Faucet or valve handle turning tool

a faucet handle and handle technology, applied in the field of plumbing tools, can solve the problems of affecting the operation damage to the handle, and difficulty in accessing the valve and obtaining the leverage, so as to reduce the possibility of damage to the handle surface of the faucet handle, and reduce the possibility of damage to the handle surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Although the disclosure hereof is detailed and exact to enable those skilled in the art to practice the invention, the physical embodiments herein disclosed merely exemplify the invention that may be embodied in other specific structures.

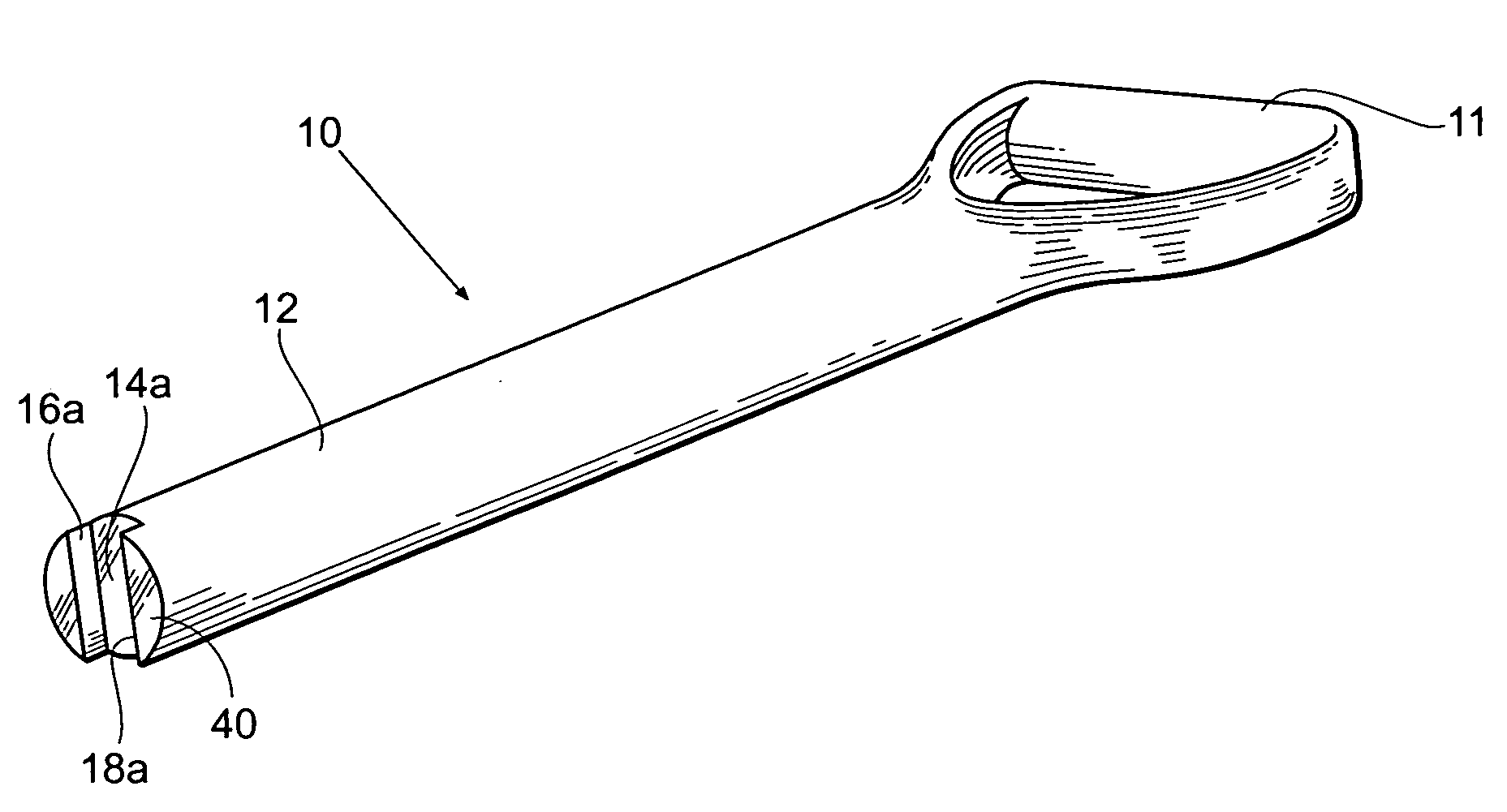

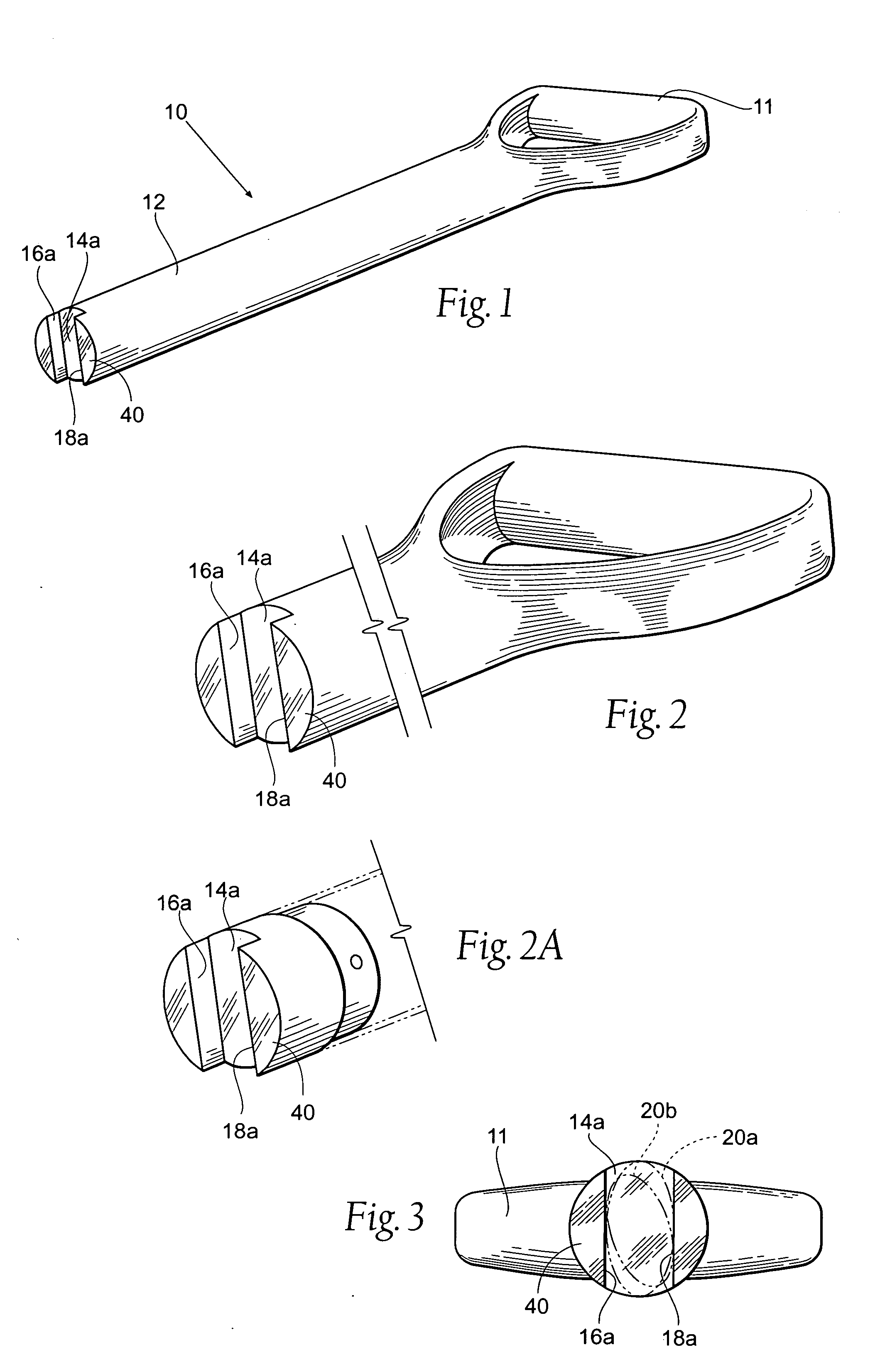

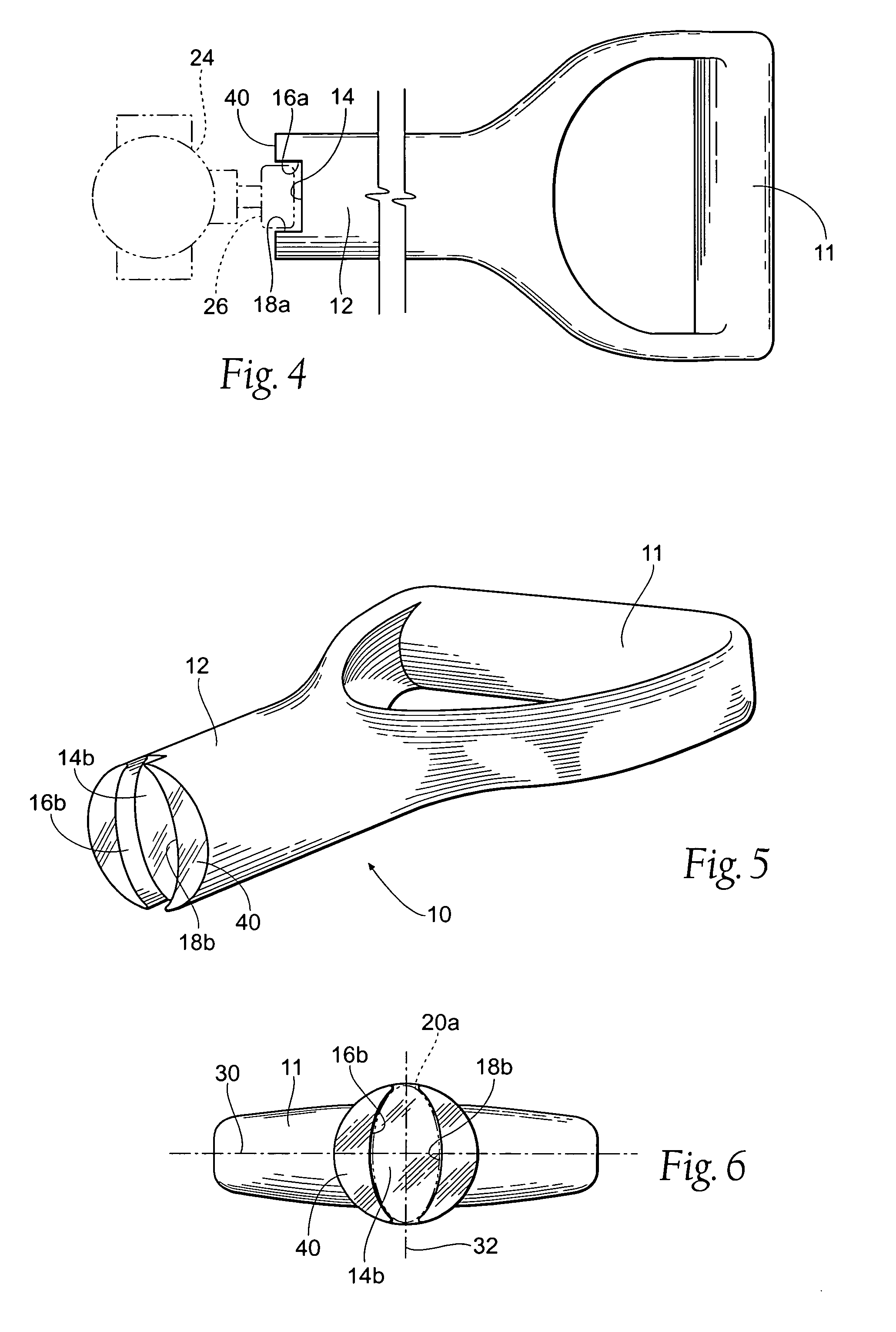

[0023] Referring to the drawings, there is illustrated the tool 10 of this invention having a generally cylindrical, elongated, body 12 with a radially extended lever arm or handle 11 and distal end 40. The lever arm 11 extends from the periphery of the cylindrical body 12 to provide manually rotatable leverage to the tool for rotation of a valve handle (not shown in FIG. 1). In the present case, it has been found to be convenient to form the lever arm 11 in the shape of a conventional “shovel-type” handle which may be formed as an integral part of the body 12, as shown. A preformed handle (not shown) may be made of two mating elongate members affixed or otherwise joined in mating relationship to surround the cylindrical body 12. In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com