Patents

Literature

33results about How to "Avoid excessive hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

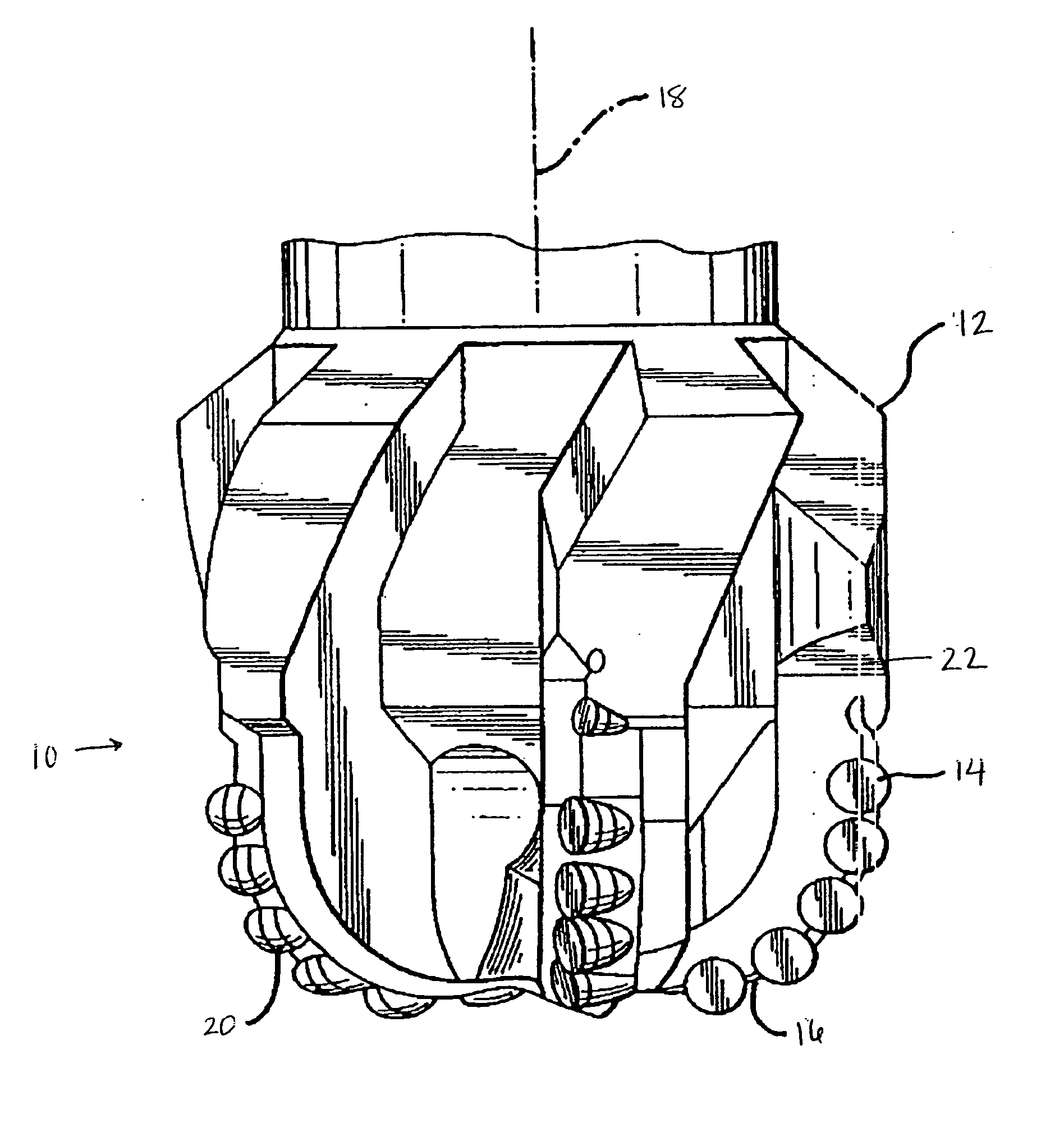

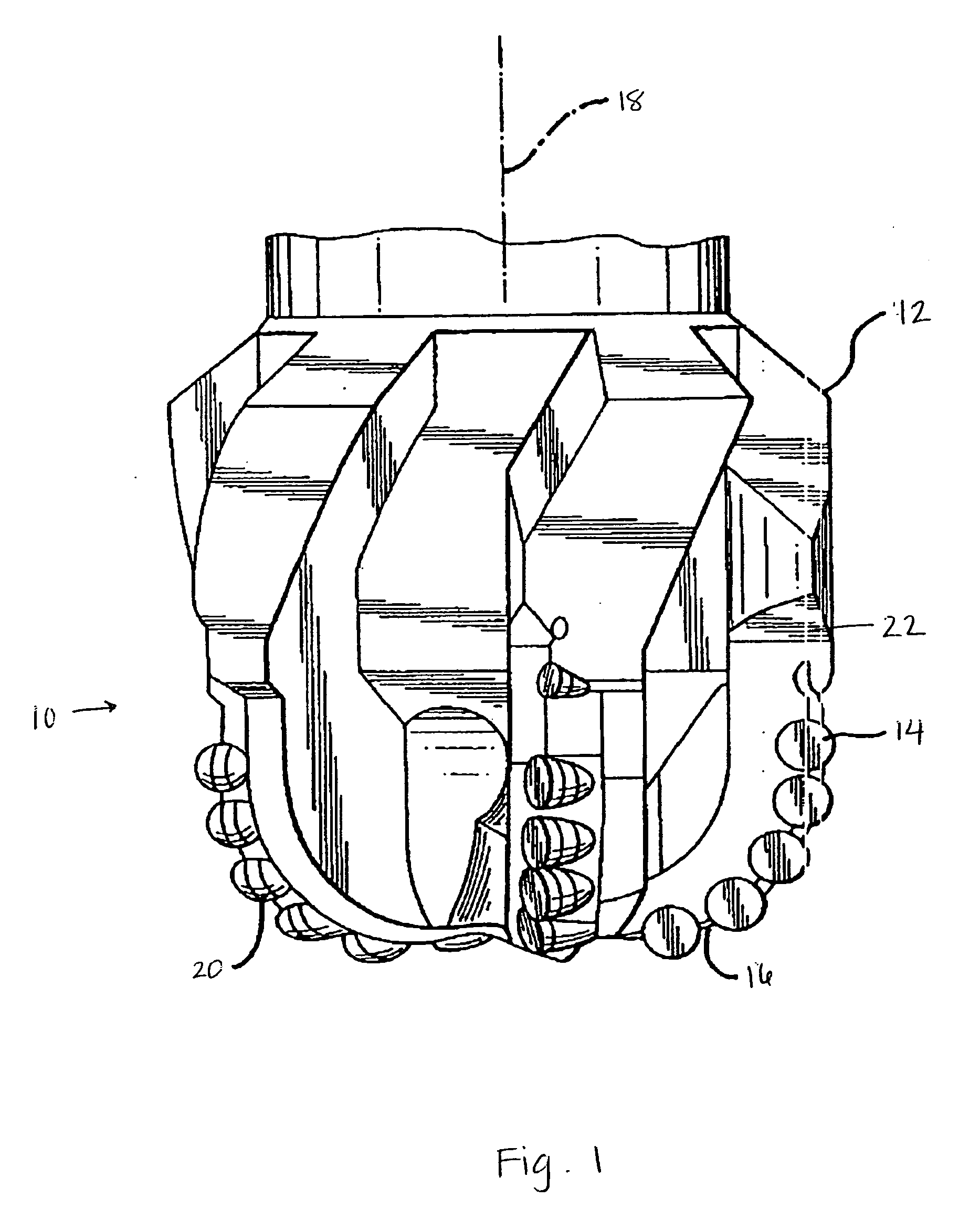

Layered hardfacing, durable hardfacing for drill bits

A drill bit having a bit body having at least one blade thereon, at least one cutter pocket disposed on the at least one blade, at least one cutter disposed in the at least one cutter pocket, hardfacing applied to at least a selected portion of the drill bit is shown and described. The hardfacing includes a first hardfacing layer disposed on the selected portion of the drill bit, a second hardfacing layer disposed on the first hardfacing layer, wherein the first hardfacing layer has a hardness different than a hardness of the second hardfacing layer.

Owner:SMITH INT INC

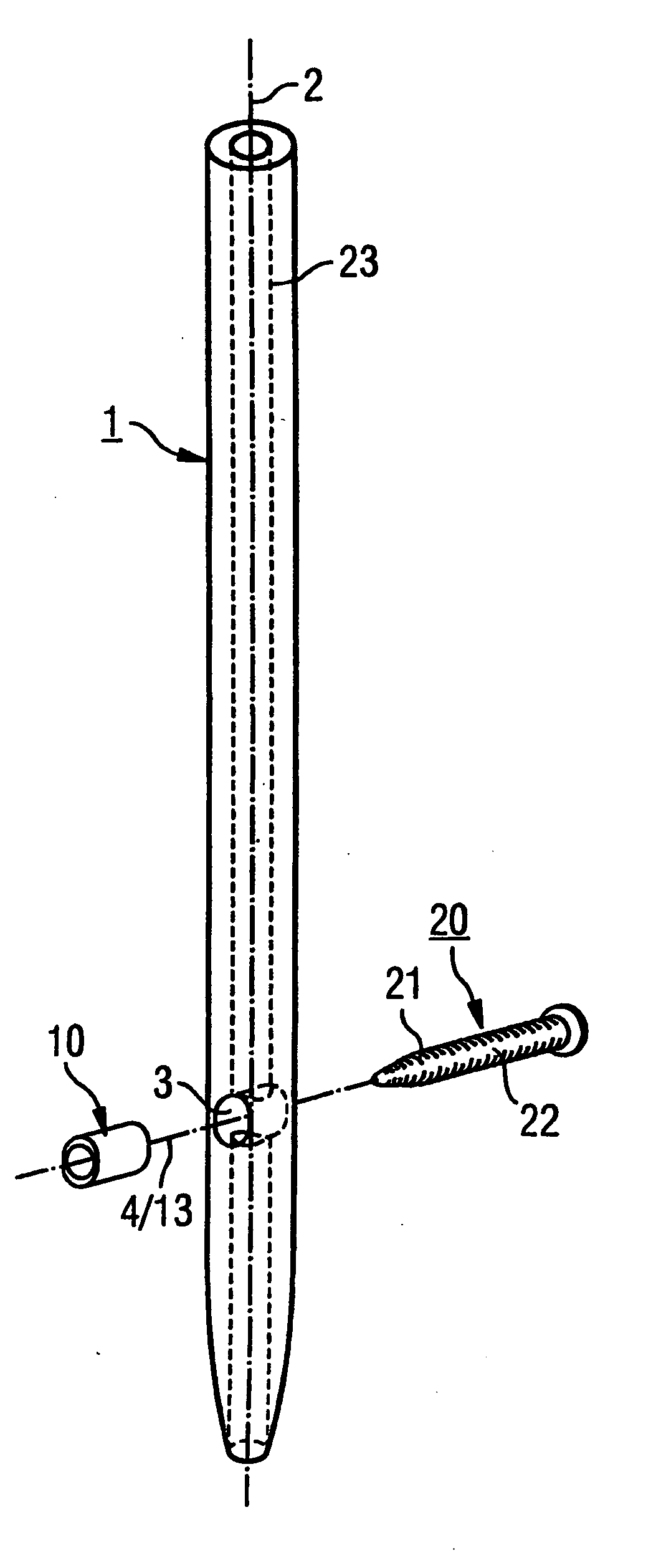

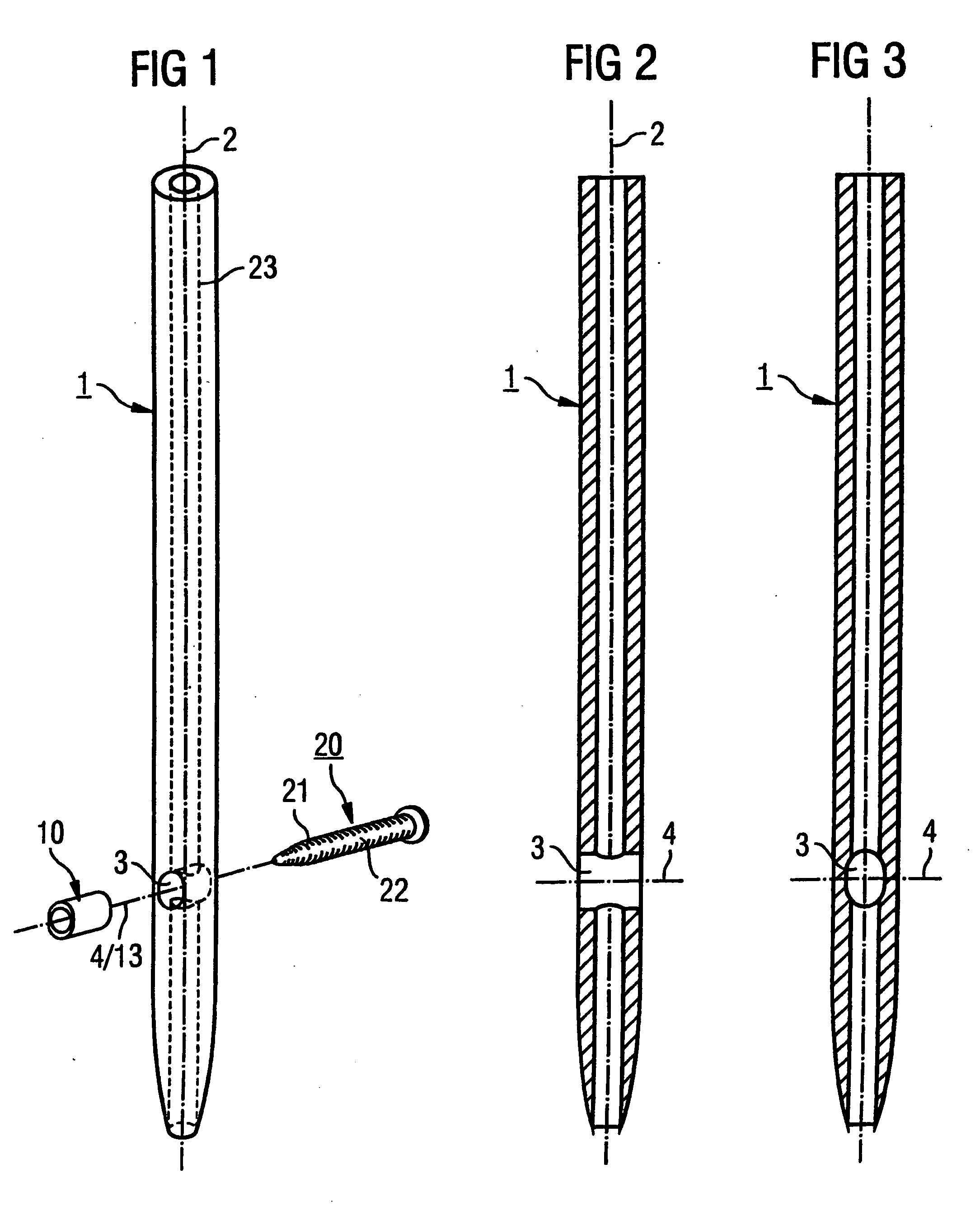

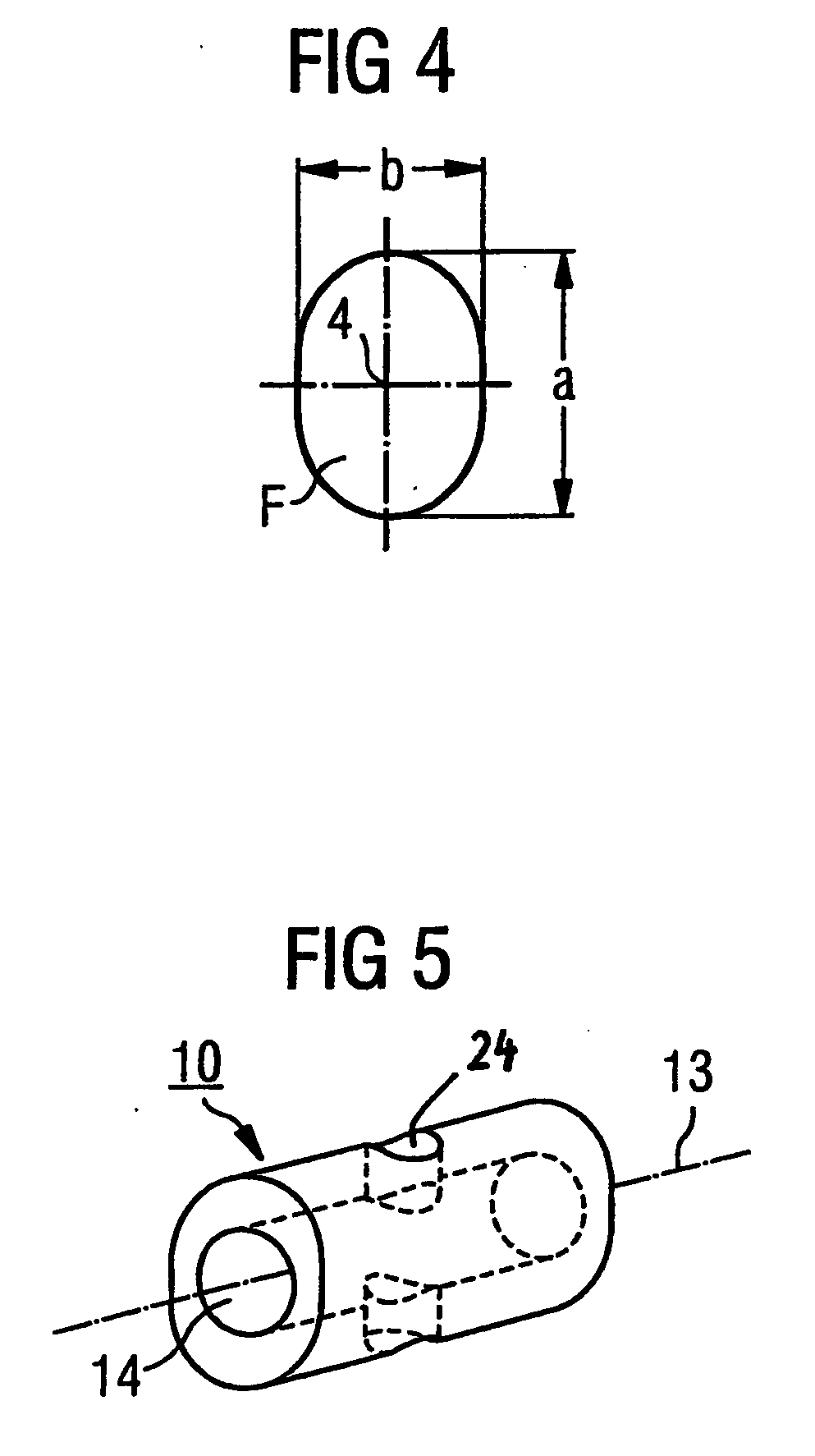

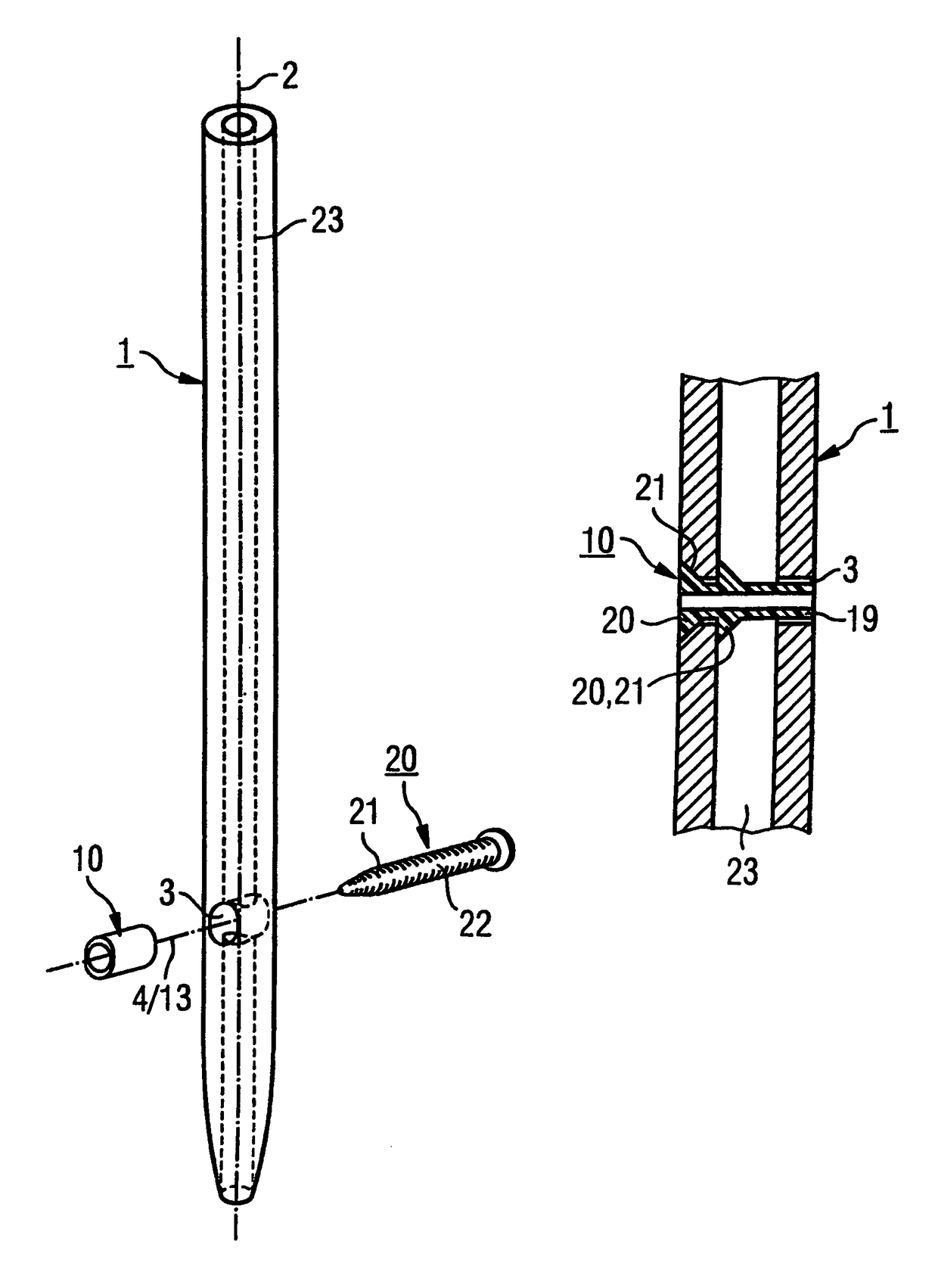

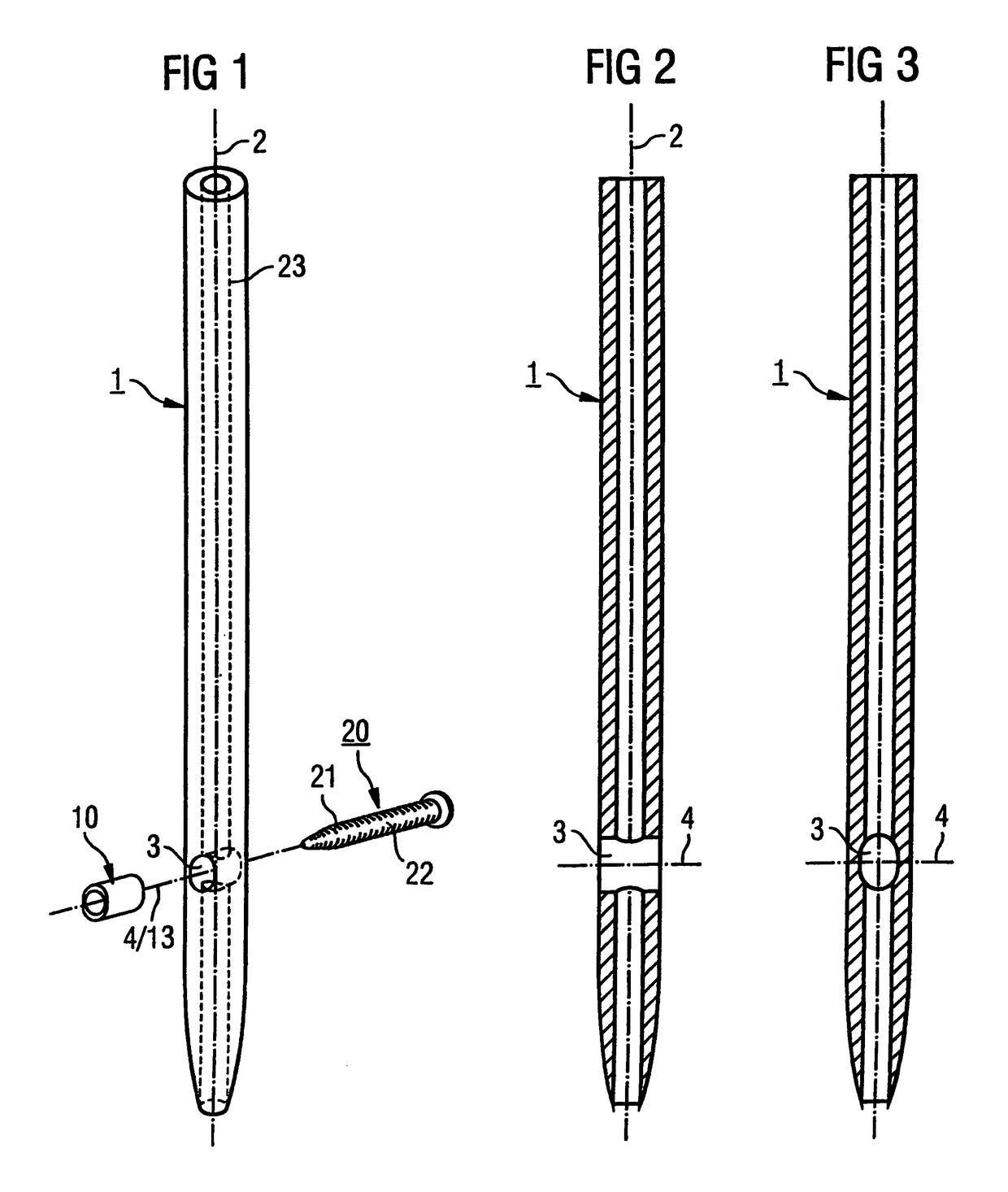

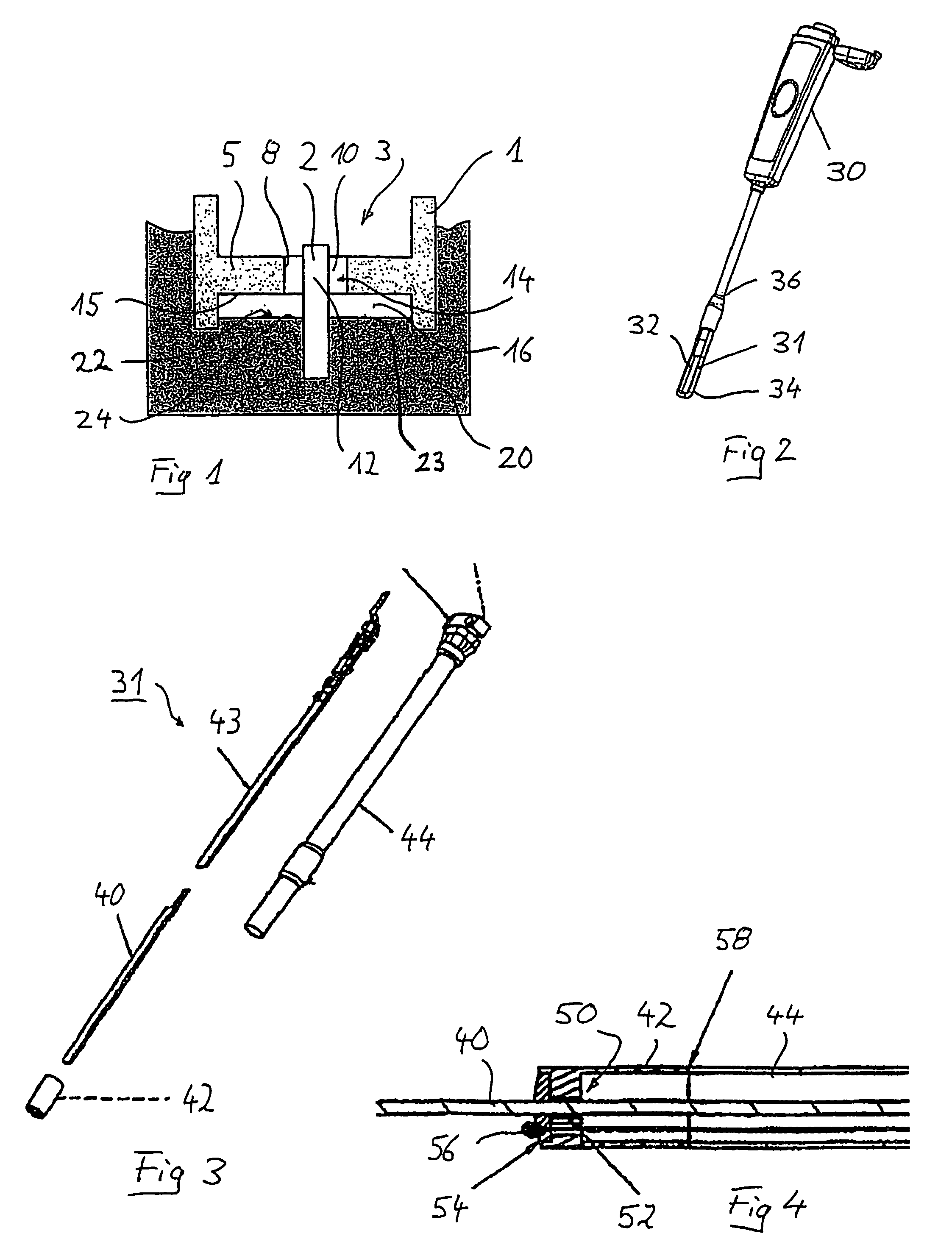

Surgical nail

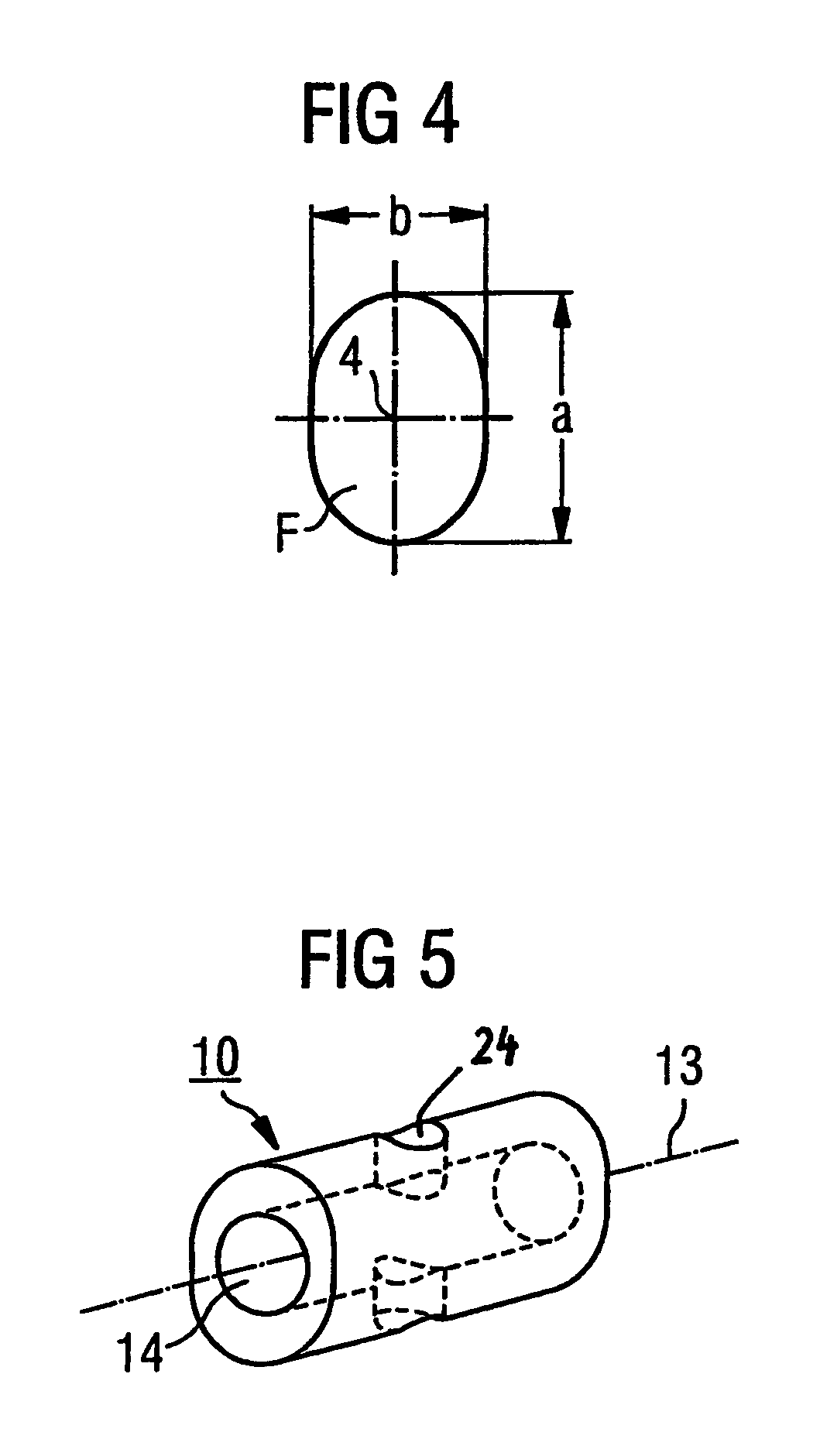

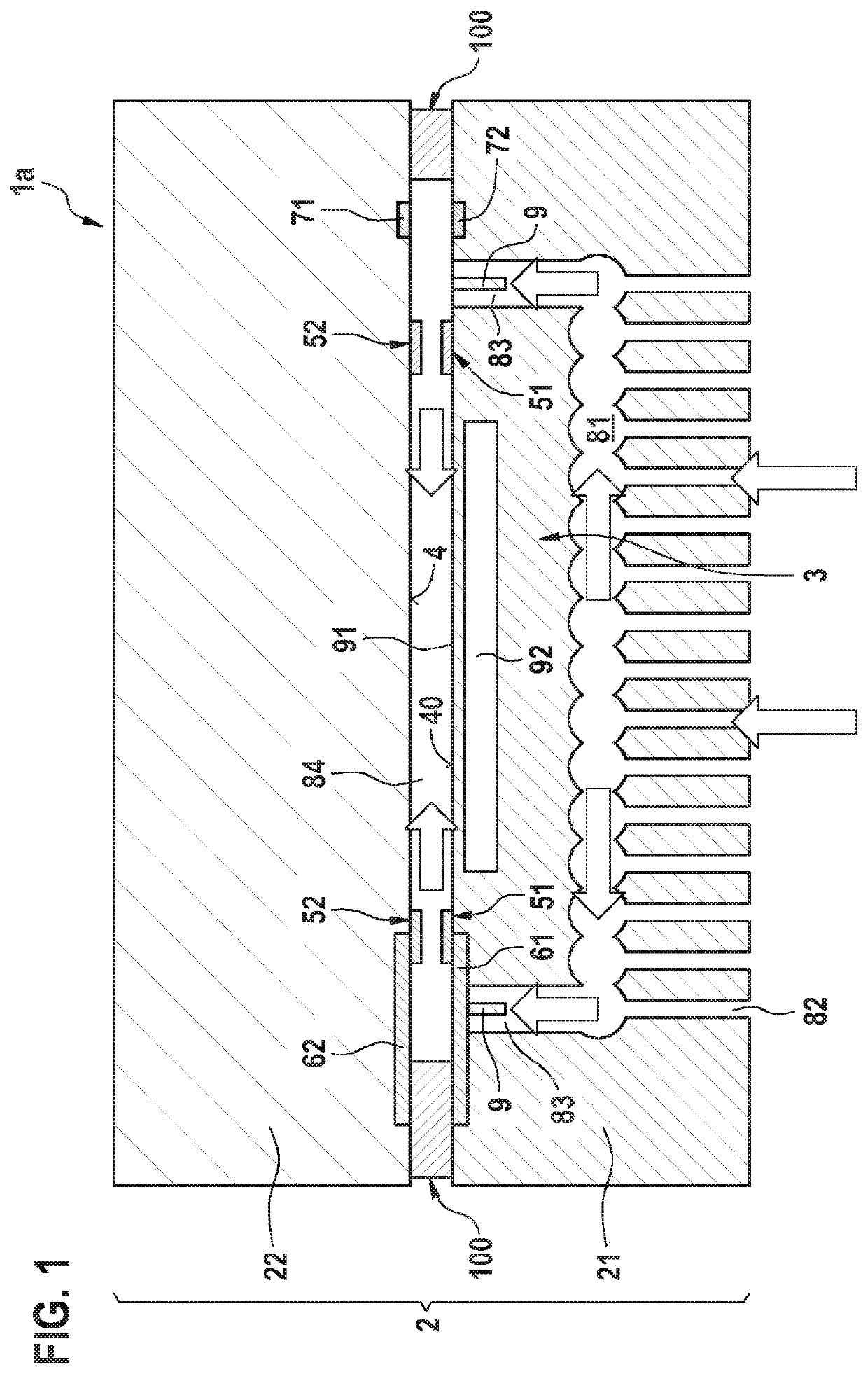

ActiveUS20060149248A1ClearanceImprove retentionInternal osteosythesisJoint implantsElastic modulusTransverse axis

The invention relates to a surgical nail in the form of an intramedullary nail with a central axis made from a material M with a tensile strength Fz, compressive strength Fd, density ρ2 and modulus of elasticity E. Said nail has a transverse bore extending transversely to the central axis and having a cross-sectional profile F and a transverse axis, the cross-sectional profile F having a maximum length a that runs in the direction of the central axis and a maximum width b that runs perpendicular to the length. An insert with the longitudinal axis, made from material m and having a modulus of elasticity e that is smaller than the modulus of elasticity E of material M, can be introduced into the transverse bore. The insert also has a length L that runs in the direction of its longitudinal axis and satisfies the condition L>0.2 D.

Owner:DEPUY SYNTHES PROD INC

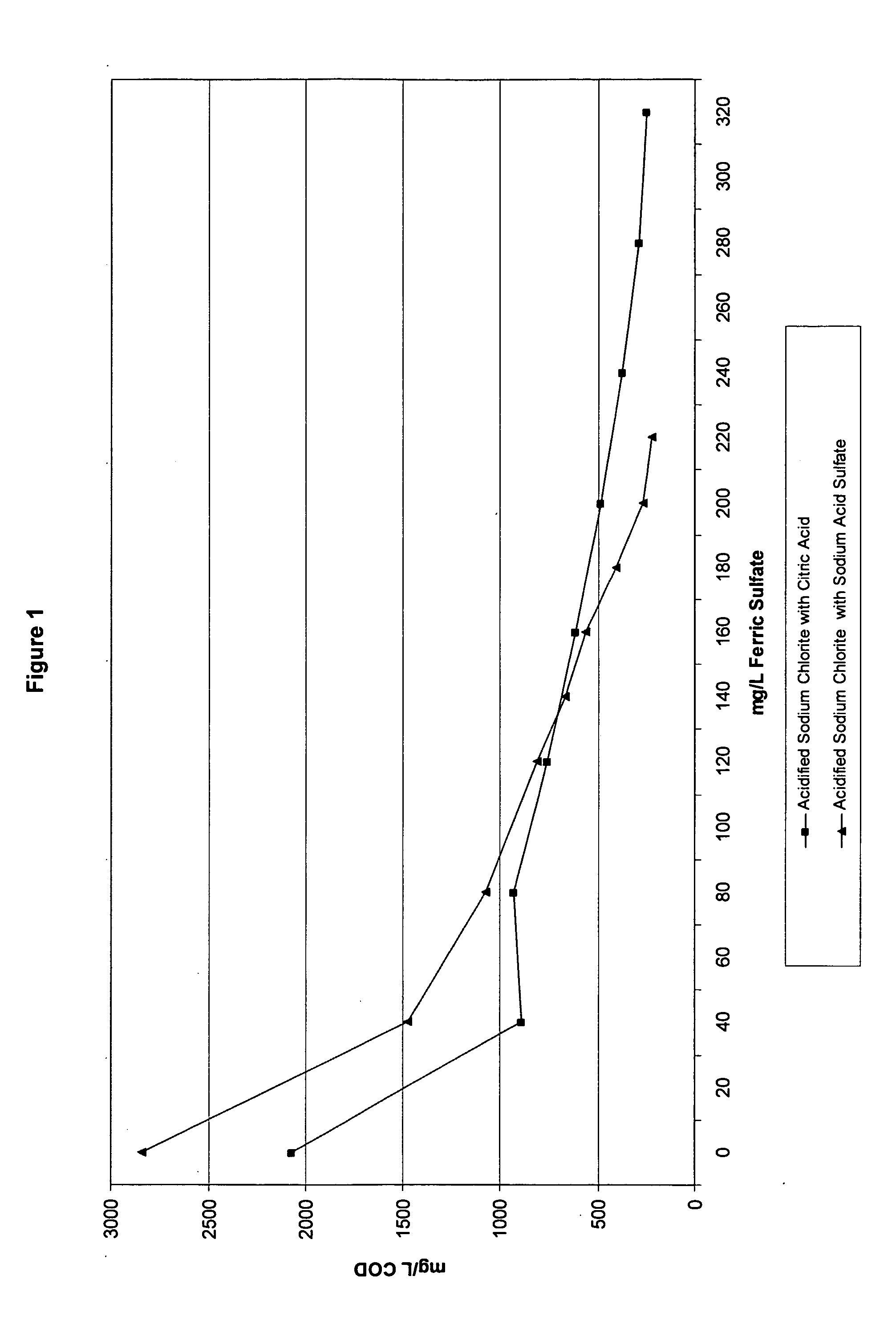

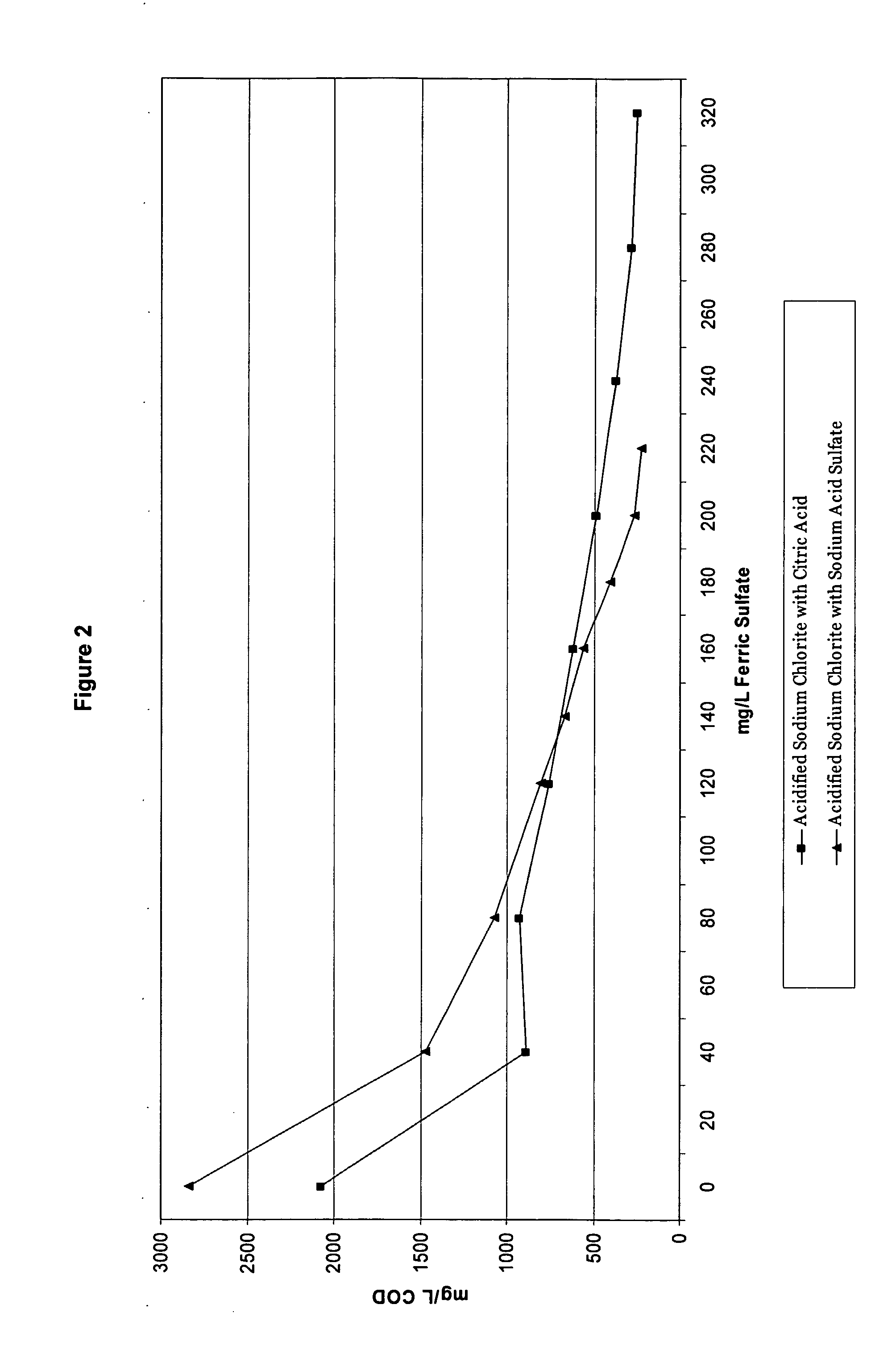

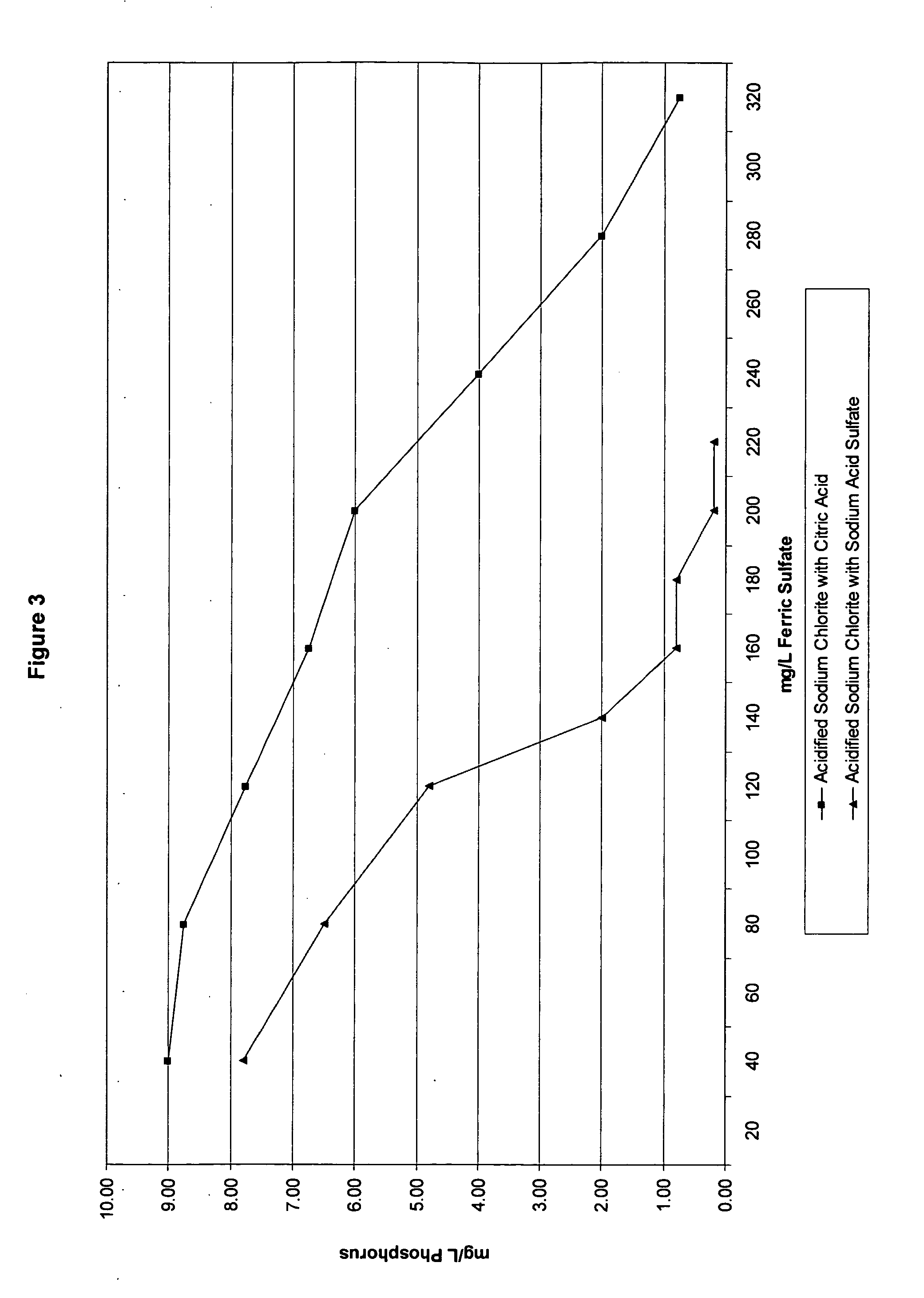

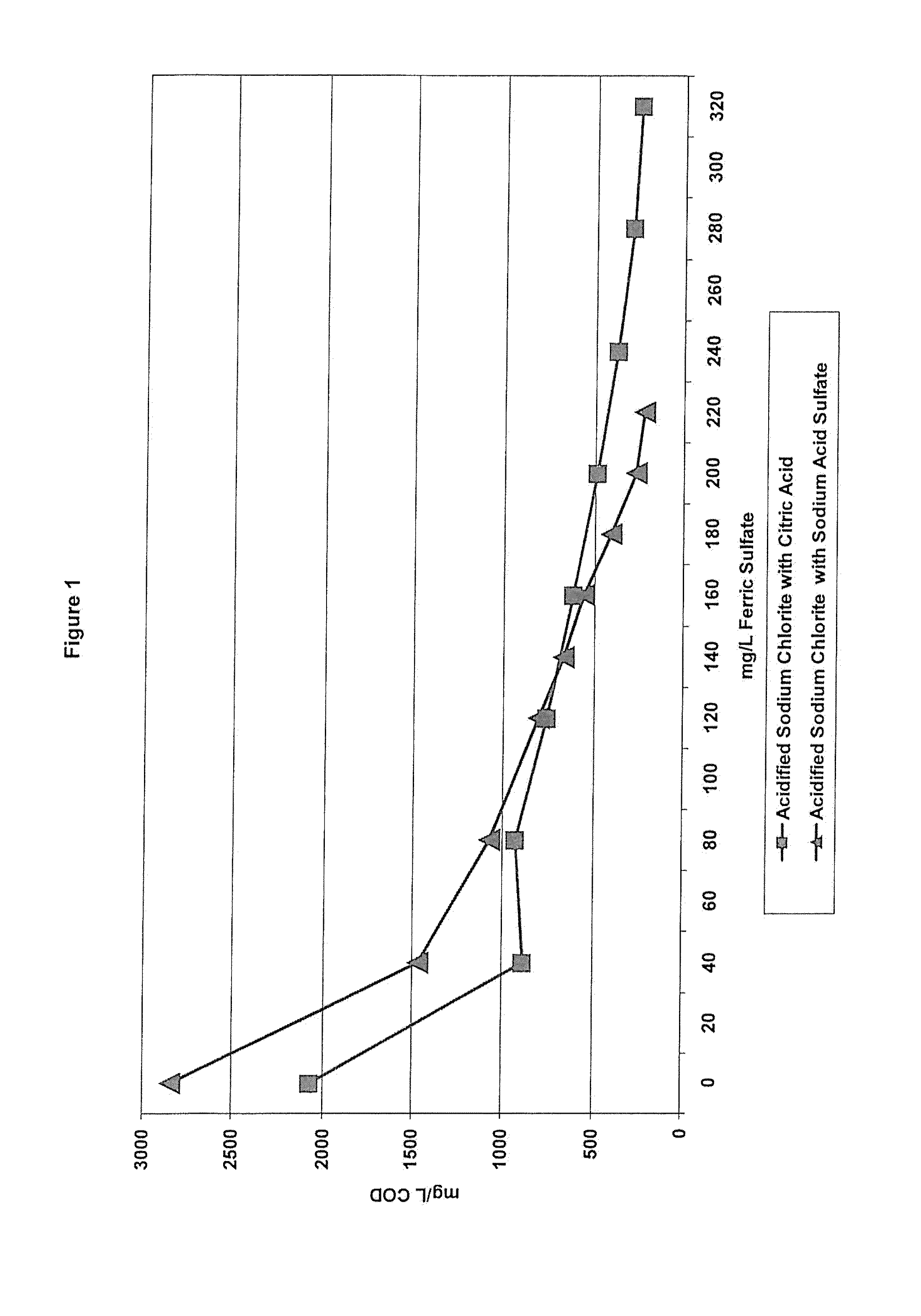

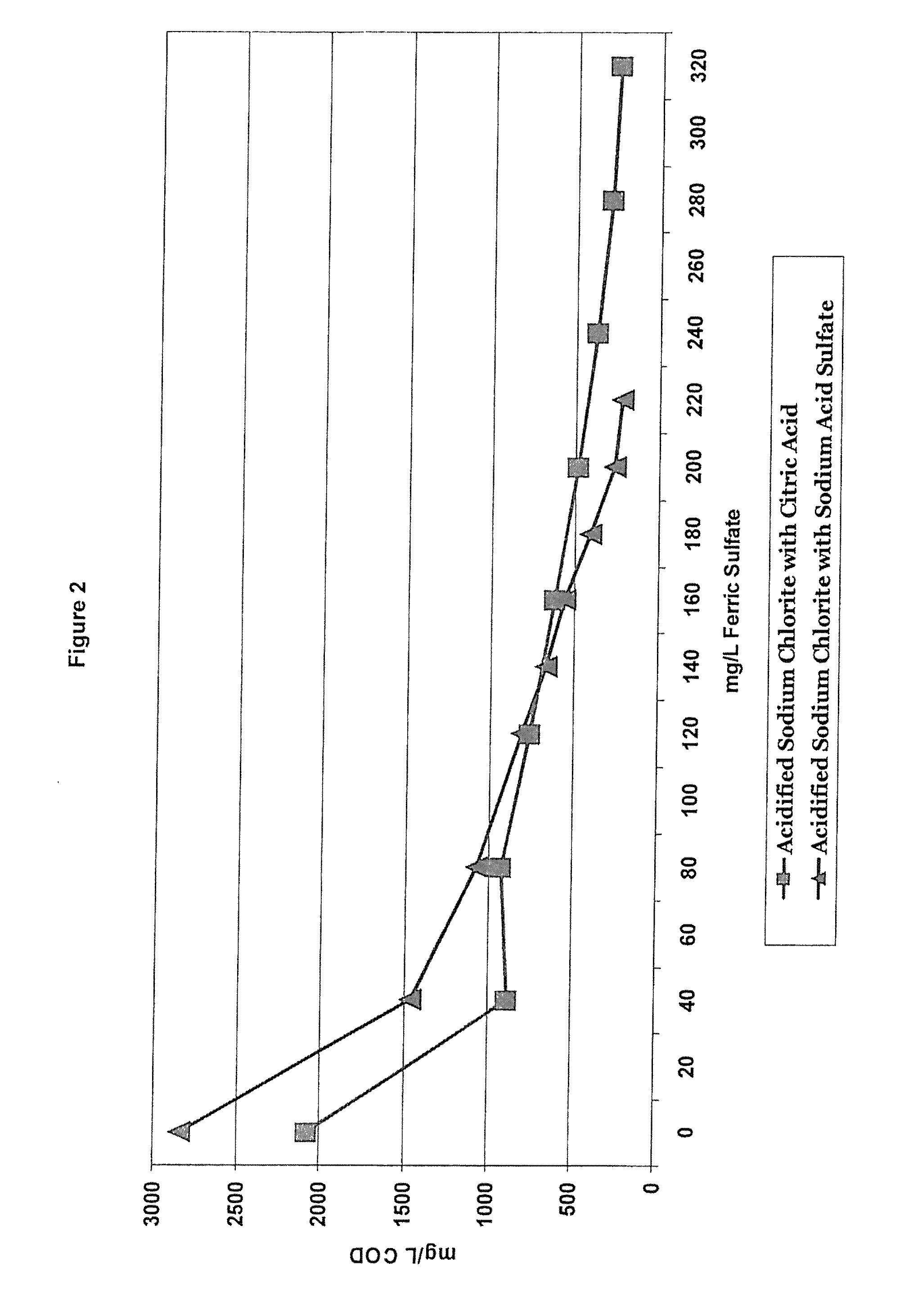

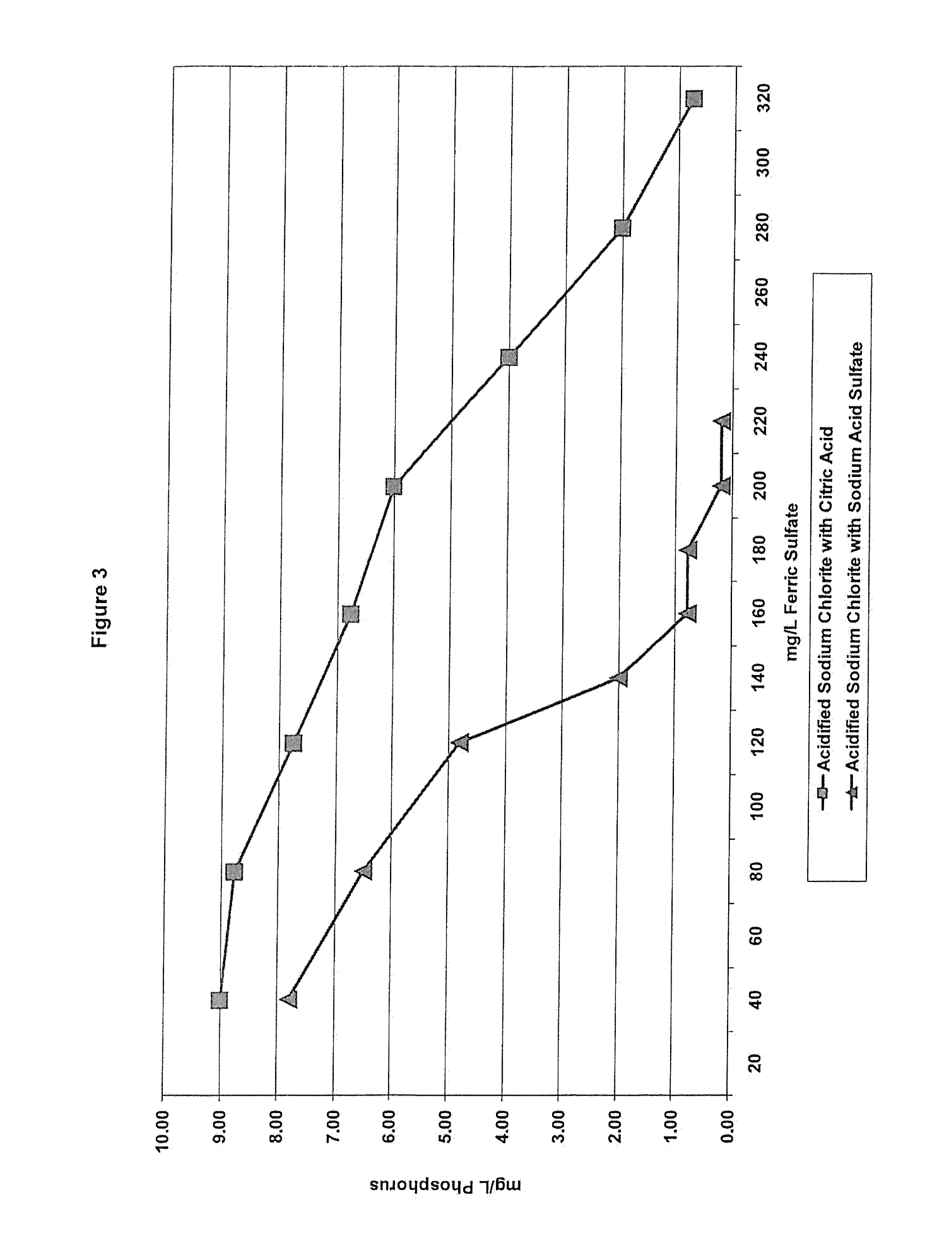

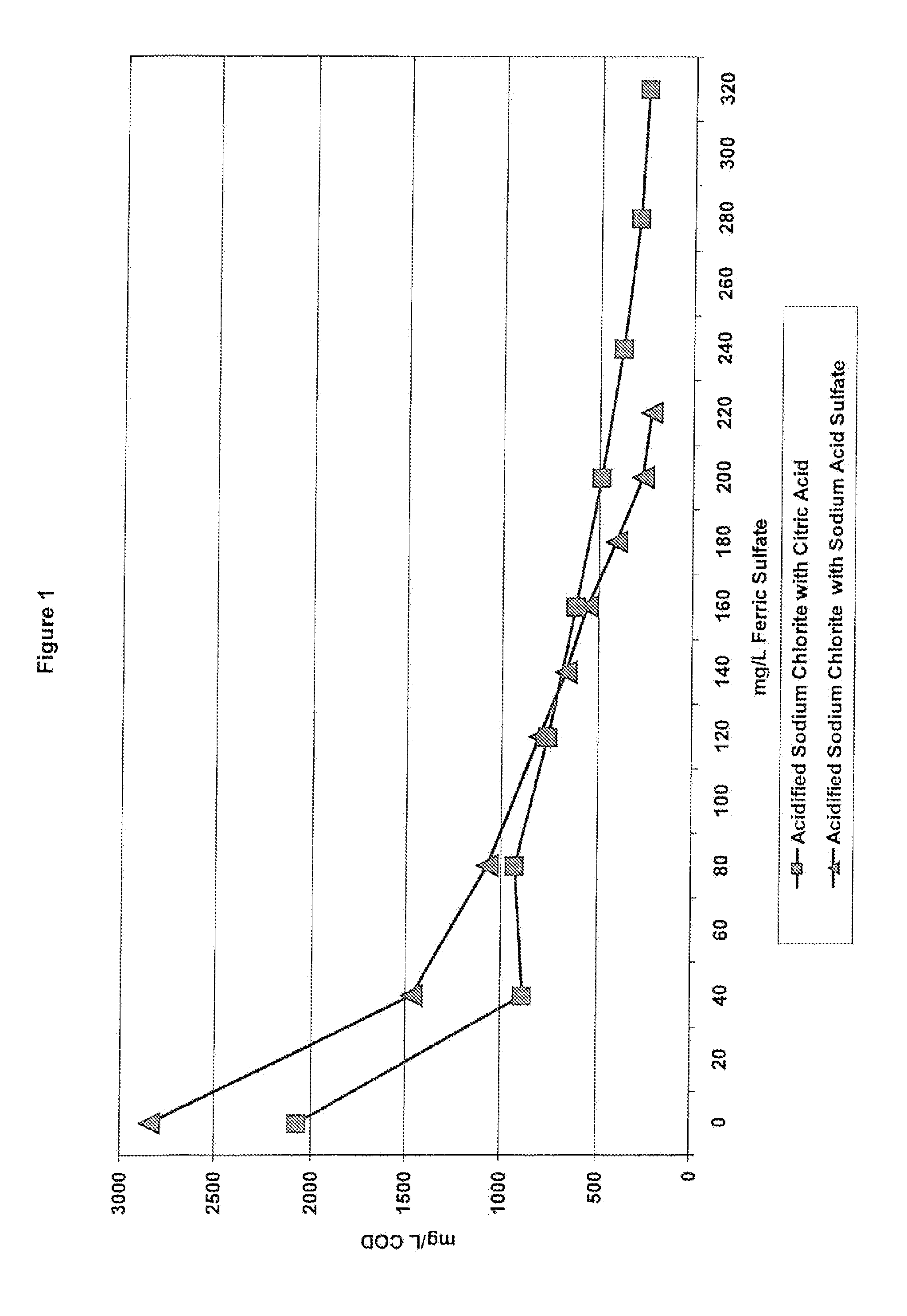

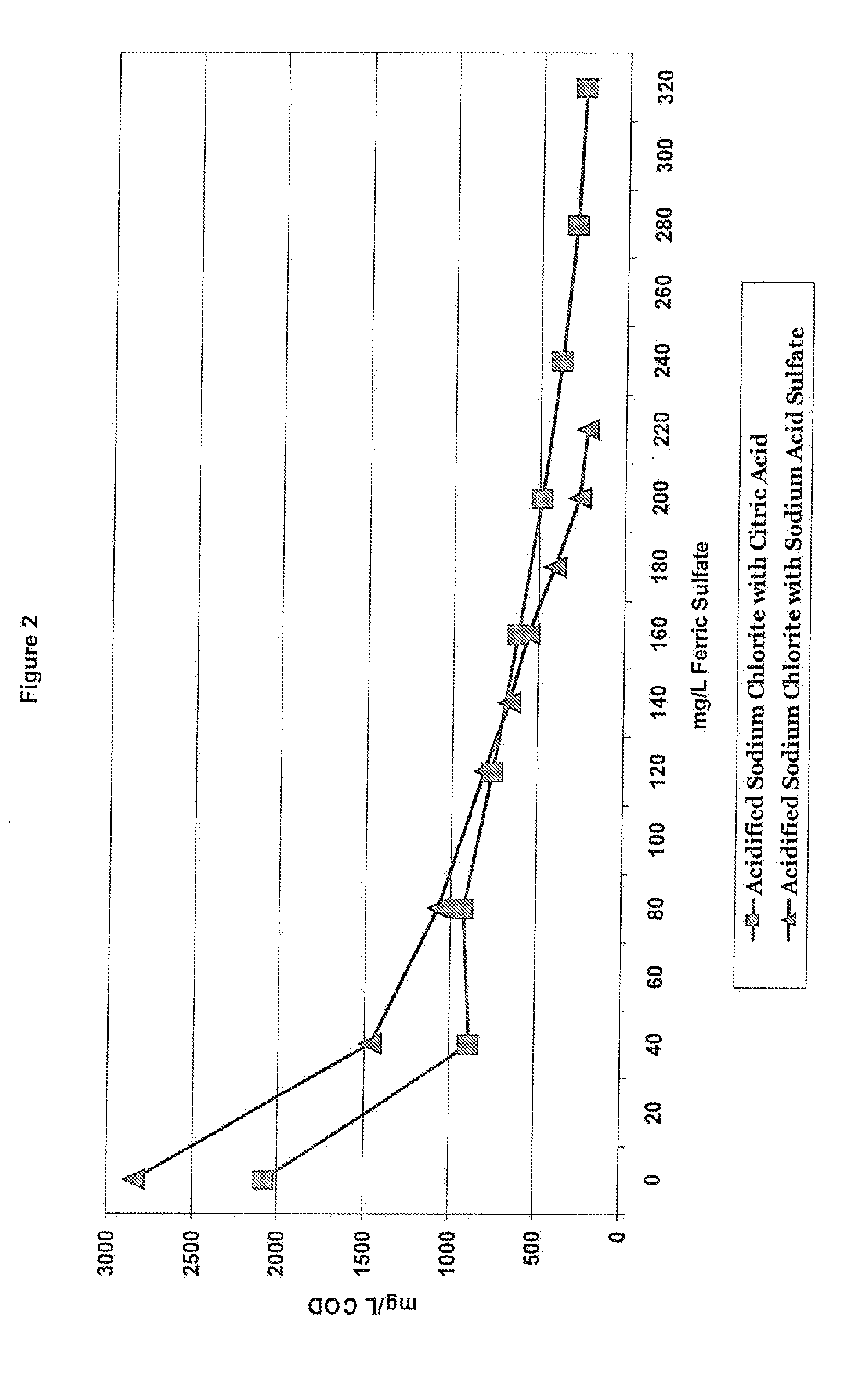

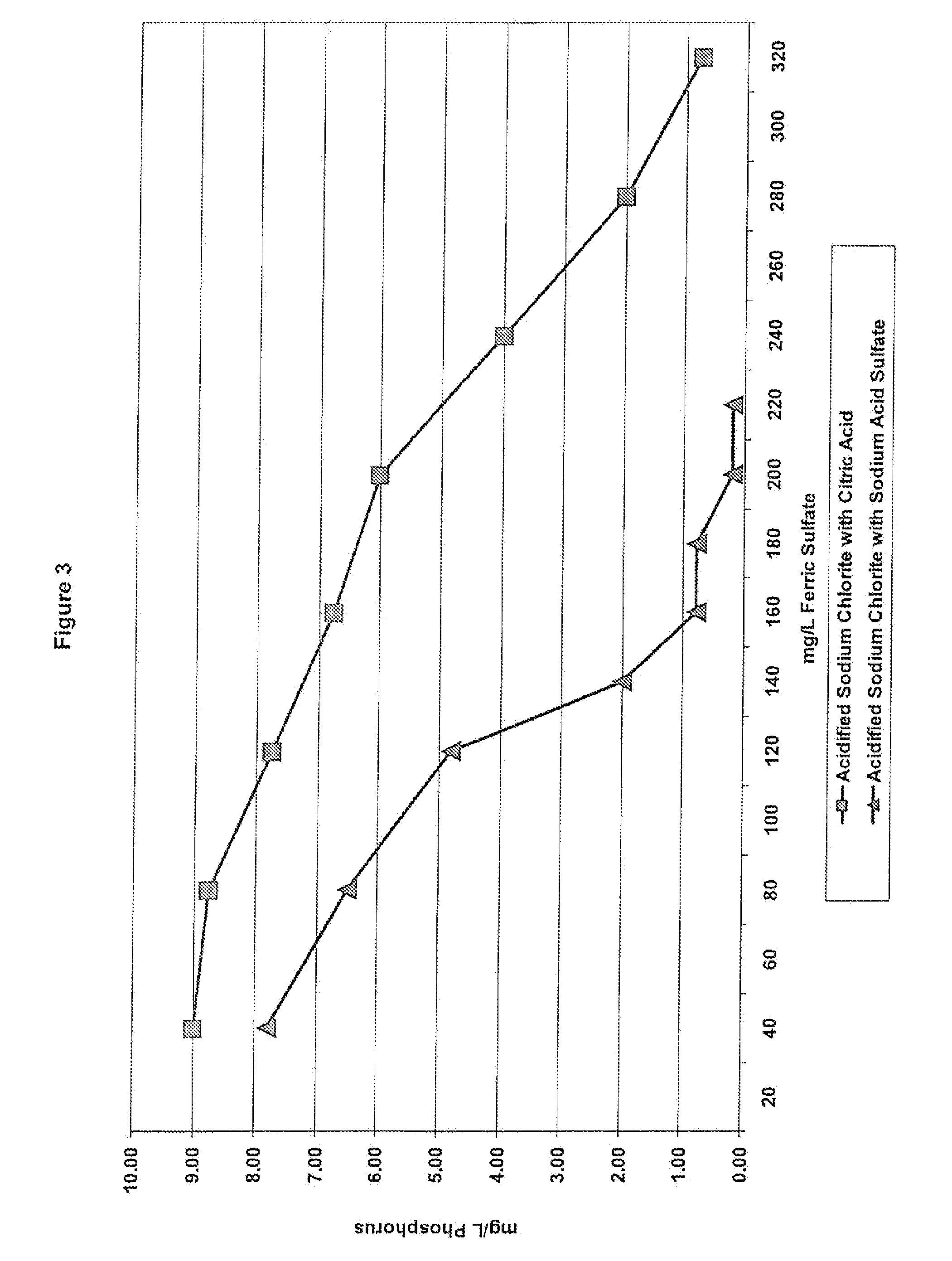

Oxidation method and compositions therefor

InactiveUS20070042094A1Great range of controlIncrease flexibilityBiocideMilk preservationSulfateSodium sulfate

The present invention generally relates to an improved two-part oxidizing system, as well as oxidizing compositions and methods for making and using the same, and in a particular embodiment to a two-part oxidizing system that, when mixed, yields an oxidizing composition. The two-part oxidizing system includes a metal chlorite first part, and an acid second part where the acid is sodium acid sulfate or a derivative thereof.

Owner:ALCIDE CORP

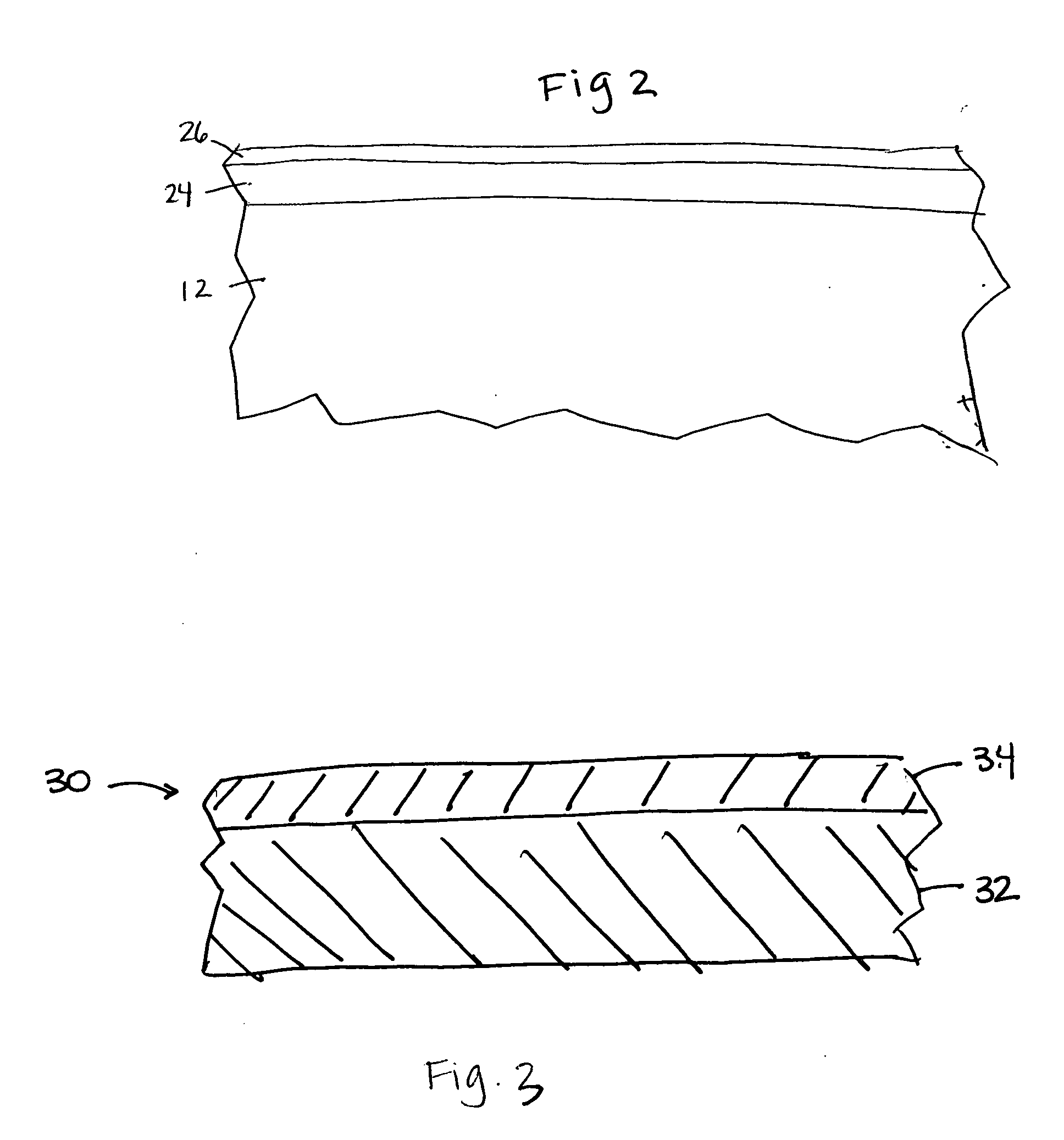

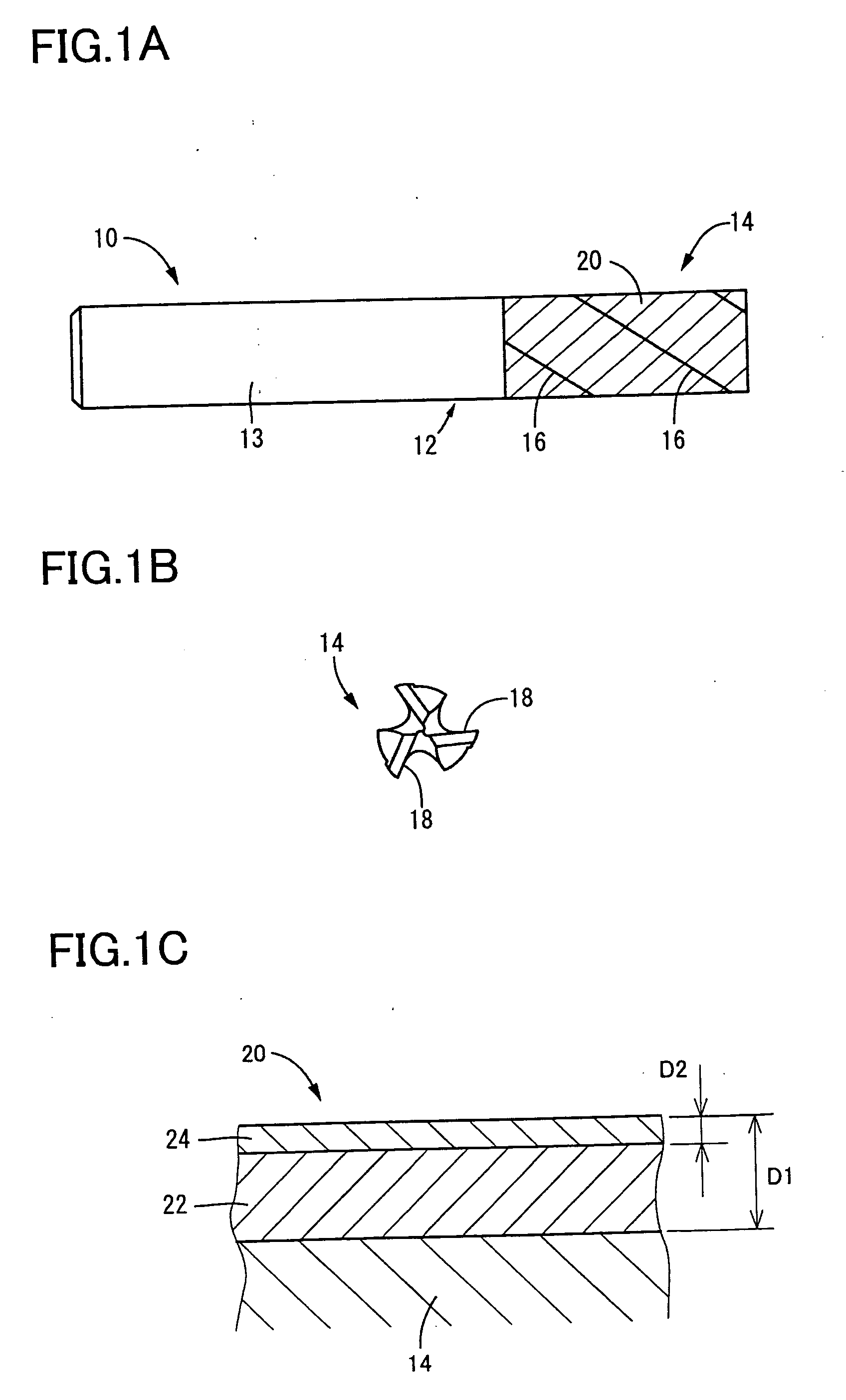

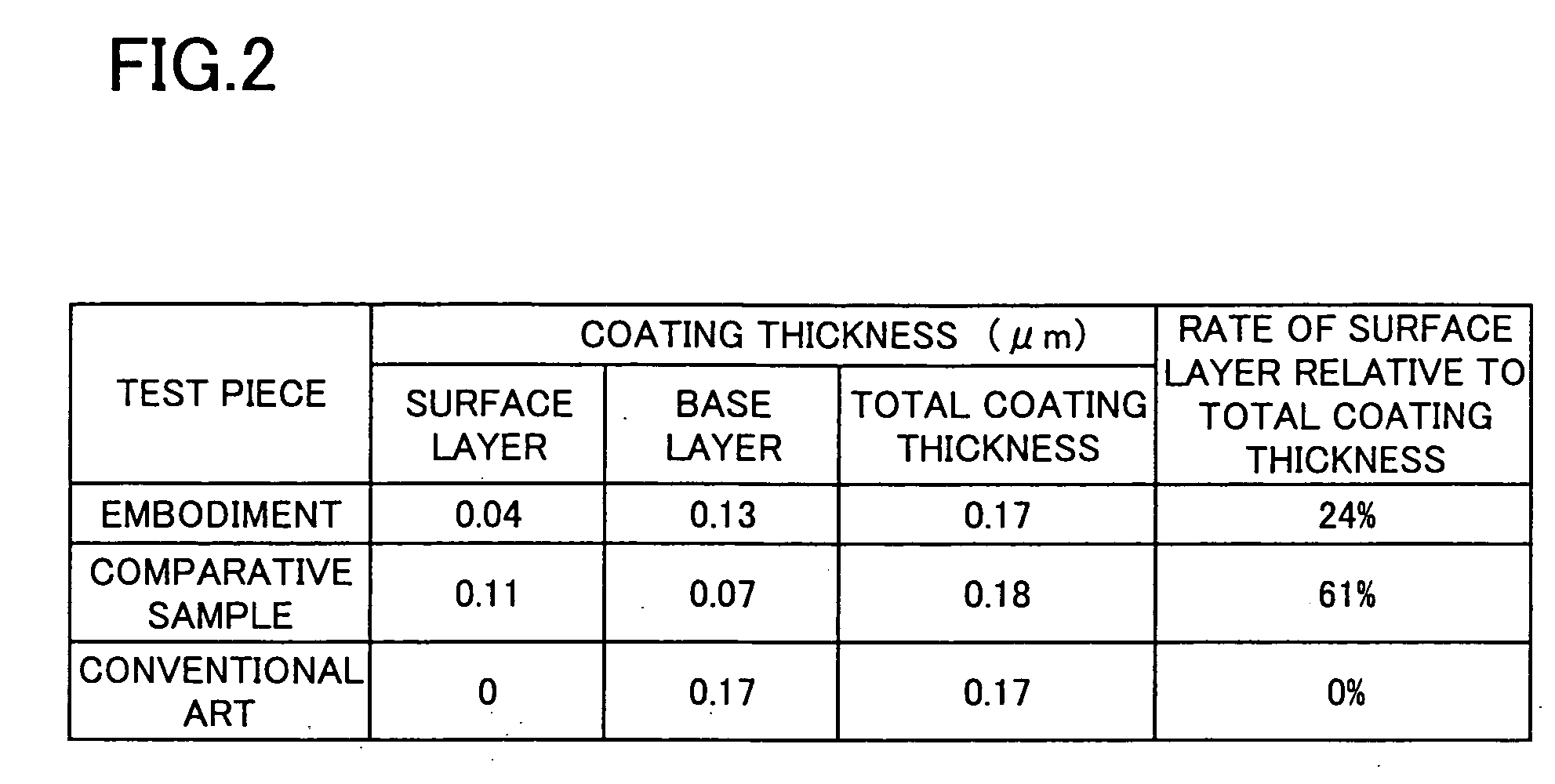

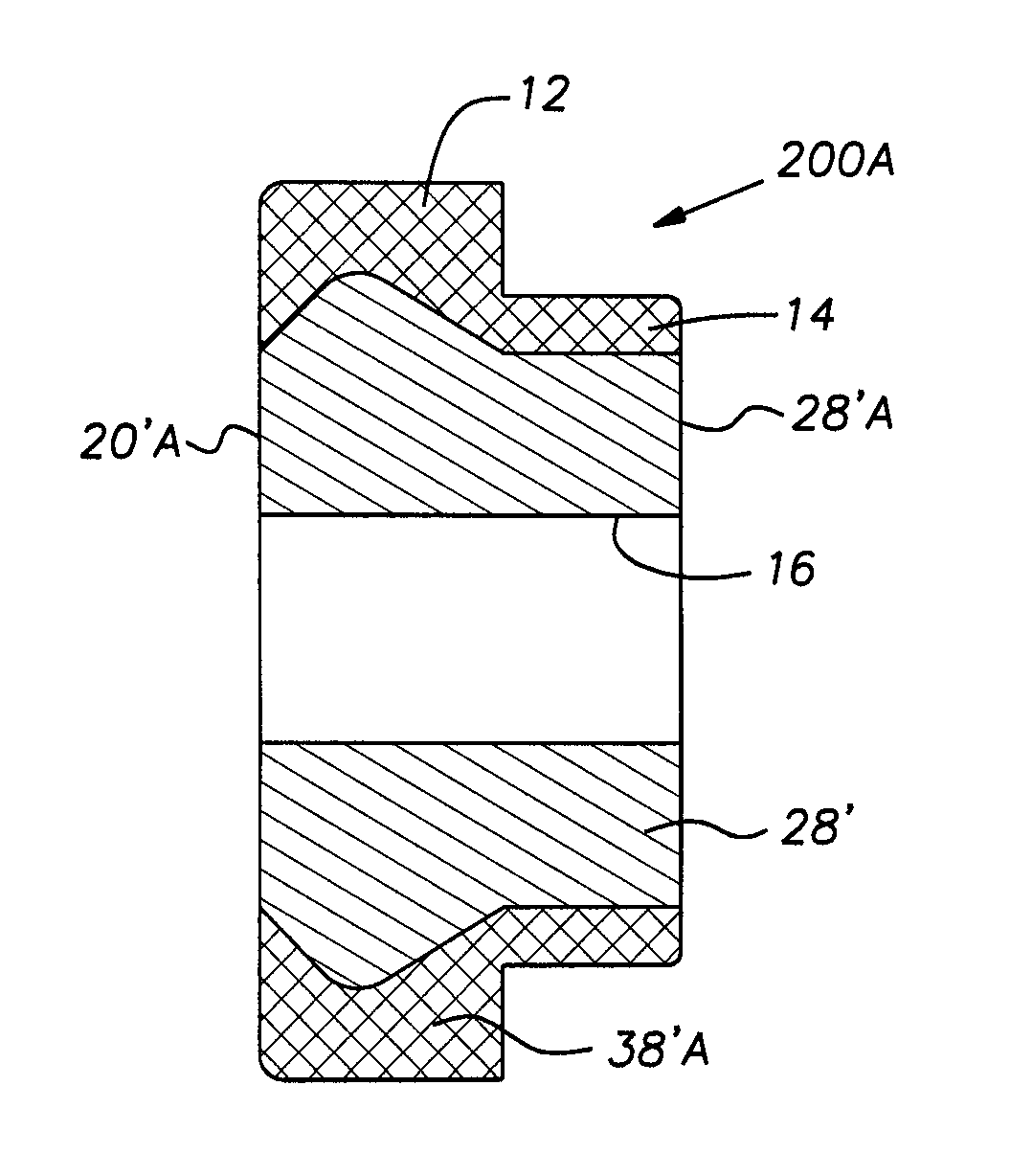

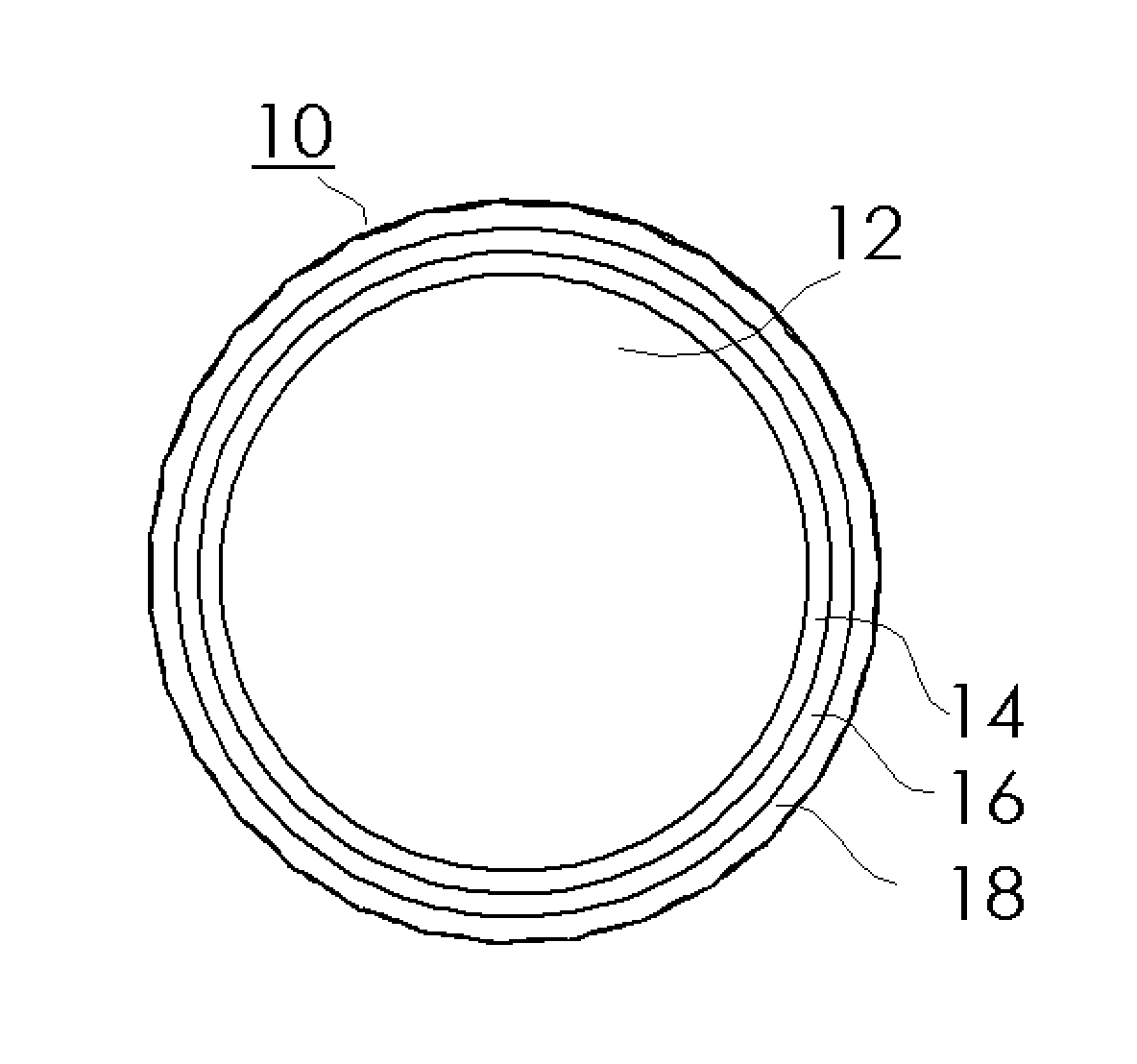

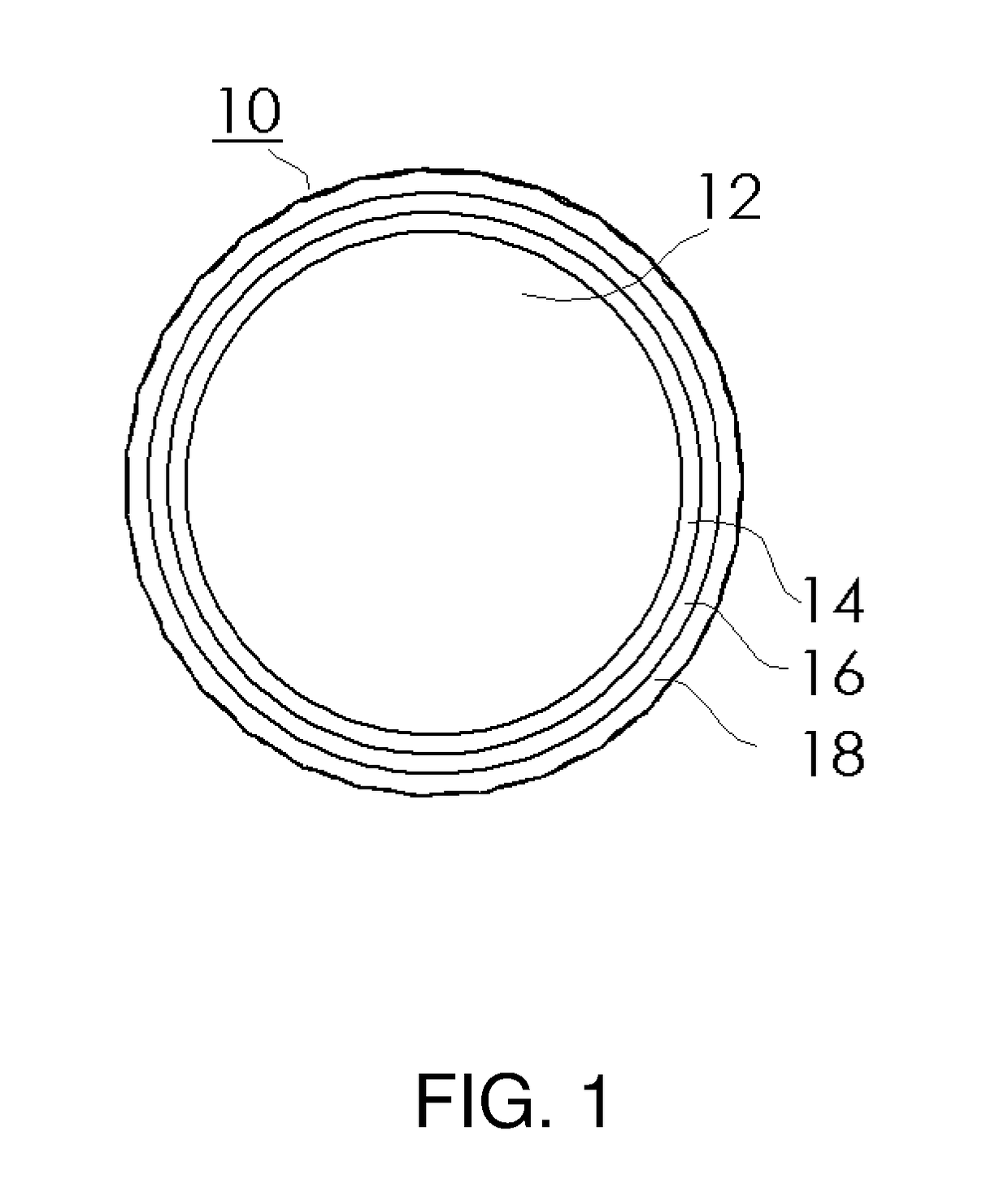

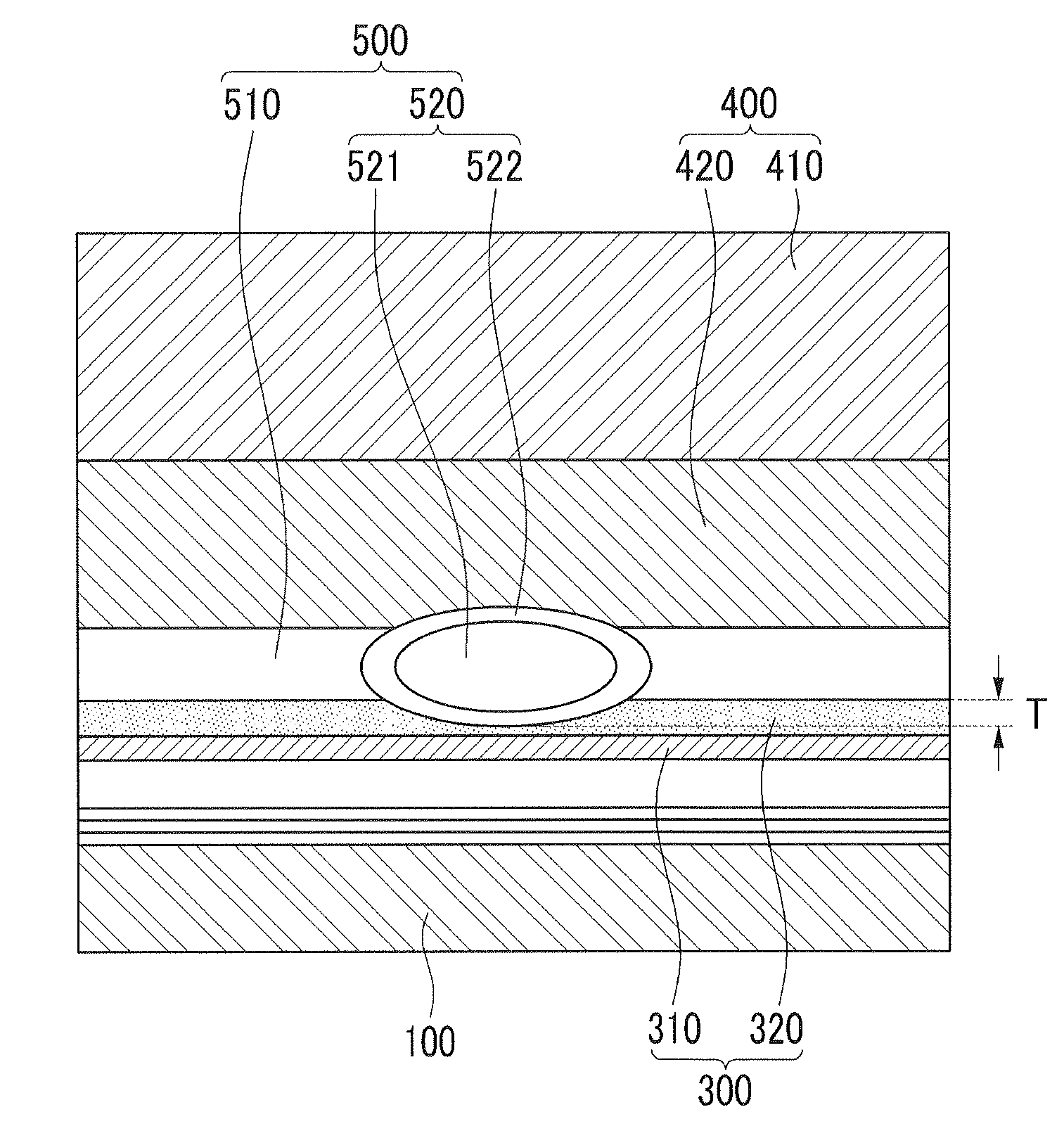

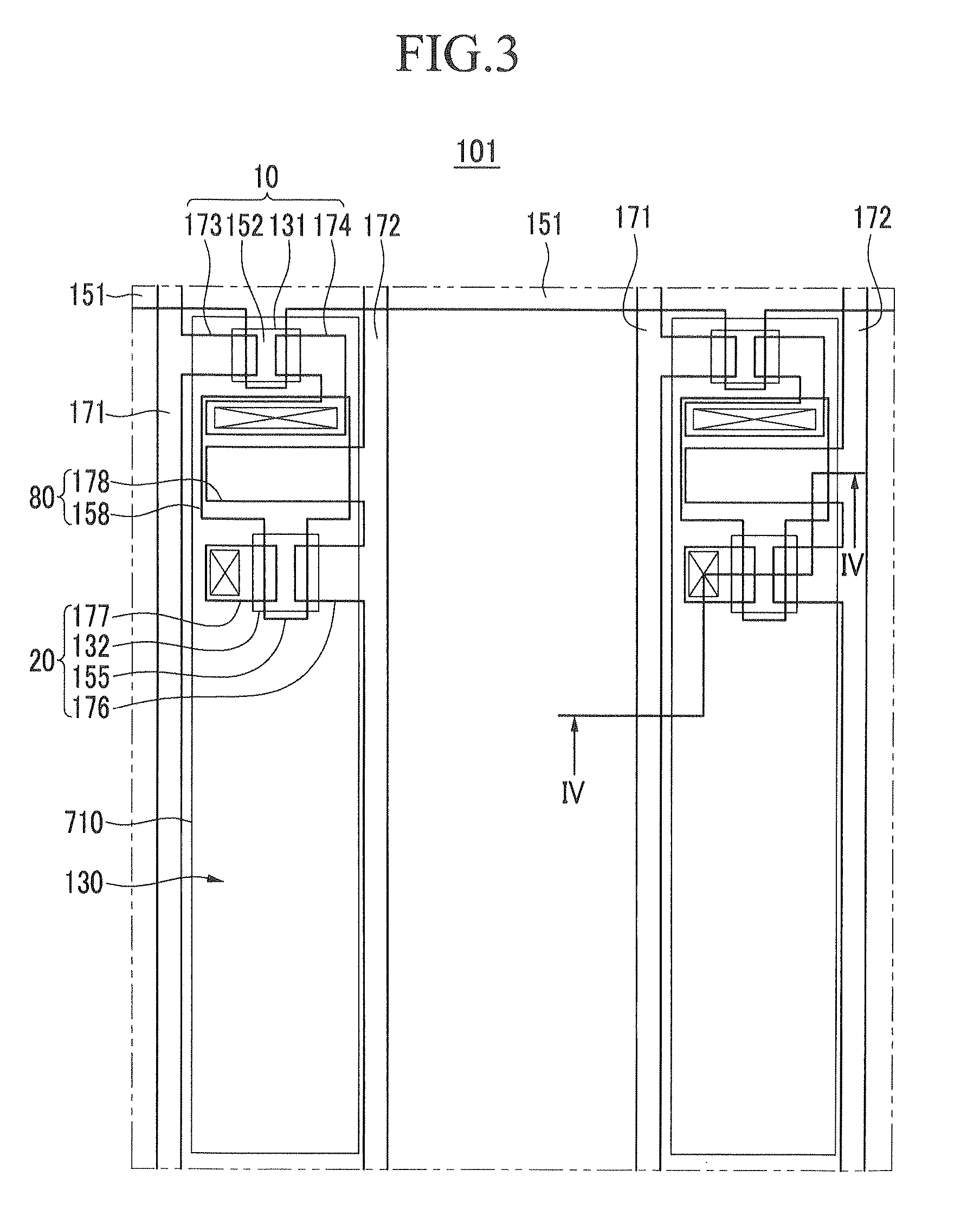

DLC coating, and DLC coating coated tool

InactiveUS20070104953A1Satisfactory lifetimeAvoid excessive hardnessLayered productsMilling cuttersDlc coatingHydrogen

A DLC coating (20) coating a surface of a predetermined member (12) comprises a base layer (22) not containing hydrogen substantially, and a hydrogen containing layer (24) containing hydrogen ranging from 2 atom % to 20 atom %. The base layer (22) and the hydrogen containing layer (24) disposed thereon constitute a two-layer structure.

Owner:OSG

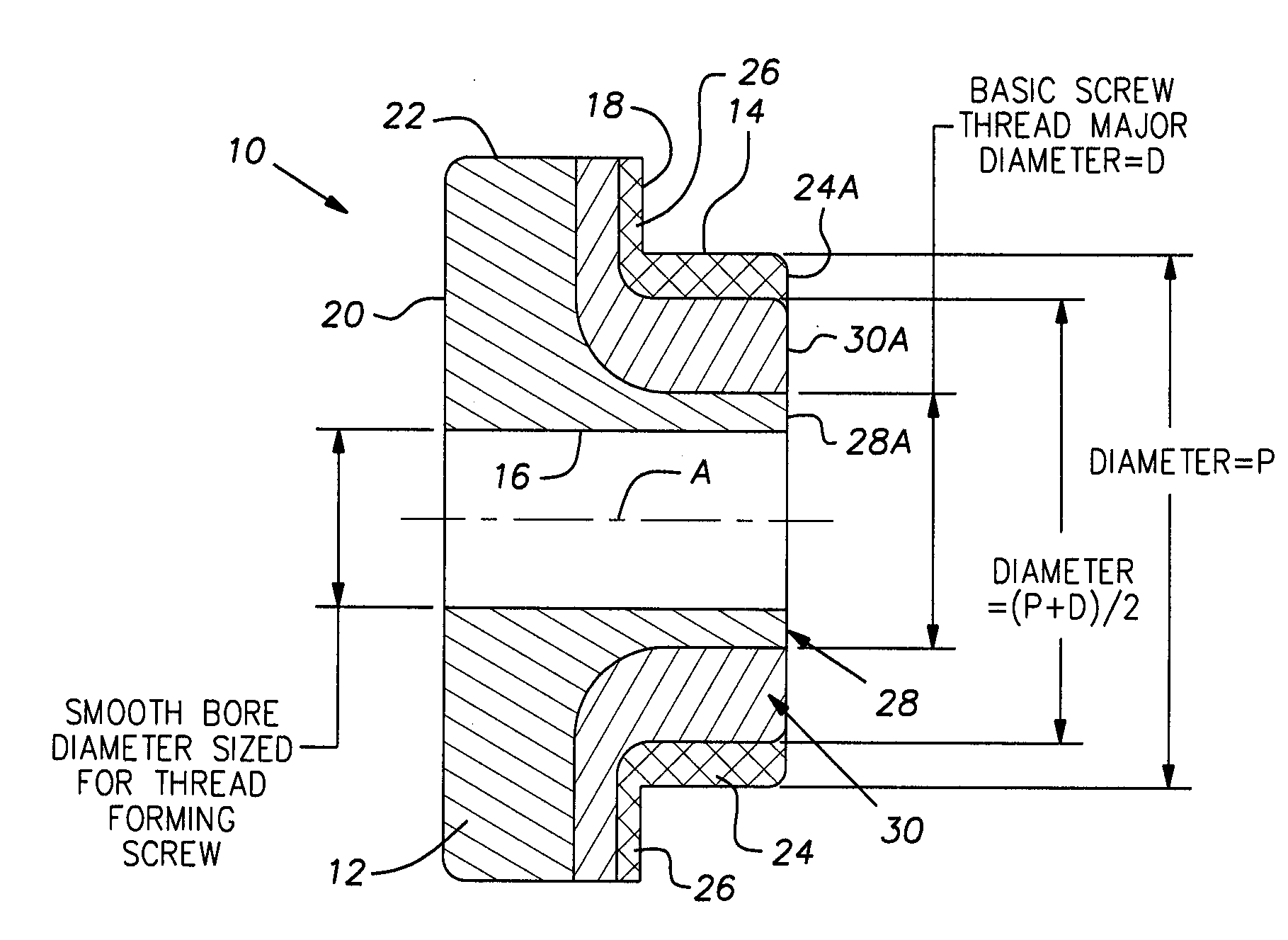

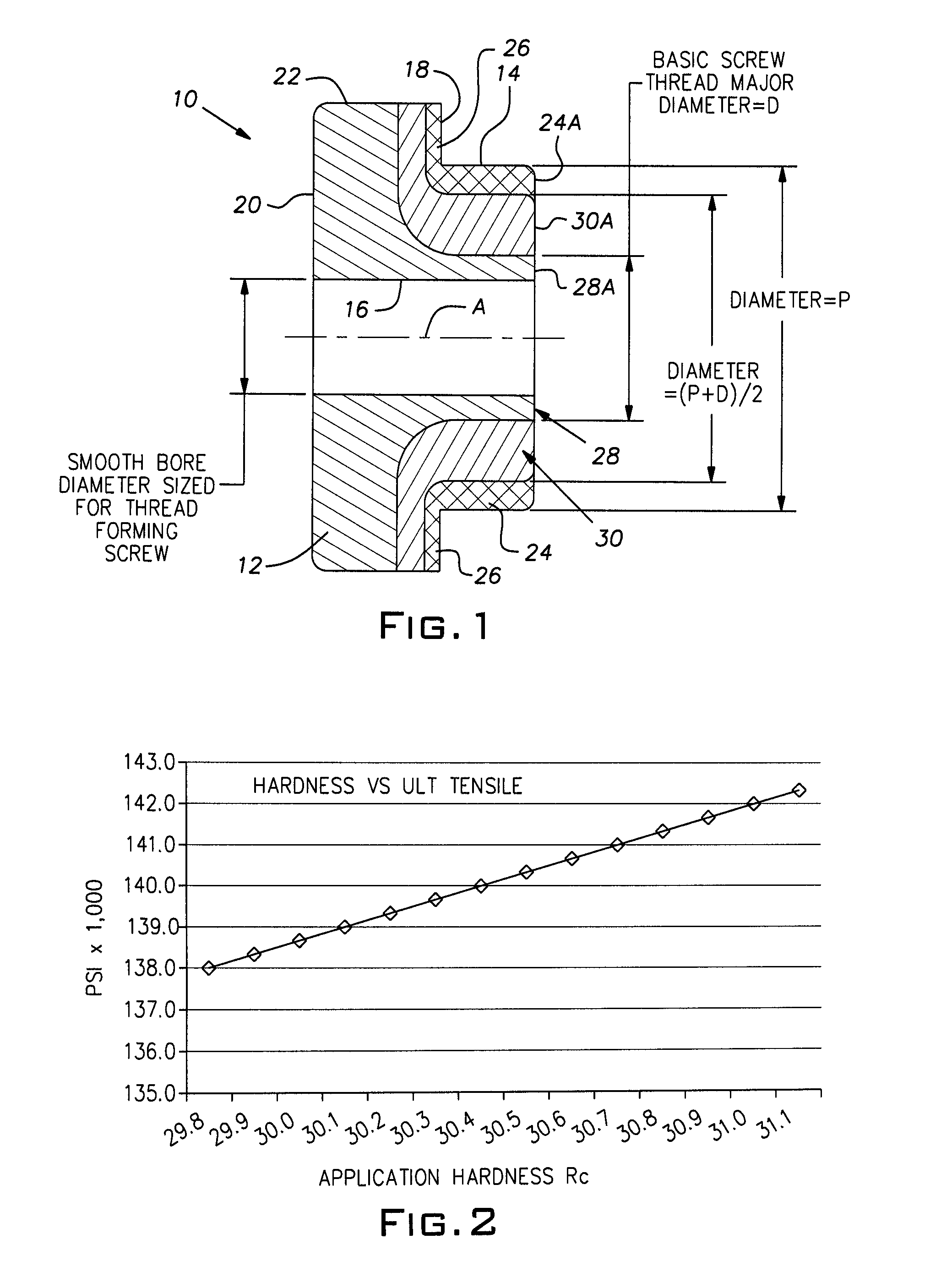

Clinch nut

A metal clinch fastener has portions thereof selectively hardened to enable use of the fastener with metal members of differing hardness values. The selective hardening of the fastener enables mounting with application of required forces for piercing and / or plastic deformation of the metal member without undesirable deformation or distortion of the fastener. The screw thread region or zone of the fastener has a relatively lesser hardness suitable and may be pre-threaded or later threaded by engagement with a thread forming screw.

Owner:R B & W MFG

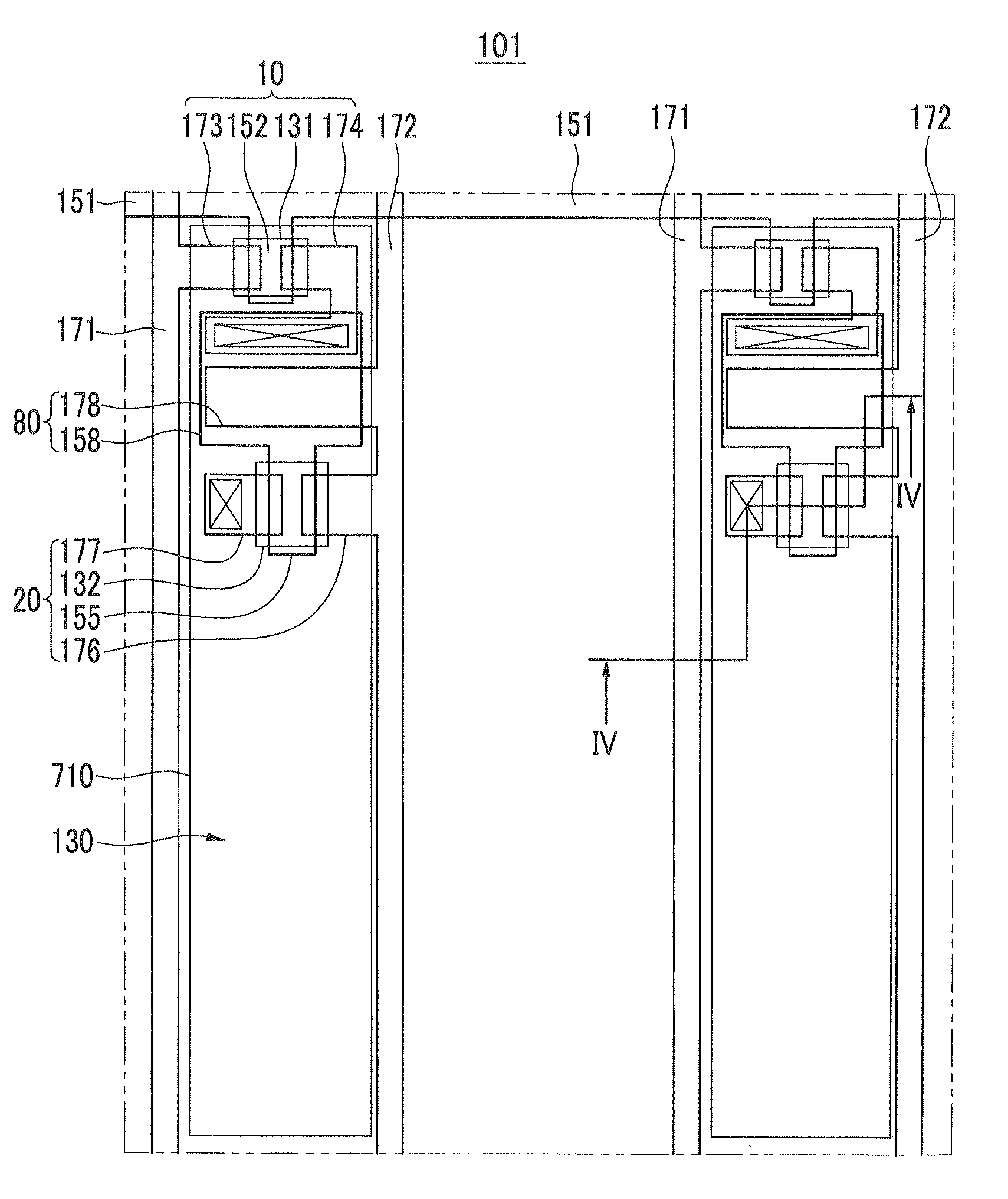

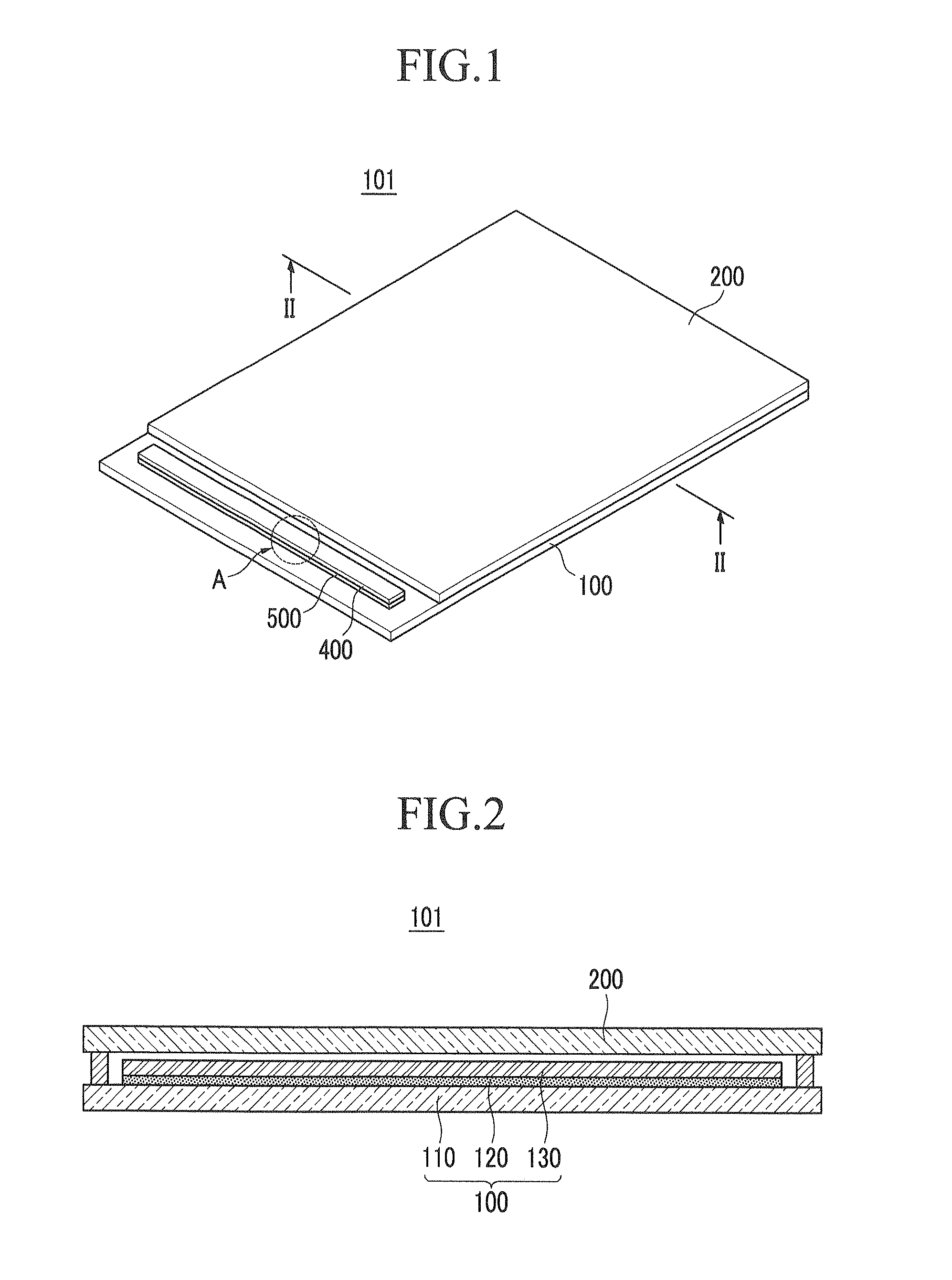

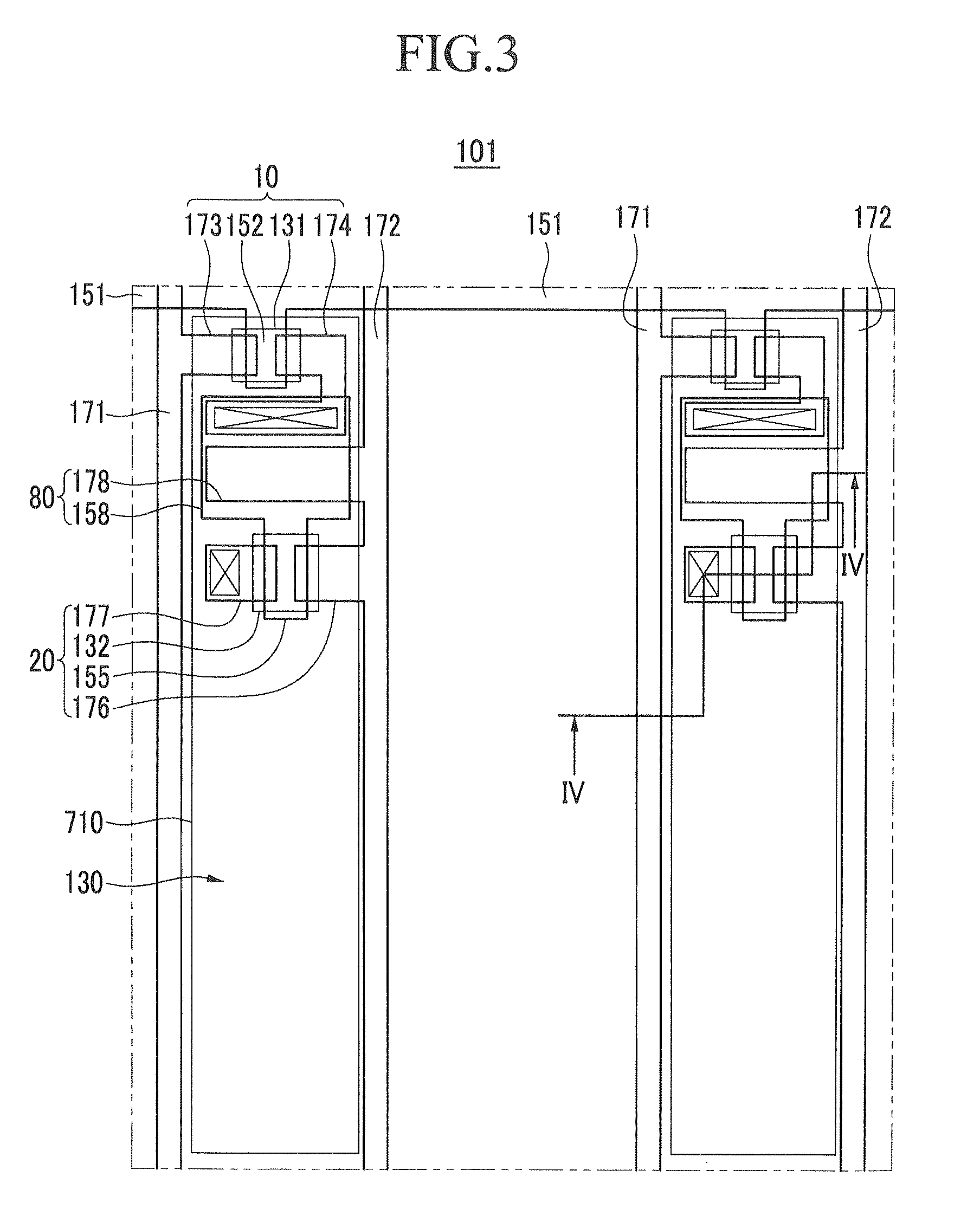

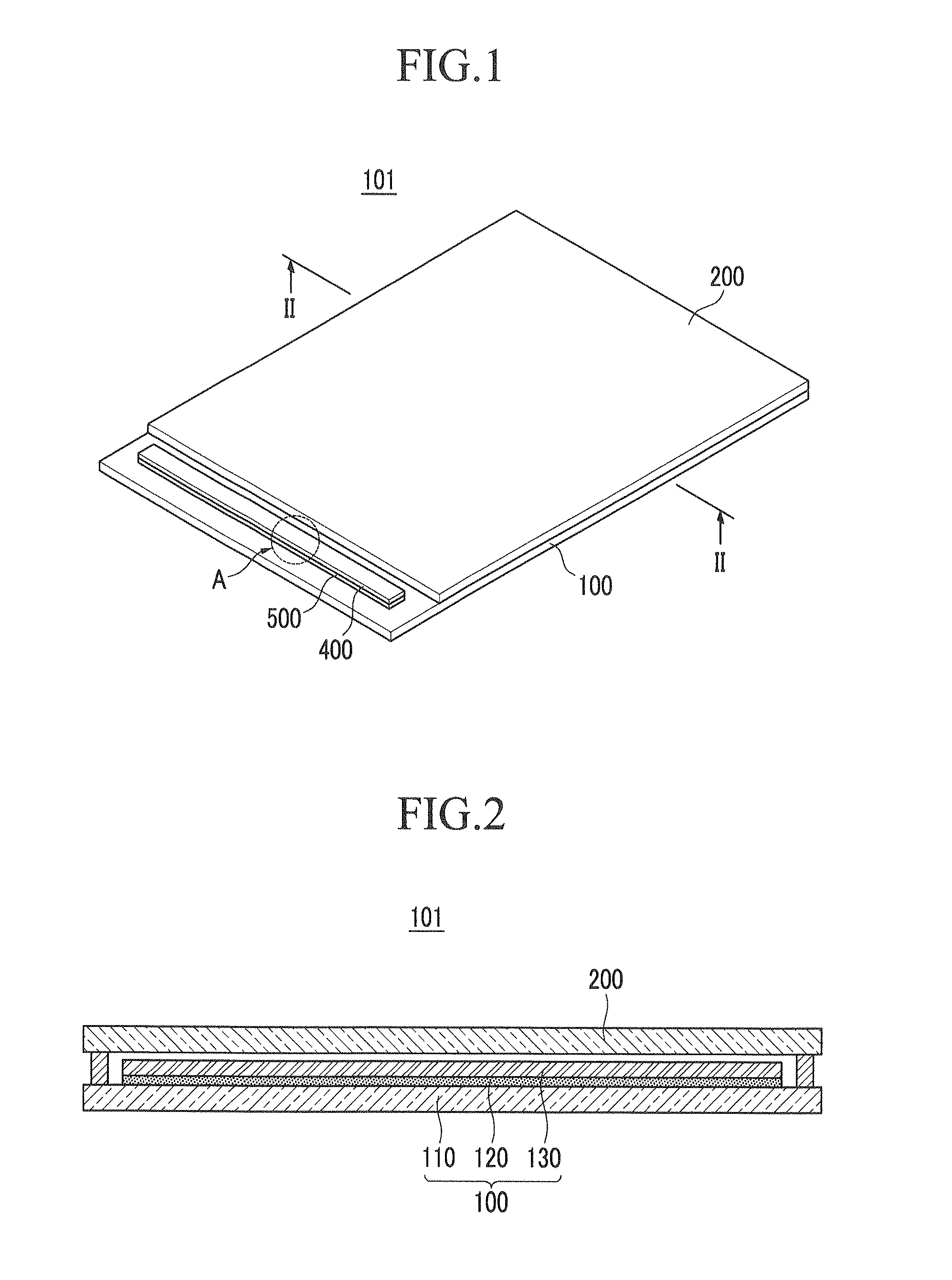

Display device

ActiveUS20110068346A1Avoid excessive hardnessContact resistanceSemiconductor/solid-state device detailsElectroluminescent light sourcesDisplay deviceIntegrated circuit

A display device includes a wire substrate including a wire unit for driving the display device, an integrated circuit chip mounted at the wire substrate, and a pad unit extended from the wire unit to be disposed between the wire substrate and the integrated circuit chip. The pad unit is connected to the integrated circuit chip. The pad unit includes a first conductive layer extended from the wire unit, and a second conductive layer disposed on the first conductive layer. The hardness of the second conductive layer is less than the hardness of the first conductive layer.

Owner:SAMSUNG DISPLAY CO LTD

Clinch nut

A metal clinch fastener has portions thereof selectively hardened to enable use of the fastener with metal members of differing hardness values. The selective hardening of the fastener enables mounting with application of required forces for piercing and / or plastic deformation of the metal member without undesirable deformation or distortion of the fastener. The screw thread region or zone of the fastener has a relatively lesser hardness suitable and may be pre-threaded or later threaded by engagement with a thread forming screw.

Owner:R B & W MFG

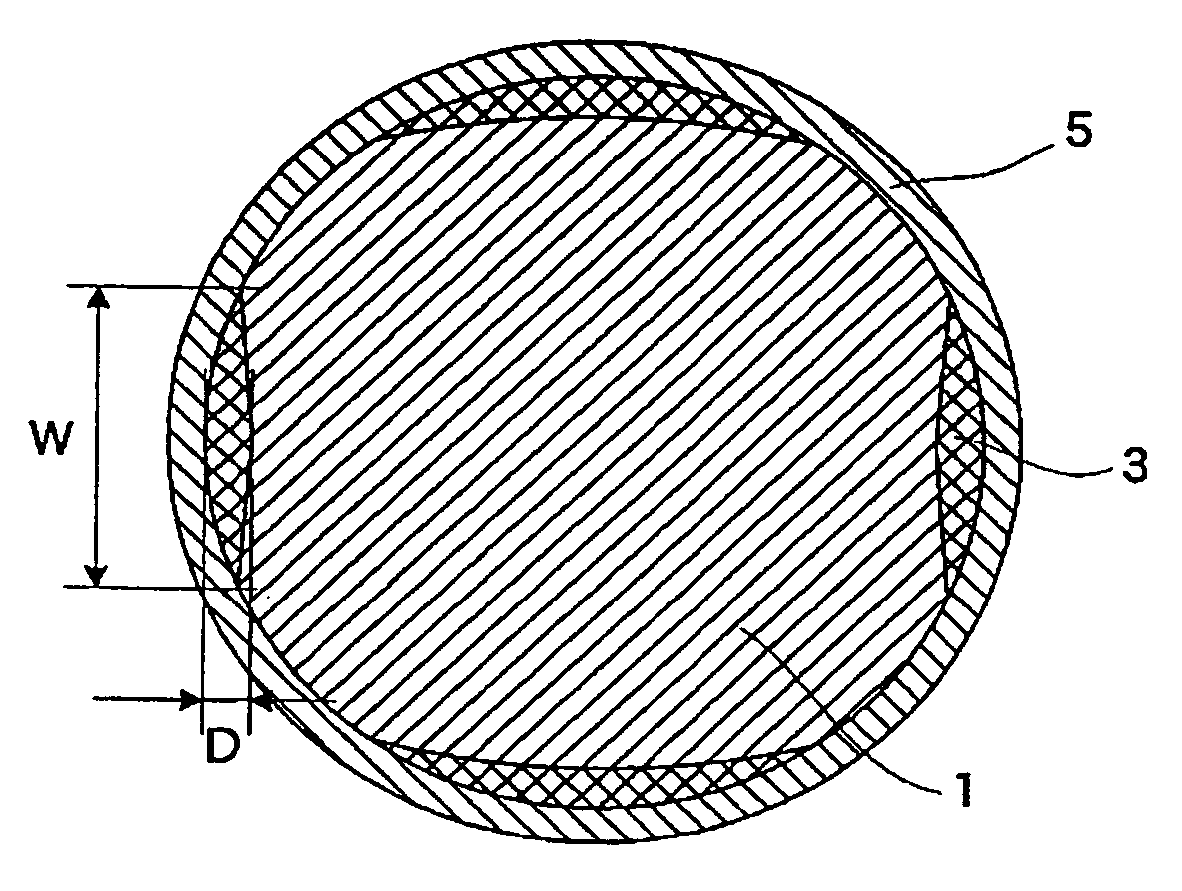

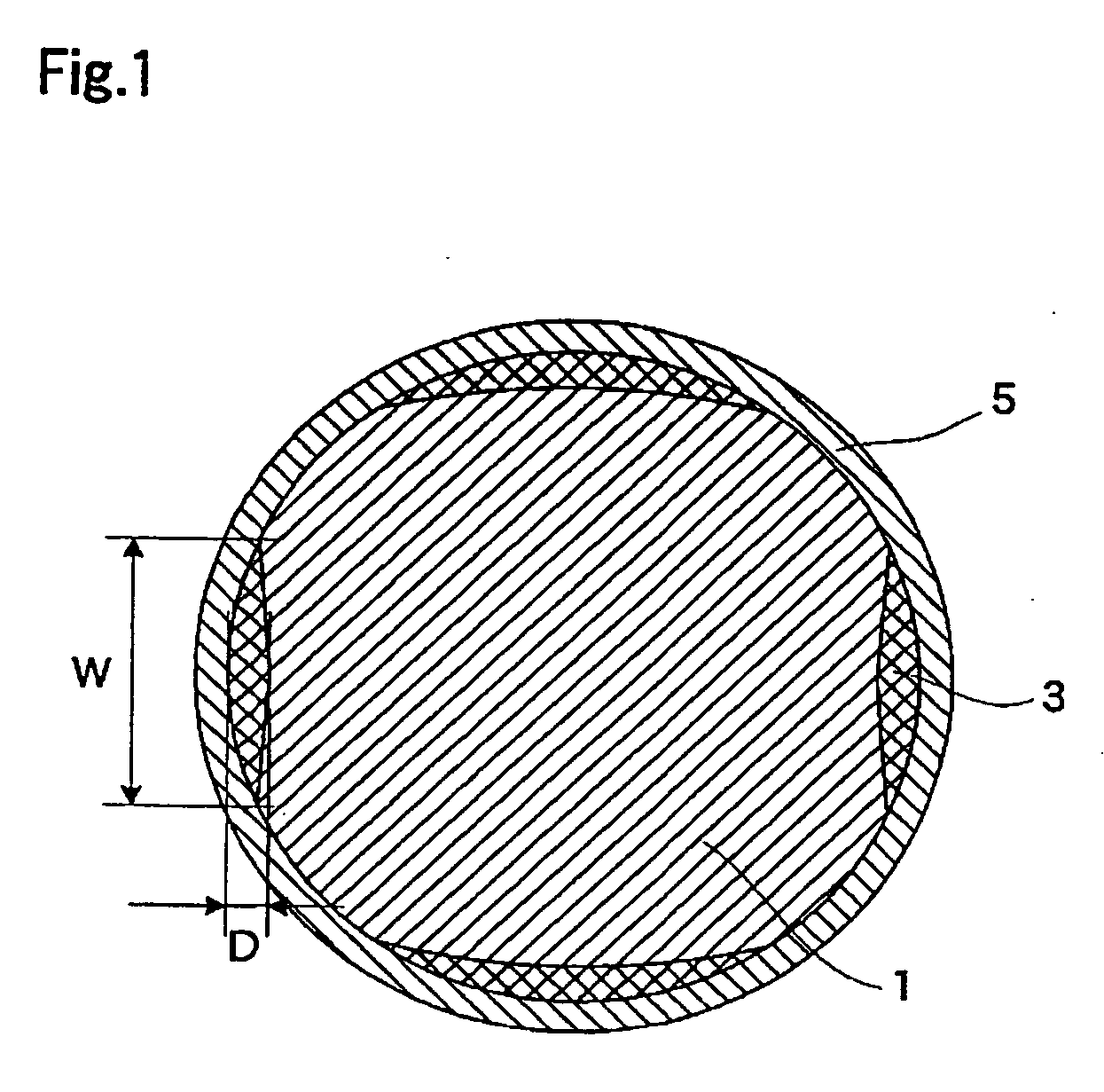

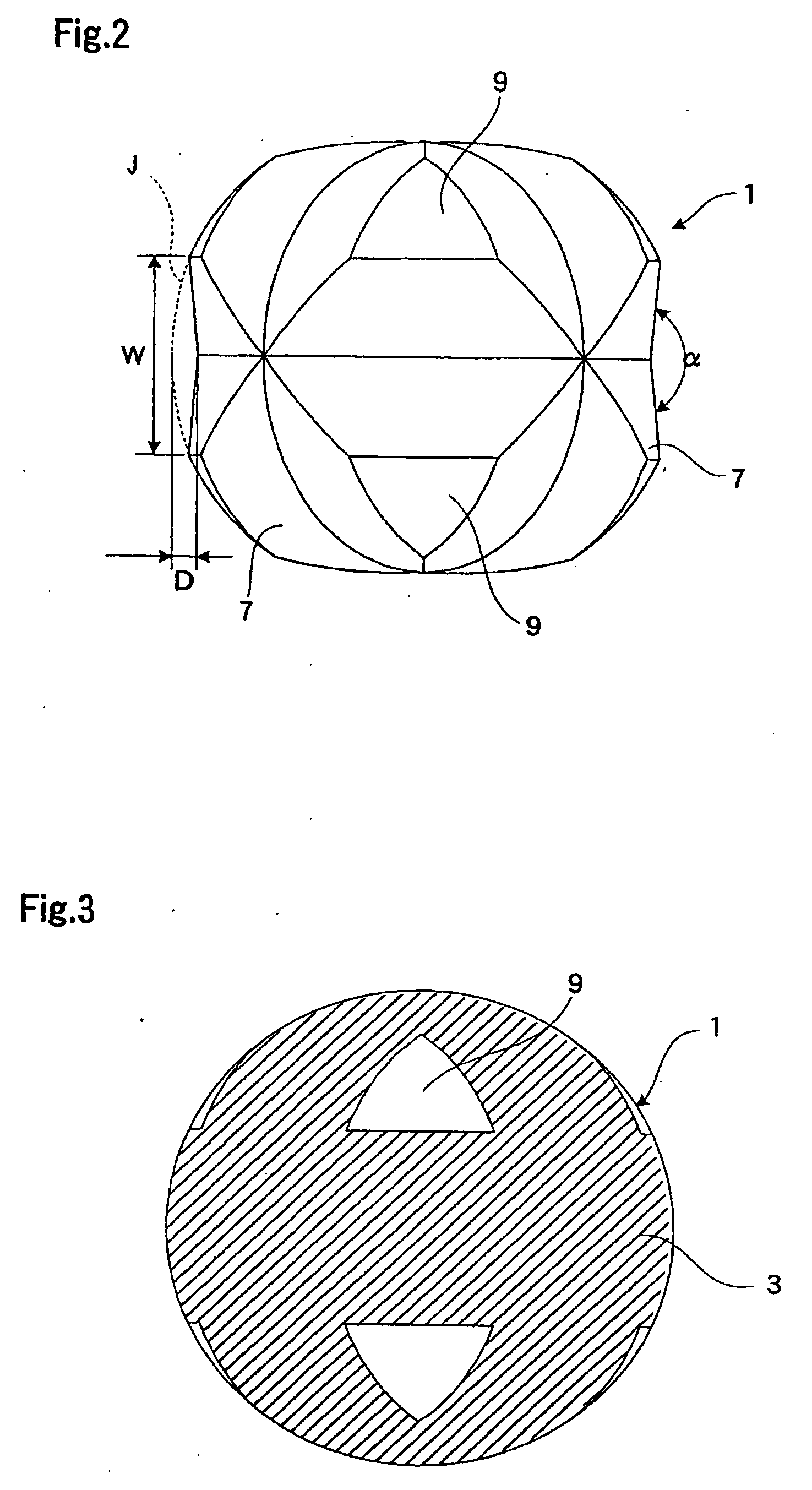

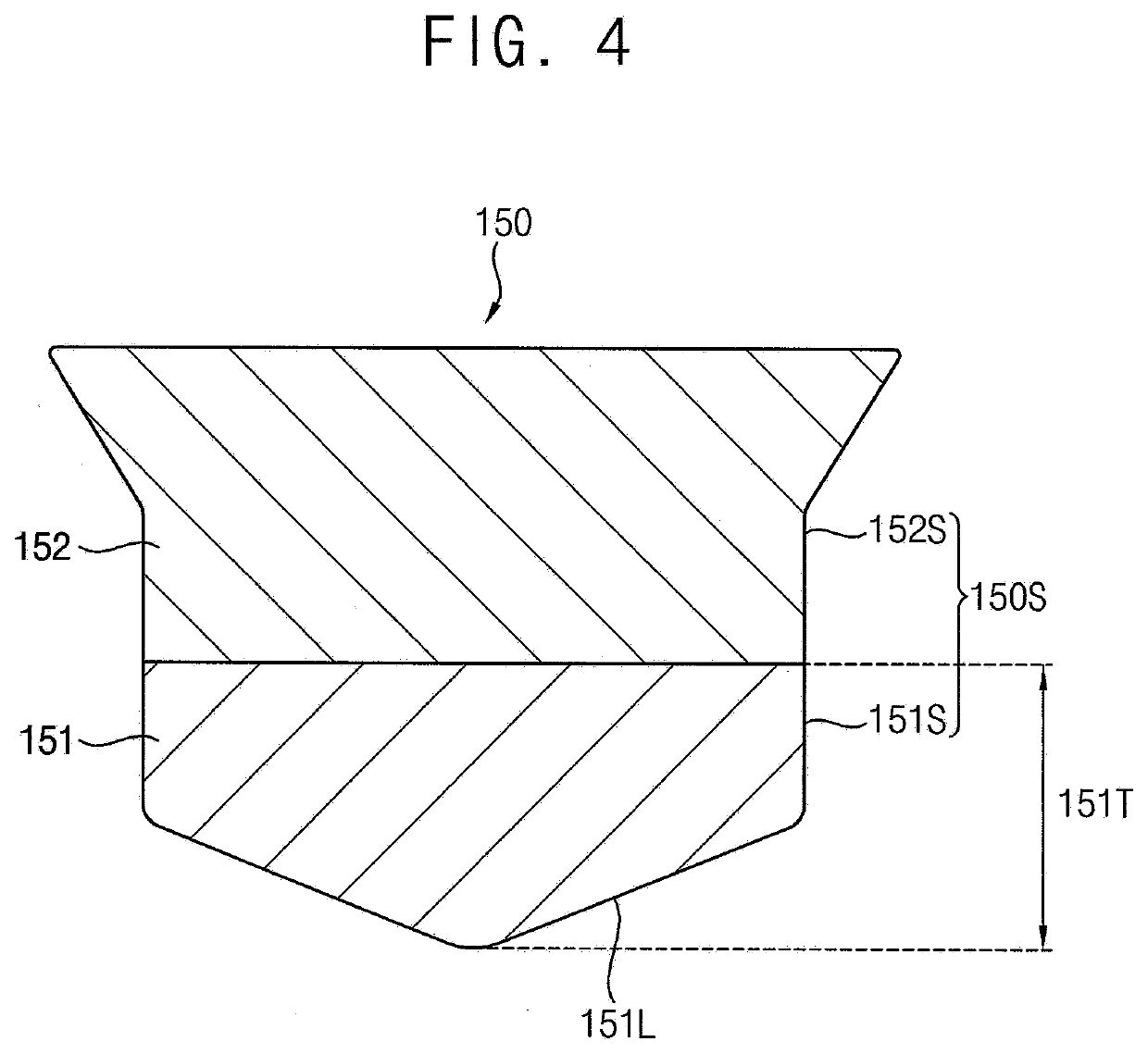

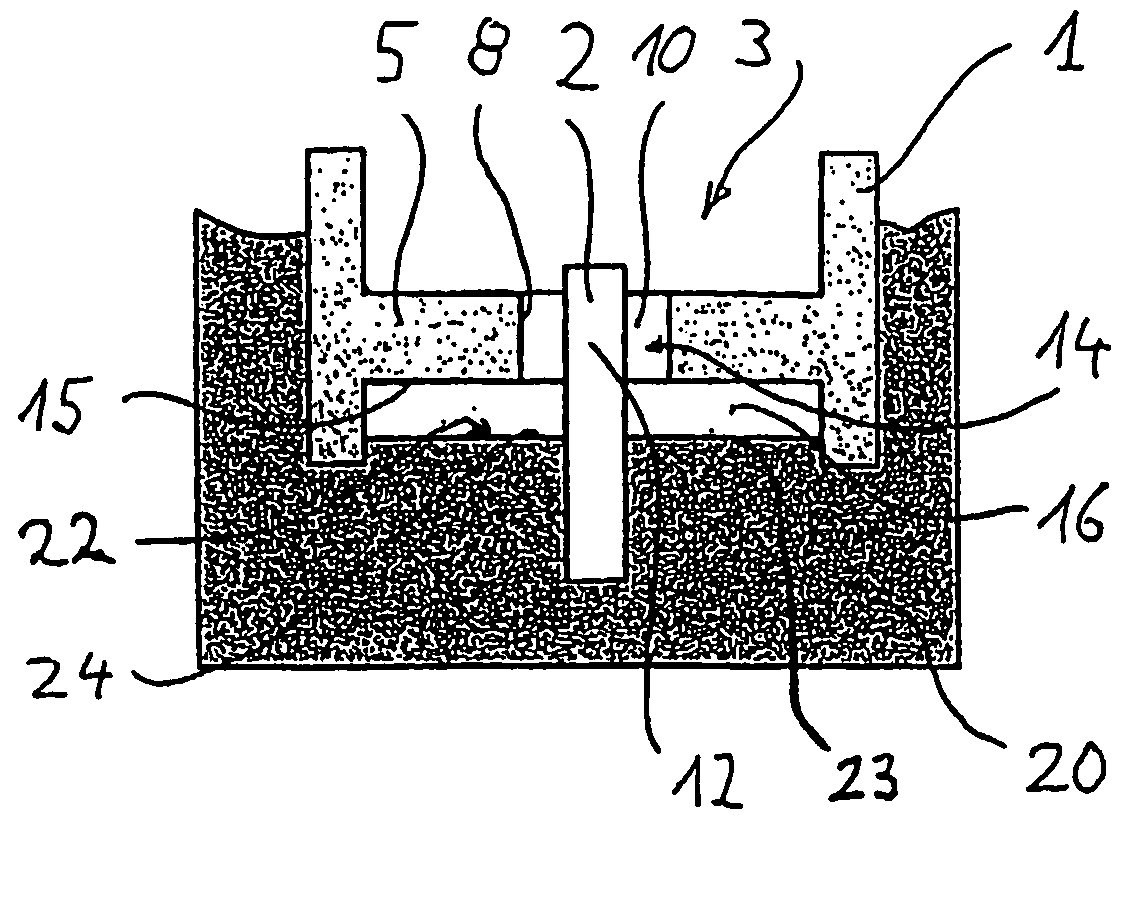

Golf ball and mold for manufacturing core thereof

Owner:MIZUNO CORPORATION

Golf ball and mold for manufacturing core thereof

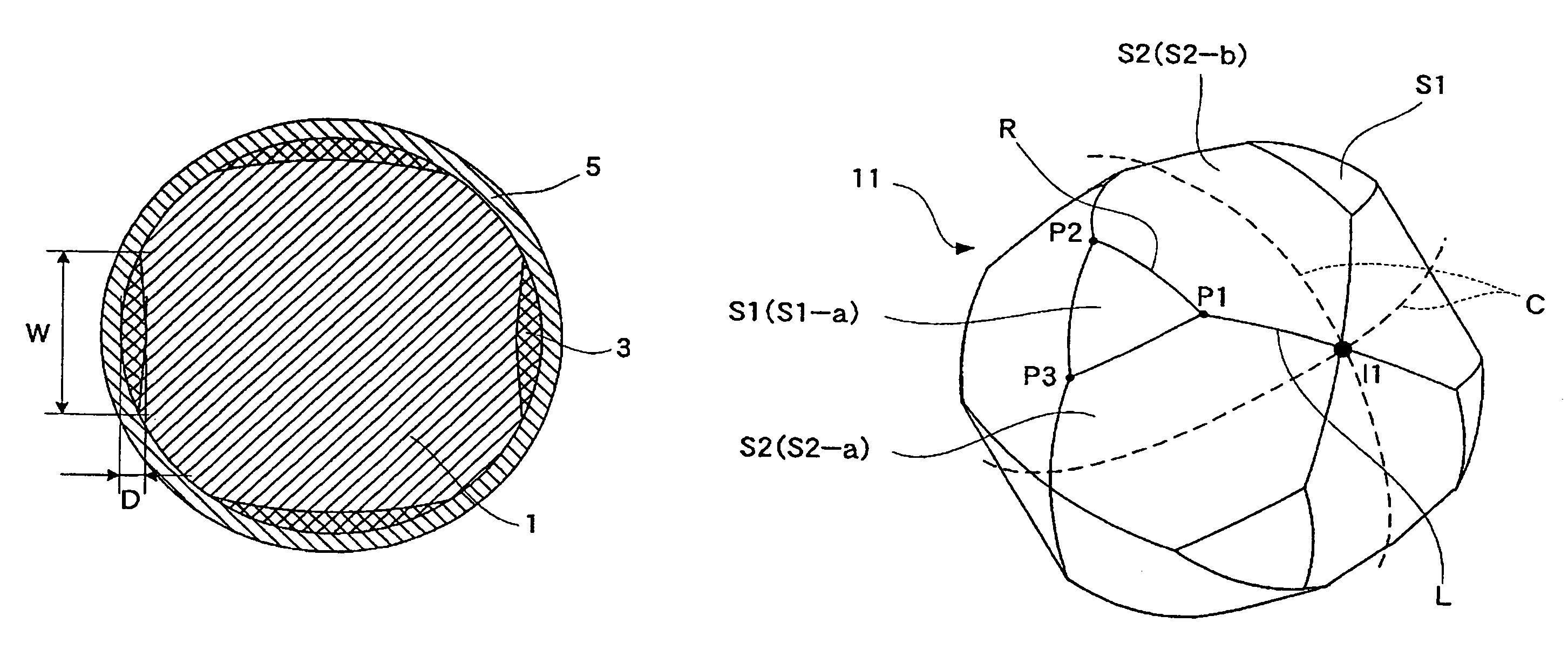

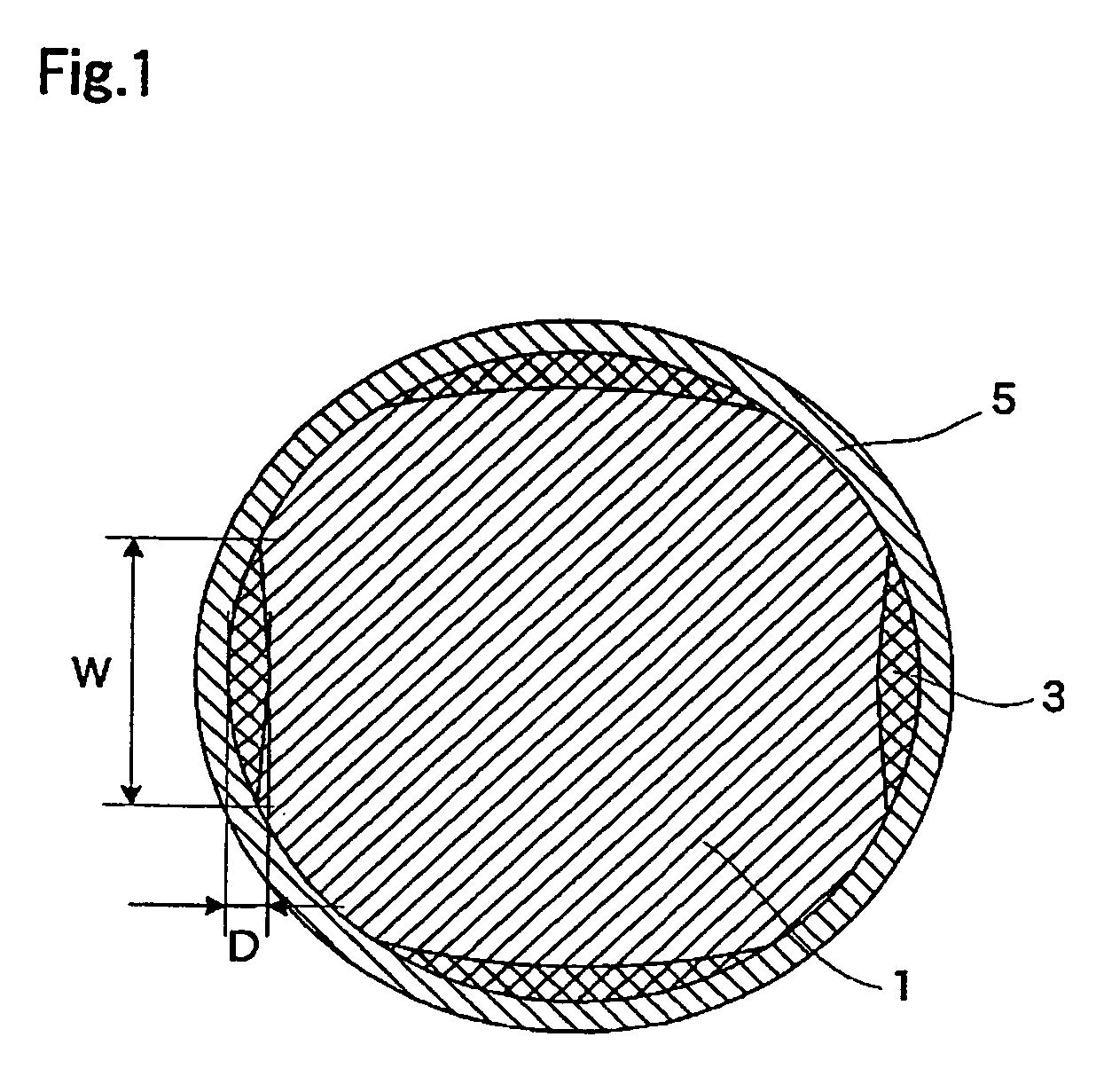

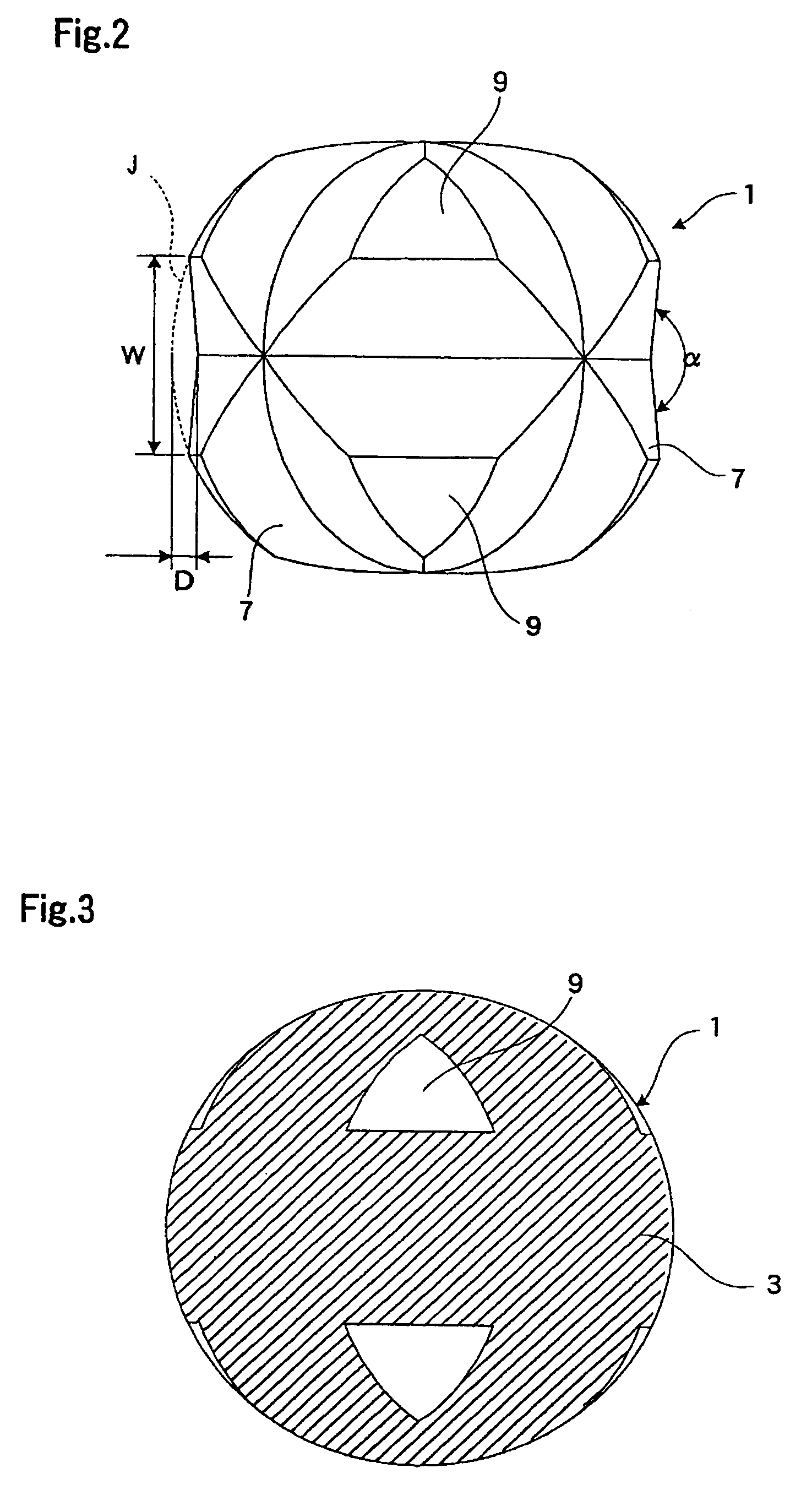

A golf ball comprising a core (1), intermediate layer (3), and cover (5), wherein the intermediate layer (3) is provided with a plurality of apertures through which the core (1) is exposed, wherein the outer surface of the intermediate layer (3) and the surface of the core (1) exposed through the apertures are on substantially the same spherical surface, and wherein the hardness of the intermediate layer (3) is greater than that of the core (1). The golf ball achieves both a high ball resilience and a soft impact feel.

Owner:MIZUNO CORPORATION

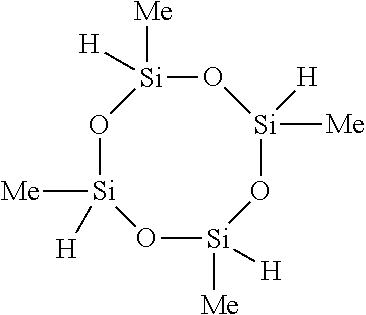

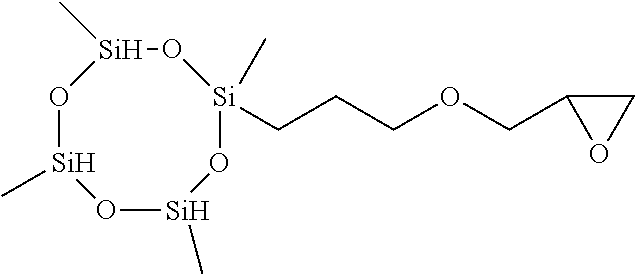

Addition curable type silicone resin composition, process for producing composition, and optical semiconductor apparatus

ActiveUS20180315906A1High transparencyExcellent heat discoloration resistanceSemiconductor/solid-state device detailsSolid-state devicesMetal catalystHardness

An addition curable type silicone resin composition includes (a) an organopolysiloxane having an alkenyl group bonded to a silicon atom, (b) an organopolysiloxane represented by the formula, (R1R22SiO1 / 2)m(R1R2SiO2 / 2)n(R22SiO2 / 2)p(R1SiO3 / 2)q(R2(OR3)SiO2 / 2)r(SiO4 / 2)s, (c) an organohydrogen polysiloxane represented by R4aHbSiO(4-a-b) / 2), (d) a platinum group metal catalyst, and (e) a polyorganometallosiloxane containing an Si—O—Ce bond, and an Si—O—Ti bond, and contents of Ce and Ti of which are each 50 to 5,000 ppm, which cures by heating. According to this constitution, it is provided an addition curable type silicone resin composition which can provide a cured product excellent in transparency, and less change in hardness and weight loss under high temperature conditions.

Owner:SHIN ETSU CHEM IND CO LTD

Multi-component fluffy fiber and manufacturing method thereof

The invention discloses a multi-component fluffy fiber, which consists of at least one center thread and at least one surface thread, wherein the center thread is formed by viscose fibers, high-shrinkage yarns and modified polyester fibers in a combination way, the adding amount of the high-shrinkage yarns in the center thread accounts for more than 35 percent of the total weight of the center thread and the shrinkage rate of the center thread is 33 percent; the surface thread is formed by viscose fibers and polyester fibers in a combination way and the shrinkage rate of the surface thread is 12 percent. Compared with the prior art, after the multi-component fluffy fiber provided by the invention is used for making a fabric, during the subsequent treatment of the fabric, the center thread and the surface thread are shrunk differently and the surface thread with small shrinkage rate is raised on the surface of the center thread to form a fluffy feeling. Moreover, the different shrinkage enables a great number of air holes to occur in the fabric and the warmth keeping effect of the fabric is effectively improved. The invention additionally provides a manufacturing method of the multi-component fluffy fiber.

Owner:FOSHAN NANHAI FLYING YUE TEXTILES

Method of coating a substrate and vane for vane-type compressor

InactiveUS20020064605A1Avoid temperature riseReduce harmWind motor controlPump componentsNitrideElectroplating

A method of coating a substrate includes the step of forming a chrome layer on the substrate by using a magnetron sputtering device, and the step of forming a chrome nitride layer on the chrome layer by using an arc type ion plating device while maintaining the temperature of the substrate between 100 and 200° C. A vane used for a vane-type compressor, which is subjected to a surface treatment according to the coating method of the present invention is also provided.

Owner:TOHKEN THERMO TECH CO LTD

Oxidation method and compositions therefor

The present invention generally relates to an improved two-part oxidizing system, as well as oxidizing compositions and methods for making and using the same, and in a particular embodiment to a two-part oxidizing system that, when mixed, yields an oxidizing composition. The two-part oxidizing system includes a metal chlorite first part, and an acid second part where the acid is sodium acid sulfate or a derivative thereof.

Owner:ECOLAB USA INC

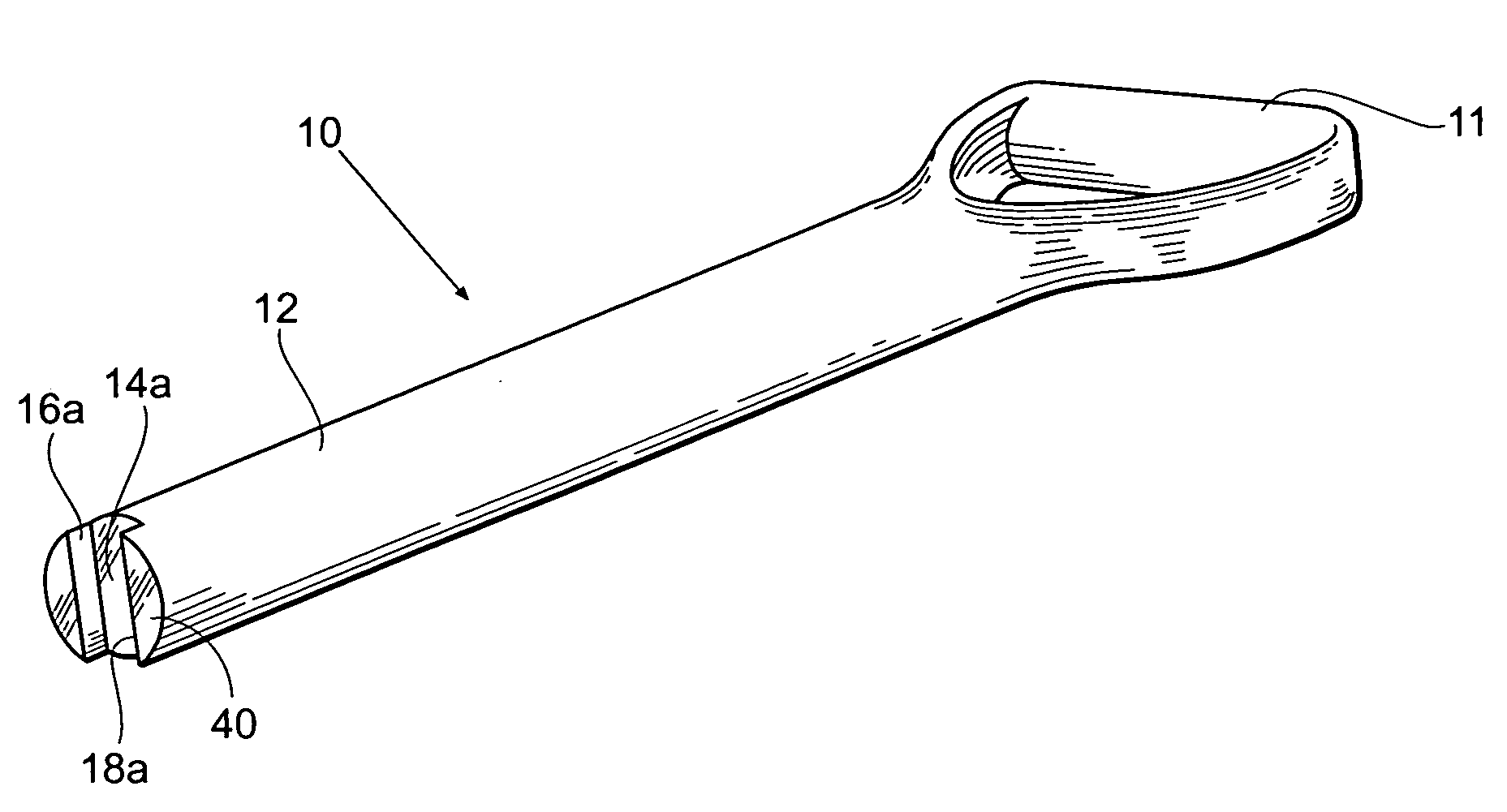

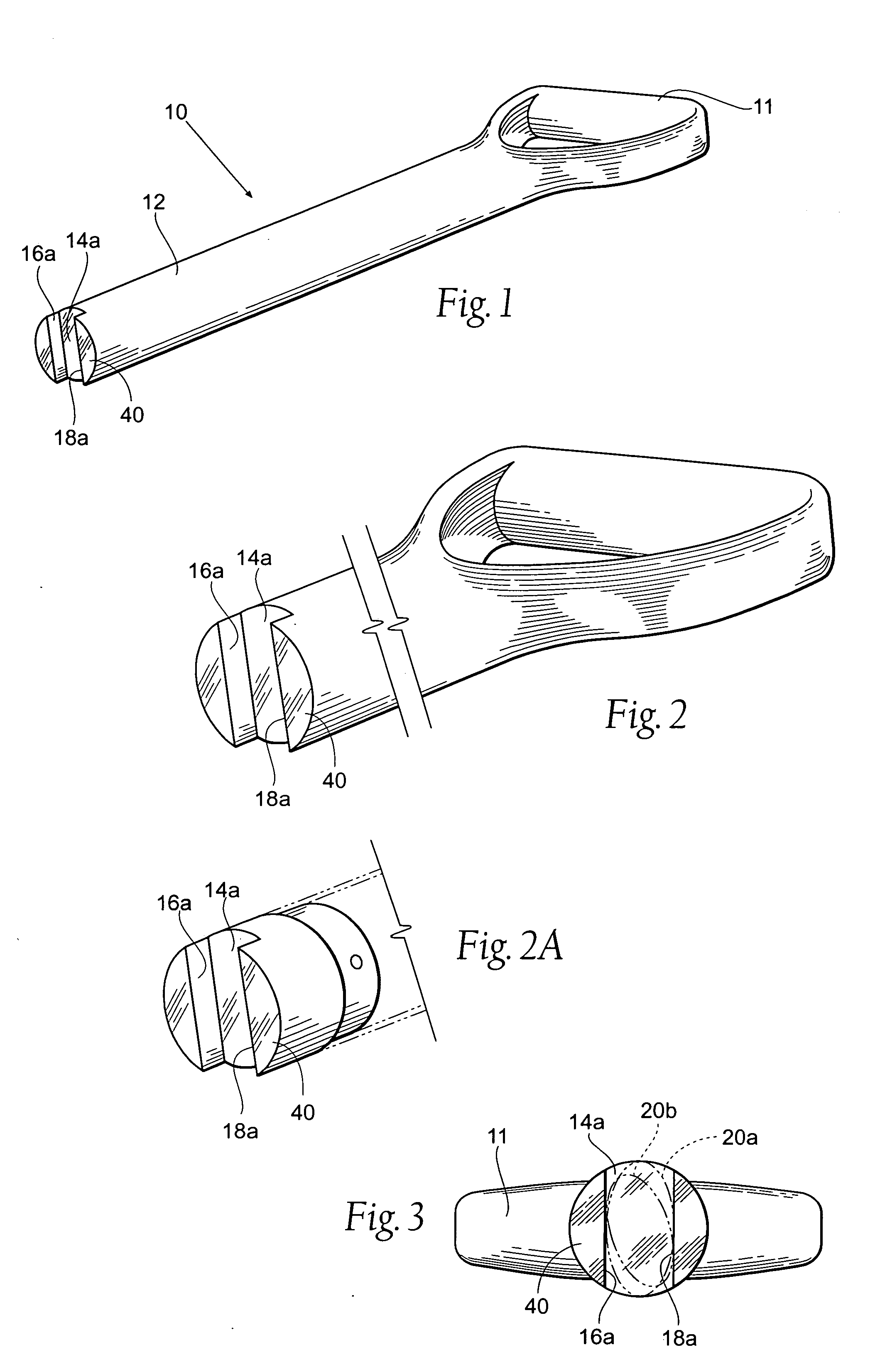

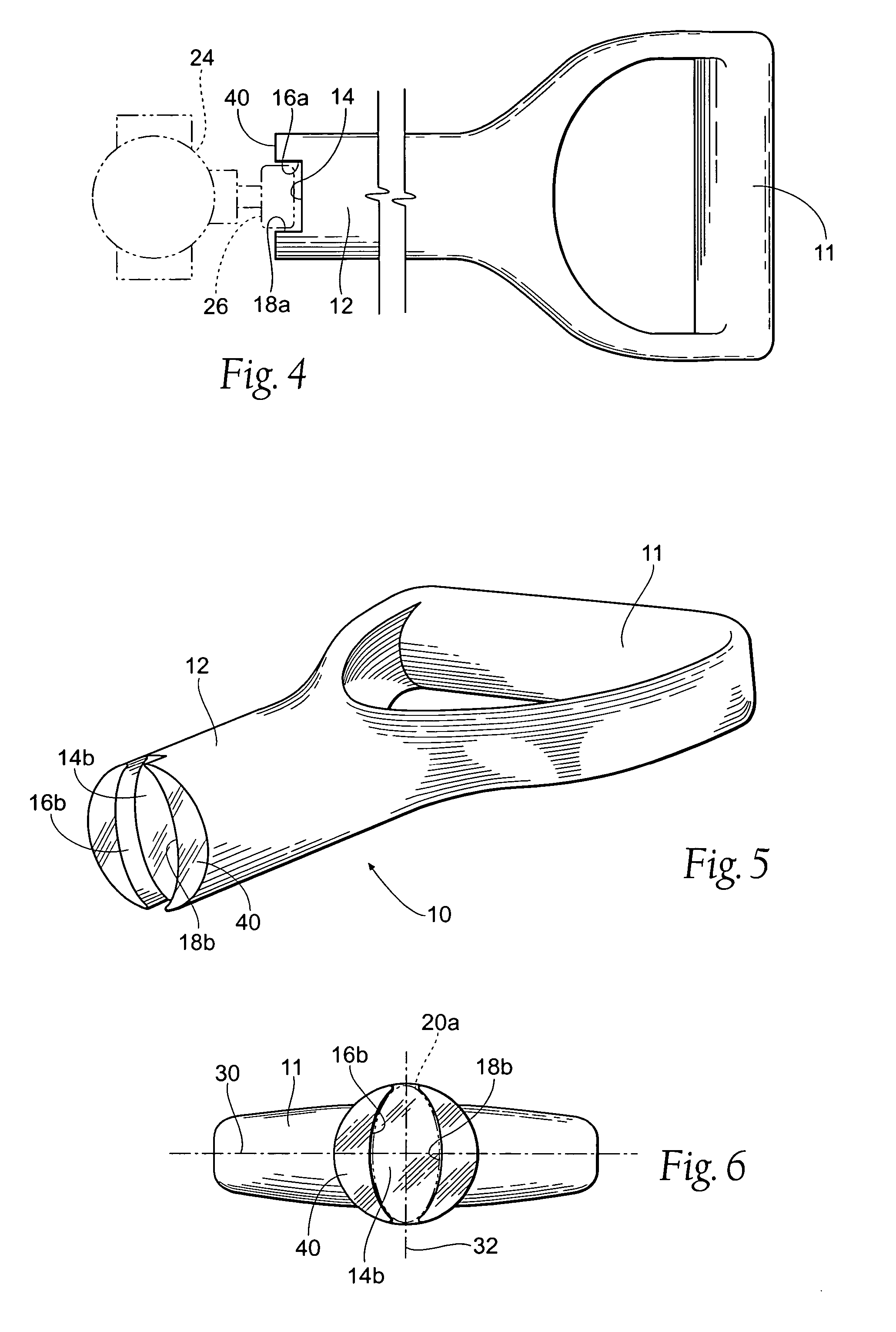

Faucet or valve handle turning tool

A faucet or valve handle turning tool is provided and includes an elongated, cylindrical body of machinable or moldable material having a handle at one end and a cavity formed in the opposite end. The cavity is formed with inwardly extending sidewalls and has at least one portion conforming to the peripheral contour of a faucet or valve handle. In particular, the sidewalls of such cavity may have similar elliptical contours. In at least one example, the cavity may be formed by means of mechanical routing and removal of material from the tool body. In use, the tool thereby reduces the possibility of damage to a polished faucet or valve handle frequently caused by hardened conventional plumbing tools.

Owner:RHODA THOMAS J

Oxidation method and compositions therefor

ActiveUS20100227004A1Increase flexibilityOptimization rangeBiocideDough treatmentSulfateSodium sulfate

The present invention generally relates to an improved two-part oxidizing system, as well as oxidizing compositions and methods for making and using the same, and in a particular embodiment to a two-part oxidizing system that, when mixed, yields an oxidizing composition. The two-part oxidizing system includes a metal chlorite first part, and an acid second part where the acid is sodium acid sulfate or a derivative thereof.

Owner:ECOLAB USA INC

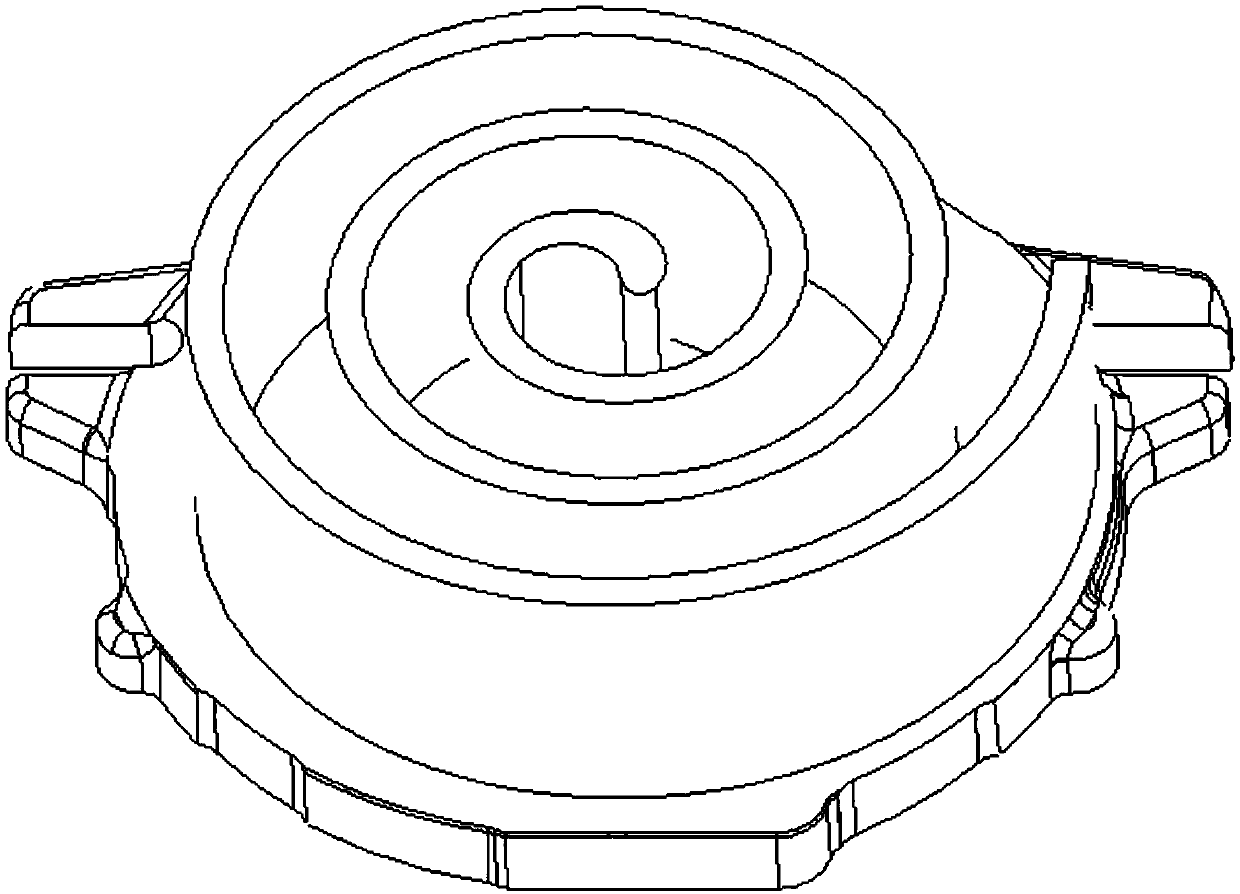

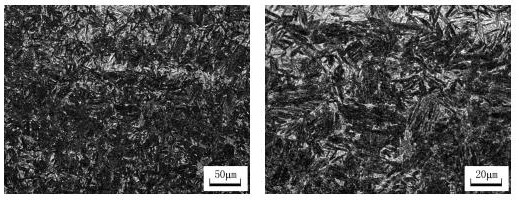

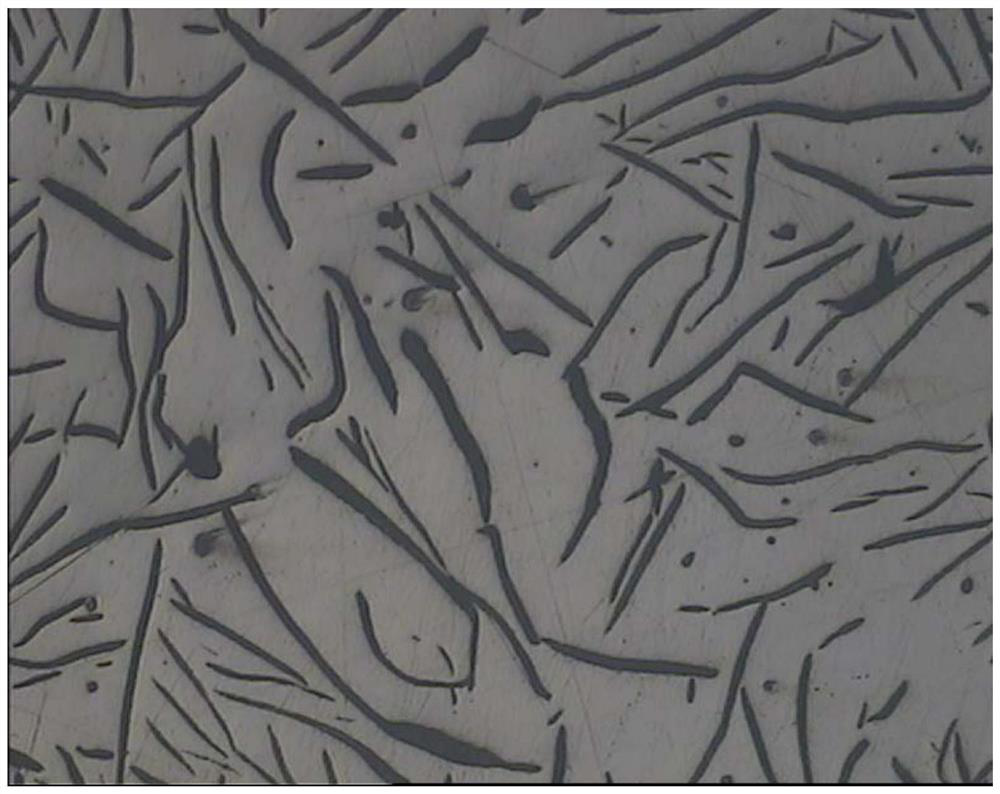

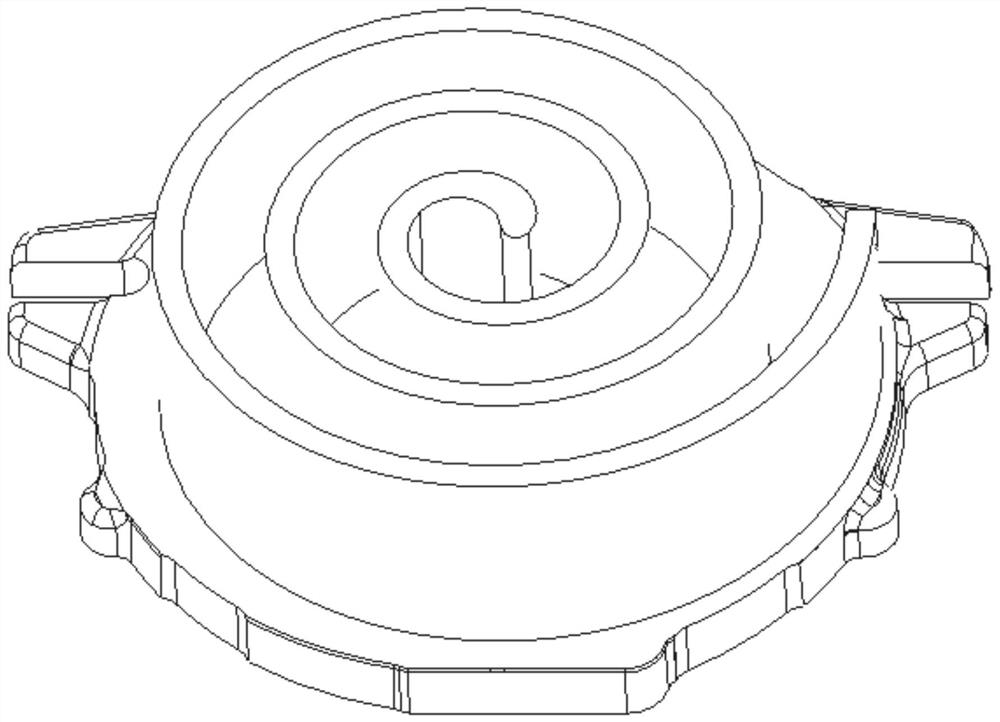

Vermicular graphite cast iron scroll plate and production process thereof

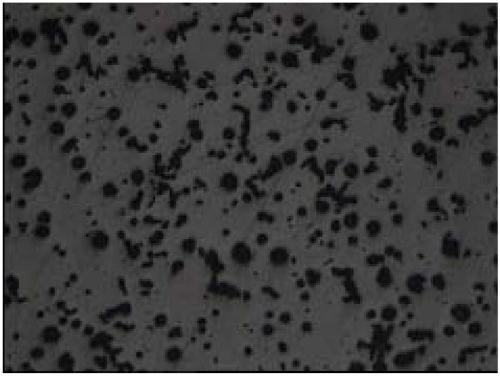

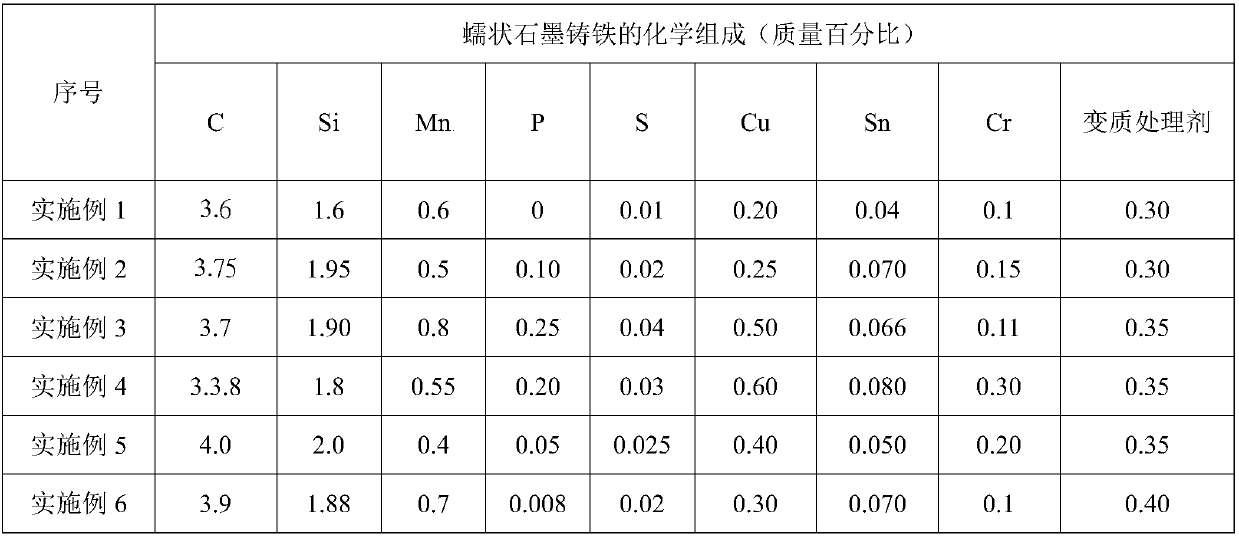

ActiveCN109536664AGuaranteed pearlite contentAvoid excessive hardnessRotary piston pumpsRotary piston liquid enginesCreep rateGraphite

The invention discloses a vermicular graphite cast iron scroll plate and a production process thereof. The plate is prepared by casting vermicular graphite cast iron, a raw material for the plate comprises the following components of, by mass: 3.6%-4.0% of C, 1.6%-2.0% of Si, 0.4%-0.8% of Mn, 0%-0.25% of P, 0.01%-0.04% of S, 0.20-0.6% of Cu, 0.04-0.08% of Sn, 0.10%-0.3% of Cr and the balance Fe and accompanying impurities. According to the vermicular graphite cast iron scroll plate, in the raw material production process, 0.30%-0.40% of a modification treating agent is adopted to control the creep rate of the graphite form to be 20%-60%, the mechanical performance of the scroll plate is greatly improved, the tensile strength is larger than or equal to 450N / mm<2>, the yield strength is larger than or equal to 315N / mm<2>, the elongation rate is less than or equal to 3%, and the hardness range is HB200-HB250, and the durability life test is up to 2600 hours.

Owner:苏州勤美达精密机械有限公司

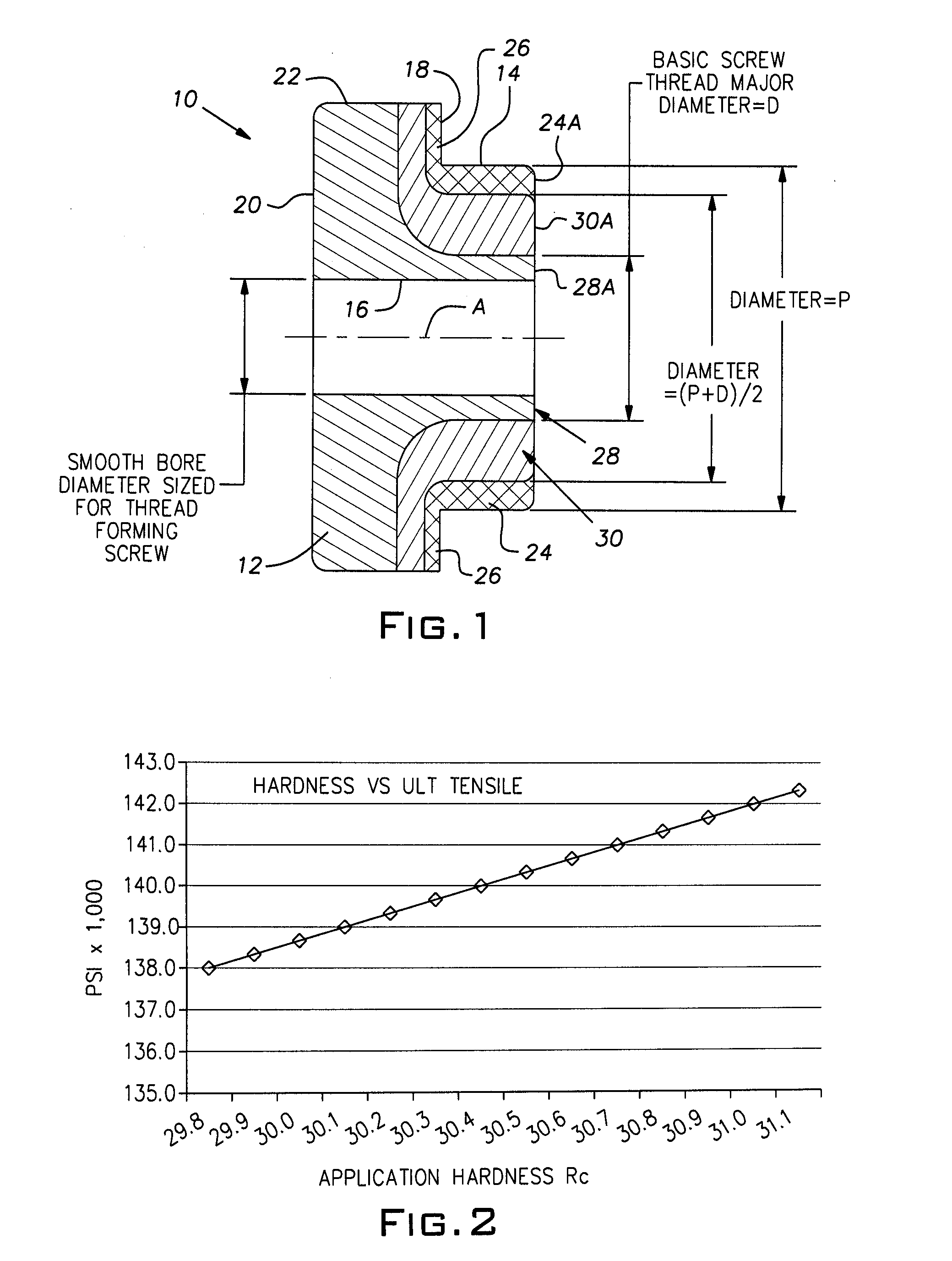

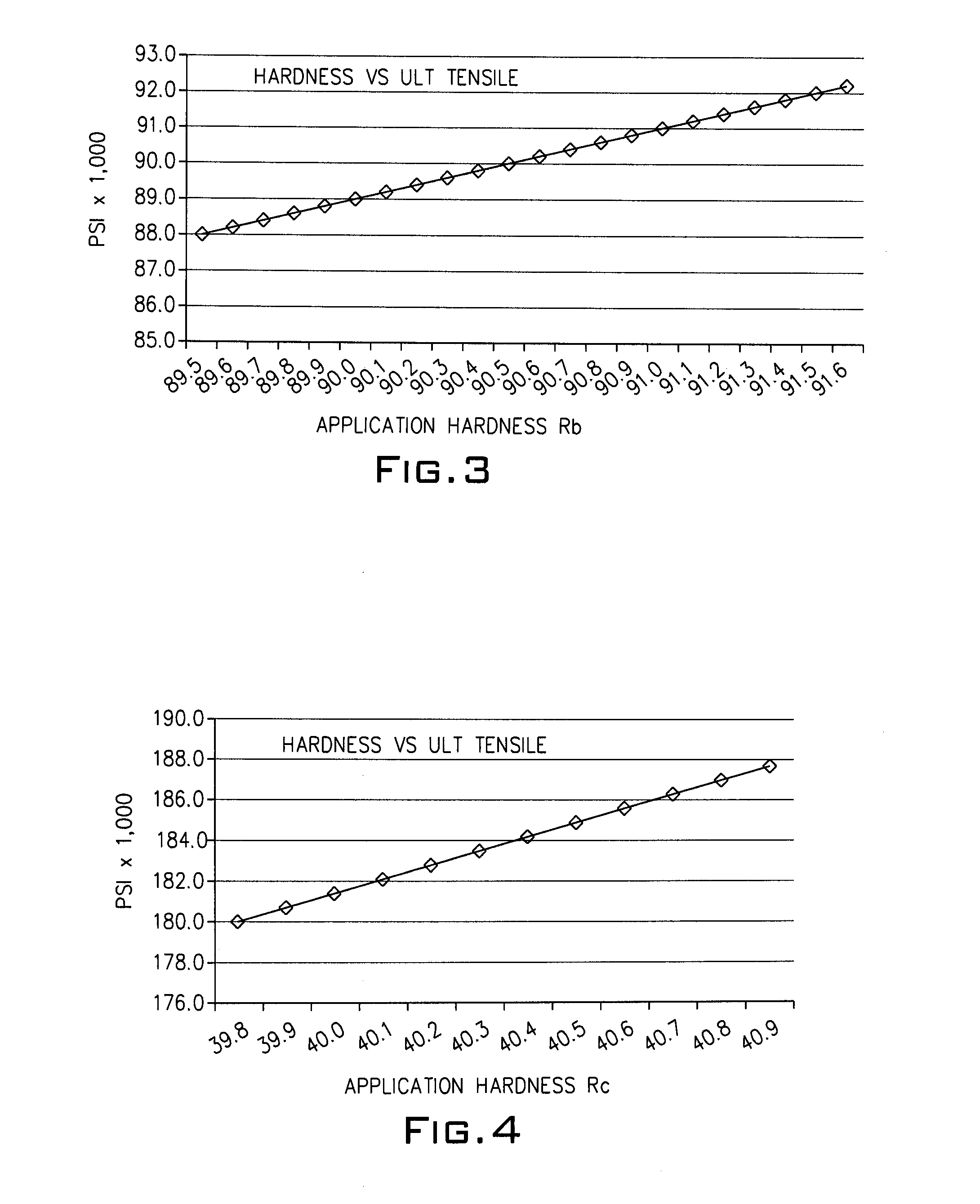

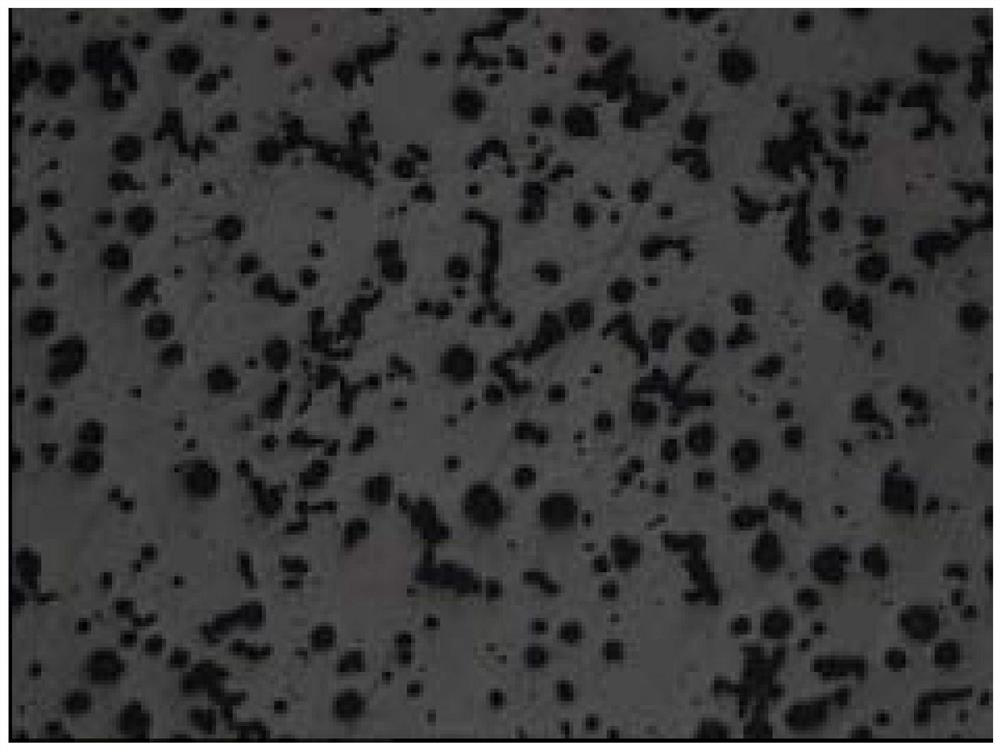

Vermicular graphite cast iron and preparation process and application thereof

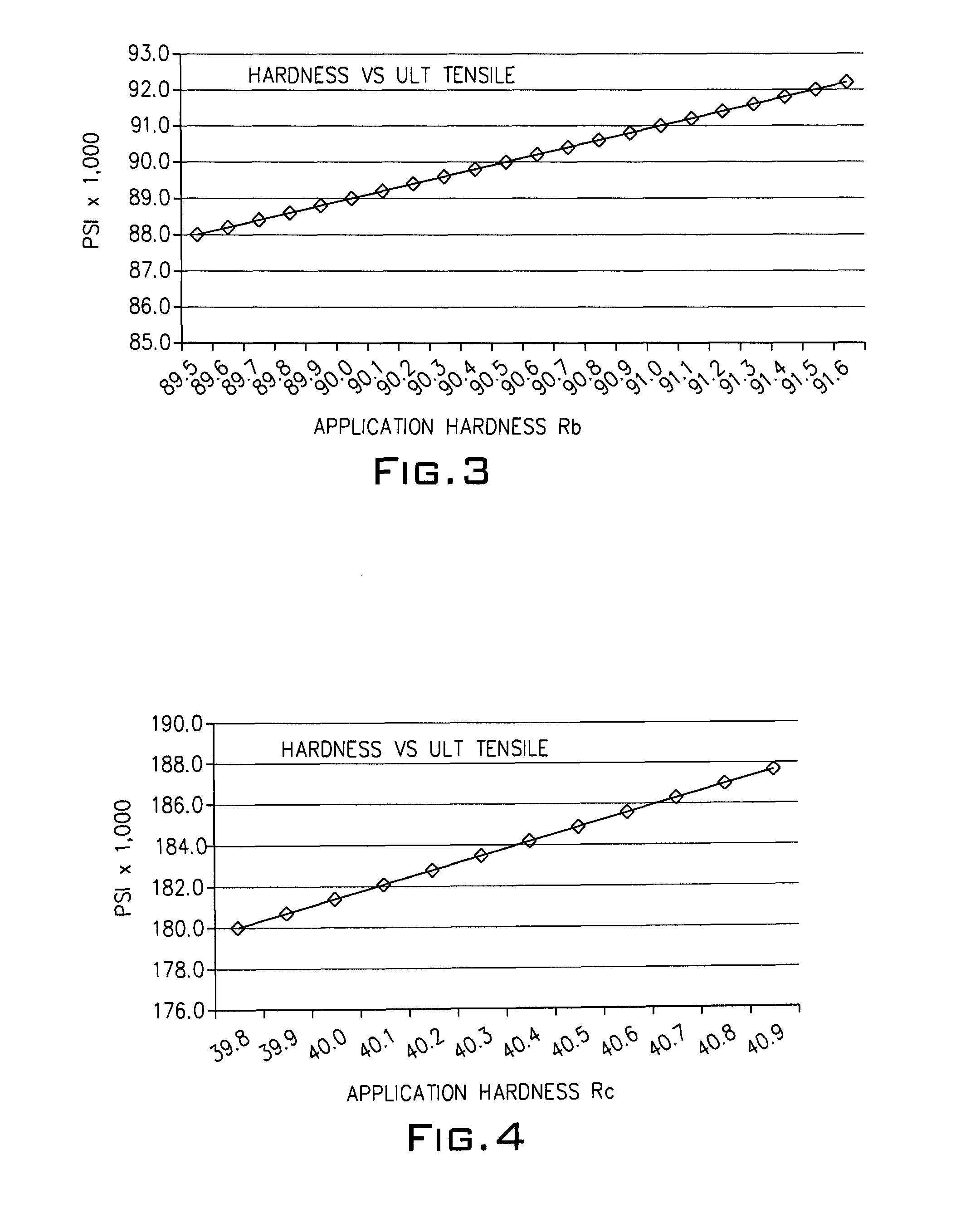

ActiveCN109594007AGuaranteed pearlite contentAvoid excessive hardnessRotary piston pumpsRotary piston liquid enginesHardnessUltimate tensile strength

The invention discloses vermicular graphite cast iron and preparation process and application thereof. By mass percentage, 3.6%-4.0% of C, 1.6%-2.0% of Si, 0.4%-0.8% of Mn, 0%-025% of P, 0.01%-0.04% of S, 0.20-0.6% of Cu, 0.04%-0.08% of Sn, 0.10%-0.3% of Cr, and the balance Fe and accompanying impurities are included. In the production process, 0.30%-0.40% of a modification agent is adopted in theproduction process to control the vermicularity of the graphite form to be 20%-60%, the mechanical performance of a material is greatly improved, the strength of extension is larger than or equal to450 N / mm<2>, the yielding strength is larger than or equal to 315 N / mm<2>, the elongation at break is smaller than or equal to 3%, a hardness range is HB200-250, the endurance service life reaches 2600 h according to a test, and the vermicular graphite cast iron can be applied to a compressor core part vortex disk high in mechanical strength requirement.

Owner:苏州勤美达精密机械有限公司

Surgical nail

ActiveUS9737347B2ClearanceImprove retentionInternal osteosythesisTransverse axisCompressive strength

Described herein is a surgical nail in the form of an intramedullary nail with a central axis made from a material M with a tensile strength Fz, compressive strength Fd, density ρ2 and modulus of elasticity E. The nail has a transverse bore extending transversely to the central axis and having a cross-sectional profile F and a transverse axis, the cross-sectional profile F having a maximum length a that runs in the direction of the central axis and a maximum width b that runs perpendicular to the length. An insert with the longitudinal axis, made from material m and having a modulus of elasticity e that is smaller than the modulus of elasticity E of material M, can be introduced into the transverse bore. The insert also has a length L that runs in the direction of its longitudinal axis and satisfies the condition L>0.2 D.

Owner:DEPUY SYNTHES PROD INC

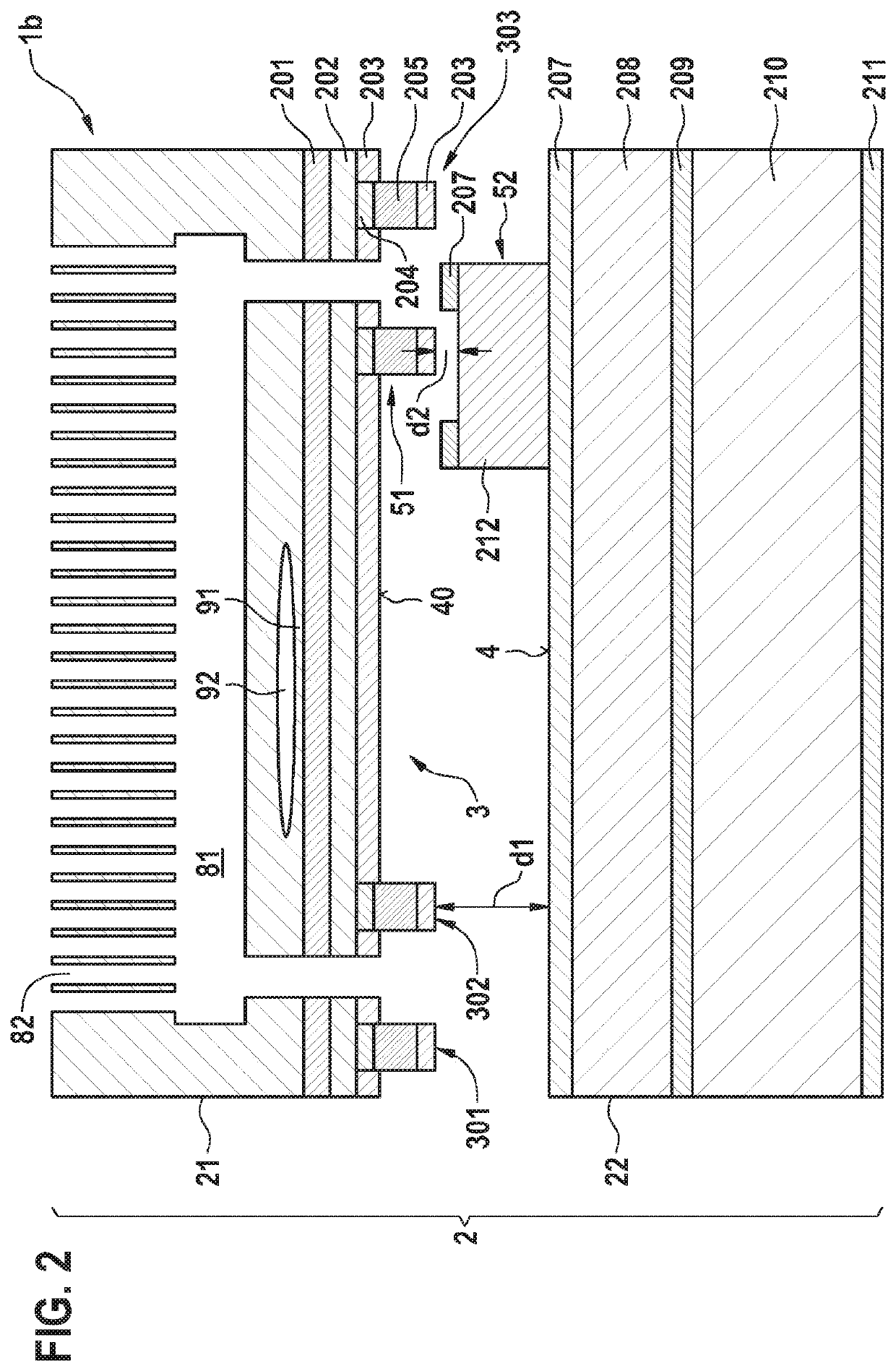

Micromechanical device and method for manufacturing a micromechanical device

ActiveUS11486782B2Avoid damageLimit oscillation and deflectionCapacitance measurementsFluid pressure measurement by electric/magnetic elementsMicromachineryMechanical engineering

Owner:ROBERT BOSCH GMBH

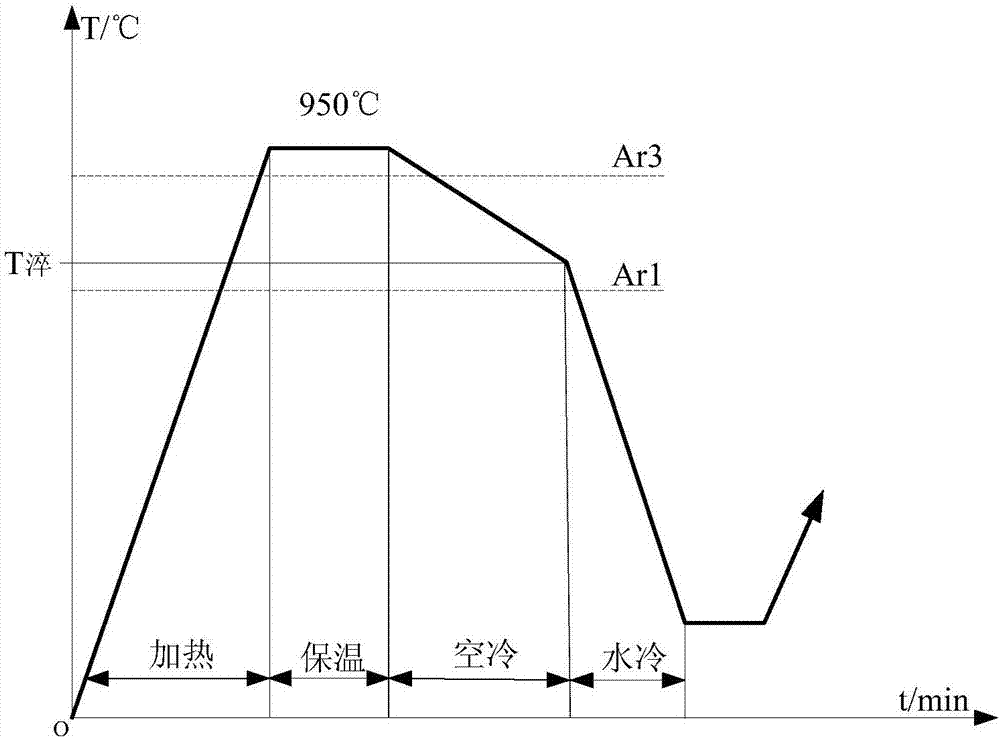

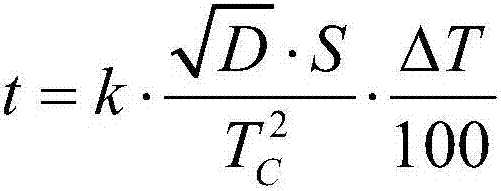

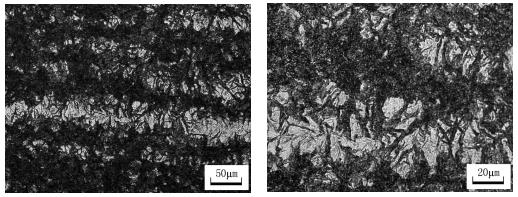

Heat treatment process used after rolling of 12Cr1MoVG high-pressure steel pipe

ActiveCN107058684AGood room temperature processabilityExcellent high temperature mechanical propertiesFurnace typesHeat treatment furnacesHigh pressureSlow cooling

The invention discloses a heat treatment process used after rolling of a 12Cr1MoVG high-pressure steel pipe. The heat treatment process comprises the steps that (1), the 12Cr1MoVG high-pressure steel pipe obtained after hot rolling is subjected to heat preservation at the austenitizing temperature of 970-1020 DEG C for 60 minutes or more; (2), the steel pipe is taken out and subjected to air cooling, and the temperature is dropped to 920-980 DEG C from the initial temperature; (3), quenching is performed at the temperature of 820-850 DEG C; (4), high-temperature tempering is performed at the temperature of 720-760 DEG C, and the heat preservation time is larger than or equal to 120 minutes. The heat treatment process has the advantages that an aerial slowing-cooling process is performed before quenching and water entering, after a sufficient amount of ferrite F tissues are precipitated, water entering for rapid cooling is performed, and the problem of excessively high hardness is avoided, so that the steel type has good room-temperature machining performance, high-temperature mechanical performance and low crack sensitivity, and the pipe suitable for a high-pressure boiler is suitable for a high-temperature, high-pressure and corrosion environment.

Owner:TIANJIN PIPE GROUP CORP

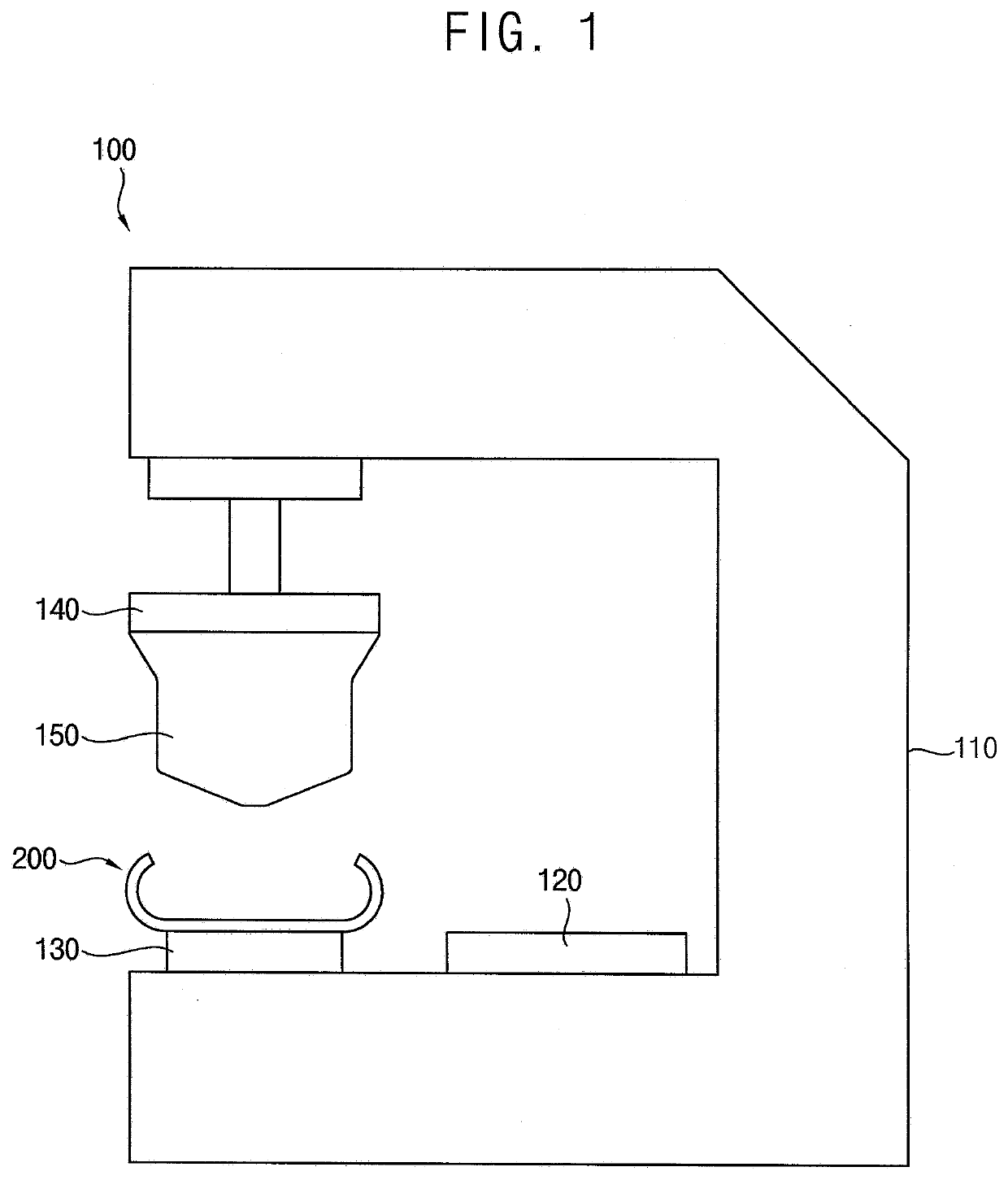

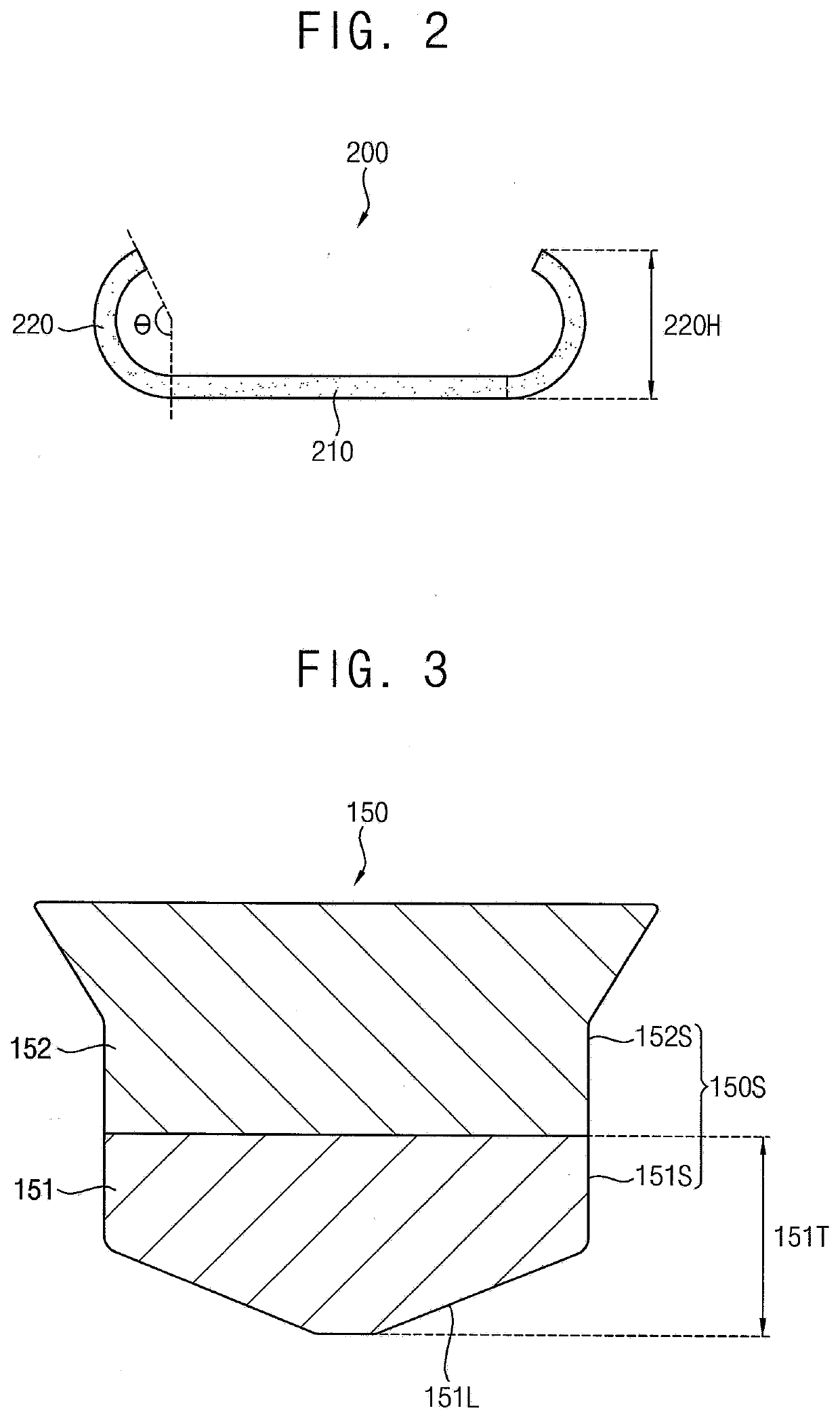

Pad printing device

A pad printing device for printing a window of a display device includes a pad to transfer ink to the window. The pad includes a printing portion to transfer the ink to the window by being pressed against the window and a body portion disposed on the printing portion and to apply a pressure to the printing portion. A hardness of the printing portion is less than a hardness of the body portion, and a sidewall of a portion of the pad where the printing portion contacts the body portion is substantially perpendicular to the window.

Owner:SAMSUNG DISPLAY CO LTD

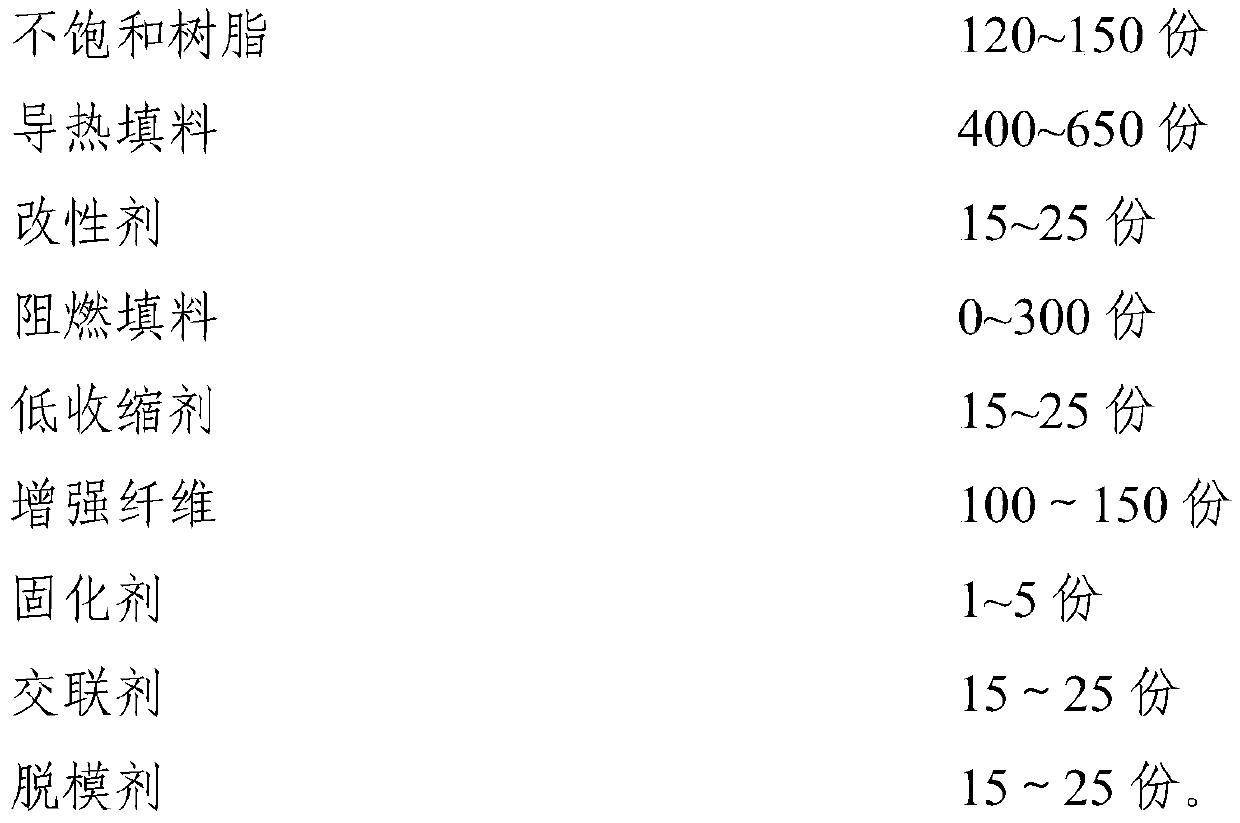

Unsaturated resin-based composite material, preparation method and applications thereof

The invention relates to the field of unsaturated resin materials, particularly to an unsaturated resin-based composite material, a preparation method and applications thereof, wherein the raw materials of the unsaturated resin-based composite material comprise a unsaturated resin, a thermal conduction filler and a modifier, the unsaturated resin is a unsaturated polyester resin and / or vinyl esterresin, the thermal conduction filler is alumina and silicon carbide, the modifier is polyethylene and / or polytetrafluoroethylene, and a weight ratio of the modifier to the thermal conduction filler is 15-25:400-650. According to the present invention, the thermal conductivity of the unsaturated resin-based composite material of the present invention is more than 2W / m''K, and is more than twice the thermal conductivity of the conventional unsaturated polyester resin and / or vinyl ester resin-based composite material; and the unsaturated resin (unsaturated polyester resin and / or vinyl ester resin) has good compatibility with the thermal conduction filler, such that the problem of excessive hardness caused by the addition of the thermal conduction filler can be avoided, the Barcol hardness ofthe material is less than 70, and the wear on the mold and the contact member is reduced.

Owner:SHANGHAI SHOWA HIGHPOLYMER CO LTD

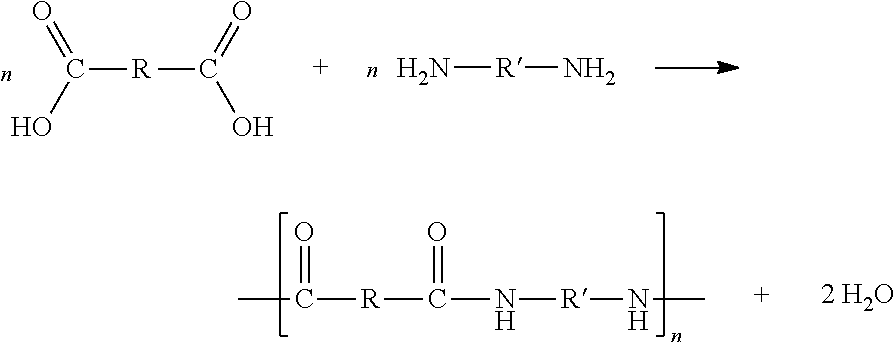

Three-cover-layer golf ball having transparent or plasticized polyamide intermediate layer

A golf ball includes a core and a three-layer cover disposed adjacent the core. The three-layer cover includes an inner cover, an intermediate cover, and an outer cover. The inner cover includes a non-ionomeric E / Y copolymer where E is an olefin and Y is a carboxylic acid. The inner cover has a hardness of about 45 to 68 Shore D. The outer cover includes a castable thermoset polyurethane and has a hardness of about 40 to 62 Shore D. The intermediate cover layer, disposed between the inner and outer cover layers, is formed from a polyamide composition, where the polyamide composition includes a transparent polyamide having a light transmission of about 50% or greater.

Owner:ACUSHNET CO

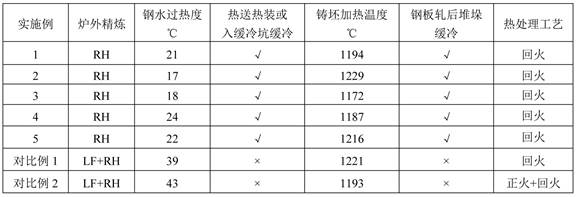

Low-cost plastic mold steel with uniform hardness in cross section direction and production method of low-cost plastic mold steel

The invention relates to low-cost plastic mold steel with uniform hardness in a cross section direction and a production method of the low-cost plastic mold steel. The steel comprises the following chemical components in percentage by mass: 0.40-0.50% of C, 0.70-1.00% of Si, 1.60-2.00% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.80-1.00% of Cr, 0.010-0.050% of Als, 0.010-0.030% of Ti, 0.0010-0.0020% of B, 0.0030-0.0080% of N and the balance of Fe and inevitable impurities. Meanwhile, the chemical components further need to meet the formula: B= -0.001507 + 0.0455Als + 0.0318Ti + 0.171N. According to the steel, precious metal elements such as Mo and Cu are not added, only vacuum treatment is adopted for refining molten steel, the rolling process is not limited, through the production process path of stacking cooling and tempering after rolling, normalizing heat treatment generally adopted by the plastic mold steel after rolling is omitted, so that the plastic mold steel is produced at low cost; and the steel disclosed by the invention is high in hardenability, uniform in hardness distribution along the cross section, and suitable for manufacturing plastic molds which have strict requirements on dimensional accuracy, surface roughness and the like and have complex cavities.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

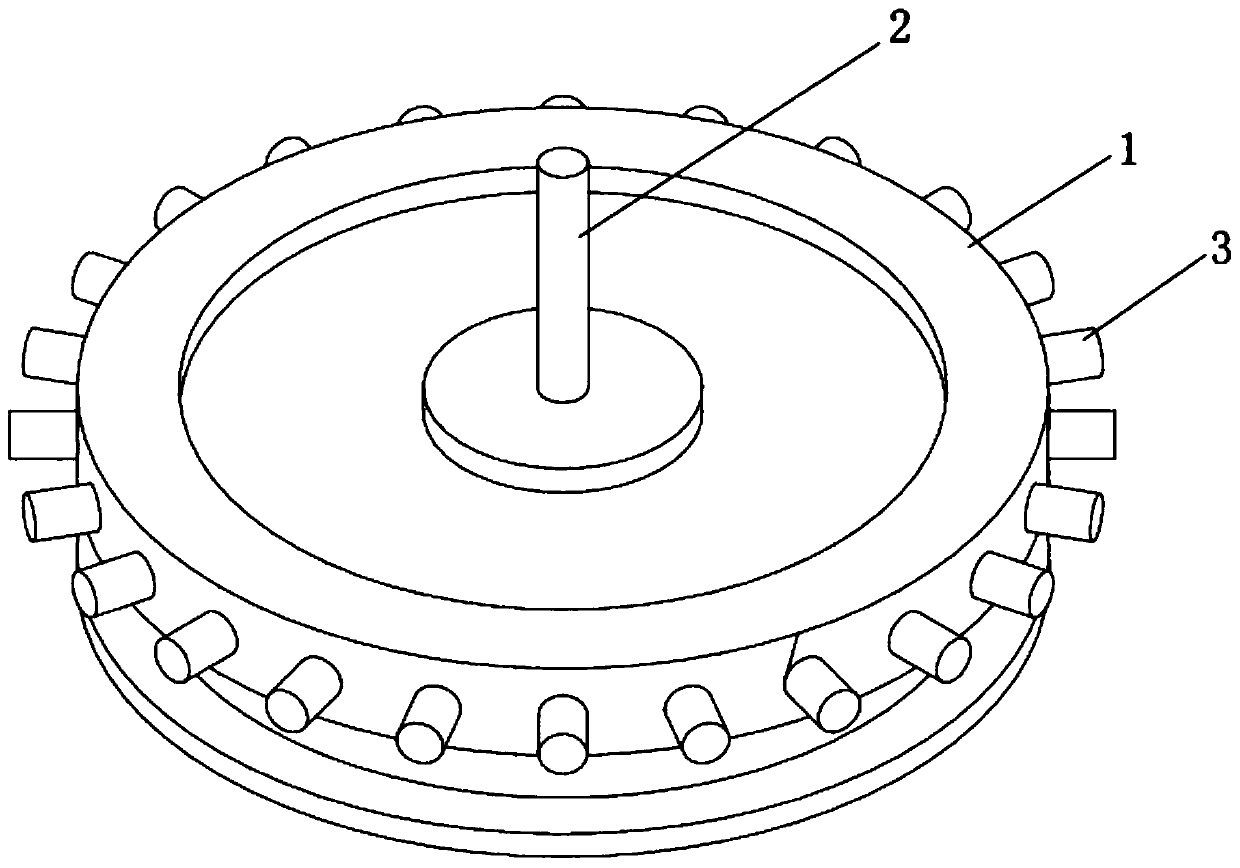

Edge starching wheel structure of edge starching device

InactiveCN110835816AReduce areaReduce consumptionTextile selvedgesLiquid/gas/vapor textile treatmentTextile printerStructural engineering

The invention relates to an edge starching wheel structure of an edge starching device. The edge starching wheel structure comprises a wheel disc and a connecting rotary shaft, wherein the connectingrotary shaft is fixed at the central axis of the wheel disc, a plurality of raised edge starching columns are evenly arranged on the outer side of the wheel disc along the circumferential direction atintervals, and the axis directions of the edge starching columns are arranged along the radial direction of the wheel disc. The edge starching wheel structure has the advantages that edge starching area can be reduced, sizing agent consumption for edge starching can be reduced favorably, the problem of excessively high fabric edge hardness caused by linear edge starching in the prior art can be avoided, the tightness difference between the edge of the edge-starched fabric and middle fabric, and the difficulties in the follow-up printing or composite processing of the fabric can be lowered favorably.

Owner:上海嘉麟杰纺织科技有限公司 +1

A vermicular graphite cast iron scroll and its production process

ActiveCN109536664BSmall sizeAvoid explosionRotary piston pumpsRotary piston liquid enginesUltimate tensile strengthGraphite morphology

The invention discloses a vermicular graphite cast iron scroll plate and a production process thereof. The plate is prepared by casting vermicular graphite cast iron, a raw material for the plate comprises the following components of, by mass: 3.6%-4.0% of C, 1.6%-2.0% of Si, 0.4%-0.8% of Mn, 0%-0.25% of P, 0.01%-0.04% of S, 0.20-0.6% of Cu, 0.04-0.08% of Sn, 0.10%-0.3% of Cr and the balance Fe and accompanying impurities. According to the vermicular graphite cast iron scroll plate, in the raw material production process, 0.30%-0.40% of a modification treating agent is adopted to control the creep rate of the graphite form to be 20%-60%, the mechanical performance of the scroll plate is greatly improved, the tensile strength is larger than or equal to 450N / mm<2>, the yield strength is larger than or equal to 315N / mm<2>, the elongation rate is less than or equal to 3%, and the hardness range is HB200-HB250, and the durability life test is up to 2600 hours.

Owner:苏州勤美达精密机械有限公司

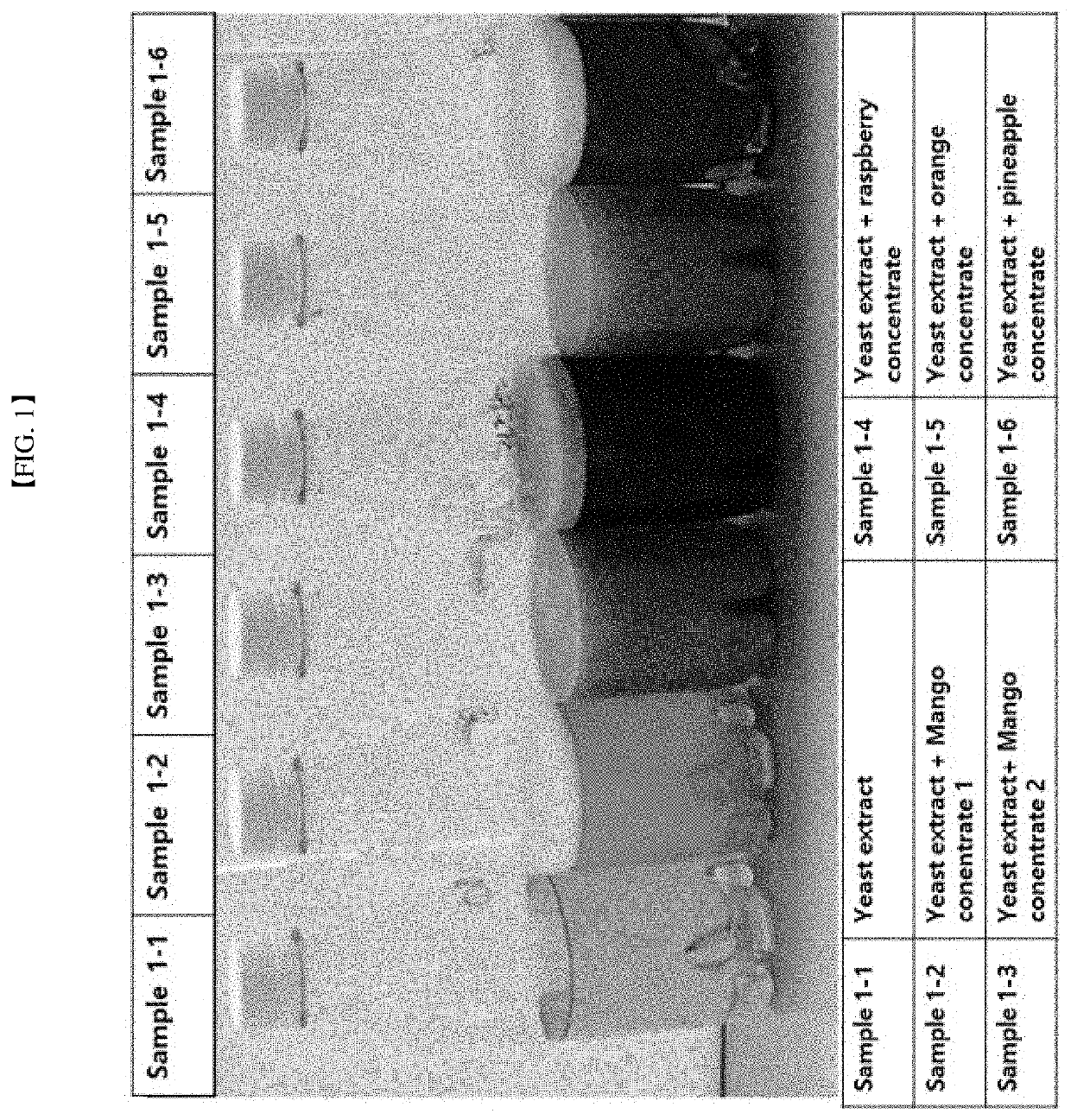

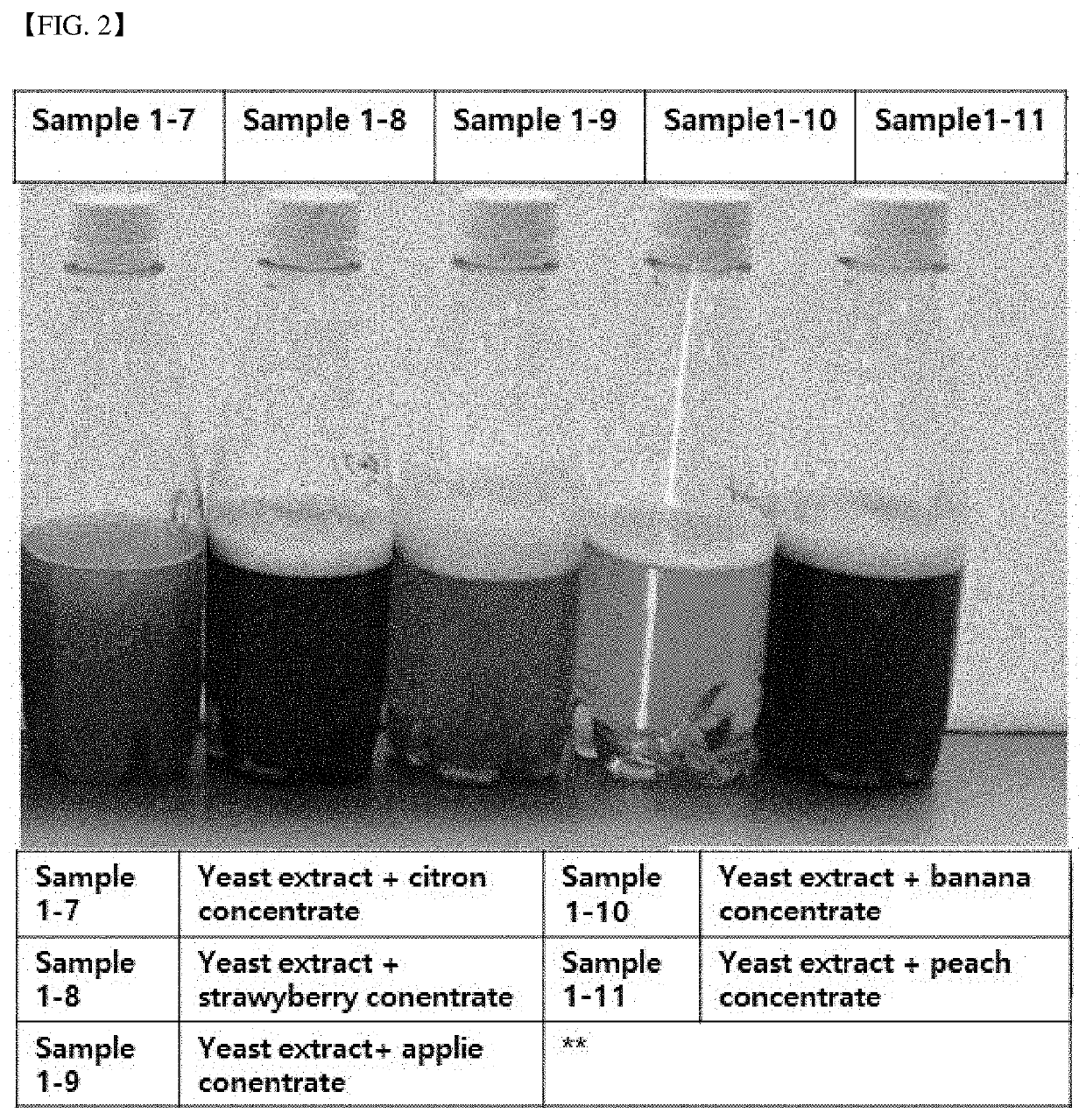

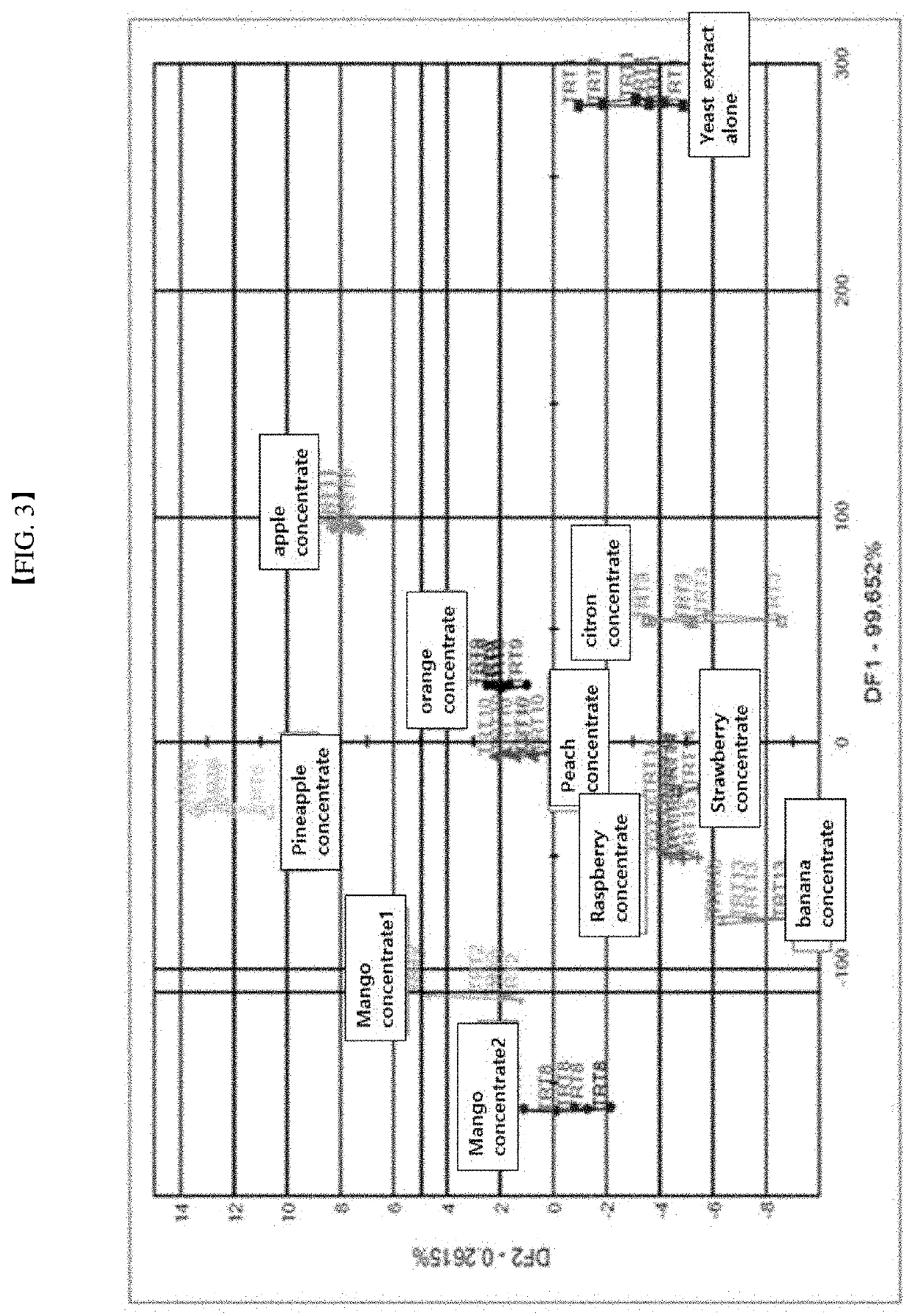

Gel-type food composition and manufacturing method therefor

PendingUS20210259292A1Less syneresisCertain shapeFood shapingNatural extract food ingredientsBiotechnologyBiology

The present invention relates to a gel type food composition with excellent storage stability and a method for preparing thereof, and more specifically, relates to a gel type food composition having excellent physical properties by reducing changes of physical properties, contamination and syneresis during storage or distribution.

Owner:SAMSANG CORP

Thermally stable and liquid-tight joint between a first ceramic, metal, or plastic component and a second ceramic, metal or plastic component, and the use of one such joint

InactiveUS7764505B2Increase elasticityAvoid contactLayered productsDigital storageAdhesiveComputer module

The invention relates to a joint which can be subjected to the temperature influences of an external medium (20) and joins an especially ceramic component (2) to an especially metallic component (1). Said joint consists of a first adhesive joint (14) between the metallic component and the ceramic component, and a second adhesive joint (22), the adhesive (16) of the second joint having a higher elasticity than that (10) of the first adhesive joint (14), and the second joint being arranged in such a way that it prevents direct contact between the first adhesive joint (14) and an external medium (20). The inventive joint can preferably be used, for example, preferably in a sensor module of a measuring appliance which can be introduced into a medium to be analyzed.

Owner:TESTO AG

Display device

ActiveUS8466470B2Increase resistanceAvoid excessive hardnessSemiconductor/solid-state device detailsElectroluminescent light sourcesDisplay deviceEngineering

A display device includes a wire substrate including a wire unit for driving the display device, an integrated circuit chip mounted at the wire substrate, and a pad unit extended from the wire unit to be disposed between the wire substrate and the integrated circuit chip. The pad unit is connected to the integrated circuit chip. The pad unit includes a first conductive layer extended from the wire unit, and a second conductive layer disposed on the first conductive layer. The hardness of the second conductive layer is less than the hardness of the first conductive layer.

Owner:SAMSUNG DISPLAY CO LTD

Golf ball with a non-ionomeric inner cover, stiff TPU intermediate cover, and cast thermoset outer cover

ActiveUS20100234140A1Avoid excessive hardnessGolf ballsSolid ballsThermoplastic polyurethaneHardness

A golf ball including a core and a cover disposed about the core. The cover includes a thermoplastic inner cover layer having a hardness between 55 and 60 Shore D; an outer cover layer having a hardness between 55 and 60 Shore D; and a stiff intermediate cover layer disposed between the inner and outer cover layers and having a hardness greater than the inner cover layer and the outer cover layer. The inner cover layer is formed from a non-ionomeric composition including a non-ionomeric stiffening polymer and at least one E / Y copolymer or E / X / Y terpolymer, where E is an olefin, Y is a carboxylic acid, and X is a softening comonomer. The intermediate cover layer is formed from a stiff thermoplastic polyurethane or polyurea composition and the cover outer cover layer is formed from a thermoset polyurethane, a polyurea, or a urethane-urea blend.

Owner:ACUSHNET CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com