Directive water-based acrylic resin with excellent aluminite powder and preparation and coating thereof

A water-based acrylic and directional technology, applied in the application field of aluminum powder coating and aluminum profile water-based coating, can solve the problem of not introducing water-based acrylic resin synthesis, etc., and achieve good spraying workability, good orientation of aluminum powder, and good gloss. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

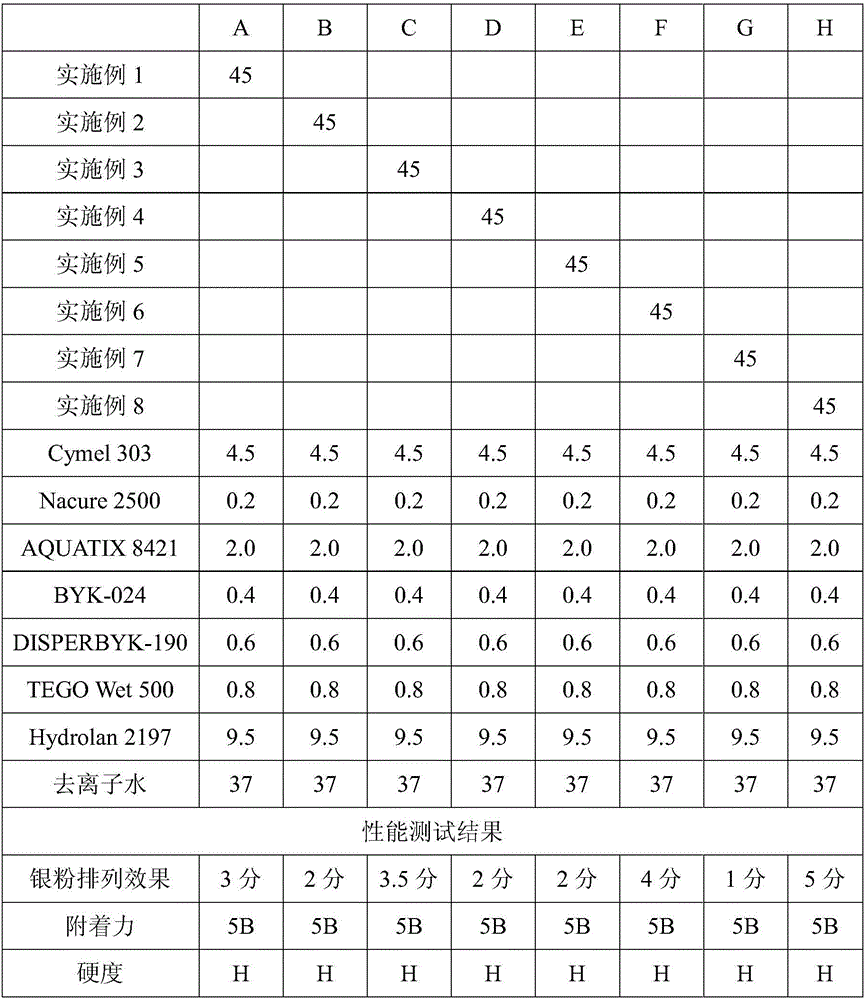

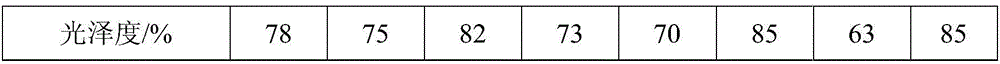

Examples

Embodiment 1

[0064] 154g of ethylene glycol butyl ether was pre-loaded into a reaction vessel equipped with stirring, condensation and heating devices, and the material was heated to 105°C, and 363.8g of methyl methacrylate, 51.8 g styrene, 259 g hydroxyethyl methacrylate, 264.3 g butyl acrylate, 36 g butyl methacrylate, 25 g acrylic acid mixture, and in parallel to this, 60.5 g benzoyl peroxide and 80 g ethylene glycol were added over 5.5 hours After the butyl ether was dissolved evenly, the mixture was stirred at 105°C for 2 hours, then cooled to 80°C, added with 30.9g N,N-dimethylethanolamine, stirred for 30 minutes, cooled to 60°C, and then cooled to 60°C for 1 hour 1200g of deionized water was added to obtain a water-based acrylic resin with the following data: acid value 23mgKOH / g; hydroxyl value 65mgKOH / g; viscosity 2100mPa·s; pH value 7.5; average particle size 160nm; solid content 40%.

Embodiment 2

[0066] 77 g of ethylene glycol butyl ether and 77 g of Solvesso 100 were precharged into a reaction vessel equipped with a stirring, condensing and heating device, and the mass was heated to 105° C., at which temperature 363.8 g of methyl methacrylate were added within 5 hours ester, 51.8g styrene, 259g hydroxyethyl methacrylate, 264.3g butyl acrylate, 36g butyl methacrylate, 25g acrylic acid mixture, in parallel with this, add 60.5g benzoyl peroxide and 80g After ethylene glycol butyl ether is dissolved evenly, the mixture is stirred at 105°C for 2 hours, then cooled to 80°C, 30.9g of N,N-dimethylethanolamine is added, stirred for 30 minutes, and then cooled to 60°C. Add 1200g of deionized water within 1 hour to obtain a water-based acrylic resin with the following data: acid value 23mgKOH / g; hydroxyl value 65mgKOH / g; viscosity 2700mPa·s; pH value 7.5; average particle diameter 210nm;

Embodiment 3

[0068] 77g of ethylene glycol butyl ether was pre-loaded into a reaction vessel equipped with a stirring, condensing and heating device, and the material was heated to 105°C, and 363.8g of methyl methacrylate, 51.8 g styrene, 259 g hydroxyethyl methacrylate, 264.3 g butyl acrylate, 36 g butyl methacrylate, 25 g acrylic acid mixture, and in parallel to this, 60.5 g benzoyl peroxide and 80 g ethylene glycol were added over 5.5 hours After the butyl ether was dissolved uniformly, the mixture was stirred at 105°C for 2 hours, then cooled to 80°C, 77g of isopropanol was added, stirred for 10 minutes, then 30.9g of N,N-dimethylethanolamine was added, and stirred for 30 Minutes later, the temperature was lowered to 60°C, and 1200g of deionized water was added within 1 hour to obtain a water-based acrylic resin with the following data: acid value 23mgKOH / g; hydroxyl value 65mgKOH / g; viscosity 3000mPa·s; pH value 7.5; average particle size Diameter 180nm; solid content 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com