Patents

Literature

93results about How to "High rotational strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

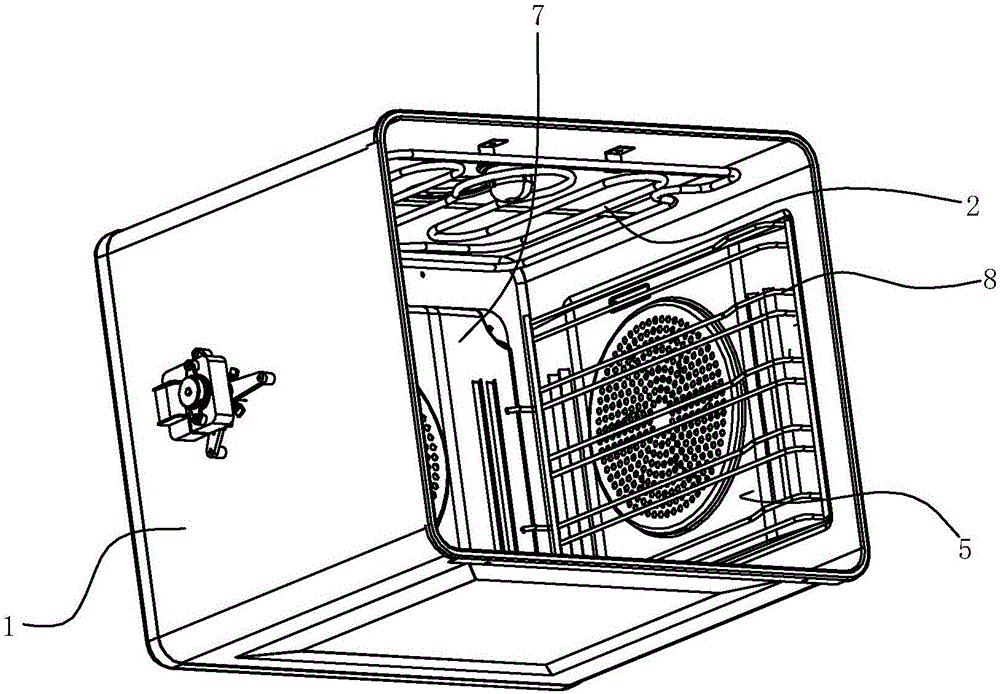

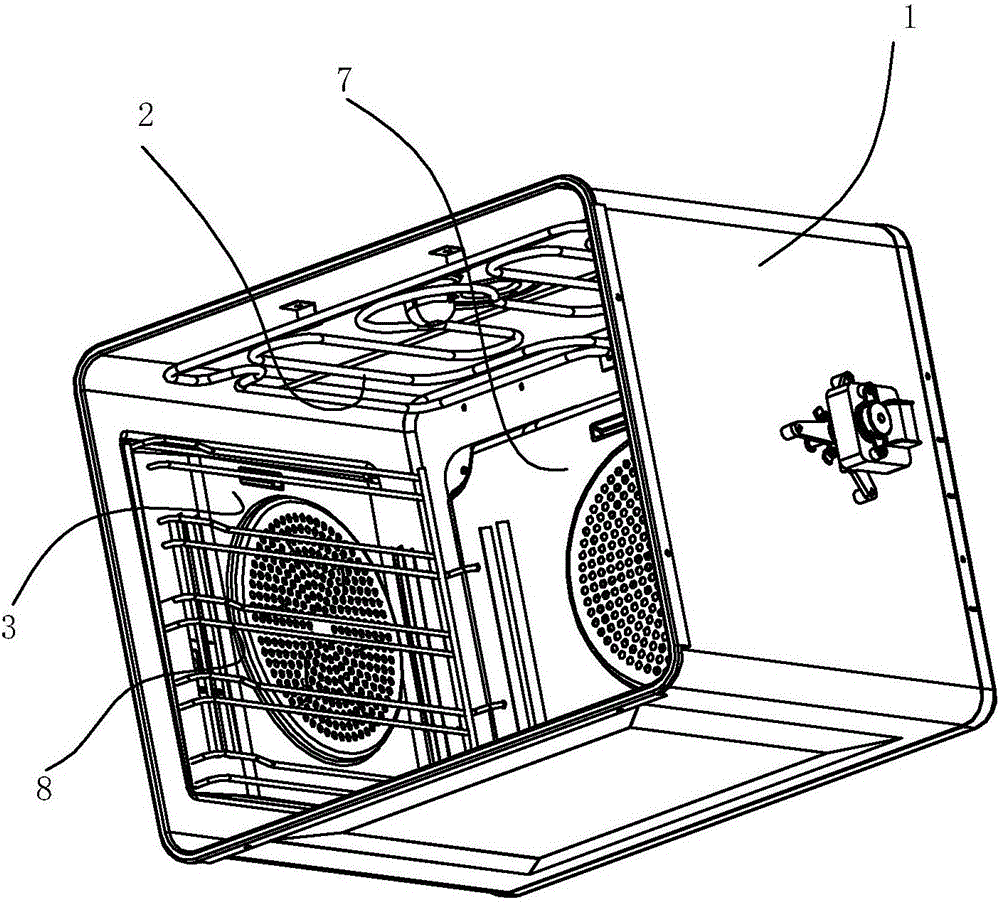

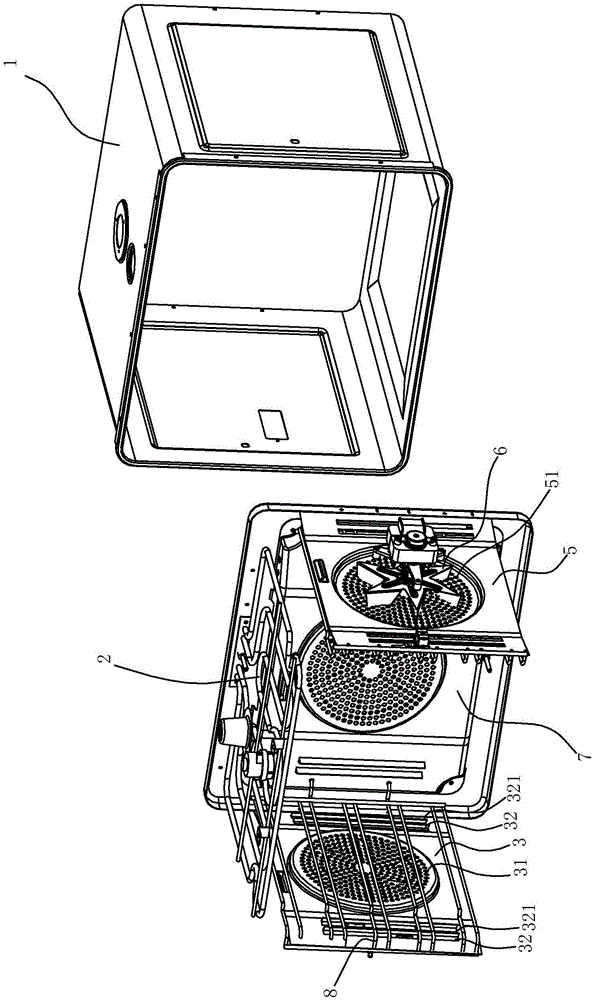

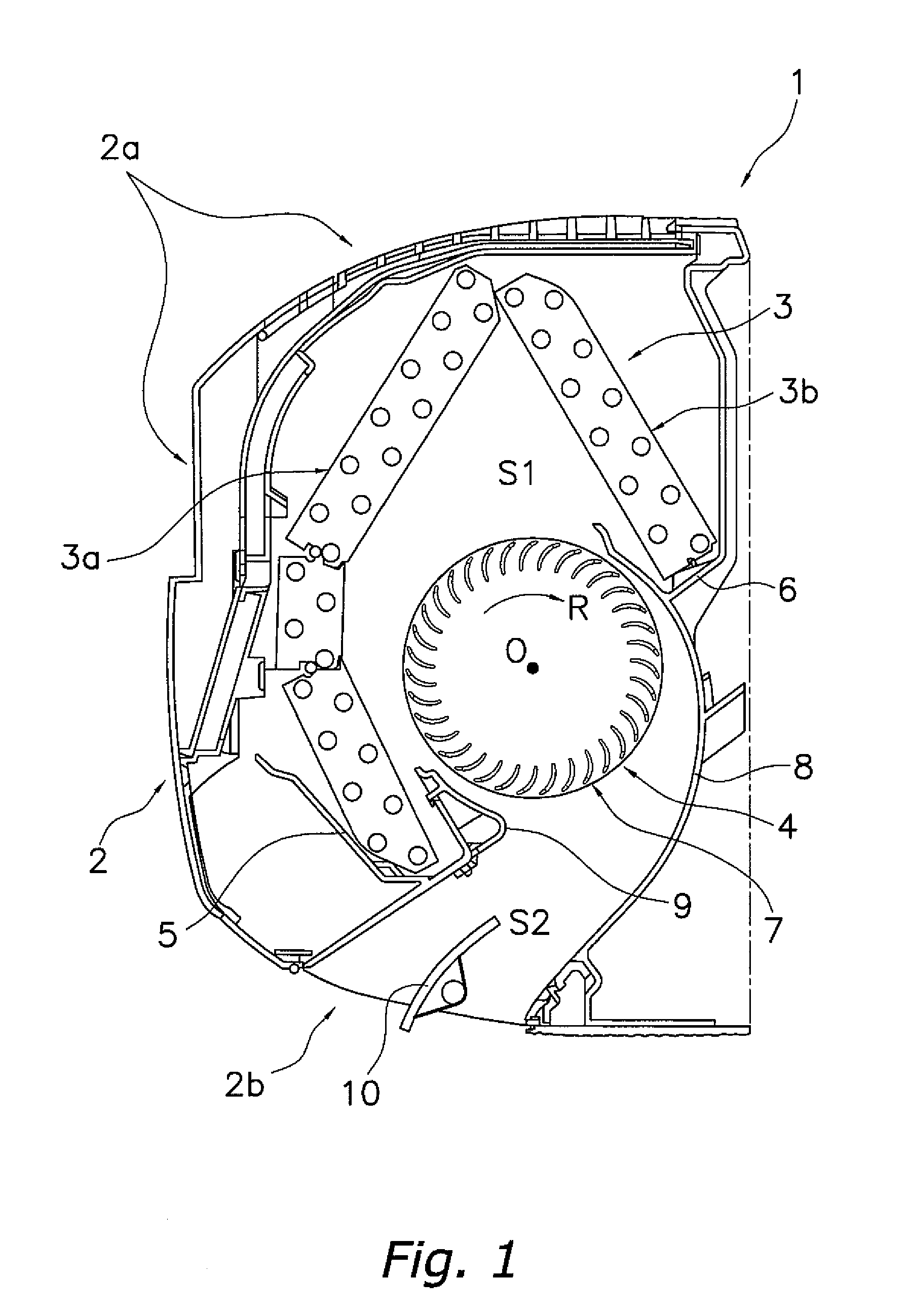

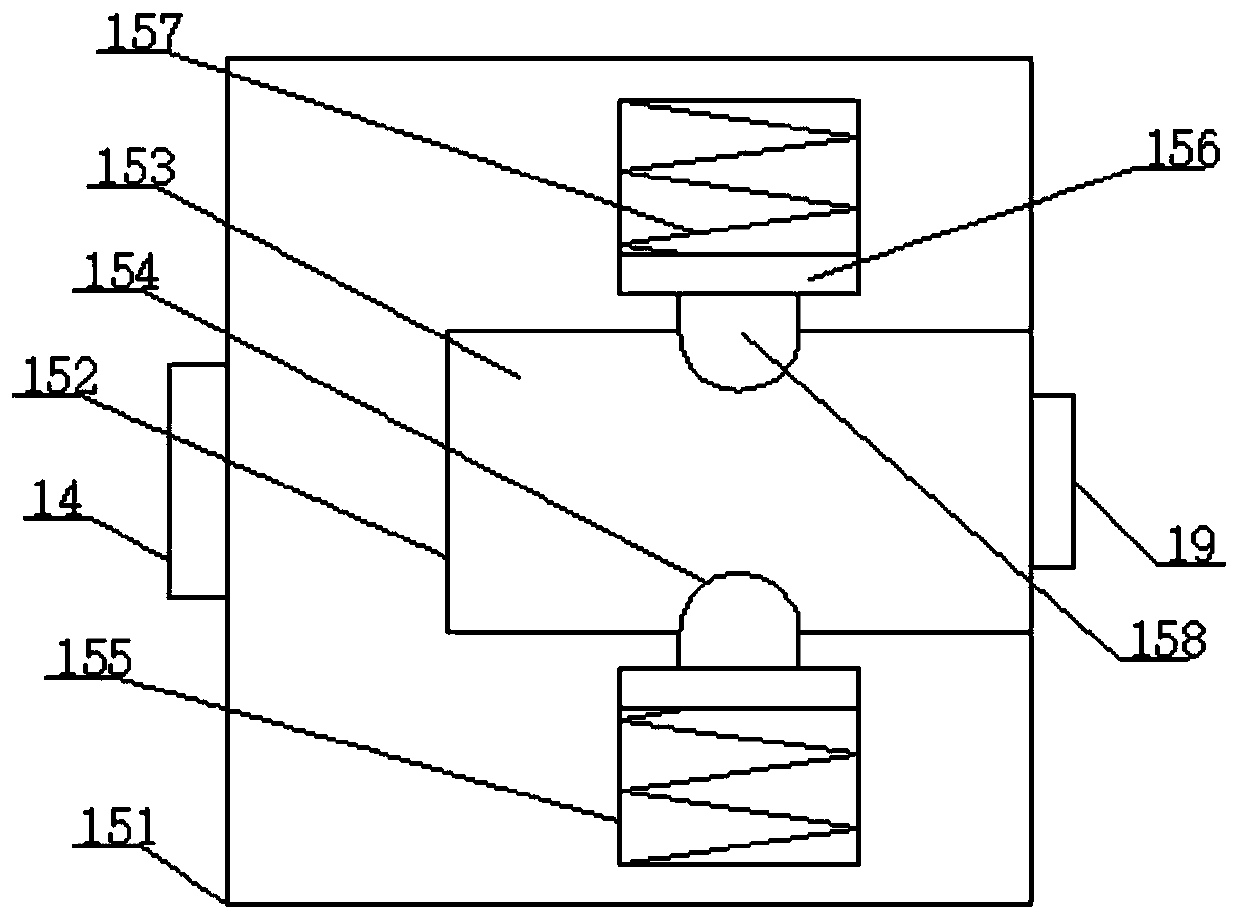

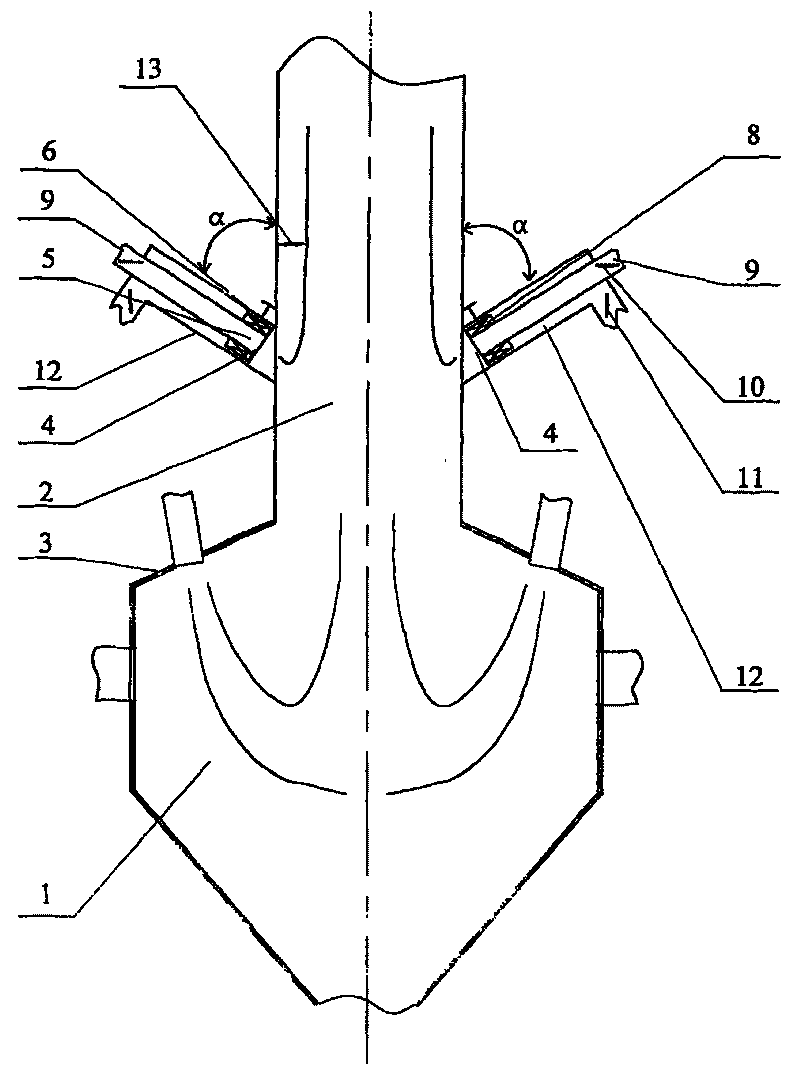

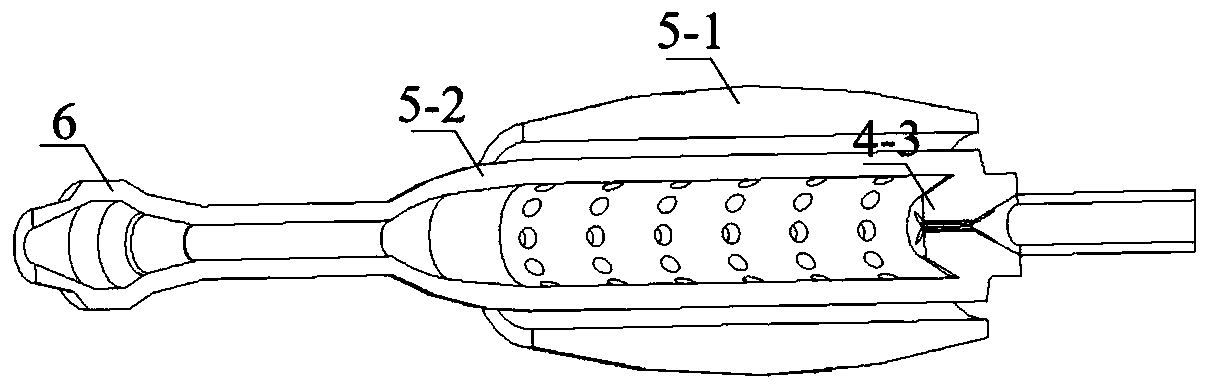

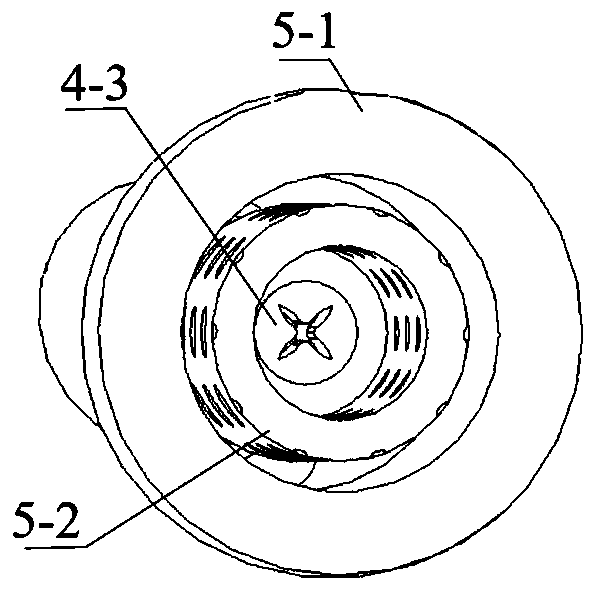

Oven liner structure

ActiveCN106063680AThe strength of the airflow rotation increasesHigh rotational strengthRoasters/grillsEngineeringAir blower

The invention relates to an oven liner structure which comprises a liner casing used for defining a baking cavity as well as a heater arranged in the liner casing. The oven liner structure is characterized in that a left baffle, a right baffle and a rear baffle are respectively arranged on the left side, the right side and the rear side of the inner wall of the liner casing; a gap is formed between the middle of each of the left baffle, the right baffle and the rear baffle and the inner wall of the liner casing; the peripheries of the left baffle, the right baffle and the rear baffle are tightly clung onto the inner wall of the liner casing; a first hot air blower, a second hot air blower and a third hot air blower are respectively arranged between the left baffle and the inner wall of the liner casing, between the right baffle and the inner wall of the liner casing, and between the rear baffle and the inner wall of the liner casing; air inlets are formed in the middle part of each of the left baffle, the right baffle and the rear baffle; air outlets are formed on the left side and the right side of each of the left baffle, the right baffle and the rear baffle. The oven liner structure has the advantages that the rotation intensity of airflow in a liner can be increased, the disturbance is also increased, and the thermal field of the whole liner is relatively uniform.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

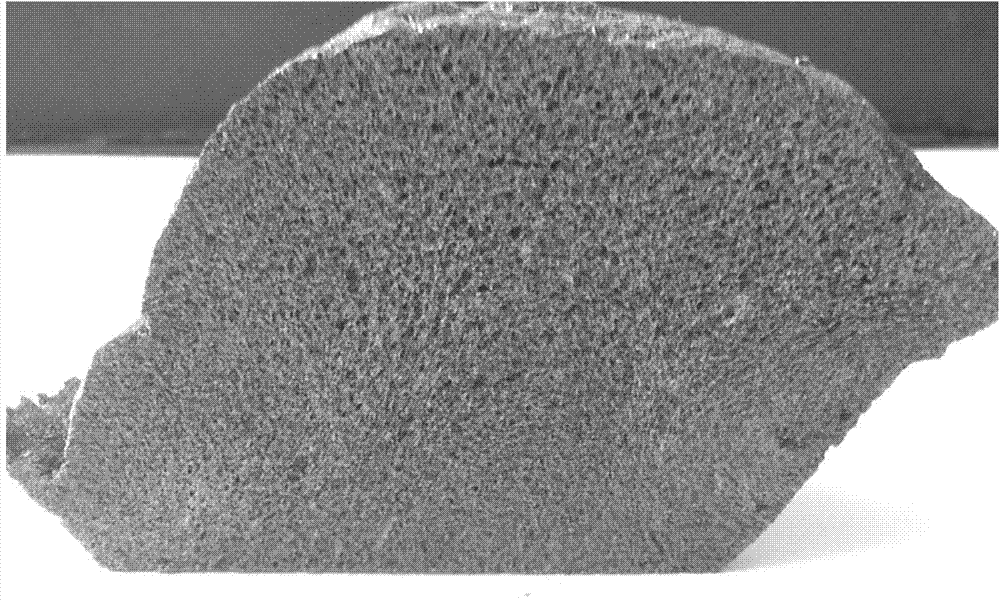

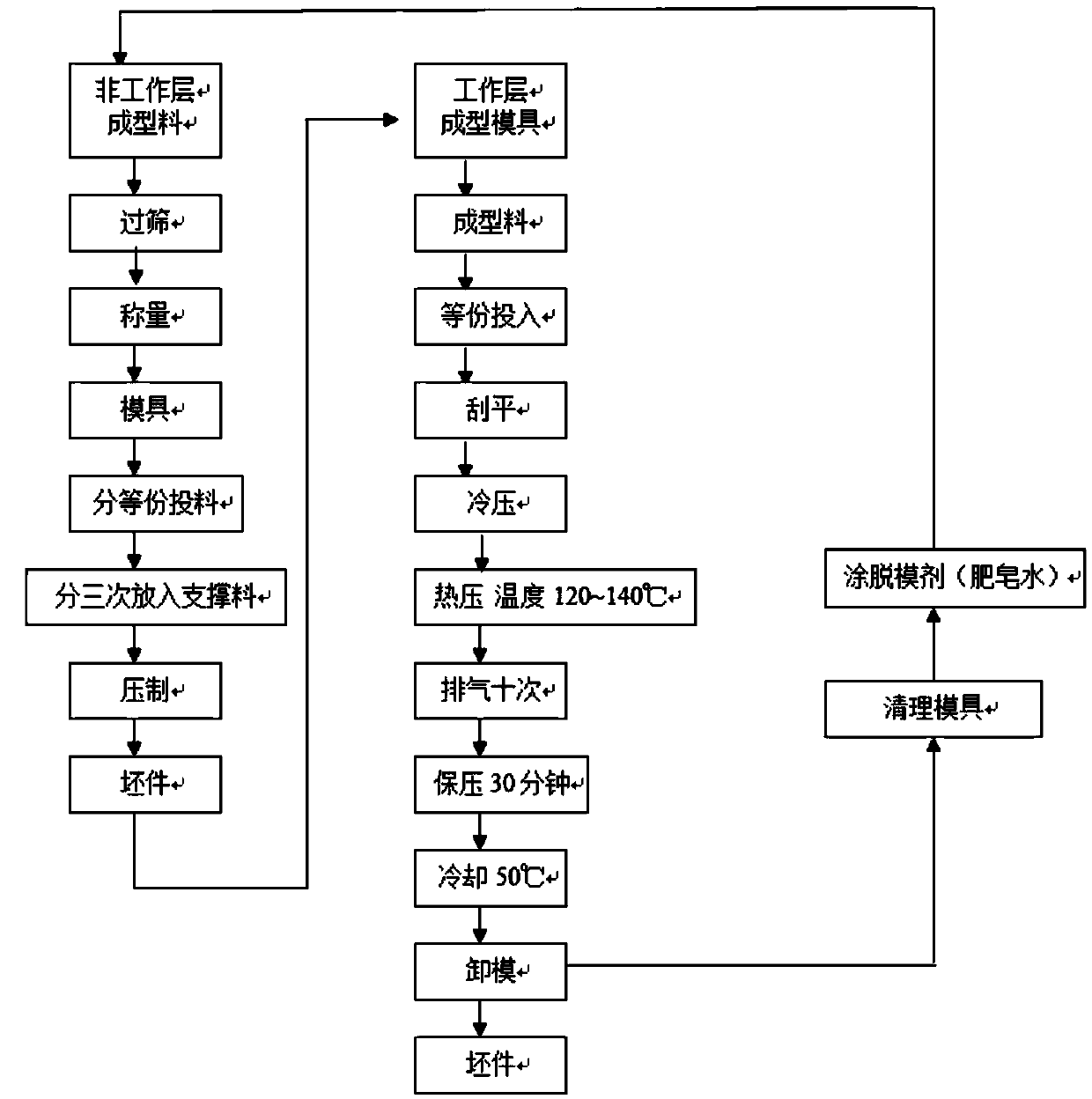

Method for manufacturing ceramic diamond composite grinding wheel

ActiveCN102699833AHigh rotational strengthImprove retentionAbrasion apparatusGrinding devicesCompression moldingAdhesive

The invention discloses a method for manufacturing a ceramic diamond composite grinding wheel, which is characterized by comprising the following steps of: by mass, mixing and pelletizing diamond, silicon carbide and a bonding agent, carrying out compression molding, drying, pre-burning and then sintering to obtain a joint unit; and placing the joint unit and a grinding wheel matrix into a die, pouring a polyimide composite material between the joint unit and the grinding wheel, carrying out pressing, then carrying out cooling and sintering to obtain the grinding wheel. According to the composite grinding wheel manufactured by the method disclosed by the invention, an integrated pressing sintering or embedding splicing mode is adopted; the polyimide composite material is used as a transition adhesive; and the integral grinding wheel is manufactured after carrying out secondary hot pressing and sintering. The chip accommodating and drainage space surface coverage rate of the ceramic diamond composite grinding wheel can reach 30 to 70 percent. The ceramic diamond composite grinding wheel has the following excellent grinding characteristics that the cutting depth is large; the grinding precision is high; in the forming and grinding process, the retentivity of a molded surface is good; the application range is wide; the grinding wheel can be used for dry grinding and has resistance to the high temperature of 350 DEG C and splicing units cannot fall off and blocks cannot fall off; and the grinding wheel has high revolving strength.

Owner:贵州荣清工具有限公司

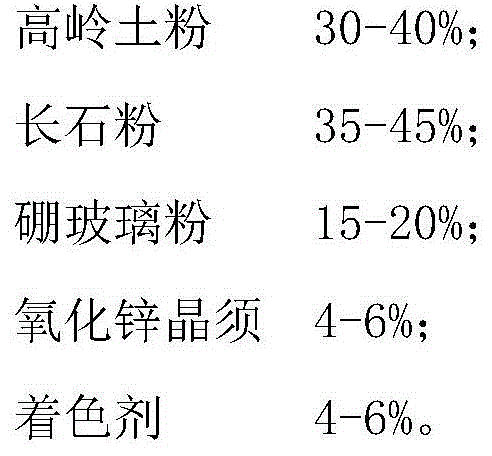

Ceramic bond and preparation method thereof

ActiveCN105150122ALower firing temperatureImprove gripAbrasion apparatusGrinding devicesChromium sesquioxideLithium carbonate

The invention relates to a ceramic bond and a preparation method thereof, and belongs to the technical field of grinding wheel bonds. The ceramic bond is prepared from, by weight, 20%-40% of borosilicate glass, 22%-43% of feldspar, 10%-35% of nepheline syenite, 5%-13% of clay, 2%-5% of lithium carbonate and 3%-13% of chromium sesquioxide. According to the ceramic bond, all the components are subjected to a synergistic effect within a limited dosage range, the firing temperature of the ceramic bond is lowered to be 1000 DEG C, high-temperature burning loss of ceramic microcrystal grinding materials is avoided, the revolving strength of a grinding wheel manufactured through the bond is improved, and the grinding linear velocity reaches 80 m / s maximally. The preparation method is easy and convenient to operate, easy to control and suitable for industrial application and popularization.

Owner:白鸽磨料磨具有限公司

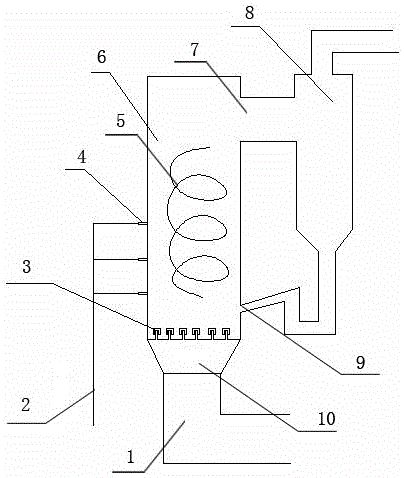

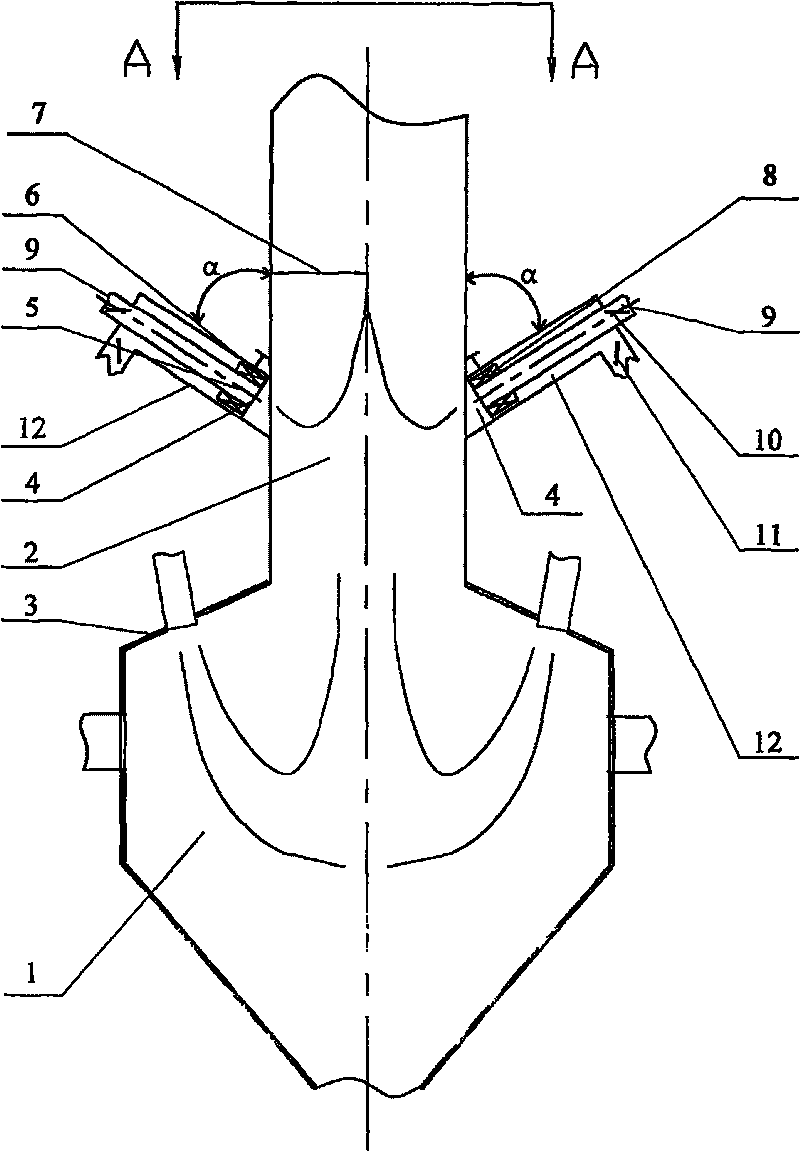

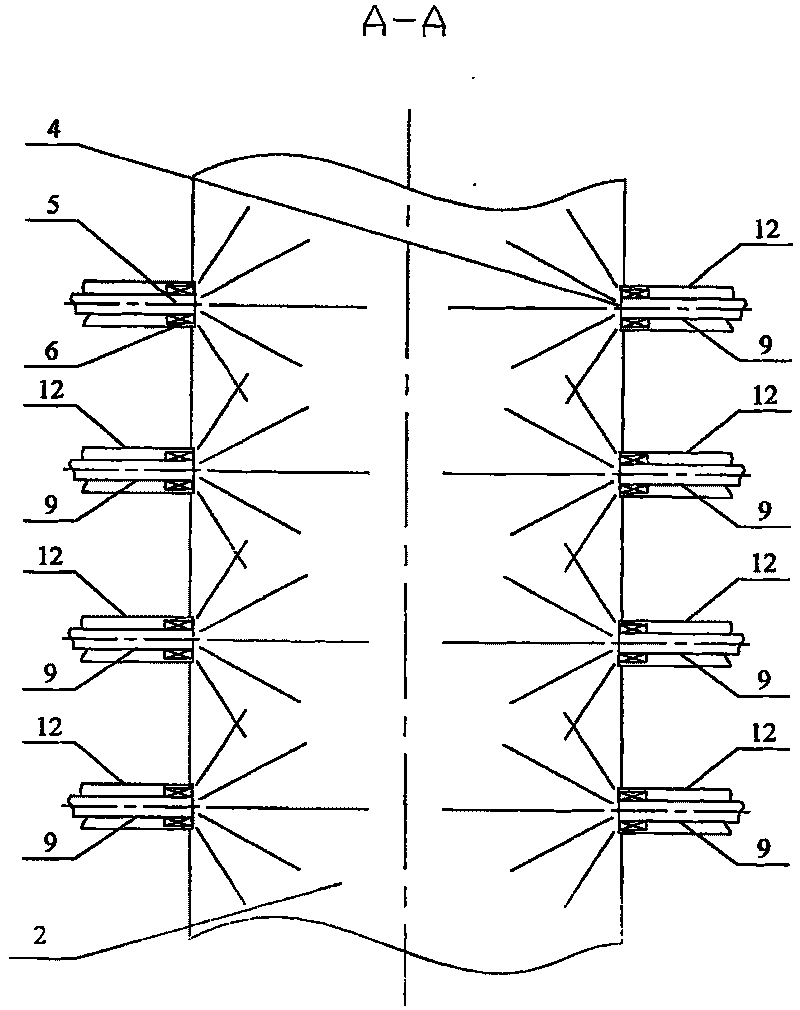

Spiral-flow type fluidized bed incinerator

ActiveCN105090980AEnhanced lateral mixingReduce carbon contentIncinerator apparatusCombustionFluidized bed

The invention discloses a spiral-flow type fluidized bed incinerator which comprises an incinerator body and a cyclone separator. The incinerator body is used for providing combustion space for a fluidized bed, and the cyclone separator is used for recycling insufficiently-combusted ingredients for secondary combustion. At least three layers of secondary air jet orifices are further formed in the walls of the incinerator body and located in a transition zone between a dense-phase zone and a lean-phase zone. The other ends of the secondary air jet orifices are communicated with a secondary air source. The secondary air jet orifices on the same layer are distributed in the walls of the incinerator body. The air flow is spiral so as to enhance transverse mixing of particles and air in the incinerator body and prolong the residence time of the particles in the incinerator body. High-speed secondary air is jetted into the lean-phase zone on the upper portion of an air distribution plate of the circulation fluidized bed incinerator body in a classified manner through wall type tangential firing, so that transverse mixing of particles and air is enhanced, temperature distribution in different areas in the dense-phase zone is more uniform, the combustion efficiency and the desulphurization efficiency are improved, NOx emissions are lowered, the heat transferring is enhanced, and the equipment size is reduced.

Owner:潍坊联荣环保设备有限公司

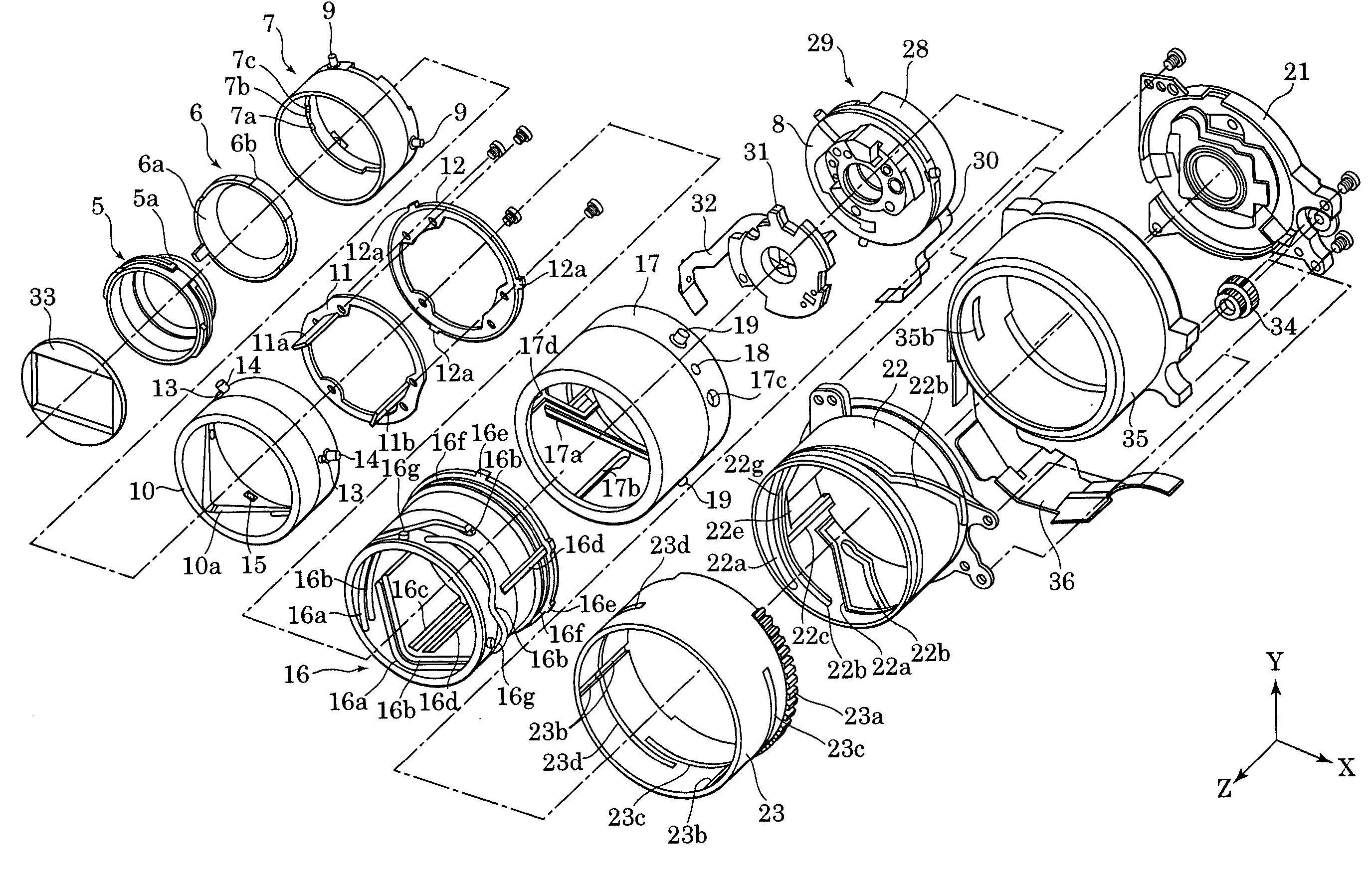

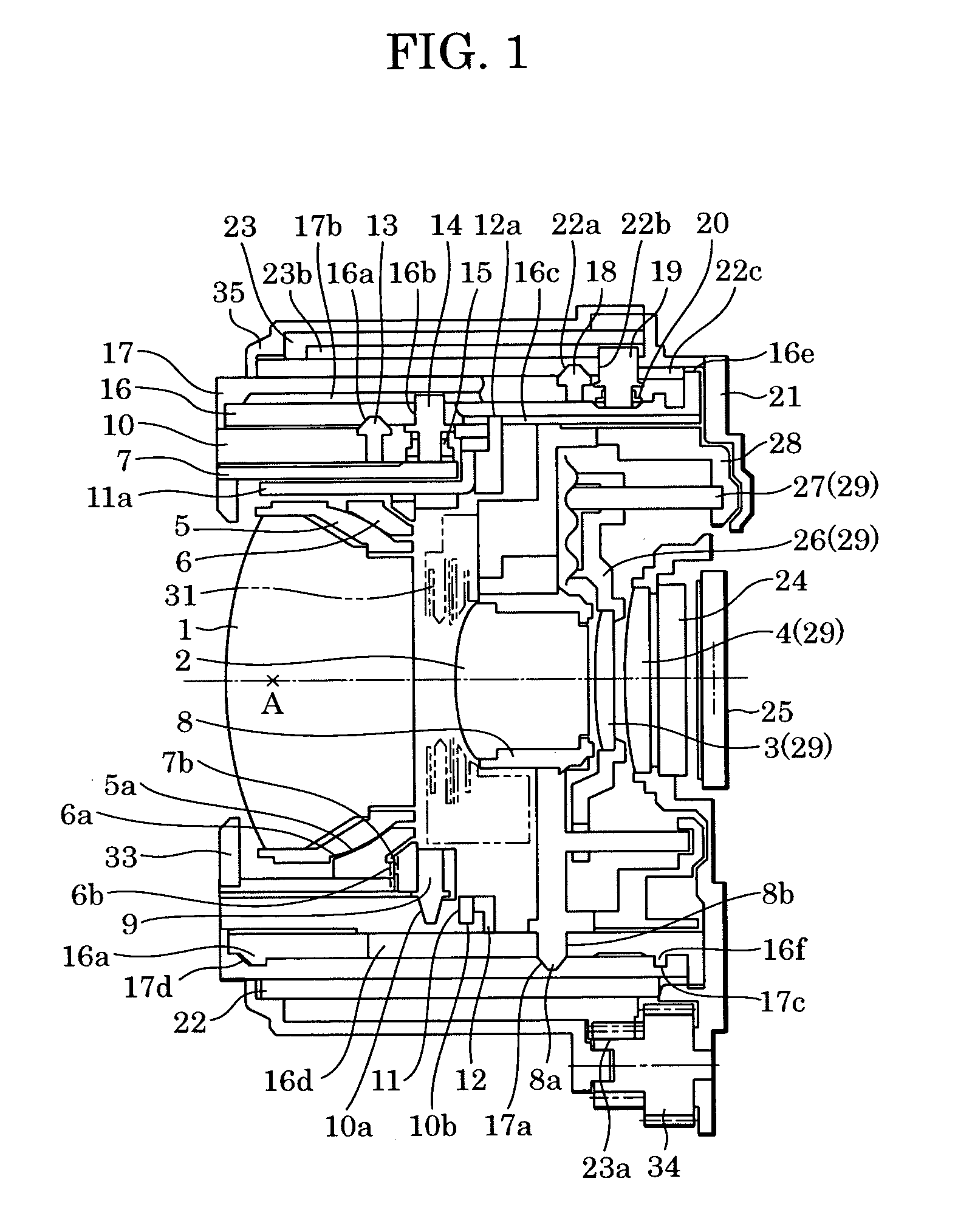

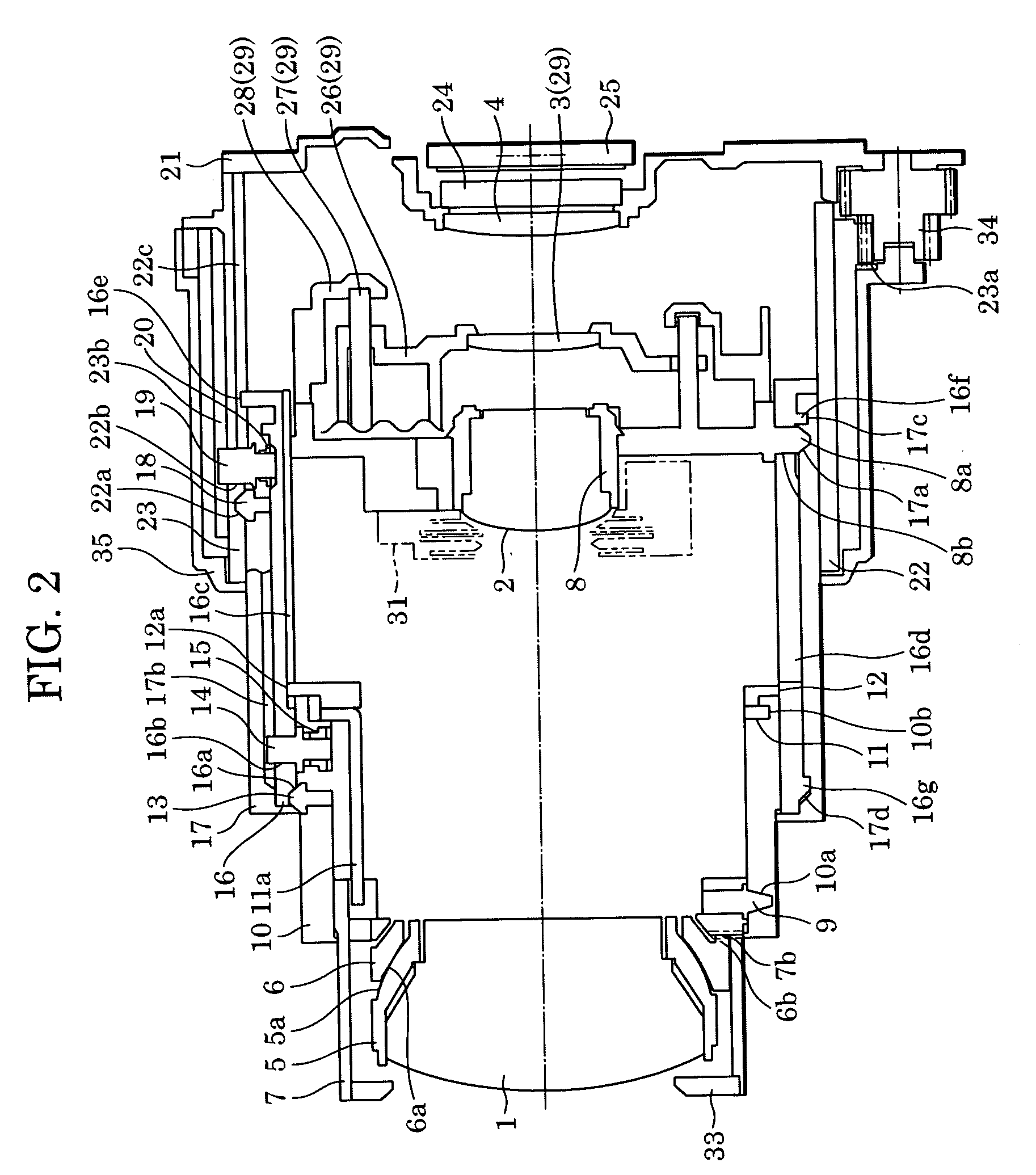

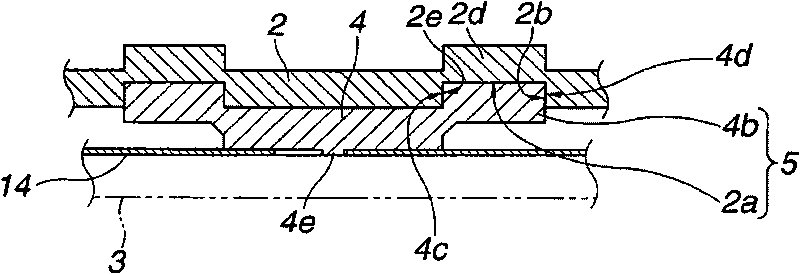

Lens barrel for camera

ActiveUS7302175B2High rotational strengthHigh strengthTelevision system detailsPrintersCamera lensOptical axis

Flexible printed boards are introduced to a camera body respectively through a plurality of slit holes formed in a rotating barrel at different positions in the direction of an optical axis. The outer dimension of the lens barrel is kept from increasing.

Owner:CANON KK

Resin grinding wheel and preparation method thereof

InactiveCN105234839AImprove thermal stabilityHigh hardnessAbrasion apparatusGrinding devicesCross-linkBond energy

The invention discloses a resin grinding wheel. The resin grinding wheel is composed of the following raw materials in parts by weight: 570-600 parts of CBN grinding material, 90-100 parts of phenol, 96-110 parts of 35-40% formaldehyde solution, 5-7 parts of boric acid, 2-6 parts of hexamethylenetetramine, 13-20 parts of aniline, 47-60 parts of kaolin powder, and 18-20 parts of chlorinated paraffin. According to the grinding wheel disclosed by the invention, the comprehensive performance of the finished product is improved by introducing boron in phenolic resin, due to that phenolic resin is connected with a benzene ring by a C-C bond, boron-containing phenolic resin is connected with a benzene ring by a B-' bond, wherein the bond energy of the C-C bond is 347KJ / mol, and the bond energy of a B-O bond is 523KJ / mol, and far higher than the bond energy of the C-C bond, thus forming a boron-containing three-dimensional cross-linked structure; therefore, the heat resistance, instantaneous high-temperature resistance and ablation resistance of the grinding wheel can be obviously improved.

Owner:WUHU HONGKUN AUTO PARTS

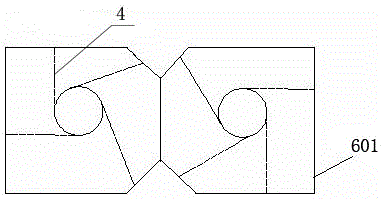

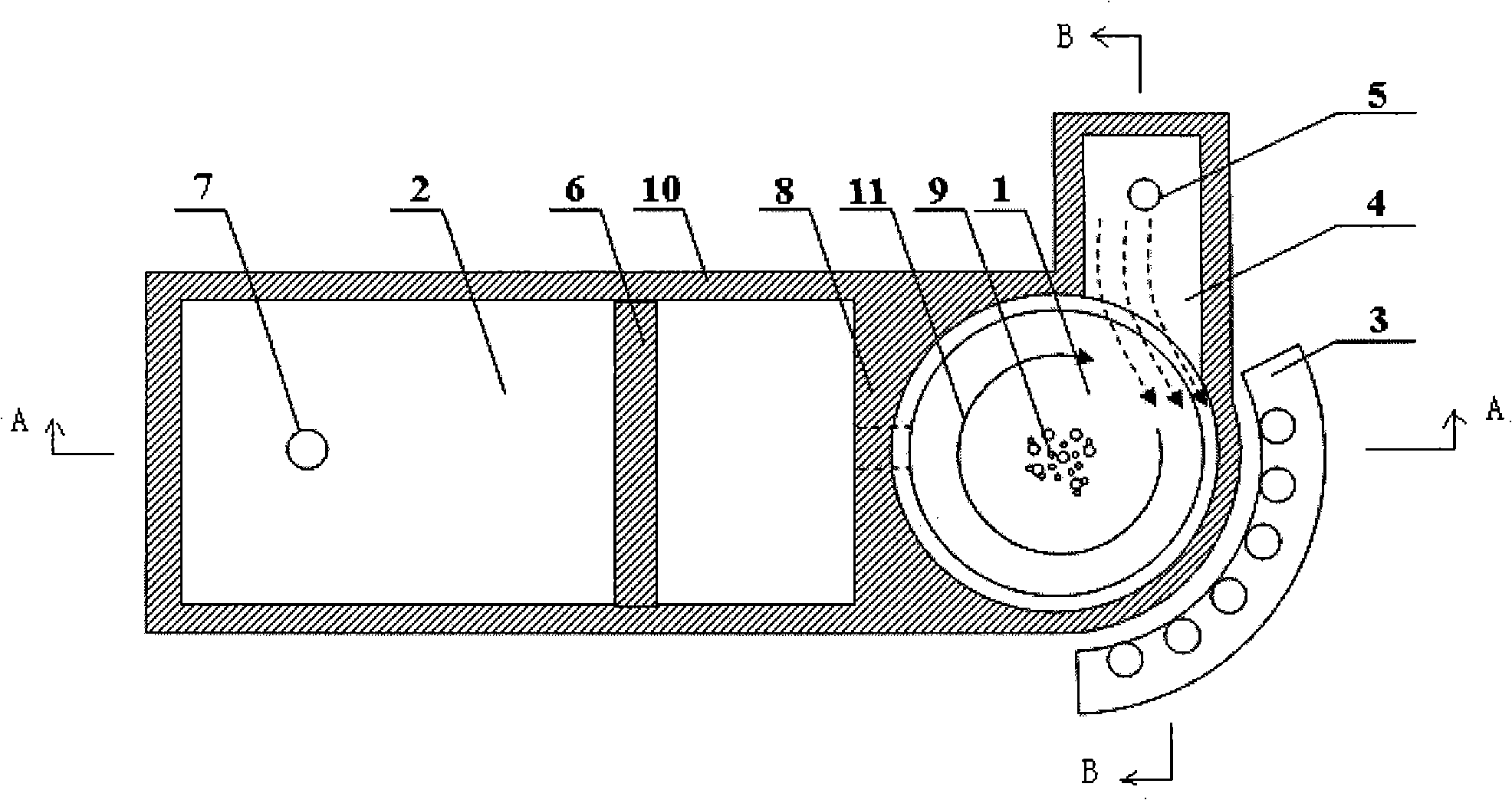

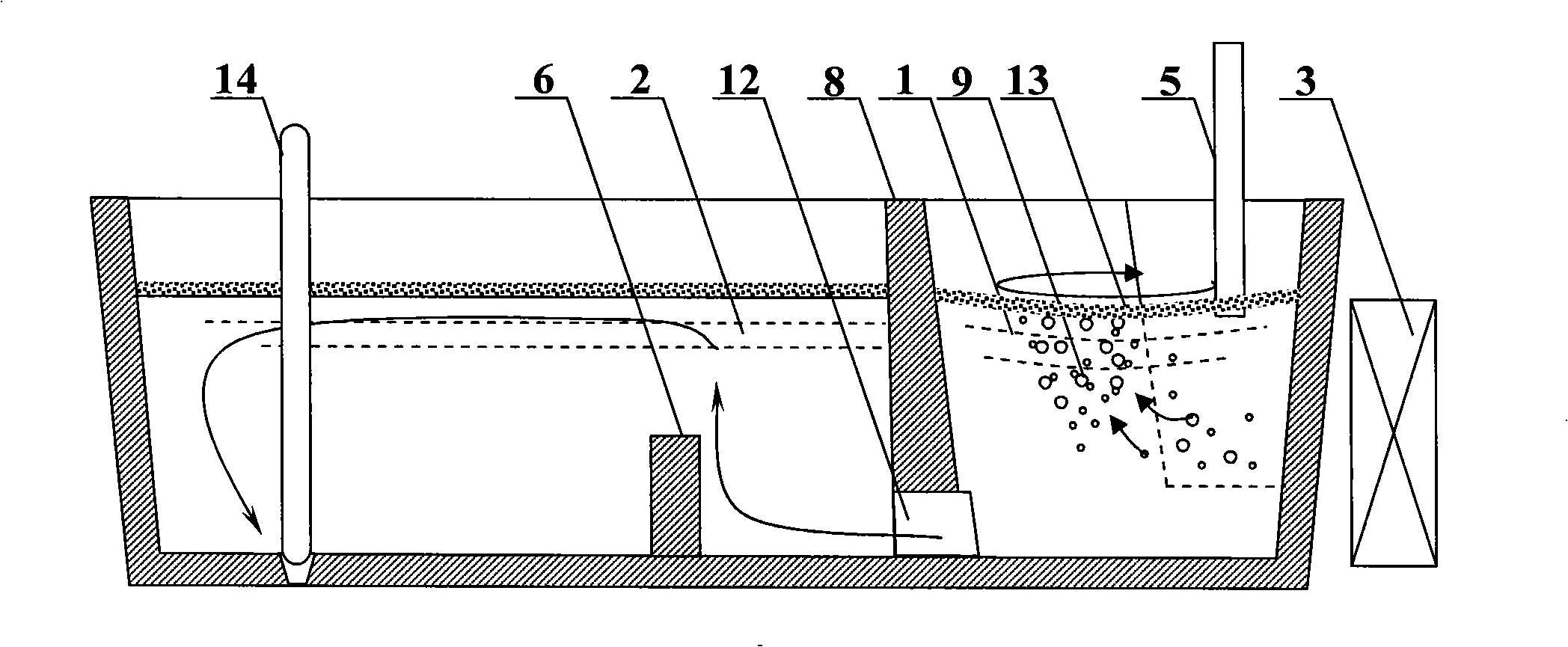

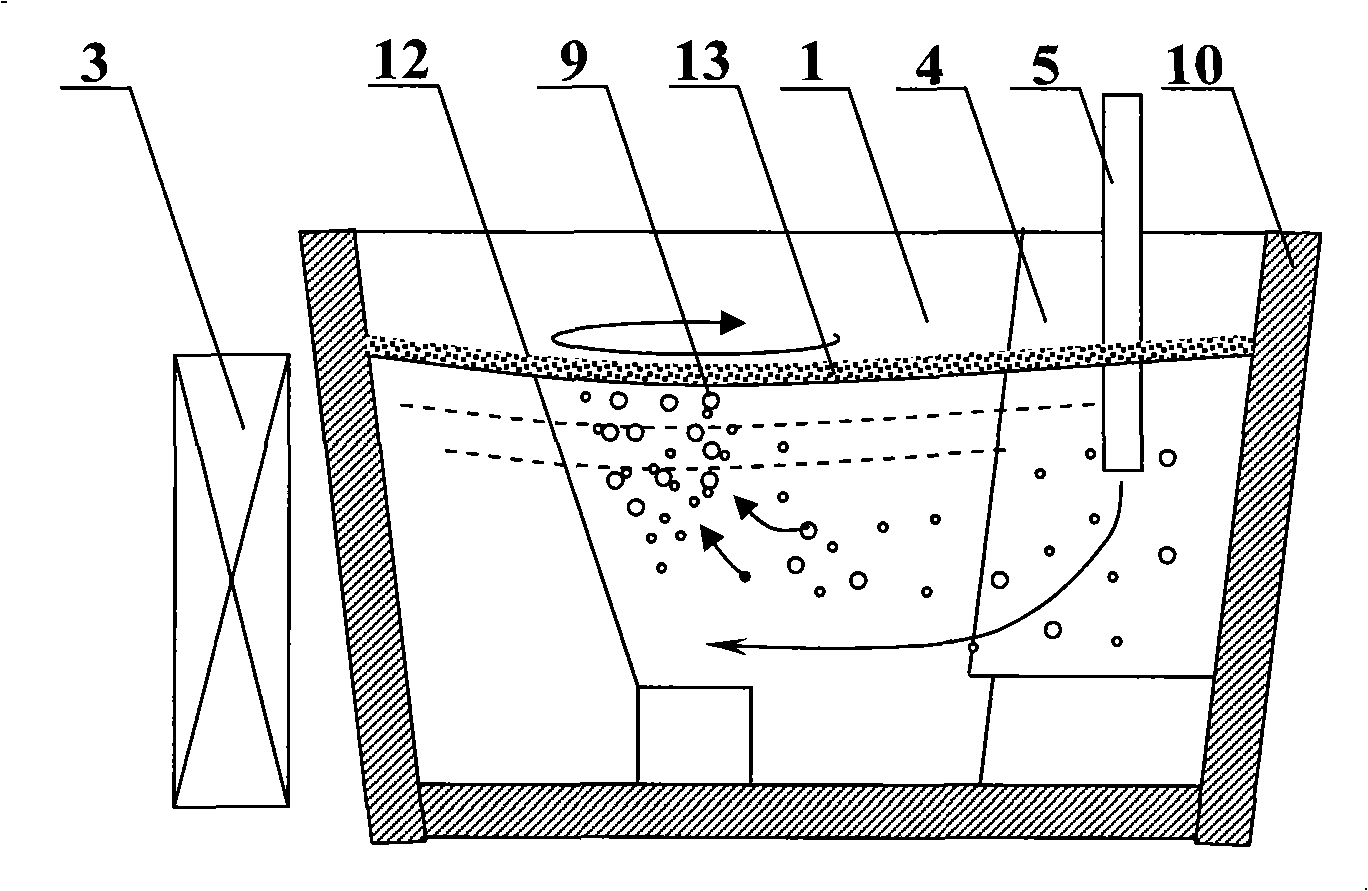

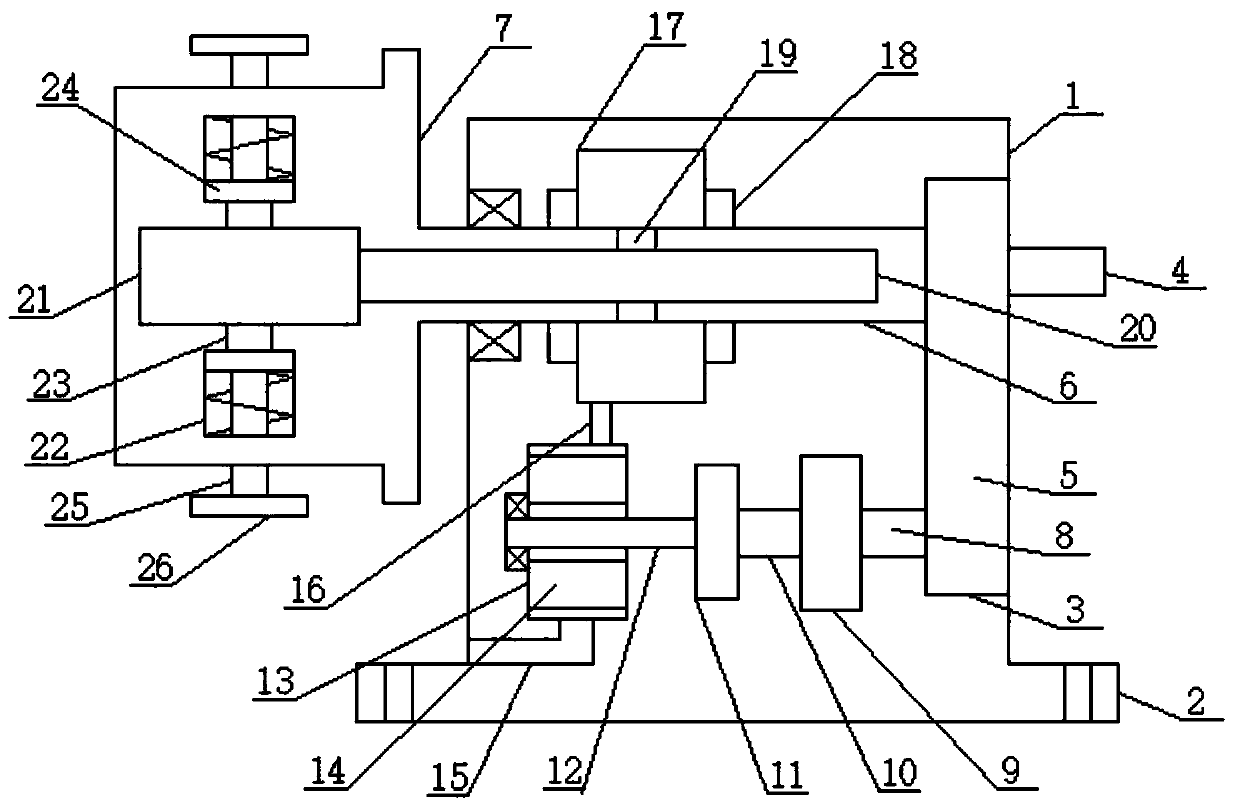

Rotating electromagnetic field and tangential flow guiding composite purifying tundish steel liquid method and device

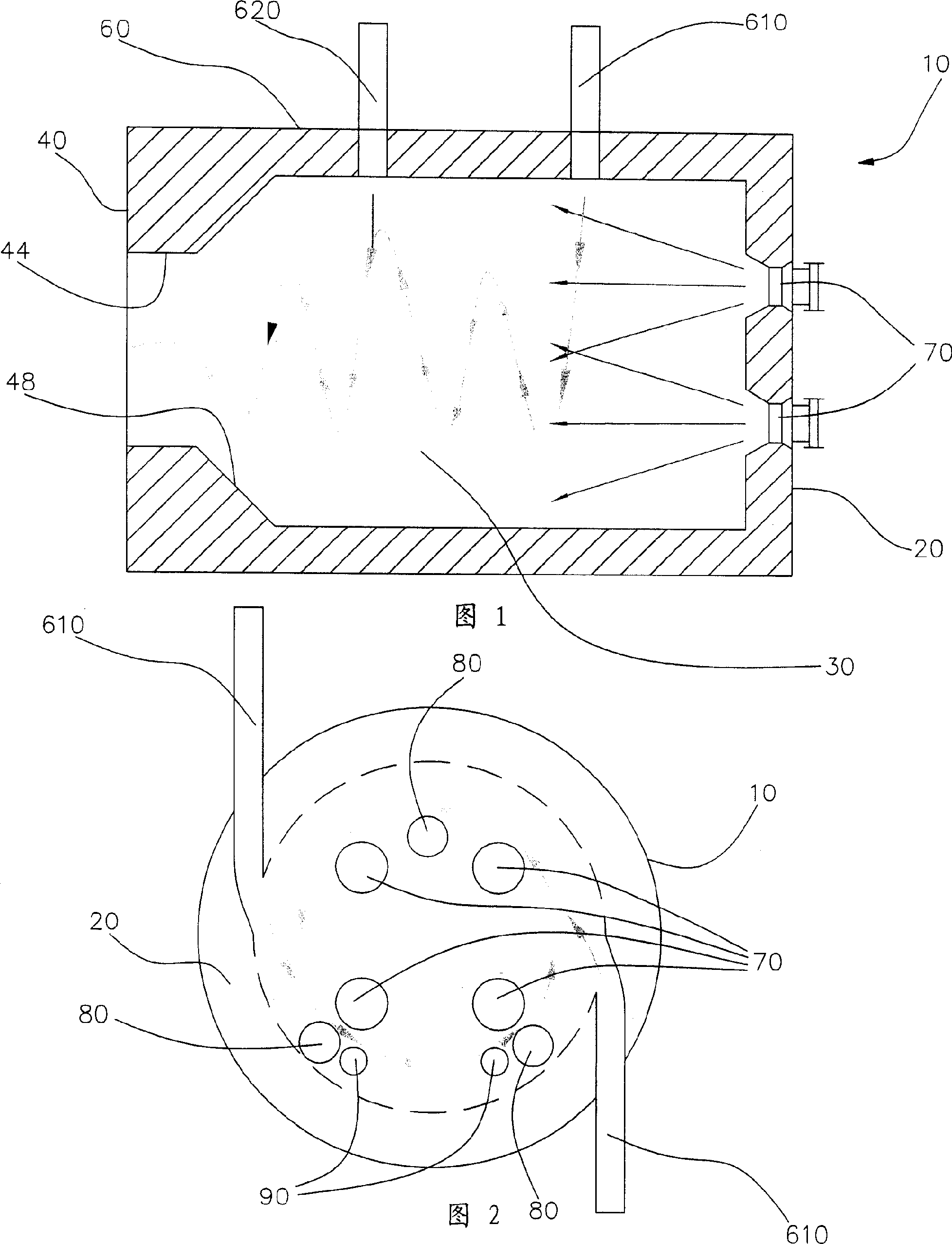

The invention relates to a method for purifying liquid steel in tundish by the composition of a rotary electromagnetic field and a tangential diversion and a device. The method is that the generating device of the rotary magnetic field generates the rotary electromagnetic force to drive steel water in a tundish rotary chamber to generate the rotary flow, which is characterized in that the vertical impact flow of a ladle nozzle is guided to horizontal tangential to flow into the rotary chamber to form the power of the rotary flow, then the power of the rotary flow is composed with the rotary electromagnetic force to allow the steel water in the rotary chamber to generate the symmetric rotary flow, and the centrifugal force is utilized to separate the non-metallic impurities from the steel water. The device is the tundish which contains the rotary chamber, which is characterized in that the rotary chamber is connected with a guide slot along the tangent, the ladle nozzle is arranged in the guide slot, and the outside of the rotary chamber is provided with a generating device of the fan-shaped rotary magnetic field. The invention adopts the composition of the rotary electromagnetic field and the tangential guide flow, thus enhancing the rotation intensity of the steel water, reducing the input power and the energy consumption of the generating device of the rotary magnetic field, eliminating the damage function of the ladle injection flow on the centrifugal separation of inclusions and improving the purification effect.

Owner:SHANGHAI UNIV

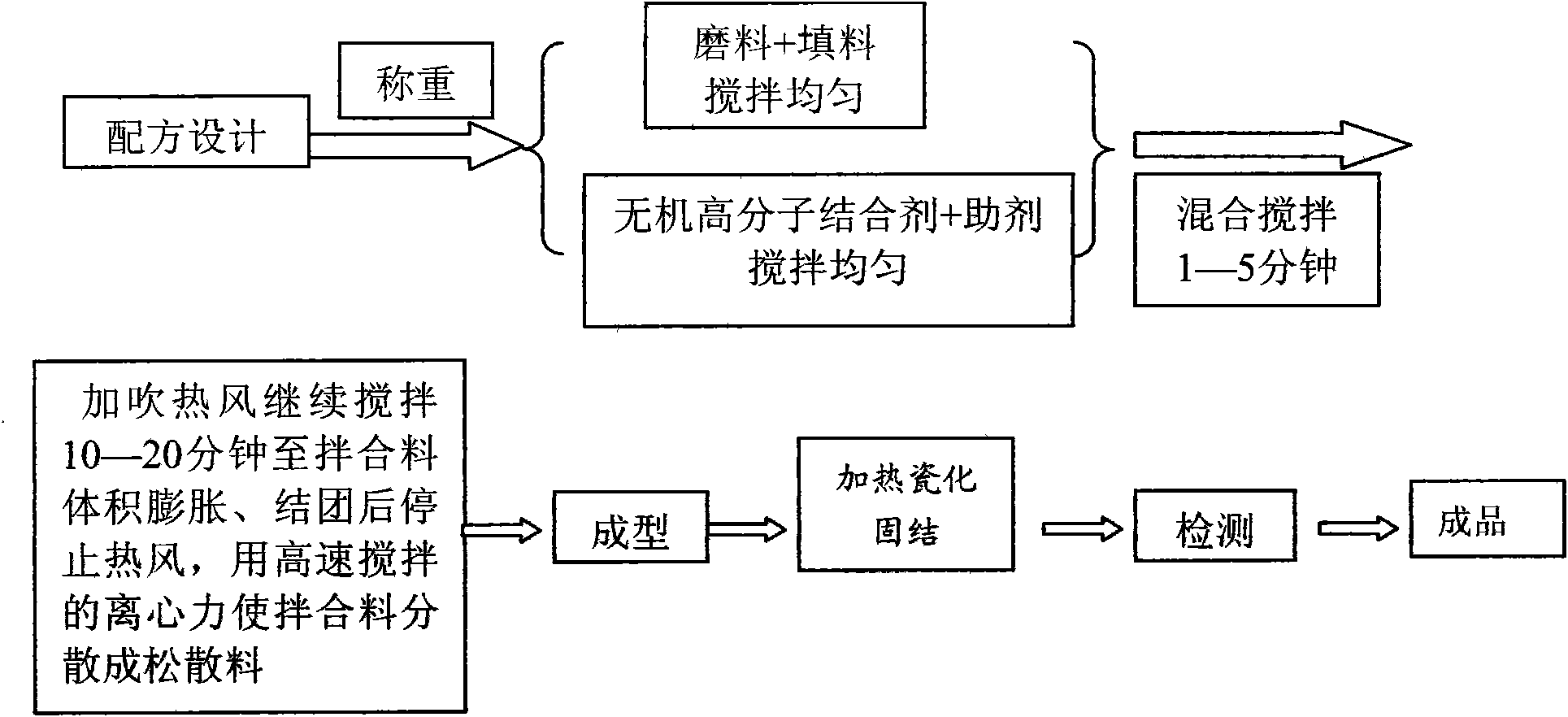

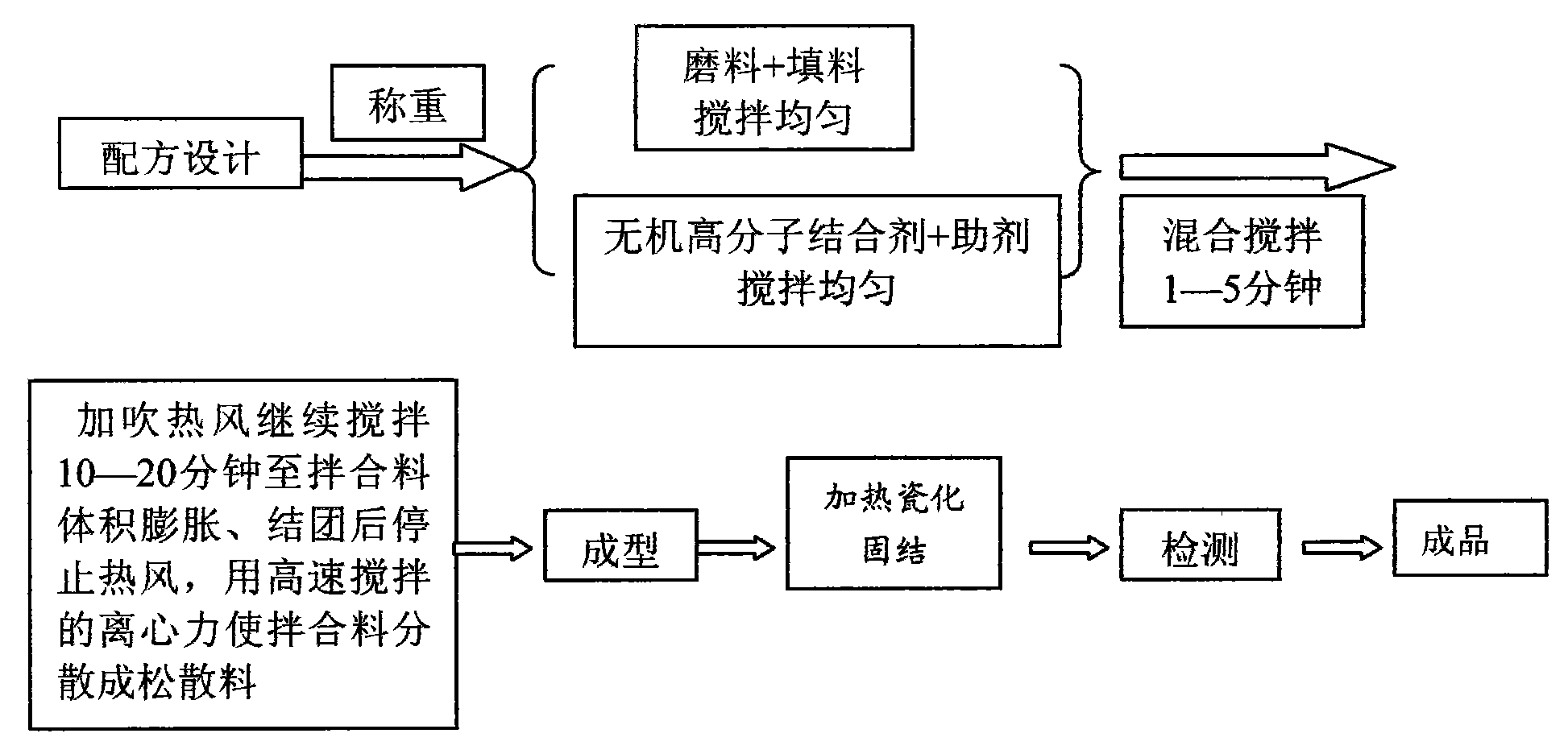

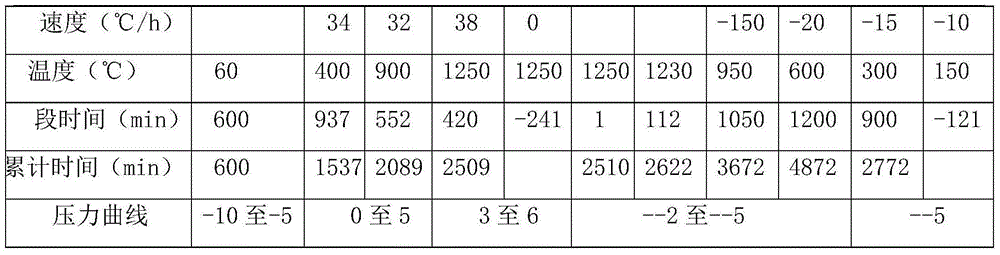

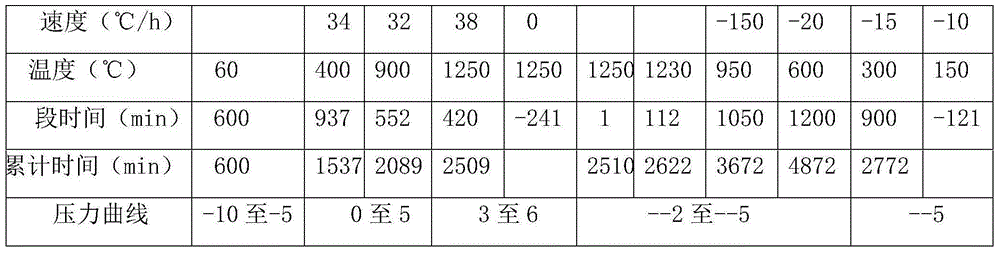

Preparation method of inorganic high molecular abrasive tool

InactiveCN101927464AHigh bonding strengthImprove wettabilityAbrasion apparatusGrinding devicesCompression moldingPolymer science

The invention relates to a preparation method of an inorganic high molecular abrasive tool, which comprises the following steps: designing the formula of the product according to the product standard, weighing the materials according to the proportion, evenly stirring, and blowing with hot air until the mixture expands in volume, cakes and forms wires; after 1-5 minutes, stopping the hot air, stirring at high speed until the abrasive grains are dispersed, compression-molding, and heating the molded abrasive tool so that the abrasive tool is vitrified and solidified; and finally, processing the vitrified and solidified abrasive tool, trimming and detecting to obtain the finished product. The invention solves the technical problems of complex production technique, high energy consumption, environment pollution, easy burnout at high temperature and unstable chemical properties of the existing abrasive tool. The abrasive tool produced by the method has the advantages of wide applicability, unique function, environmental protection, energy saving, high quality, high performance and the like.

Owner:黄曦

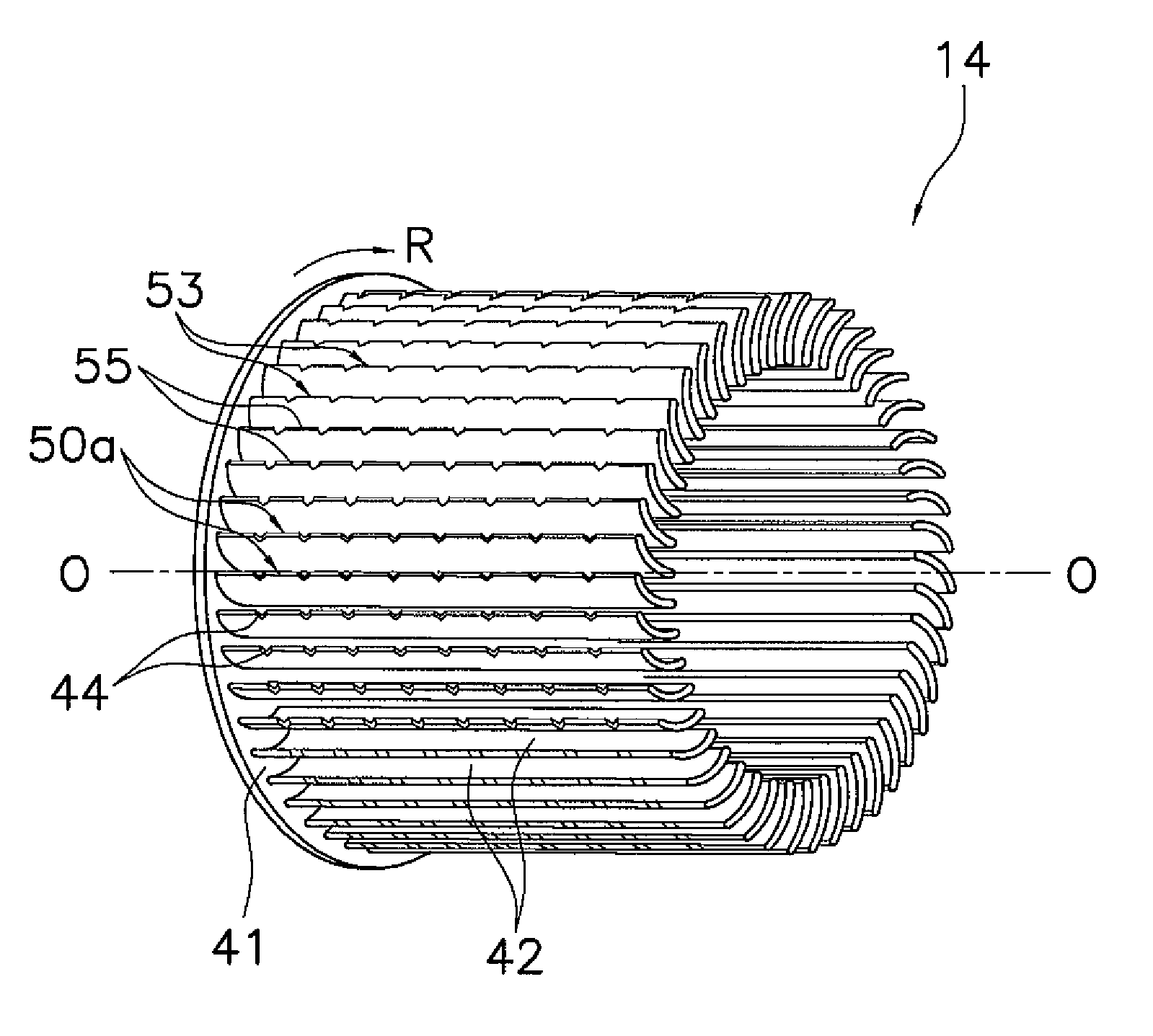

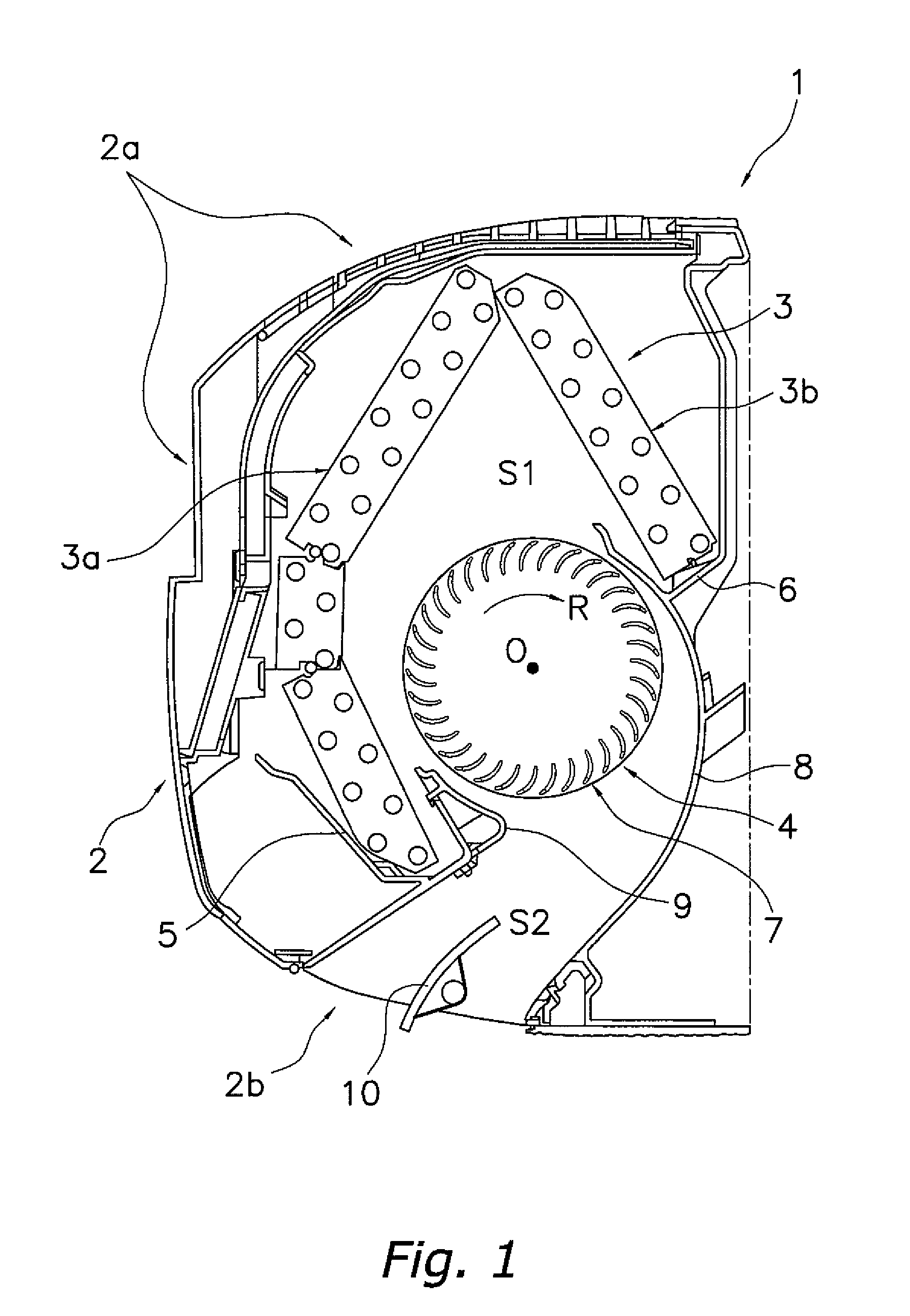

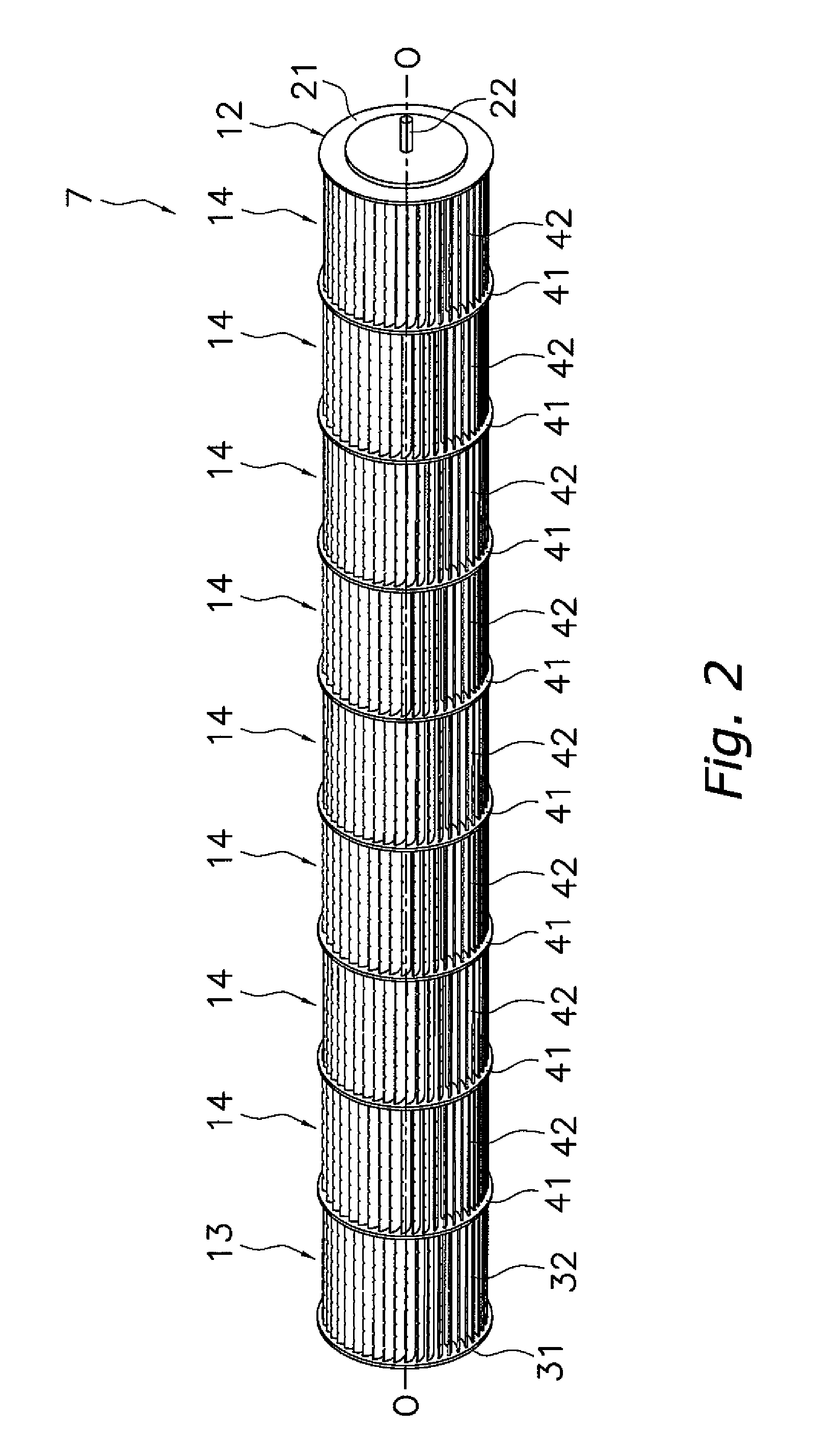

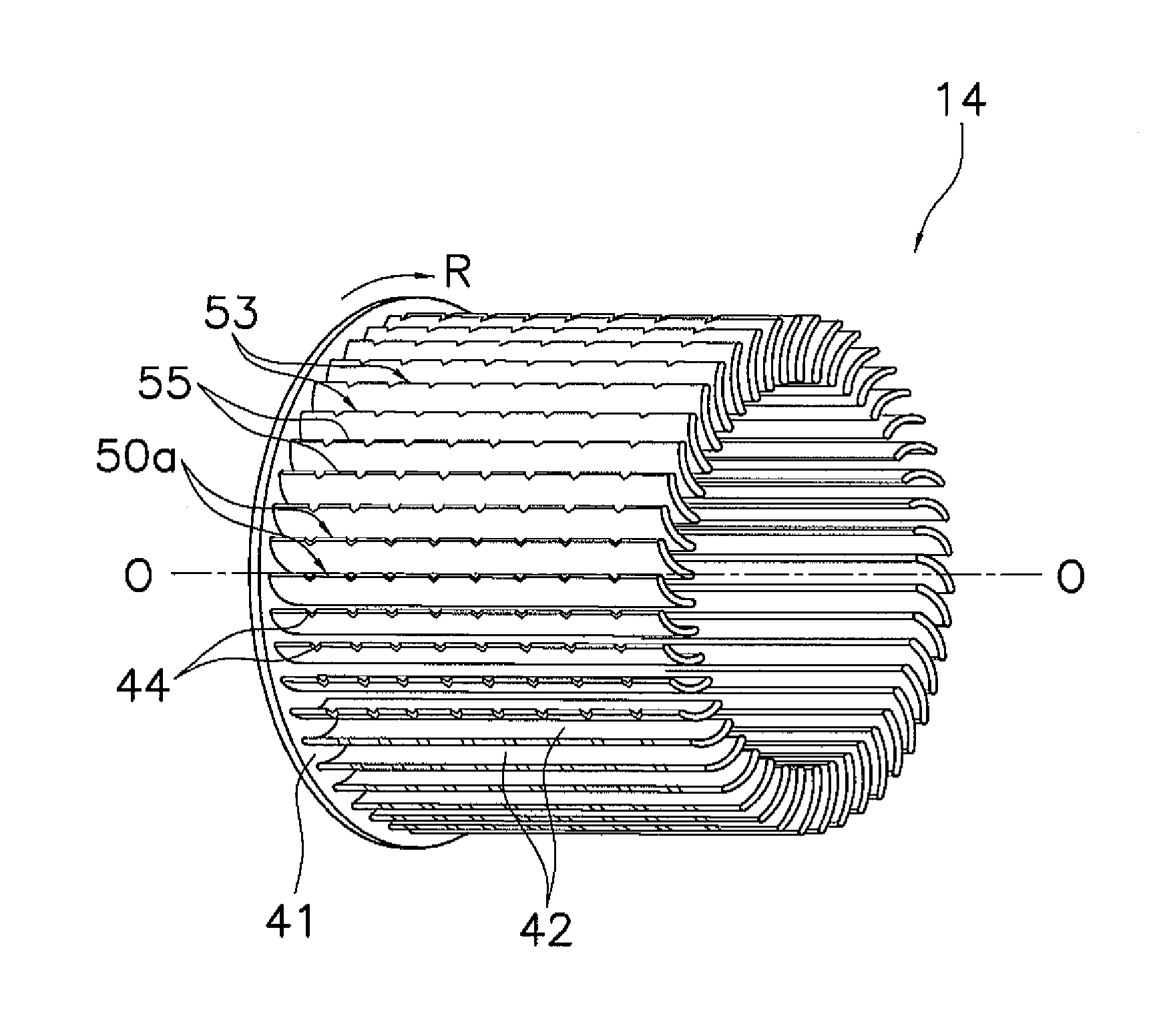

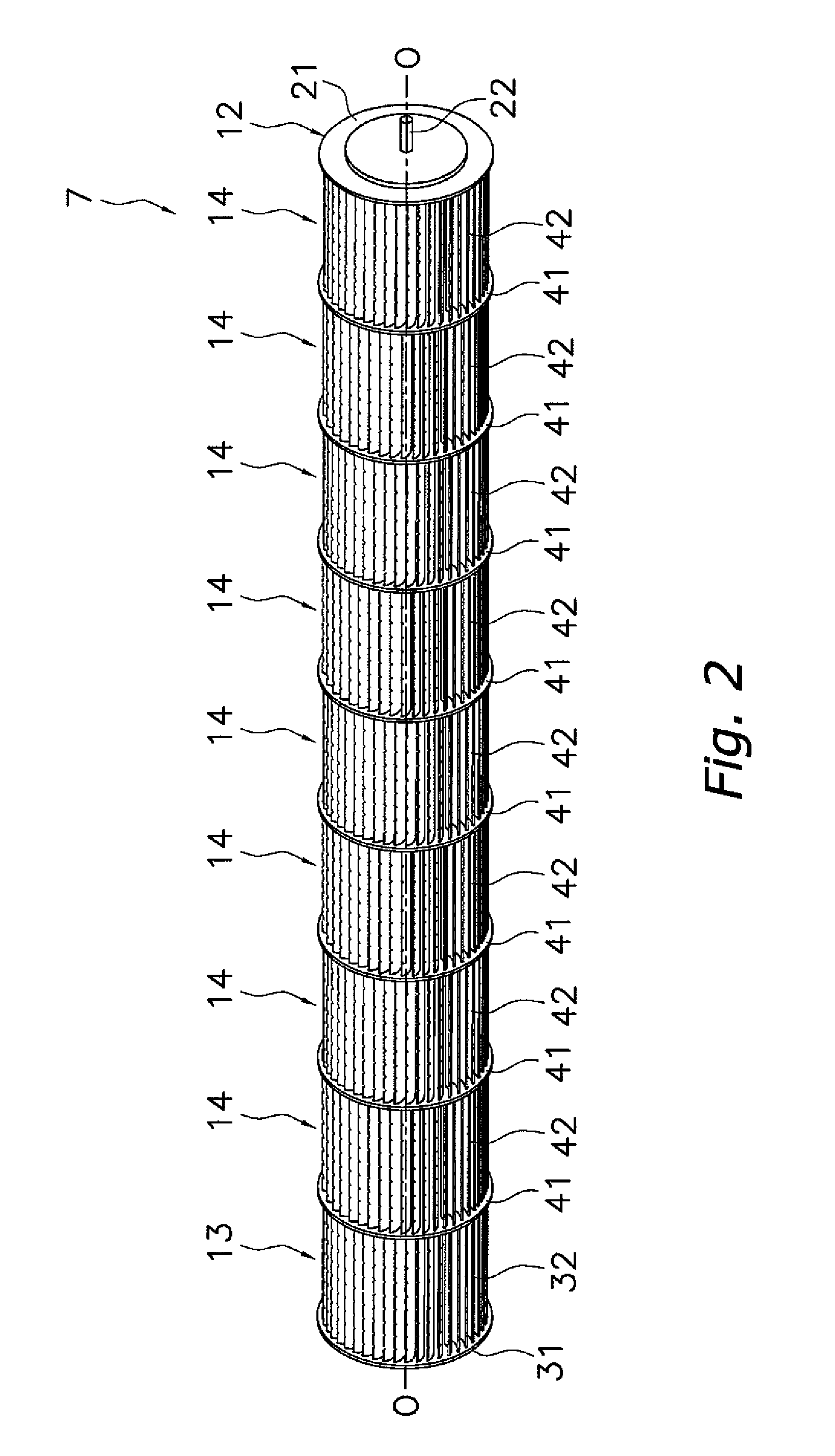

Impeller of multiblade blower and method of manufacuturing the same

InactiveUS8177484B2Reduce in quantityVariations in the positional accuracy of the bladesPropellersCircumferential flow pumpsImpellerEngineering

Owner:DAIKIN IND LTD

Resin grinding wheel

ActiveCN103522209AIncreased porosity ratioImprove cut resistanceAbrasion apparatusActive agentEngineering

The invention provides a resin grinding wheel which comprises grinding materials, phenolic resin, active agents and wetting agents. The active agents are made of methylolation lignin and participate in resin curing in the preparation process of the resin grinding wheel, cured substances form a microcellular structure when the resin is cured, so that the proportion of air holes of the resin grinding wheel is increased, and the resin grinding wheel has higher cutting resistance and cutting efficiency.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

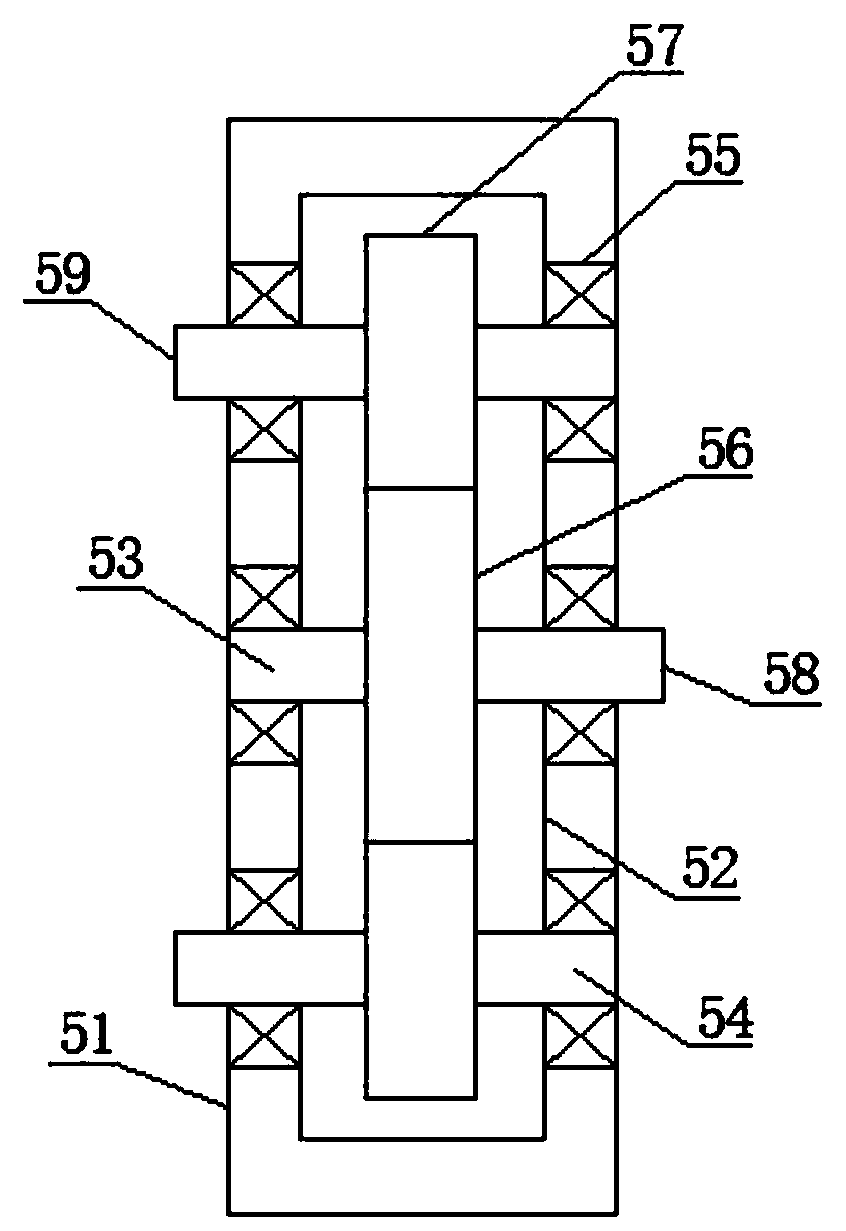

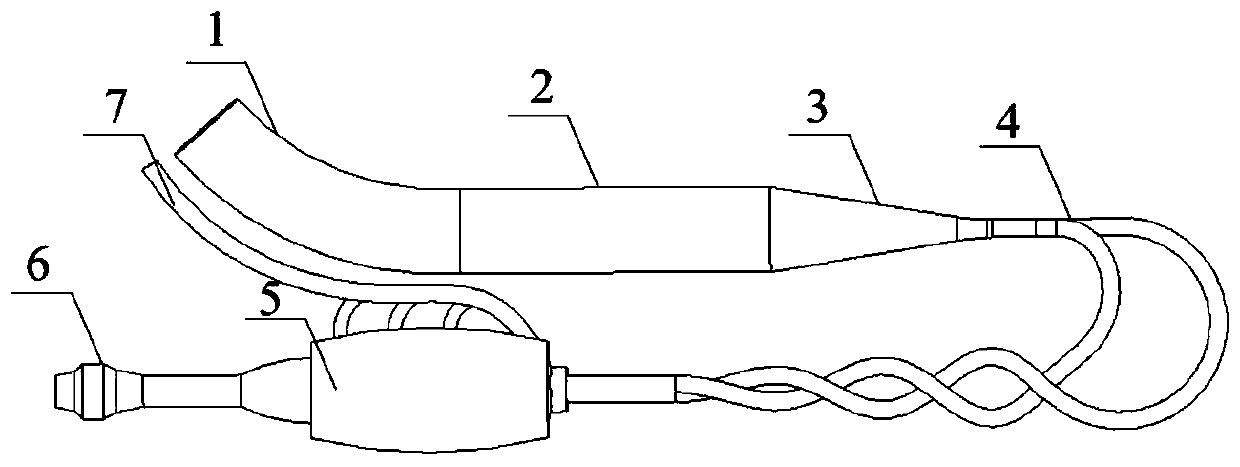

Multi-purpose electric wire winding driving device

InactiveCN110642087AAvoid negative effectsAchieve fixationFilament handlingGear wheelElectric machine

The invention discloses a multi-purpose electric wire winding driving device which comprises a main body shell. According to the multi-purpose electric wire winding driving device, a power source, namely a driving motor is utilized, the necessary rotating function during winding can be achieved, the fixing effect on a winding wheel during electrical wire winding can also be achieved, fixing has the controlling effect, the maximum rotating strength can be controlled autonomously, the effect of controlling the longest guiding wire winding length is also achieved, control performance is high, thepart utilization rate is high, furthermore, the multi-purpose electric wire winding driving device is provided with a gear combination type rotating state dividing-into-two mechanism, a driving statecan be differentiated, thus the driving effects of different functions are achieved, in addition, the multi-purpose electric wire winding driving device is provided with a gear engagement type rotating speed increasing mechanism, the rotating speed can be increased, the air pressure is enhanced, in addition, the multi-purpose electric wire winding driving device is provided with an annular arrayspiral spring abutting type maximum rotating strength controlling mechanism, the maximum resistance during rotating can be controlled, and the negative effects caused by excessively-large air power assistance on the driving motor are effectively prevented.

Owner:胡立泉

Modified silicon oxide resin grinding wheel and preparing method thereof

InactiveCN105382711AImprove thermal stabilityHigh hardnessAbrasion apparatusGrinding devicesPotassium persulfatePolymer science

The invention discloses a modified silicon oxide resin grinding wheel. The modified silicon oxide resin grinding wheel comprises, by weight, 0.2-0.35 part of 25-28 weight percent of ammonium hydroxide, 0.1-0.2 part of sp800, 570-600 parts of CBN abrasive, 90-100 parts of phenol, 96-110 parts of 35-40% of formaldehyde solution, 5-7 parts of boric acid, 2-6 parts of hexamethylenetetramine, 13-20 parts of aniline, 4-5 parts of tributyl citrate, 10-13 parts of styrene, 0.3-0.6 part of divinyl benzene, 0.8-2 parts of methacrylic acid, 0.2-0.3 part of potassium persulfate and 60-76 parts of tetraethoxysilane. According to the modified silicon oxide resin grinding wheel, the tetraethoxysilane is adopted as the precursor, polystyrene latex is used for modifying, and modified silicon oxide particles are obtained. The particles have very high strength and very high bonding strength, and the comprehensive performance of the finished grinding wheel is effectively improved.

Owner:WUHU HONGKUN AUTO PARTS

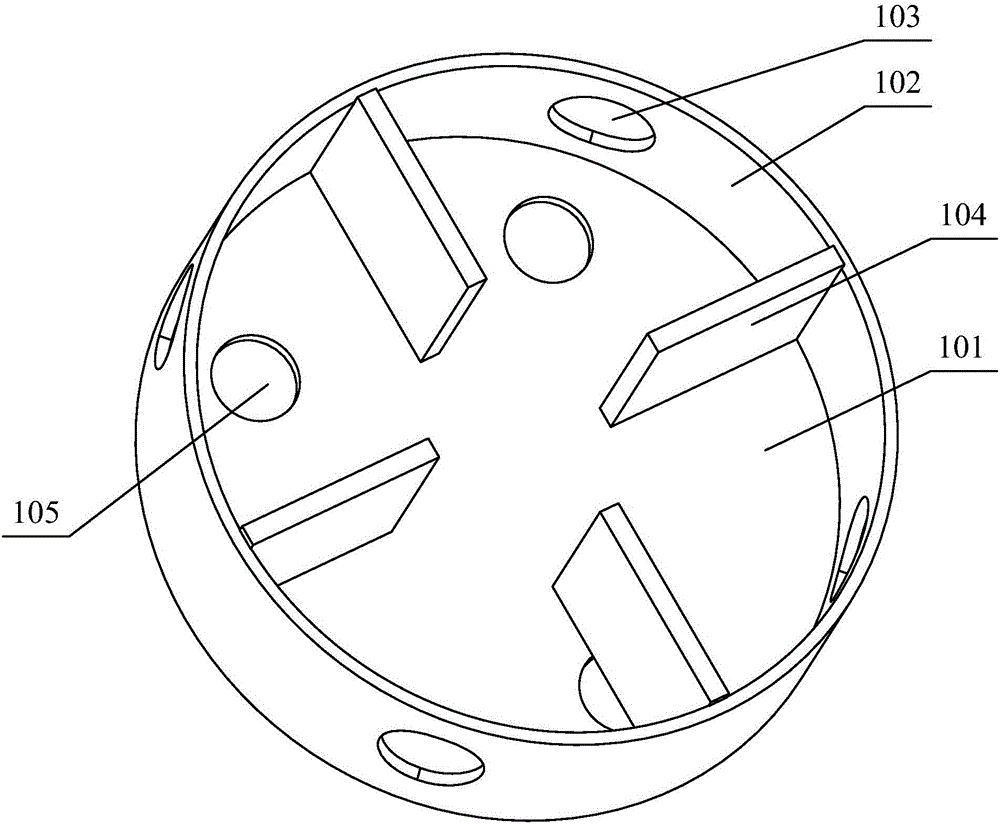

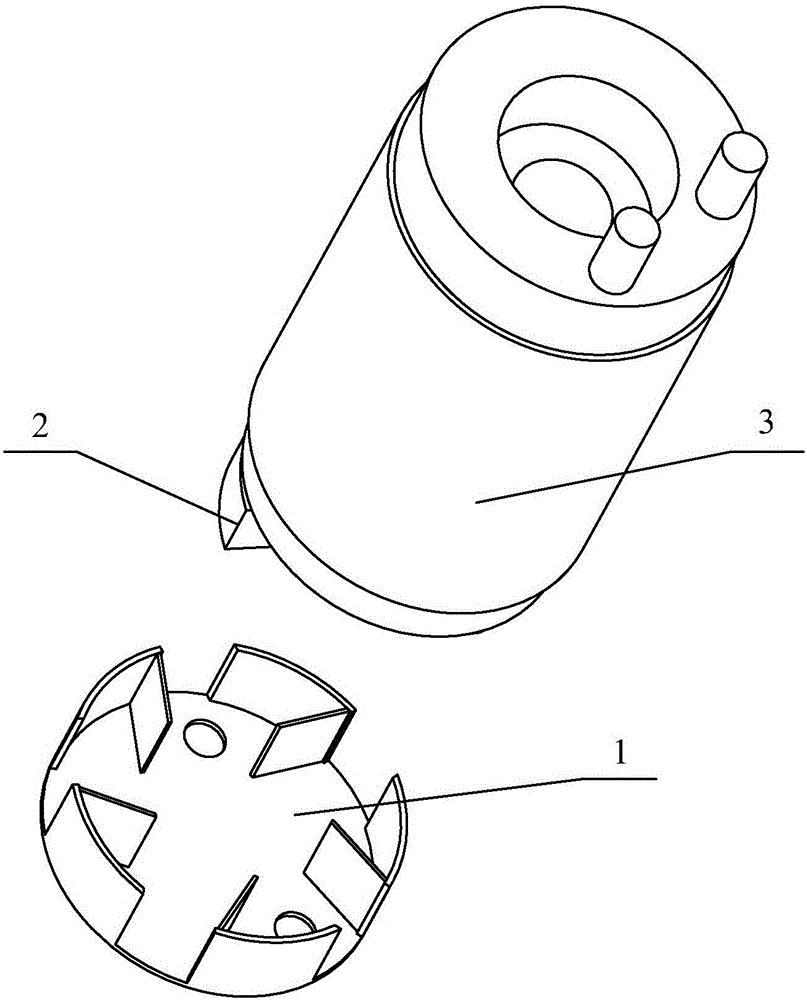

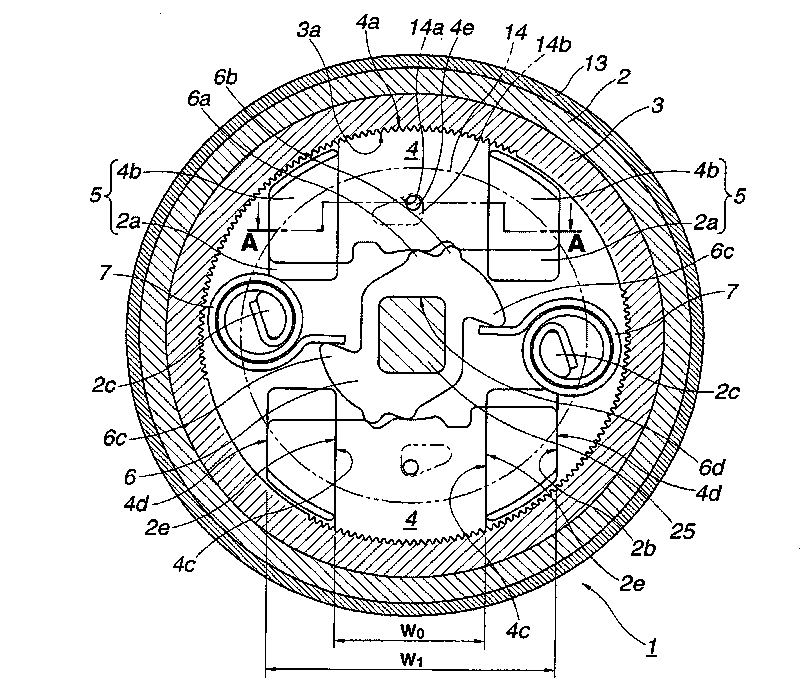

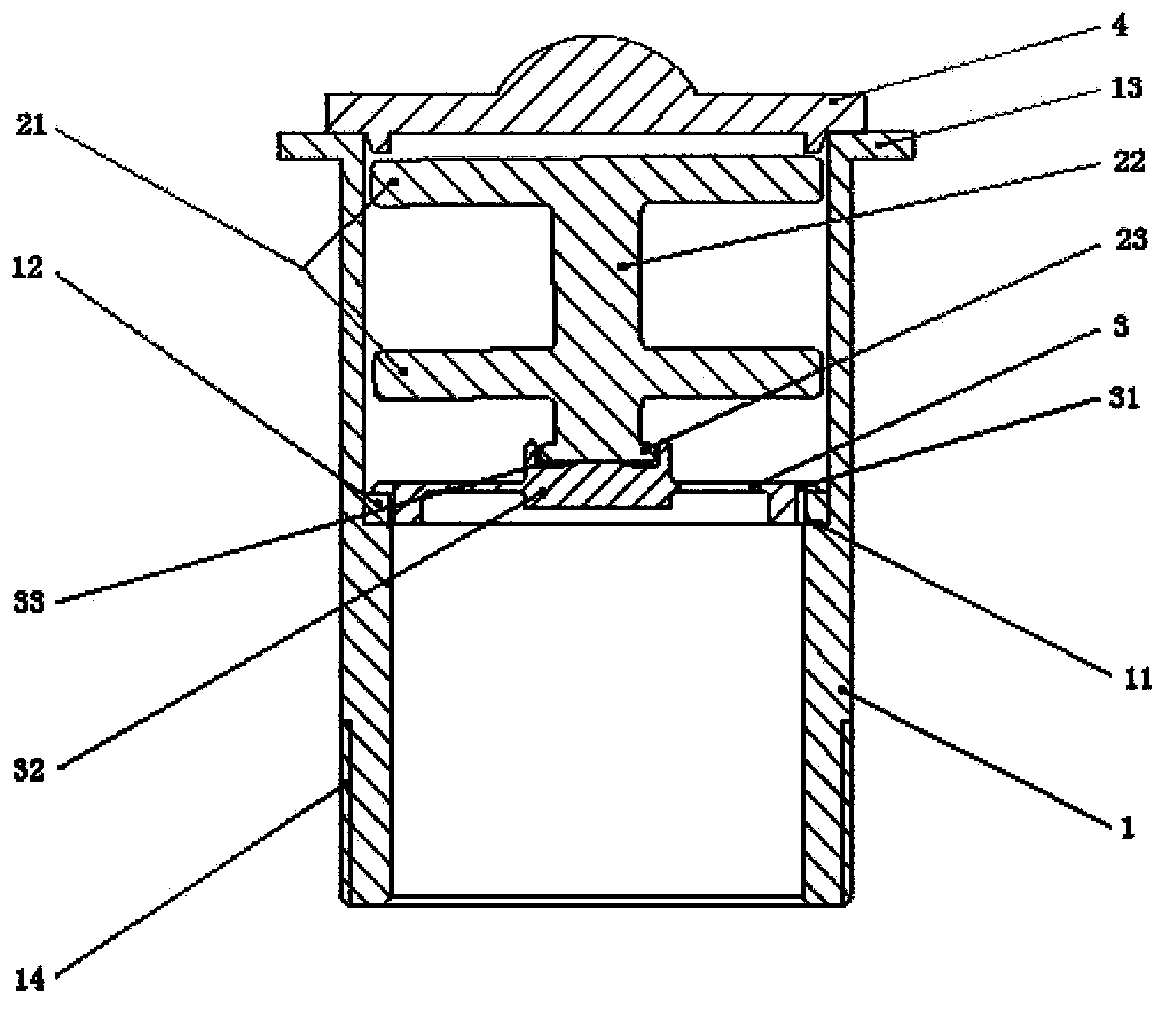

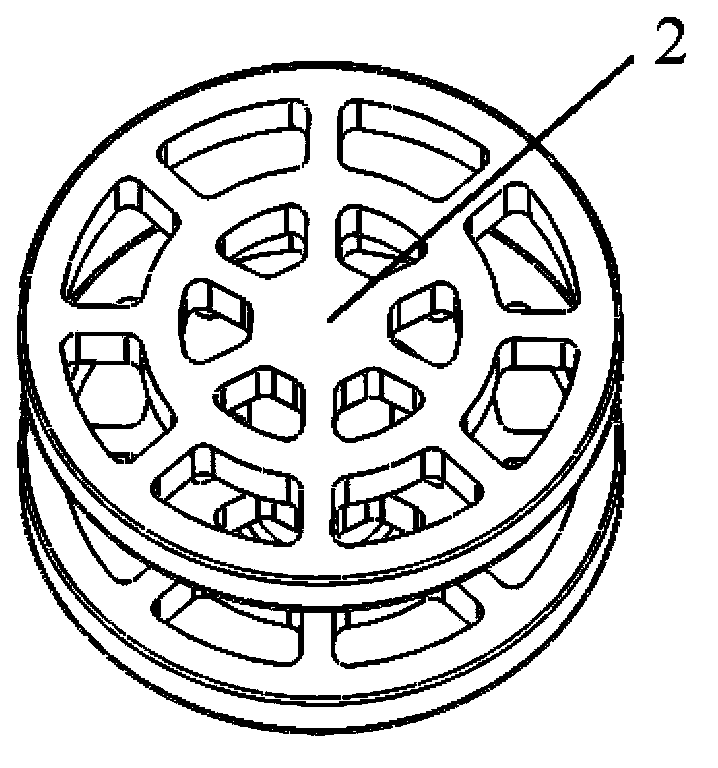

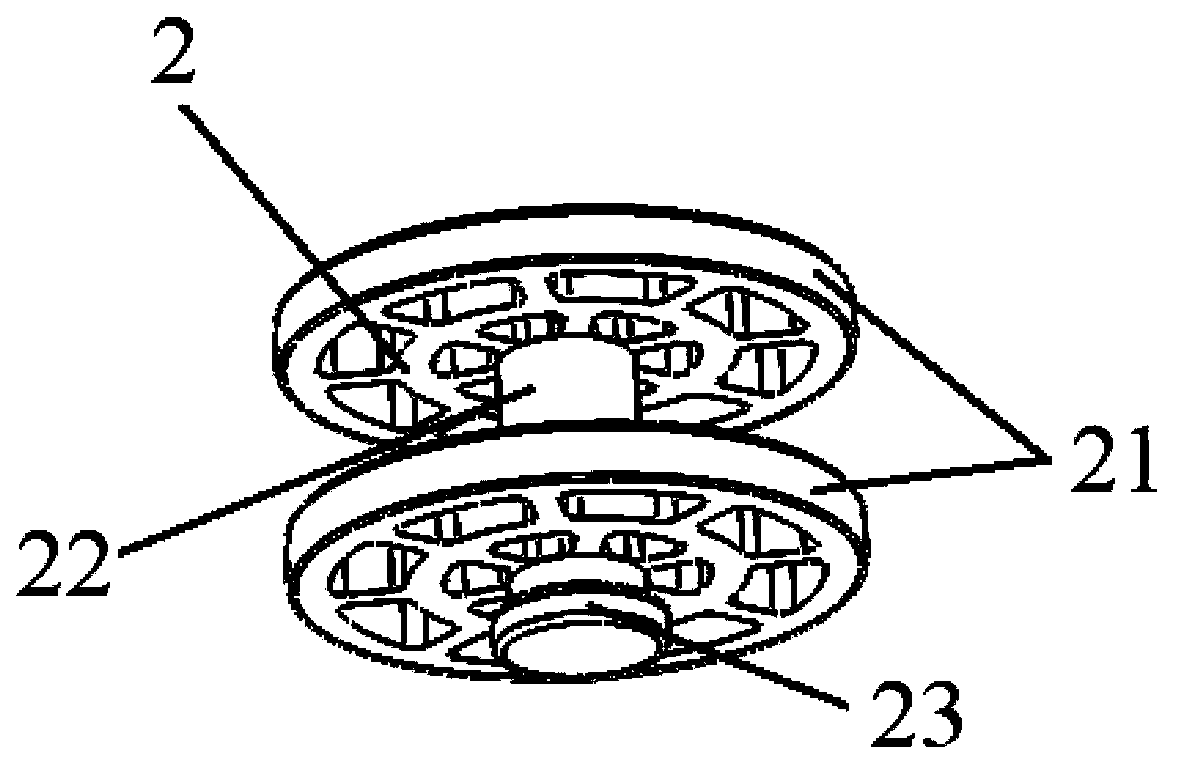

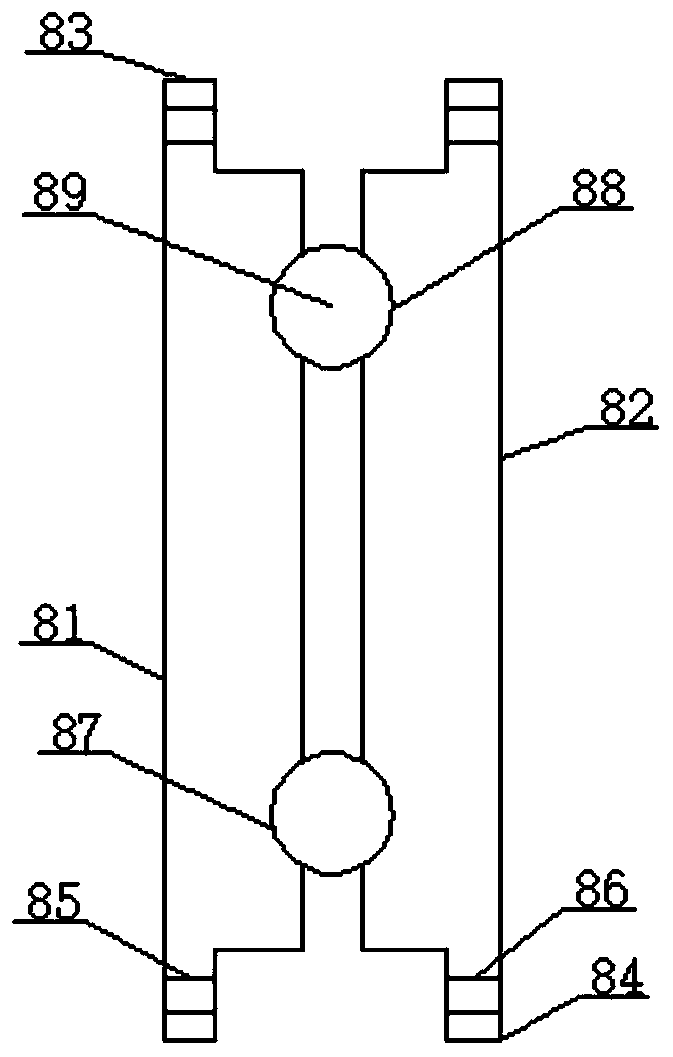

Oil baffle plate, compressor rotor assembly, compressor and air conditioner

InactiveCN106015007AHigh rotational strengthEasy to separateRotary/oscillating piston pump componentsLiquid fuel engine componentsPetroleum engineeringGas separation

An oil baffle disclosed in an embodiment of the present invention includes an oil baffle body, the surface of the oil baffle body facing the rotor is an oil-gas separation surface, and an oil-gas separation surface arranged on the oil baffle body side guide vanes. For the oil baffle provided by the present invention, when the oil baffle rotates together with the rotor, the guide vanes located on the oil-air separation surface of the oil baffle body will rotate together with the oil baffle body, because the turbulence caused by the rotation of the guide vanes The function enhances the rotation strength of the refrigerant flow field and assists the gas circulation, thereby enhancing the separation effect of the oil-gas mixture, reducing the oil discharge of the compressor, and improving the overall performance of the compressor. The invention also discloses a compressor rotor assembly, a compressor and an air conditioner.

Owner:ZHUHAI LANDA COMPRESSOR +1

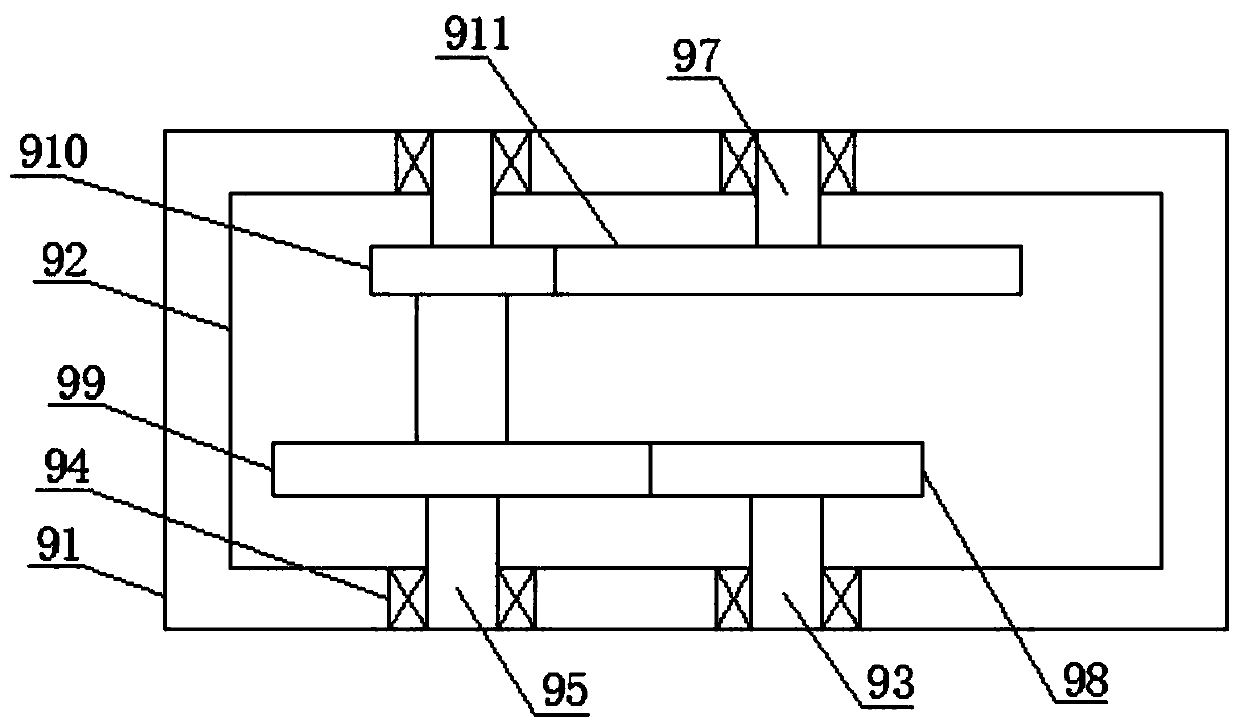

Wide flow multi-flow high-efficiency gas-liquid separator

ActiveCN110075619AEfficient separationHigh impact heightLiquid degasificationDispersed particle separationImpellerVapor–liquid separator

The aim of the invention is to provide a wide-flow multi-flow type high-efficiency gas-liquid separator. The wide-flow multi-flow type high-efficiency gas-liquid separator comprises an outer cylinderbody and an inner cylinder body, wherein the inner cylinder body extends into the inner part of the outer cylinder body, the lower end of the inner cylinder body remains outside the outer cylinder body, a first-stage impeller is mounted in the middle of the inner cylinder body, a second-stage impeller is mounted at the top of the inner cylinder body, a liquid discharge section is arranged on the inner cylinder body between the first-stage impeller and the second-stage impeller, a liquid discharge hole which is communicated with the inner space of the inner cylinder body and the inner space ofthe outer cylinder body is formed in the liquid discharge section, a separator liquid-phase extraction outlet is formed in the lower end of the outer cylinder body, a separator gas-phase extraction outlet is formed in the top of the outer cylinder body, and a separation chamber which causes the liquid phase to fall back is formed between the second-stage impeller and the separator gas-phase extraction outlet. The wide-flow multi-flow type high-efficiency gas-liquid separator disclosed by the invention comprehensively utilizes the centrifugal separation principle, the gravity separation principle and the inertial separation principle, is simple and compact in device structure, and can realize high-efficiency gas-liquid separation in a wide flow range and multi-flow pattern.

Owner:HARBIN ENG UNIV

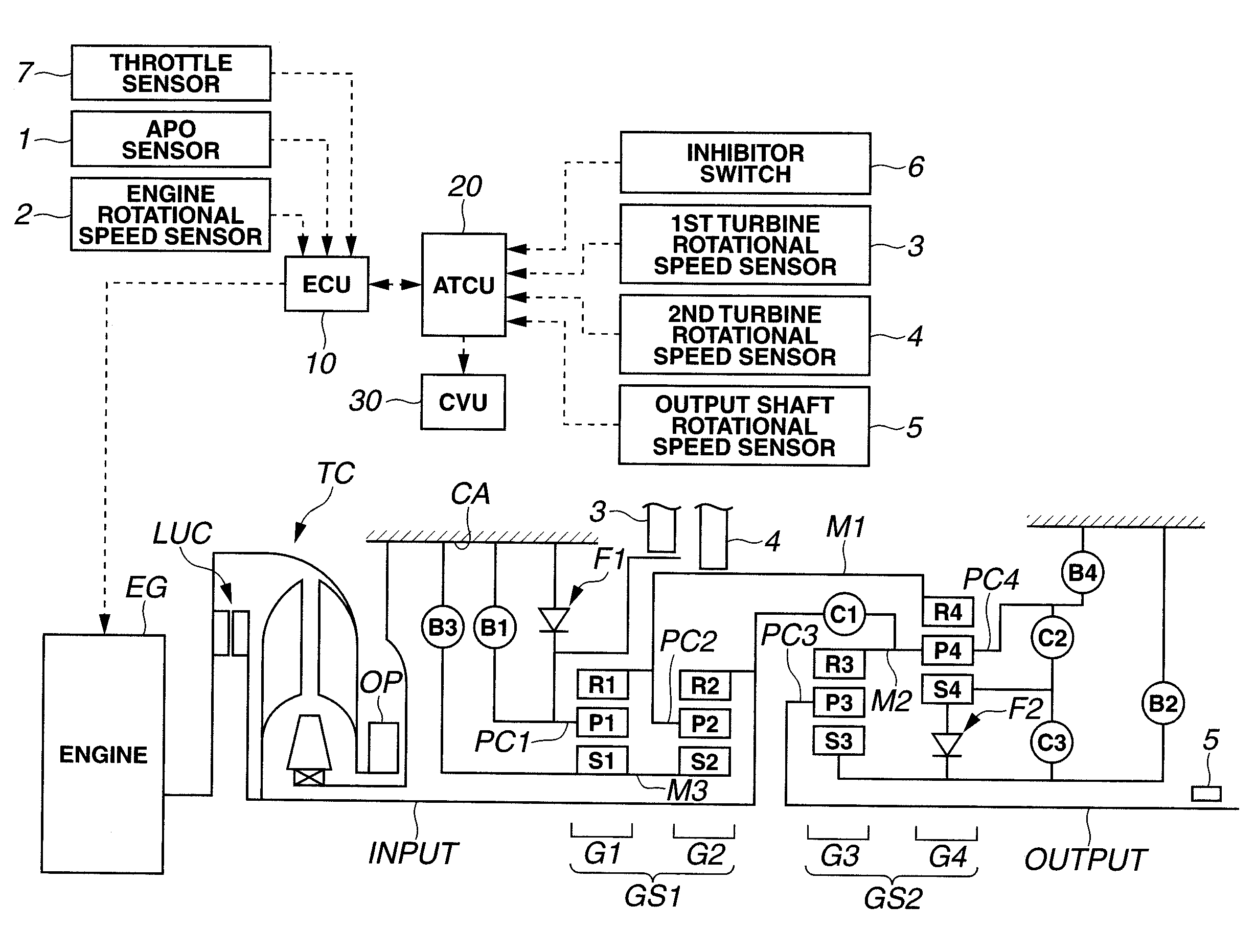

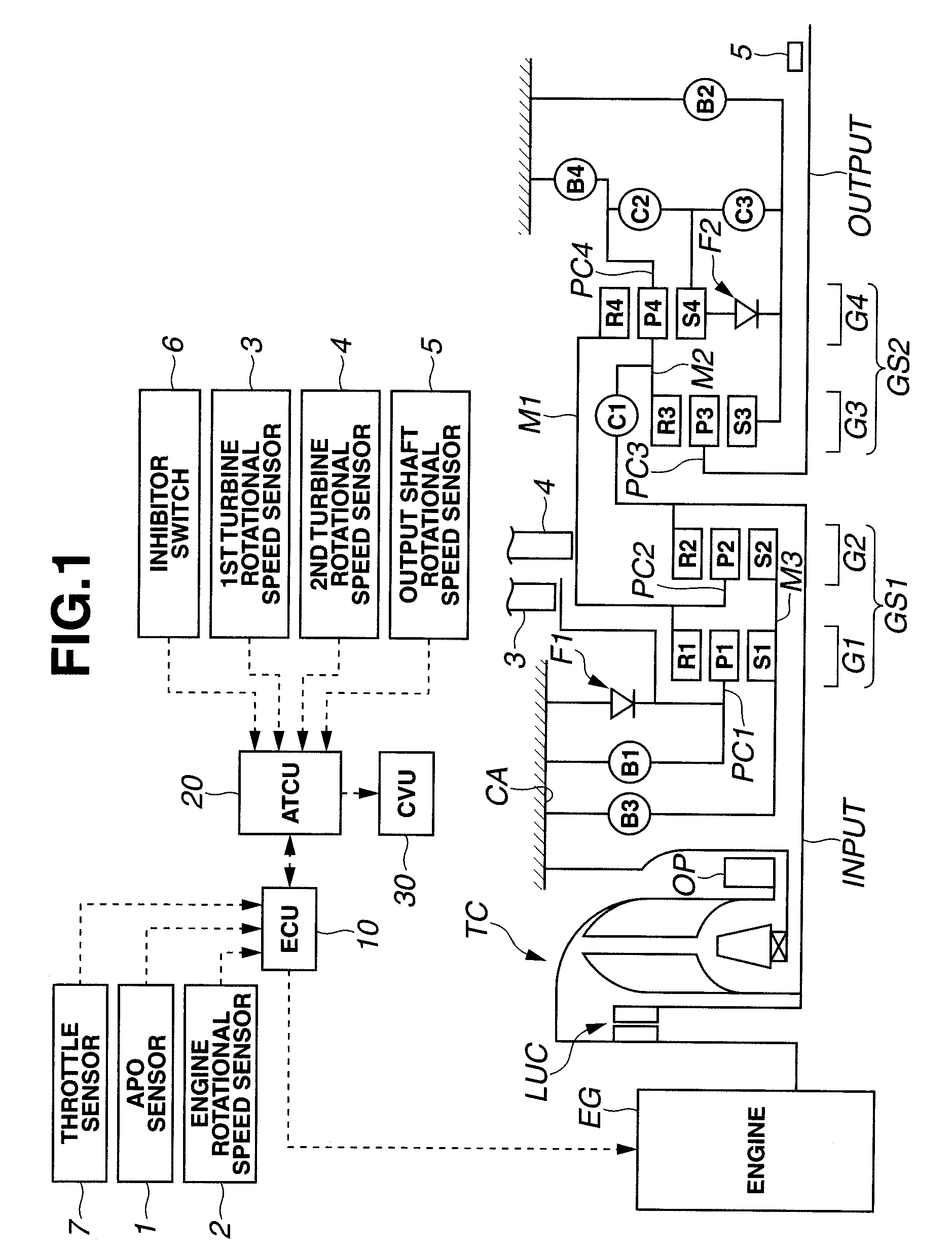

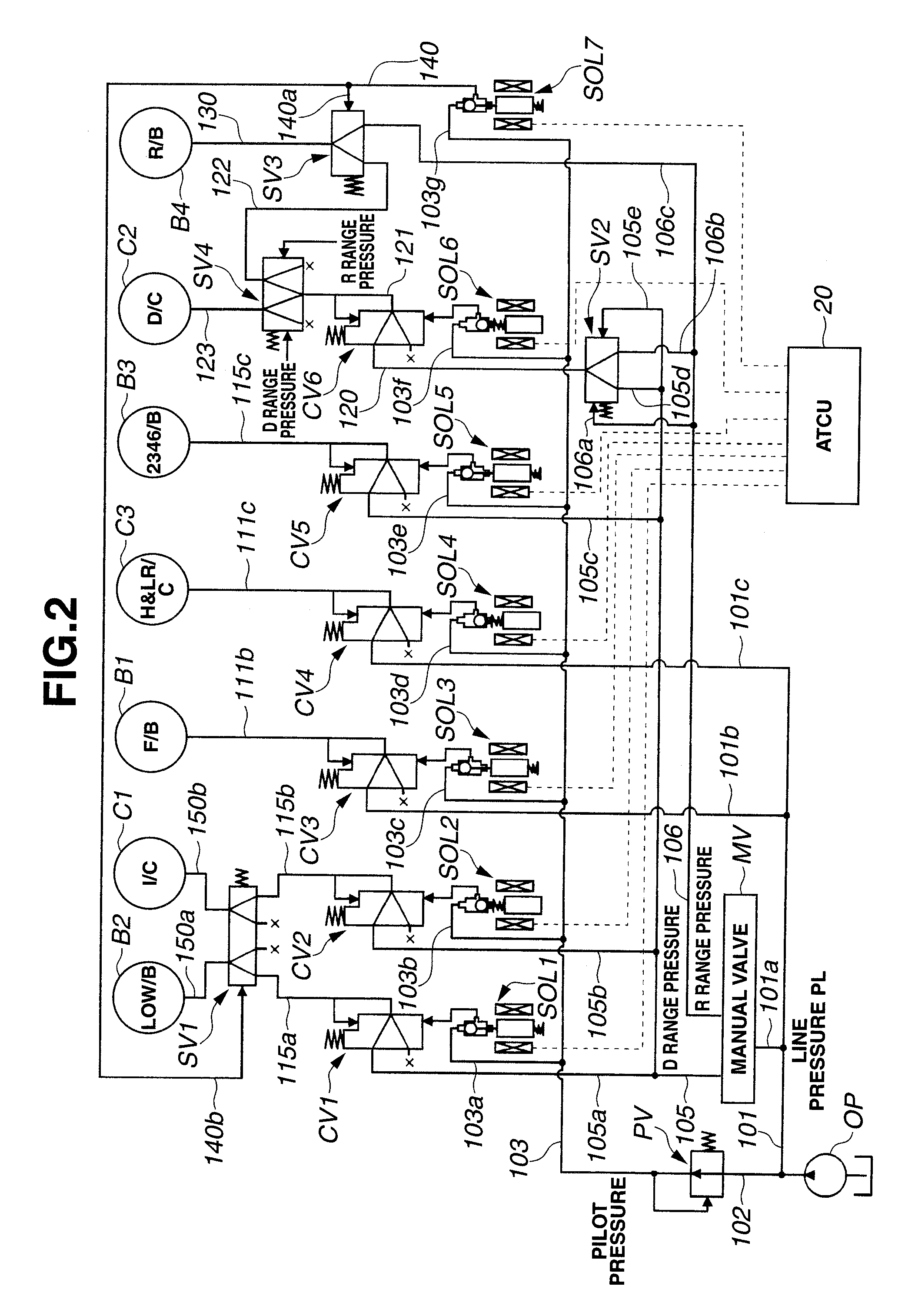

Automatic transmission and method of preventing over-revolution of the same

ActiveUS20080227580A1Preventing over-revolutionHigh rotational strengthDigital data processing detailsGearingAutomatic transmissionControl theory

An automatic transmission comprising a plurality of planetary gears disposed between an input shaft and an output shaft and having a plurality of rotational elements, a plurality of frictional elements selectively engaged and released for controlling rotations and connections of the plurality of rotational elements in accordance with instructions so as to realize a plurality of gear positions, rotational speed detecting means for detecting a rotational speed of a predetermined one of the plurality of rotational elements, other than the input shaft and the output shaft, and frictional element release means for releasing all of the plurality of frictional elements when it is judged that the rotational speed of the predetermined one of the plurality of rotational elements is higher than a predetermined rotational speed.

Owner:JATCO LTD +1

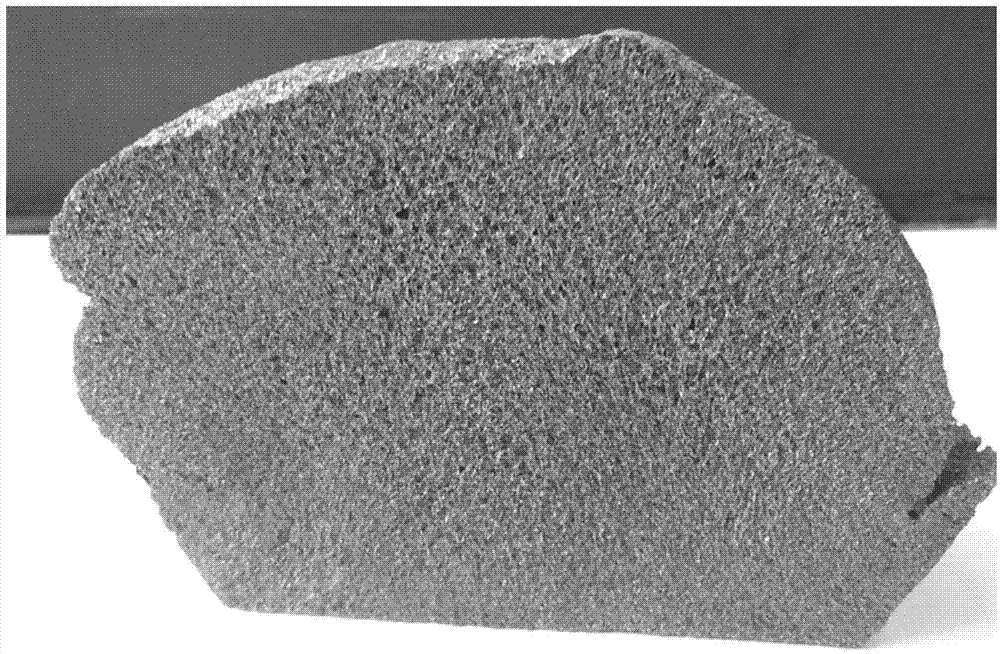

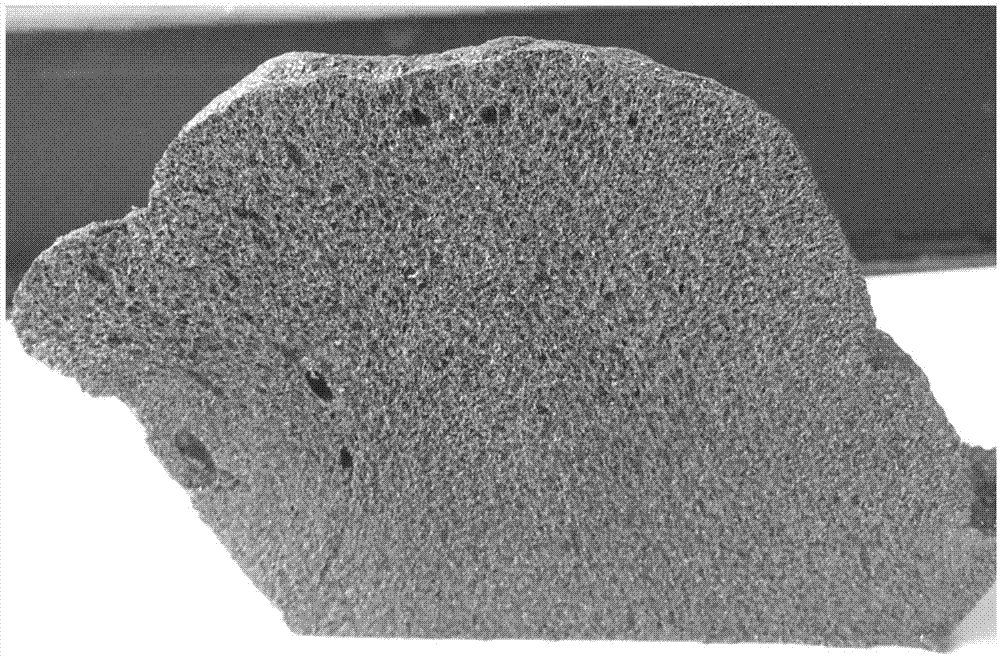

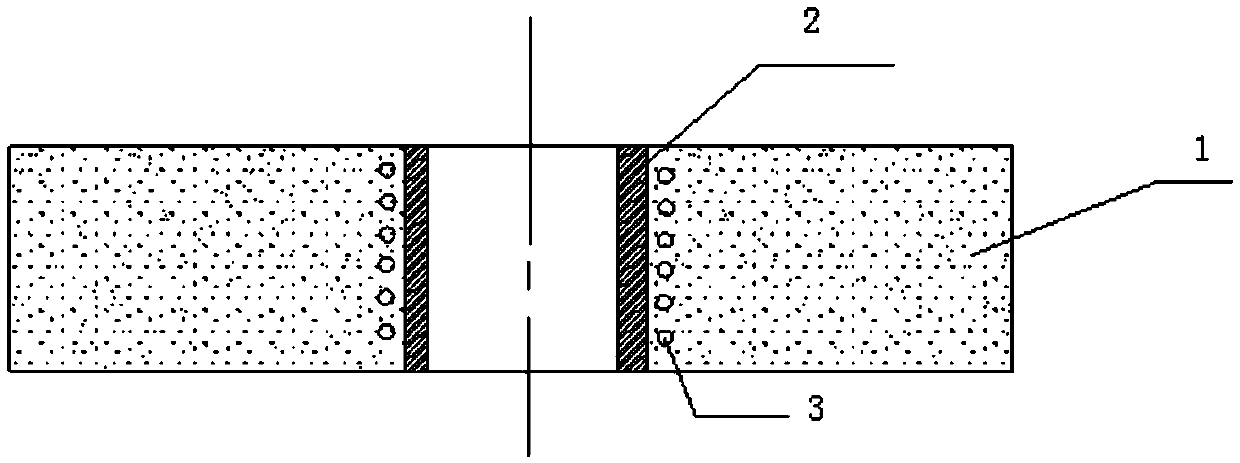

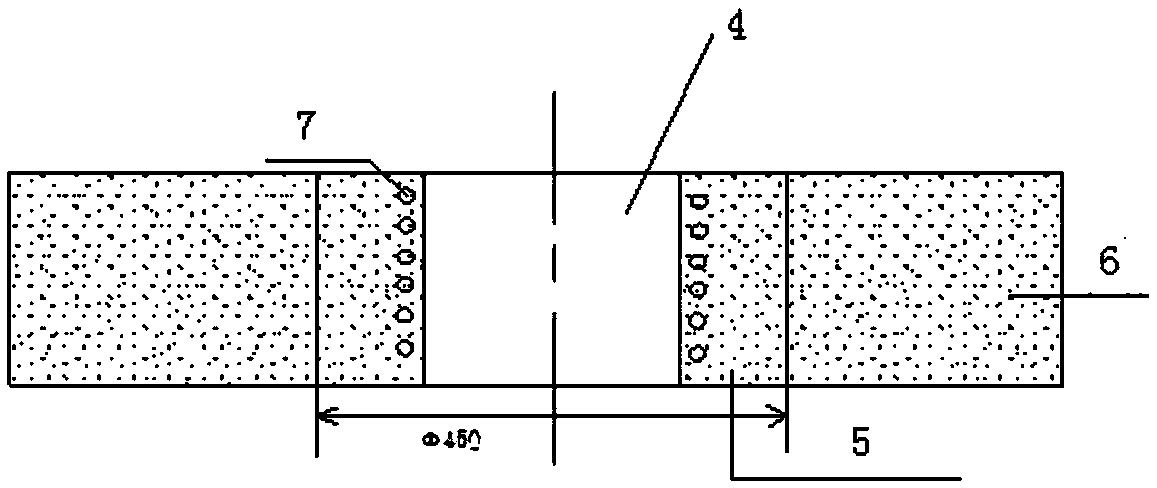

Heavy-load grinding wheel and machining method thereof

ActiveCN105364731AAvoid breakingBroken notBonded abrasive wheelsGrinding devicesGranularityResin adhesive

The invention belongs to the technical field of machining, particularly relates to a heavy-load grinding wheel and further discloses a machining method of the heavy-load grinding wheel. The heavy-load grinding wheel comprises an inner-layer portion and an outer-layer portion made of different raw materials. The raw materials of the two portions and the ratio of the raw materials are screened elaborately, sand of two granularities is combined to form sand with the fine granularity within phi 450 for pressing, and the strength can be effectively enhanced. Meanwhile, the sand of the granularity being C No. 120 is adopted as the raw materials of the inner-layer portion preferentially, the rotation strength achieved after the sand of the fine granularity and a resin adhesive are combined is higher than that of sand of the crude granularity by 20% or above; and the portion with the phi 450 is a non-working face, the portion outside the phi 450 is a working face of the outer-layer portion, and the grinding wheel is used for grinding a steel plate or a round steel workblank. Accordingly, the heavy-load grinding wheel has the beneficial effects of being not likely to be broken and being high in grinding efficiency.

Owner:沈阳市盛世磨料磨具有限公司

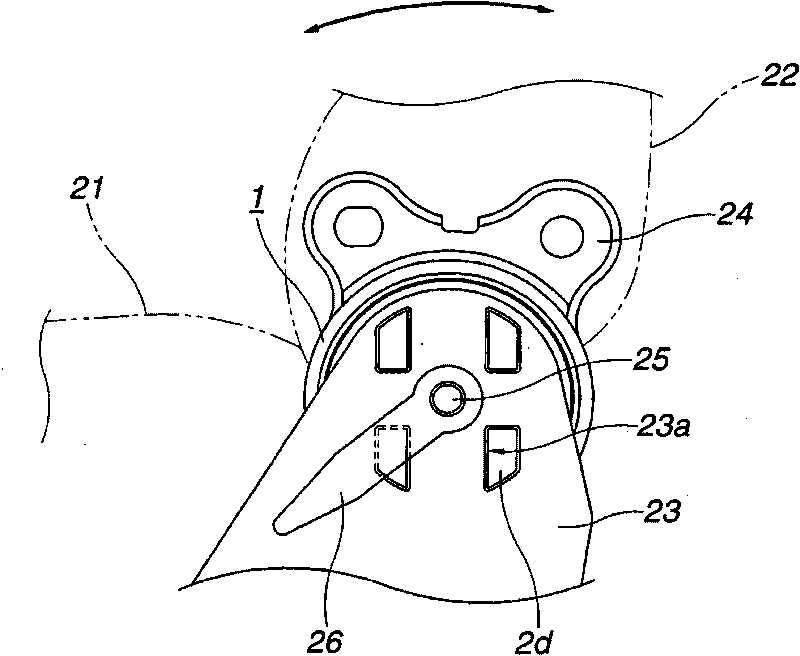

Seat reclining apparatus

A seat reclining apparatus includes: a fixing member; a pivot member having an internal tooth located on an inner circumference surface of the circular recessed portion; a lock tooth having an external tooth arranged to be engaged with the internal tooth of the pivot member, the lock tooth being arranged to be moved along an orbit between an engagement position and a disengagement position; a cam; an urging member; the lock tooth including a pair of guide protrusions which are disposed on both sides of the lock tooth, and which protrude axially toward the fixing member, and the fixing member including a pair of guide grooves formed on an inside surface of the fixing member, and arranged to receive, respectively, the guide protrusions of the lock tooth to guide the lock tooth along the orbit between the engagement position and the disengagement position.

Owner:FUJI KIKO CO LTD

Impeller of multiblade blower and method of manufacuturing the same

InactiveUS20090290986A1High rotational strengthReduce in quantityPropellersCircumferential flow pumpsImpellerEngineering

An impeller of a blower is disposed with circular support plates that are made of a resin and rotate about an axis of rotation and a plurality of blades that are made of a resin. The blades are disposed on outer peripheral portions of the circular support plates so as to be parallel to an axis of rotation, and serrated shapes are formed on the blades by cutting out blade tips at plural places. Additionally, a step is formed in a blade face of each of the blades at a position a predetermined distance from the blade tip where the serrated shape is formed.

Owner:DAIKIN IND LTD

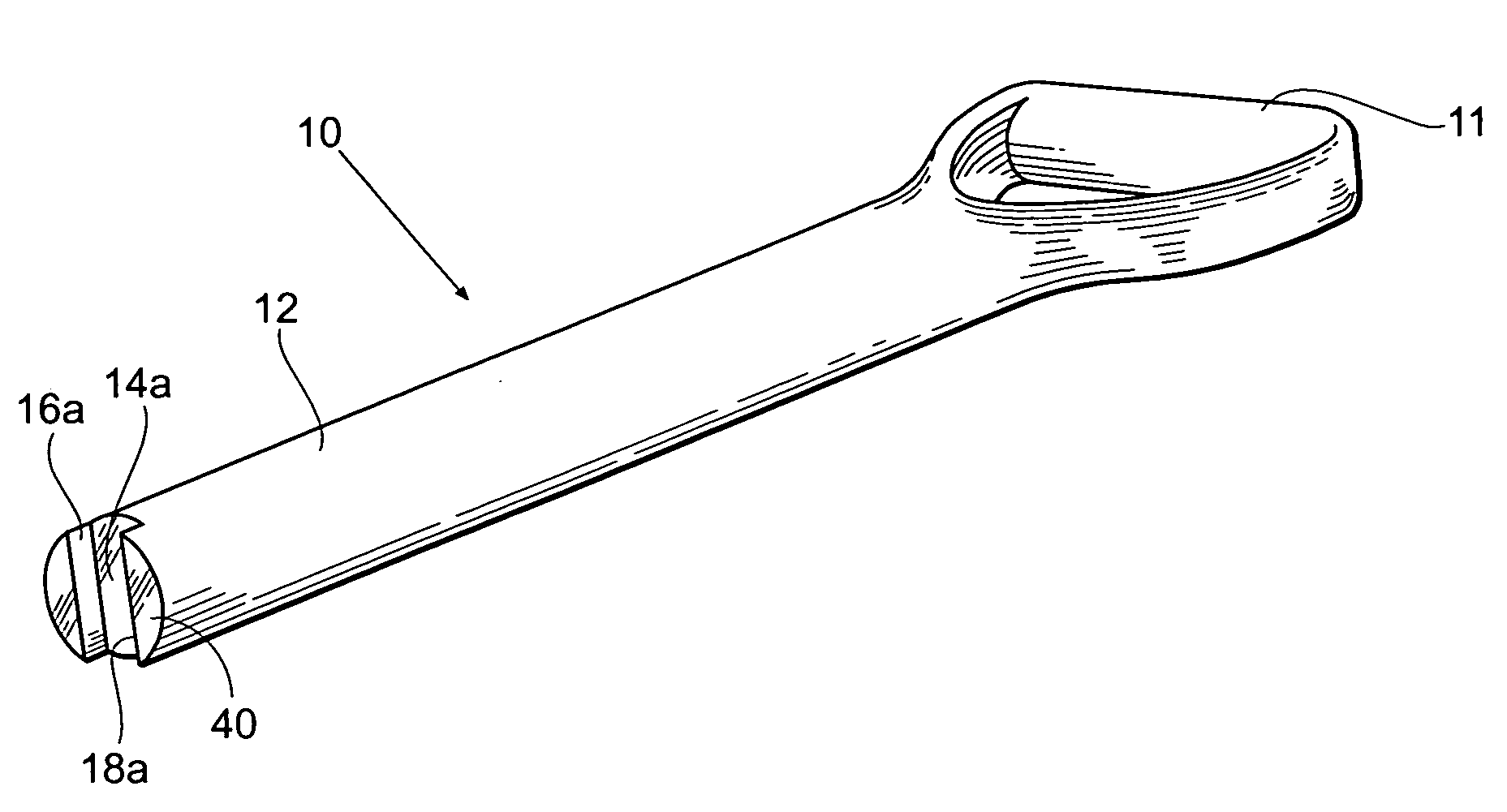

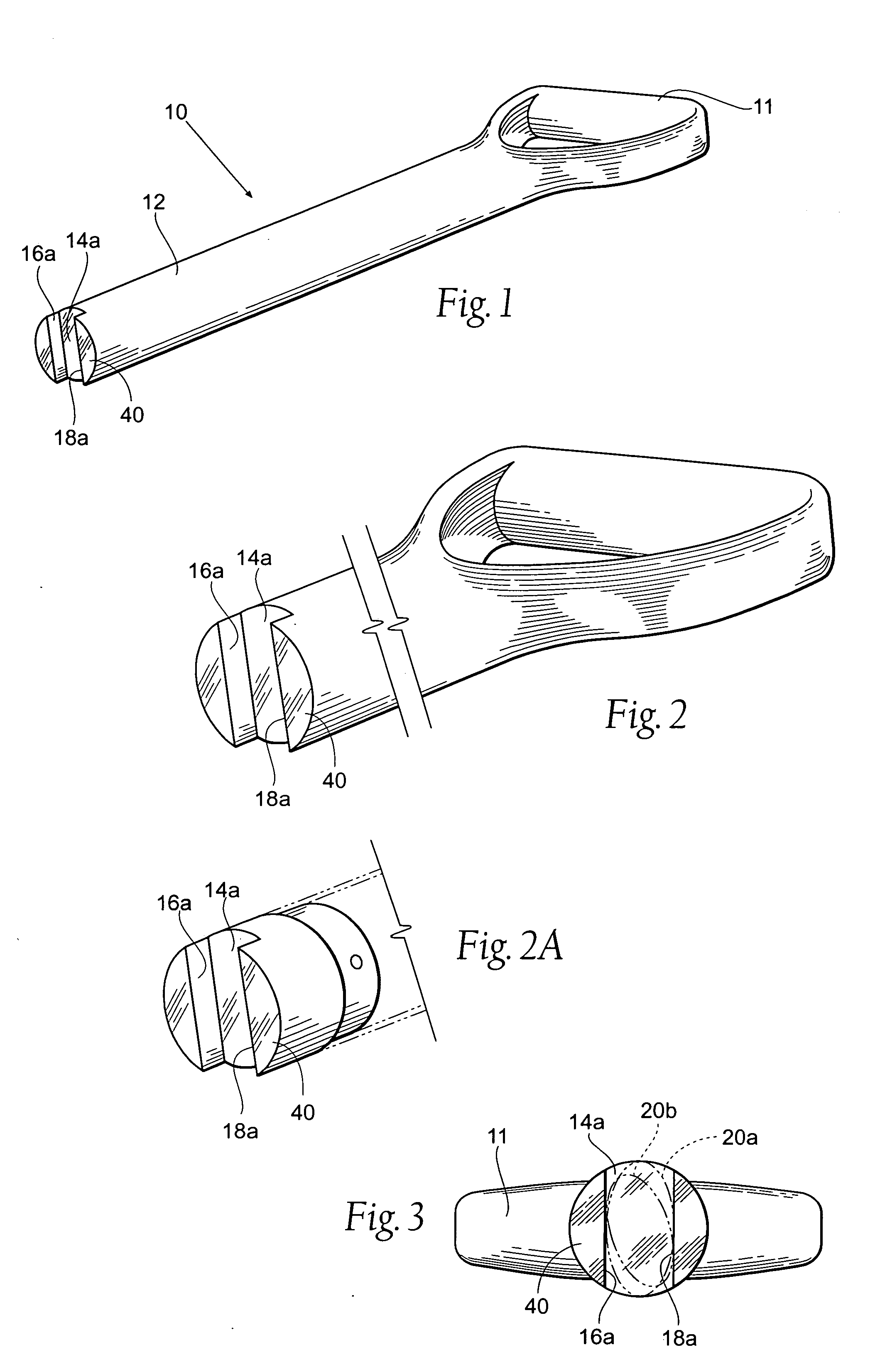

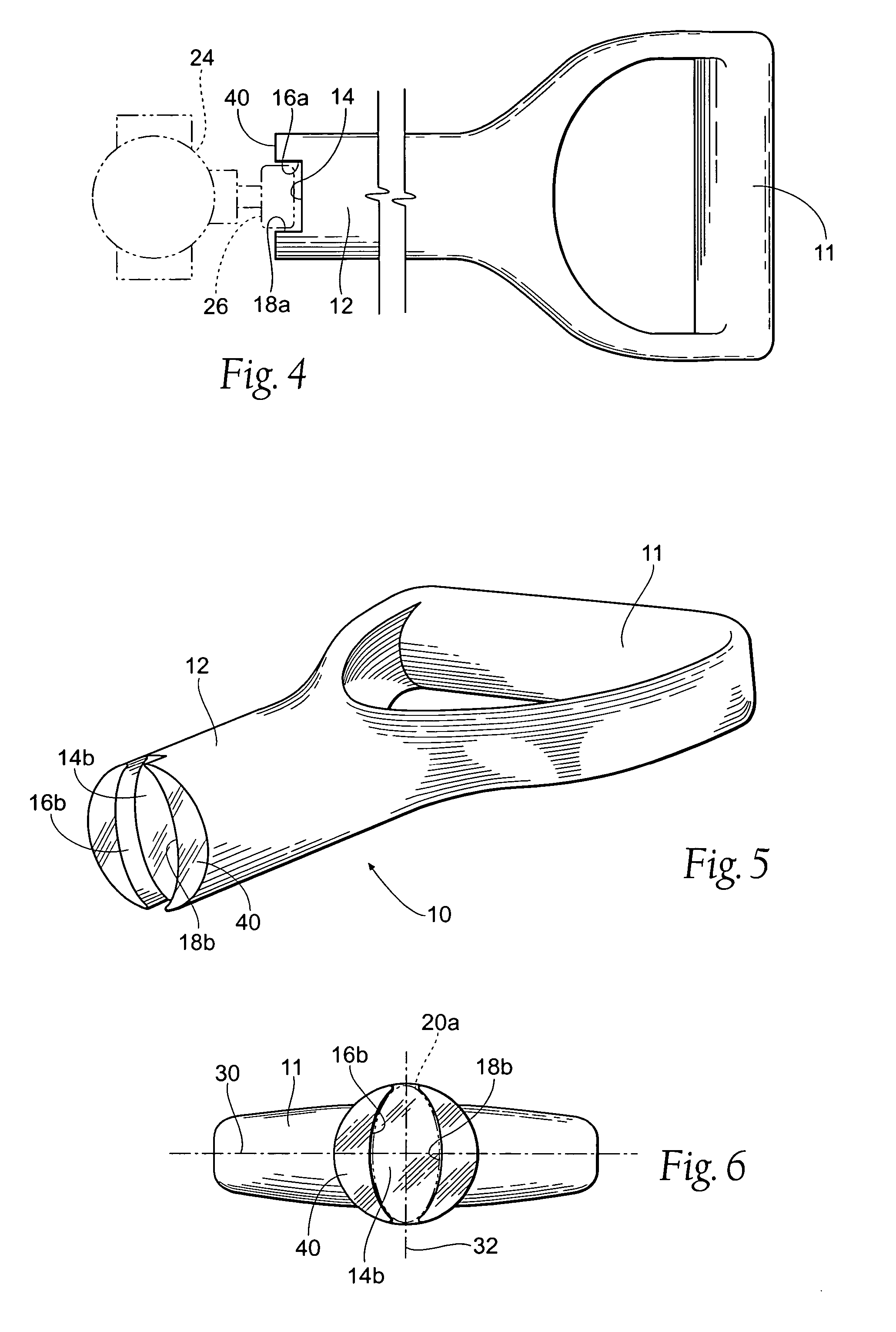

Faucet or valve handle turning tool

A faucet or valve handle turning tool is provided and includes an elongated, cylindrical body of machinable or moldable material having a handle at one end and a cavity formed in the opposite end. The cavity is formed with inwardly extending sidewalls and has at least one portion conforming to the peripheral contour of a faucet or valve handle. In particular, the sidewalls of such cavity may have similar elliptical contours. In at least one example, the cavity may be formed by means of mechanical routing and removal of material from the tool body. In use, the tool thereby reduces the possibility of damage to a polished faucet or valve handle frequently caused by hardened conventional plumbing tools.

Owner:RHODA THOMAS J

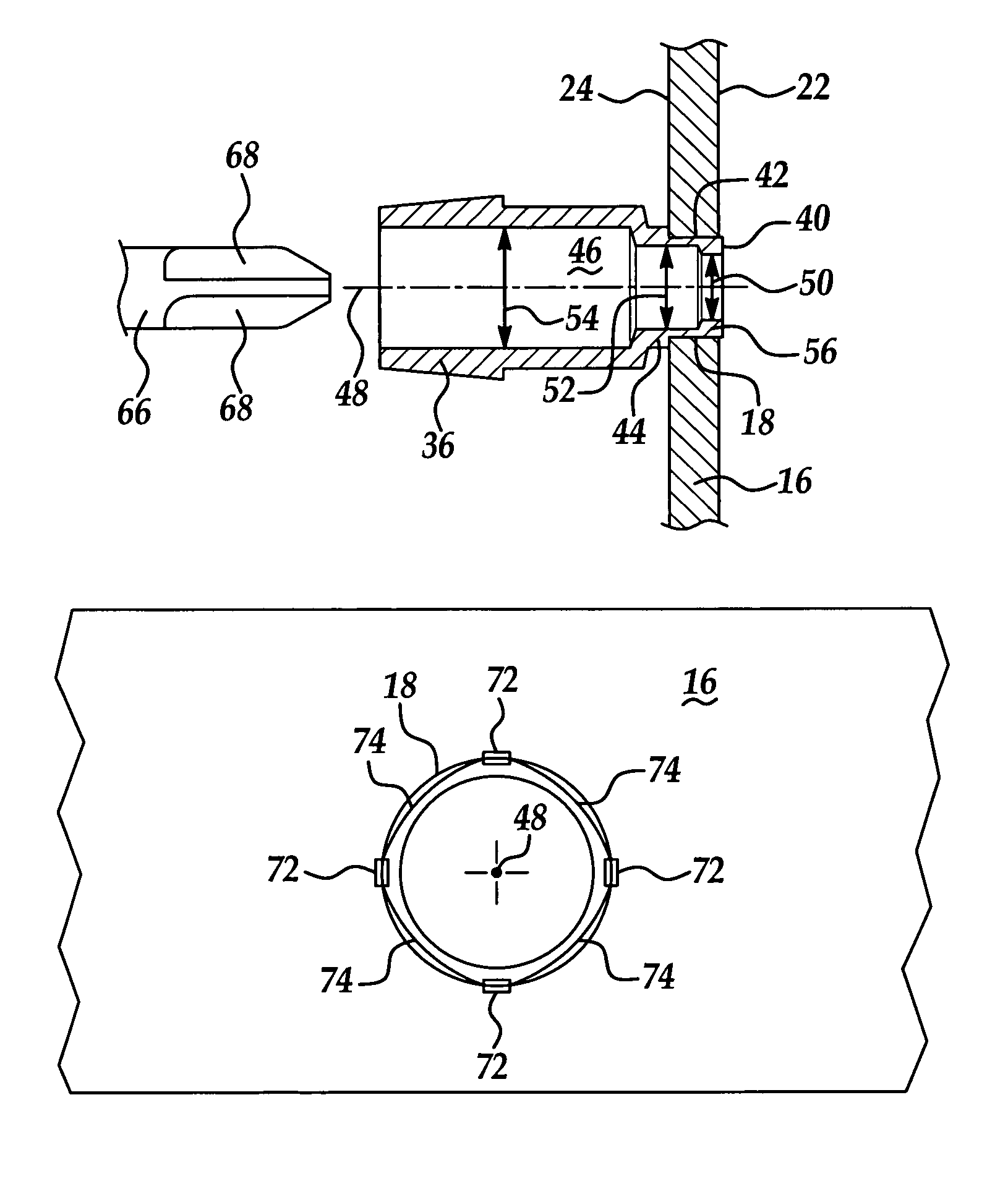

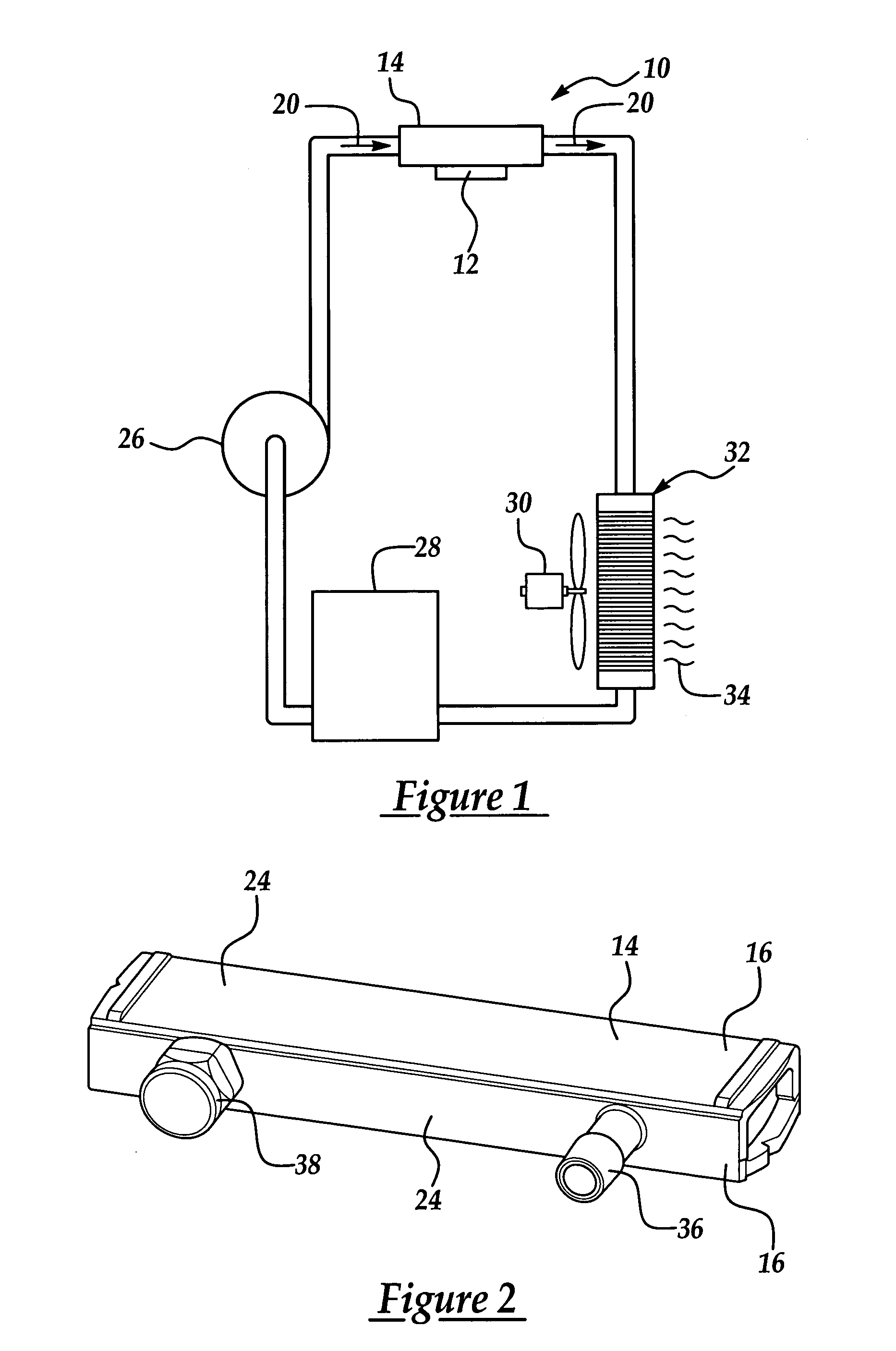

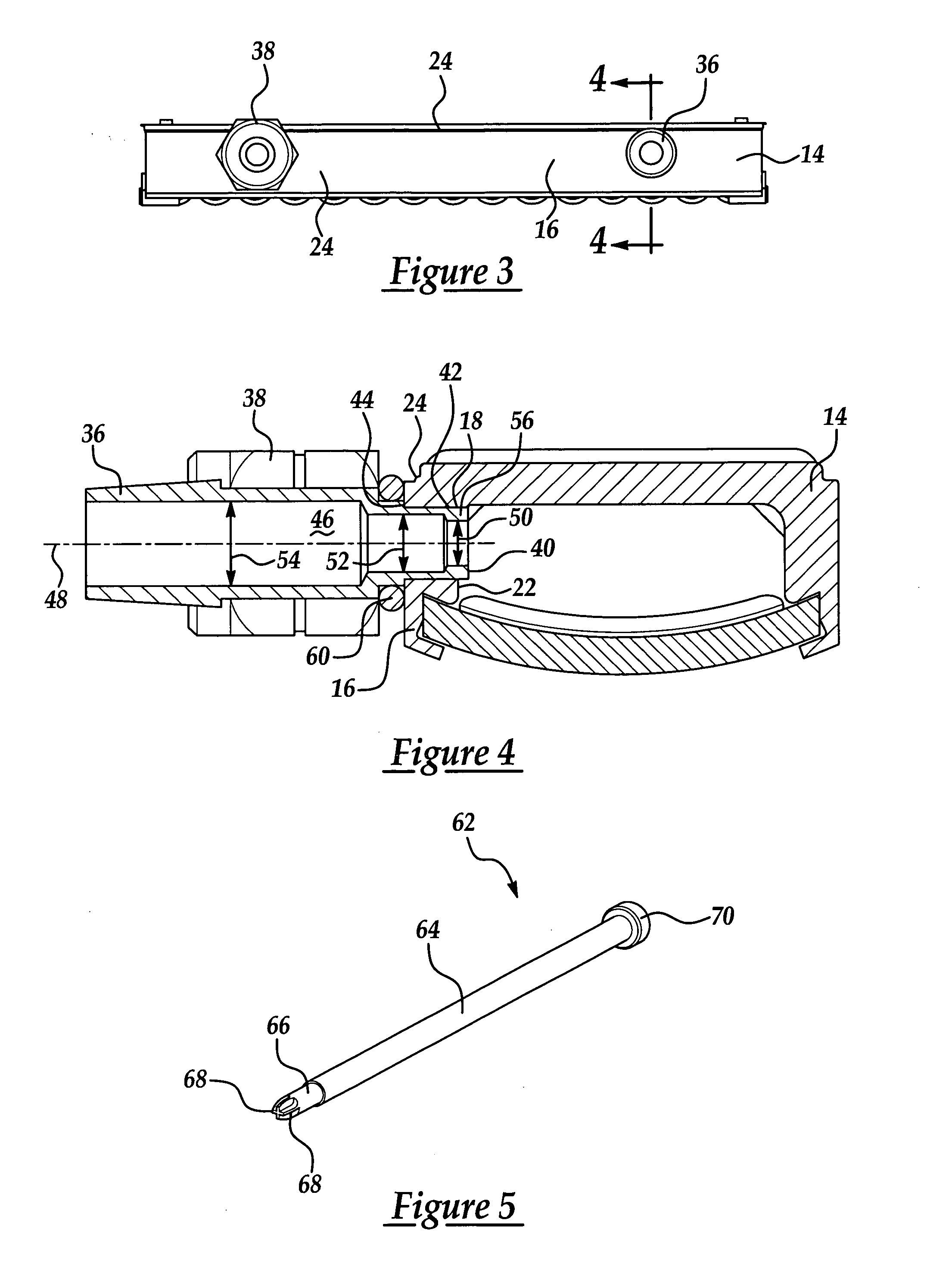

Heat exchanger assembly having fitting secured thereto and method of securing the same

ActiveUS7213640B2Avoid rotational movementImprove the immunityHeat exchanger casingsStationary tubular conduit assembliesEngineeringHeat exchanger

The subject invention provides a heat exchanger assembly including a tank having a wall defining an aperture with a fitting secured thereto and a method of securing the fitting thereto. The fitting has a first end with an outer perimeter disposed exteriorly thereof and smaller than the aperture for inserting the first end of the fitting into the aperture. The fitting also has an internal tunnel extending along an axis thereto from the first end. A step of material is disposed in the tunnel at the first end, which is at least in part, radially and longitudinally displaced relative to the axis into contact with the wall to prevent rotational movement of the fitting in the aperture.

Owner:MAHLE INT GMBH

High-speed cutting resin grinding wheel and preparing method thereof

InactiveCN105382712AImprove thermal stabilityHigh hardnessAbrasion apparatusGrinding devicesAnilineGrinding wheel

The invention discloses a high-speed cutting resin grinding wheel. The high-speed cutting resin grinding wheel comprises, by weight, 410-500 parts of CBN abrasive, 70-100 parts of white corundum powder, 96-110 parts of 34-40% of formaldehyde solution, 5-7 parts of boric acid, 2-6 parts of hexamethylene tetramine, 13-20 parts of aniline, 2-3 parts of potassium oxide, 90-100 parts of phenol, 3.6-4 parts of sodium fluosilicate and 0.6-1 part of pentaerythritol. The high-speed cutting resin grinding wheel is particularly suitable for high-speed cutting, and the grinding efficiency is high.

Owner:WUHU HONGKUN AUTO PARTS

High-thermal-reduction abrasive material resin grinding wheel and manufacturing method thereof

InactiveCN105328590AImprove thermal stabilityHigh hardnessOther chemical processesAbrasion apparatusHexamethylenetetramineCerium

The invention discloses a high-thermal-reduction abrasive material resin grinding wheel. The high-thermal-reduction abrasive material resin grinding wheel is composed of, by weight, 430 to 500 parts of a CBN adhesive material, 70 to 100 parts of quartz sand, 10 to 17 parts of cerous nitrate, 40 to 50 parts of ethylene glycol, 10 to 14 parts of 25-28wt% ammonium hydroxide, 2 to 3 parts of hydrogen peroxide, 90 to 100 parts of phenol, 96 to 110 parts of a 35-40% formaldehyde solution, 5 to 7 parts of boric acid, 2 to 6 parts of hexamethylenetetramine, 13 to 20 parts of phenylamine, 10 to 13 parts of barium chloride, 13 to 20 parts of coke and 1 to 2 parts of sodium chloride. The coke is adopted for conducting thermal reduction on a cerium precursor, so that a high-strength reducing abrasive material is obtained, and the self-sharpening performance of the grinding wheel can be improved.

Owner:WUHU HONGKUN AUTO PARTS

Petroleum coking-slurry burner

InactiveCN101029735AEnhanced atomization strengthShorten the shot lengthBurnersLiquid fuel feeder/distributionSlurryPetroleum coke

This invention shows a fossil oil serum coke burning device including the shell that consists of fuel pouring wall, flame outpouring wall and the side wall. There is a burning space inside the shell of which the side wall sets interval two or more tangential intakes. The fuel pouring wall sets at least three atomization burners of fossil oil serum coke and at least one oil burner together with at least a gas burner. The inside diameter of the burning space inside the shell is 1 / 4 to one time of the vertical distance between the inside wall of the flame outpouring wall and the inside wall of the fuel pouring wall.

Owner:GUANGZHOU DEVOTION THERMAL TECH

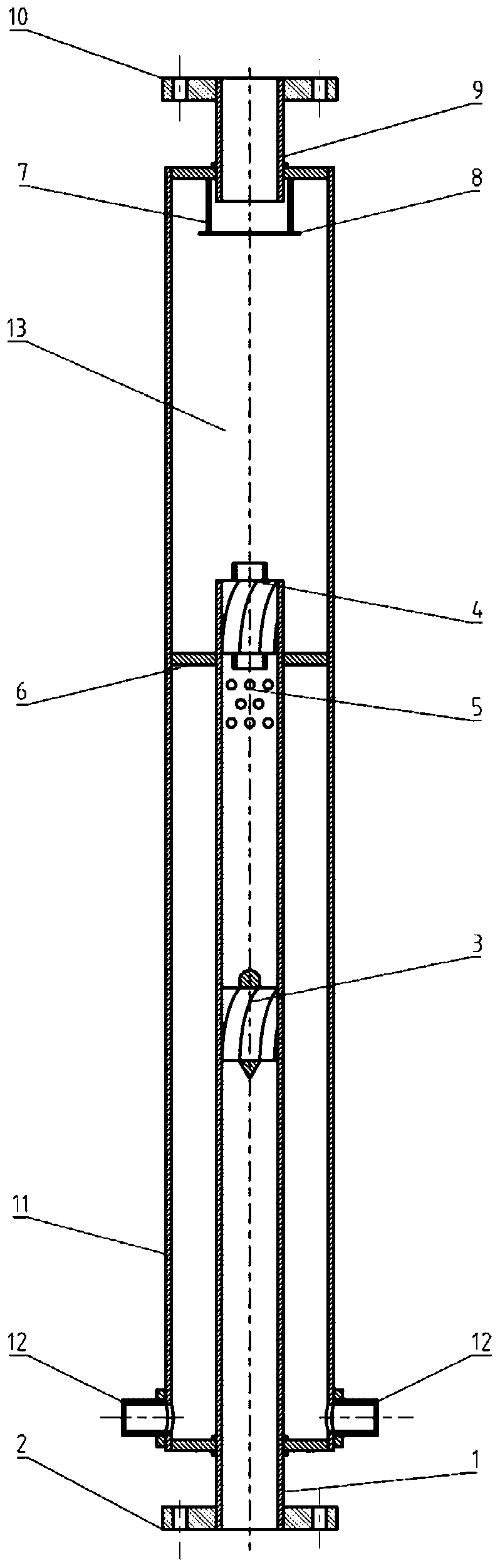

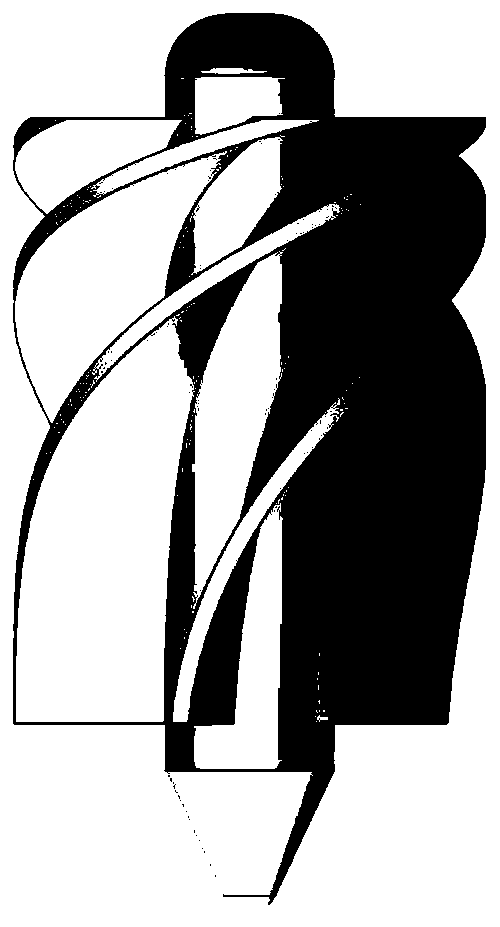

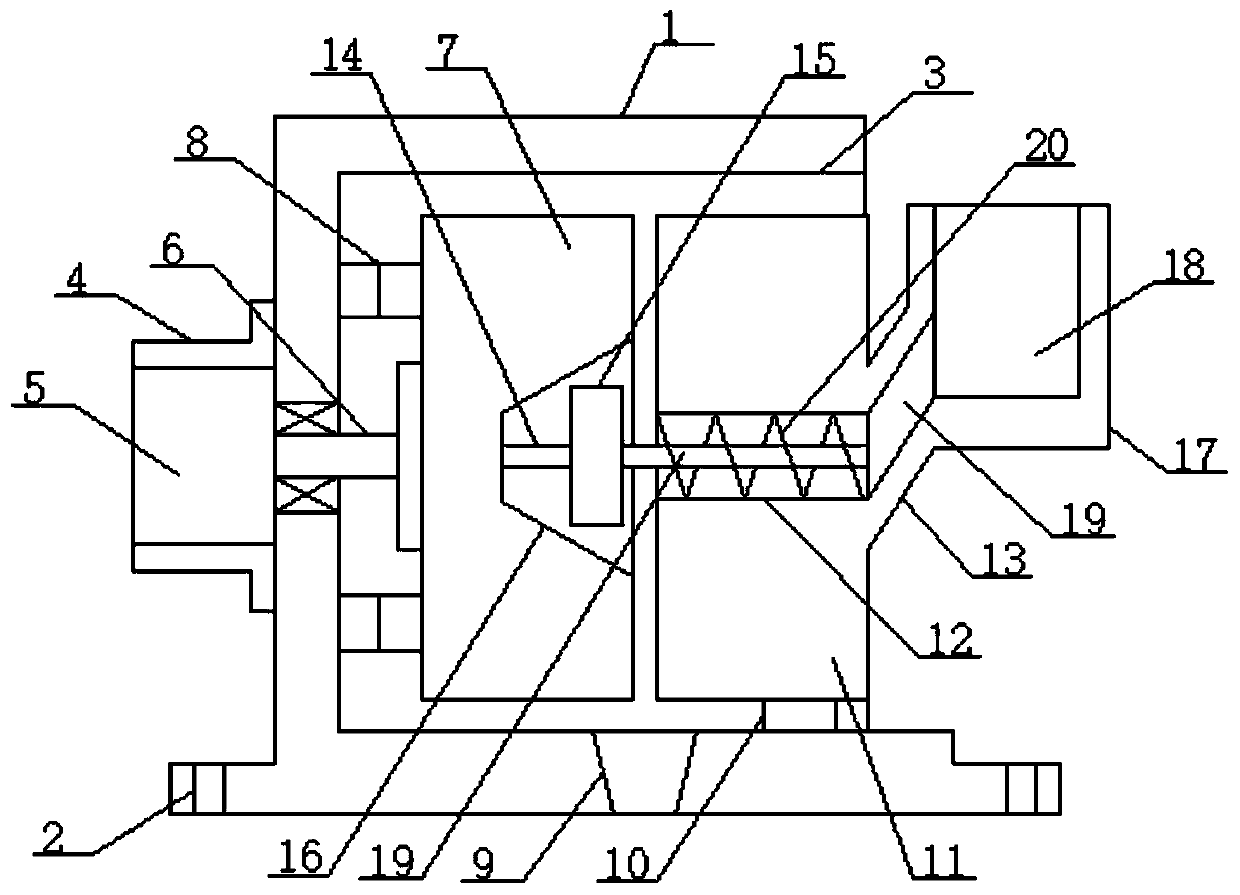

Drainer based on rotary draining core structure

InactiveCN104120765ARealize intelligent drainageHigh rotational strengthDomestic plumbingFiltrationEngineering

The invention relates to a drainer based on a rotary draining core structure. The drainer includes a drainer body, a draining core, an annular lower disc and a soft rubber cover. The drainer body is a cylindrical structure provided with a hollow cavity, the draining core and the annular lower disc are disposed in the cavity of the drainer body from top to bottom, and the soft rubber cover plugs a drainer upper opening to cut off water. Compared with the prior art, the invention is a detachable novel drainer with a rotary draining core structure and a filtering function, realizes intelligent drainage of an unpowered device, and has the advantages of difficult oscillation, long service life, large filtration area, and small flow resistance, etc.

Owner:SHANGHAI UNIV OF ENG SCI

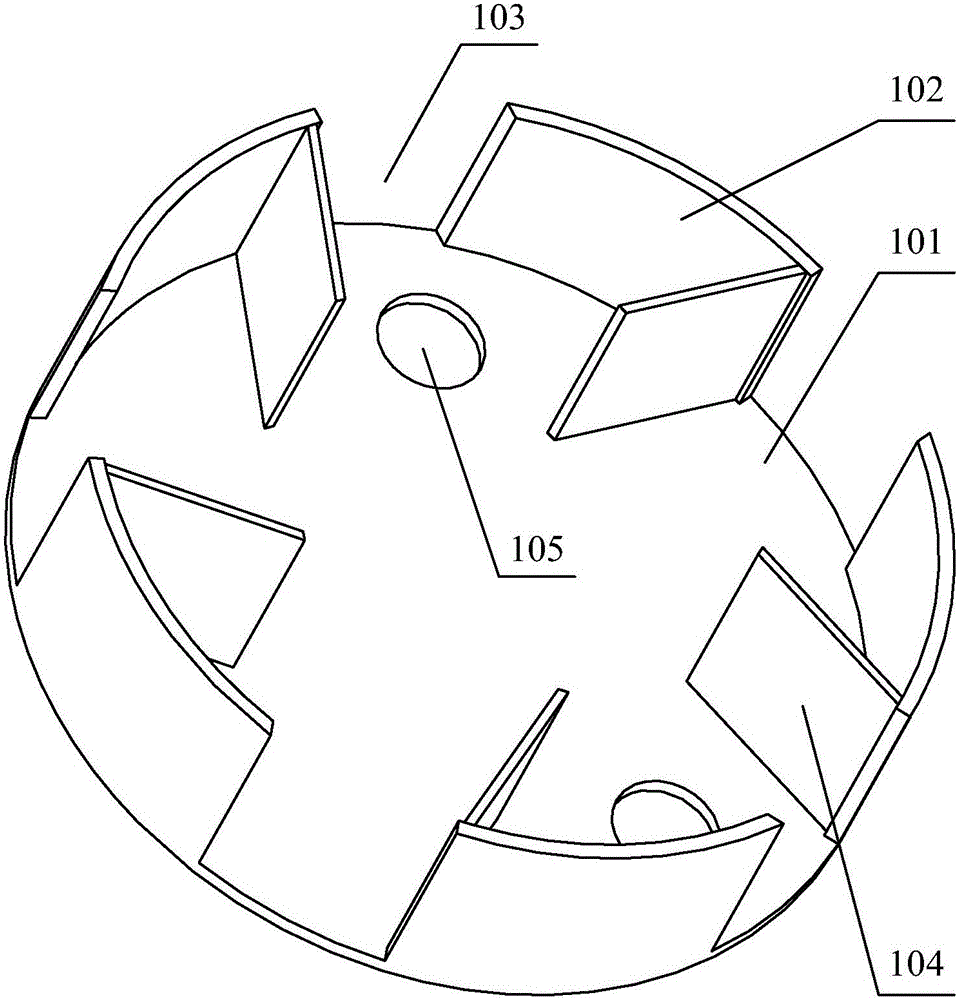

Vertical sand making machine

InactiveCN110369036AImprove grinding efficiencyHigh rotational strengthCocoaGrain treatmentsCircular discSpiral blade

Owner:王国周

Complete mixing W type flame boiler combustion exhausted wind apparatus

ActiveCN101324339BStrong jet rigidityWell mixedNon-combustible gases/liquids supplyJet flowCombustion

A full-mixing overfire air device of a W-shaped flame boiler relates to an overfire air device of a boiler. The invention aims to solve the problems of the prior W-shaped flame boiler adopting overfire air nozzles in direct flow structure form, such as higher carbon content in fly ash resulting from the fact that the gas and pulverized coal in the jet flow of the conventional boiler are unlikely to be mixed with those between adjacent jet flows due to the poor lateral diffusion capacity. The higher carbon content in the ash can lower the heat efficiency of the boiler and increase coal consumption of power plants. One end of an outer air channel of the overfire air device is fixed on the outer side wall of an upper furnace at an overfire air nozzle, wherein the overfire air accounts for 25to 30% of the total amount of air fed into the boiler. The overfire air is divided into two portions when entering the overfire air channel, one portion enters an inner air channel and is ejected to the furnace to achieve higher momentum, and the other portion enters the outer air channel to achieve higher rotation intensity, so that the two portions of the overfire air can achieve higher lateraldiffusion capacity when entering the upper furnace and can be mixed with gas between two adjacent portions of the overfire air jet flow.

Owner:HARBIN INST OF TECH

Composite calcium-based resin grinding wheel and manufacturing method thereof

InactiveCN105328586AImprove thermal stabilityHigh hardnessOther chemical processesAbrasion apparatusHexamethylenetetramineGrinding wheel

The invention discloses a composite calcium-based resin grinding wheel. The composite calcium-based resin grinding wheel is composed of, by weight, 570 to 600 parts of a CBN adhesive material, 90 to 100 parts of phenol, 96 to 110 parts of a 35-40% formaldehyde solution, 5 to 7 parts of boric acid, 2 to 6 parts of hexamethylenetetramine, 13 to 20 parts of phenylamine, 30 to 40 parts of gibbsite, 0.1 to 0.2 part of zinc naphthenate, 1 to 2 parts of fatty alcohol-polyoxyethylene ether, 3 to 4 parts of calcium ricinoleate, 6 to 10 parts of calcium stearate and 10 to 13 parts of calcium phosphate. The calcium ricinoleate and the calcium stearate are added so that the adhesion performance improving effect can be achieved to a certain extent and the thermal stability can be improved as well.

Owner:WUHU HONGKUN AUTO PARTS

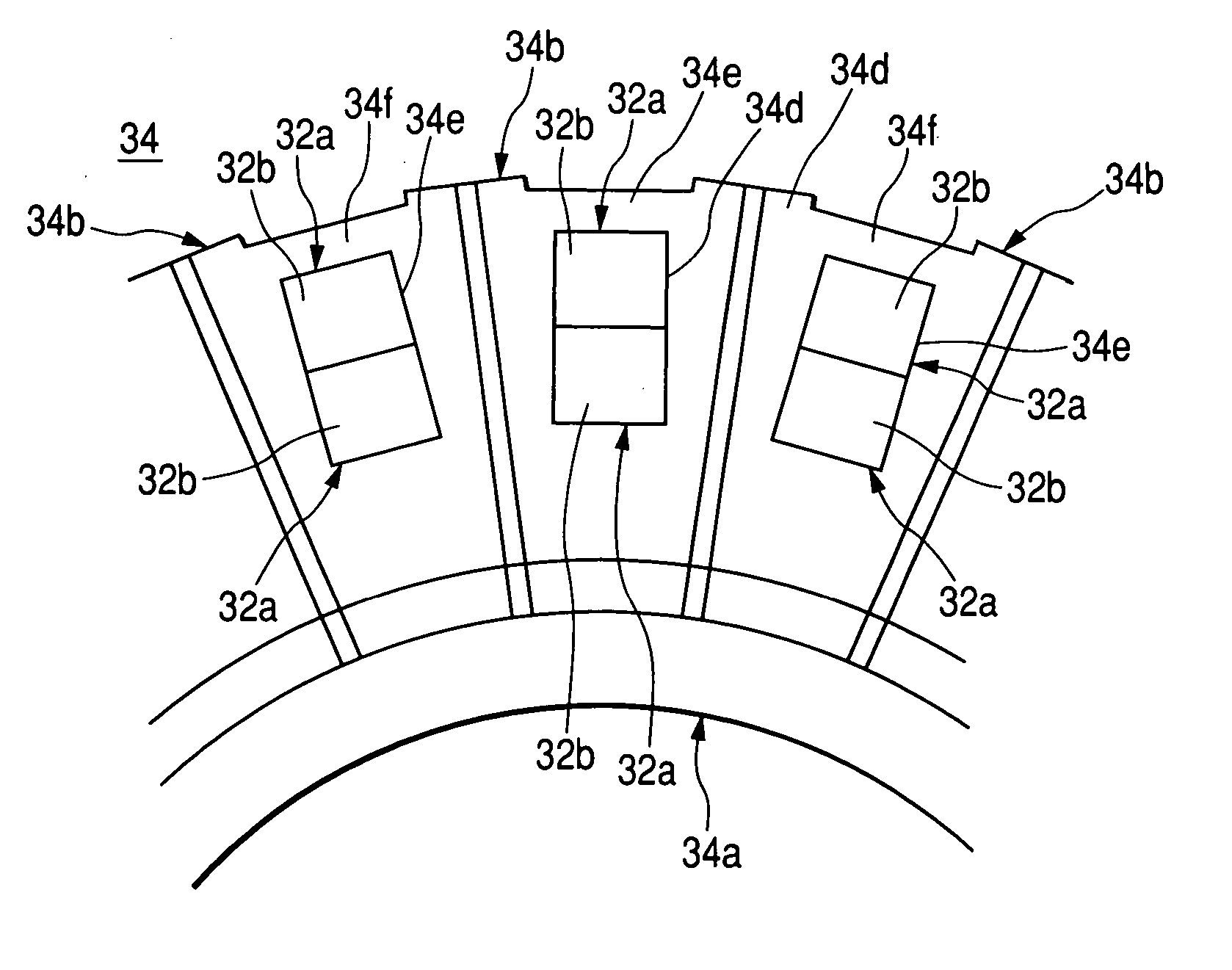

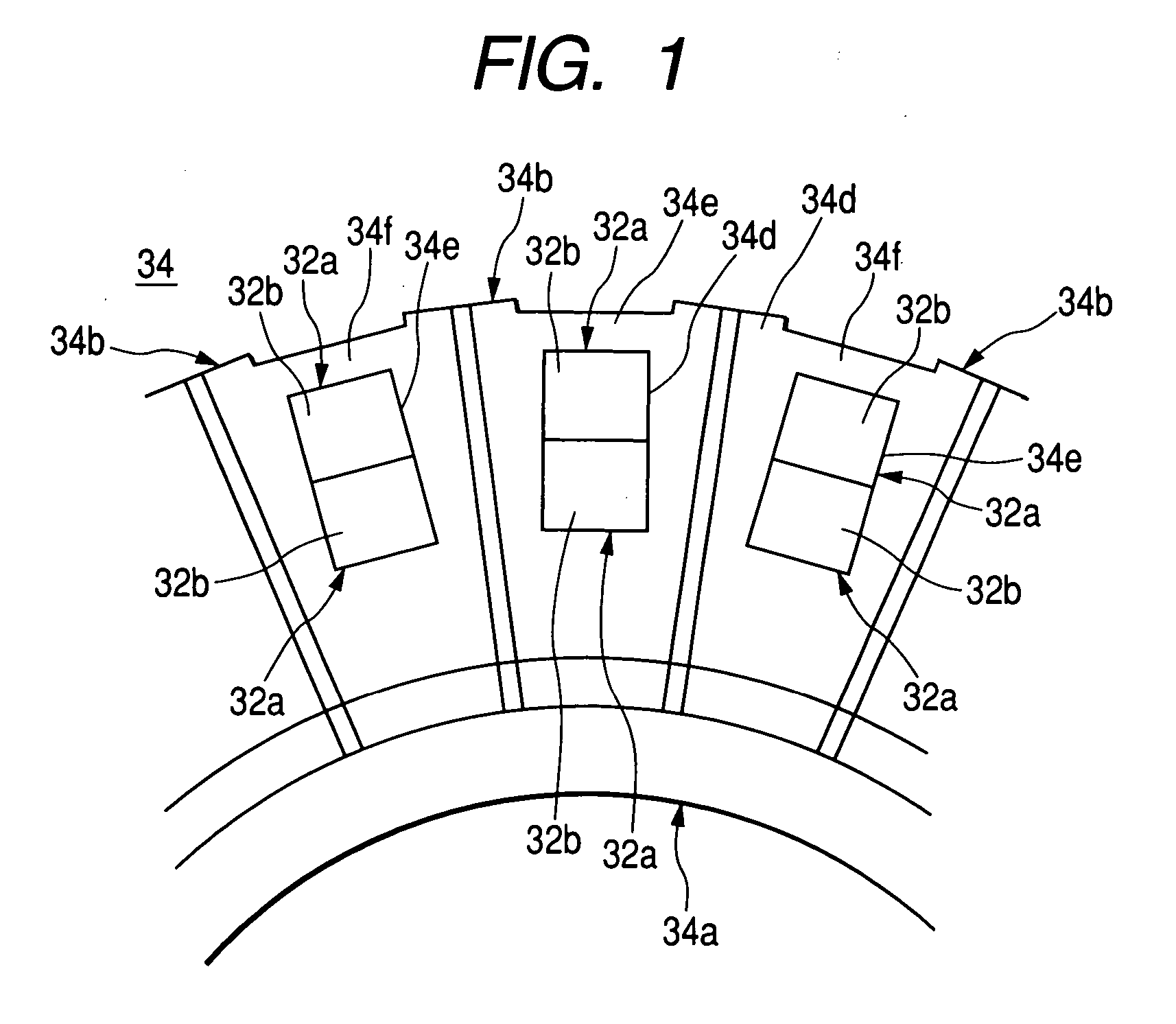

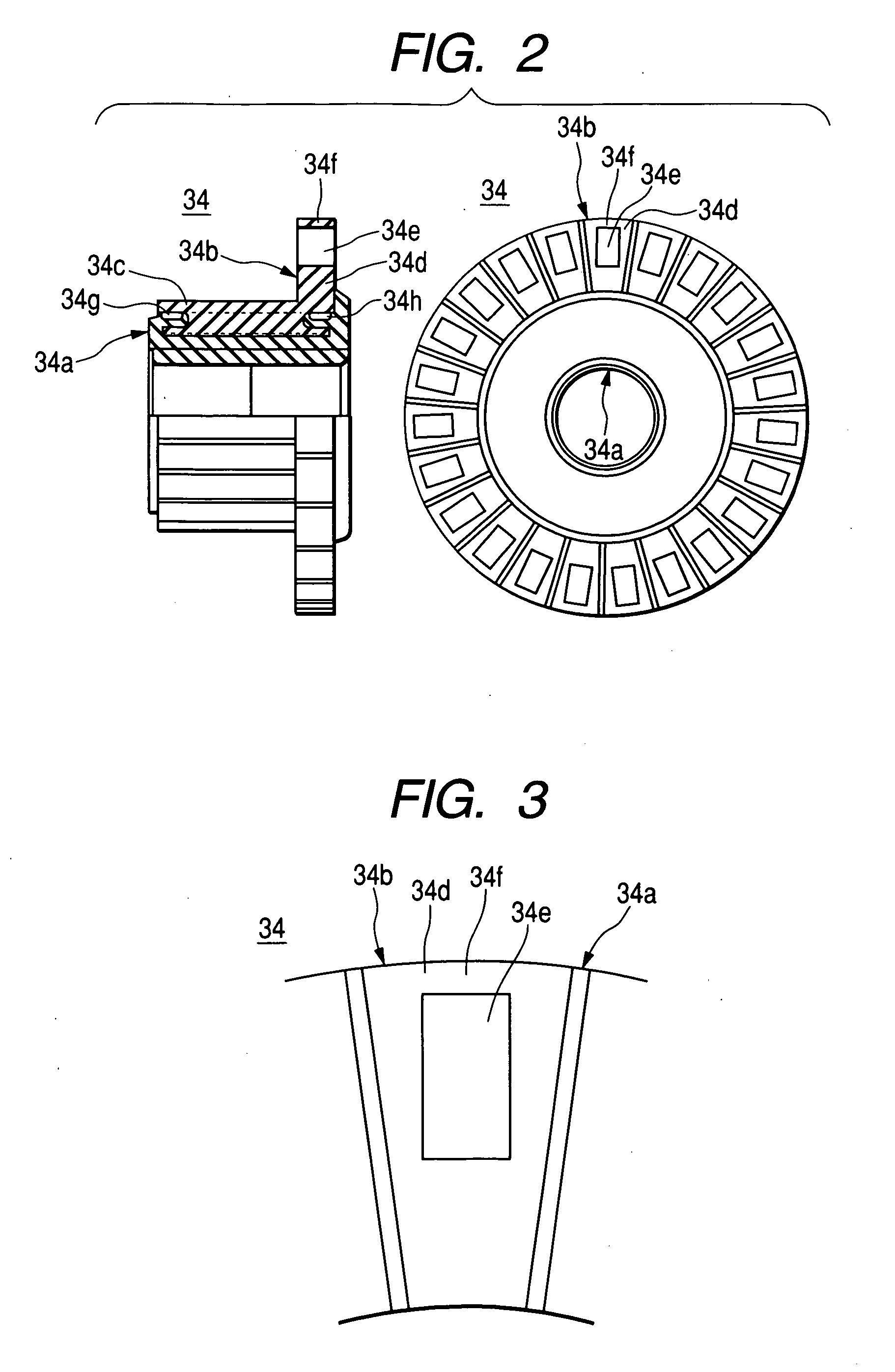

Electric motor with commutator, and manufacturing method of armature and starter motor for engine

InactiveUS20050168100A1Increase production costHigh rotational strengthPower operated startersRotary current collectorElectrical conductorEngineering

To accomplish the above object, this embodiment forms the coil connecting parts 34e on the vertical sections 34d of the commutator segments 34b so that the coil conductors 32a may be assembled axially. On the outer circumference of the coil connecting part 34e, this can form the commutator segments 34b in a body with the lock members 34f that prevent the coil conductor 32a from going out in the centrifugal direction from the coil connecting part 34e. Therefore, the rotating strength (the centrifugal strength) of coil conductors 32a can be improved in the coil connecting part 34e without any additional member for the lock member 34f and without increasing the number of manufacturing steps pertaining to the lock member 34f.

Owner:HITACHI CAR ENG CO LTD +1

Corrugated roller grinding wheel and manufacturing method thereof

ActiveCN104889894AUniform hardnessUniform tissueAbrasion apparatusGrinding devicesGranularityGrinding wheel

The invention belongs to the field of grinding wheels and manufacturing method thereof and particularly relates to a corrugated roller grinding wheel and a manufacturing method thereof. The grinding wheel is characterized in that raw material component and weight percentage of grinding parts are that 68-80% of grinding materials with granularity of 36 [mu]m-120 [mu]m; 8-15% of ceramic bond; and 10-15% of pore-forming materials. The manufacturing method comprises following steps of 1) mixing materials; 2) forming; 3) drying; 4) kiln placing; 5) sintering; and 6) blank drying and size processing. The grinding wheel is advantageous in that the grinding wheel is high in rotation strength, rigidity, structure uniformity, static balance performance, heat radiation performance, grinding performance, grinding efficiency and grinding precision.

Owner:QINGDAO SISA ABRASIVES CO LTD

Rotational-flow air mixing type water spraying device

PendingCN110005029AHigh rotational strengthStrong rotational forward motionLavatory sanitoryLiquid spraying apparatusSpray nozzleMixing effect

The invention provides a rotational-flow air mixing type water spraying device. The rotational-flow air mixing type water spraying device comprises a water inlet section, a pre-rotating section, an accelerating section, a rotational flow section, an air mixing chamber, a front-end spray nozzle and an air ventilating pipe, wherein the pre-rotating section is a pipeline with flow guide grooves distributed on the surface of the inner wall; the accelerating section is a gradually-shrinking flow channel with the wall face forming the hopper shape; the rotational flow section comprises a flow diverting section, a rotational-flow pipeline and a jet flow nozzle, the flow diverting section is a pipeline with a flow diverting plate arranged inside, the rotational-flow pipeline comprises two conveying pipelines distributed in a double helix structure along the horizontal line direction, and the jet flow nozzle is a flow channel with the outlet forming an X-shaped gap; and the air mixing chamber comprises an air mixing chamber outer protection wall and an air mixing cavity. The rotational-flow air mixing type water spraying device can well generate rotational jet flow, then the air-mixing property of the jet flow is promoted, the air mixing effect is improved, and the property of a spray head is improved.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com