Patents

Literature

143 results about "Ktp laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

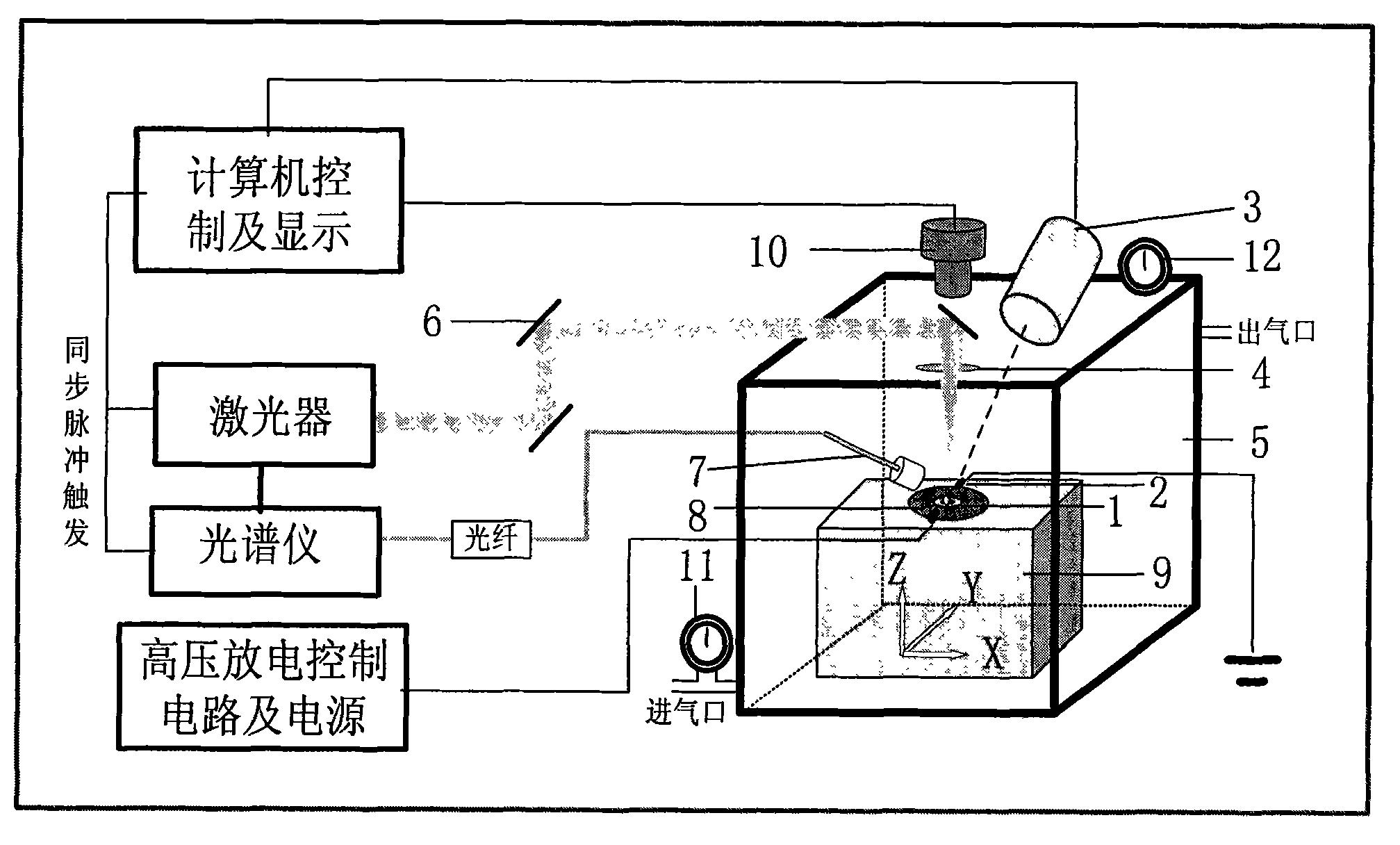

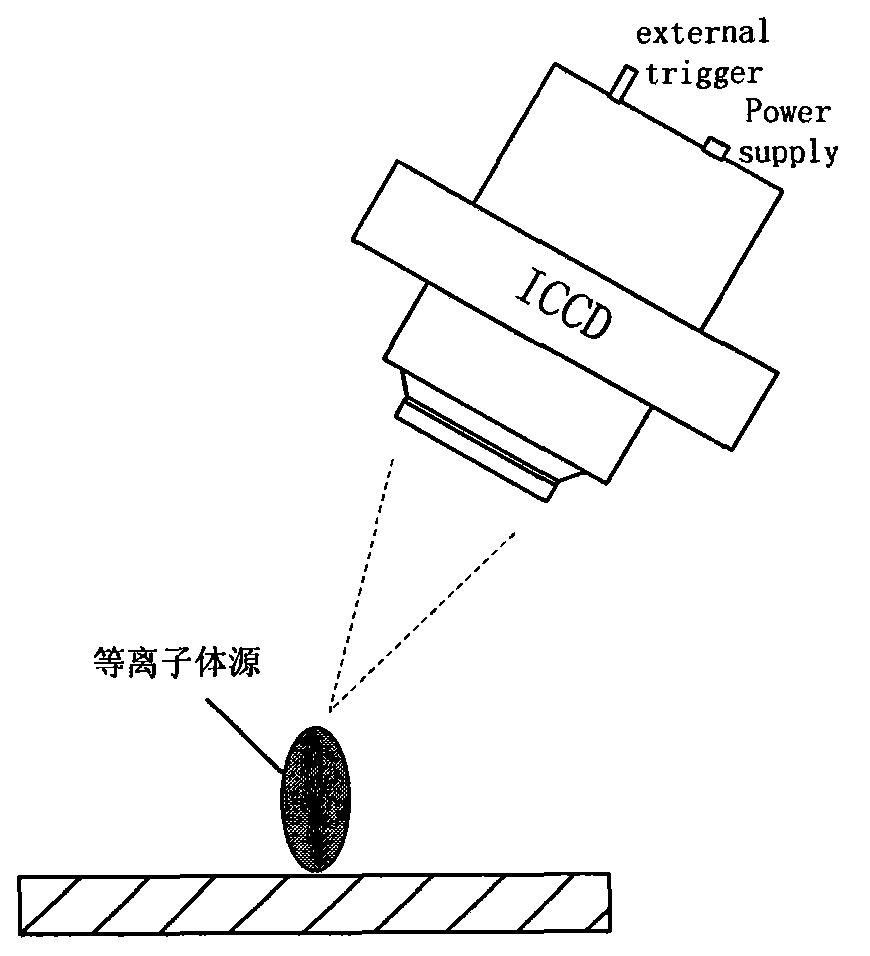

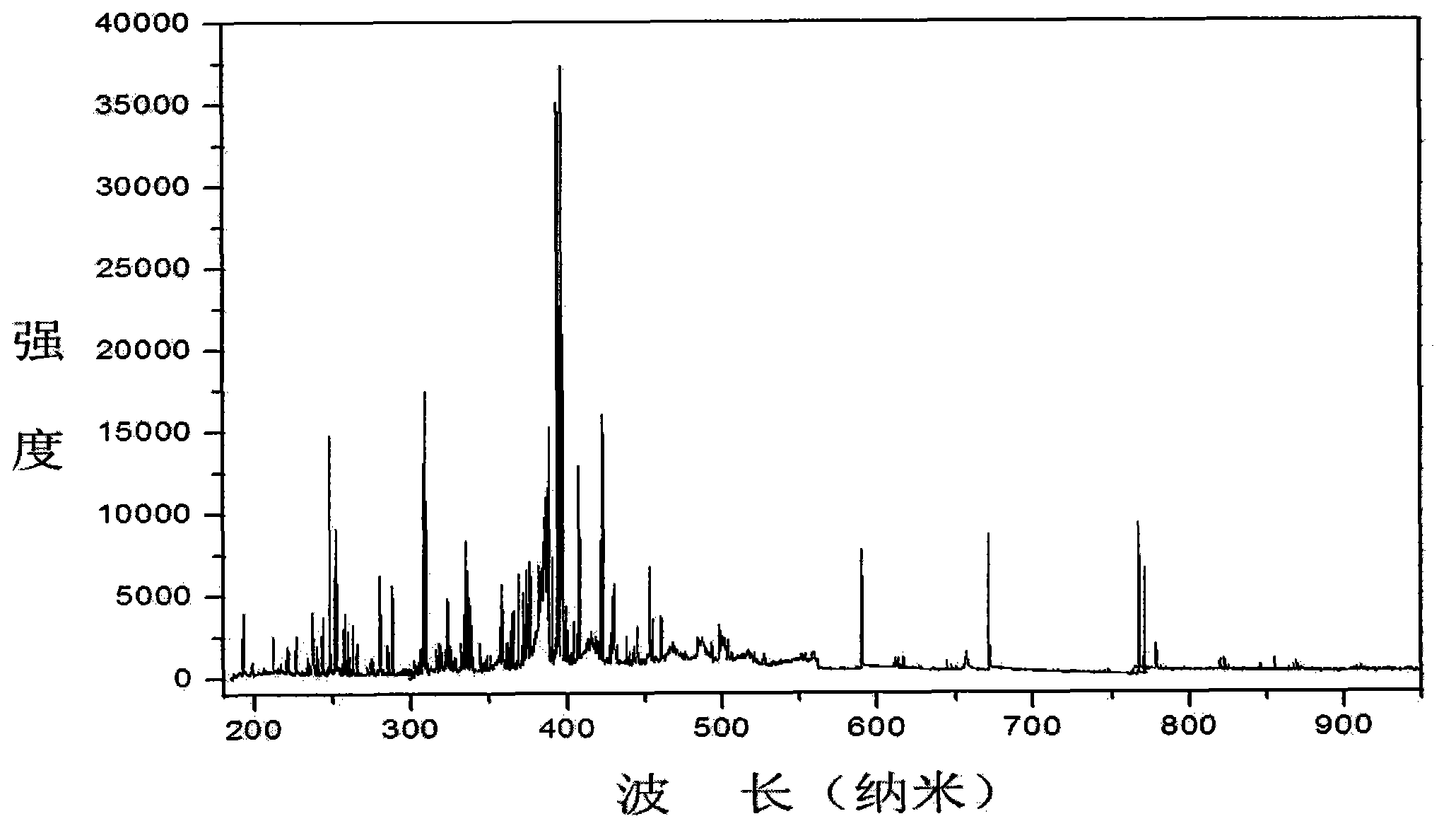

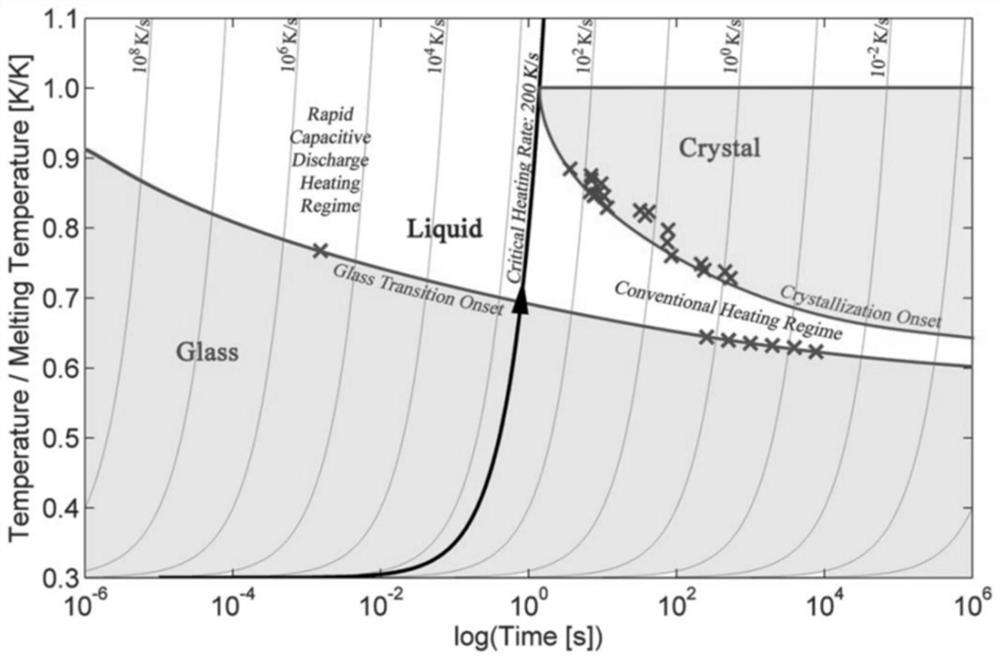

Integrated laser-induced enhanced plasma spectrum acquisition system

InactiveCN102841078AAccurate measurementIncrease production capacityAnalysis by material excitationLaser-induced breakdown spectroscopyHigh pressure

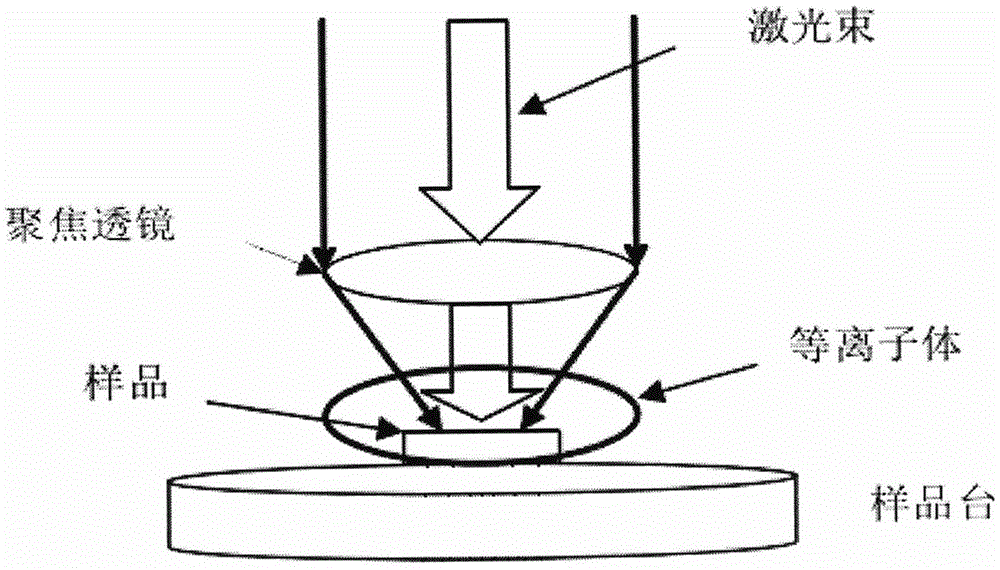

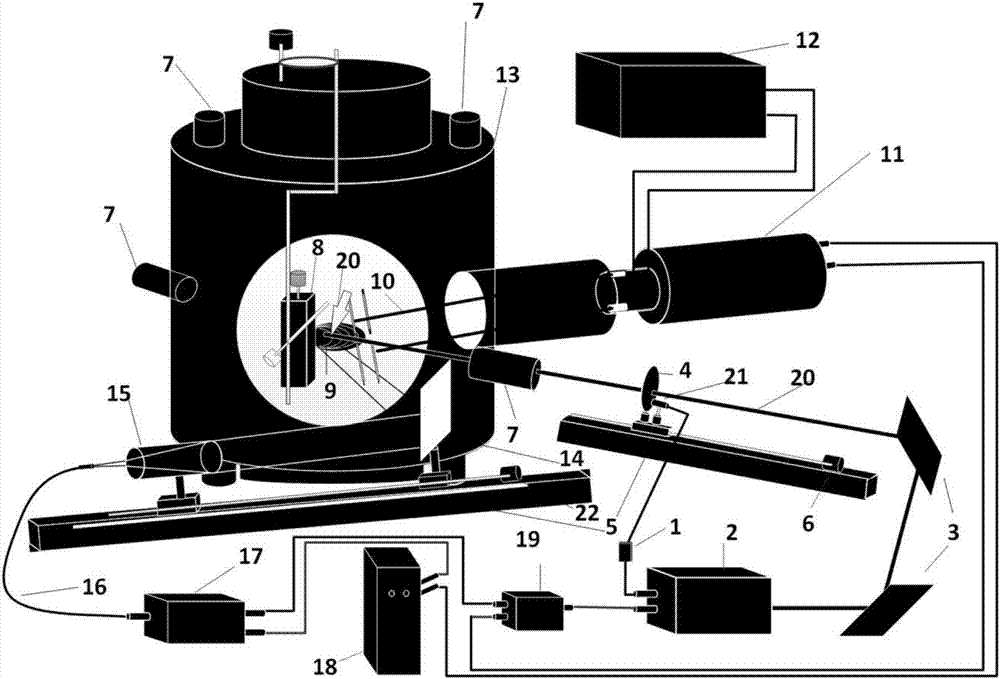

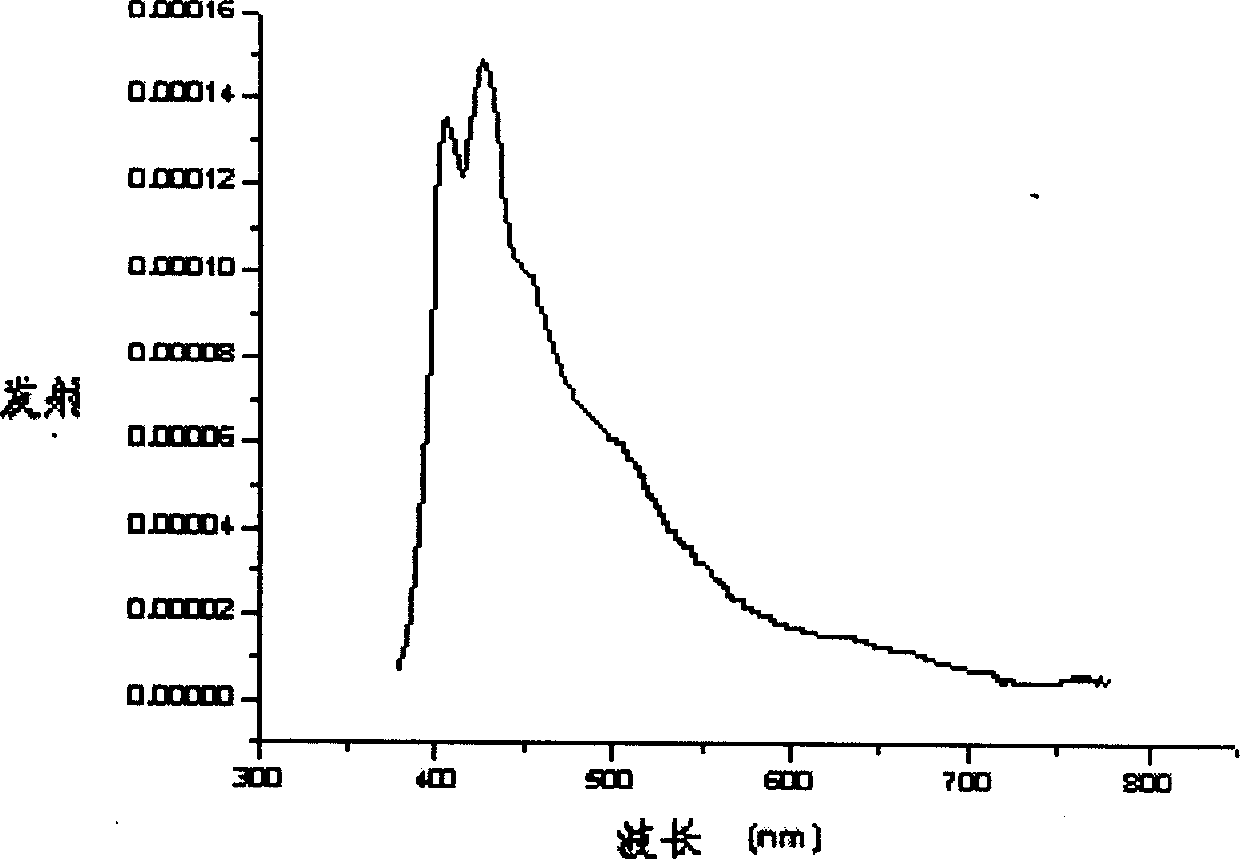

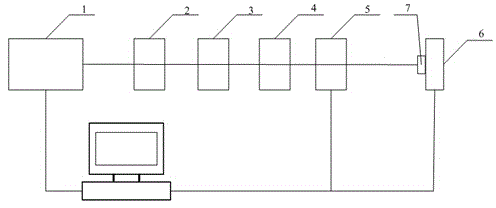

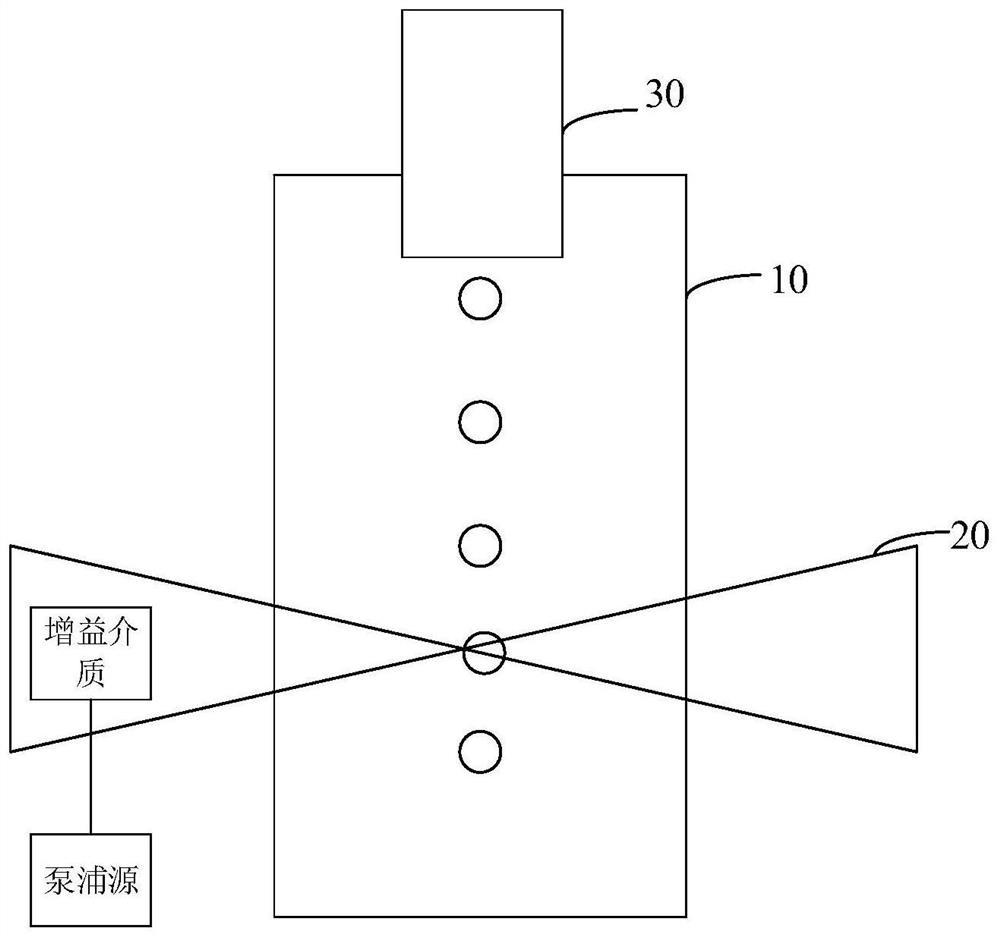

The invention relates to an integrated laser-induced enhanced plasma spectrum acquisition system and belongs to the field of laser plasma spectrum detection. The integrated laser-induced enhanced plasma spectrum acquisition system comprises a pulse laser device, a light beam lifter, a spectrometer, a domain limiting loop, a high voltage discharge electrode, an ICCD (Intensified Charge Coupled Device) camera, a focusing lens, a sample chamber, a reflector, an adjustable optical fiber optical receiving system, a sample to be detected, a three-dimensional electric control translation platform, an imaging CCD (Charge Coupled Device), a gas flow meter and a gas pressure meter. According to the integrated laser-induced enhanced plasma spectrum acquisition system, different LIBS (Laser-induced Breakdown Spectroscopy) signals are collected by utilizing control and synchronous control of internal environments of smaller independent sealed spaces so that integration is realized; a high voltage discharge enhanced and loop limited domain synchronous enhanced LIBS system with the functions of spectrum acquisition, dynamic image analysis and the like is integrated; and more accurate measurement are realized by utilizing environment stress around the sample and control of protection gas; and the system is quick and convenient, and is favorable for industrial production and application.

Owner:刘瑞斌

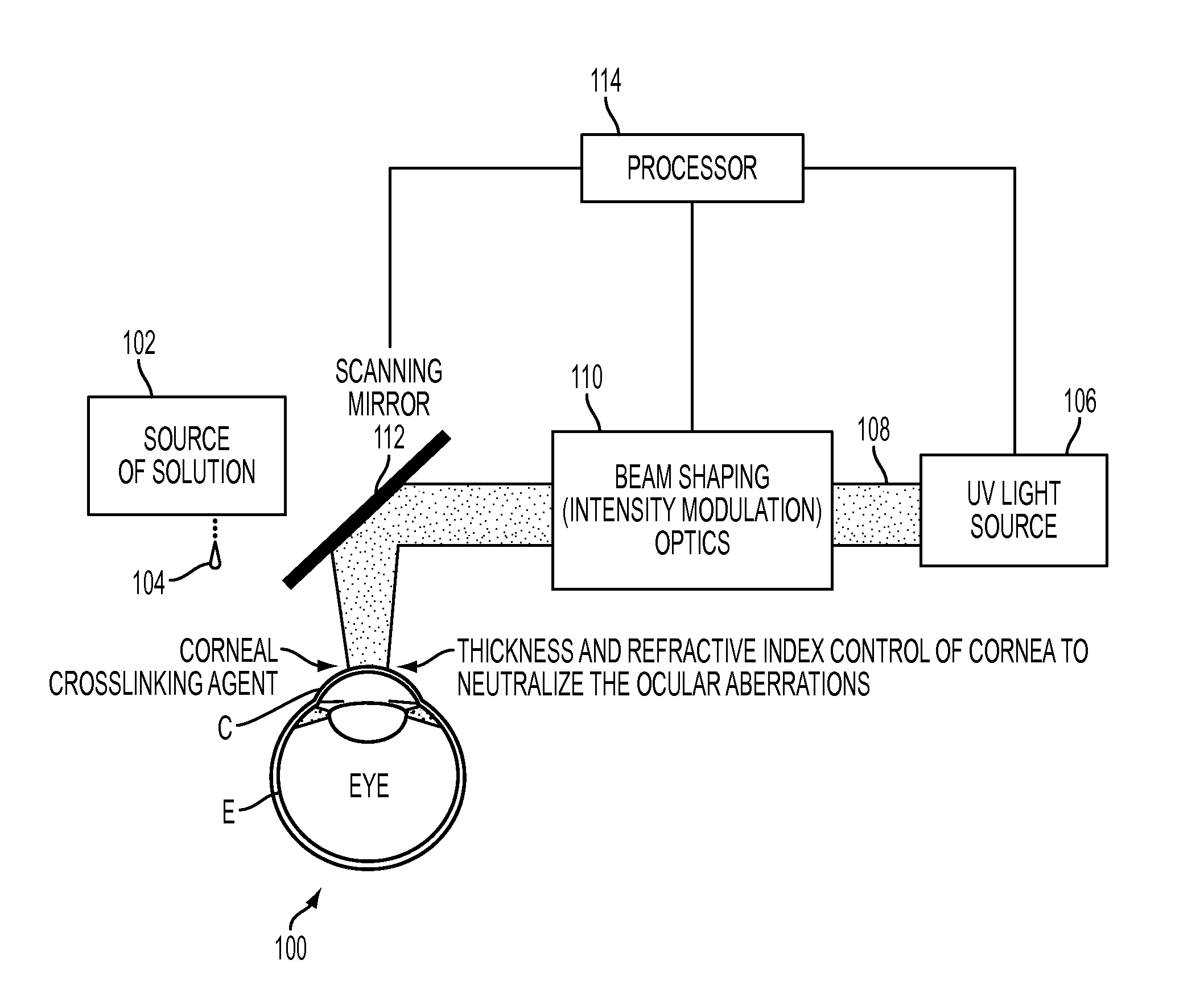

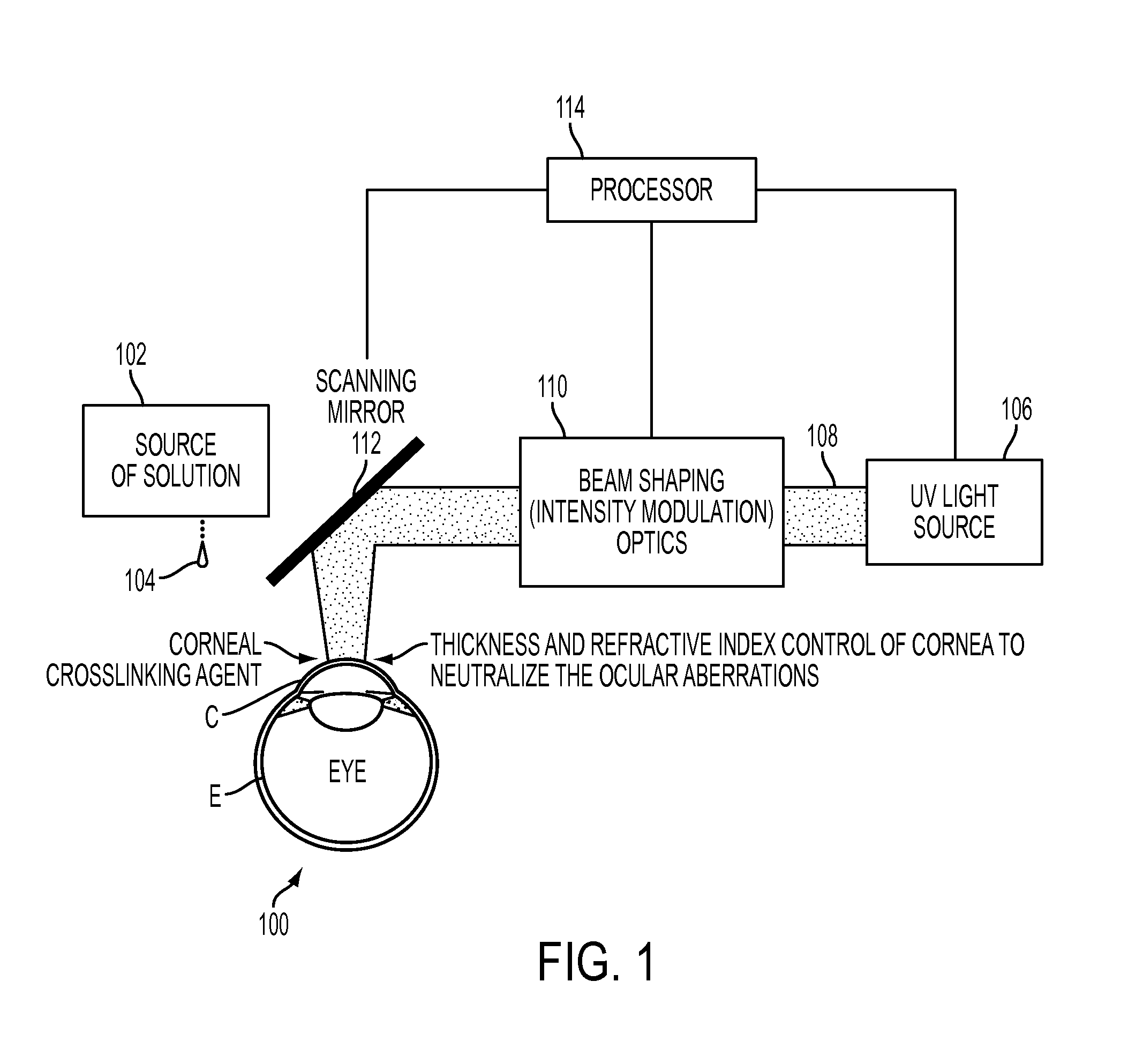

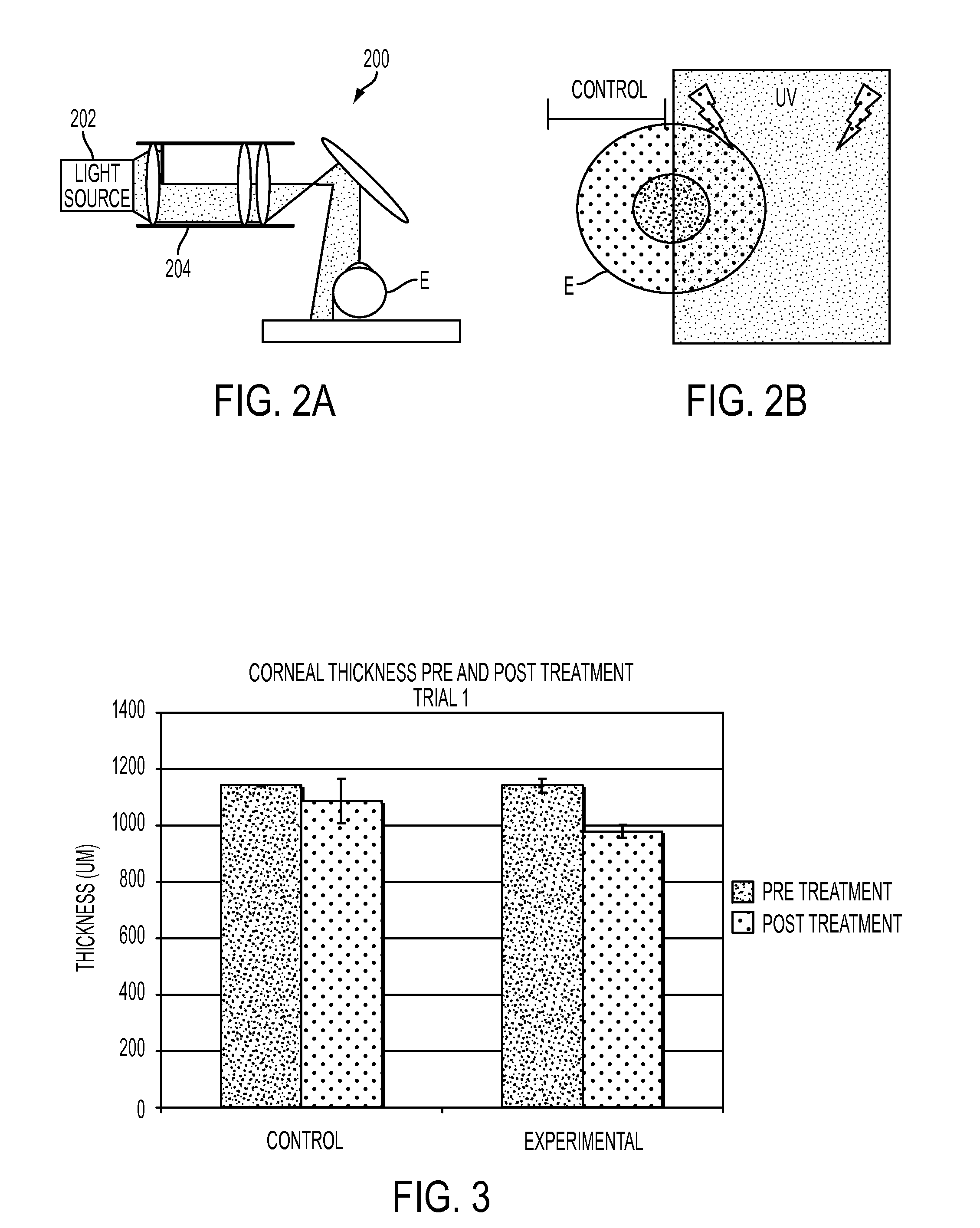

Aberration control by corneal collagen crosslinking combined with beam-shaping technique

Corneal collagen crosslinking is used to alter a characteristic of the cornea, such as thickness or refractive index, to correct wavefront aberrations, including higher-order aberrations. A scanning laser or the like is used to perform the corneal collagen crosslinking by locally altering the optical path length (thickness, refractive index, or both).

Owner:UNIVERSITY OF ROCHESTER

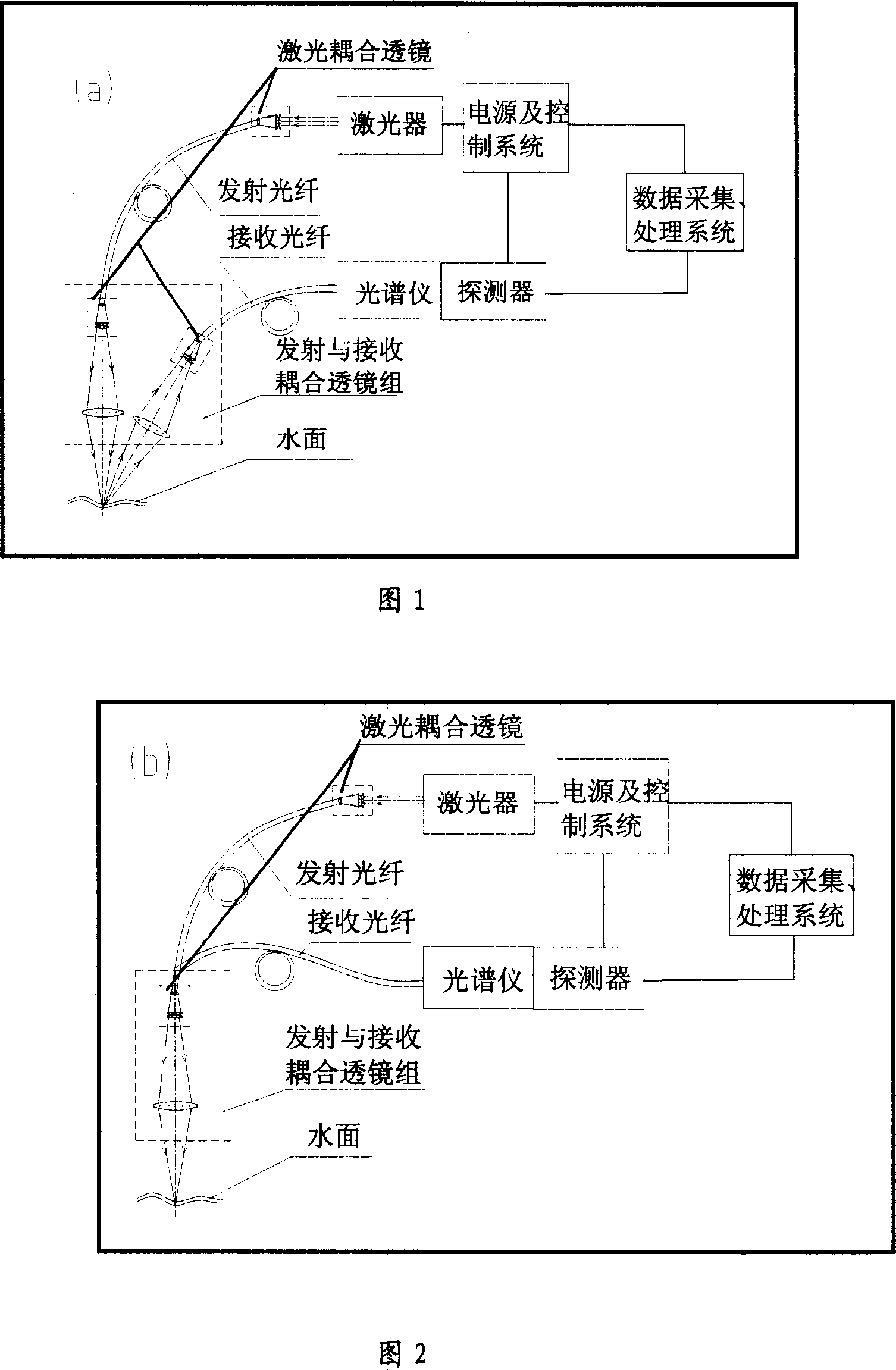

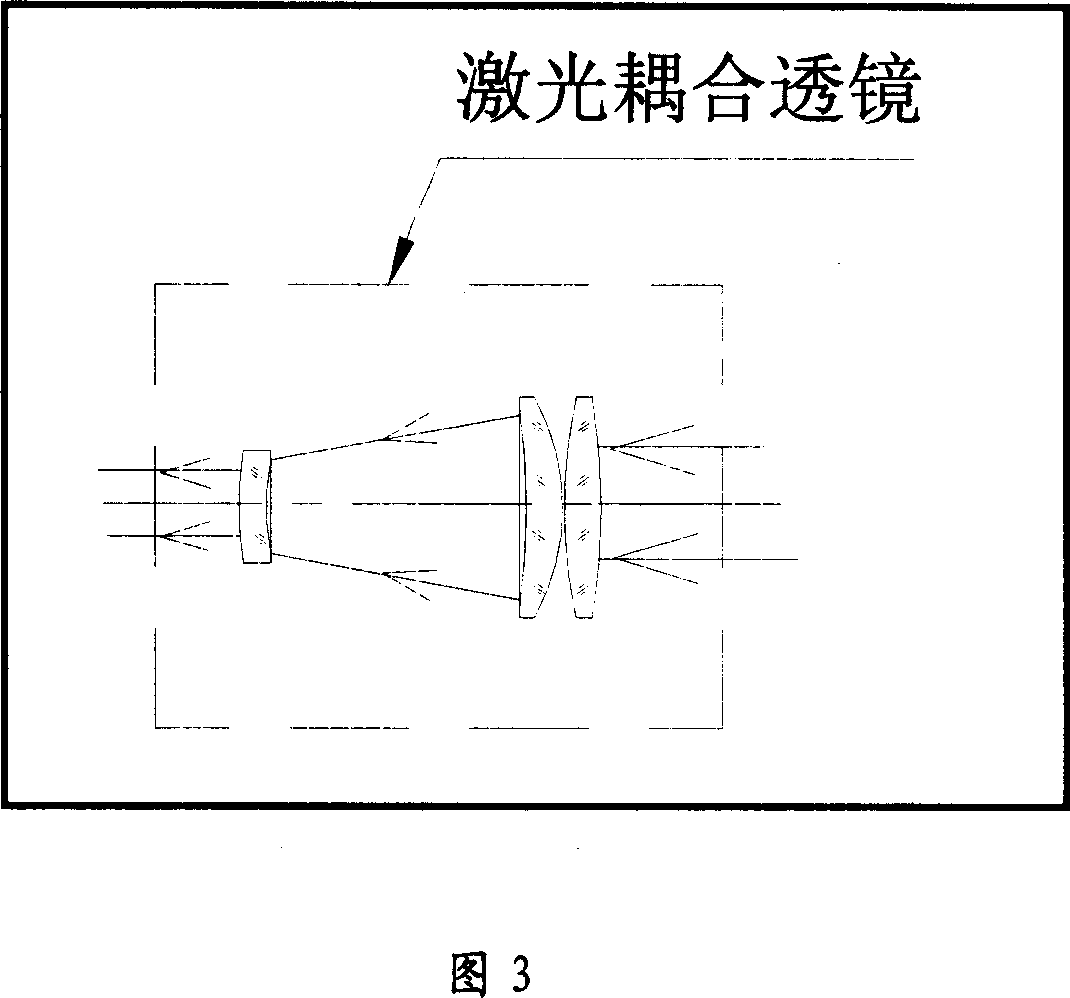

Laser breakdown spectrographic detection method and system for metal pollutants in water body

ActiveCN1995979AAvoid influenceReduce volumeColor/spectral properties measurementsData acquisitionHandling system

The water body metal pollution laser optical spectral penetration uses short pulse laser accumulation to generate high temperature ion on the water surface, excited atom, icon and molecule emitting lines of generated element component feature, through plasma spectrochemistry of the water sample to make strength analysis of the particular element line to decide the element content. The laser coupled to the emitting optical fiber through coupling lens, which receives the laser plasma signal, which is transmitted to optical spectrometer for light splitting, making photoelectric signal conversion by the CCD detector, coming into data collection and settlement system for treatment. It can be used for timely monitoring of poisonous metals.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

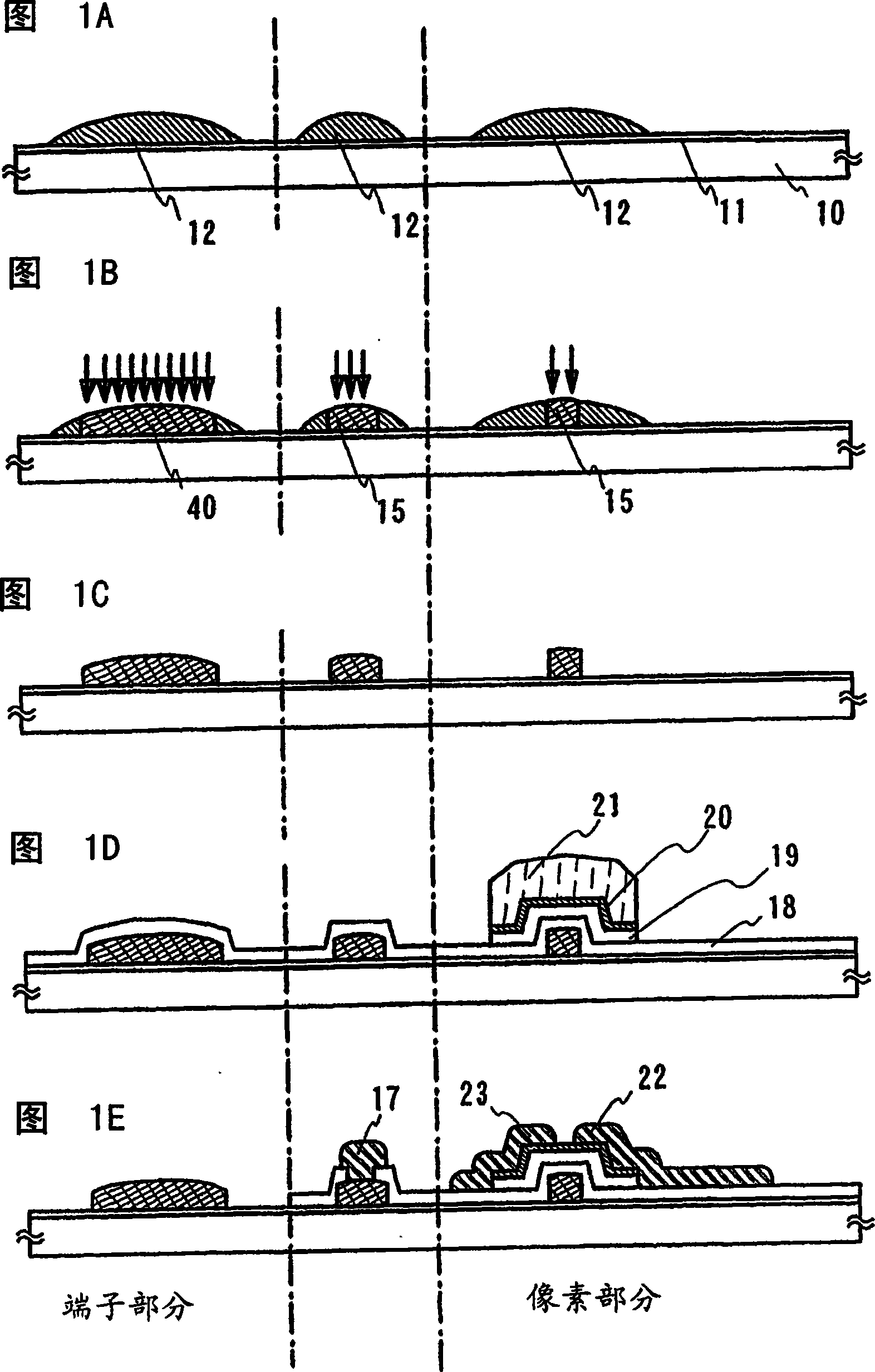

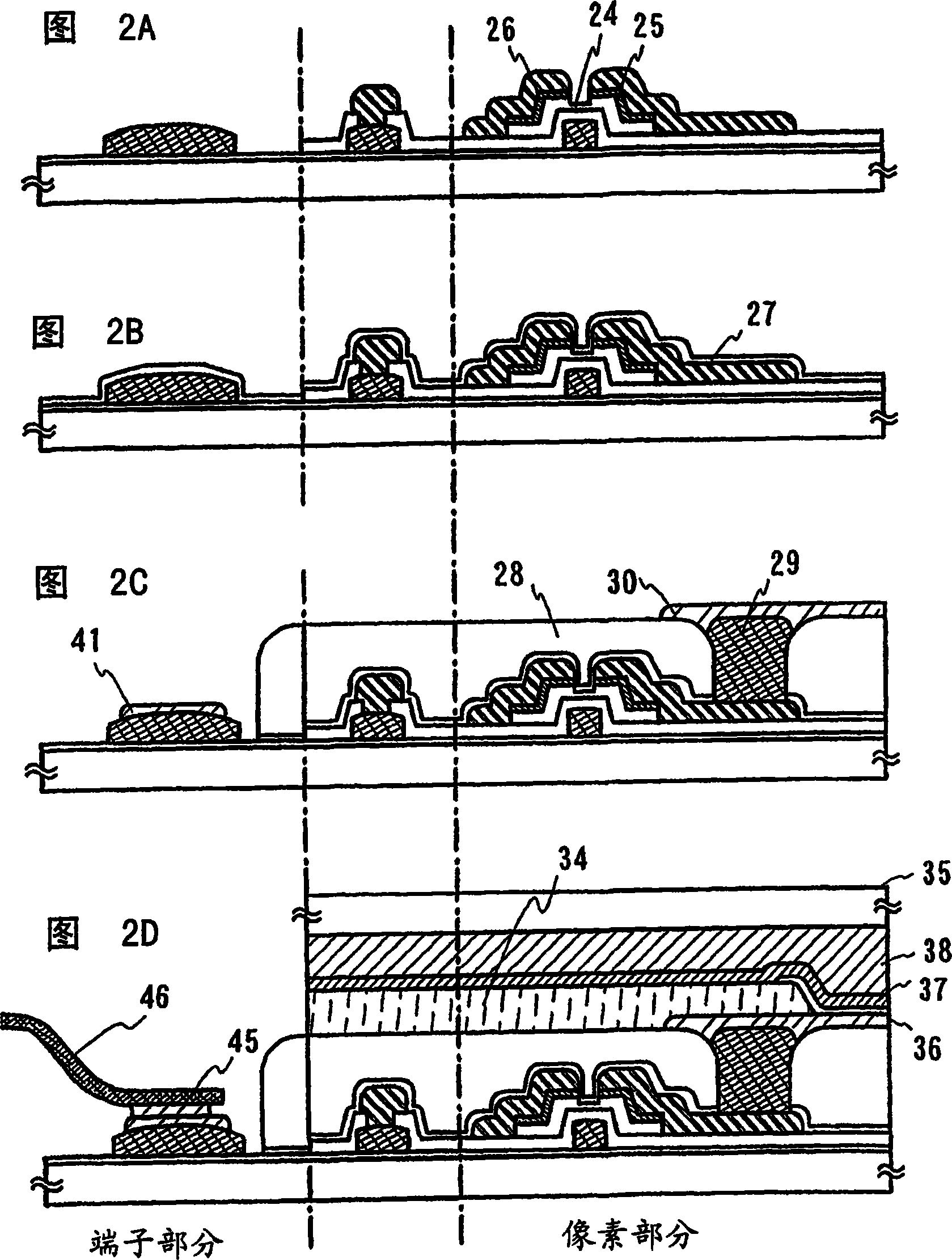

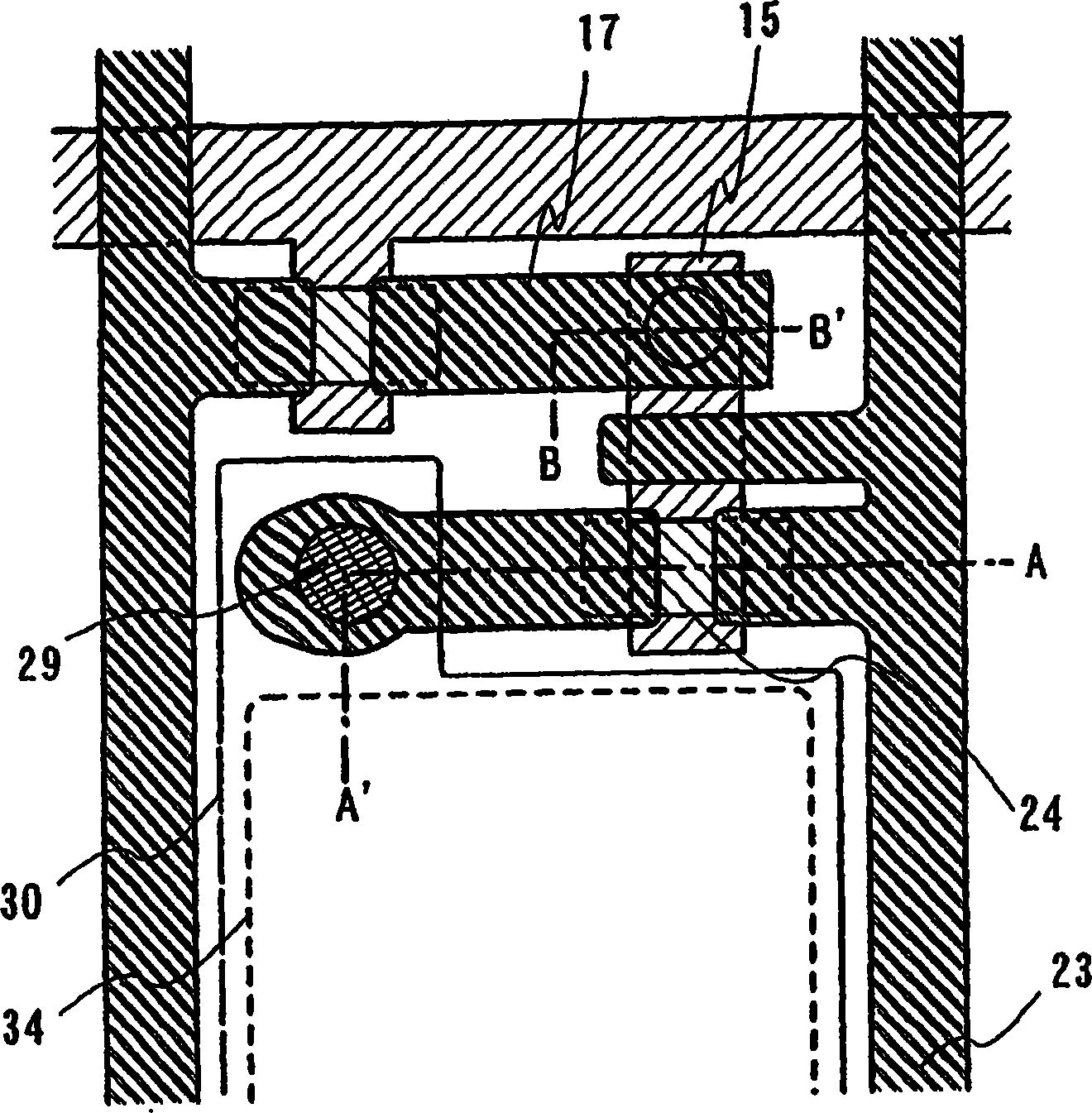

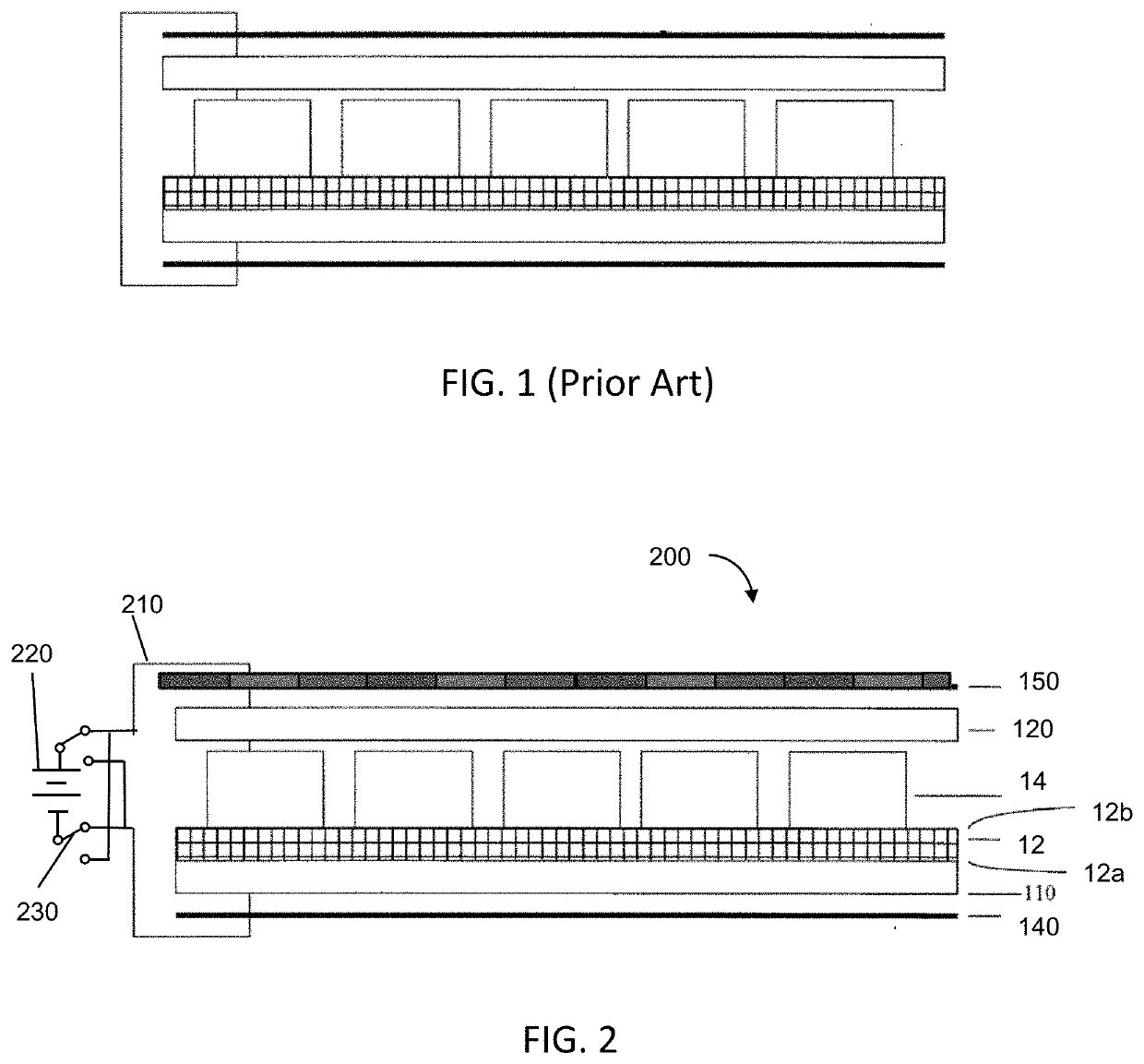

Electronic device, semiconductor device and its manufacturing method

InactiveCN1914552AReduce in quantityLow costTransistorElectroluminescent light sourcesLaser lightConductive materials

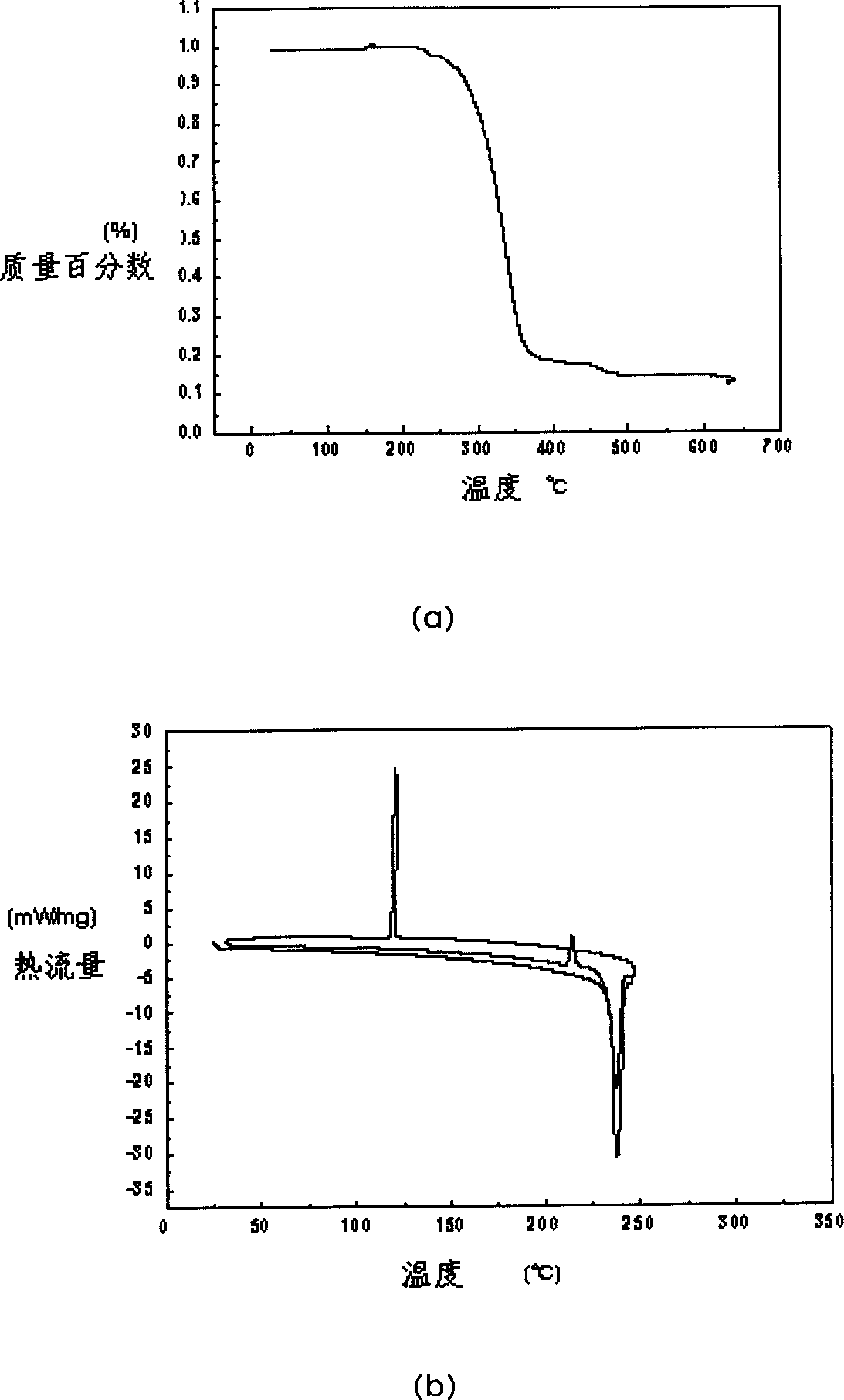

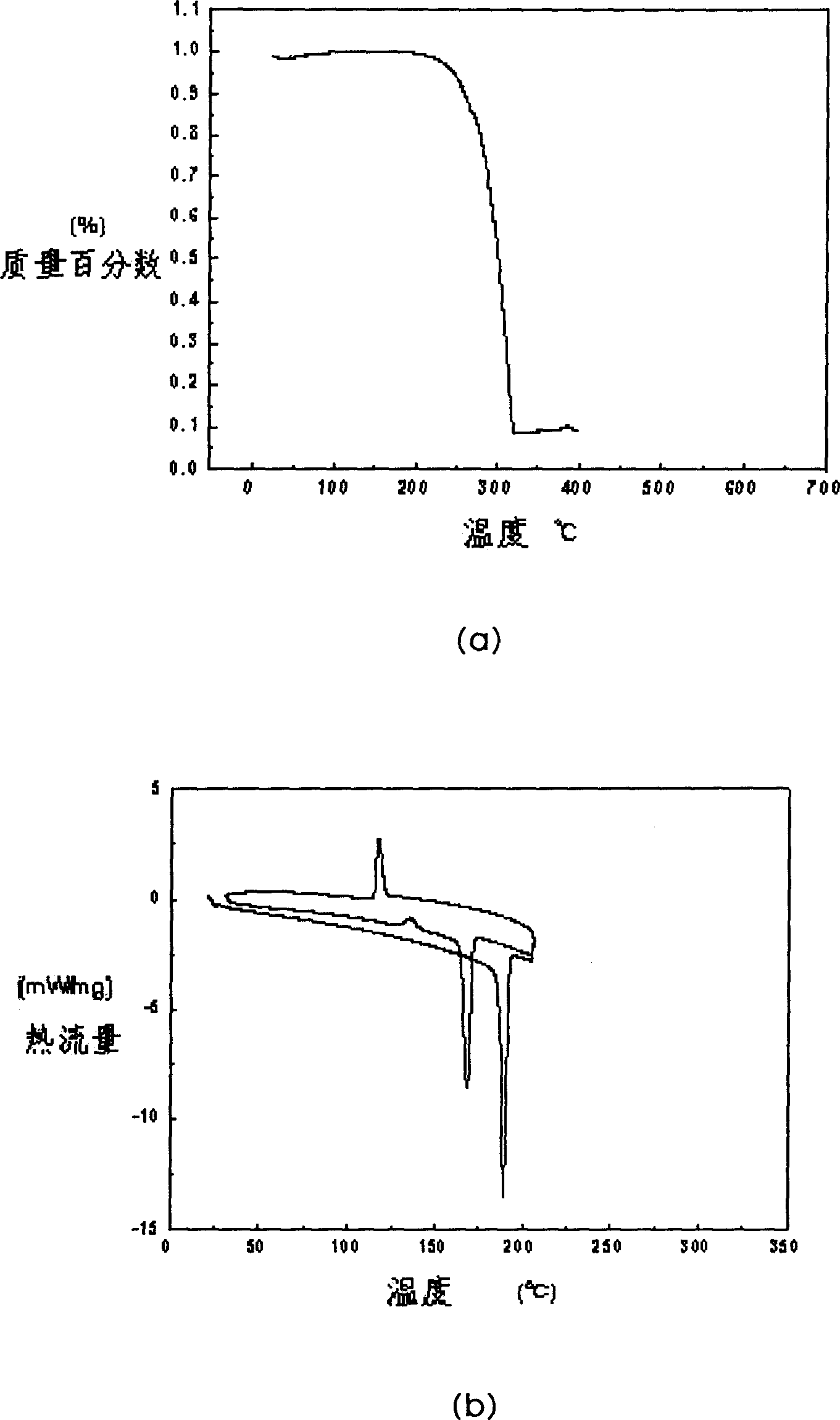

In the present circumstances, a film formation method of using spin coating in a manufacturing process is heavily used. As increasing the substrate size in future, the film formation method of using spin coating becomes at a disadvantage in mass production since a mechanism for rotating a large substrate becomes large, and there is many loss of material solution or waste liquid. According to the present invention, in a manufacturing process of a semiconductor device, a microscopic wiring pattern can be realized by delivering selectively photosensitive conductive material solution by droplet discharging, exposing selectively to laser light or the like, and developing. The present invention can reduce drastically costs since a patterning process can be shortened and an amount of material in a process of forming a conductive pattern can be reduced. Accordingly, the present invention can be applied to manufacture a large substrate.

Owner:SEMICON ENERGY LAB CO LTD

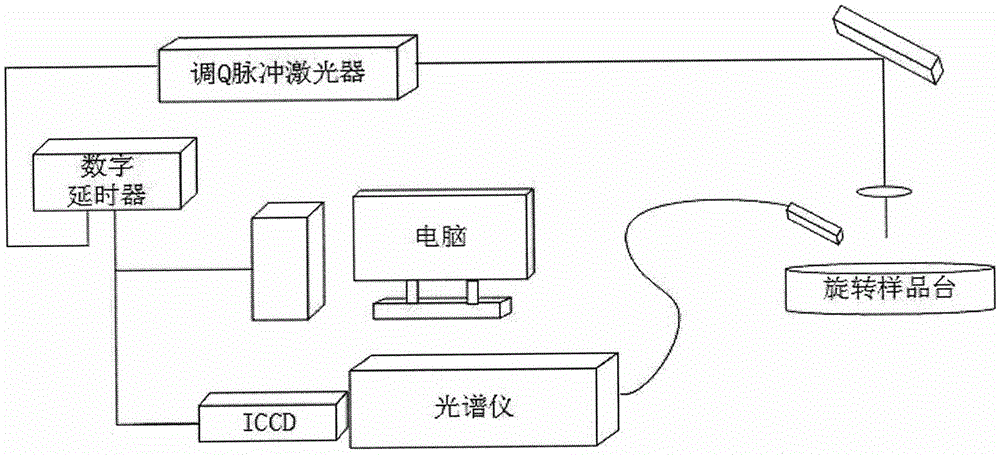

Method for quantitatively detecting multiple heavy metals in leather at same time based on LIBS (Laser-Induced Breakdown Spectroscopy) technology

PendingCN105572103ARealize in-situ online detectionApplicable to on-site evidence collection tasksAnalysis by thermal excitationGratingCollection system

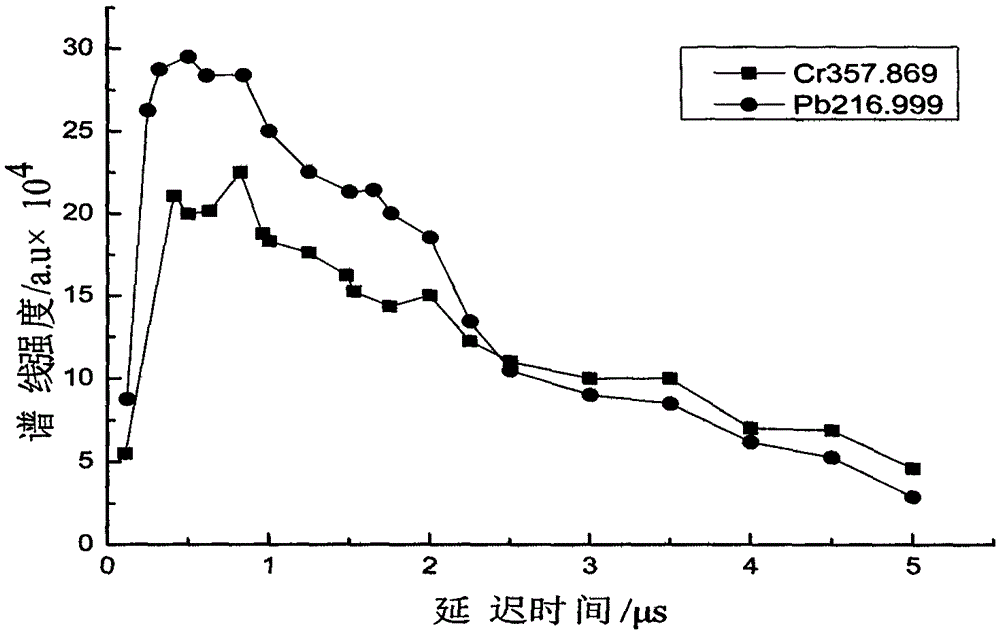

The invention discloses a method for quantitatively detecting multiple heavy metals in leather at the same time based on an LIBS (Laser-Induced Breakdown Spectroscopy) technology. The method adopts an LIBS detecting system which is formed by a Q-switched pulse Nd:YAG (Yttrium Aluminum Garnet) laser, an echelle grating spectrometer, an ICCD (Intensified Charge-Coupled Device) detector, a rotating platform and the like. The method comprises the following steps: firstly, regulating laser energy by an energy attenuation system consisting of a half-wave plate and a laser Glan prism, gathering the laser energy on the surface of a sample which is fixed to the rotating platform through a focusing lens, and ablating, gasifying and ionizing substances on the surface of the detected sample, thus forming laser plasma; secondly, obtaining a spectral signal of the laser plasma through a spectrum collection system, analyzing and converting element types corresponding to a spectral line, and obtaining content information of characteristic elements through conversion; thirdly, obtaining concentrations of heavy metal elements by combining a CF (Calibration-free)-LIBS method according to the obtained information of the elements.

Owner:TAIZHOU ENTRY EXIT INSPECTION & QUARANTINE BUREAU PEOPLES REPUBLIC OF CHINA +1

Material contg. thiophene spirane structure, its synthesis and application

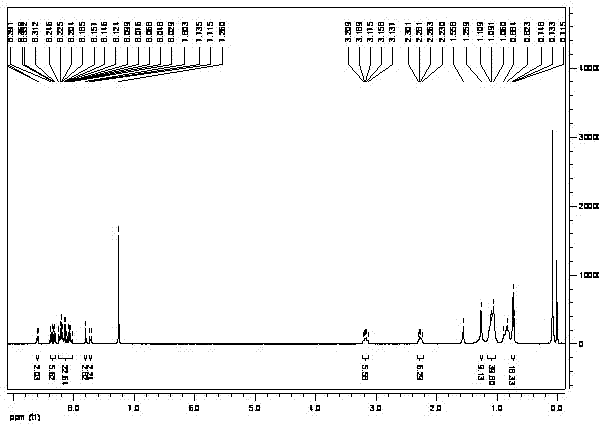

InactiveCN1757645AEasy to introduceFlexible routingOrganic chemistryElectrical apparatusVoltElectricity

This invention belongs to photo-electricity field, particularly a kind of thiophene spiral ring material and its preparation method, and its application in organic flat plate display, photo-volt cells, organic field effect tube and laser etc. organic electron field. This kind of compound introduces thiophene and functional thiophene in to conjugate semi-conductor material through spiral ring structure. The virtue are: (1) the synthesis is convenient and easy to get, and may be further modified; (2) may effectively realize photo-electricity property of modulate material; (3) with the virtue of high spectrum stability of spiral difluorene structure. The luminescence apparatus incurred by electricity prepared with this invent material has satisfaction result in brightness and luminescence efficiency. Thiophene spiral ring will be a potential commercialised photo-electricity material.

Owner:FUDAN UNIV

Hyperbranched poly-fluorene material containing space steric hindrance group and manufacture method thereof

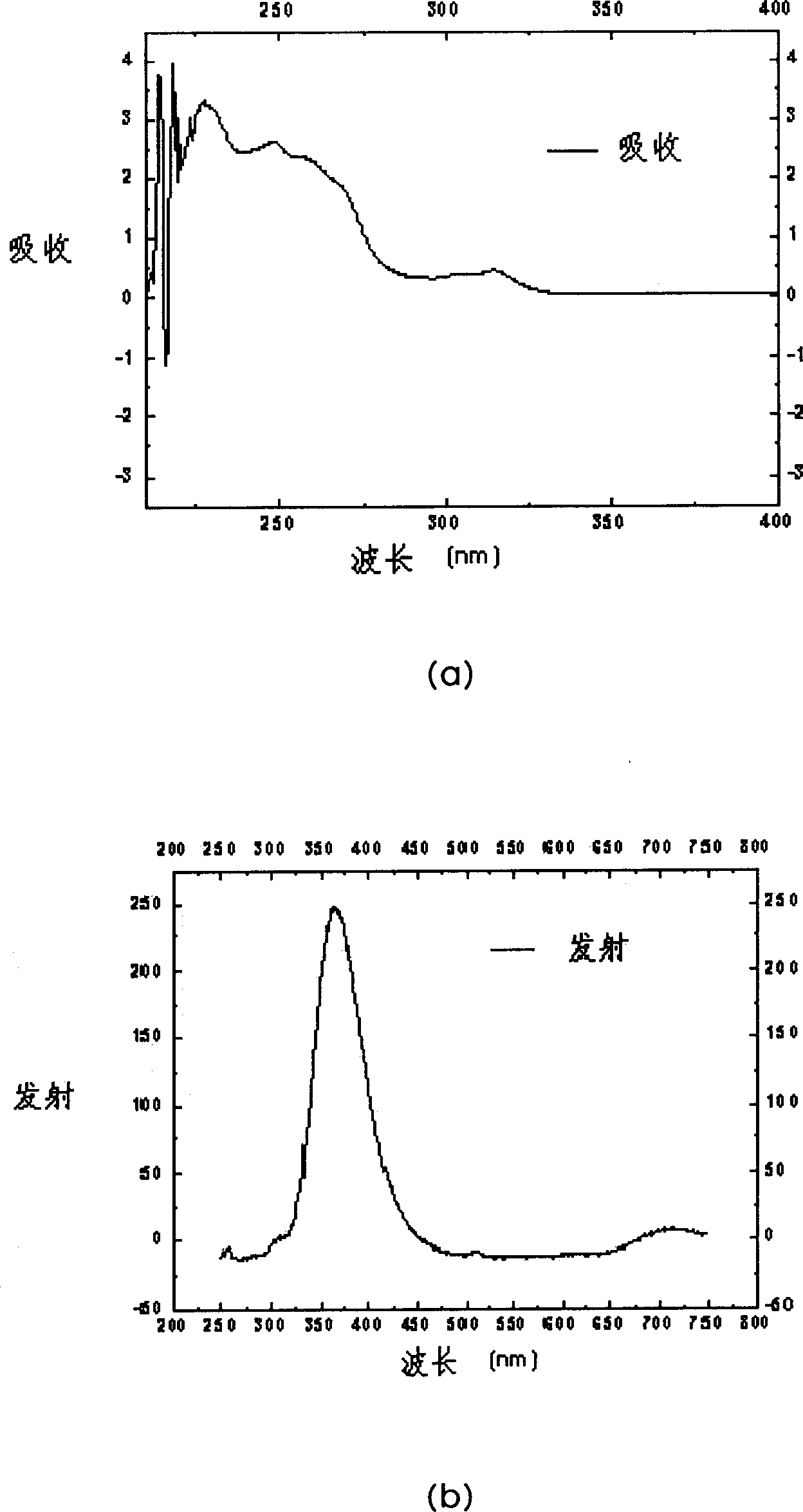

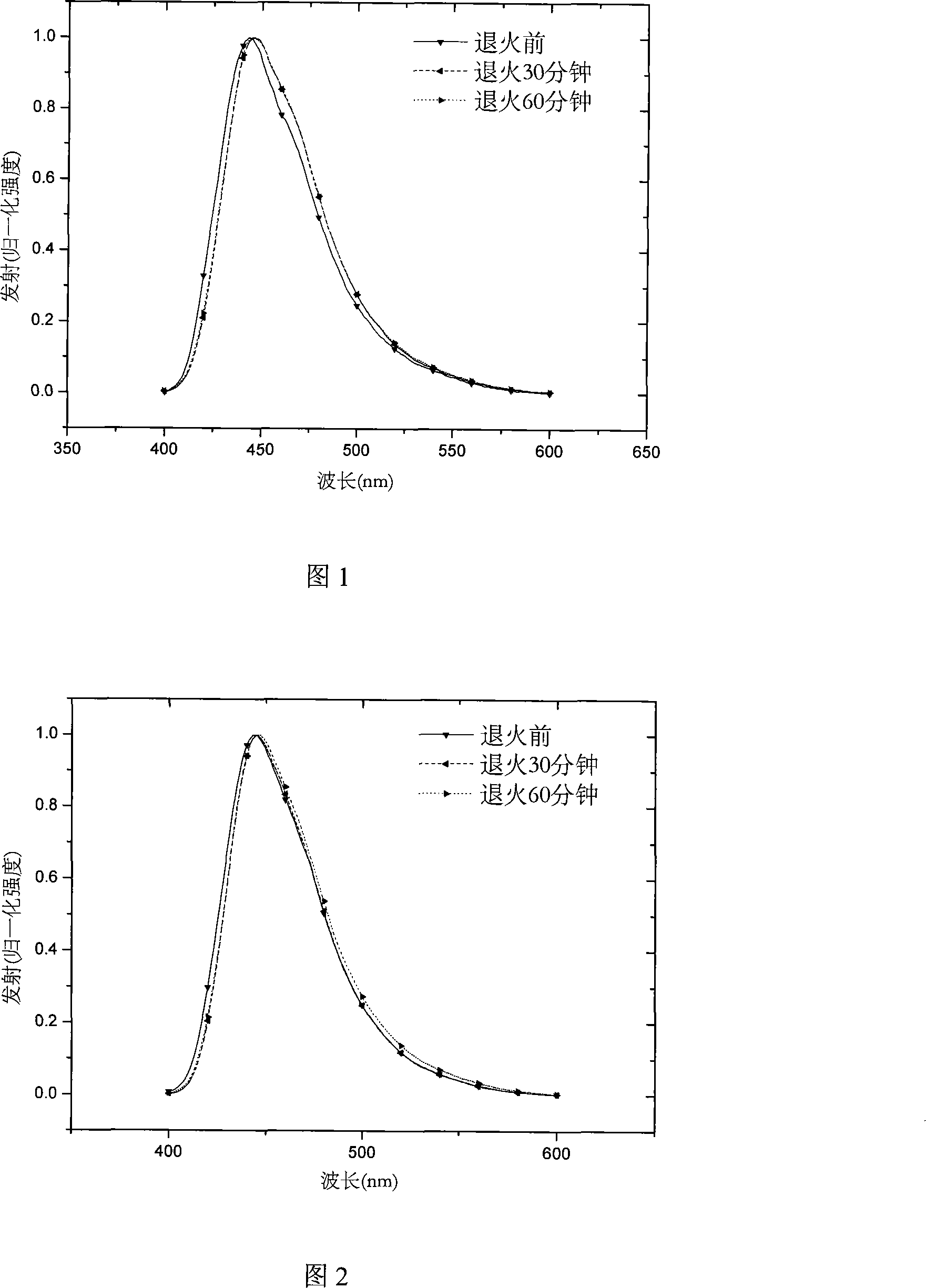

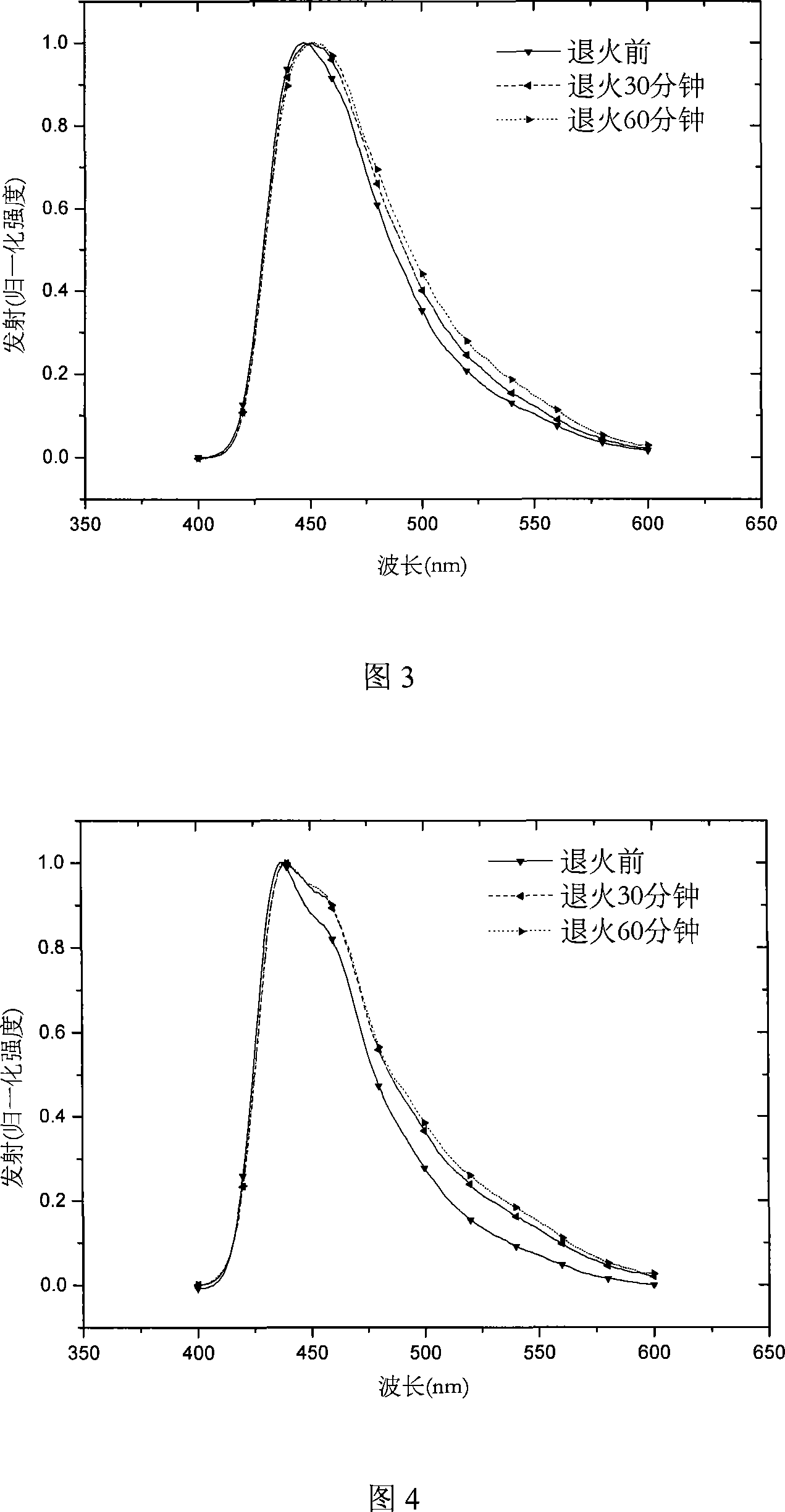

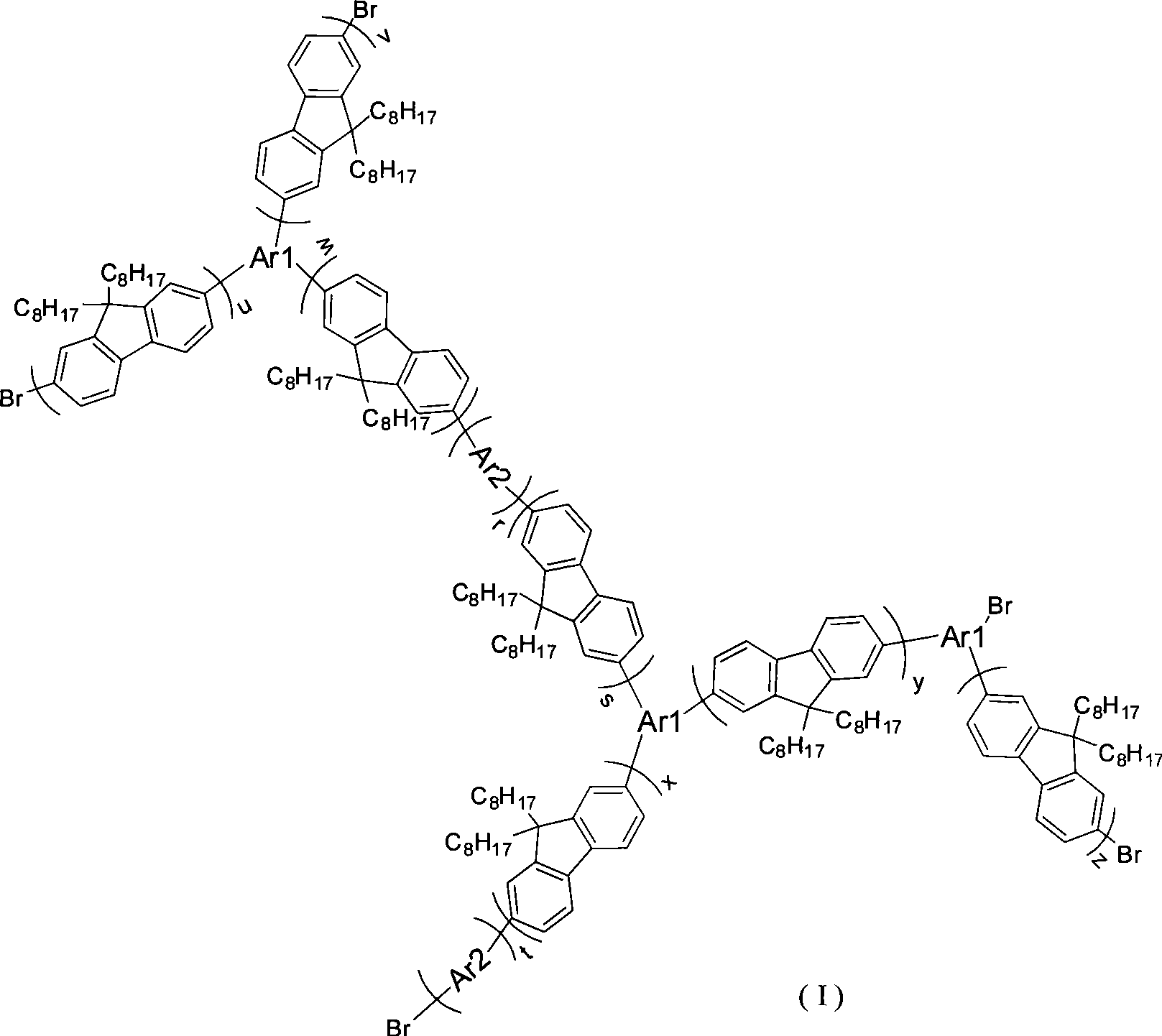

InactiveCN101245131AExacerbated distortionInhibit aggregationElectroluminescent light sourcesSolid-state devicesOrganic field-effect transistorPolyfluorene

The invention pertains to the technical field of organic and organometalic electro-active material, which more particularly relates to a hyperbranched polyfluorenes material comprising steric blockade and a preparation method thereof. The material introduces high blockade on the basis of hyperbranched polyfluorenes structure to distort considerately the synthesis molecular chain, thus efficiently inhibiting molecular aggregation, avoiding formation of excimer and fluorescence quenching, improving the material with luminous efficiency. As organic electro-active material with high inoxidability, thermal shock resistance and photostability, the material can be widely used in organic electronics industry such as organic / synthesis electroluminescent, photovoltaic cell, organic field-effect transistor and laser etc.

Owner:FUDAN UNIV

Spectroscopy-mass spectrometry combined quantitative analysis device for elements in unknown sample

PendingCN107219214AHigh detection sensitivityHigh precisionMaterial analysis by electric/magnetic meansAnalysis by thermal excitationResolution (mass spectrometry)Collection system

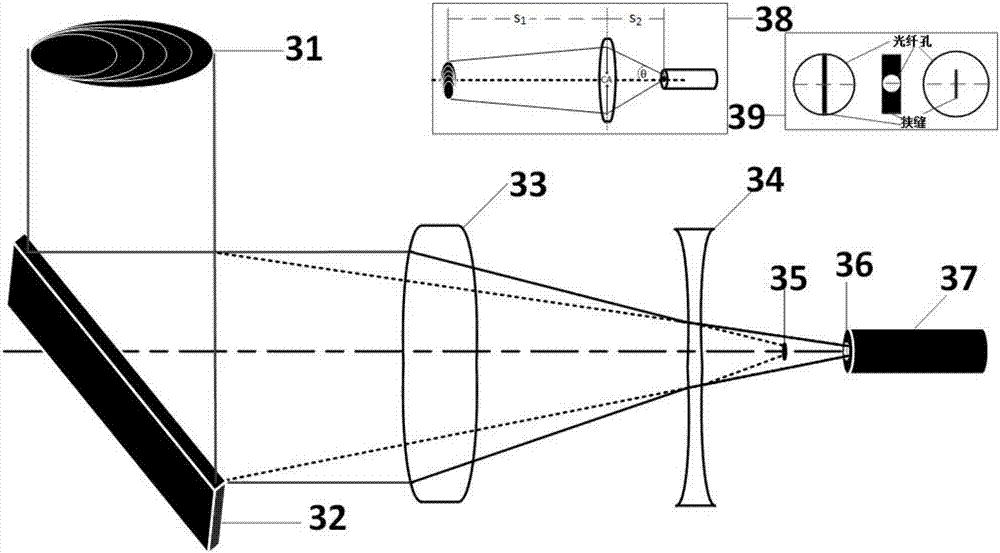

The invention discloses a spectroscopy-mass spectrometry combined quantitative analysis device for elements in an unknown sample. The device uses a quantitative analysis structure and a method by using a laser-induced breakdown spectroscopy combining with a second level extraction field time-of-flight mass spectrometry (TOF). The quantitative analysis device with high detection sensitivity, real time, quickness, high accuracy, no contact, capability of simultaneously detecting multiple elements, and no need of pretreating the sample is realized. Due to dual-wavelength laser in the device, photofragments and molecular clusters are re-ionized conveniently, the mass spectrometry signal stability is improved, and a laser plasma emission spectroscopy signal is improved; due to a second level extraction field in the device, the TOF resolution ratio is improved conveniently and the signal is optimized conveniently; due to a spectroscopy collection system in the device, the capability of collecting plasma emission light to couple to optical fiber can be improved, an optical path can be folded, the integration and the miniaturization of an instrument are facilitated, and the commercialization of the instrument is realized conveniently.

Owner:DALIAN UNIV OF TECH

Passive electric detection device and method for laser plasma

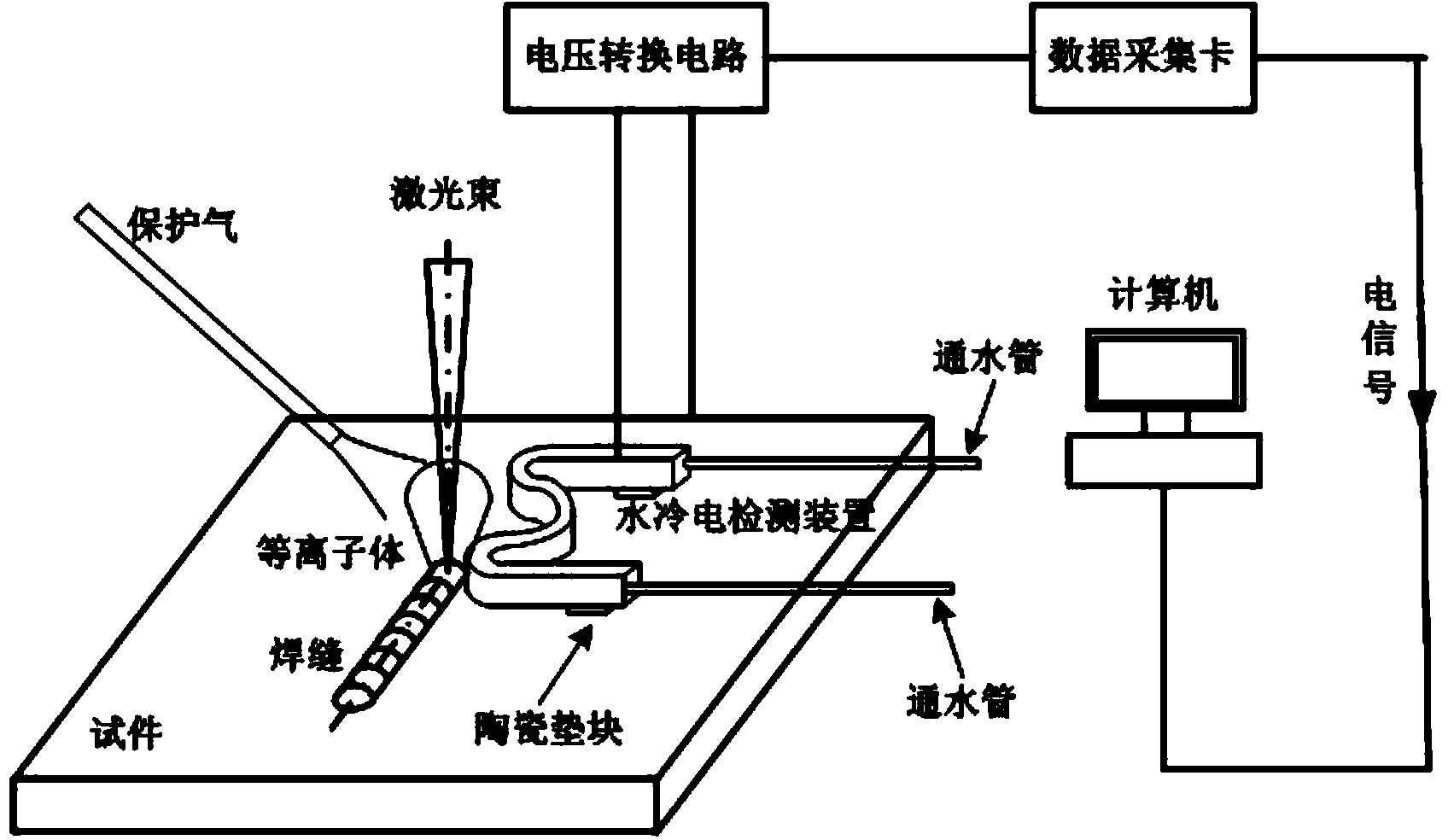

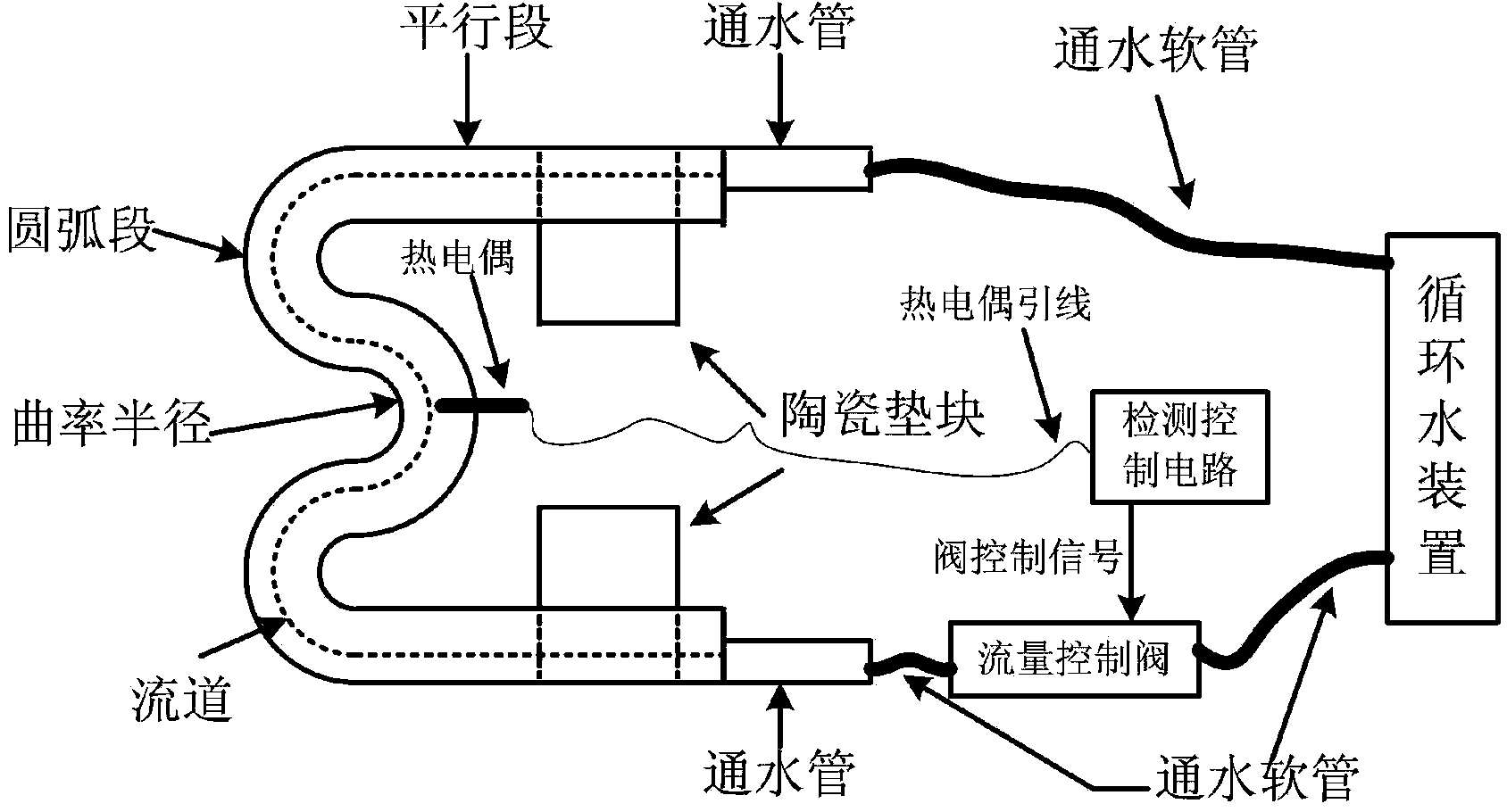

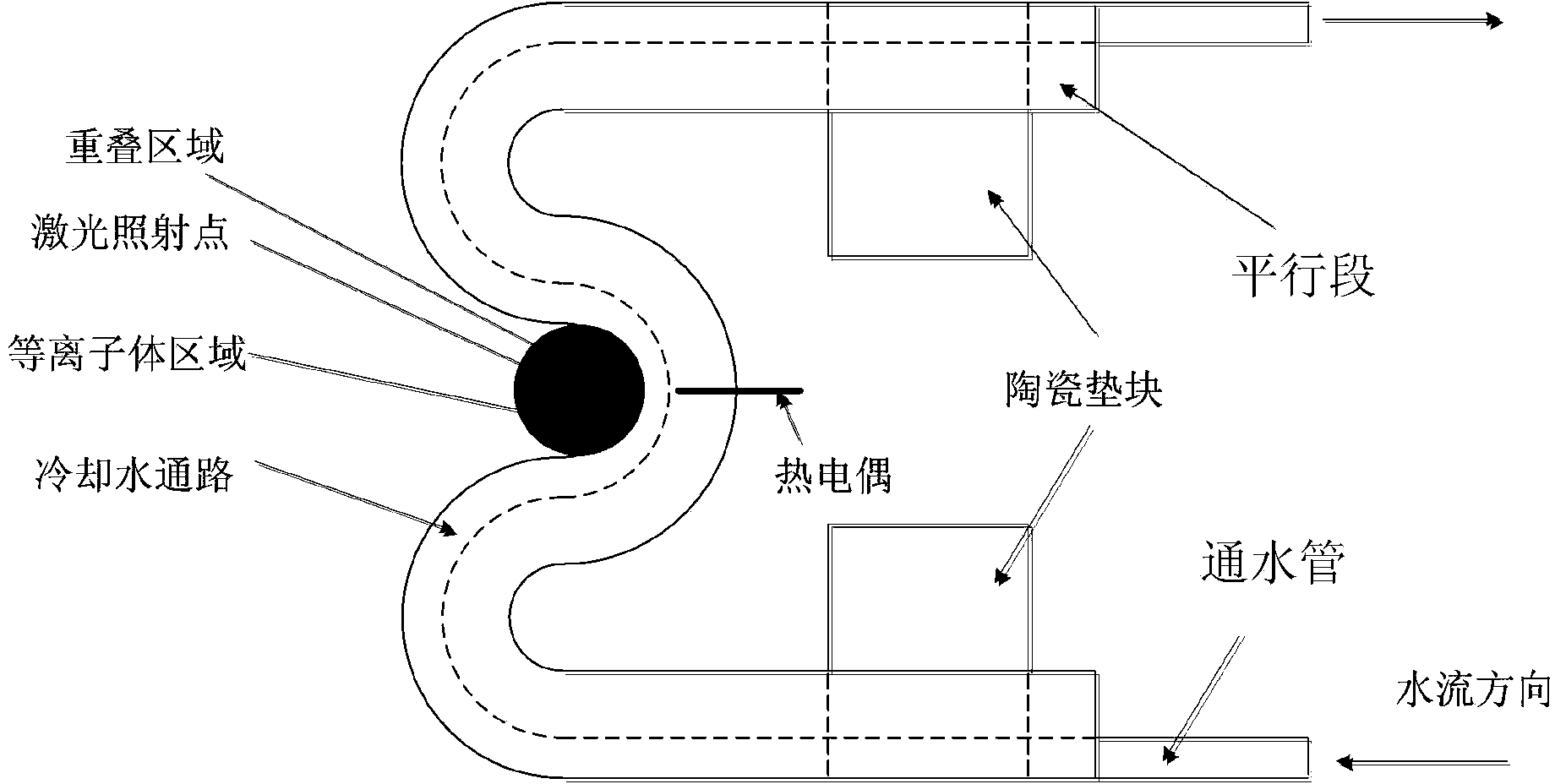

InactiveCN103528703AStable detectionExtend detection timeThermometers using electric/magnetic elementsUsing electrical meansData acquisitionEngineering

The invention discloses a passive electric detection device and method for laser plasma. The device consists of two parallel sections and an arc section, wherein the two parallel sections are parallel to each other and connected through the arc section; the whole device is in an M shape; a cross section of the electric detection device is rectangular; a flow channel is formed inside the electric detection device and used for flowing and circulation of water; the two parallel sections are connected with water pipes respectively; and a lead is arranged on the electric detection device and used for performing electric signal detection on the laser plasma. During testing, a laser acting point is located in a concave part of the device, and a ceramic pad is arranged between a to-be-welded object and the M-shaped electric detection device to keep insulation and avoid short circuit; the electric detection lead is connected with a data acquisition card, the data acquisition card is connected with a computer, and data acquisition preparation work is ready; and then water is supplied for cooling. According to the electric detection method for the laser plasma, the stability and the reliability of a real-time electric detection process for the temperature of the laser plasma during laser welding are improved, and the method is easy to implement.

Owner:TIANJIN UNIV

Double spiro material containing heteroaton and its synthetic method and use

InactiveCN1749254AGood body materialFacilitates electron transportSilicon organic compoundsElectroluminescent light sourcesVitrificationSemiconductor materials

The present invention belongs to the field of photoelectronic material technology, and is especially double spiro material containing hetero atom and its preparation process and application in organic plate display, photovoltaic cell, organic FET, laser and other organic electronics fields. The compounds are conjugate semiconductor material with double spiro structure introduced hetero atom. The double spiro material has the advantages of simple synthesis, capacity of further modification, effective realization of the photoelectronic property of modulation material, high heat stability, high vitrification point, etc. The material of the present invention may be used in producing photoluminescent device with satisfied brightness and light emitting efficiency, and has commercial application latent.

Owner:FUDAN UNIV

Method of utilizing laser plasma thin filaments to prepare metal multifunctional surface

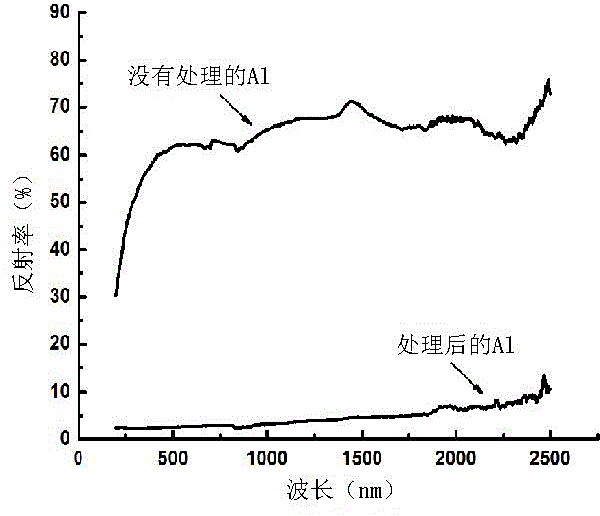

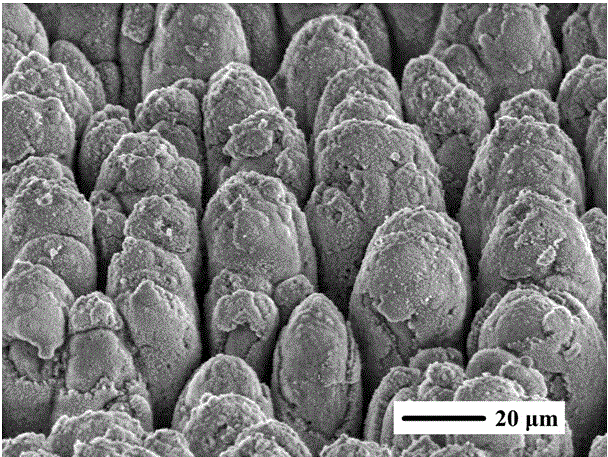

InactiveCN106141438AImprove performanceImprove featuresLaser beam welding apparatusFemto second laserMaterials science

The invention discloses a method of utilizing laser plasma thin filaments to prepare a metal multifunctional surface. Femtosecond laser plasma thin filaments carry out irradiation treatment on the surface of metal to integrate broadband spectrum high light absorption optical property with super-hydrophobic self-cleaning wetting property at one step, and any after-treatment including film coating (hydrophobic film) is not needed. Compared with the traditional method, the method has the following advantages: the surface functional characteristics are lasting and durable, the manufacturing flow is simple, and the production efficiency is high. The metal multifunctional surface can be applied in the fields of outdoor solar energy, a biological detector and a chip laboratory.

Owner:CHANGCHUN UNIV OF SCI & TECH

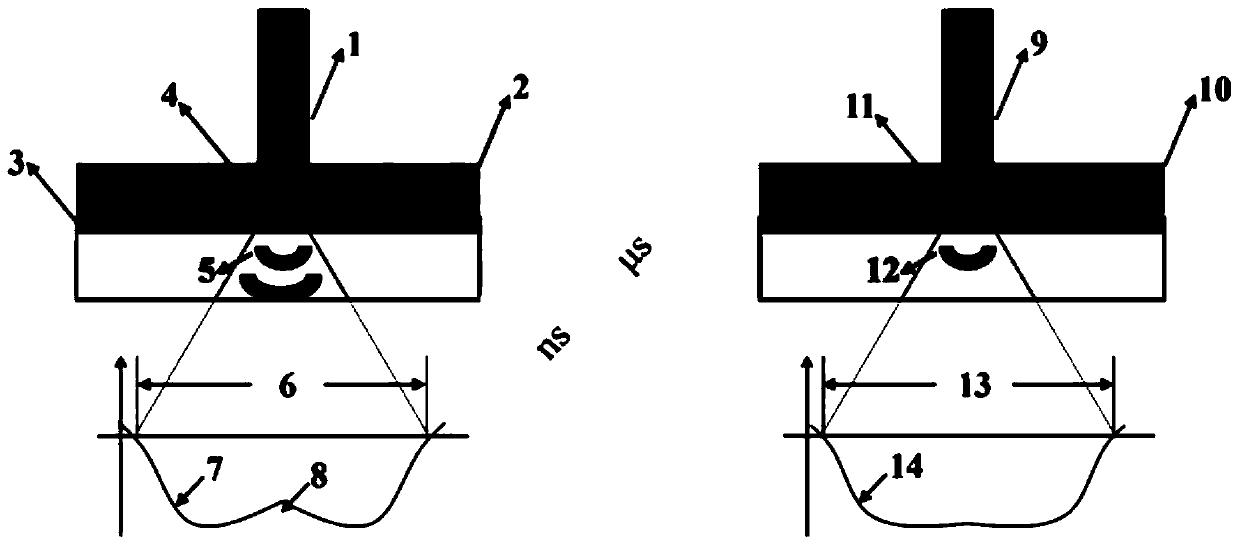

Uniform surface strengthening method based on laser shock wave

ActiveCN111074061AEliminate residual stress holesUniform distribution of residual stressShock waveKtp laser

The invention relates to a uniform surface strengthening method based on a laser shock wave. The uniform surface strengthening method based on the laser shock wave comprises the specific steps that anabsorption layer and a constraining layer are arranged on the surface of a workpiece sequentially in a clamped mode, a laser generator is arranged at a position opposite to the workpiece, the laser generator is located on the side close to the constraining layer of the workpiece, the workpiece is subjected to laser shock, the constraining layer is deionized water, and the thickness of a deionizedwater layer is 2-5 mm. The energy of the laser is 3-7J, the pulse width is 15-20ns, and the spot diameter is 1-4mm. The laser-induced "cavitation" effect is used for performing secondary strengthening on the workpiece to suppress or eliminate "residual stress holes" caused by the laser plasma shock wave on the surface of the workpiece, so that the residual stress is distributed on the surface ofthe workpiece uniformly.

Owner:SHANDONG UNIV

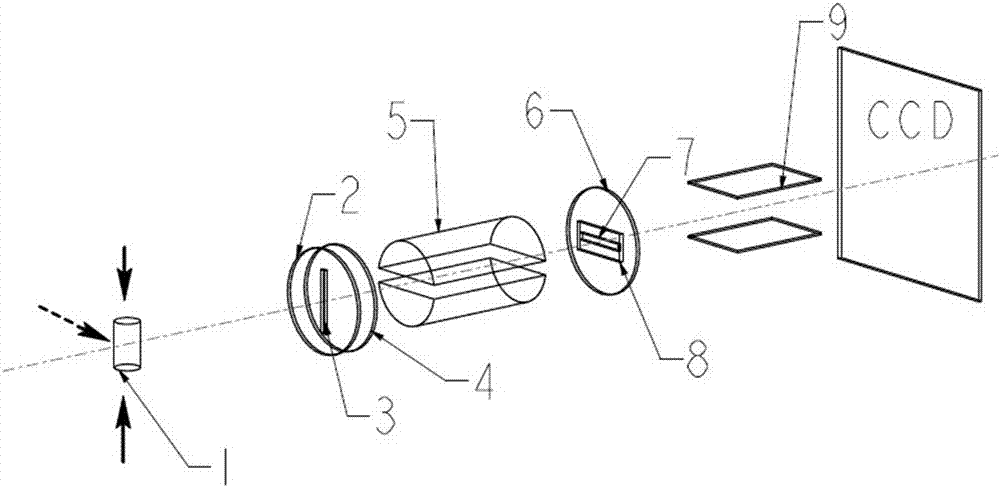

Sequential diagnosis system used for nanosecond and picosecond laser beam combined targeting

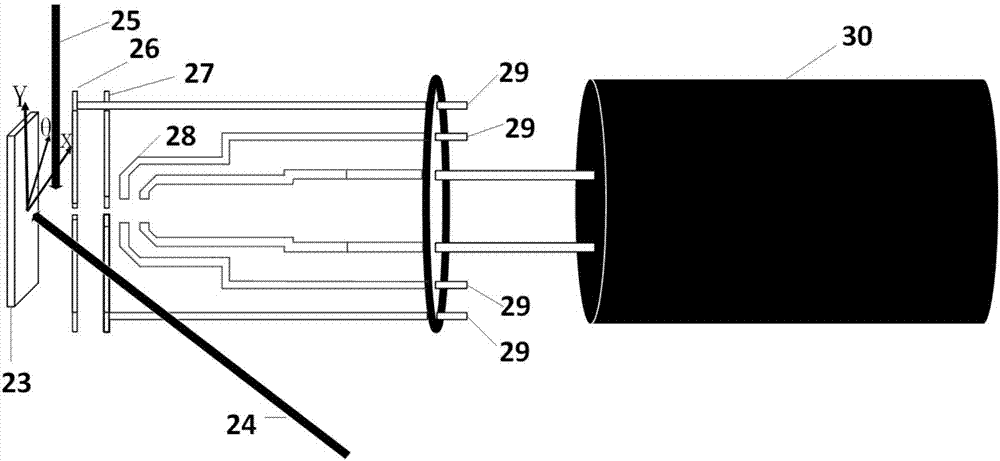

ActiveCN106908829AGood time resolutionNuclear energy generationX/gamma/cosmic radiation measurmentPicosecond laserPhotocathode

The invention discloses a sequential diagnosis system used for nanosecond and picosecond laser beam combined targeting, and is used for sequential precision diagnosis in combined targeting by using nanosecond laser beams and picosecond laser beams simultaneously in a laser plasma experiment. The sequential diagnosis system comprises an imaging slit plate, a hard X-ray shielding body, a photocathode slit plate, a photocathode and a streak camera which are arranged in turn along a horizontal direction. In the experiment, soft X-rays generated by nanosecond laser beam targeting are imaged through the slit plate and then irradiated to the partial area of the photocathode; and hard X-rays generated by picosecond laser beam targeting directly penetrate through the slit plate (without imaging) and then irradiate all the area of the photocathode. Two types of X-rays of which the original light source positions are overlapped can be spatially separated on the images recorded by the streak camera so that diagnosis of the sequential relationship between the nanosecond laser beams and the picosecond laser beams can be realized. The sequential diagnosis system has ten picosecond level time discrimination and also has certain soft X-ray spatial discrimination so as to have wide application prospect.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

End capped thiofuran small-molecule and polymer material, treating method and use thereof

InactiveCN1743409AElectroluminescent light sourcesSolid-state devicesOrganic field-effect transistorElectron

This invention relates to an organic photoelectric material containing thiophene small molecules and polymers processed by capping agent and its preparation method used in organic panel display, photovoltaic cells, organic field-effect transistors and laser, which is advantaged at: 1, the convenient and easy method with light-duty reaction, 2, having the structured high heat stability and a glass temperature.

Owner:FUDAN UNIV

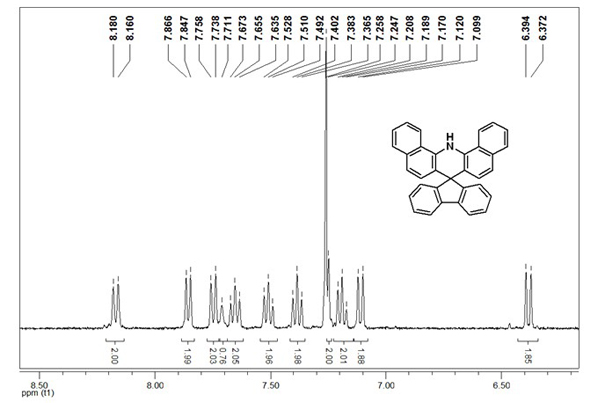

Preparation method of spirofluorene acridine intermediate

InactiveCN102050782ARaw materials are easy to getEasy to operateOrganic chemistryOrganic synthesisOrganic laser

The invention relates to a preparation method of a spirofluorene acridine intermediate, relating to the fine organic synthesis field and the photoelectric material application field. The spirofluorene acridine material with the structure shown as below is used as an important organic intermediate in the new fields such as the organic electroluminescence, the photovoltaic cell, the organic electrical storage, the organic nonlinear optics and the organic laser. The invention relates to a novel preparation method of spirofluorene acridine monomer, in particular to a two-step tandem reaction adopting the one pot method. The preparation method comprises the following steps: heating arylamine, arylamine hydrochloride and fluorenone or a derivative of fluorenone to fully react and generate open-loop 9,9'-diaryl intermediate product; and (2) adding polyphosphoric acid and arylamine in the reaction tank to close the loop, alkalifying, stirring, filtering, and washing to obtain the high purity product. The preparation method of the spirofluorene acridine intermediate has the following characteristics: (1) the one pot method is adopted for the tandem preparation process, the middle separation step is not required, the raw materials are cheap and accessible, the yield is high, the product is easy to separate and purify; and (2) the method has mass production value and is environmental friendly.

Owner:NANJING FANGYUAN GLOBAL DISPLAY TECH

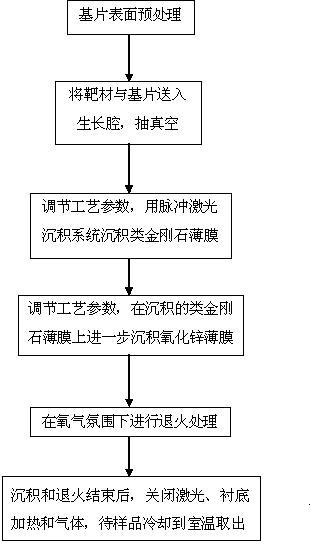

Preparation method of zinc oxide/diamond-like surface acoustic wave device composite film

InactiveCN102286722AReduce lossHigh crystallinityVacuum evaporation coatingSputtering coatingComposite filmElectromechanical coupling coefficient

A diamond-like carbon (DLC) film has high sound velocity and smooth surface and is an ideal substrate material of the surface acoustic wave device; and the zinc oxide (ZnO) film with c-axis preferred orientation has piezoelectric property. The invention relates to a surface acoustic wave device and provides a preparation method of a ZnO / DLC surface acoustic wave device composite film structure which can be used in the field of surface acoustic wave devices with high frequency, electromechanical coupling coefficient and power. In the method, a pulse laser plasma deposition technology is utilized and uses graphite and ZnO as the target. The method comprises the following steps: depositing a DLC film on a silicon substrate, and further depositing a ZnO film with c-axis preferred orientation on the DLC film to obtain the ZnO / DLC composite film structure for the film surface acoustic wave device. The method is simple and practical in preparation technology; and the ZnO / DLC composite film structure can be used for preparing the surface acoustic wave device which has the advantages of low insertion loss, high frequency and high power.

Owner:NANJING UNIV OF SCI & TECH

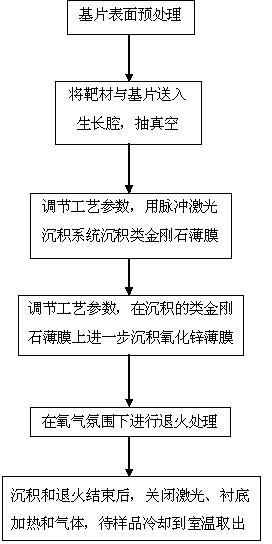

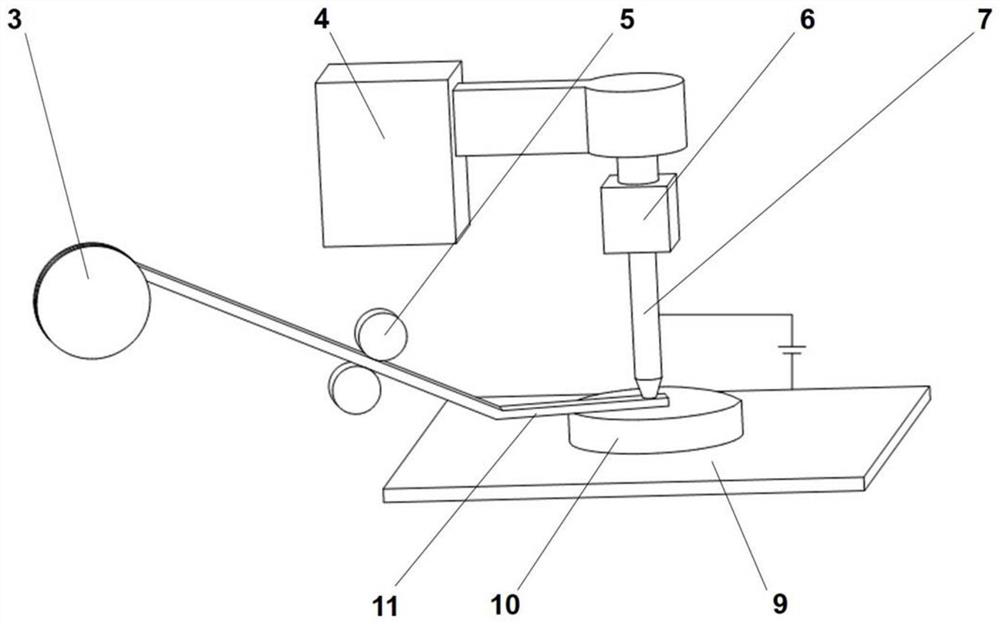

3D printing method and device based on pulse current

ActiveCN112590196AImprove stabilityAccurate and controllable heat action timeAdditive manufacturing apparatus3D object support structuresMolten stateHigh energy

The invention provides a 3D printing method based on pulse current. The method comprises the following steps of using an amorphous alloy wire or a strip as a raw material, carrying out spot pressing on the amorphous alloy wire or the strip, welding by the pulse current, and stacking layer by layer to form a three-dimensional sample piece. According to the method, the pulse current is used as a heat source for amorphous alloy space additive manufacturing, on one hand, power consumption needed in the manufacturing process is far smaller than that of electron beams, lasers and other traditional heat sources, the energy utilization rate is increased, low-power-consumption additive manufacturing is achieved, on the other hand, the pulse current is used for rapid heating, so that an amorphous alloy is in a non-molten state with low viscosity, the problems that a molten pool is difficult to control under microgravity and heat dissipation and solidification are difficult and the like in a high-vacuum environment in a traditional 3D printing method of metal materials can be solved, and the stability of the space additive manufacturing process can be improved. Besides, point pressure rapid welding and layer-by-layer additive manufacturing are conducted on the amorphous alloy through the pulse current, the thermal action time in the additive manufacturing process is accurate and controllable, the amorphous structure of the raw materials can be kept, and the mechanical property of an additive sample piece is improved.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

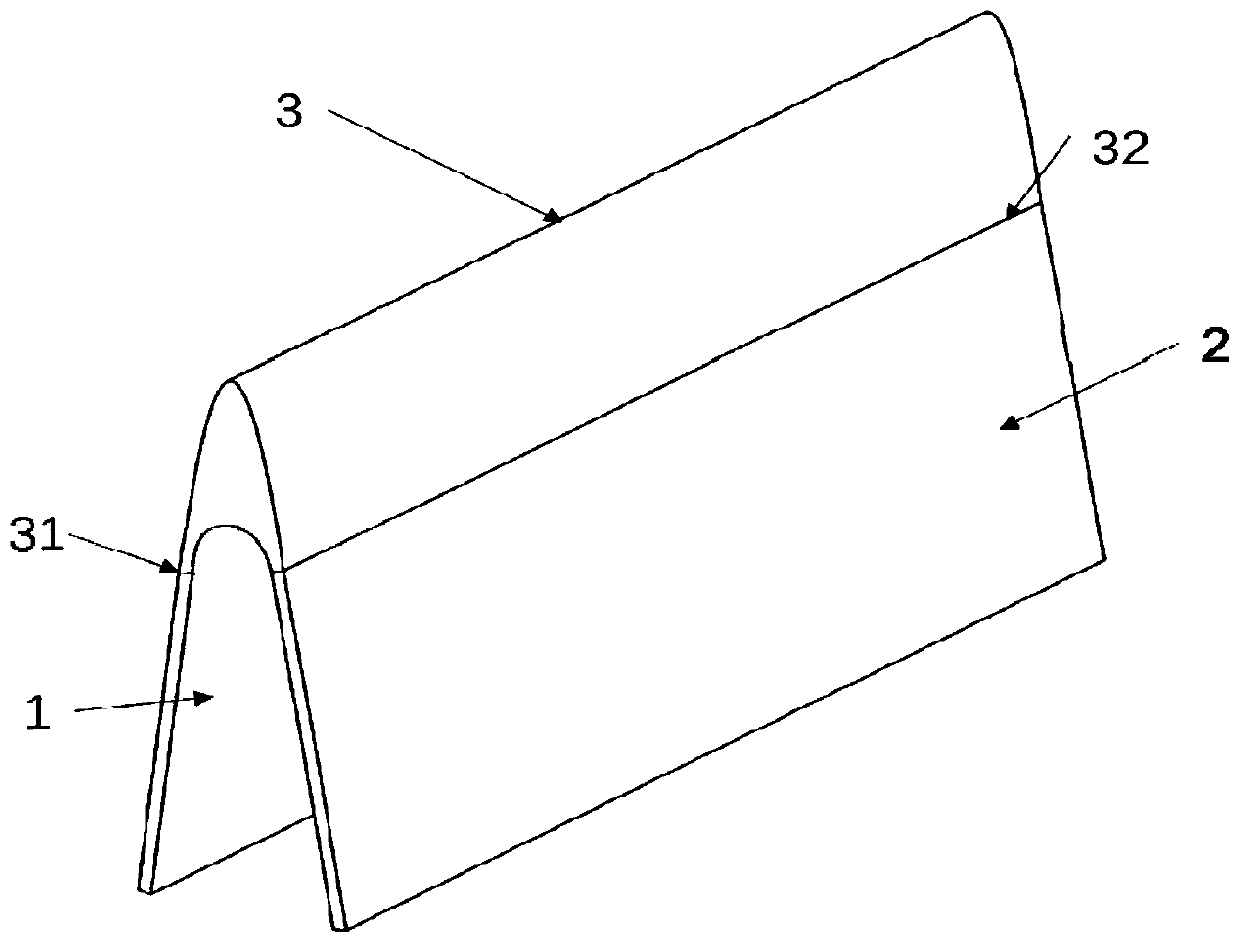

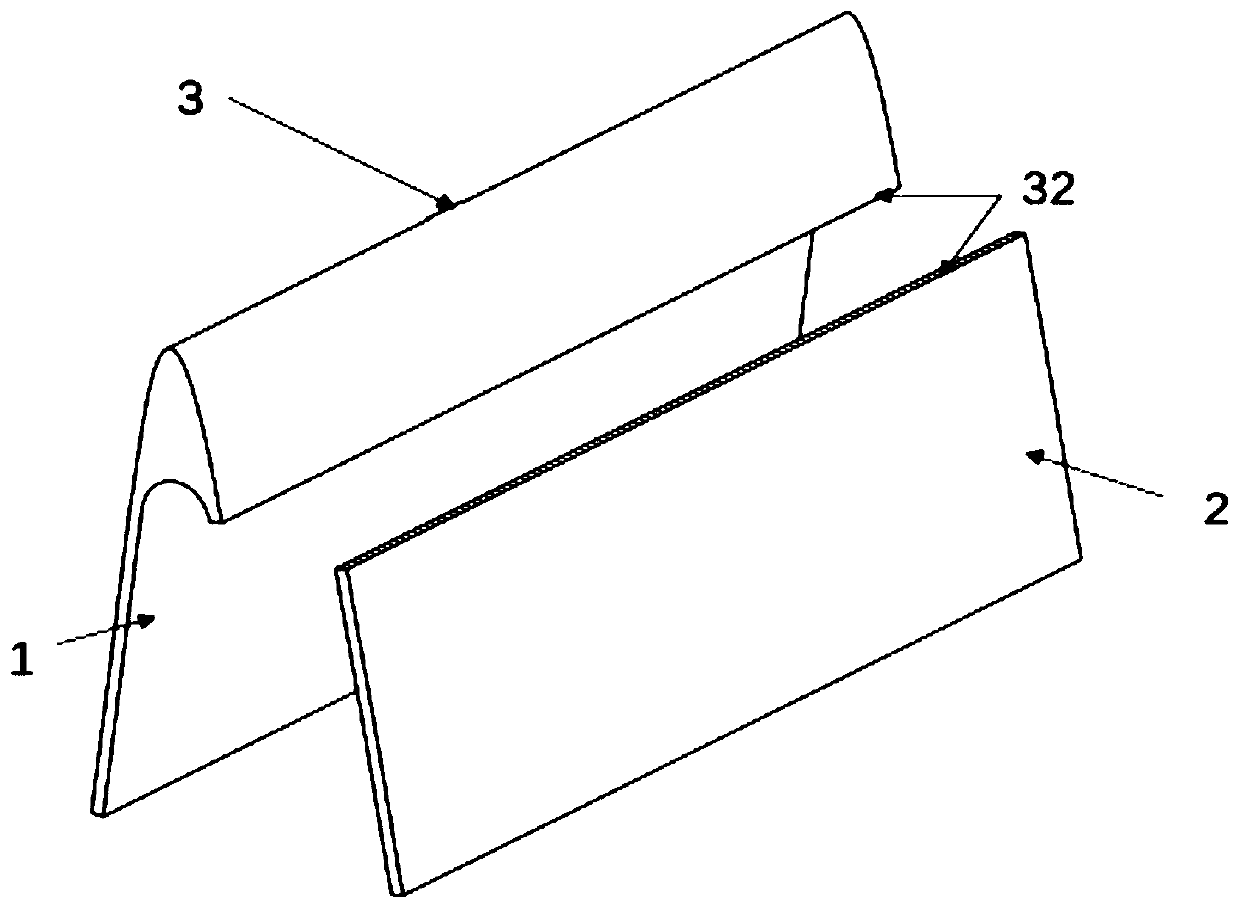

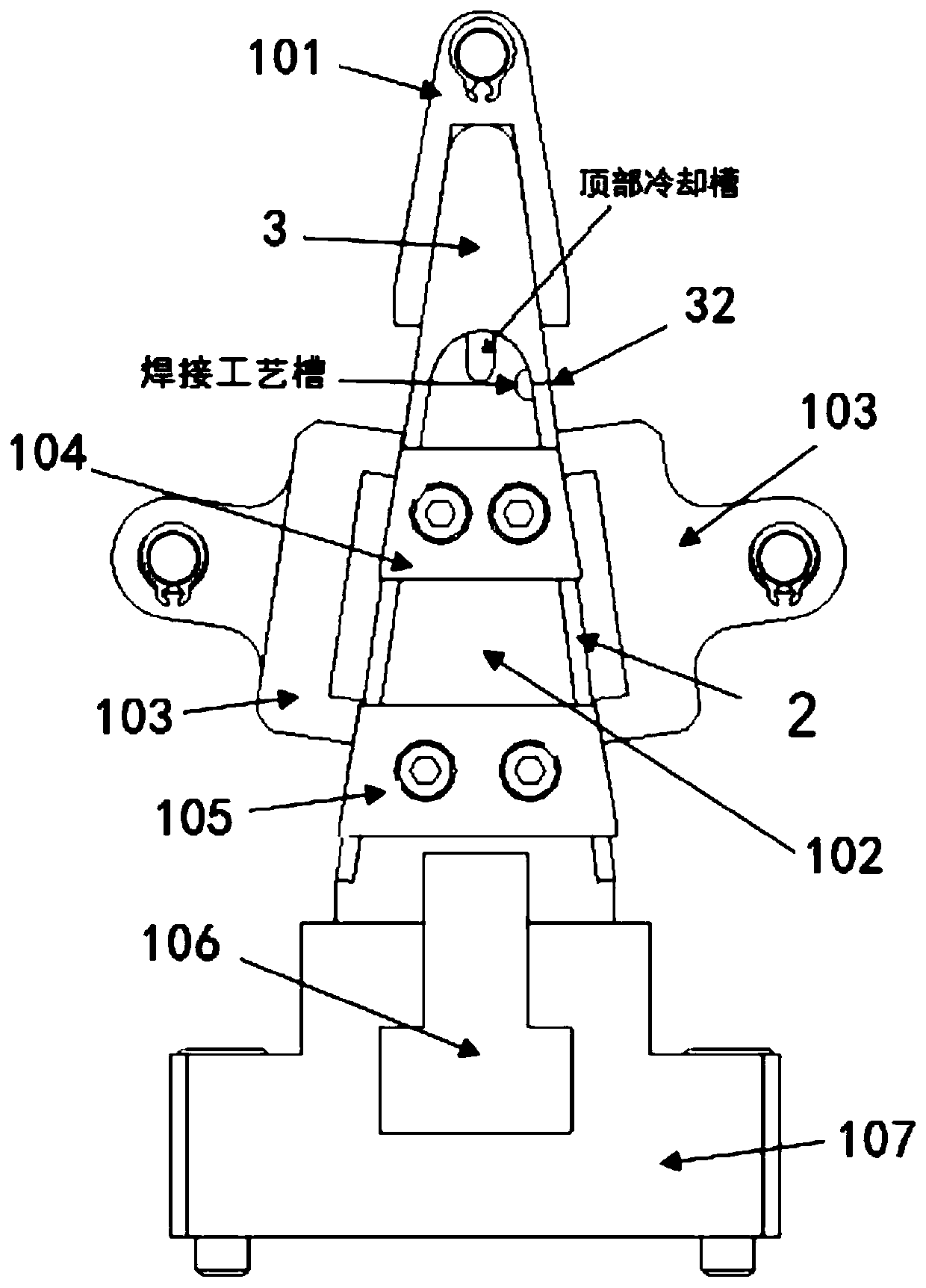

Metal edge wrapper for aircraft engine fan blade, machining tool and machining method

PendingCN110439623AReduce processing costsGuaranteed orthopedic effectPump componentsBlade accessoriesManufacturing technologyMachine tool

The invention discloses a metal edge wrapper for an aircraft engine fan blade, a machining tool and a machining method and belongs to the aircraft component manufacturing technology. The metal edge wrapper comprises side plates and a nose wing. The machining tool comprises a pressure part, an inner strutting piece, side pressing plates, end clamping plates, a built-in fixing part and an external pull fixed base. The pressure part and the side pressing plates are in pivot connection through four-link pressing and locating assemblies. The machining method comprises the steps of preparing the tool, clamping the metal edge wrapper, welding the metal edge wrapper, conducting distressing heat treatment and removing the tool to complete machining. The machining method is adopted for conducting welding on the metal edge wrapper clamped and located by the tool and can adapt to multi-curvature complicated 3D-shape metal edge wrappers. The clamped metal edge wrapper is leveled first. Implementation of the machining method is not limited to the welding manners such as electron beams, CMT or laser. The welded metal edge wrapper can be subjected to heat treatment along with the machining tool. The shaping effect is ensured. Through the machining method, the machining cost of the metal edge wrapper can be remarkably reduced, and the efficiency can be improved.

Owner:上海两擎机电科技合伙企业(有限合伙)

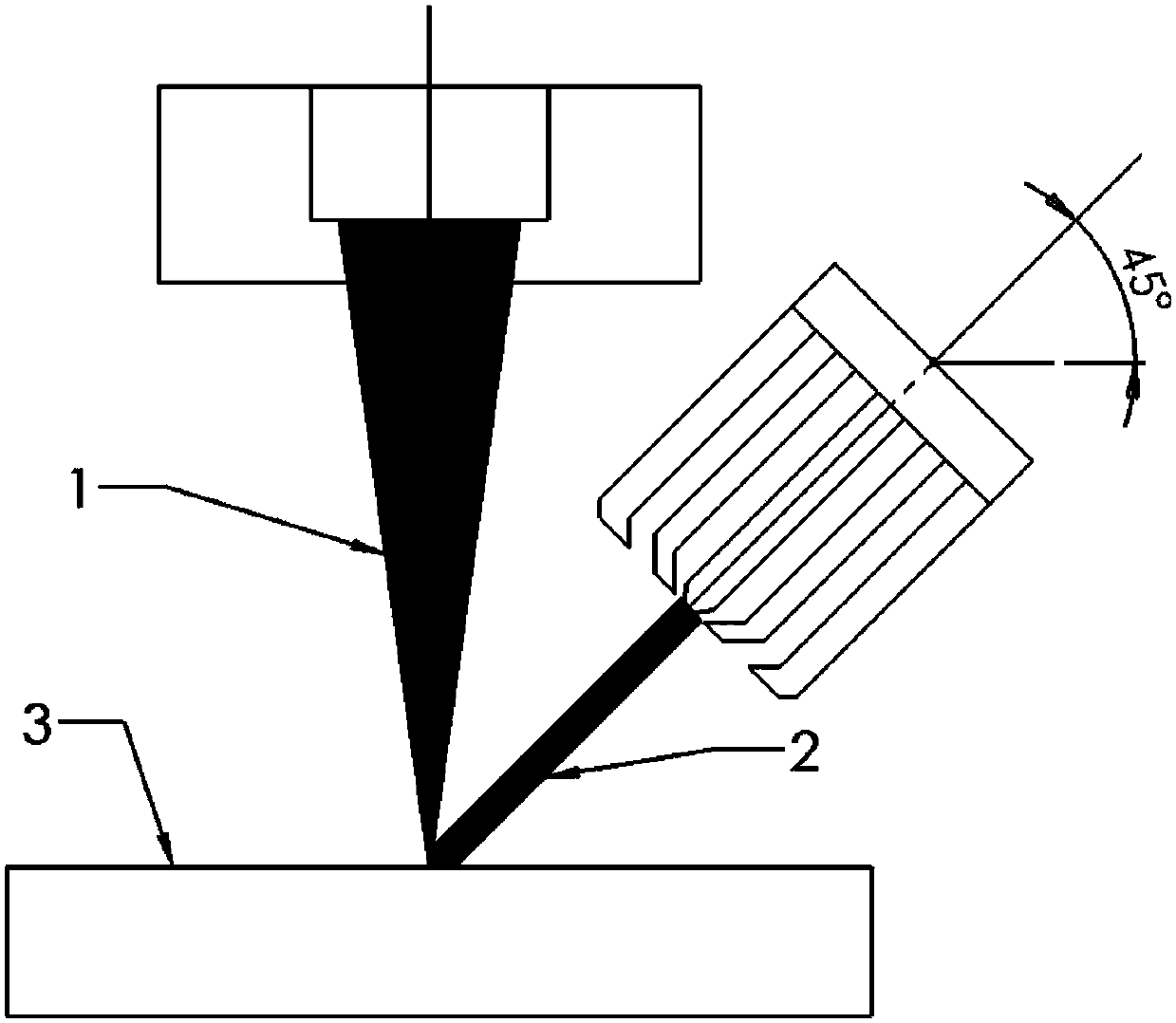

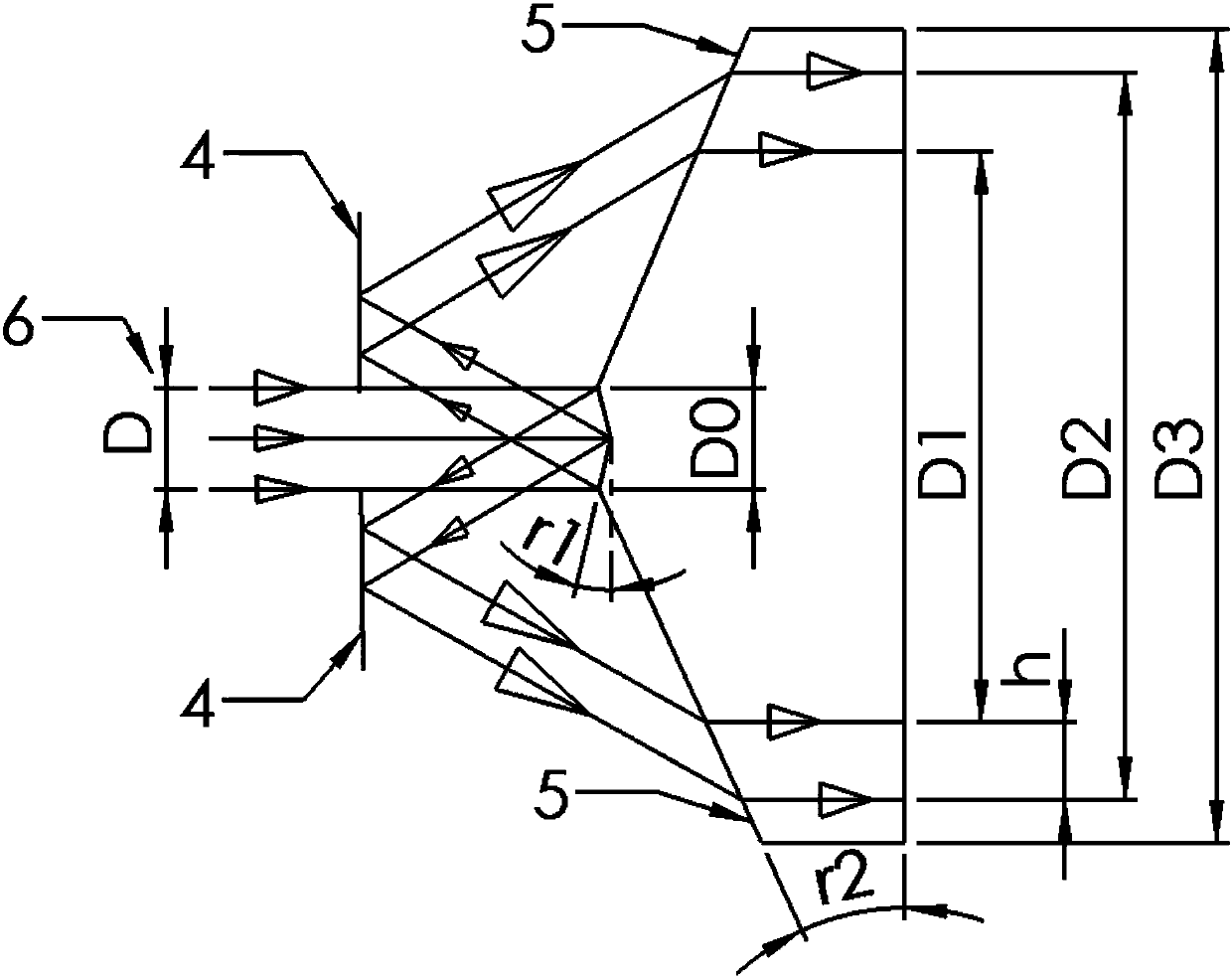

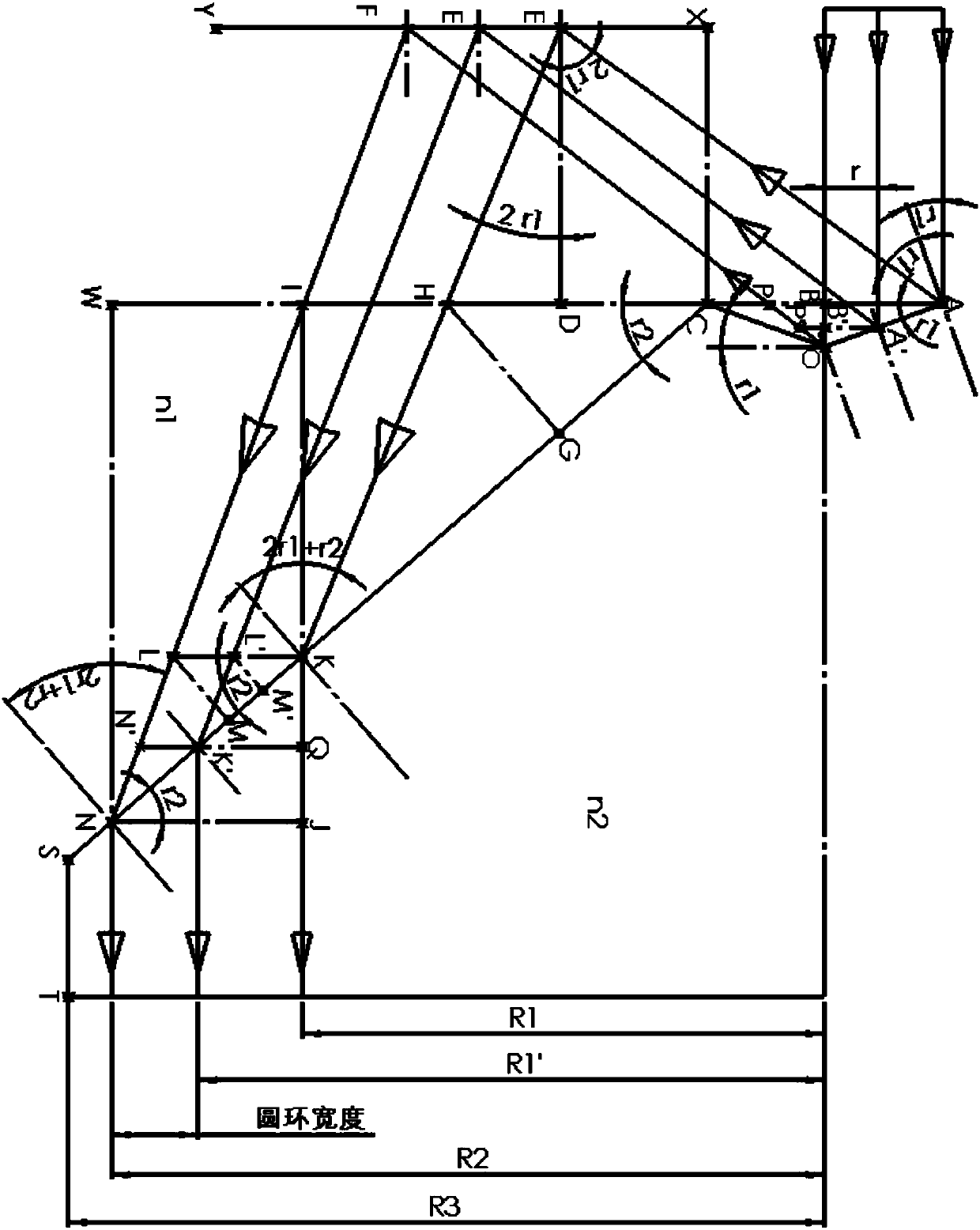

Beam shaping method for laser-plasma arc coaxial hybrid welding

Provided is a beam shaping method for laser-plasma arc coaxial hybrid welding. The method is based on the laser-plasma arc coaxial hybrid welding and can be applied to curve welding and three-dimensional welding. The diameter of an incident beam is determined, namely, the diameter D of a central round hole of a plane mirror and the inner cone diameter D0 of a conscope are determined; the inner conical angle gamma 1 and the outer conical angle gamma 2 of the conscope are determined; the distance between the plane mirror and the conscope is calculated; the largest inner ring diameter D1 and the largest outer ring diameter D2, which can be obtained through the conscope, of an annular beam are determined; the largest diameter D3 of the conscope is determined in the outer conical direction; it is determined that light, which is r far from a beam center, emitted from the inner round hole of the plane mirror enters the conscope and comes out to form an annular beam, wherein r is not smaller than 0 but not larger than D / 2; the width h of a circular ring is determined. By means of the method, the size of the device used in a prior shaping method is reduced, and the method has important significance to application of laser-plasma arc coaxial hybrid welding.

Owner:嘉兴琥珀科技有限公司

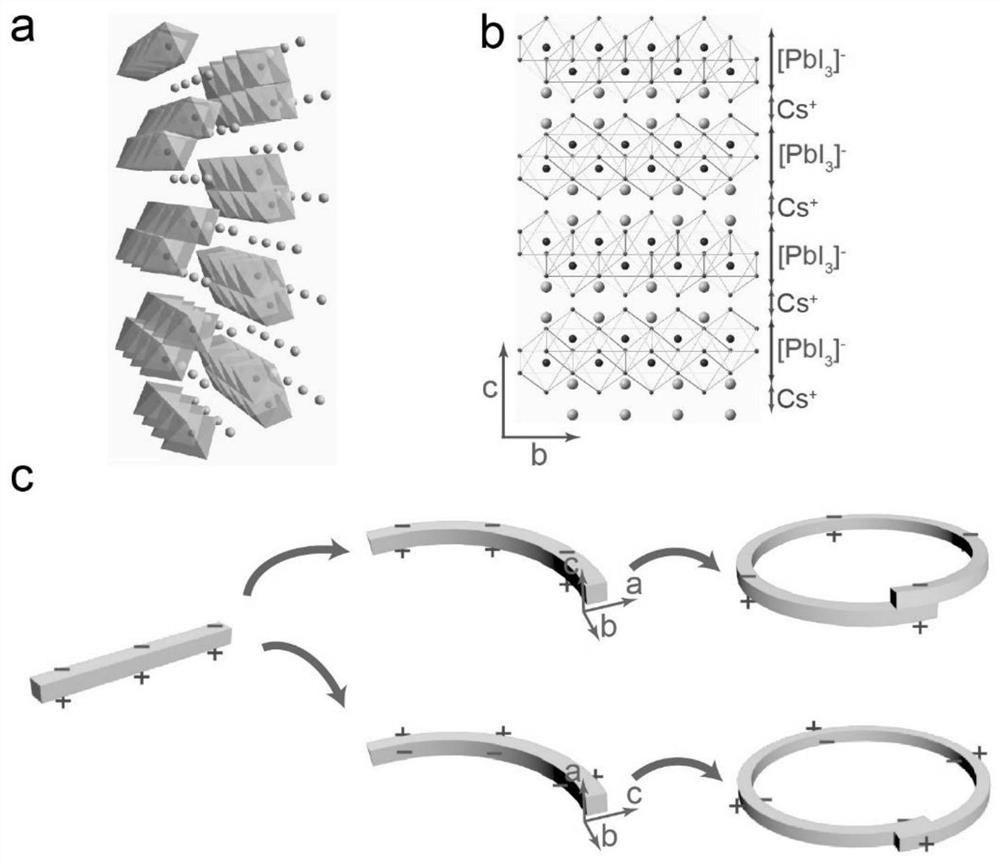

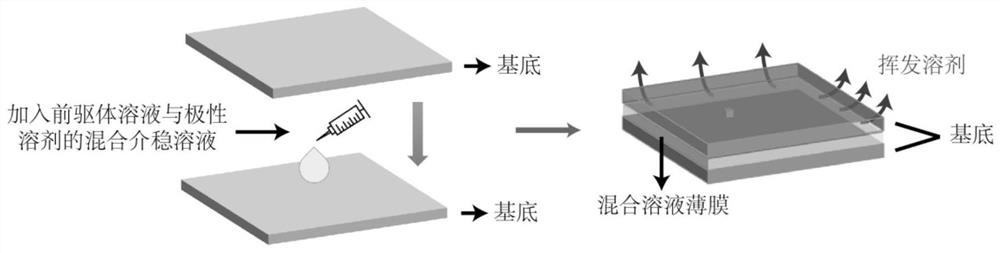

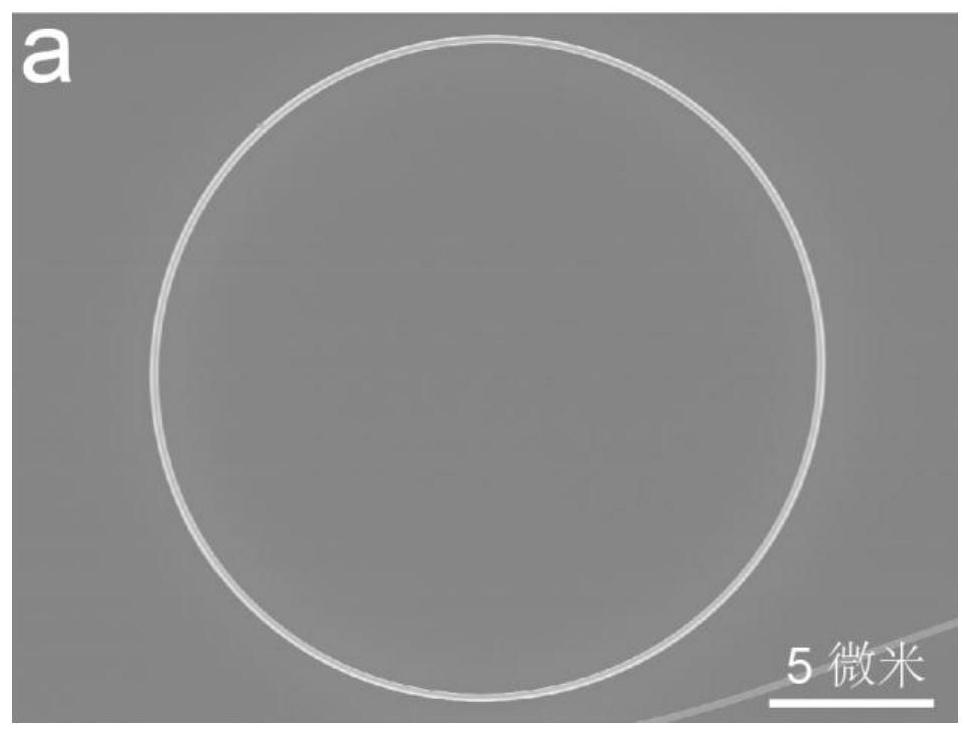

Perovskite single crystal nanoring and preparation method and application thereof

PendingCN111908417AEasy to prepareEasy to operateMaterial nanotechnologySemi-permeable membranesOrganic solventPerovskite (structure)

The invention discloses a perovskite single crystal nanoring and a preparation method and application thereof. The perovskite single crystal nanoring has an annular morphology and a single crystal structure, is an independent and continuous nanoring, is regular in morphology, has no visible surface defect structures such as grain boundaries and pores, and has good crystal quality. A two-dimensional confinement space is formed by a substrate, a metastable solution formed by the perovskite precursor solution and a polar organic solvent grows in the two-dimensional confinement space to form a single-crystal nanoring structure, the perovskite single-crystal nanoring is prepared through the two-dimensional confinement space of the substrate and solvent regulation and control engineering, and compared with other methods, the invention is small in energy consumption, low in cost and suitable for industrial production. The invention is low in cost, simple in process, clear in product, single in product configuration and suitable for large-scale production; the perovskite single crystal nanoring disclosed by the invention is of a single crystal structure, has the advantages of higher crystal quality, no crystal boundary and small defect density, and has huge potential application value in the fields of laser and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

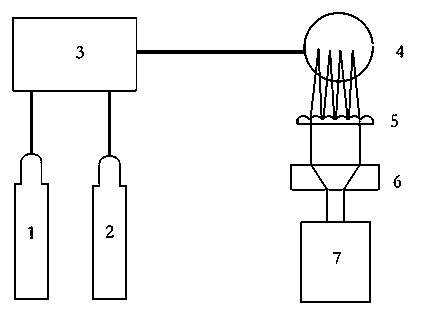

Method and device for realizing combustible gas multi-point laser plasma ignition based on microlens array

InactiveCN103982303AImprove reliabilityIncrease redundancyGas turbine plantsRocket engine plantsOptical axisCombustible gas

The invention discloses a method and a device for realizing combustible gas multi-point laser plasma ignition based on a microlens array. The method comprises the steps of 1, feeding combustible gas into a nozzle; 2, enabling a laser device to emit laser which is incident to the microlens array after being expanded and collimated, inducing to generate a plurality of plasmas in mixed fuel gas above the axial line of the nozzle, and igniting the combustible gas. The device comprises a fuel gas source, an oxidizing agent gas source, a gas distribution system, the nozzle, and the laser device, a beam expansion and collimation system and the microlens array which are arranged in sequence along the optical axis direction, wherein gas outlets of the fuel gas source and the oxidizing agent gas source are connected with the gas inlet of the gas distribution system; the gas outlet of the gas distribution system is connected with the gas inlet of the nozzle; the nozzle is positioned at a focal length of the microlens array. By adopting the method and the device, the reliability of laser plasma ignition can be greatly improved.

Owner:HARBIN INST OF TECH

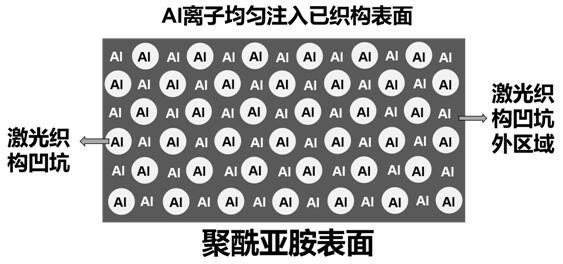

Method for modifying polyimide surface by laser texturing of circular pit array and injection of metal ions

ActiveCN112376030AWith oil storageImprove carrying capacityVacuum evaporation coatingSputtering coatingSpaceflightIon implantation

The invention discloses a method for modifying a polyimide surface by laser texturing of a circular pit array and injection of metal ions The method comprises the following steps: carrying out circular pit array texturing treatment on the polyimide surface by using a laser processing system and a single-pulse same-point multiple-interval process, and injecting Al metal ions into the textured polyimide surface by adopting a Mevva-5.Ru vacuum arc ion source to obtain modified polyimide. The friction coefficient of the modified polyimide is reduced from 0.80 to about 0.20, and the modified polyimide has low friction performance, can be used in the fields of aviation, spaceflight, microelectronics, nanometer, liquid crystal, separation films, laser and the like, and can also be used as a new technology for surface treatment of bridges and building sliding plates to improve the surface wear resistance and lubricating performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

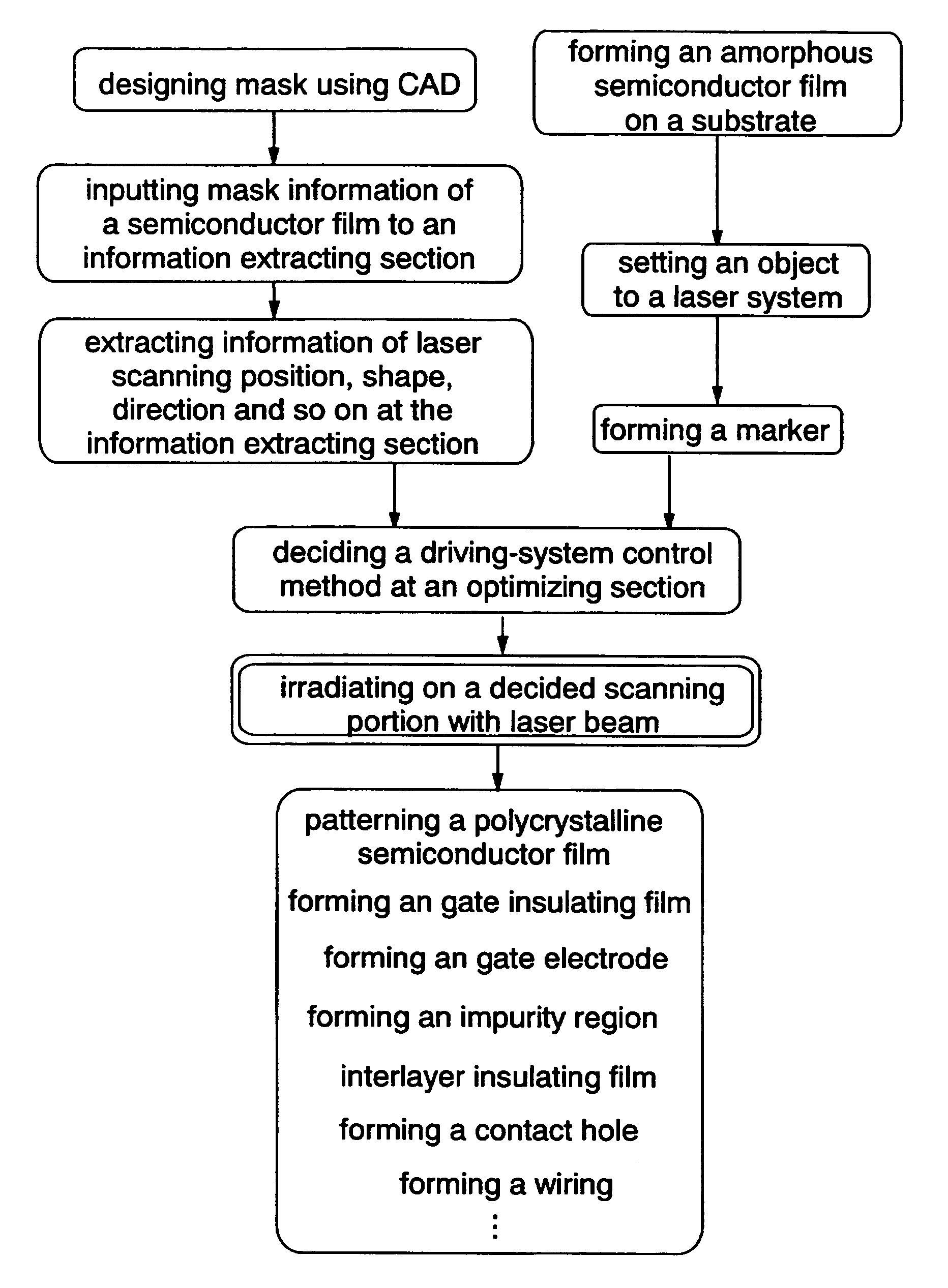

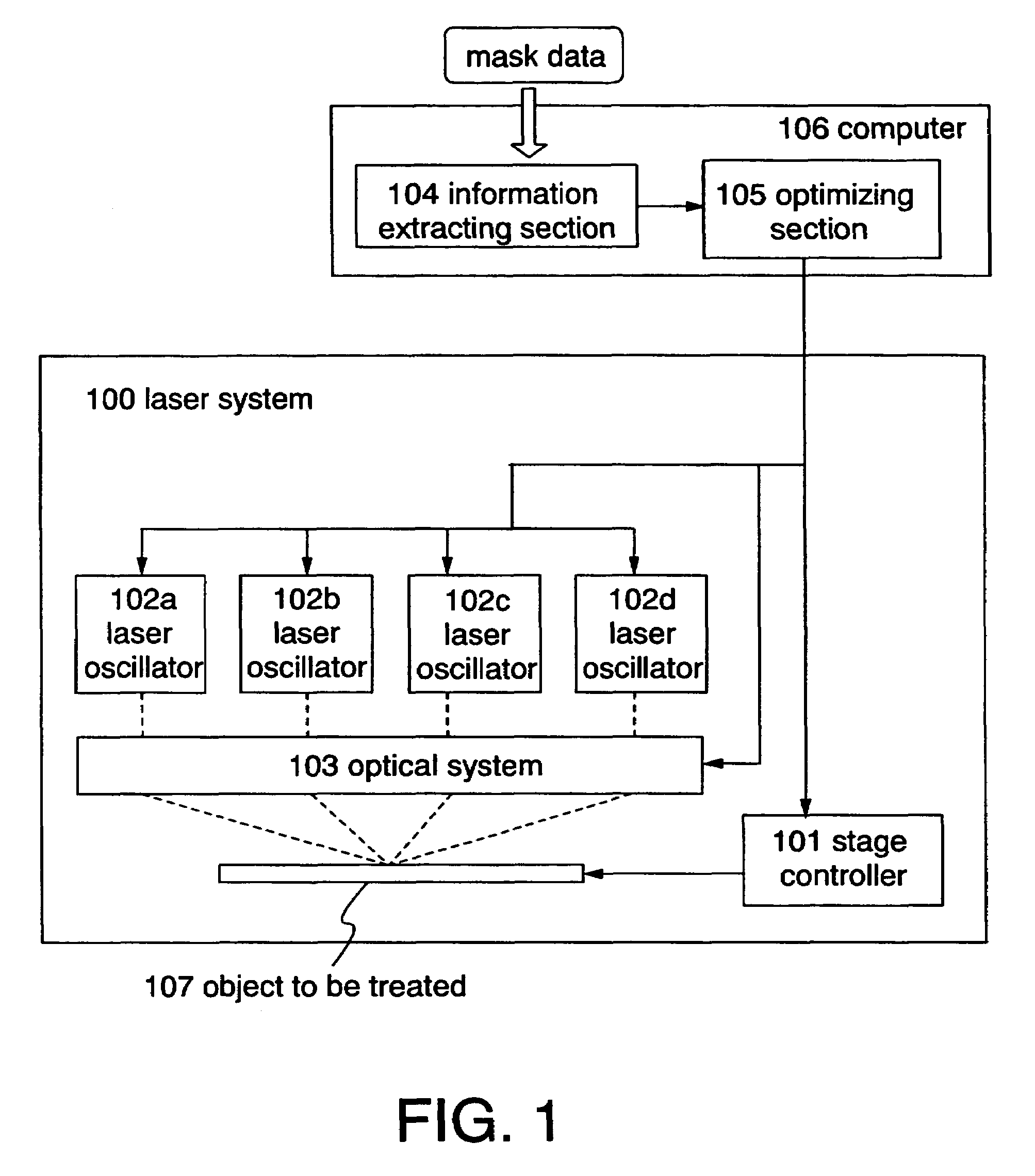

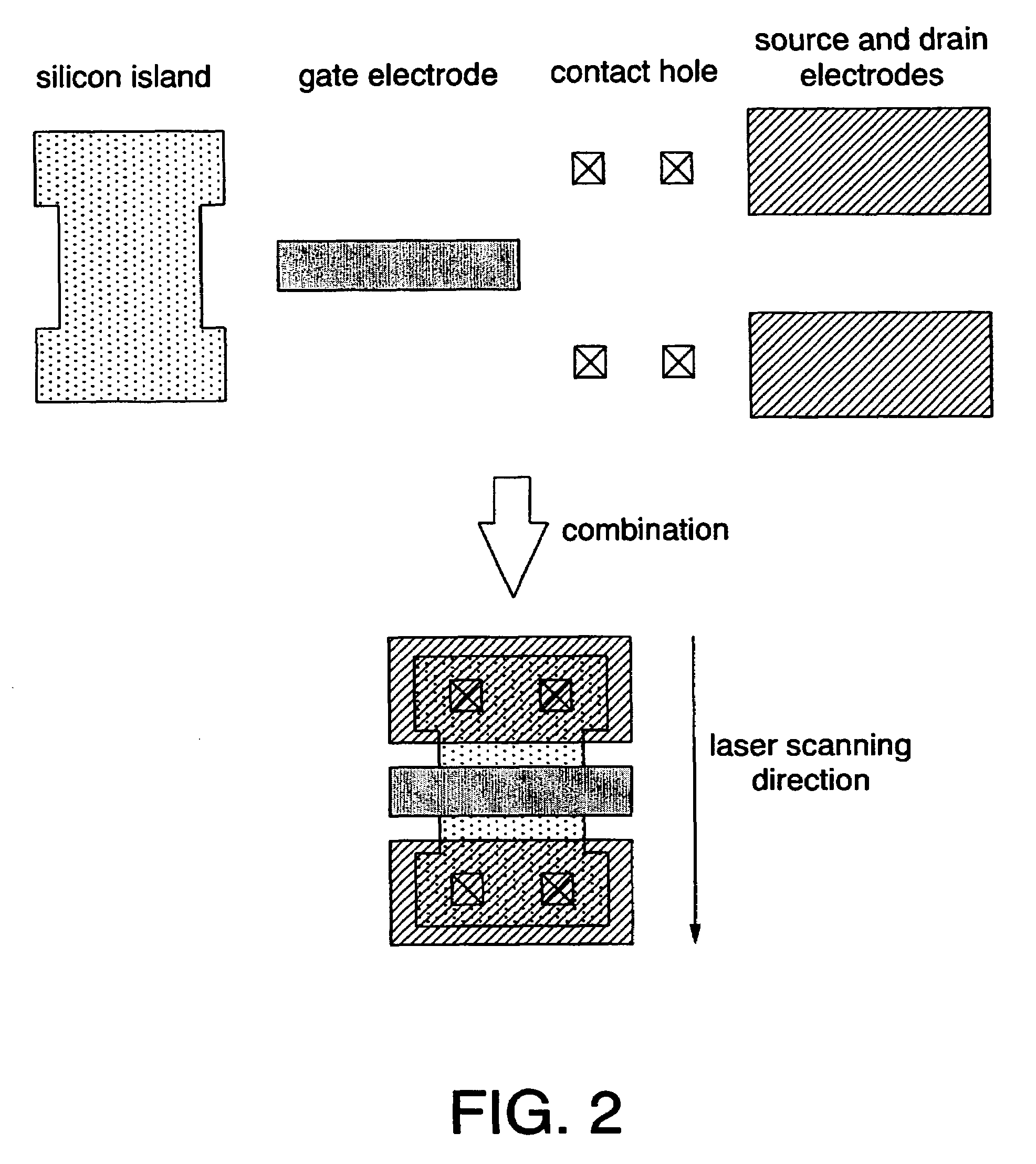

Program for controlling laser apparatus and recording medium for recording program for controlling laser apparatus and capable of being read out by computer

InactiveUS7133737B2Shorten the timeHigh treatment rateProgramme controlComputer controlLaser beamsSemiconductor

The object of the present invention is to solve problems treatment time when using an SLS method or continuous-oscillation laser. An indispensable portion is scanned with a laser beam in order to crystallize a semiconductor film by driving a laser and so on in accordance with the positions of islands instead of scanning and irradiating the whole semiconductor film. The present invention makes it possible to omit the time for irradiating a portion to be removed through patterning after crystallizing the semiconductor film with a laser beam and greatly shorten the treatment time for one substrate.

Owner:SEMICON ENERGY LAB CO LTD

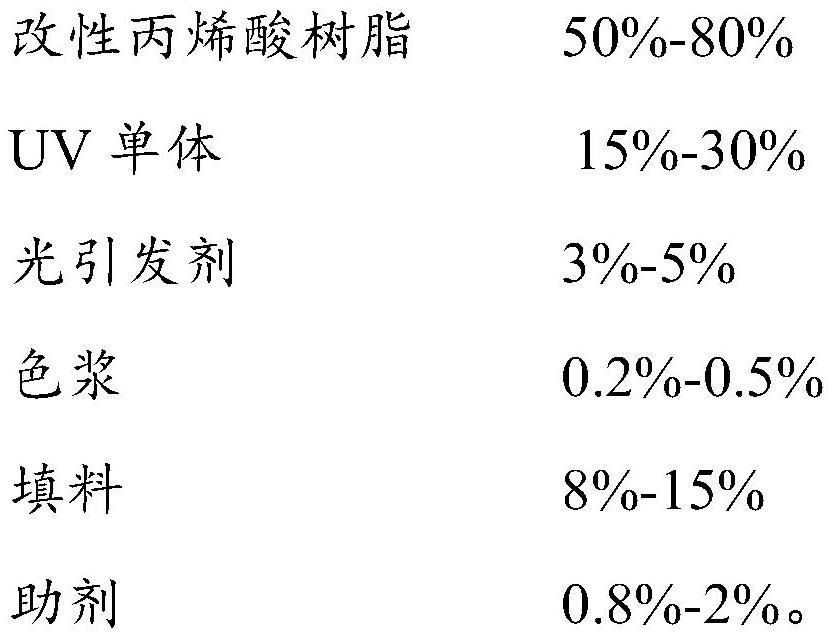

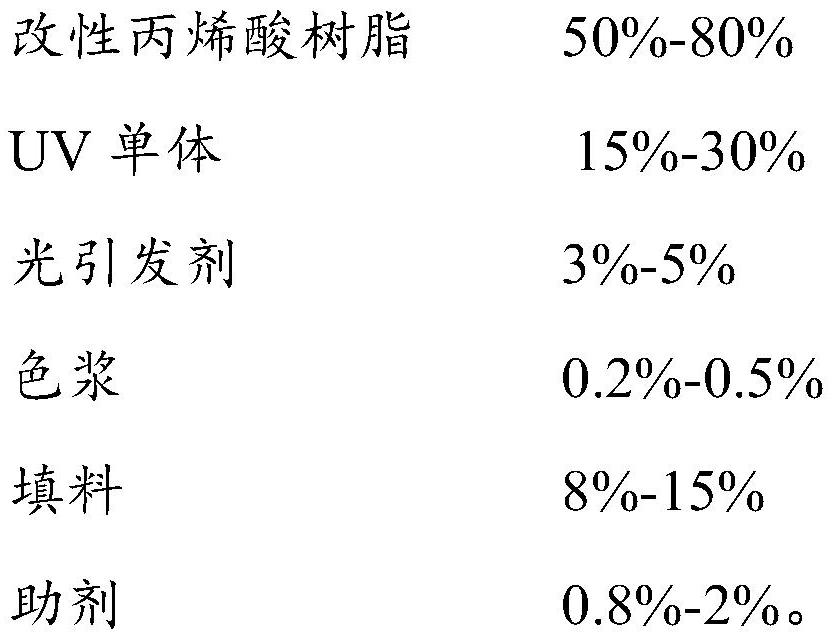

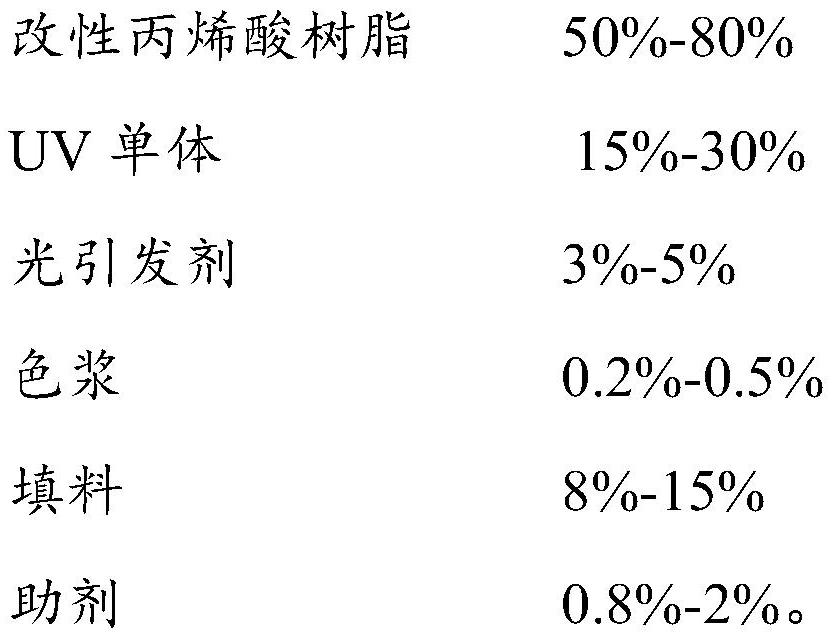

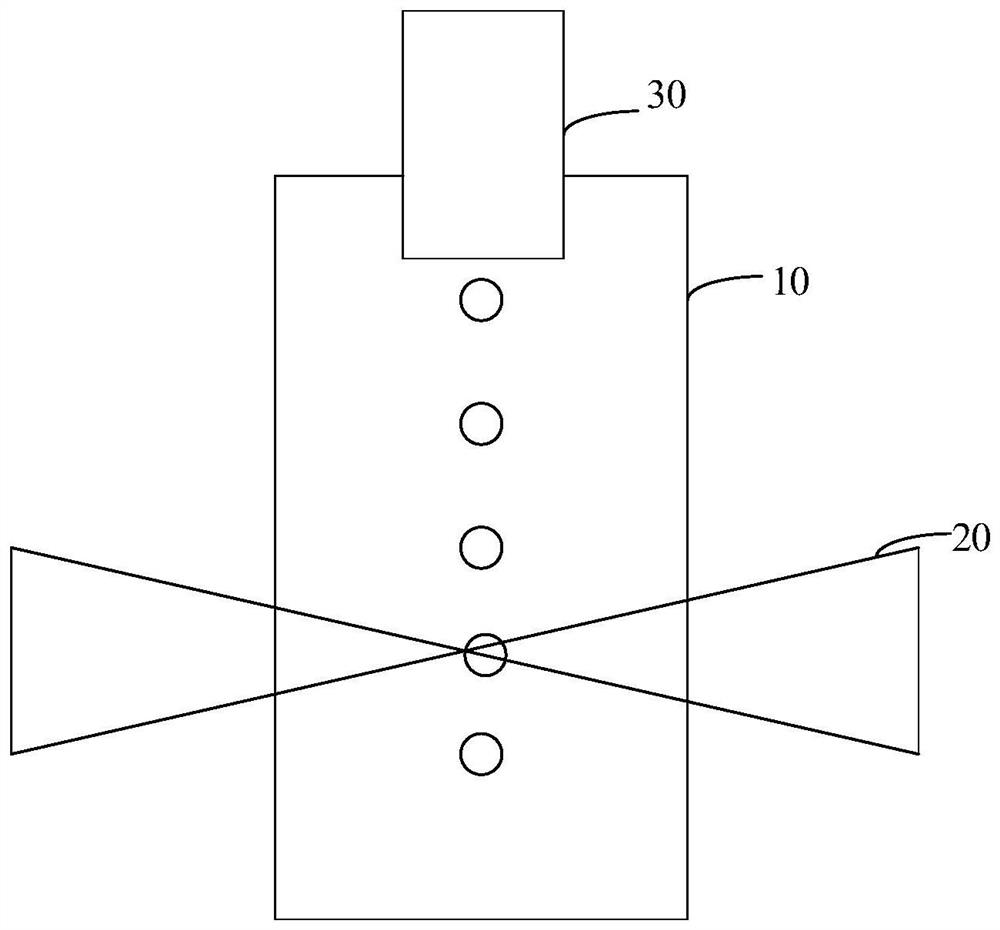

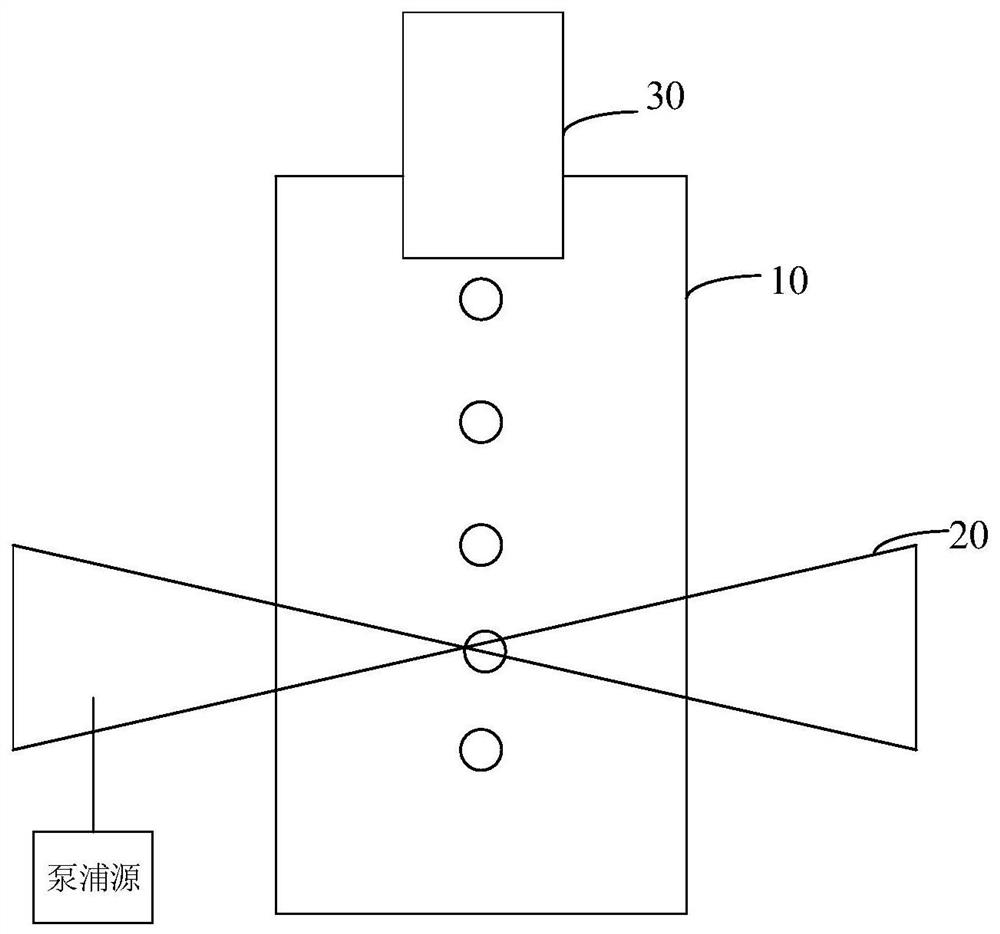

Drilling ink and application thereof

The invention belongs to the technical field of electronic materials, and particularly relates to drilling ink and application thereof. The drilling ink is prepared from the modified acrylic resin, a UV monomer, a photoinitiator, color paste, a filler and auxiliaries, an ink film formed after the drilling ink is cured has high hardness, the drilling ink can replace a traditional cover plate to be used for drilling in the drilling process of the printed circuit board, the ink film can be simply removed through laser and other methods after drilling is completed, and the drilling efficiency and the drilling precision can be remarkably improved. Meanwhile, due to the fact that traditional aluminum sheets, cold punching plates and the like are not used as cover plates, the production cost can be reduced, and the problems that chippings wind a cutter and the like can be solved.

Owner:SHENZHEN BAROY NEW MATERIAL TECH CO LTD

Laser plasma extreme ultraviolet light source and extreme ultraviolet light generating method

PendingCN111999989AImprove conversion efficiencyImprove collection efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusExtreme ultravioletKtp laser

The invention relates to a laser plasma extreme ultraviolet light source and an extreme ultraviolet light generation method. The laser plasma extreme ultraviolet light source comprises a vacuum targetchamber, an optical lens module, a droplet target generator and a collecting mirror for collecting extreme ultraviolet light, wherein an optical focus formed by the laser through the optical lens module is located in the vacuum target chamber; the droplet target generator is used for providing droplets for the vacuum target chamber; the moving line of the liquid drop in the vacuum target chamberpasses through the optical focus, and the liquid drop generated by the liquid drop target generator and the laser generate extreme ultraviolet light at the optical focus; the collecting direction of the collecting mirror is perpendicular to the laser incident direction and is not parallel to the moving direction of the liquid drops. The focus of the optical lens module is in a vacuum environment,and therefore damage to other equipment is prevented. Meanwhile, the collection direction of the collector is perpendicular to the laser incident direction, and no hole needs to be formed in the middle of the collection mirror, so that more light can be collected, the collection efficiency is improved, and the conversion efficiency of the light source is further improved.

Owner:GUANGDONG INTELLIGENT ROBOTICS INST

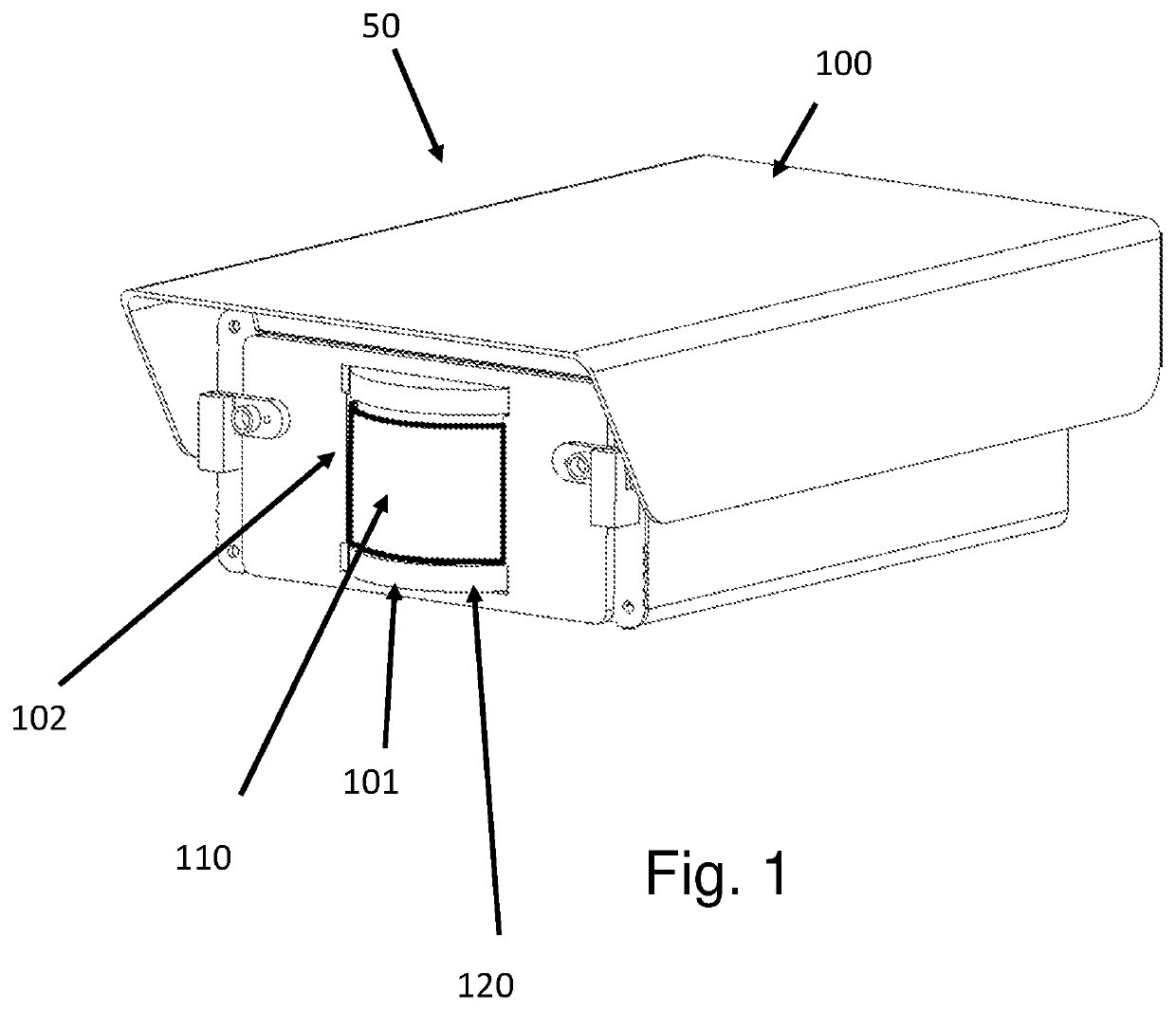

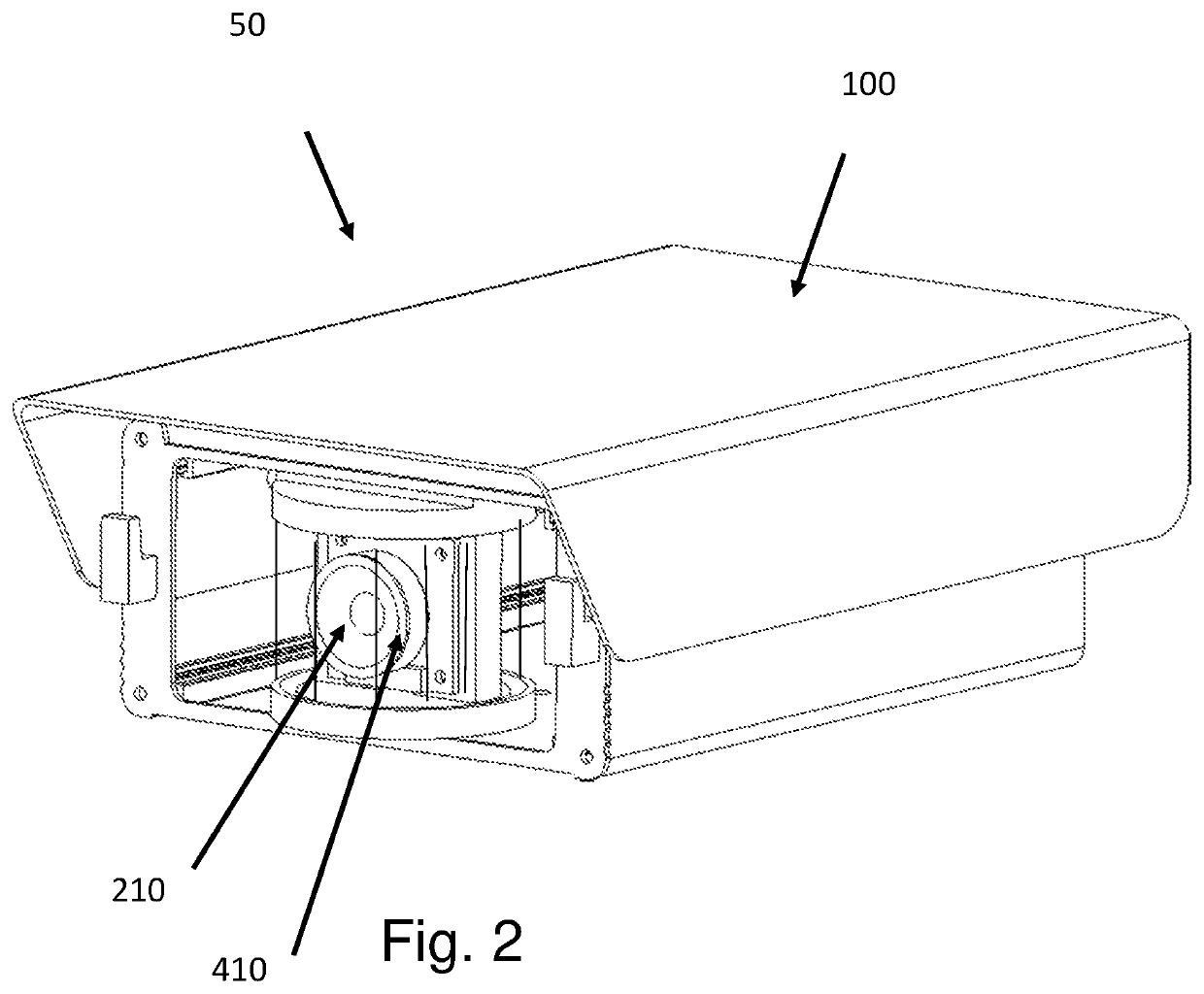

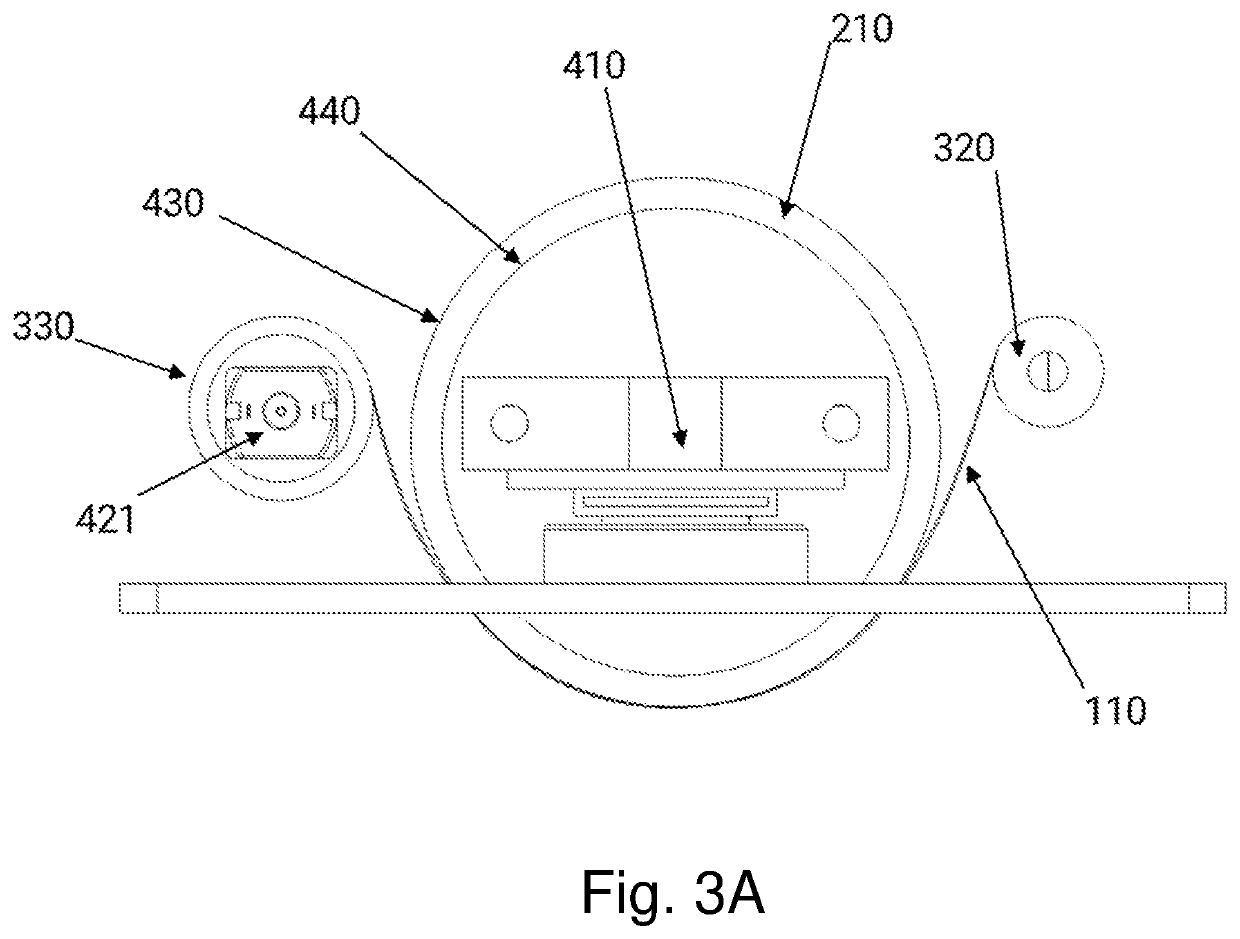

Optical device field of view cleaning apparatus

ActiveUS20210227113A1Avoid damageEnsures optical transparencyTelevision system detailsColor television detailsEngineeringKtp laser

The invention relates to a method and apparatus for keeping the field of view of an optical device (camera, laser, etc.) clean and unobstructed from dirt, contaminants, dust, chemicals, or other physical or chemical obstructions that hinder the performance of the optical device and, more particularly it employs a sacrificial transparent film positioned in front of and radially around a transparent main cylinder, within which an optical device is to be located.

Owner:MONOMER SOFTWARE LLC

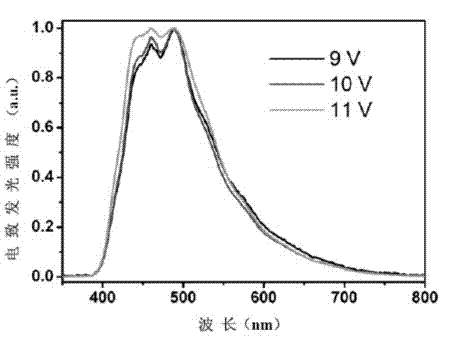

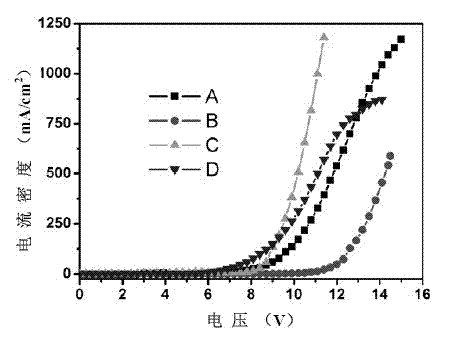

Tri-indene-pyrene derivative blue-light emitting material, and preparation method and application thereof

InactiveCN103242129AClear chemical structureModerate chemical structureSolid-state devicesSemiconductor/solid-state device manufacturingBlue emissionOrganic laser

The invention relates to a tri-indene-pyrene derivative blue-light emitting material, and a preparation method and application thereof. The material is a polysubstituted compound taking tri-indene as a core and seals the end by pyrene; the general formula structure is shown in the specification, wherein R is alkyl of C1-C12; the material has the characteristics that the material is simple in synthetic process, easy for volume production and easy to purify, and high chemical purity can be obtained by a simple column chromatography method; and the material displays excellent luminescence property, thermal stability, amorphous performance and spectral thermal stability when being applied as a luminescent film material, and has important application potential in the fields such organic electroluminescence and organic laser. In particular, an organic electroluminescence device using the material as the luminescent layer has efficient electroluminescent blue emission, improved color purity and excellent spectrum and apparatus stability; and the material is a blue organic electroluminescent material with practical prospect.

Owner:NANJING UNIV OF POSTS & TELECOMM

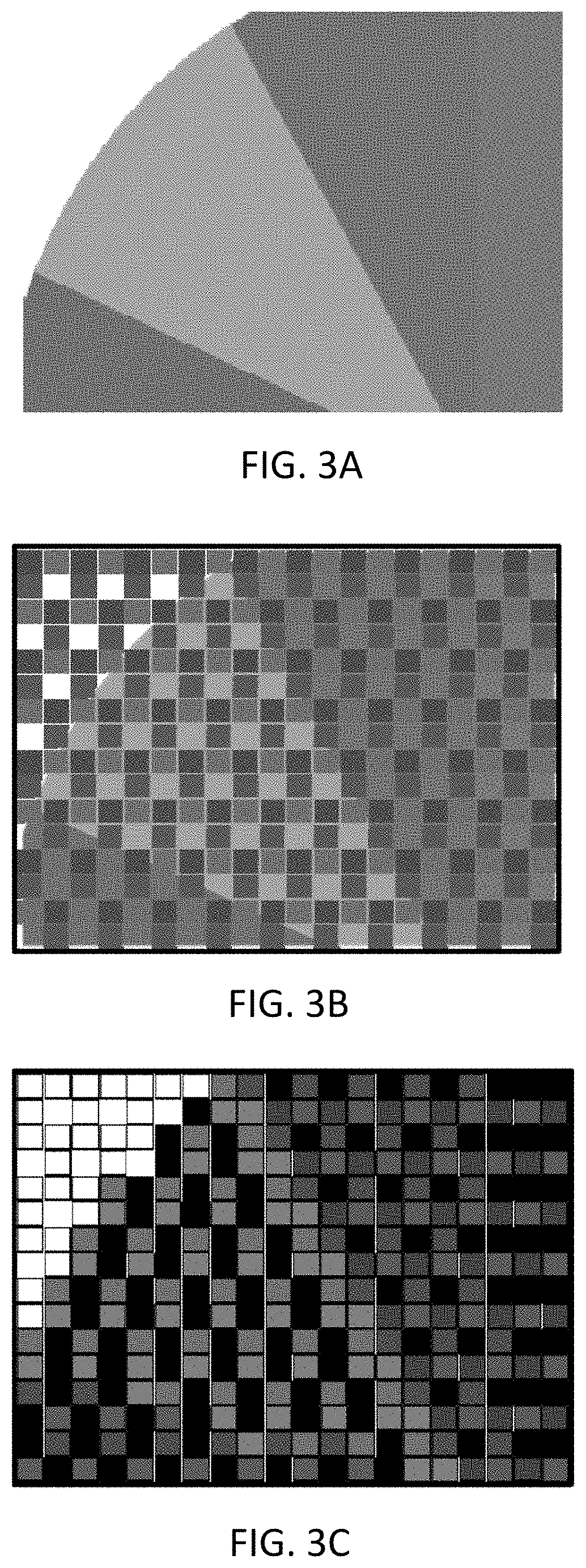

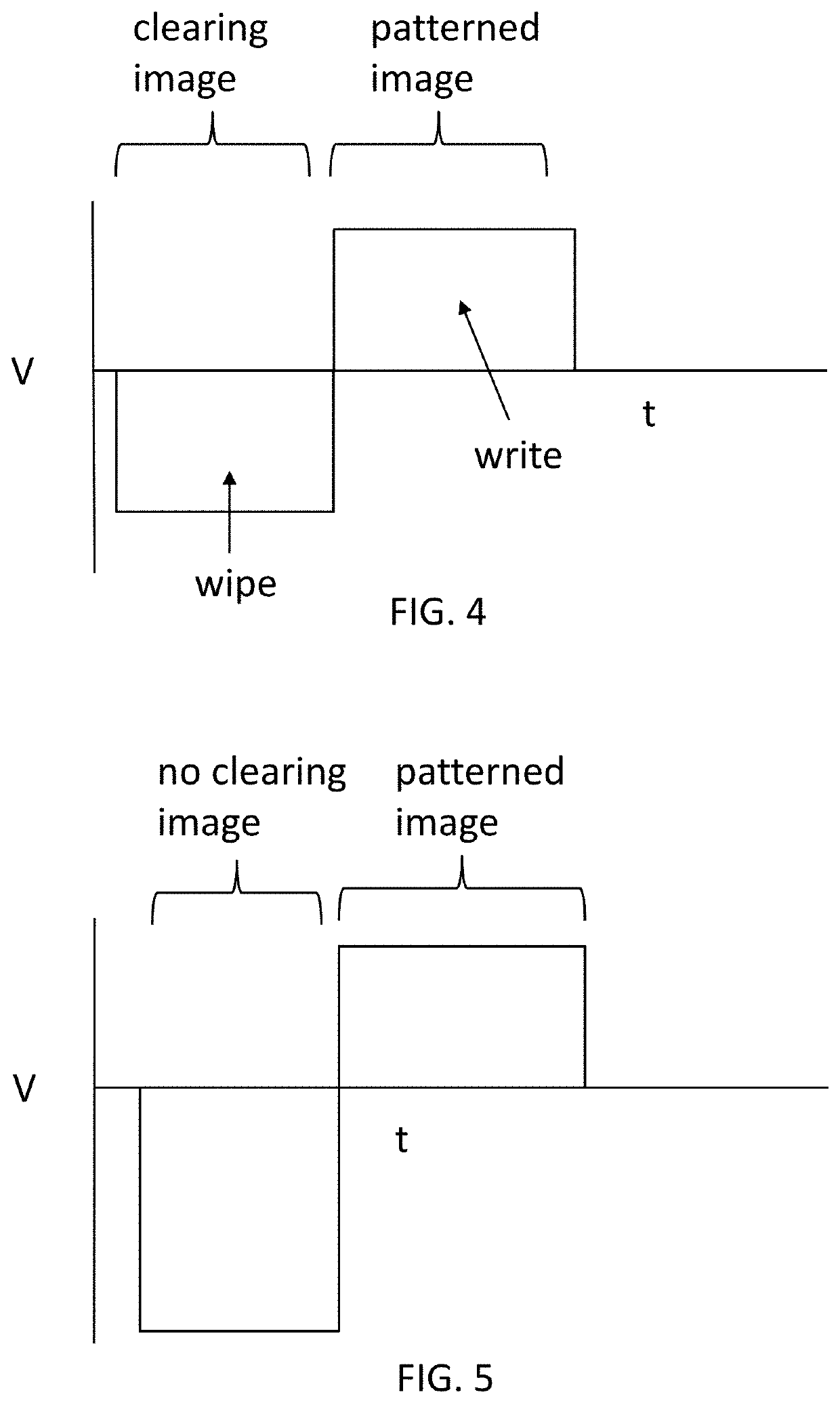

Reusable display addressable with incident light

A reflective color display that can be addressed from the front (viewing surface side) of the display with a light source, such as a projector, LED, or laser. The display comprises (in order) a color filter array, a transparent electrode, an electro-optic medium, a photoconductive material, and a rear electrode. The color displays of the invention are useful for large format color signage, such as billboards and wayfinding.

Owner:E INK CORPORATION

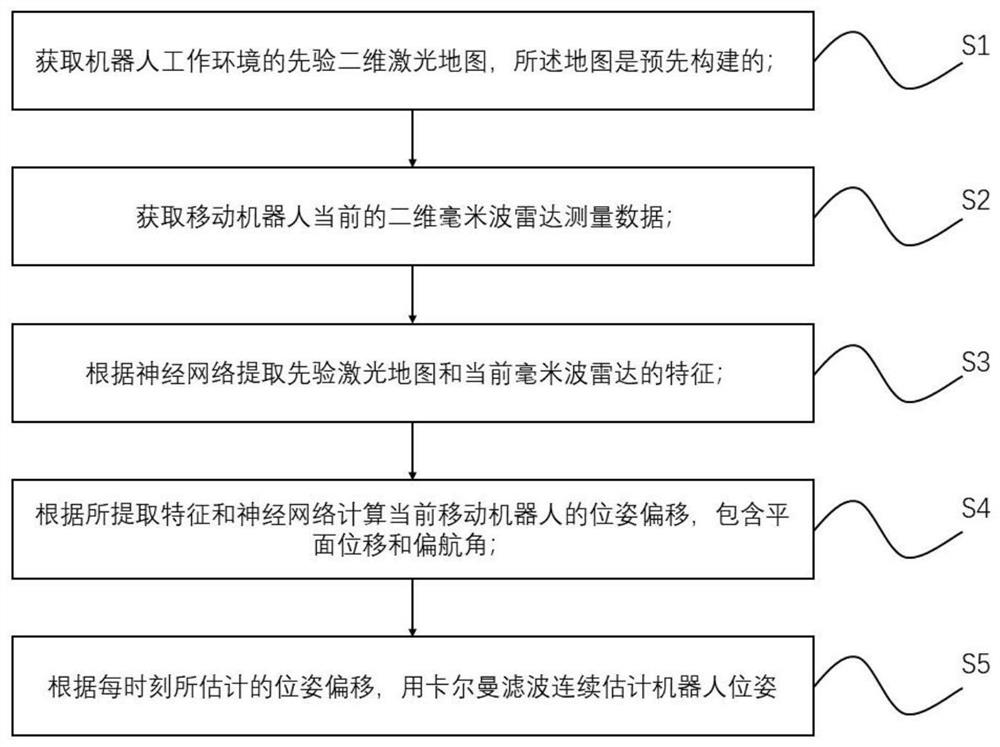

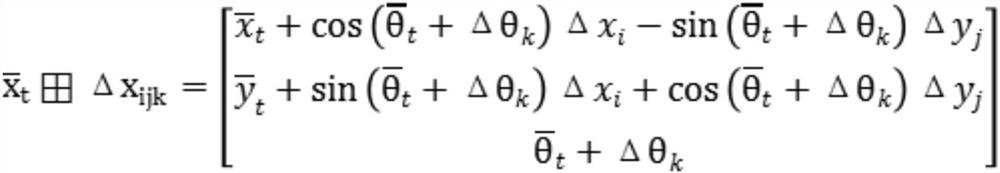

Millimeter wave radar continuous positioning method and device based on laser map

PendingCN113759364AHigh positioning accuracyNavigational calculation instrumentsNeural architecturesNerve networkEngineering

The invention discloses a millimeter wave radar continuous positioning method and device based on a laser map. The method comprises the steps of obtaining a priori two-dimensional laser map of a working environment of a robot, obtaining current two-dimensional millimeter wave radar measurement data of the mobile robot, extracting the priori laser map and current millimeter wave radar features according to a neural network and the like. According to the invention, in atrocious weather, such as rainy and snowy weather environment, data provided by a visual sensor, a laser sensor and the like has large noise and even cannot work normally. The millimeter wave radar is robust to illumination and weather changes. Therefore, the method and the device provided by the invention are suitable for continuous positioning of the robot in severe weather and environment.

Owner:ZHEJIANG UNIV

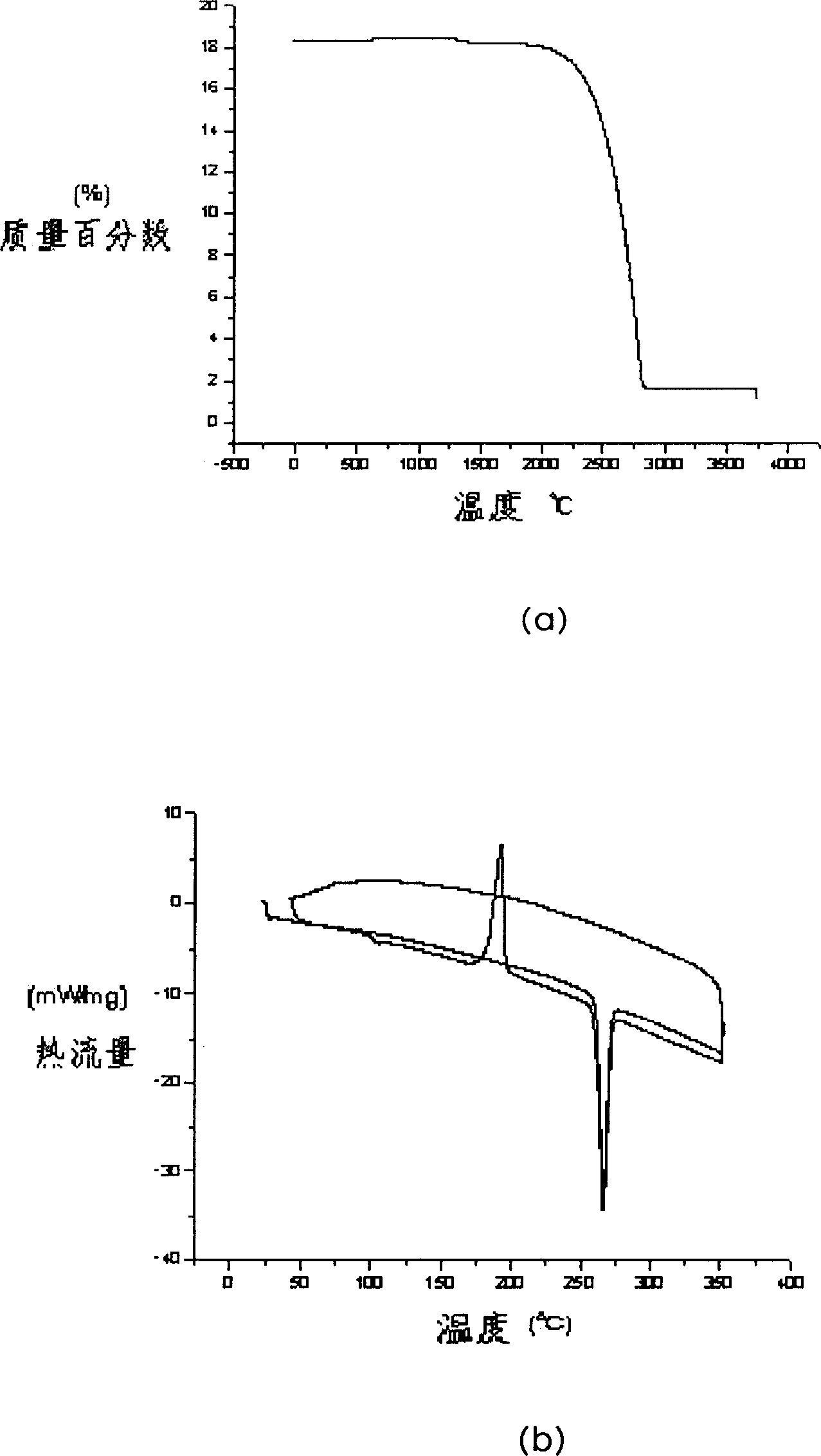

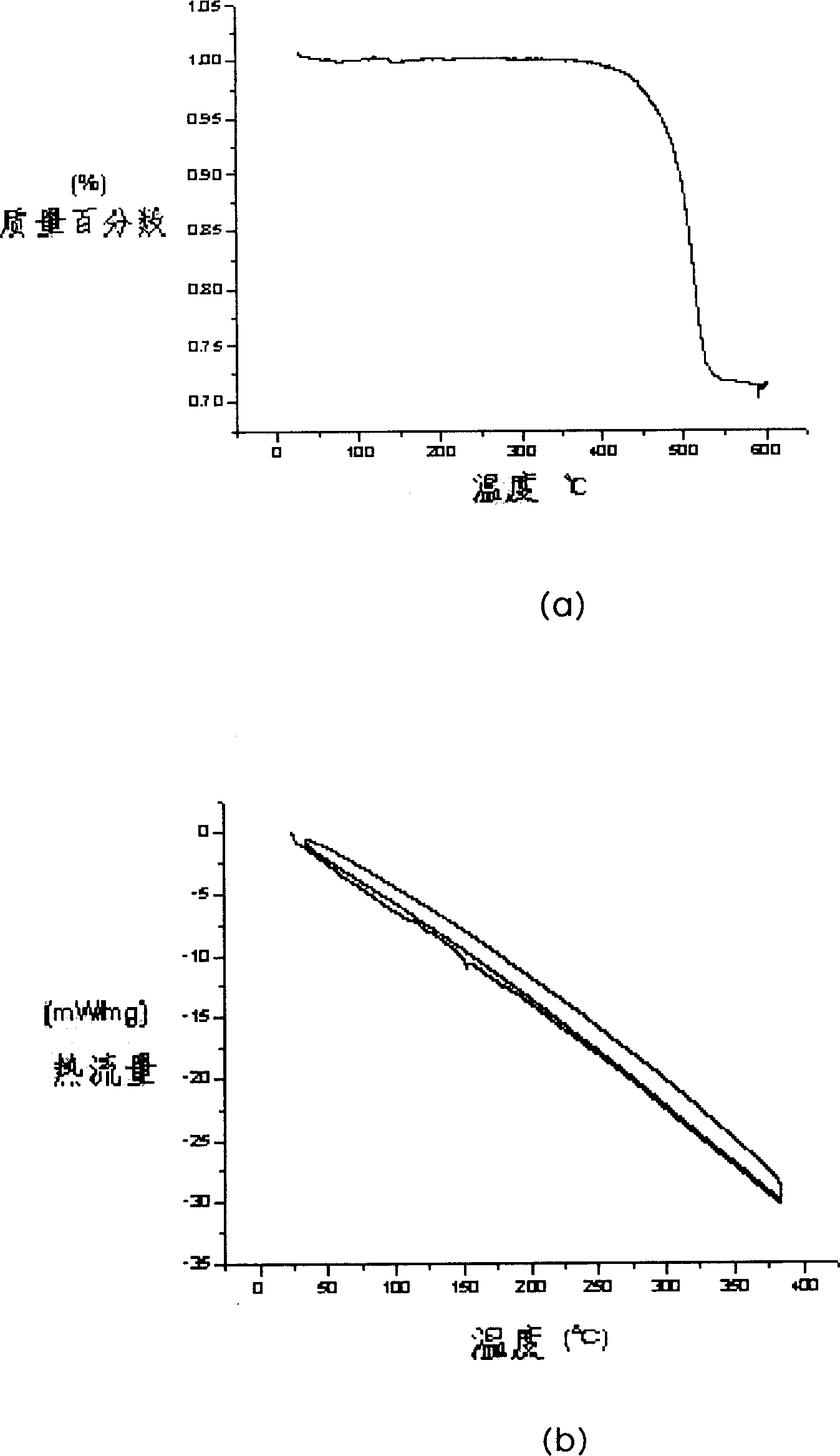

Equivalent LET calculation method for pulse laser single event effect test

PendingCN112230081AAchieving Equivalence Evaluation of Radiation HazardsExpand engineering applicationsElectrical testingParticle physicsKtp laser

The invention discloses an equivalent LET calculation method for a pulse laser single event effect test. The calculation method comprises the following steps: calculating deposition charge QL generated when pulse laser enters a device according to the fact that the single event effect caused by the pulse laser and heavy ions to the device is equivalent when the charge quantities deposited by the pulse laser and the heavy ions in the sensitive volume of the device are equal, and obtaining the sensitive depth z of the device through a pulse laser test, wherein the pulse laser equivalent LET is LETL[MeV.cm<2> / mg] = (Ep / rho) * QL[pC] / z [mu]m]. According to the invention, equivalent evaluation of single event effect radiation harm of pulse laser and heavy ions to the device is realized, and application of the pulse laser in the aspect of satellite anti-radiation reinforcement technology is further expanded.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com