Corrugated roller grinding wheel and manufacturing method thereof

A technology for grinding corrugated and corrugated rollers, which is applied in the field of grinding corrugated rollers and its manufacturing field. It can solve the problems of high price, high production cost, and the inability of grinding corrugated rollers to meet processing requirements, so as to improve grinding accuracy and prolong service life. , Improve the effect of appearance commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Abrasive (chrome corundum)

Pore former (almond shell)

Binding agent

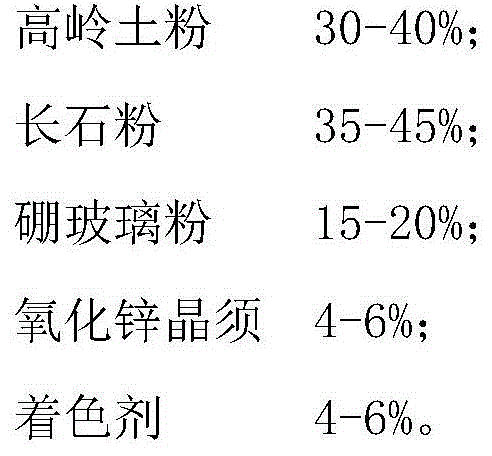

[0051] Vitrified Bond Formulation

[0052] Kaolin powder

ZnO whiskers

31%

42%

16%

5%

6%

[0053] In the above vitrified bond, the coloring agent is chromium oxide, and the product is green after firing.

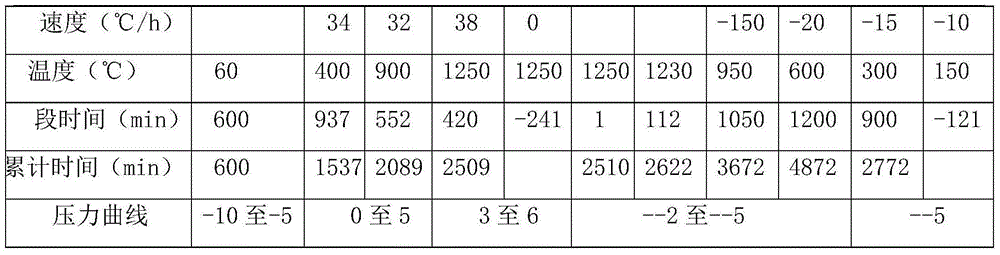

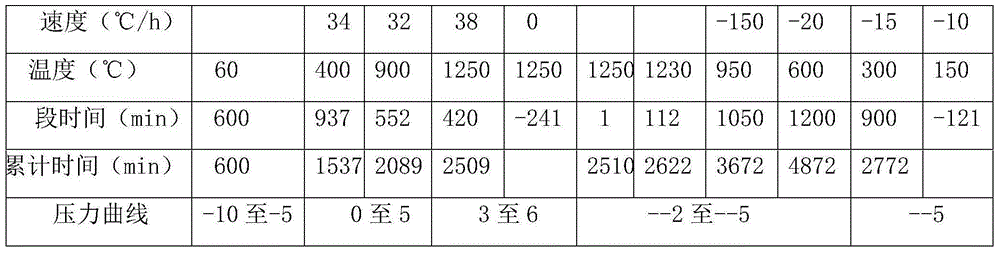

[0054] The steps of this embodiment are as follows:

[0055] 1. Mixing

[0056] 1.1 Use water glass and dextrin solution to soak the pore forming agent, water glass: water = 1:10, add 15% of the total amount of dextrin into the mixed solution for use;

[0057] 1.2 Prepare vitrified bond;

[0058] 1.3 Put the weighed abrasive into the mixing pot, add water glass and mix for 5-6 minutes according to 1-3% of the abrasive amount, then add the mixed binder and dextrin (the remaining 85% dextrin) and pour Mix in the mixing pot for 10-20 min...

Embodiment 2

[0082] Abrasive (white corundum)

Pore-forming material (corundum hollow sphere)

vitrified bond

75%

11%

14%

[0083] Vitrified Bond Formulation

[0084] Kaolin powder

Feldspar powder

boron glass powder

ZnO whiskers

32%

40%

18%

4%

6%

[0085] In the above vitrified bond, the coloring agent is iron oxide, and the product appears light yellow or orange after firing.

[0086] The processing steps of this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0089] Abrasive (1:1 mixture of single crystal corundum and white corundum)

Pore former (walnut shell)

vitrified bond

78%

13%

9%

[0090] Vitrified Bond Formulation

[0091] Kaolin powder

Feldspar powder

boron glass powder

ZnO whiskers

34%

40%

17%

4%

5%

[0092] In the above vitrified bond, the coloring agent is cobalt oxide, and the product appears blue after firing.

[0093] Use the grinding wheel research and development index that the present invention makes to compare with national standard allowable value as follows

[0094]

[0095] The use effect comparison of the emery wheel that the present invention makes and traditional emery wheel are as follows

[0096] Unit: mm

[0097]

[0098] The research and development index comparison of the emery wheel that the present invention makes and traditional emery wheel is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com