Thermosetting phenolic resin abrasive cutting wheel and preparation method thereof

A technology for cutting grinding wheels and phenolic resin, which is applied in the direction of bonding grinding wheels, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the sharpness of grinding wheels, metal corrosion, burrs on the section, etc., and achieve improved heat dissipation, increased bonding strength, and high The effect of sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

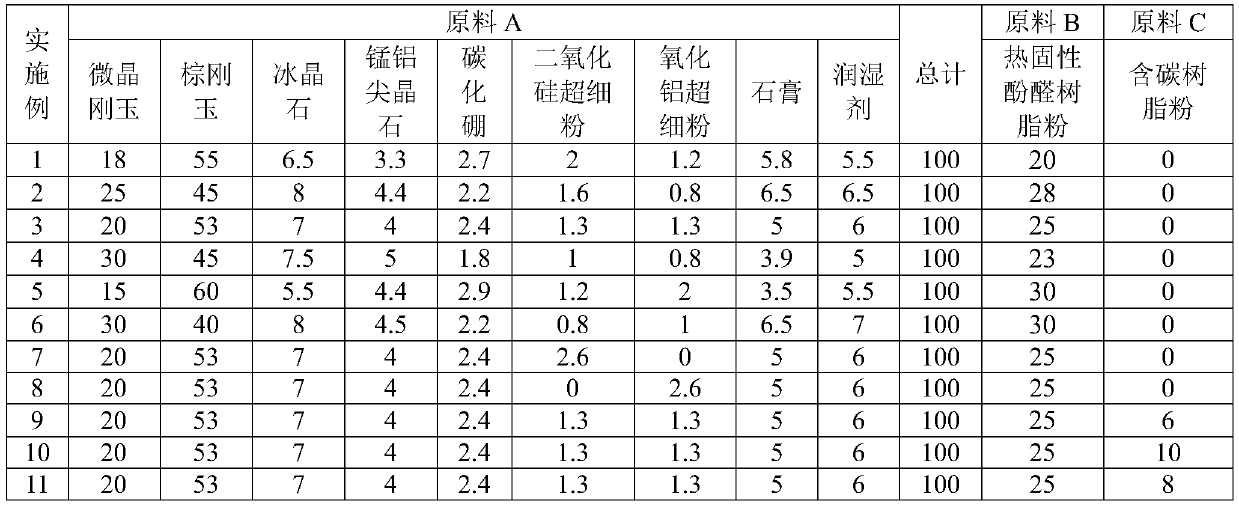

[0045] A thermosetting phenolic resin cutting wheel, its raw material ratio is shown in Table 1.

[0046] S1. Raw material A ingredients

[0047] Under the condition of constant stirring, mix microcrystalline corundum and brown corundum evenly, then add cryolite, manganese aluminum spinel, boron carbide, silicon dioxide superfine powder, alumina superfine powder, gypsum, mix well, and then Add a wetting agent and mix evenly to obtain raw material A;

[0048] Among them, Al in microcrystalline corundum 2 o 3 The weight content of the microcrystalline corundum is 95.5%, and the gradation of microcrystalline corundum is: 15-10mm 4kg, 10-8mm 9kg, 8-5mm 5kg; Al in brown corundum 2 o 3 The weight content of brown corundum is 95%, and the gradation of brown corundum is: 10-8mm 8kg, 8-5mm 16kg, 5-3mm 22kg, 3mm-0mm 9kg; Na in cryolite 3 AlF 6 The weight content is 97%, the particle size is less than or equal to 0.074mm; MnAl in manganese aluminum spinel 2 o 4 The weight content...

Embodiment 2

[0056] A thermosetting phenolic resin cutting wheel, its raw material ratio is shown in Table 1.

[0057] S1. Raw material A ingredients

[0058] Under the condition of constant stirring, mix microcrystalline corundum and brown corundum evenly, then add cryolite, manganese aluminum spinel, boron carbide, silicon dioxide superfine powder, alumina superfine powder, gypsum, mix well, and then Add a wetting agent and mix evenly to obtain raw material A;

[0059] Among them, Al in microcrystalline corundum 2 o 3 The weight content of the microcrystalline corundum is 95.5%, and the gradation of microcrystalline corundum is: 15-10mm 5kg, 10-8mm 13kg, 8-5mm 7kg; Al in brown corundum 2 o 3 The weight content of brown corundum is 95%, and the gradation of brown corundum is: 10-8mm 6kg, 8-5mm 14kg, 5-3mm 18kg, 3mm-0mm 7kg; Na in cryolite 3 AlF 6 The weight content is 97%, the particle size is less than or equal to 0.074mm; MnAl in manganese aluminum spinel 2 o 4 The weight conten...

Embodiment 3

[0068] A thermosetting phenolic resin cutting wheel, its raw material ratio is shown in Table 1.

[0069] S1. Raw material A ingredients

[0070] Under the condition of constant stirring, mix microcrystalline corundum and brown corundum evenly, then add cryolite, manganese aluminum spinel, boron carbide, silicon dioxide superfine powder, alumina superfine powder, gypsum, mix well, and then Add a wetting agent and mix evenly to obtain raw material A;

[0071] Among them, Al in microcrystalline corundum 2 o 3 The weight content of the microcrystalline corundum is 95.5%, and the gradation of microcrystalline corundum is: 15-10mm 4kg, 10-8mm 10kg, 8-5mm 6kg; Al in brown corundum 2 o 3 The weight content of brown corundum is 95%, and the gradation of brown corundum is: 10-8mm 8kg, 8-5mm 16kg, 5-3mm 21kg, 3mm-0mm 8kg; Na in cryolite 3 AlF 6 The weight content is 97%, the particle size is less than or equal to 0.074mm; MnAl in manganese aluminum spinel 2 o 4 The weight conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com