Electronic device, semiconductor device and its manufacturing method

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, identification devices, etc., can solve problems such as high cost and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

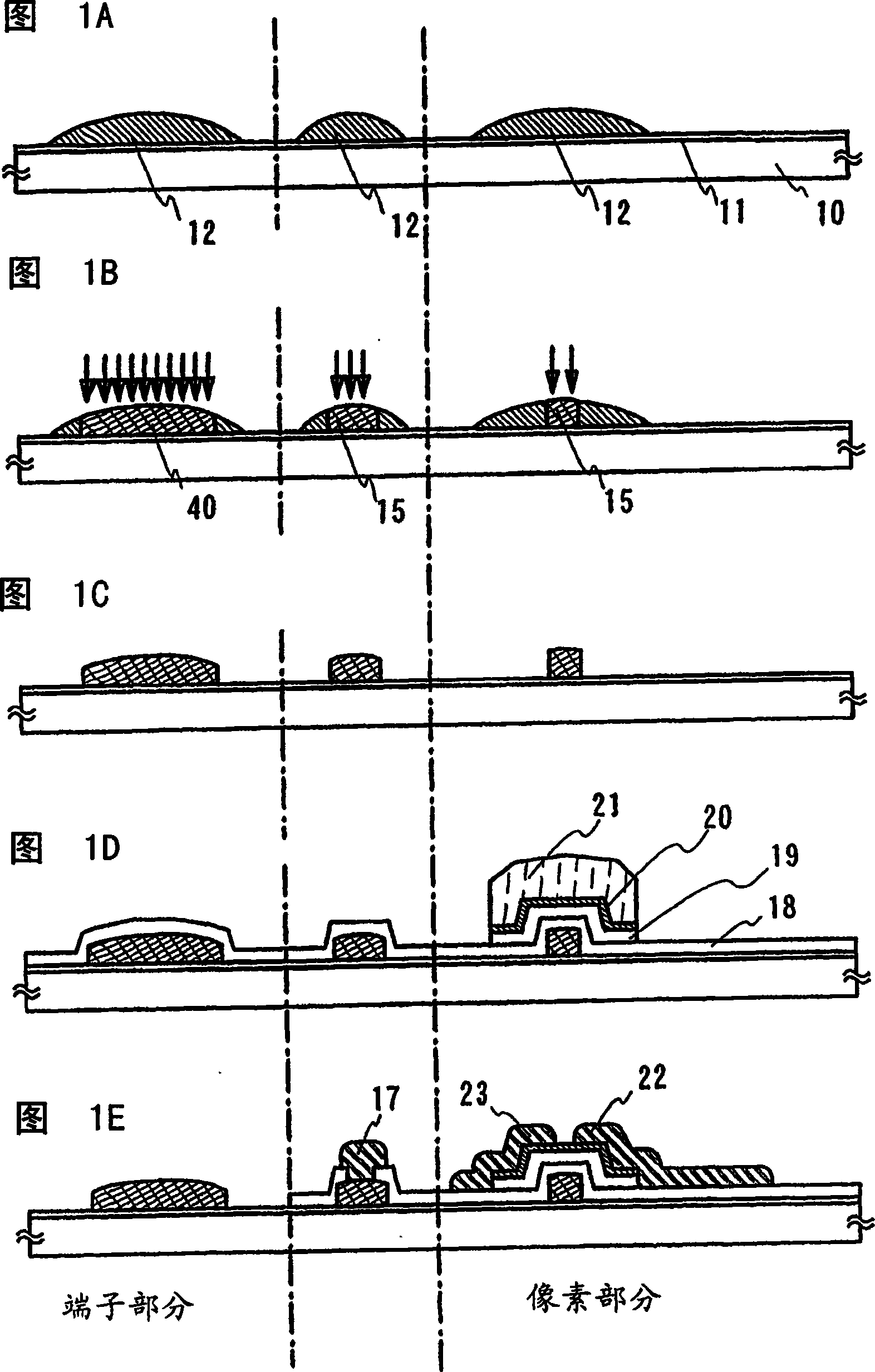

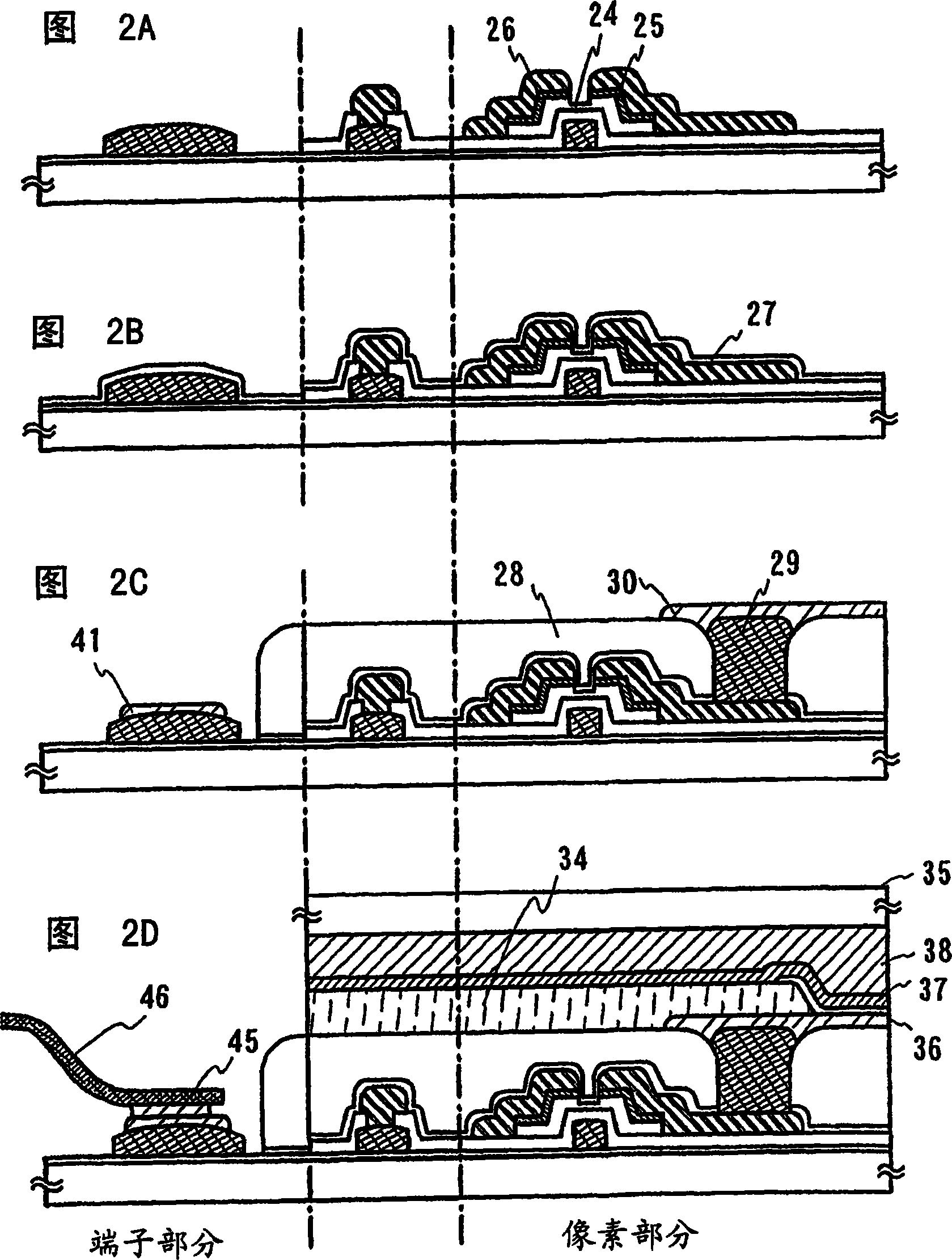

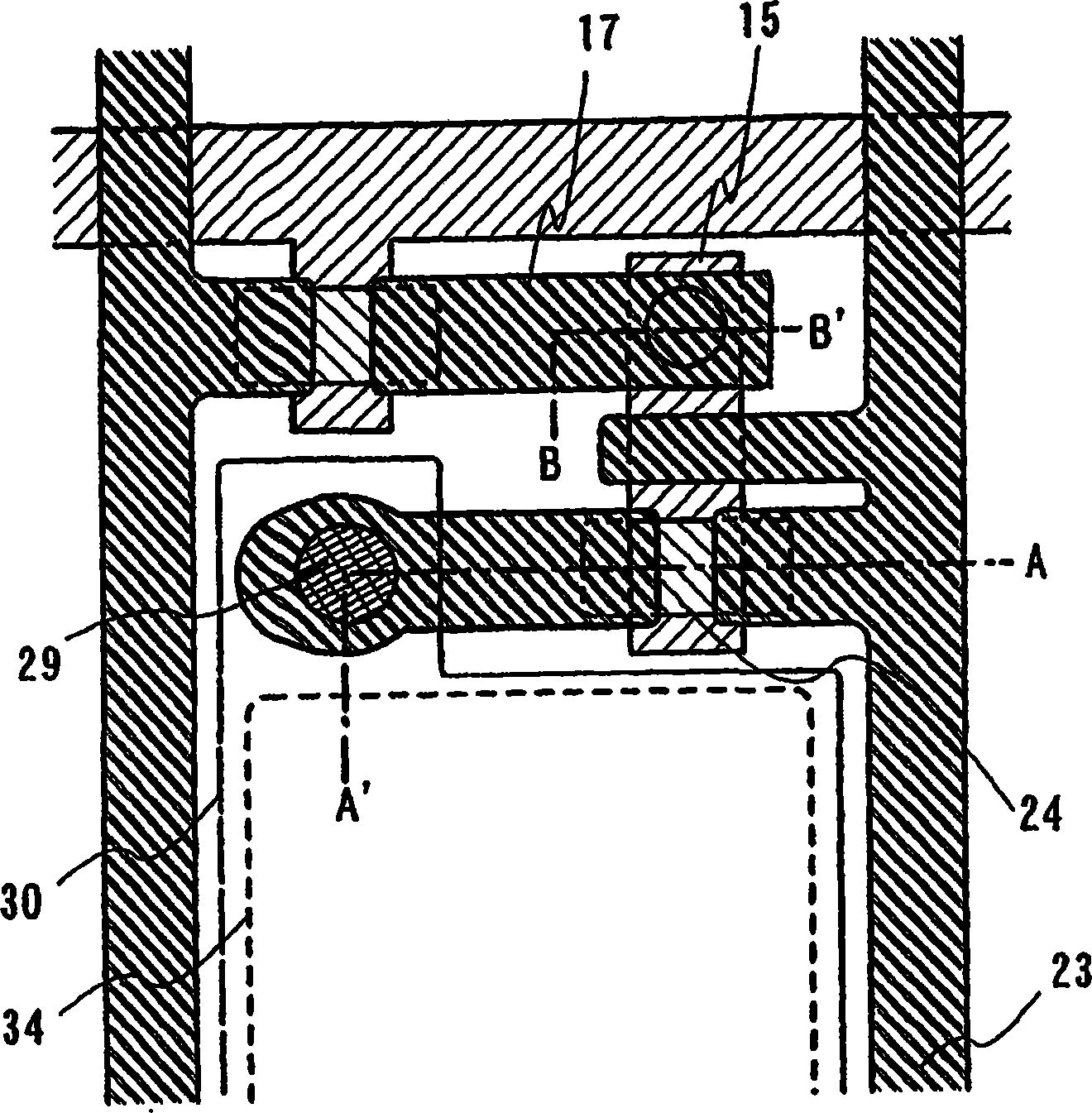

[0082] 1A to 2D show a method of manufacturing an active matrix light-emitting display device including a channel-etched TFT used as a switching element.

[0083] A base layer 11 for improving adhesion between the substrate 10 and a material layer subsequently formed by droplet discharge is formed on the substrate 10 . Since the base layer 11 is made to have an extremely thin thickness, it is not required that the base layer always have a layered structure. The preparation of the substrate layer 11 can be regarded as substrate pretreatment. Incorporation of photocatalyst materials (titanium oxide (TiO x ), strontium titanate (SrTiO 3 ), cadmium selenide (CdSe), potassium tantalate (KTaO 3 ), cadmium sulfide (CdS), zirconia (ZrO 2 ), niobium oxide (Nb 2 o 5 ), zinc oxide (ZnO), iron oxide (Fe 2 o 3 ), tungsten oxide (WO 3 )) Drops of treatment on the entire surface. Alternatively, selective formation of an organic material (polyimide, acrylic, or a coated insulating f...

Embodiment 2

[0158] Embodiment 1 explains an example of exposing gate wiring by a laser beam drawing device. An example of a process of forming source wiring or gate wiring using a laser beam drawing device is described here with reference to FIG. 5 .

[0159] This process is slightly different from that shown in Example 1, so for the sake of simplicity, the same process part will not be further explained.

[0160] It is similar to Embodiment 1 until the patterning process of the semiconductor thin film is performed. Next, a conductive thin film pattern 220 is formed by droplet discharge (FIG. 5A). In the conductive film pattern 220, a positive type photosensitive material is mixed.

[0161] Next, use Figure 4 The apparatus shown selectively exposes the conductive film pattern 220 to laser light (FIG. 5B). The portion 221 irradiated by the laser undergoes a chemical reaction.

[0162] The portion 221 irradiated with laser light is removed by development, thereby forming source wiring...

Embodiment 3

[0168] 6A to 6D show examples of other processes. In FIGS. 6A to 6D , an example of using a planarizing film as the gate insulating film 260 is described. Other components are the same as those shown in Embodiment 2.

[0169] After forming the gate electrode, the gate insulating film 260 having a planar surface is formed by sputtering, planarizing a thin film obtained by chemical vapor deposition, or a coating method. This planarization treatment is typified by chemical mechanical polishing treatment.

[0170] When manufacturing a large-screen light-emitting display device, preferably, the gate wiring with low resistance is formed to have a large thickness, for example, 1 to 5 μm. When the cross-sectional area is increased by increasing the wiring thickness, a level difference between the substrate surface and the thick film wiring surface is generated, which leads to degradation of coverage. In the case of increasing the gate wiring thickness, the planar gate insulating fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com