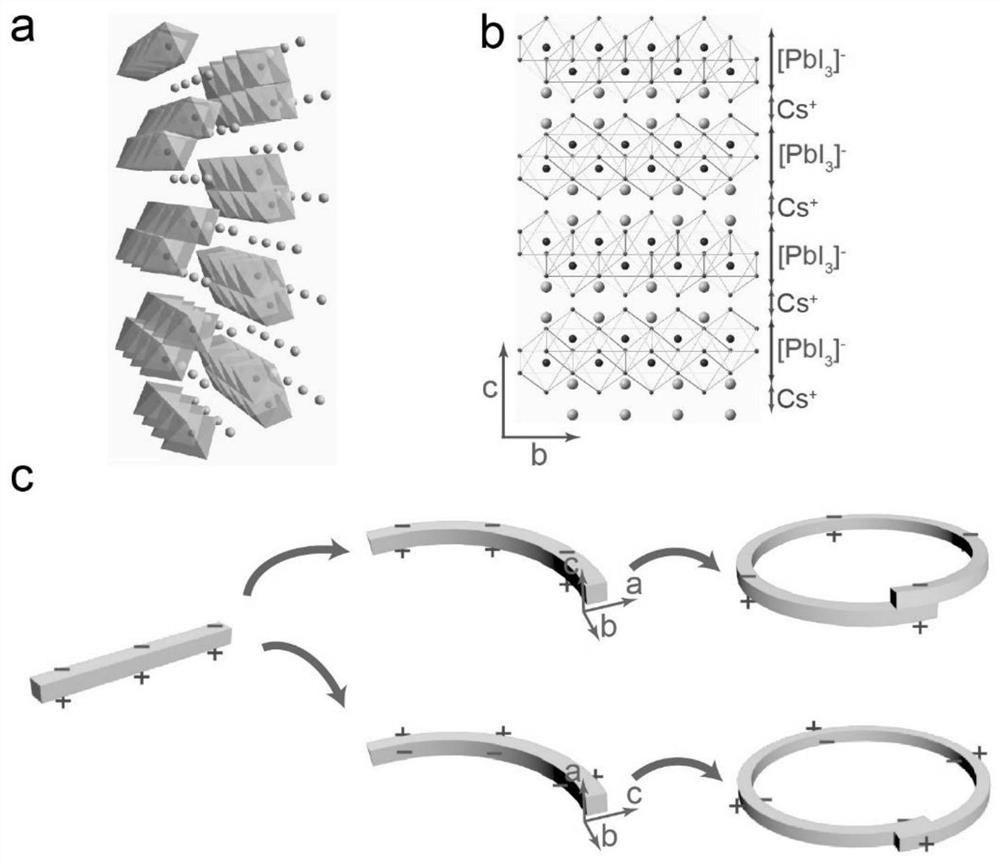

Perovskite single crystal nanoring and preparation method and application thereof

A technology of single crystal nanometer and perovskite, which is applied in nanotechnology, nanotechnology, separation methods, etc., and can solve problems such as high energy consumption and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

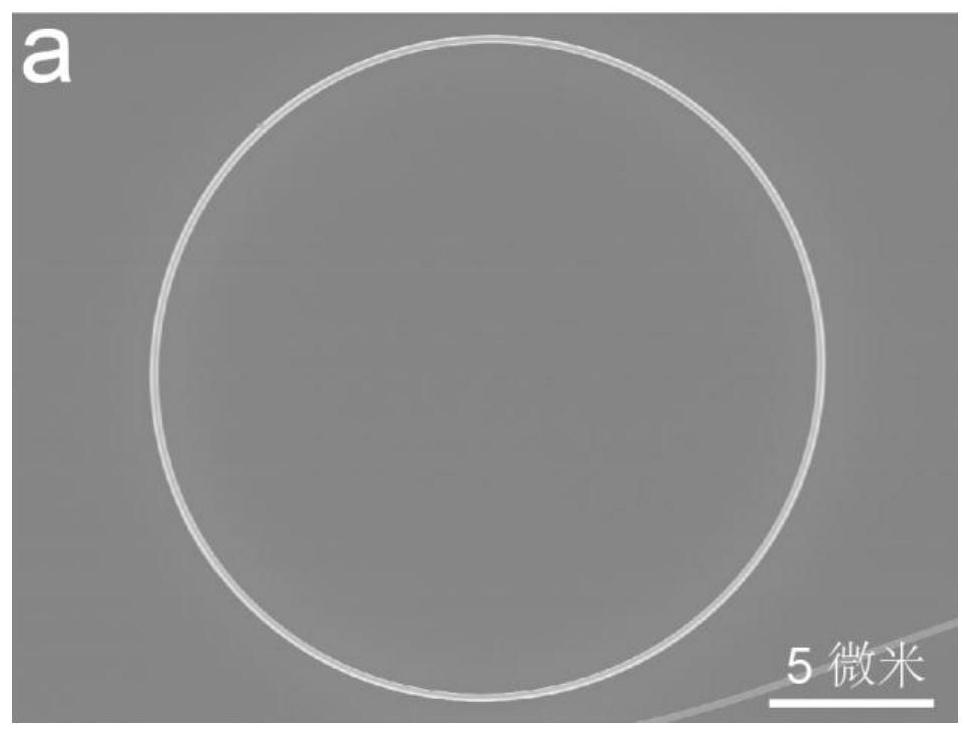

[0054] Embodiment 1, preparation lead cesium iodide perovskite single crystal nano ring

[0055] The lead cesium iodide perovskite single crystal nanorings were prepared according to the following steps:

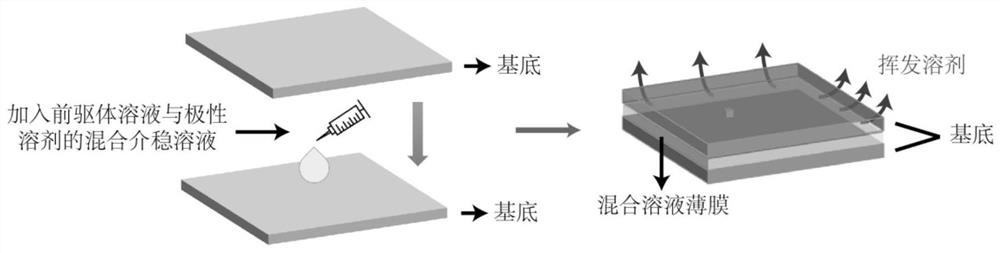

[0056] (1) Place the selected monocrystalline silicon wafer substrate on a custom-made polytetrafluoroethylene cleaning rack and put it into an ultrasonic instrument for cleaning. Ultrasonic cleaning was performed with deionized water, absolute ethanol, and acetone for 15 minutes respectively, and the base sheet was blown dry with nitrogen gas after cleaning. Part of the substrate was subjected to surface hydrophilic treatment with a UV-ozone meter at 200W power for 10 minutes; another part of the substrate was subjected to hydrophobic treatment, mixed and stirred with 100 μL octadecyl trichlorosilicon and 100 mL toluene solution, and the cleaned substrate was placed on the Soak in the prepared solution for 1 hour, then ultrasonically clean the base sheet with dichlorometha...

Embodiment 2

[0062] Embodiment 2, preparation lead cesium iodide perovskite single crystal nano ring

[0063] The perovskite single-crystal nanorings were prepared in the same manner as in Example 1, except that the concentration of the precursor solution was changed to 0.4 mol / L (lead iodide and cesium iodide remained at a ratio of 1:1). The average thickness and average radius of the obtained perovskite single crystal nanorings are basically similar to those of Example 1, and the distribution density of the product on the substrate is smaller than that of Example 1.

Embodiment 3

[0064] Embodiment 3, preparation lead cesium iodide perovskite single crystal nano ring

[0065] The lead cesium iodide perovskite single crystal nanorings were prepared according to the same method as in Example 1, except that the acetonitrile solvent and the precursor solution were mixed rapidly at a ratio of 1:1.5. The resulting mixed solvent needs to be added to the two-dimensional confinement space of the substrate within 10 minutes, and the average thickness and average radius of the obtained lead cesium iodide perovskite single crystal nanoring are smaller than that of Example 1, and the distribution density of the product on the substrate is the same as Example 1 is similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com