Secondary sand-shooting molding technique for casting sand core

A molding process and secondary sand-shooting technology, applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of inaccurate scale, unavoidable seams, burrs, flashes, and affecting the quality of castings, etc., to achieve Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

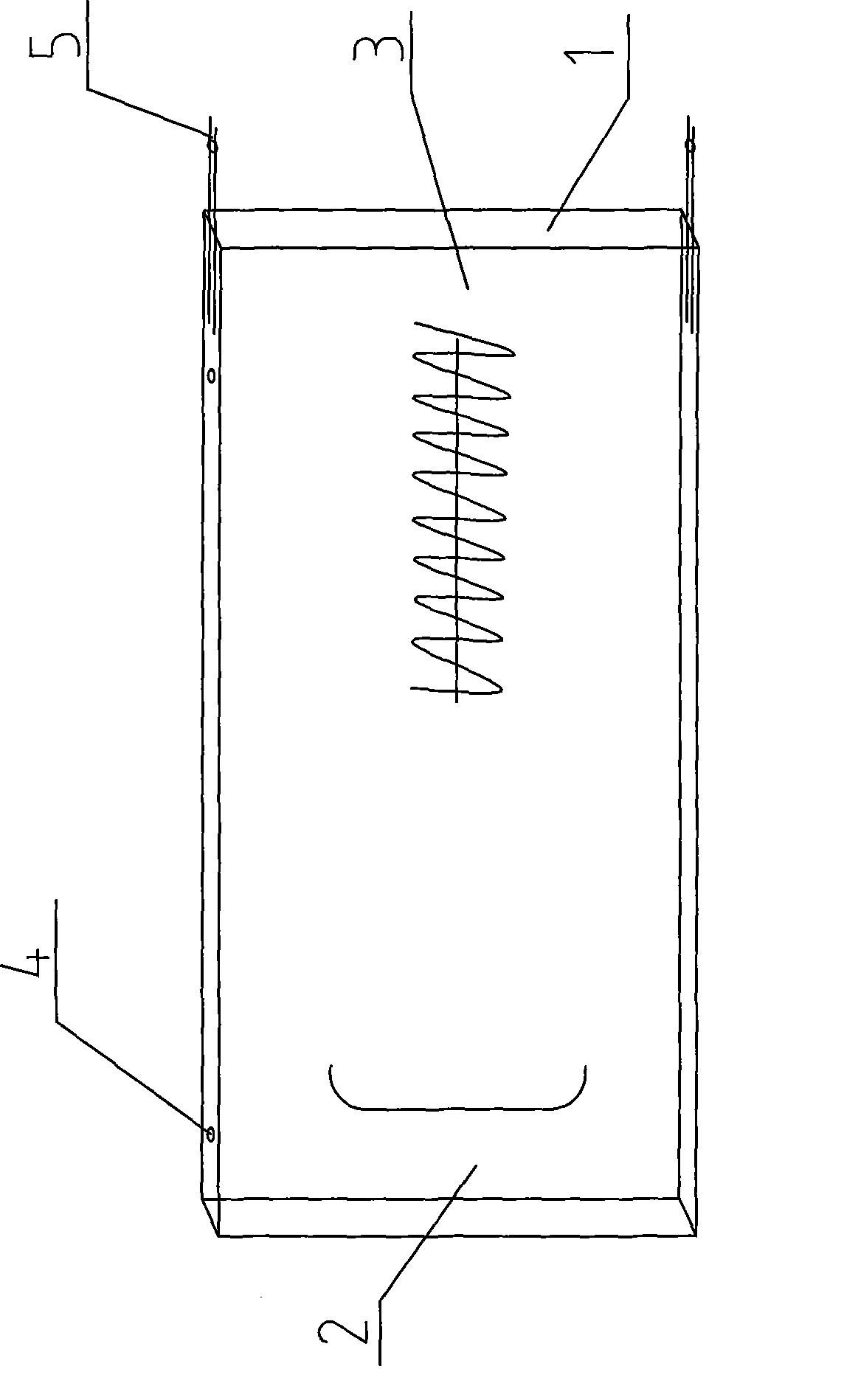

[0010] A secondary sand-shot molding process for casting clay cores, the steps are as follows: First, as shown in the figure, a small clay core cavity 2 with a parting surface different from that of the overall core is provided in the mold 1 And an integral clay core cavity 3, and a sand inlet 4 is provided on each cavity; and an electric heating device 5 is provided on the mold 1.

[0011] Then, apply a release agent in the small cavity 2 in the mold 1, then close the mold, and then pass the air

[0012] The pressure device shoots sand at an air pressure of 0.5Mpa, and then the sand is shot at a temperature above 200 degrees Celsius.

[0013] Keep it at temperature for 2-3 minutes to make small clay cores.

[0014] Open the mold, take out the small clay core, place it in the position corresponding to the cavity 3 of the overall clay core, and then

[0015] After the mold is closed, according to the above process, sand is injected into the cavity 3 of the integral clay core,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com