Uniform surface strengthening method based on laser shock wave

A uniform surface, laser shock technology, applied in the field of surface strengthening treatment of metal materials, can solve problems such as low feasibility, and achieve the effect of eliminating residual stress holes and uniform residual stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

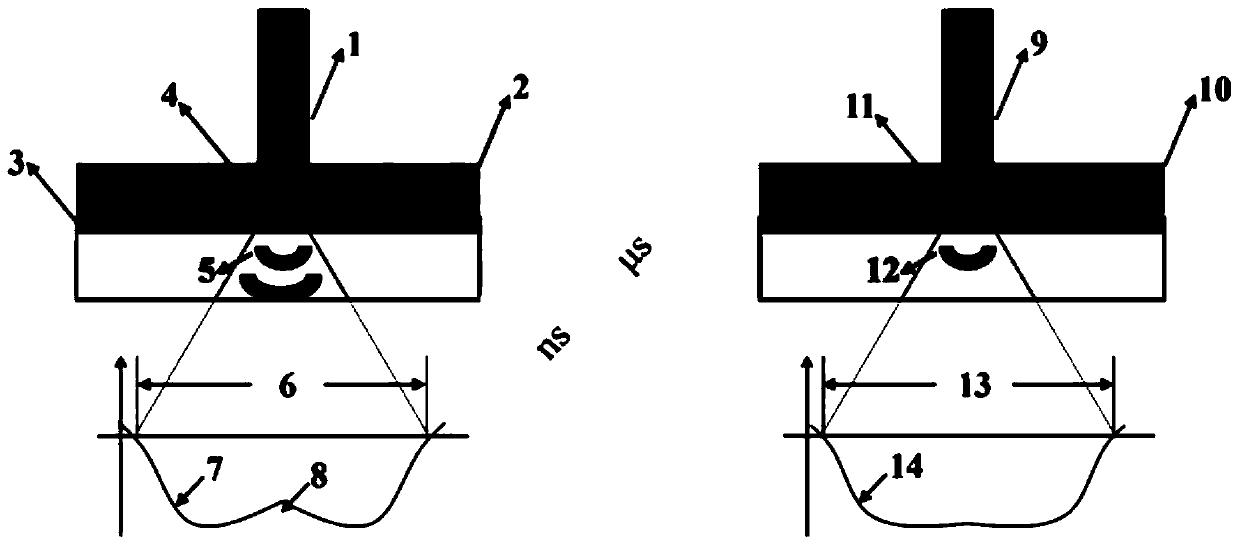

[0036] Depend on figure 1 As shown, the workpiece is 304 austenitic stainless steel material. A 3M adhesive tape with a thickness of 0.1mm was selected as the absorbing layer, and the parameters of the pulsed laser beam 1 used were: wavelength 1064nm, energy 6J, pulse width 18ns, circular beam with a diameter of 3mm. The second constrained layer 10 is a deionized water curtain with a thickness of 2.5 mm. The specific setting method is to change the flow rate of the water flow and the flow rate per unit area.

[0037] Using the above test parameters, the target metal material is subjected to single-point single-shot laser shock treatment, and the residual stress on the surface of the material is tested by X-ray diffraction method after the laser shock treatment is completed. The test conditions are: CrKβ target is used, the X-ray tube pressure and tube current are 26kV and 8mA respectively, and the counting time is 10s; in order to obtain a more accurate distribution trend, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com