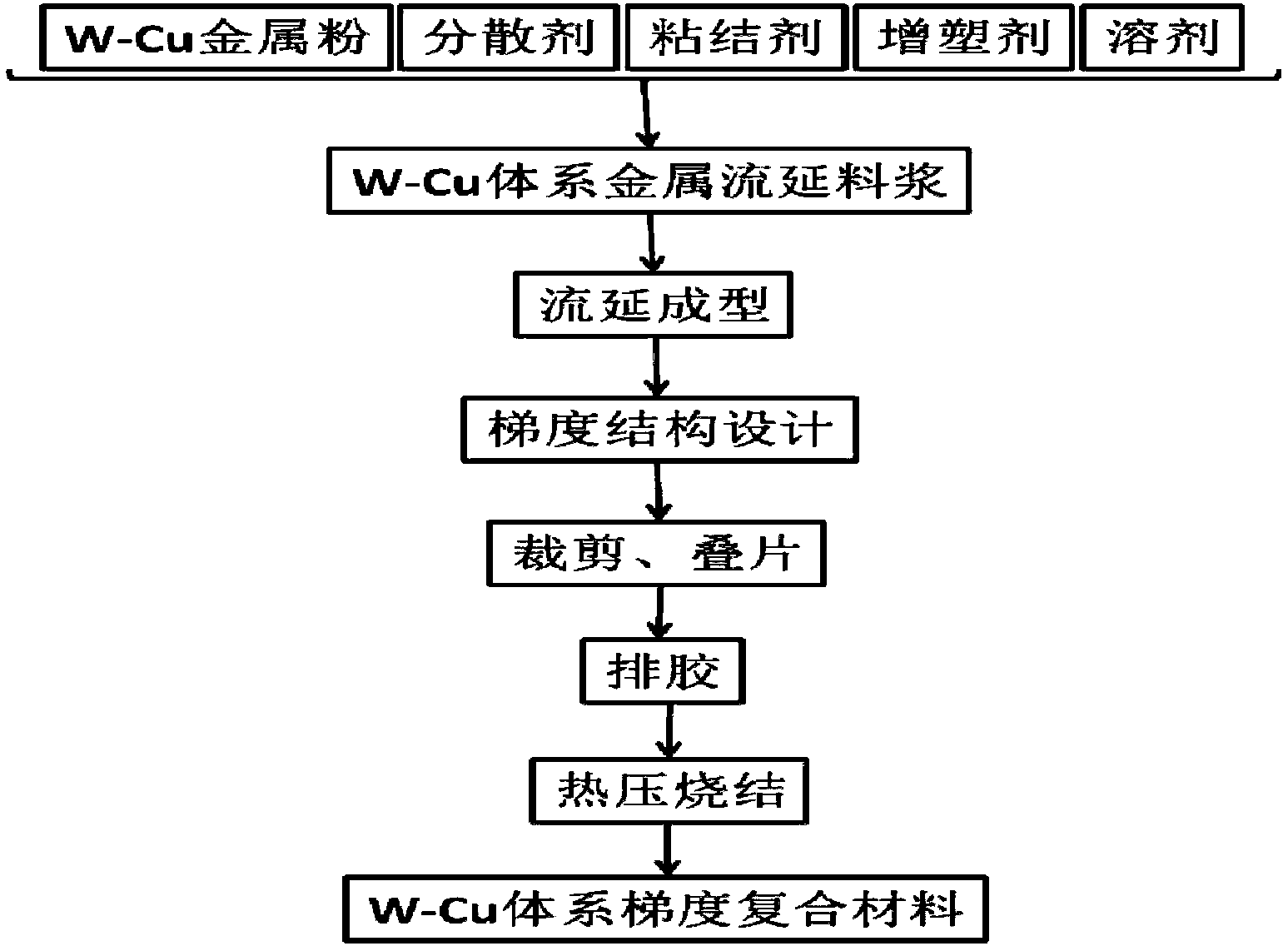

[0034] Such as figure 1 Shown, the preparation method of W-Cu system gradient composite material, it comprises the steps:

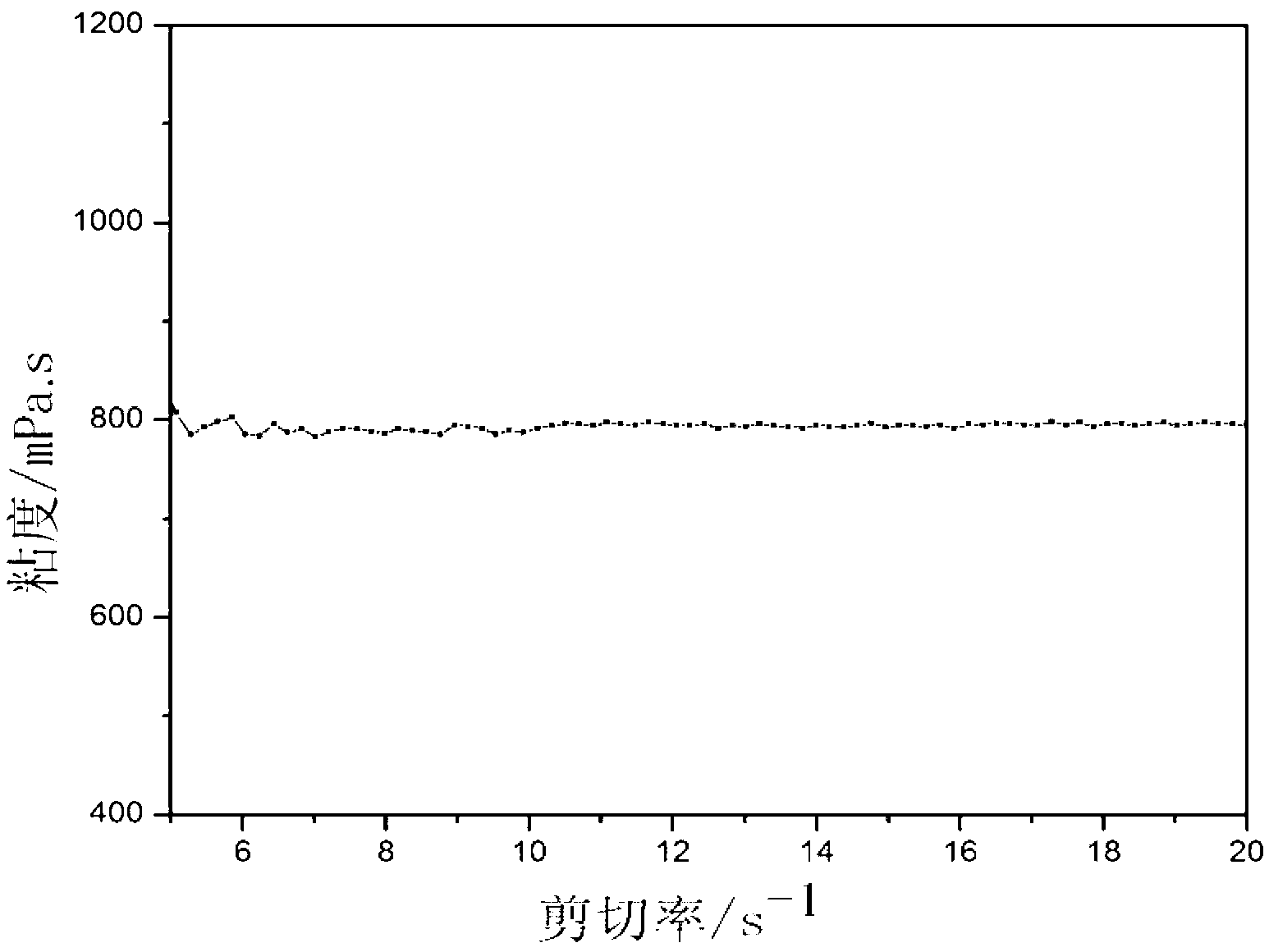

[0035]1) Preparation of casting slurry: the mass percentage of each raw material is: the solid phase content of Cu powder with a particle size of 10 μm is 60%, the dispersant Hypermer KD-11%, the binder polyvinyl butyral 3 %, plasticizer glycerin 3.2%, solvent 32.8%; solvent, dispersant Hypermer KD-1, Cu powder, binder and plasticizer are put into nylon ball mill jar, with agate ball as ball mill medium, ball-to-material ratio 1:1, ball milling and mixing on a ball mill for 24 hours to obtain a mixed slurry; the mixed slurry after ball milling was degassed (vacuum filtration using a small defoaming machine), and filtered to obtain pure Cu powder non-aqueous base tape casting slurry, its rheological properties are as follows figure 2 As shown, the viscosity basically does not change with the rotation speed, indicating that the slurry has good stability ...

Embodiment 2

[0041] Such as figure 1 Shown, the preparation method of W-Cu system gradient composite material, it comprises the steps:

[0042] 1) Preparation of casting slurry: the mass percentage of each raw material is: the solid phase content of copper powder with a particle size of 10 μm is 60%, the dispersant Hypermer KD-11%, the binder polyvinyl butyral 3 %, plasticizer glycerin 3.2%, solvent 32.8%; solvent, dispersant Hypermer KD-1, Cu powder, binder and plasticizer are put into nylon ball mill jar, with agate ball as ball mill medium, ball-to-material ratio 1:1, ball milling and mixing on a ball mill for 24 hours to obtain a mixed slurry; the mixed slurry after ball milling was degassed (vacuum filtration using a small defoaming machine), and filtered to obtain pure Cu powder non-aqueous Base casting slurry.

[0043] 2) Tape casting: inject the pure Cu powder slurry obtained in step 1) into the casting machine, adjust the height of the scraper to 0.2mm, and the casting speed to ...

Embodiment 3

[0048] Such as figure 1 Shown, the preparation method of W-Cu system gradient composite material, it comprises the steps:

[0049] 1) Preparation of casting slurry: the mass percentage of each raw material is: the solid phase content of Cu powder with a particle size of 10 μm is 60%, the dispersant Hypermer KD-11%, the binder polyvinyl butyral 3 %, plasticizer glycerin 3.2%, solvent 32.8%; solvent, dispersant Hypermer KD-1, Cu powder, binder and plasticizer are put into nylon ball mill jar, with agate ball as ball mill medium, ball-to-material ratio 1:1, ball milling and mixing on a ball mill for 24 hours to obtain a mixed slurry; the mixed slurry after ball milling was degassed (vacuum filtration using a small defoaming machine), and filtered to obtain pure Cu powder non-aqueous Base casting slurry.

[0050] 2) Tape casting: inject the pure Cu powder slurry obtained in step 1) into the casting machine, adjust the scraper height to 1.0mm, and the casting speed to 1.0m / min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com