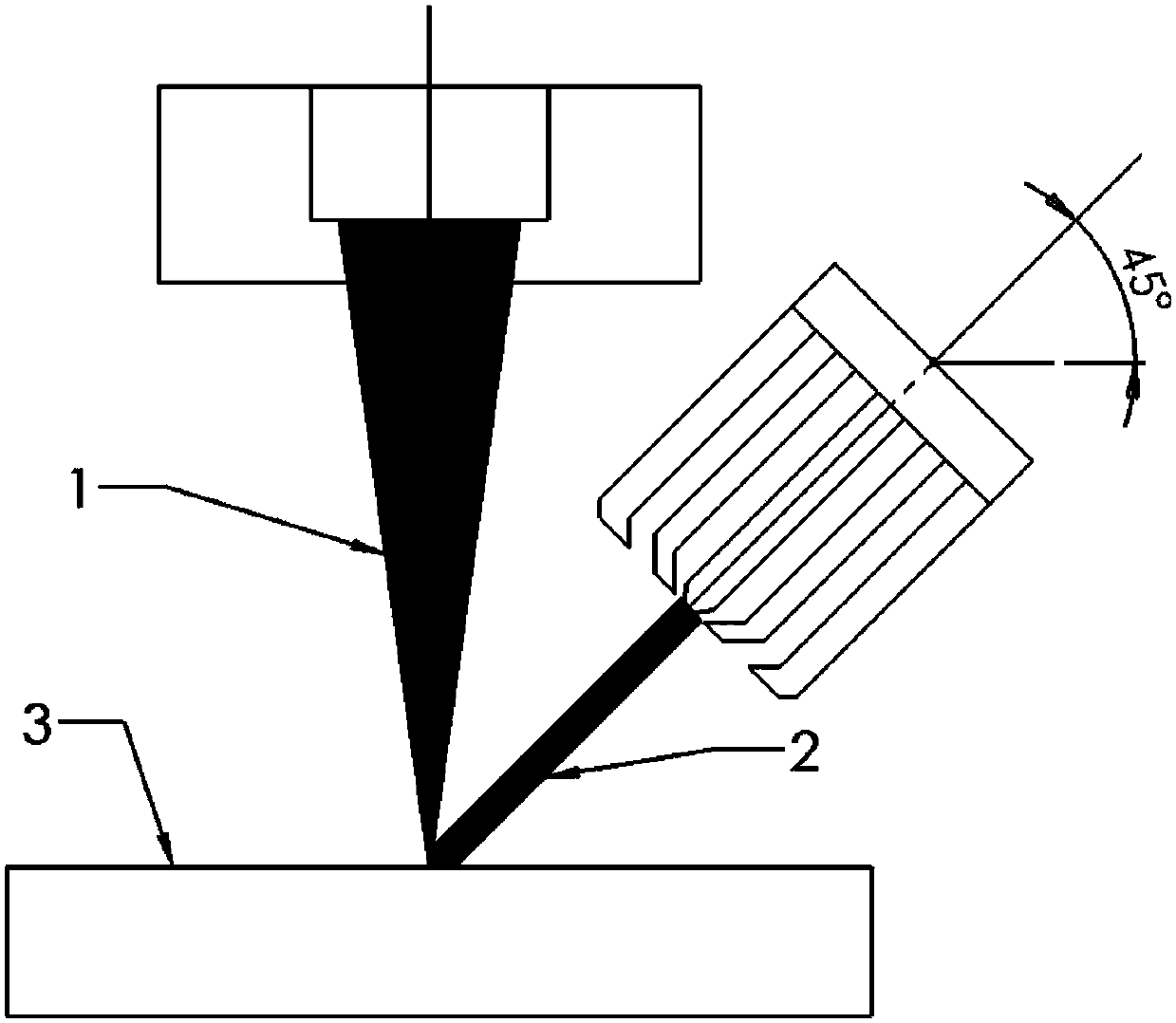

Beam shaping method for laser-plasma arc coaxial hybrid welding

A technology of beam shaping and plasma arc, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as difficult to use curves or three-dimensional welding, great influence on welding quality, asymmetric heat source, etc., and achieve ideal results , Reduce the size of the device, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

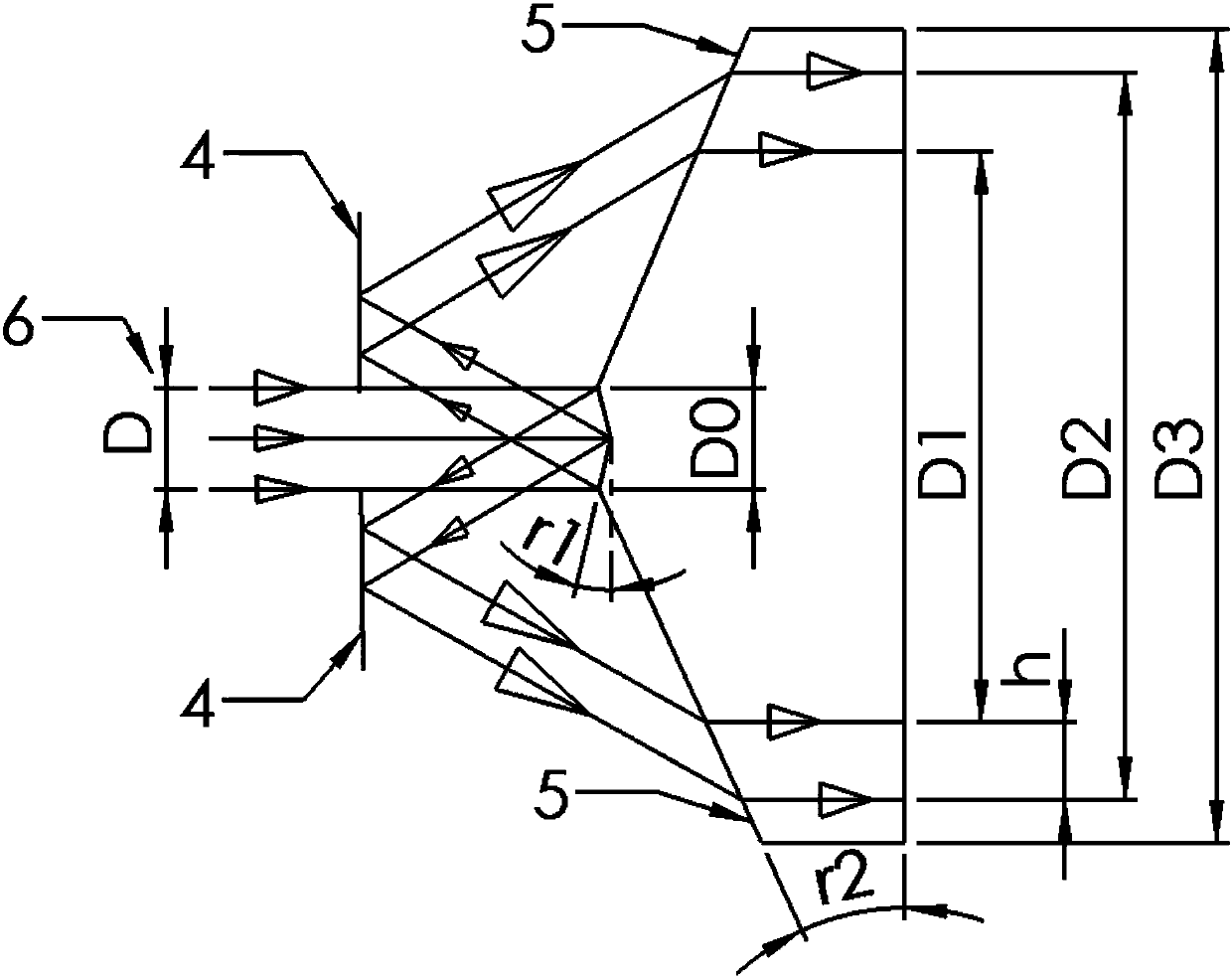

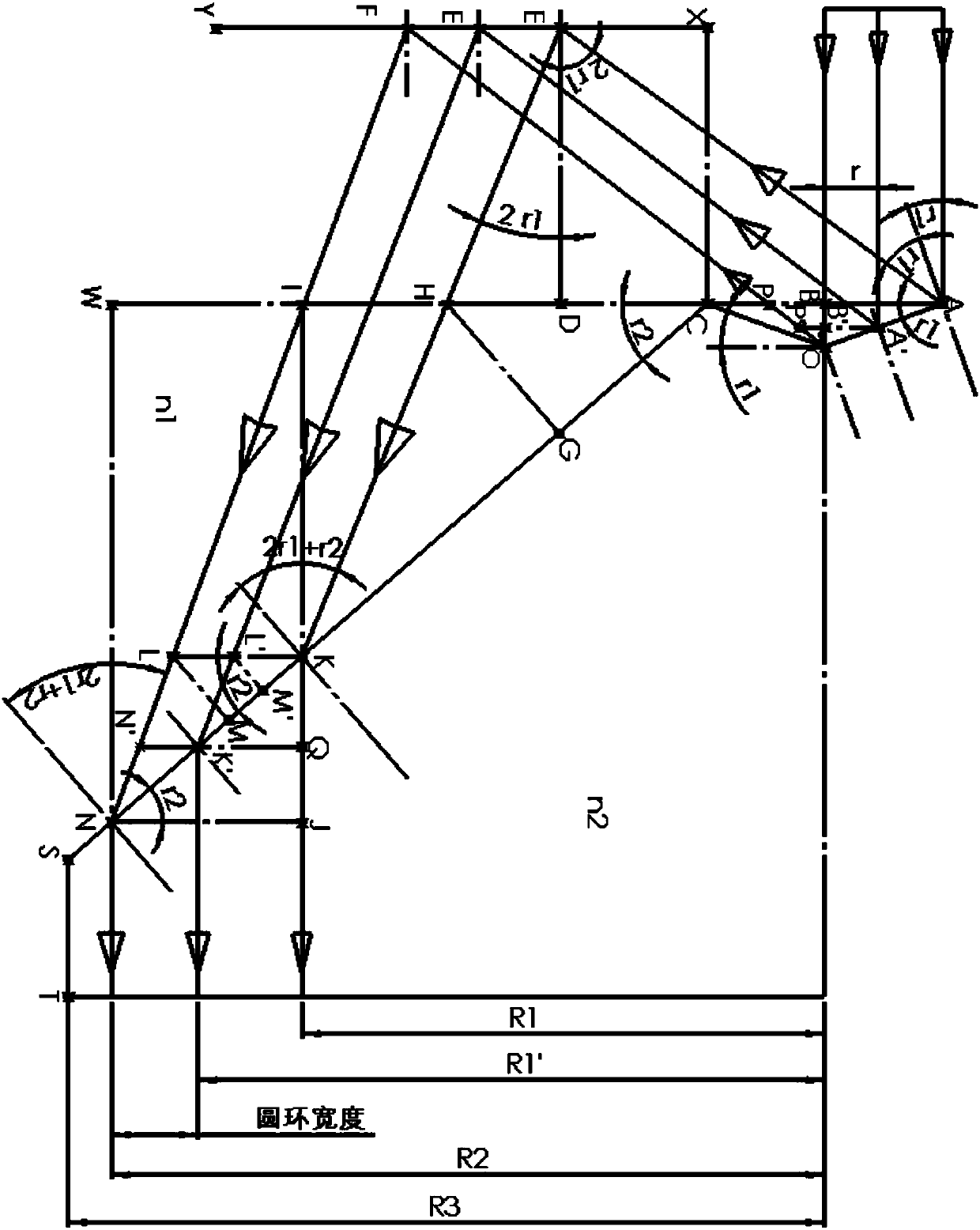

[0032] Specific implementation method: combined figure 2 , 3 , 4, 5, and 6 illustrate this implementation mode, and the circular light source used in this implementation mode is a light source coupled to a high-power semiconductor laser fiber. This implementation mode is realized according to the following steps:

[0033] The specific steps of the design method for shaping a circular beam into a circular beam are as follows:

[0034] S1 as figure 2 , determine the diameter of the incident beam, that is, the diameter of the central hole of the plane reflector D and the diameter of the inner cone of the conical mirror D 0 , and have D≤D 0 . In this embodiment, D=6mm, D 0 = 8mm;

[0035] S2 determines the inner cone angle of the conical mirror γ 1 and outer cone angle γ 2 :

[0036] According to the law of refraction and geometric relations, there are

[0037] no 1 sin(2γ 1 +γ 2 ) = n 2 sin gamma 2

[0038] 2 1 +γ 2 <90°

[0039] When the beam reflected by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com