A kind of 304l stainless steel metal powder injection molding method

An injection molding and metal powder technology, which is applied in the field of 304L stainless steel metal powder injection molding, can solve the problems of unsatisfactory dimensional accuracy and surface accuracy, easy defects in degreasing products, and complicated degreasing process, so as to achieve low production cost and high production efficiency. , to avoid the effect of complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

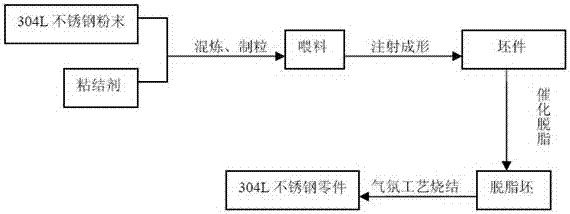

Method used

Image

Examples

Embodiment 1

[0024] The 304L stainless steel metal powder injection molding method of embodiment 1 may further comprise the steps:

[0025] (1) Prepare binder according to the following weight percentages: polyoxymethylene 86%, high-density polyethylene 8%, polypropylene 2%, paraffin 4%; 304L stainless steel powder and binder are mixed according to the volume ratio of 1:2 kneading, the kneading temperature is 170°C, the kneading time is 1.5h, and then granulated on the granulator to make feed;

[0026] (2) Add the feed material obtained in step (1) into the injection molding machine for injection molding, the injection temperature is 160°C, the injection pressure is 70MPa, the mold temperature is 120°C, and a blank is prepared;

[0027] (3) the blank that step (2) is obtained is placed in catalytic degreasing furnace and is carried out catalytic degreasing with nitric acid gas as catalyzer, and nitric acid gas feed rate is 1.6L / h, and nitrogen gas feed rate is 2L / h, and degreasing temperat...

Embodiment 2

[0030] The 304L stainless steel metal powder injection molding method of embodiment 2 comprises the following steps:

[0031] (1) Prepare binder according to the following weight percentage: polyoxymethylene 89%, high-density polyethylene 5%, polypropylene 2%, paraffin 4%; 304L stainless steel powder and binder are mixed according to the volume ratio of 1:3 kneading, the kneading temperature is 180°C, the kneading time is 1.8h, and then granulated on the granulator to make feed;

[0032] (2) Add the feed material obtained in step (1) into the injection molding machine for injection molding, the injection temperature is 180°C, the injection pressure is 100MPa, the mold temperature is 120°C, and a blank is prepared;

[0033] (3) the blank that step (2) is obtained is placed in catalytic degreasing furnace and is carried out catalytic degreasing with nitric acid gas as catalyzer, and nitric acid gas feed rate is 2L / h, and nitrogen gas feed rate is 2.3L / h, and degreasing temperatu...

Embodiment 3

[0036] The 304L stainless steel metal powder injection molding method of embodiment 3 comprises the following steps:

[0037] (1) Prepare binder according to the following weight percentages: polyoxymethylene 91%, high-density polyethylene 4%, polypropylene 2%, paraffin 3%; 304L stainless steel powder and binder are mixed according to the volume ratio of 1:4 Mixing, the mixing temperature is 195°C, the mixing time is 1.5h, and then granulated on the granulator to make feed;

[0038] (2) Add the feed material obtained in step (1) into the injection molding machine for injection molding, the injection temperature is 190°C, the injection pressure is 120MPa, the mold temperature is 125°C, and a blank is prepared;

[0039] (3) Place the blank that step (2) obtains in the catalytic degreasing furnace and use nitric acid gas as a catalyst to carry out catalytic degreasing. 130°C, the degreasing time is 3h, and the degreasing base is obtained, and the degreasing rate of the defatting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| skim rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com