Method and device for realizing combustible gas multi-point laser plasma ignition based on microlens array

A micro-lens array and plasma technology, which is applied to gas turbine devices, jet propulsion devices, rocket engine devices, etc., can solve problems such as combustion chamber explosion and impact on aircraft safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

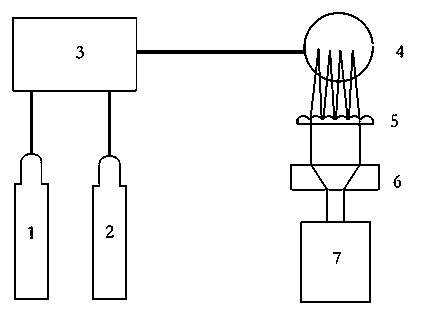

[0016] Specific implementation mode one: as figure 1 As shown, the device for multi-point laser plasma ignition of combustible gas based on the microlens array provided by this embodiment includes a fuel gas source 2, an oxidant gas source 1, a gas distribution system 3, a nozzle 4, and sequentially arranged along the direction of the optical axis. Laser 7, beam expander collimation system 6 and microlens array 5; the gas outlets of fuel gas source 2 and oxidant gas source 1 are connected with the air inlet of gas distribution system 3, and the gas outlet of gas distribution system 3 is connected with the nozzle 4 The air inlets are connected, and the nozzle 4 is located at the focal length of the microlens array 5 . When in use, the combustible gas is passed into the nozzle; the laser emits laser light, which is incident on the microlens array after beam expansion and collimation, and induces multiple plasmas in the mixed gas above the nozzle axis, and ignites the combustible...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the fuel is one of methane, propane, hydrogen, and natural gas; the oxidant is a nitrogen / oxygen mixture, and the volume fraction of oxygen is 5-100 %.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiments one and two is that the laser is a kind of pulsed solid-state laser and pulsed excimer laser, and the laser wavelength is 1064 nm and its high-order frequency multiplication, 694.3 nm and Its high-order frequency doubling, one of 308 nm and 248 nm, the laser repetition frequency is 10-1000 Hz, and the laser pulse energy is 5-2000 mJ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Focal length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com