A Production Method for Improving the Uniformity of Residual Stress in Full Section of F-rail

A technology of residual stress and production method, which is applied to the improvement of process efficiency, furnace type, furnace, etc., can solve the problems of large residual stress and poor uniformity of residual stress distribution in the whole section, and achieve simple production method, easy popularization and application, and highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

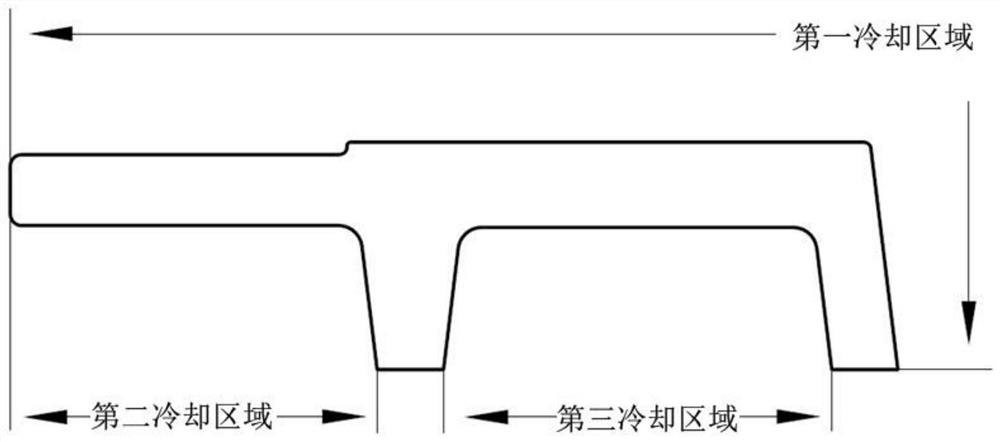

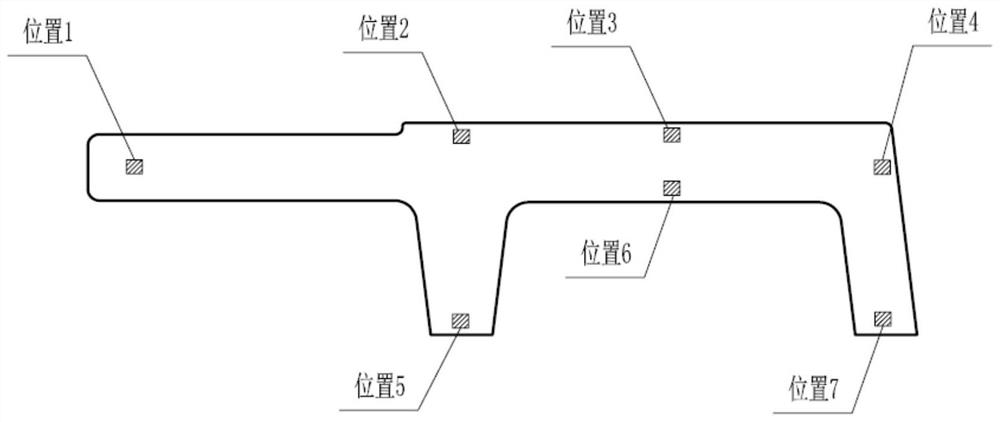

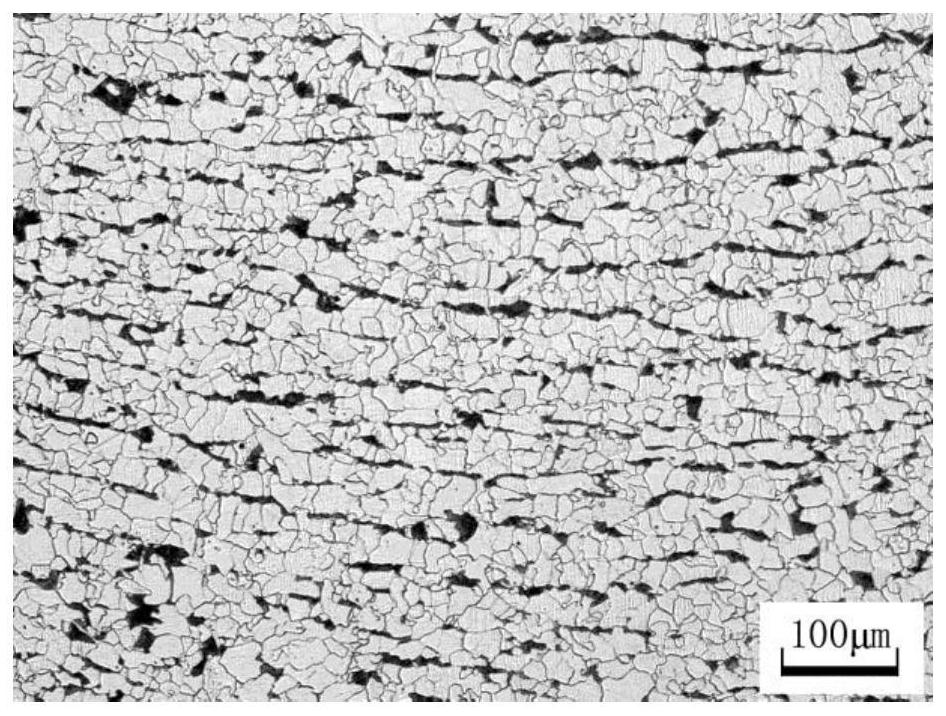

Embodiment 1

[0039] The chemical composition of F-rail is: C: 0.07%, Si: 0.26%, Mn: 0.90%, Cr: 0.10%, Nb: 0.05%, P: 0.016%, S: 0.008%, and the rest are Fe and impurities element. The production method is as follows: according to the conventional section steel smelting and casting methods, the process includes converter smelting, LF refining, vacuum treatment and continuous casting. Among them, molten iron desulfurization adopts magnesium powder desulfurization process, converter smelting adopts top-bottom combined blowing process, LF refining slag alkalinity is controlled at 1.8-2.3, RH vacuum treatment time is not less than 15 minutes, tundish temperature in continuous casting process It is controlled at 15-20°C above the liquidus line, and the casting speed is 0.6-1.0m / min. The continuous casting process should be carried out under full protection to prevent contact with air. At the same time, the cast billets should be naturally stacked and cooled to room temperature. A walking beam h...

Embodiment 2

[0041] The chemical composition of F-rail is: C: 0.09%, Si: 0.27%, Mn: 1.15%, Cr: 0.13%, Nb: 0.02%, P: 0.011%, S: 0.010%, and the rest are Fe and impurities element. The production method is carried out according to the method of Example 1, the difference is that the rolling process and post-rolling accelerated cooling process parameters are as shown in Table 1.

Embodiment 3

[0043] The chemical composition of F-rail is: C: 0.05%, Si: 0.22%, Mn: 0.85%, Cr: 0.09%, Nb: 0.03%, P: 0.013%, S: 0.009%, and the rest are Fe and impurities element. The production method is carried out according to the method of Example 1, the difference is that the rolling process and post-rolling accelerated cooling process parameters are as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com