Rotating electromagnetic field and tangential flow guiding composite purifying tundish steel liquid method and device

A composite purification and rotating magnetic field technology, applied in centrifuges and other directions, can solve the problems of inability to achieve purification effect, decline in the removal effect of inclusions, high power, etc., to avoid the danger of slag entrainment, reduce volume, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

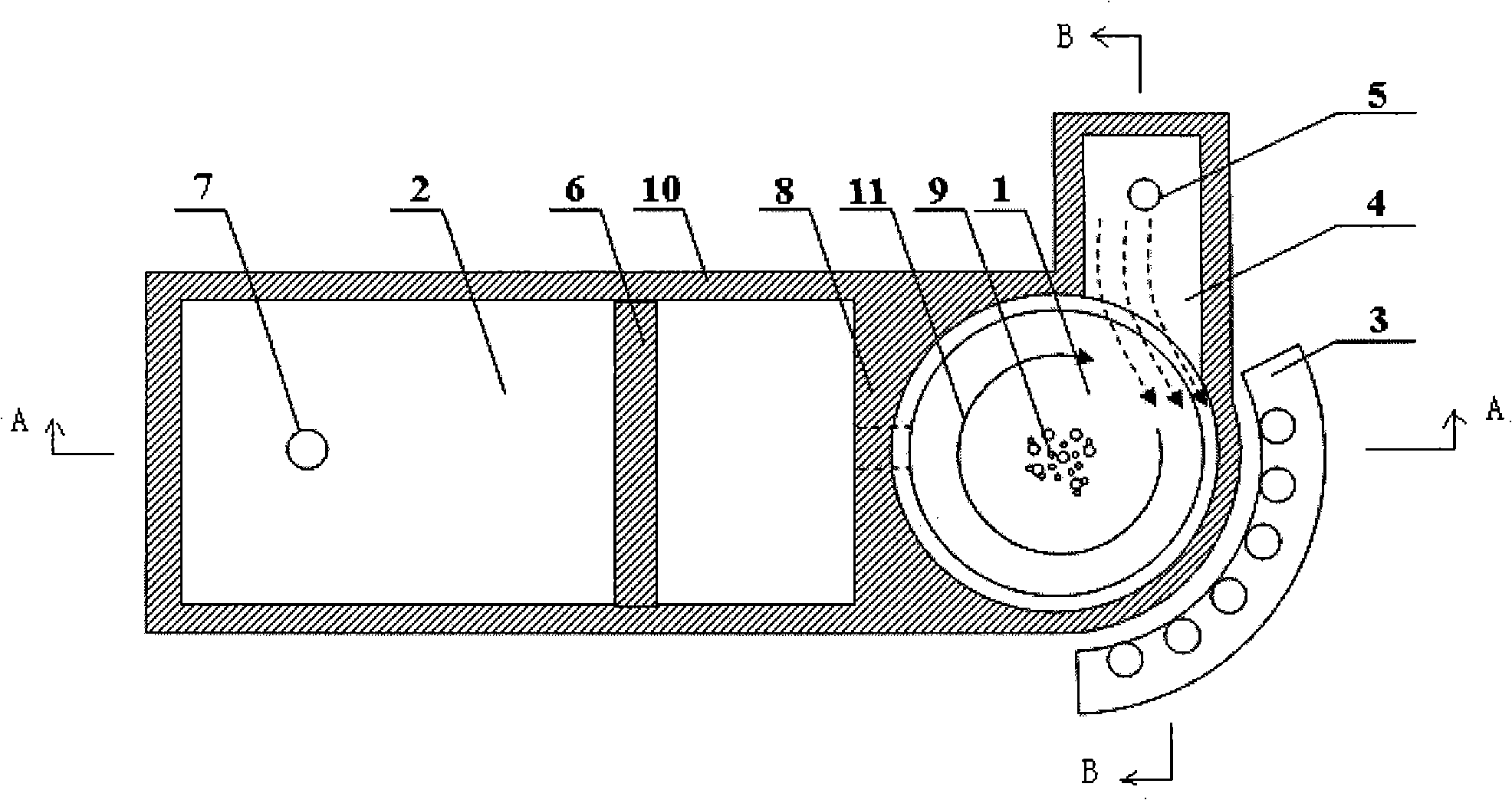

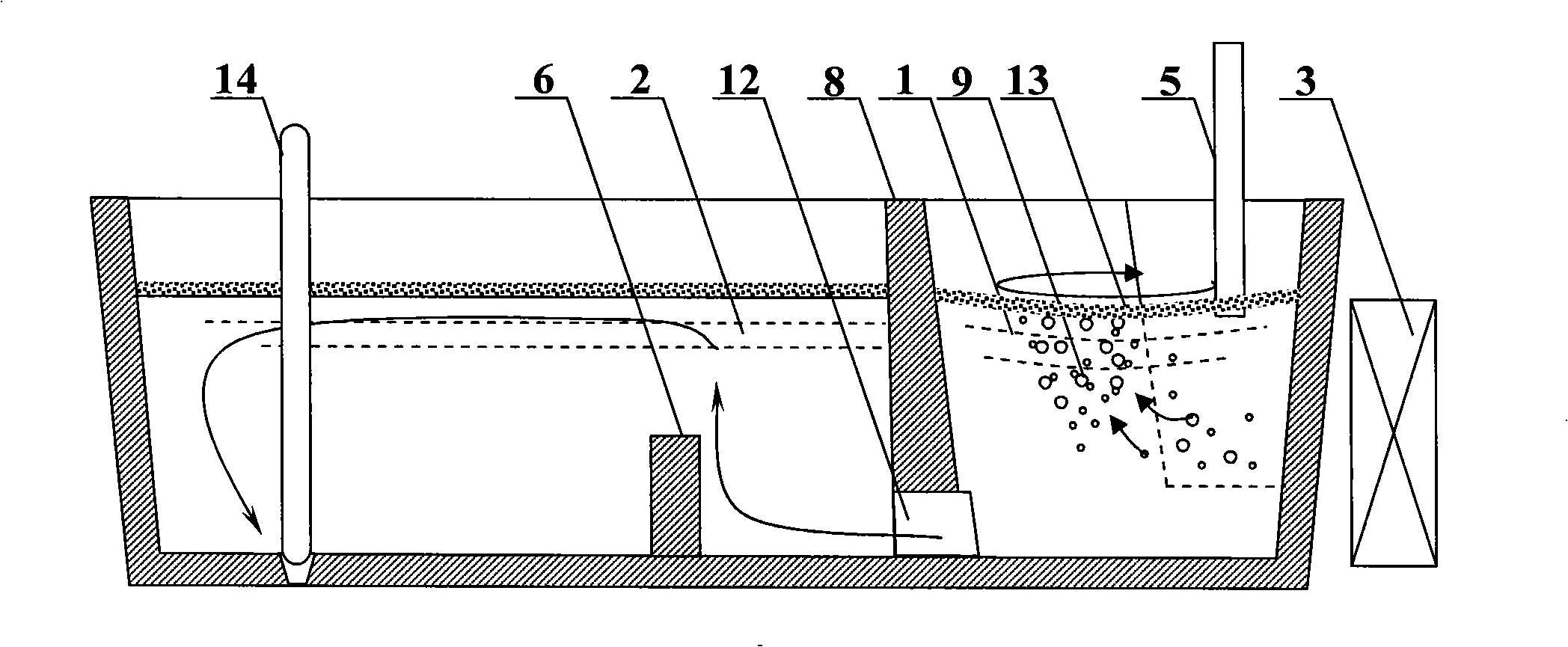

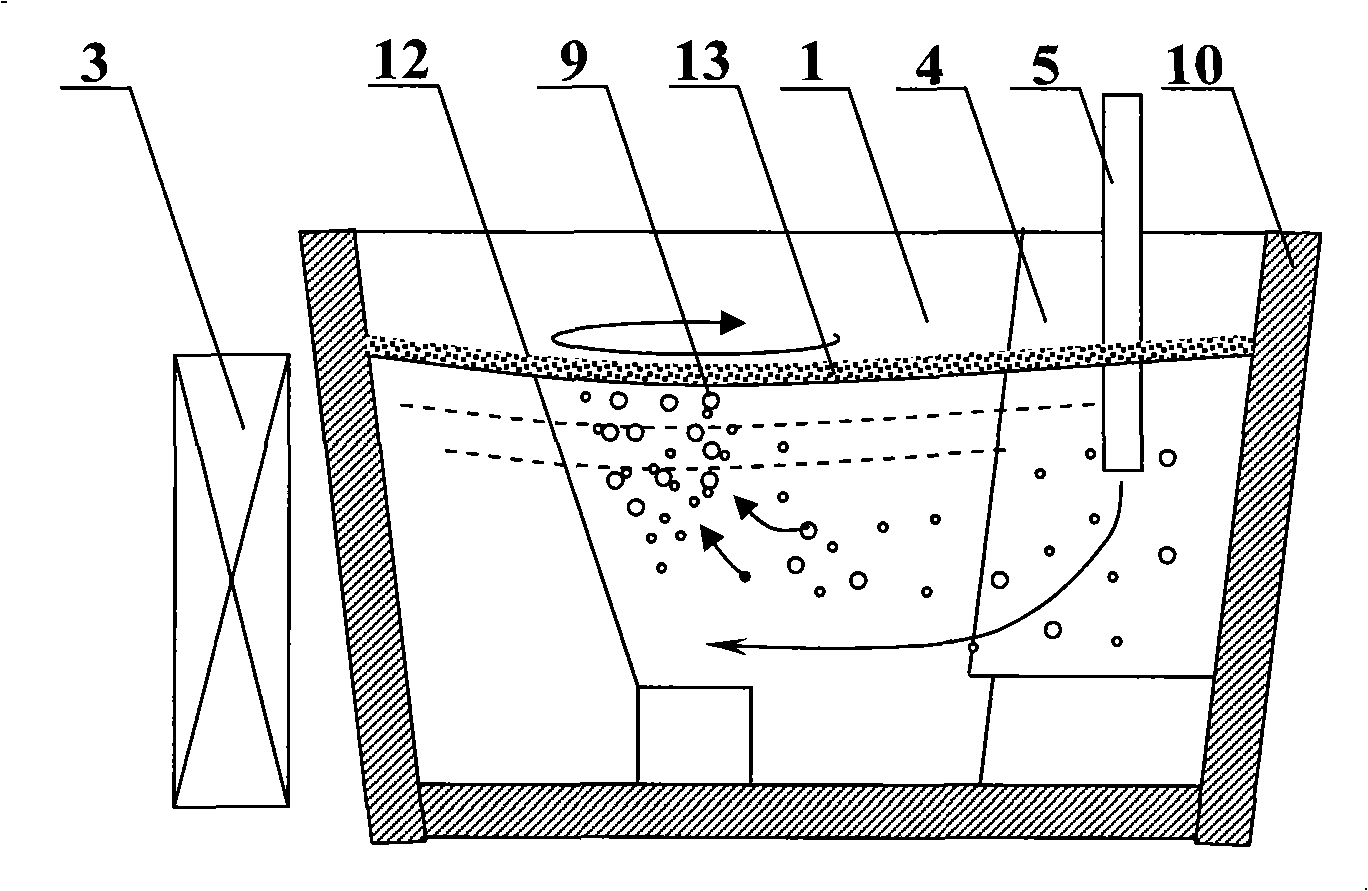

[0028] see figure 1 , figure 2 with image 3 The method for compounding and purifying molten steel in a tundish with a rotating electromagnetic field and tangential flow is as follows: a rotating magnetic field generating device generates rotating electromagnetic force to drive the molten steel in the rotating chamber 1 of the tundish to generate a rotating flow, and guide the vertical impact flow of the ladle nozzle 5 The direction is horizontal and tangentially flows into the rotating chamber 1, so that the vertical impact flow force of the molten steel is converted into a rotating flow force, and the rotating flow force is combined with the rotating flow force driven by the rotating electromagnetic force, so that the molten steel in the rotating chamber produces a symmetrical rotating flow. Centrifugal force separates non-metallic impurities in molten steel.

Embodiment 2

[0030] see figure 1 , figure 2 with image 3 The device for purifying molten steel in a tundish combined with rotating electromagnetic field and tangential flow guide includes a tundish containing a rotating chamber 1, said rotating chamber 1 is connected to a guide groove 4 along a tangent line, and a ladle nozzle 5 is placed in the diversion groove 4 , a fan-shaped rotating magnetic field generating device 3 is placed outside the rotating chamber 1 .

[0031]Its detailed structure and working principle: the tundish is mainly composed of rotating chamber 1, distribution chamber 2, diversion groove 4, retaining wall 8, retaining dam 6, fan-shaped rotating magnetic field generator 3, single-flow tundish 10, ladle nozzle 5, The tundish is composed of a stopper rod 14 and the like, and the swirling chamber 1 and the distributing chamber 2 are connected by a channel 12 at the bottom of the retaining wall 8 . A fan-shaped rotating magnetic field generating device 3 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com