Laser Shock Technology of Workpiece Surface Using Surface Micro-texture to Remove Residual Stress Hole

A technology of workpiece surface and residual stress, applied in the improvement of process efficiency, manufacturing tools, heat treatment equipment, etc., can solve the problems of reduced life, high processing cost, reduced residual compressive stress value and depth of plastic influence layer, etc. Efficiency, reduced machining costs, and the effect of eliminating residual stress holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] In this embodiment, a laser shock process on the surface of a workpiece using surface micro-texture to remove residual stress holes is characterized in that the steps are as follows:

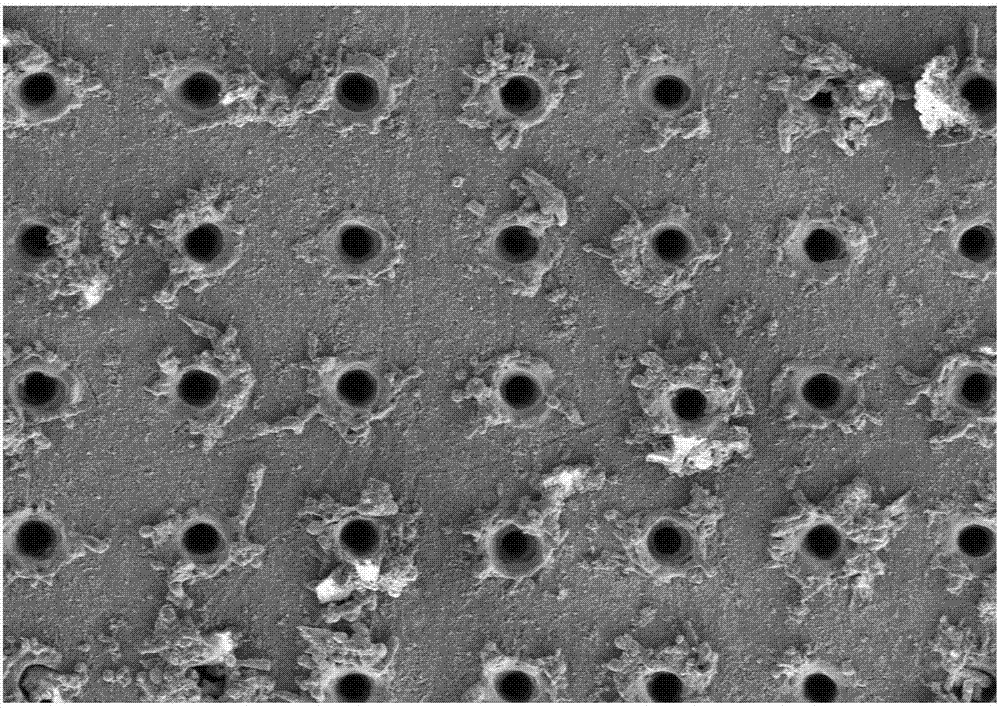

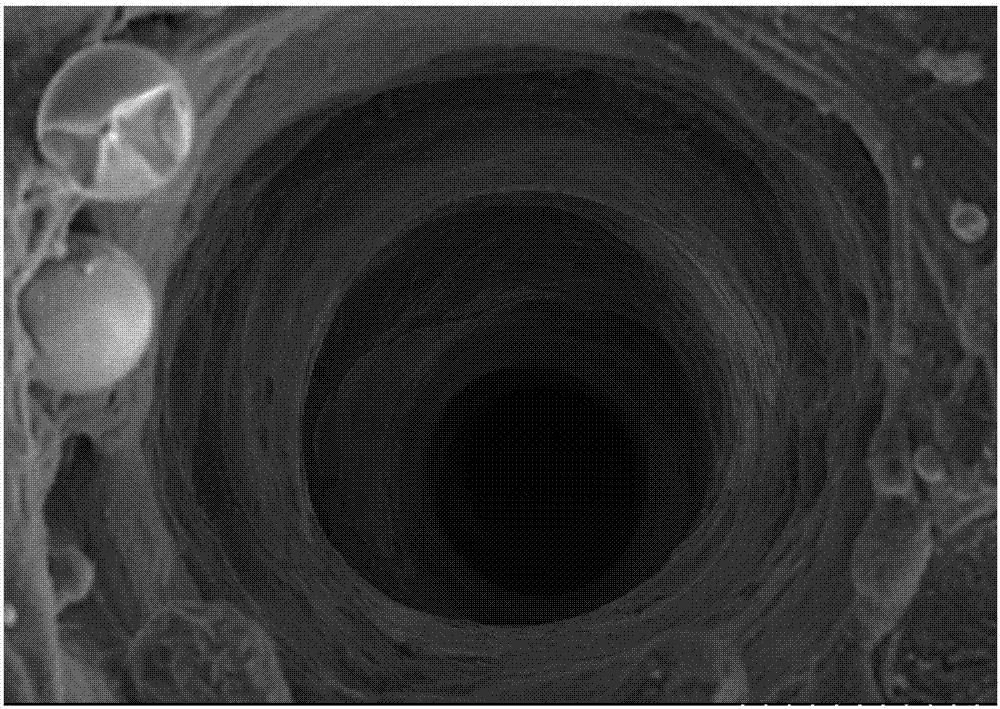

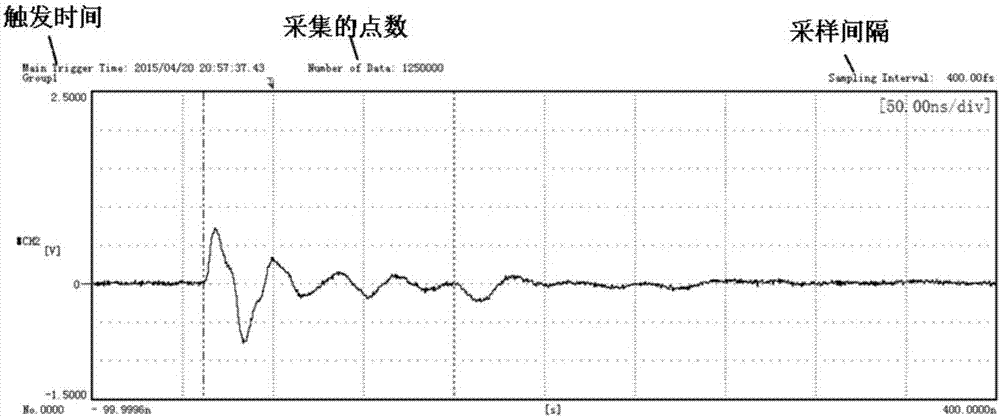

[0036] Step 1. Perform laser micro-texture treatment on the surface of the workpiece (the surface of the workpiece is pre-polished into a mirror surface) (here, the thermal effect of the laser is used for processing, using a fiber laser and a weak laser), the impact laser energy is P0, and the micro-texture density is B, The range of shock laser energy P0 is P1-P2. Preferably, the energy P0 of the shock laser is in the range of 0.2 mj-1 mj, the spot size of the shock laser is 1 μm, and the distance between the micro-texture pits is in the range of 0-140 μm. In this example, the 7050 aluminum alloy material was selected, and the laser with a single pulse e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com