Patents

Literature

47 results about "Graphite morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

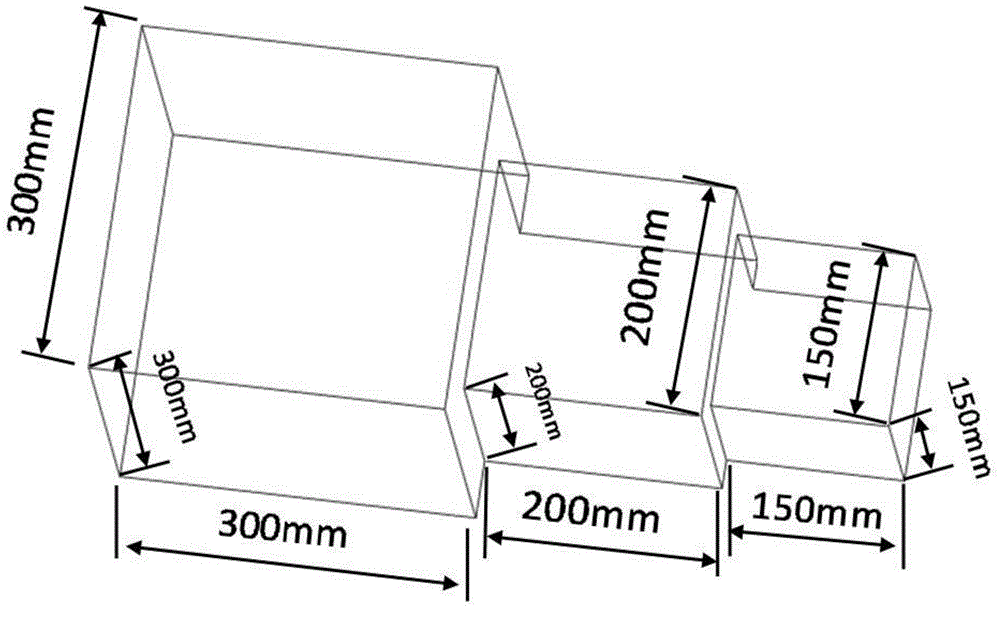

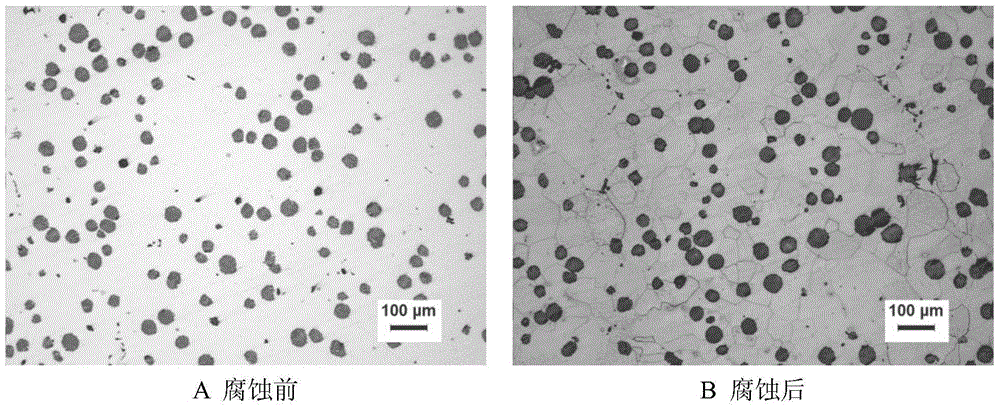

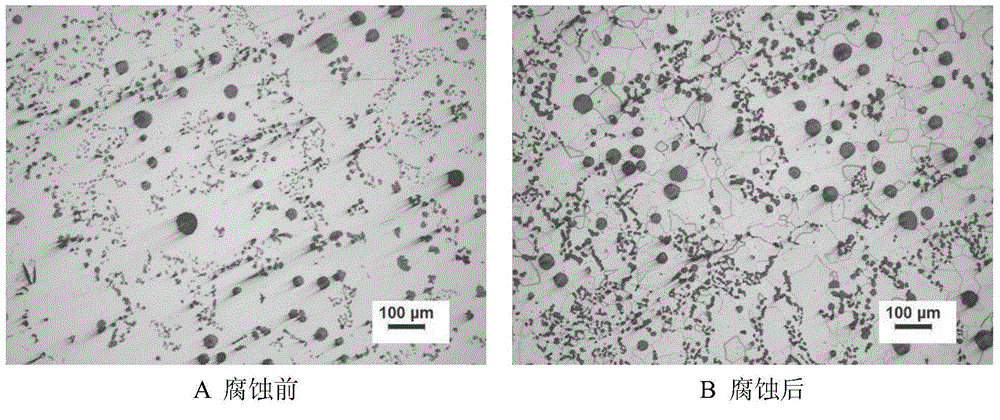

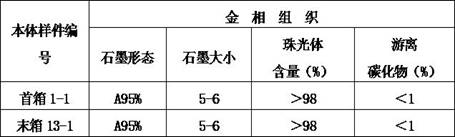

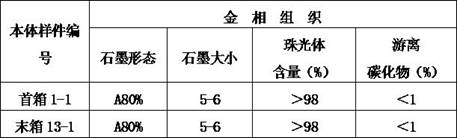

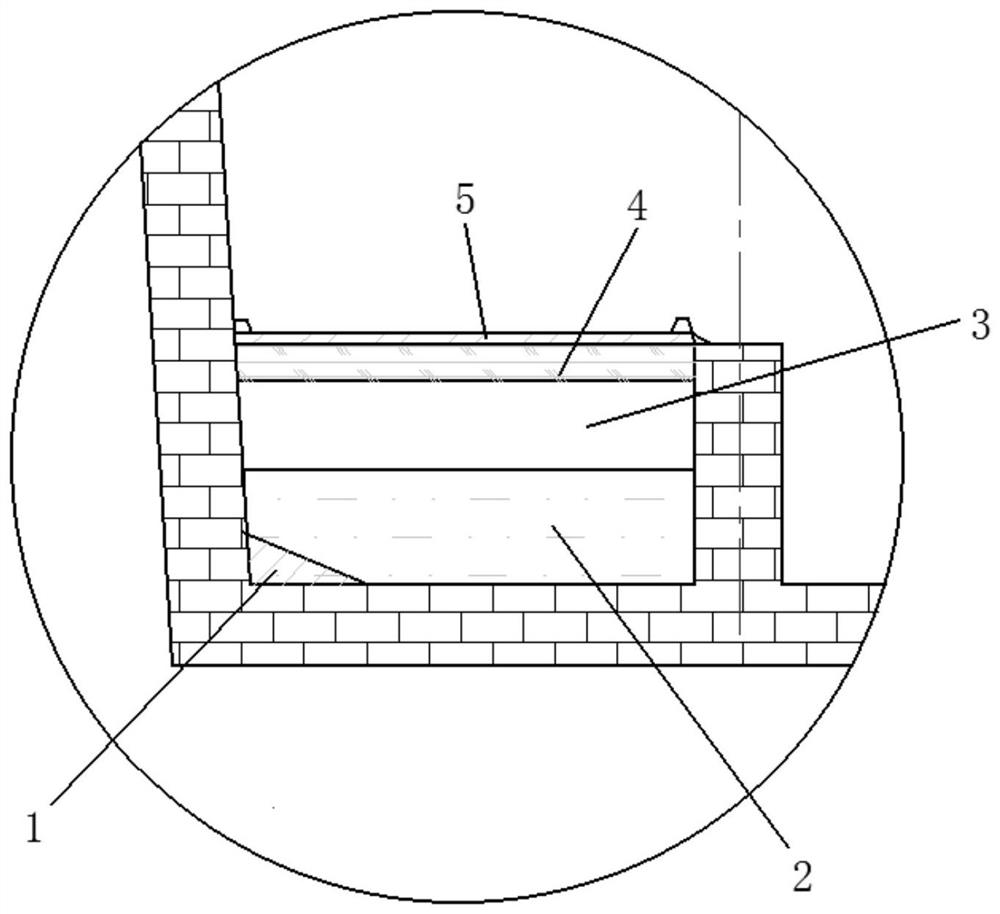

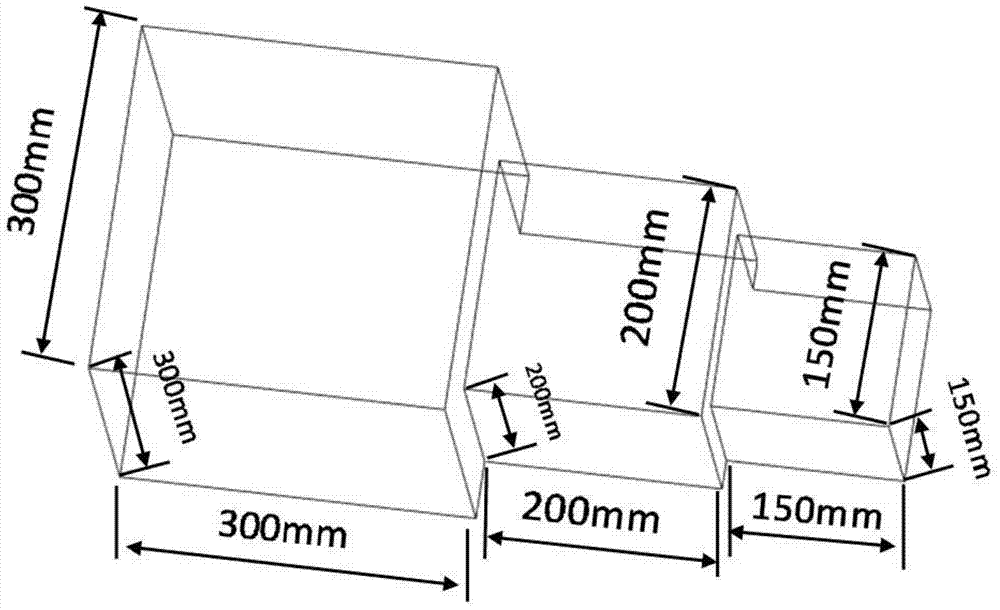

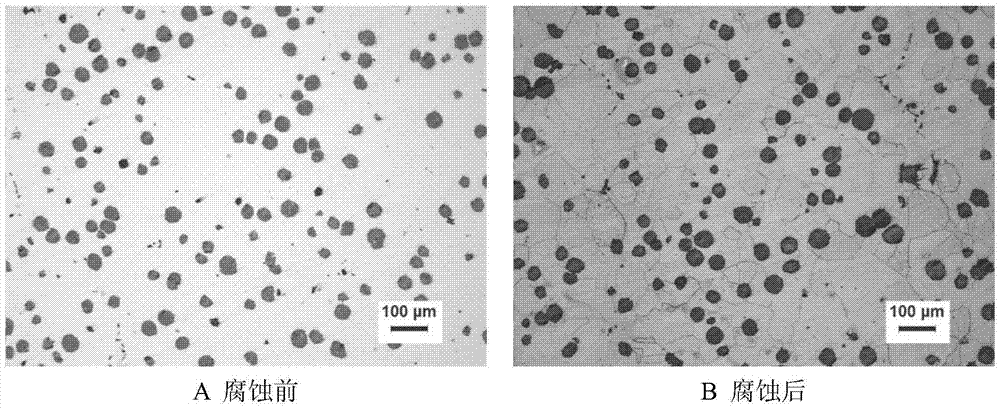

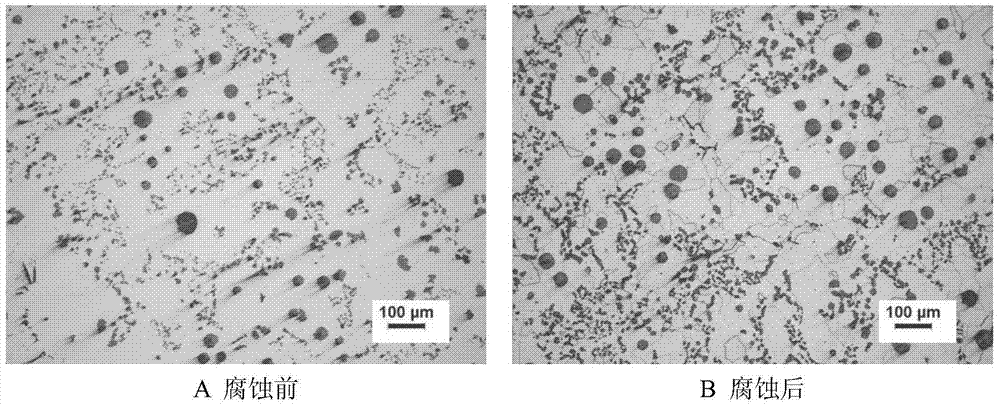

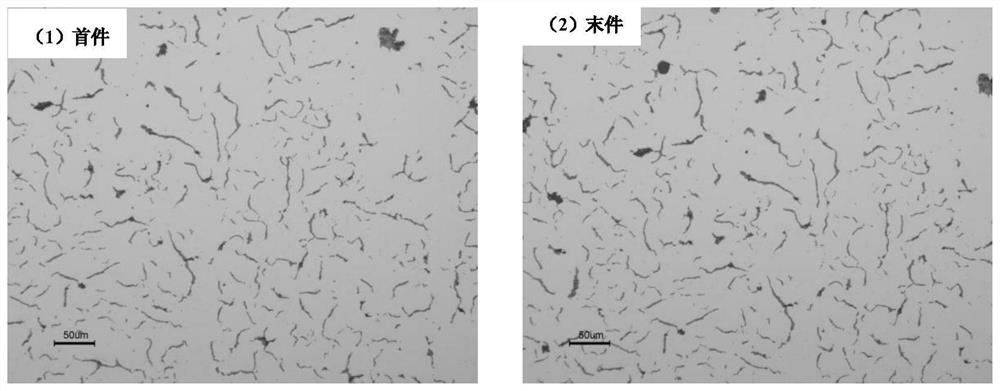

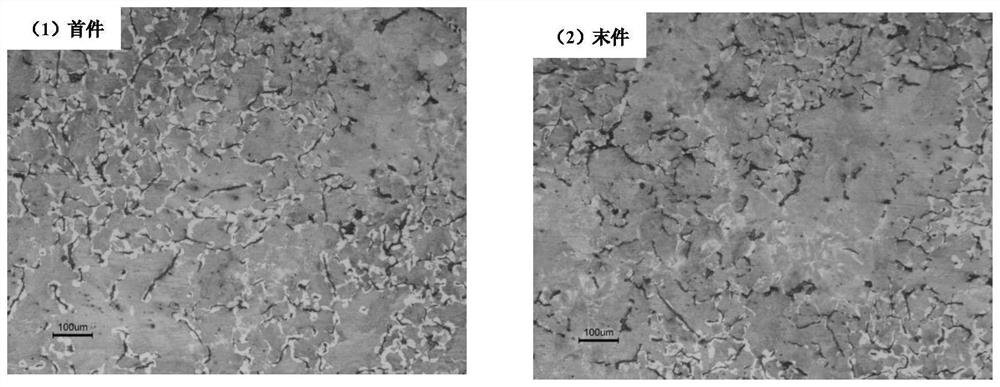

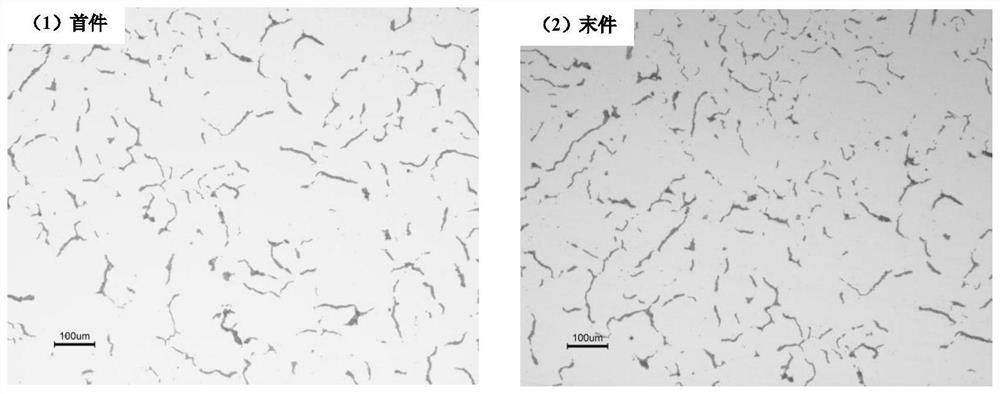

Method of controlling graphite shape of core of large-cross-section silicon solid solution strengthening ferritic nodular cast iron

The invention belongs to the technical field of cast iron, and particularly relates to a technological method of ensuring the graphite shape and performances of the core of large-cross section silicon solid solution strengthening ferritic nodular cast iron. The technical scheme of the invention is to provide a method of ensuring the graphite shape of the core of a large-cross section silicon solid solution strengthening ferritic nodular iron casting. The method comprises the following steps of: dissecting the core of an ingot bar with the wall thickness of larger than 300mm and trepanning a large casting body with the wall thickness of larger than 60mm by selecting raw materials, controlling compositions of molten iron, optimizing a nodulizing agent, a covering agent and treatment technologies thereof and determining an inoculant and a treatment technology thereof as well as the addition amount of trace alloying elements and an addition method thereof, so that on the premise of meeting requirements on related properties of materials, chunky graphite does not occur in the core of the ingot bar and the large casting body, a graphite nodule is round and complete, the nodularity is greater than or equal to 80%, the content of ferrite in a matrix structure is greater than 95%, and the content of pearlite in the matrix structure is less than 5%.

Owner:JIANGSU JIXIN WIND ENERGY TECH

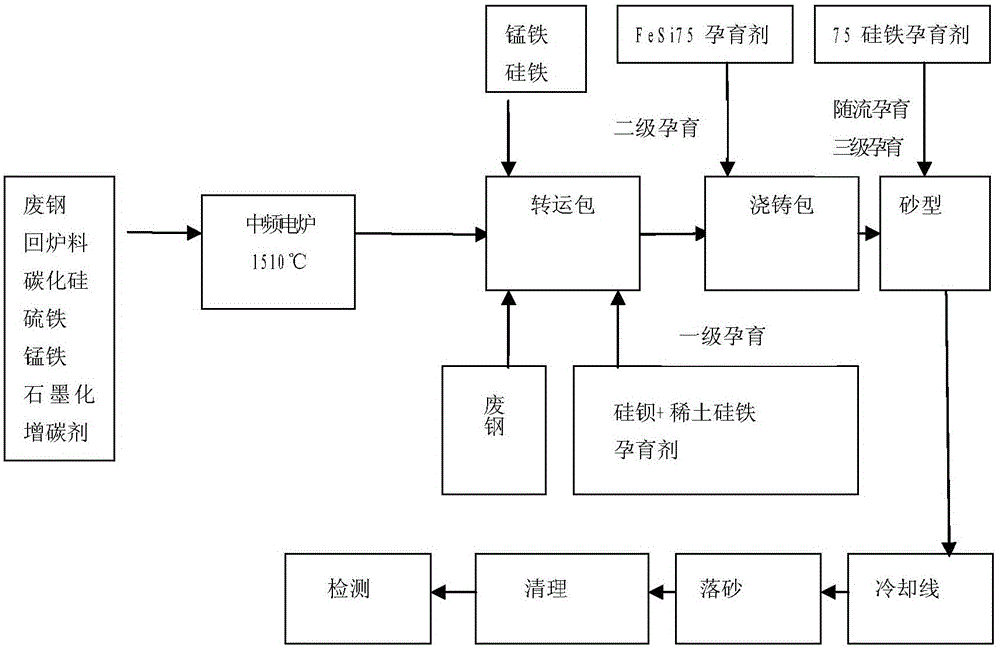

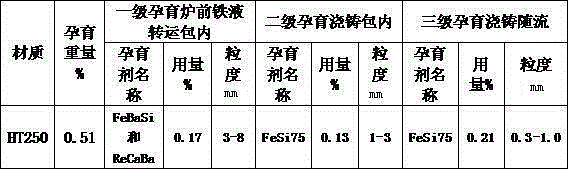

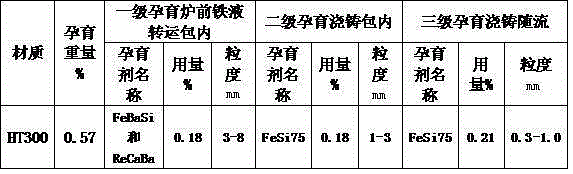

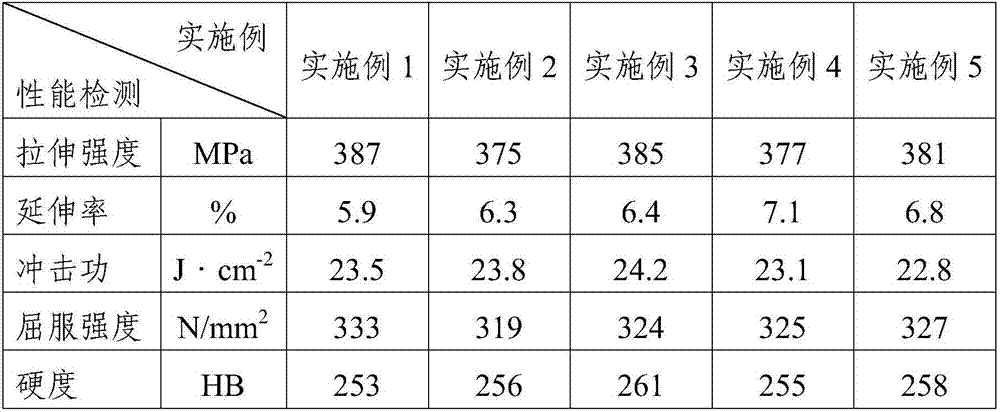

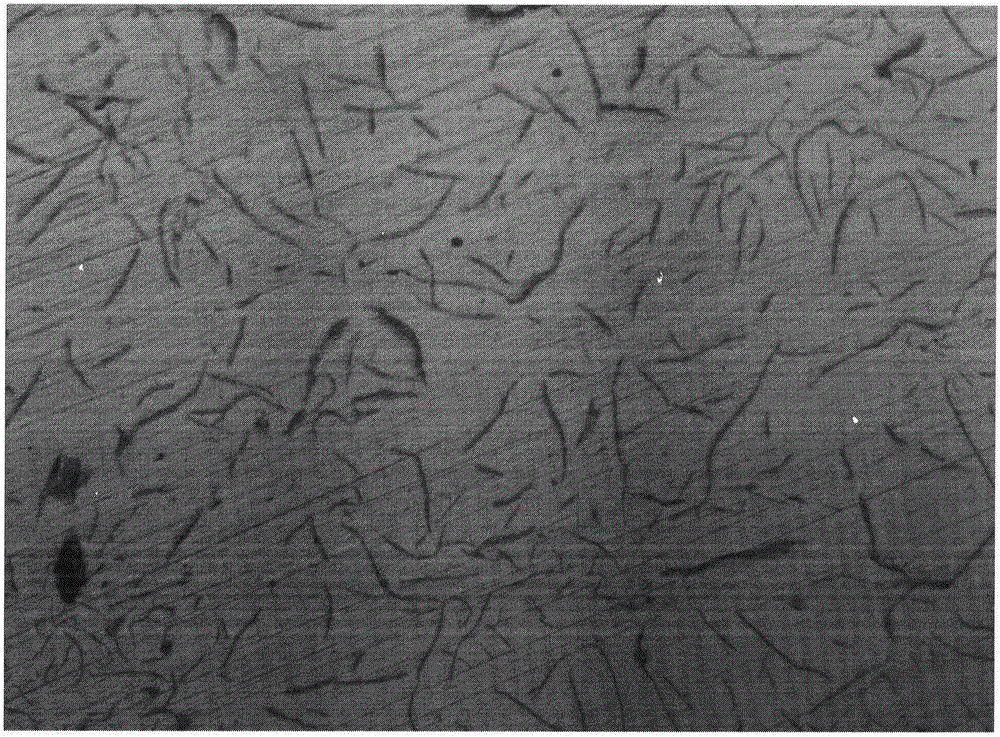

Manufacturing method for hydraulic castings produced through non-alloyed high-strength gray cast iron

InactiveCN105088056AIncrease the number ofImprove fertilityProcess efficiency improvementThree levelInduction furnace

The invention relates to a manufacturing method for hydraulic castings produced through non-alloyed high-strength gray cast iron. The method comprises the following steps that firstly, the mutual relation of elements and chemical components needed by the castings are determined; secondly, a medium-frequency induction furnace is adopted for smelting; thirdly, a stokehole molten iron transfer ladle is used for furnace charge to be mixed with alloy and steel scrap; fourthly, three-level inoculation is performed on molten iron; and fifthly, the cooling time is controlled to obtain the castings HT250 and HT300. On the non-alloyed premise, the high carbon equivalent is adopted, full steel scrap smelting silicon carbide increasing treatment is performed, a graphitizing carburant is used for adjusting the carbon quantity for synthesizing cast iron, the number of crystal nucleuses and the amount of cast iron are increased, the graphite form is improved, the overall molten iron quality is improved, and therefore the high-strength gray cast iron hydraulic castings HT250 and HT300 are stably obtained.

Owner:ANHUI DATIAN CASTING

Method for casting box-type complex water-cooling exhaust pipe by using iron mold coated sand

A method for casting a box-type complex water-cooling exhaust pipe by using an iron mold coated sand is disclosed. By using the water-free coated sand mold, the method helps to realize rapid cooling and mold filling, eliminate the defects of nail-passing-hole structure loosening and casting deformation often happening in the water-cooling exhaust pipe; and the prepared water-cooling exhaust pipe has higher tensile strength, higher hardness, better graphite morphology and better graphite grade, and the amount of stable pearlites is 98% or more. The yield of castings is improved from 54% to 96% or more. The finished product is good in texture compactness, good in texture refining capability, good in surface quality, and stable and reliable in quality. Also, during the production, the method has the advantages of being small in use level of the sand and paints, small in equipment investment, small in equipment occupied area, high in production efficiency, low in manufacture cost, good in environmental protection property, wide in prospect, and applicable to production of various engine exhaust pipes with high quality demands and complex thin-wall double-layer walls.

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

Microalloying high-strength gray pig iron piece and smelting method thereof

The invention provides a microalloying high-strength gray pig iron piece and a smelting method thereof and relates to the field of metal casting. The gray pig iron piece comprises, by weight percent, 2.92%-3.48% of C, 1.52%-2.36% of Si, 0.22%-0.78% of Mn, 0.15%-0.5% of Cr, 0.3%-0.78% of Cu, 0.011%-0.098% of Nb, 0.02%-0.1% of V, 0.015%-0.025% of Ti and the balance iron and other traces of unavoidable impurities. A casting piece base body is intensified through microalloying, the intensity and the rigidity of the casting piece are improved, a high-efficiency nucleating agent is added, graphite form, hardness and texture uniformity can be effectively improved, the sensibility is reduced, the mechanical performance of the gray pig iron piece is improved, by adopting the in-mold inoculation manner, the utilization rate of the nucleating agent can be improved, the inoculation effect is improved, and the cost is reduced.

Owner:HANSHAN ZHAOXIA CASTING

Inoculant for increasing strength of gray cast iron, preparation method and use method thereof

InactiveCN105039629APromote generationImprove and refine A-type graphiteChemical compositionHigh carbon

The present invention discloses an inoculant for increasing the strength of gray cast iron, a preparation method and a use method thereof, and belongs to the technical field of casting. According to the present invention, nitrogen is adopted as an alloy element so as to significantly refine graphite, change graphite morphology, reduce structure wall thickness sensitivity and significantly increase the pearlite content, such that the tensile strength of the gray cast iron is improved, and especially the significant effects are provided for the high-carbon equivalent gray cast iron or high-carbon gray cast iron; the chemical components of the inoculant comprise, by weight, 25-35% of Si, 10-20% of Mn, 10-20% of Cr, less than 0.1% of C, 1-5% of Ca, 1-6% of Ba, 1-6% of N, less than 0.05% of P, less than 0.02% of S, and the balance of Fe; and for the original hot metal having the same components, compared with the ferrosilicon inoculants, the tensile strength of the gray cast iron can be improved by 30-80 MPa with the inoculant of the present invention.

Owner:濮阳市中壹电子科技有限公司

Alloy gray cast iron material for automobile brake disc, automobile brake disc and preparation method thereof

InactiveCN107345285AGood shape of graphiteFast heat conductionFriction liningActuatorsWear resistanceGraphite morphology

Owner:TONGFU HEAT TREATMENT KUNSHAN +1

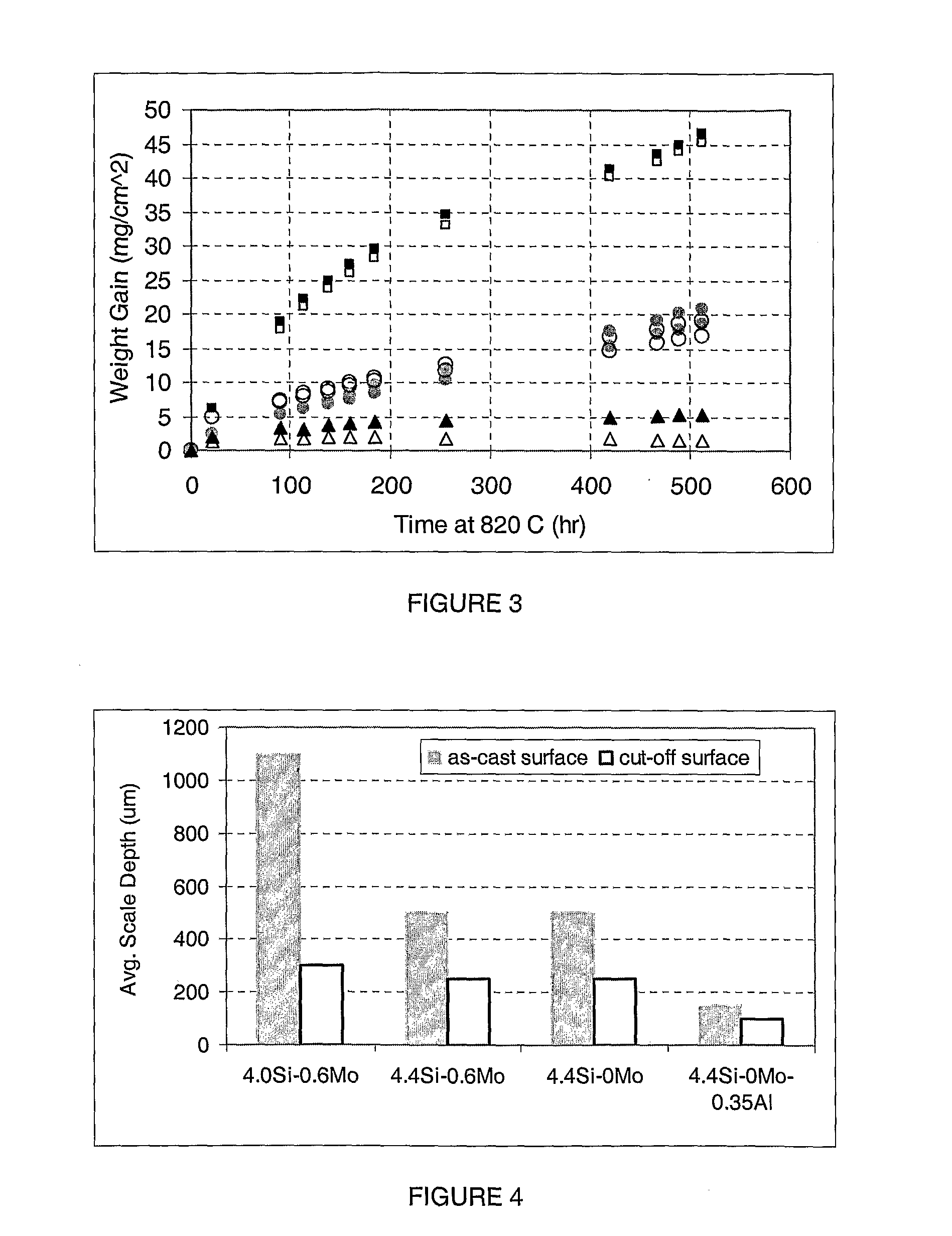

Cast Iron With Improved High Temperature Properties

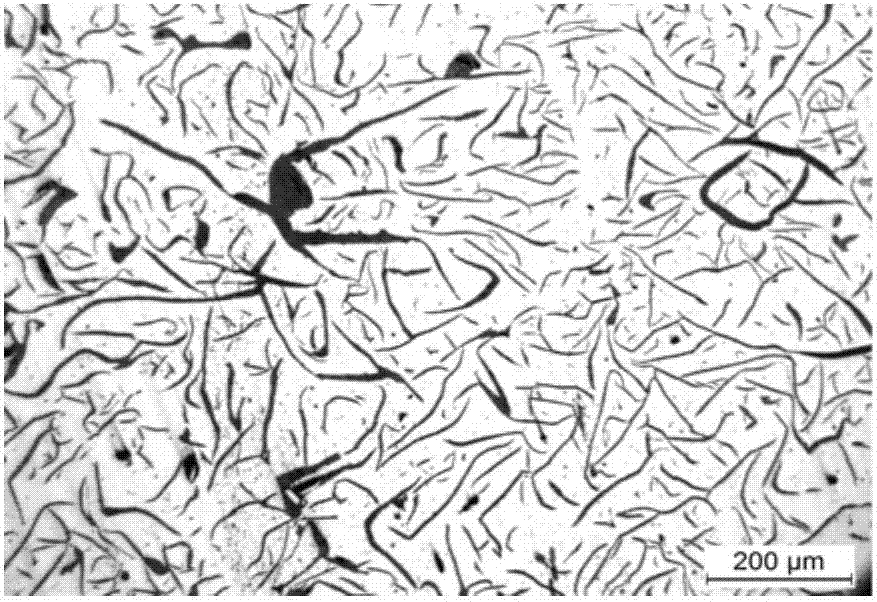

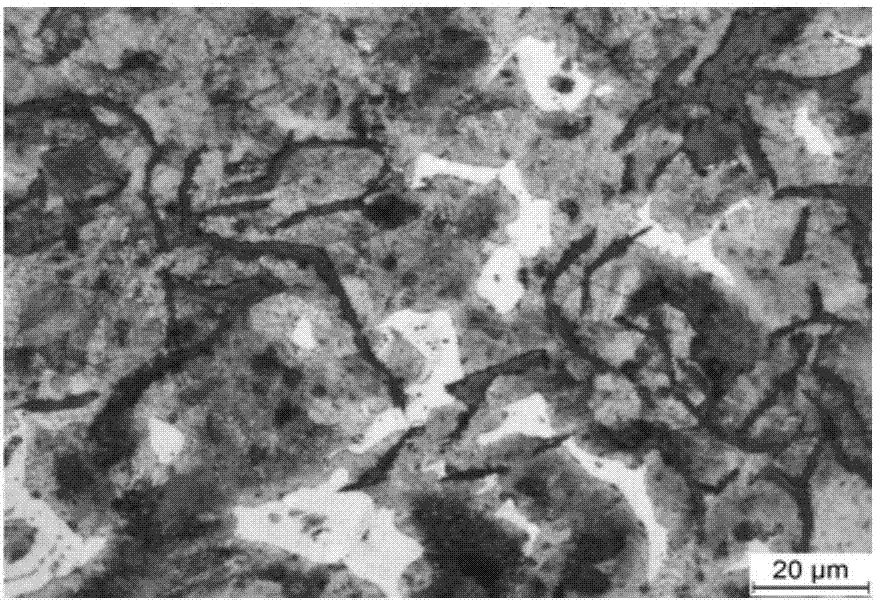

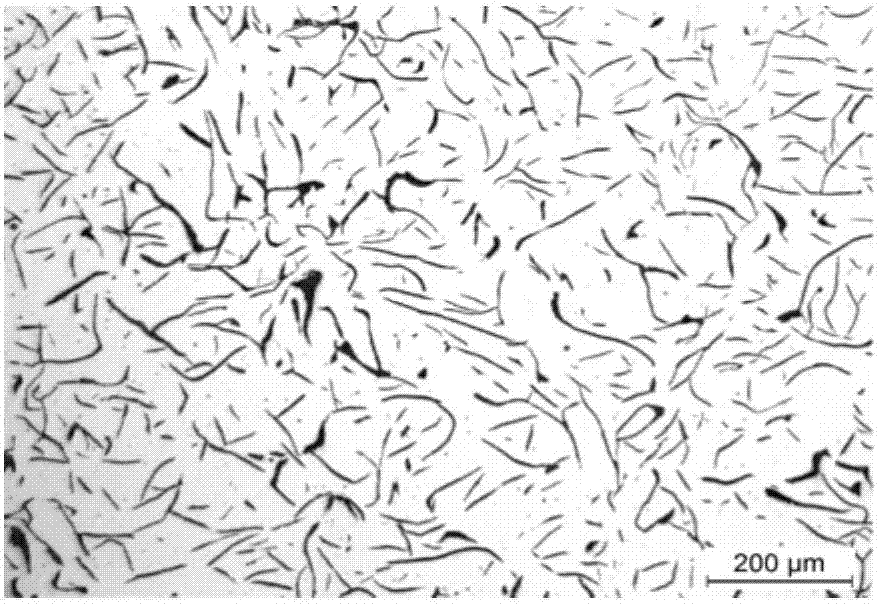

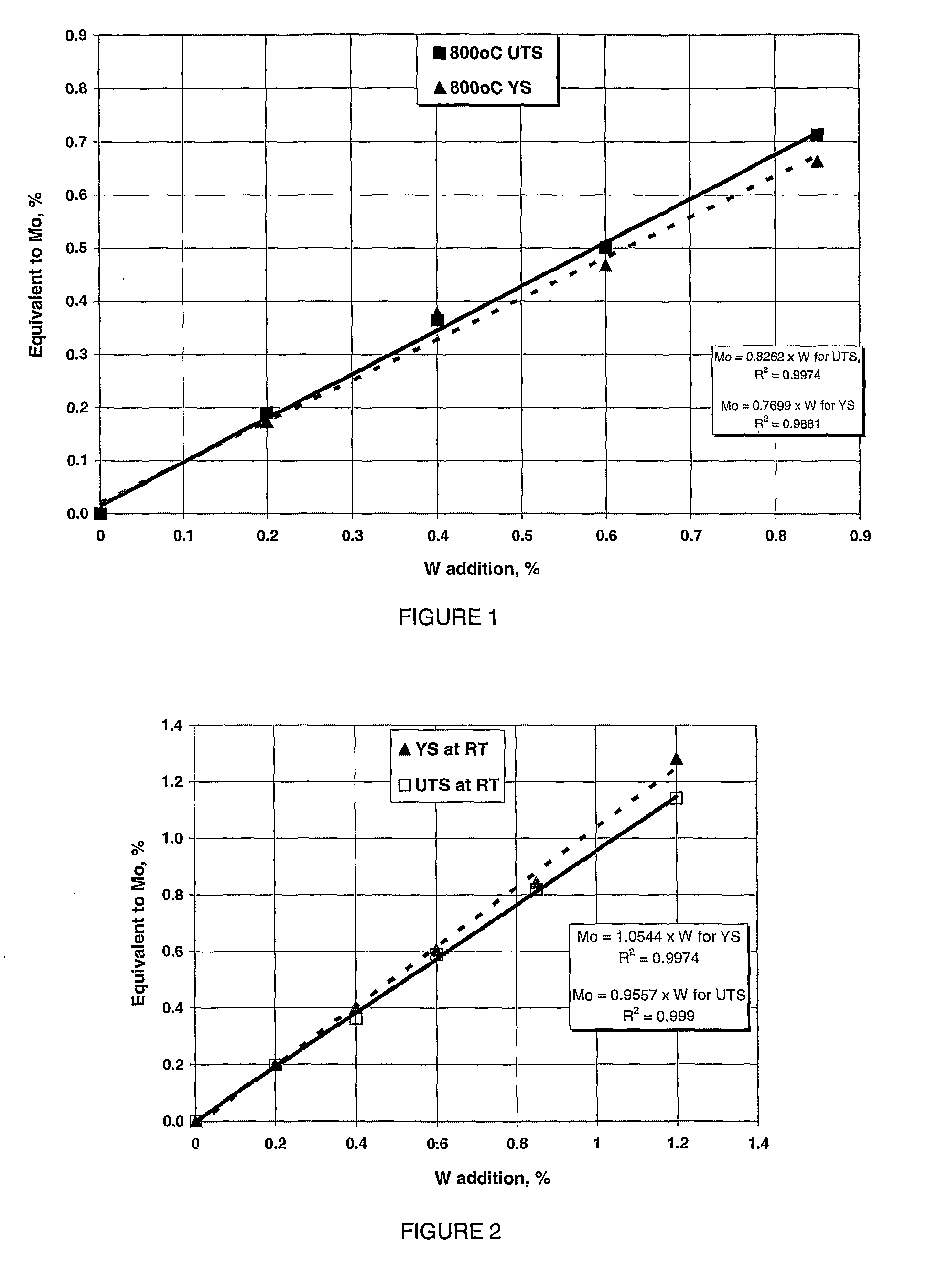

A nodular, compacted graphite or other hybrid or duplex graphite morphology cast high silicon iron is disclosed which contains up to 1.5% tungsten, up to 0.8% vanadium, and up to 1.2% niobium; and at least 60.0% iron, all percentages are based on the total weight of the composition. This cast iron exhibits high strength and good ductility over a wide temperature range compared to the conventional SiMo ductile iron. The compositions may further contain, up to 1.5% molybdenum and up to 1.0% chromium to offer improvements in material strength. The compositions may include 0.2 to 0.5% by weight aluminum and up to 1.2% chromium for further oxidation resistance and 0.5 to 5.0% nickel for corrosion resistance.

Owner:WESCAST INDS

Gray cast iron inoculation process

The invention relates to a graphitic cast iron inoculation technology. The technology is to add a composite inoculant of inoculated rare earth barium-calcium alloy with the granularity between 3 and 8 millimeters, silicon-calcium alloy with the granularity less than or equal to 5 millimeters and ferromanganese with the granularity less than or equal to 15 millimeters, which accounts for 0.3 to 0.5 percent of the weight of an iron liquor required to be treated, into a ladle for stokehole treatment. In order to prevent the fact that the inoculant can not enter into the iron liquor to be treated because the inoculant is wrapped by furnace slag, the composite inosulant can be held into a metal box provided with a plurality of vent holes, and the metal box is directly thrown into the ladle under the condition of stokehole treatment. The technology has the advantages that the technology adopts addition of the rare earth barium-calcium alloy, the silicon-calcium alloy and the ferromanganese into the ladle, is favorable for improving the inoculation capability of the iron liquor and strengthening the inoculation effect, can make the strength of graphitic cast iron reach more than 260 MPa, obviously thins pearlite in a substrate, reduces the segment pitch of the pearlite, improves the graphite form, makes the cast iron obtain good graphite tissue, and stably improves the strength of the graphitic cast iron.

Owner:大连核心铸造技术工程研究所

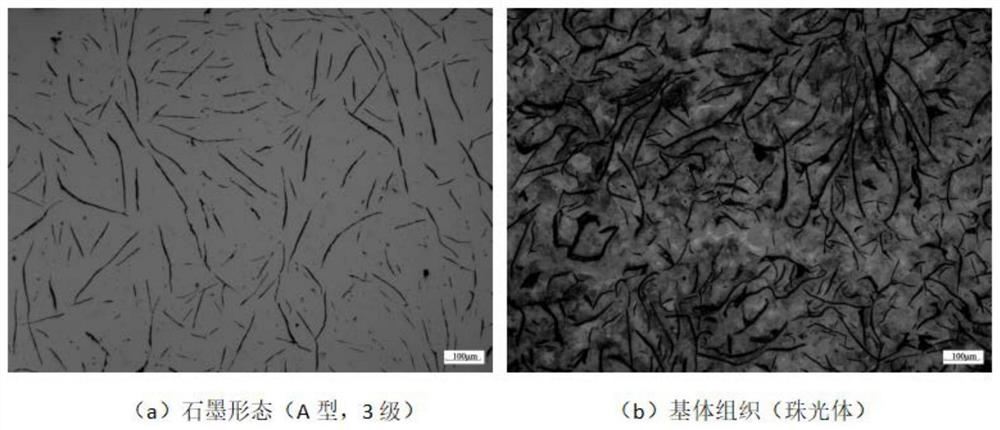

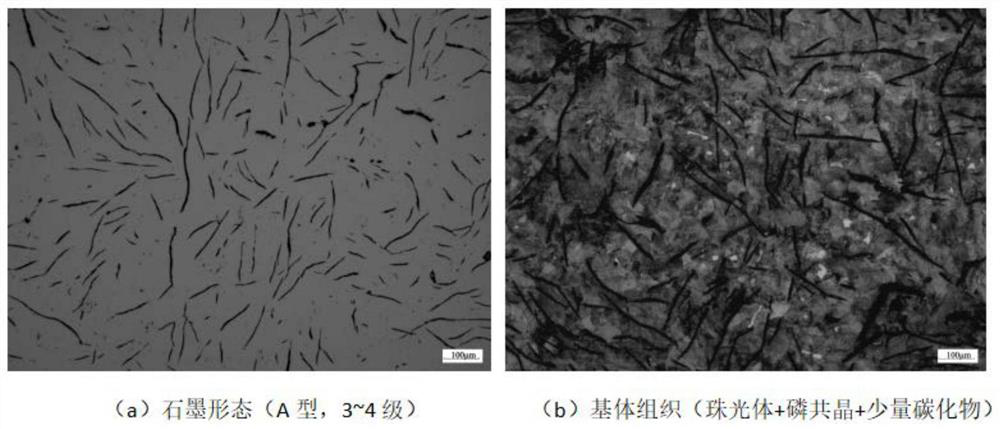

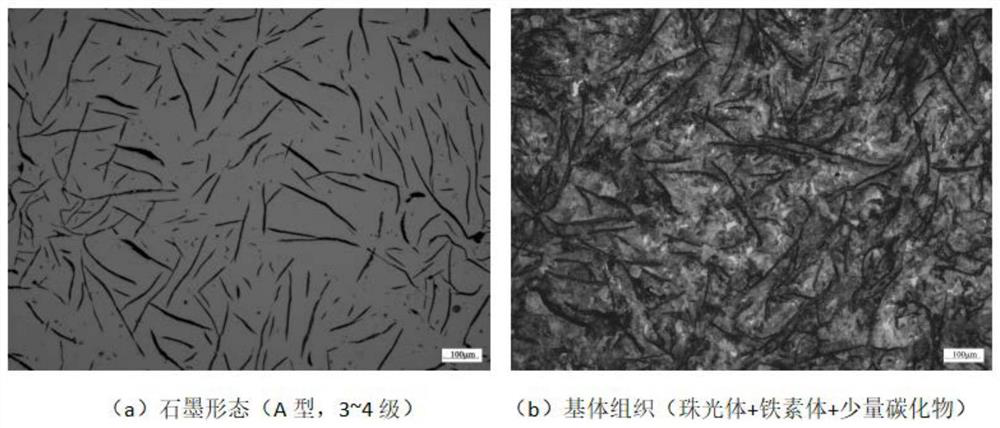

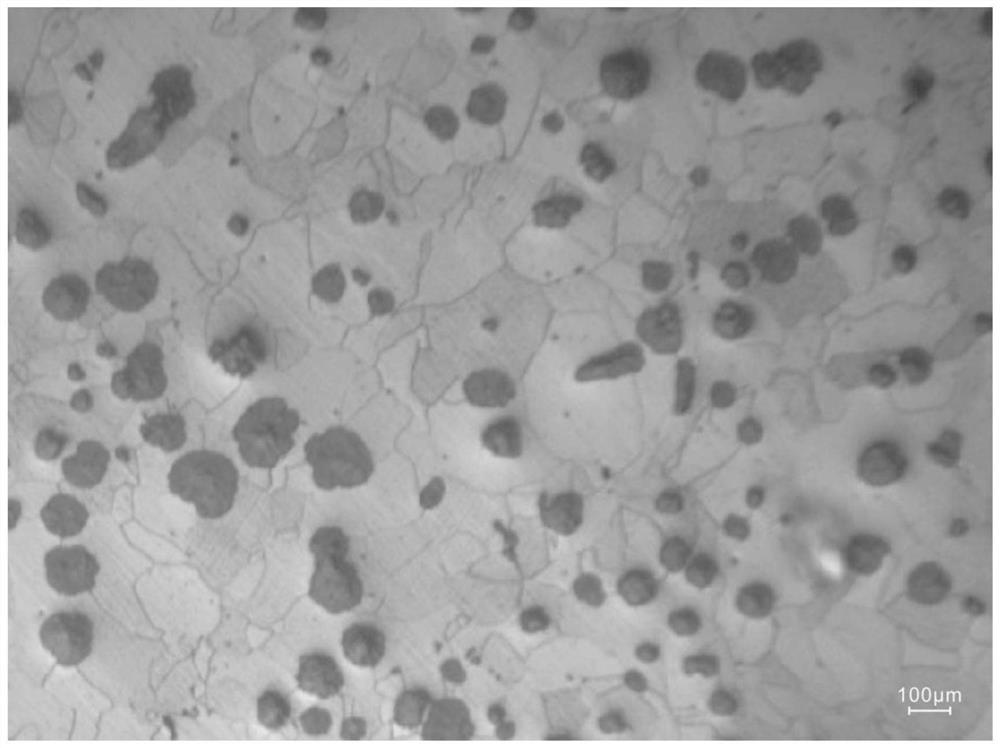

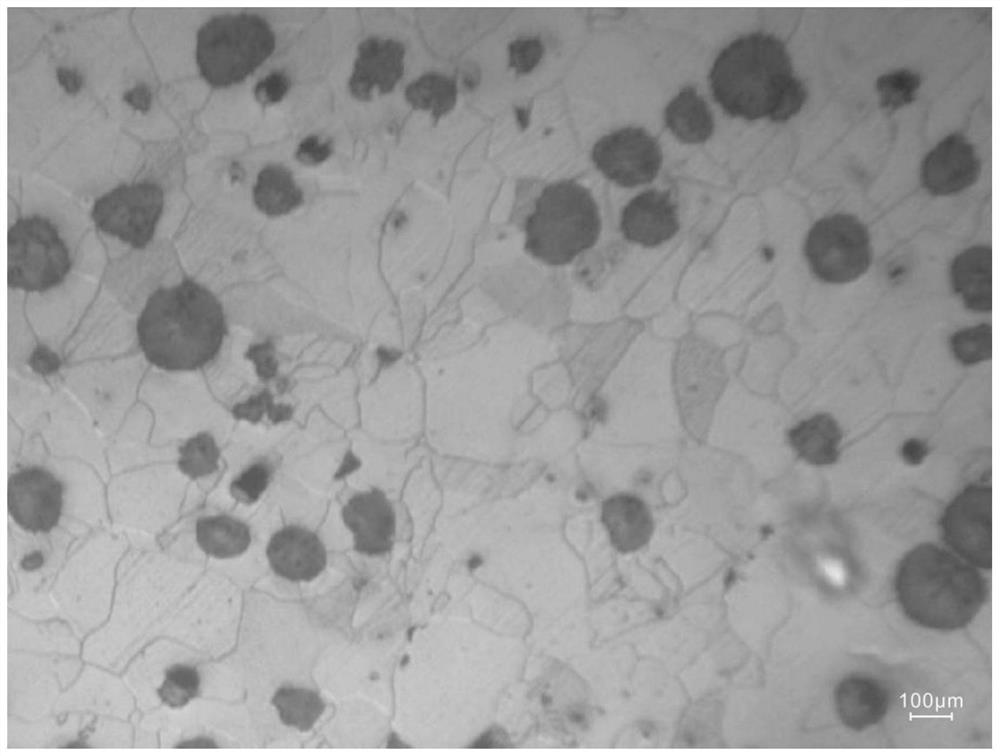

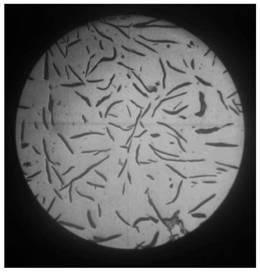

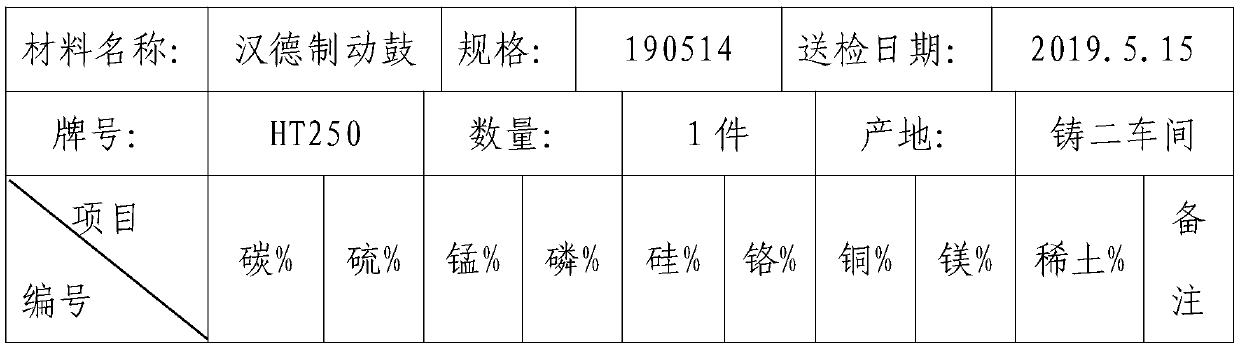

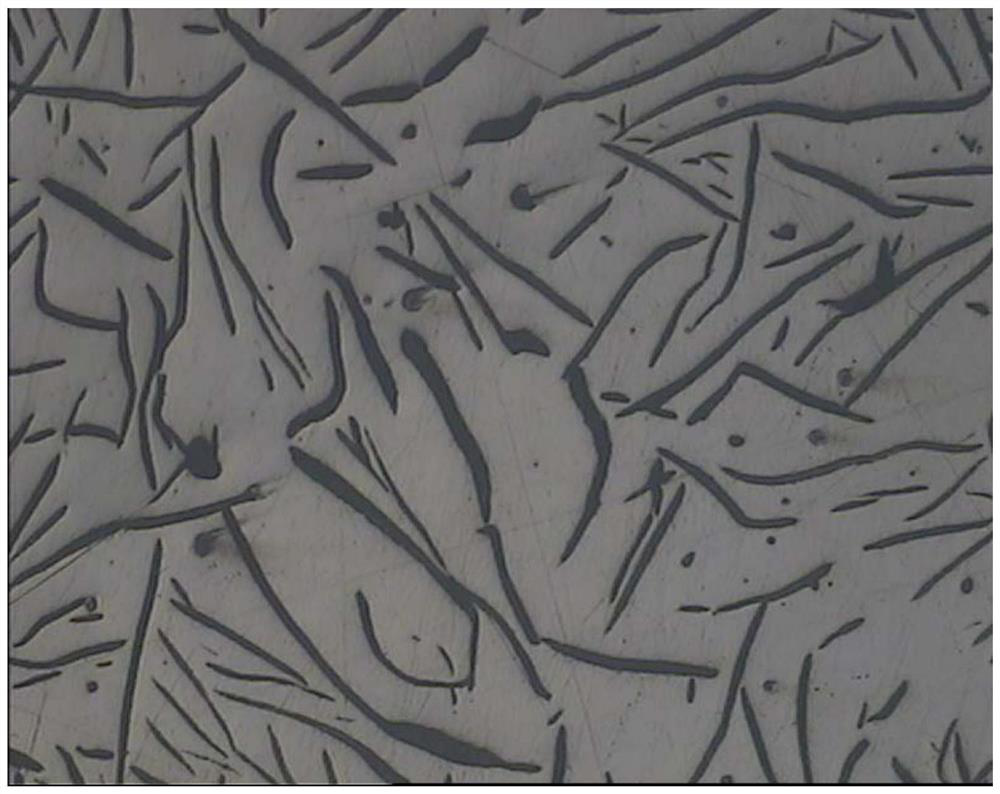

Gray cast iron material for commercial vehicle brake drum and preparation method of gray cast iron material

The invention discloses a gray cast iron material for a commercial vehicle brake drum and a preparation method of the gray cast iron material. The gray cast iron material comprises 3.7%-3.9% of C, 1.6%-2.0% of Si, 0.5%-0.7% of Mn, 0.05%-0.1% of S, 0.5%-0.7% of Cu, 0.1%-0.3% of Cr, 0.07%-0.1% of V, 0.05%-0.1% of Sn, 0.01%-0.04% of Zr, 0.007%-0.01% of La and the balance Fe and inevitable impurities. The preparation method comprises the following steps that raw materials are smelted to obtain a liquid raw material, the temperature is increased to 1500 DEG C-1530 DEG C, a pretreating agent is added, cooling is conducted to 1480 DEG C-1500 DEG C to obtain base molten iron, the base molten iron is poured into a casting ladle, an inoculant is added when the molten iron is discharged to obtain molten iron, the molten iron is poured at 1370 DEG C-1430 DEG C, and stream inoculation is carried out simultaneously to obtain the gray cast iron material for the commercial vehicle brake drum. According to the gray cast iron material for the commercial vehicle brake drum and the preparation method of the gray cast iron material, the measures of molten iron pretreatment, secondary inoculation and the like are adopted, the graphite form is A type graphite with the moderate size and a small amount of C type graphite, a matrix structure with the fine sheet pearlite larger than or equal to 95% is obtained, the tensile strength of a brake drum body is 210 Mpa-260 Mpa, the working face hardness value is 180 HBW-220 HBW, the thermal fatigue performance of the brake drum can be effectively improved, and the service life of the brake drum can be effectively prolonged.

Owner:SINO TRUK JINAN POWER

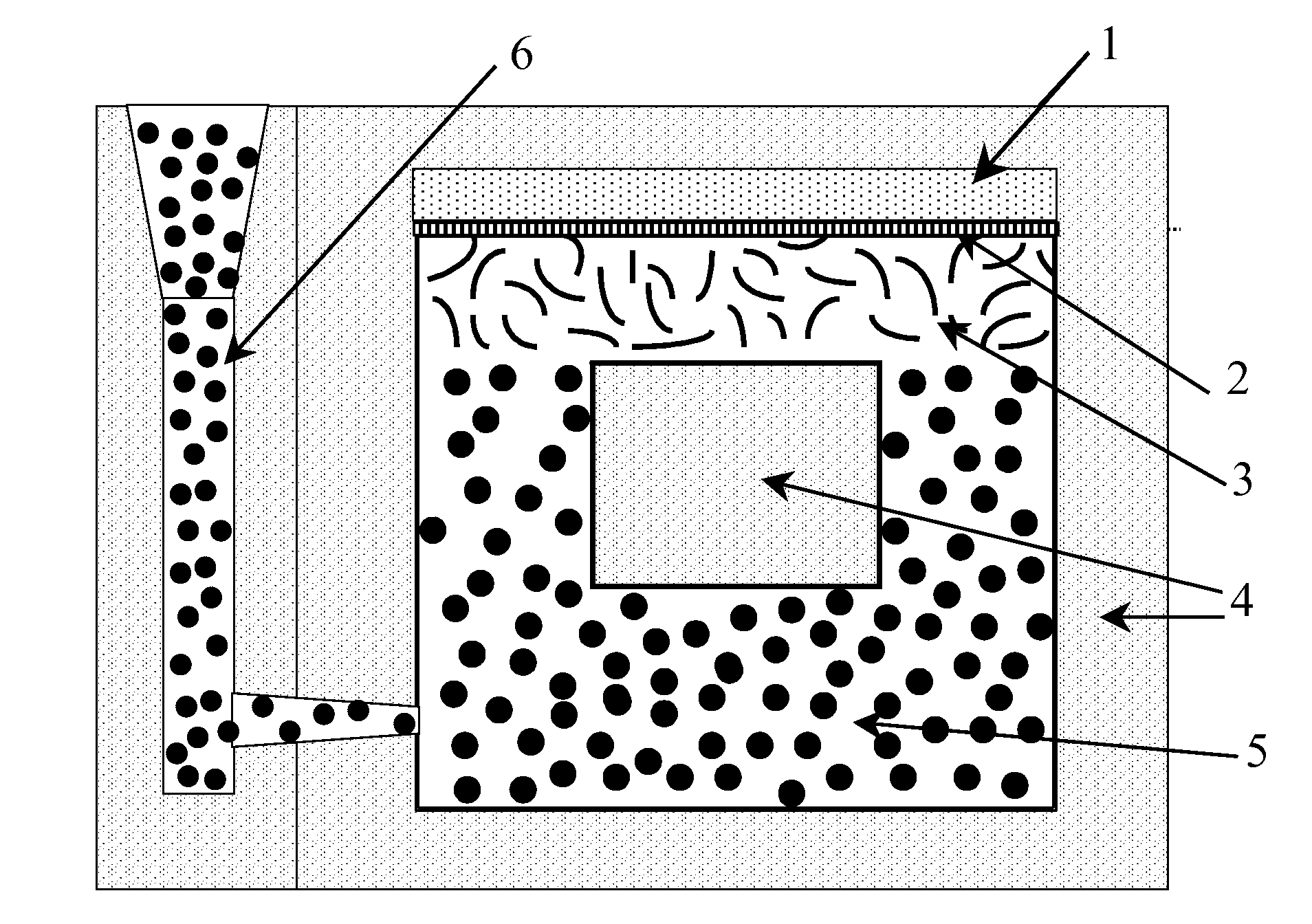

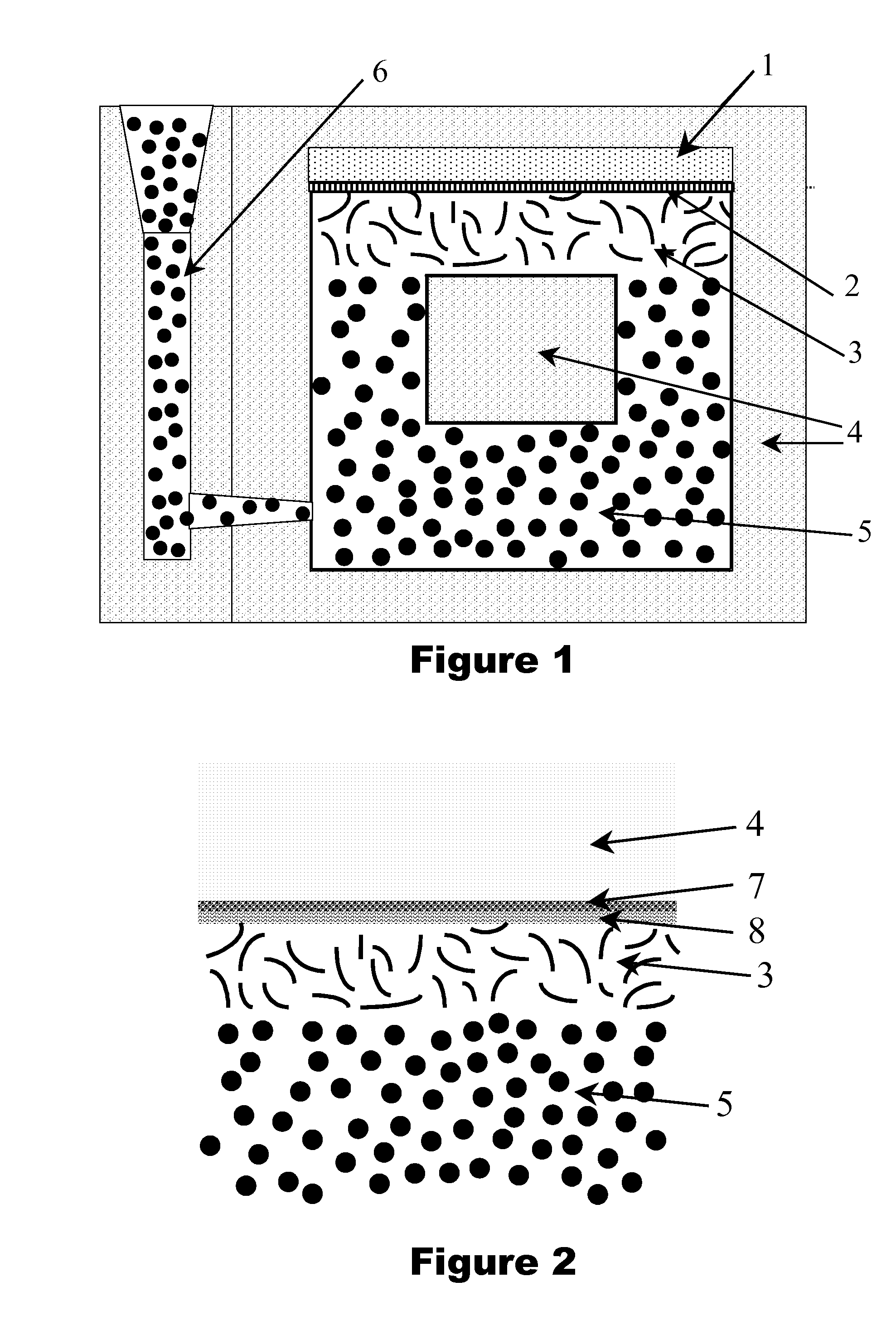

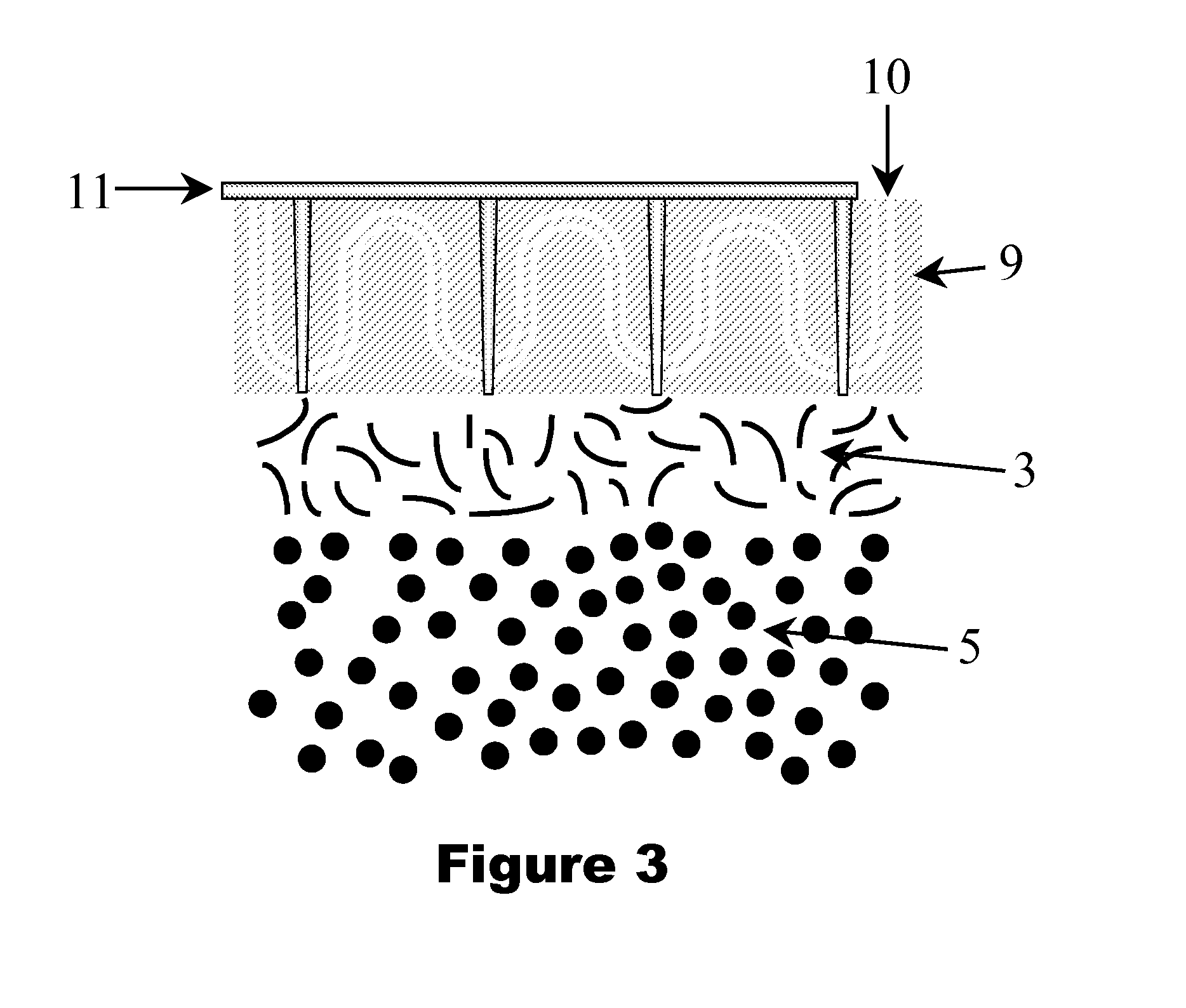

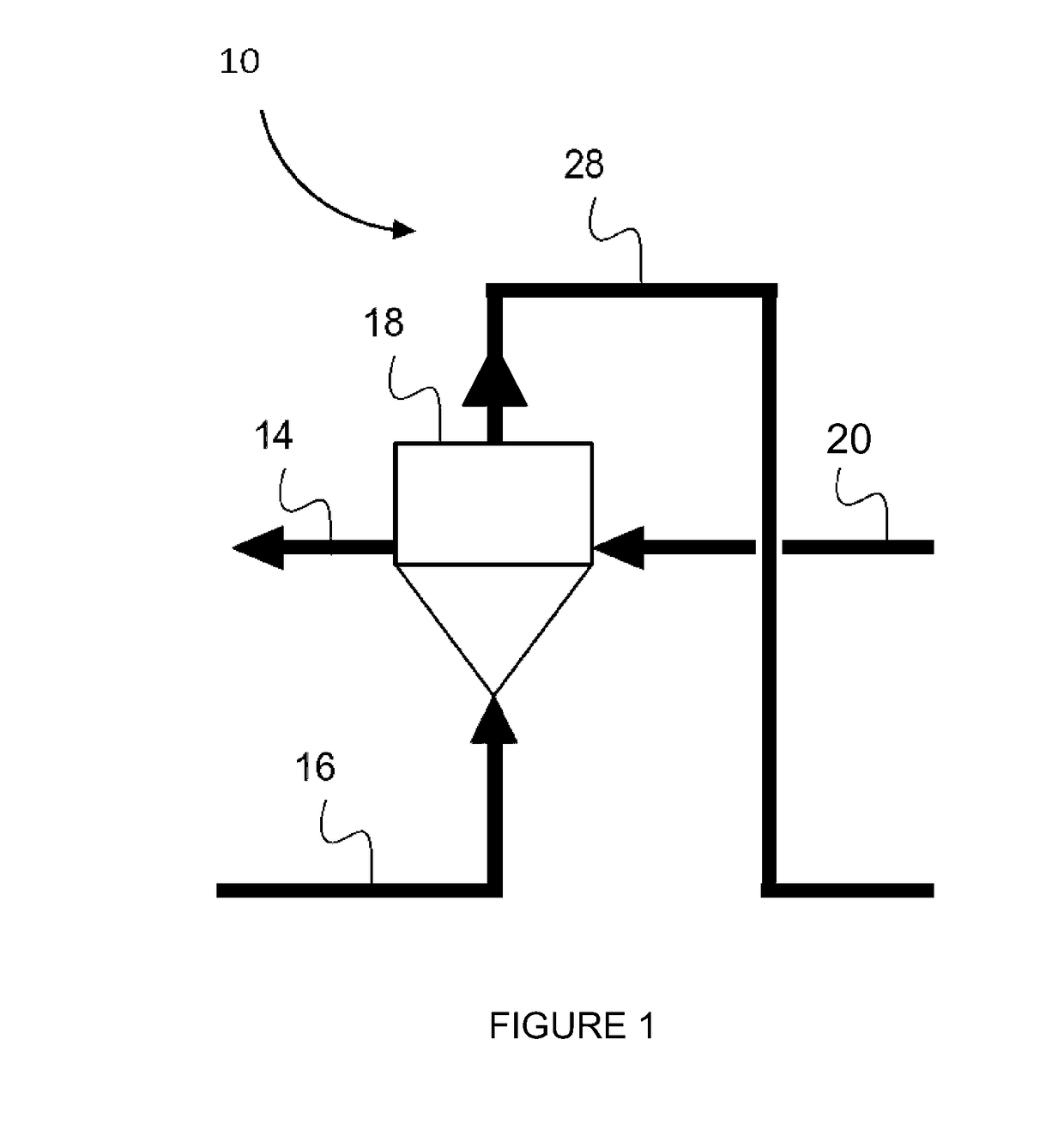

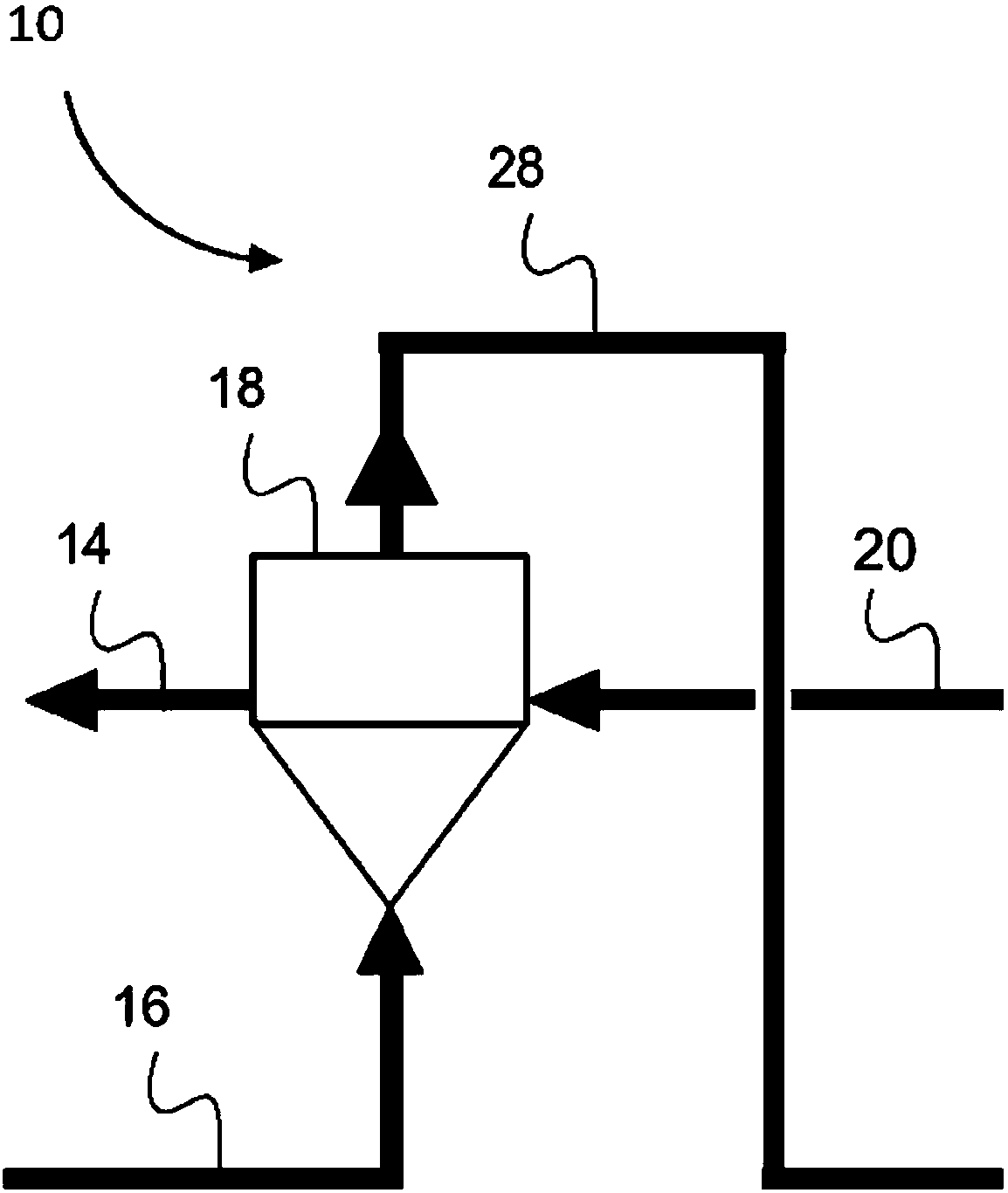

In-situ graphite shape control for iron castings

InactiveUS20110185993A1Quick mergeEvenly dispersedCylinder headsCylindersUltimate tensile strengthHeavy duty diesel

A method to produce cast iron articles with various graphite morphologies is disclosed that provides cast iron with tailored properties at different locations of the article. Flake graphite morphology is preferably created at locations requiring excellent thermal conductivity or lubricity. Spheroidal graphite morphology is preferably created at locations requiring excellent strength or mechanical fatigue life. These methods may be particularly valuable for the production of heavy duty diesel engine components.

Owner:CATERPILLAR INC

High-strength cast iron inoculation production process

The invention provides a high-strength cast iron inoculation production process. The technical method to solve technical problems comprises: adding Si-Ba inoculant into a front furnace and a tundish, wherein the content of Si is no less than 72 percent, and the specification of the Si is 3-5mm, using molten iron in the front furnace to flush the inoculant into a casting package for inoculation so that the inoculant can be fully dissolved. A Si-Sr inoculant of 0.15 percent is added into a casting crucible, stream inoculation is carried out at the temperature no lower than 1440 DEG C for casting, mold stripping is carried out when the temperature of a blank is lower than 700 DEG C, and thus the whole process of casting and composite inoculation reinforcement is completed. Due to the three inoculations, the metallographical structure of a cylinder jacket is stable, the graphite morphology can be effectively changed, the hardness is appropriately increased and the tensile strength is significantly improved based on A-type graphite, and the process is stable.

Owner:贾维珍

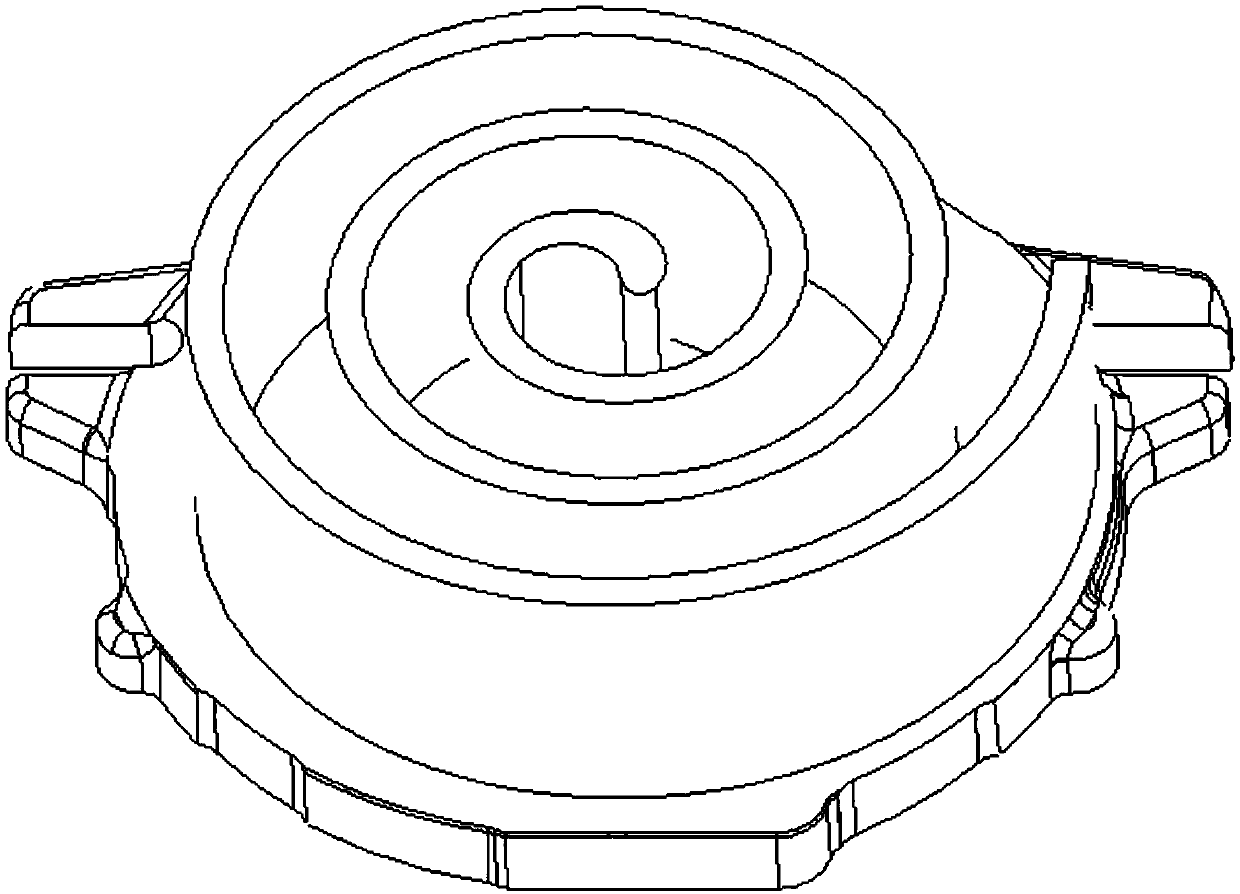

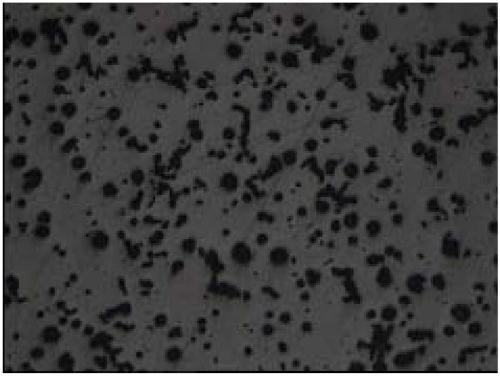

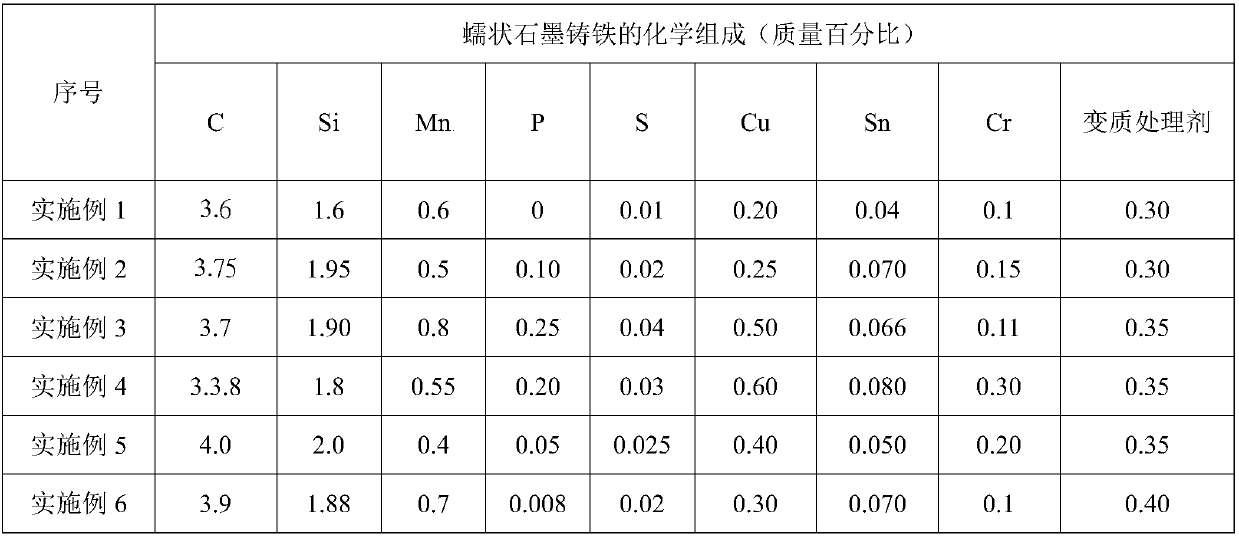

Vermicular graphite cast iron scroll plate and production process thereof

ActiveCN109536664AGuaranteed pearlite contentAvoid excessive hardnessRotary piston pumpsRotary piston liquid enginesCreep rateGraphite

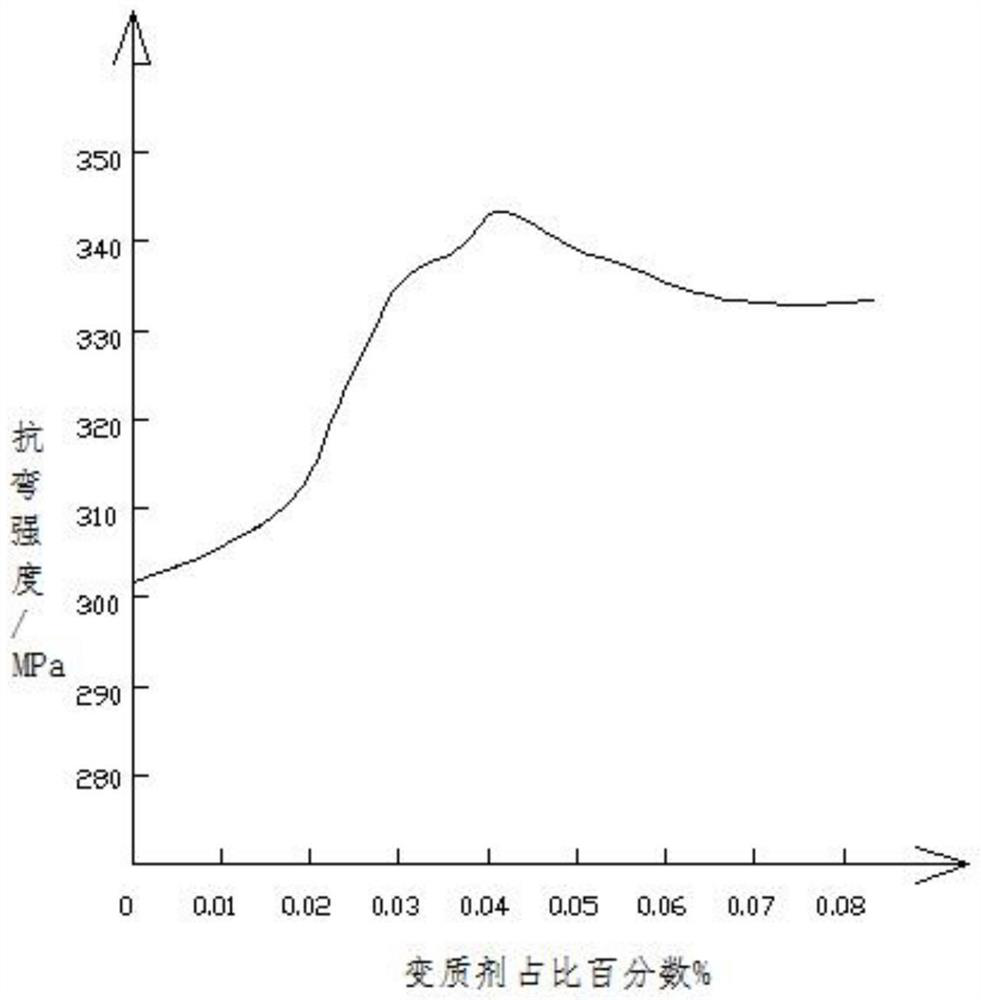

The invention discloses a vermicular graphite cast iron scroll plate and a production process thereof. The plate is prepared by casting vermicular graphite cast iron, a raw material for the plate comprises the following components of, by mass: 3.6%-4.0% of C, 1.6%-2.0% of Si, 0.4%-0.8% of Mn, 0%-0.25% of P, 0.01%-0.04% of S, 0.20-0.6% of Cu, 0.04-0.08% of Sn, 0.10%-0.3% of Cr and the balance Fe and accompanying impurities. According to the vermicular graphite cast iron scroll plate, in the raw material production process, 0.30%-0.40% of a modification treating agent is adopted to control the creep rate of the graphite form to be 20%-60%, the mechanical performance of the scroll plate is greatly improved, the tensile strength is larger than or equal to 450N / mm<2>, the yield strength is larger than or equal to 315N / mm<2>, the elongation rate is less than or equal to 3%, and the hardness range is HB200-HB250, and the durability life test is up to 2600 hours.

Owner:苏州勤美达精密机械有限公司

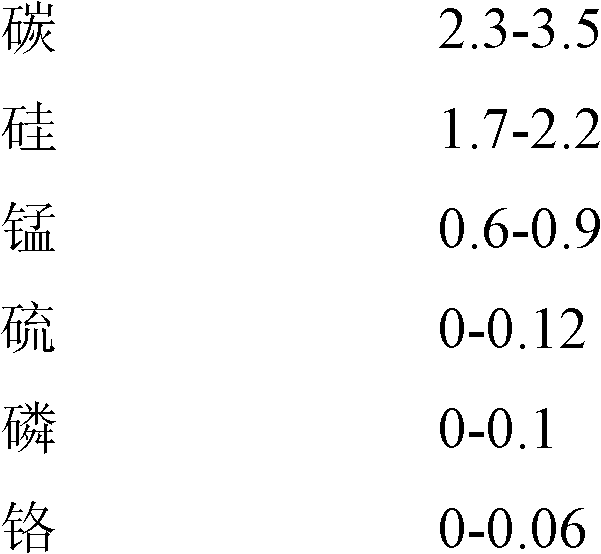

Smelting ingredients for pistons

The invention provides a melting ingredient for a piston, and the melting ingredient is mainly used for solving the problems that the pistons cast and formed from the existing melting ingredient are easy to deform and wear and have lower hardness and larger brittleness. The melting ingredient for the piston comprises the following components in percentage by weight: 2.3-3.5 of carbon, 1.7-2.2 of silicon, 0.6-0.9 of manganese, 0-0.12 of sulfur, 0-0.1 of phosphorus, 0-0.06 of chrome, 0.01-0.02 of antimony, 0.2-0.5 of copper and the balance of iron. The melting ingredient for the piston is molten, casted and formed to obtain a piston finished product; and the obtained piston finished product is not easy to deform and wear and has the advantages of high tensile strength, less brittleness, good graphite morphology and lower cost.

Owner:JIANGSU LEADER PRECISION MACHINERY

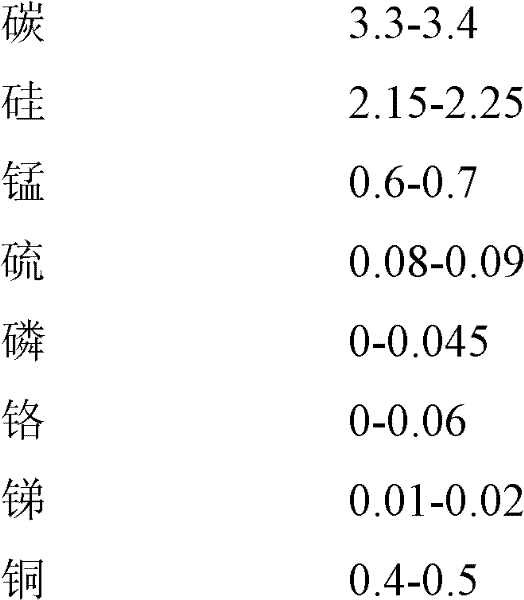

Novel spheroidizing inoculation treatment method

ActiveCN113523205AAvoid high temperature bakingEasy to pull the ropeProcess efficiency improvementDuctile ironGraphite morphology

The invention discloses a novel spheroidizing inoculation treatment method which comprises the following steps: selecting two hot metal ladles as a transfer ladle and a spheroidizing ladle respectively; after the components of the molten iron in the furnace are qualified, overheating the molten iron to 1480-1500 DEG C, discharging the molten iron into the transfer ladle, pouring out a required weight, and adding a primary inoculant into the transfer ladle, wherein a spheroidizing agent and a secondary nucleating agent are preset in the spheroidizing bag; transporting the transfer ladle and the spheroidizing ladle to a pouring site, lifting the transfer ladle to measure the weight and the temperature, rapidly pouring the molten iron into the spheroidizing ladle when the temperature of the molten iron ranges from 1400 DEG C to 1460 DEG C, and adding a third-time inoculant into the spheroidizing ladle while the molten iron is poured into the spheroidizing ladle; and during pouring, adding a nucleating agent for four times along with the molten iron. According to the method, by adopting a ladle-to-ladle spheroidizing inoculation treatment process and controlling the adding amount of the inoculant every time reasonably, the inoculation treatment effect is obviously improved, the spheroidizing effect is more ideal, the number of graphite is large, the graphite form is good, the mechanical property and the metallographic structure are stable, and finally qualified large ductile iron castings can be stably produced.

Owner:武汉武重铸锻有限公司

Nucleating agent used for improving graphite form in gray pig iron and preparing process thereof

PendingCN110257580AReduced section sensitivityHigh strengthProcess efficiency improvementFerrosiliconRare earth

The invention provides a nucleating agent used for improving graphite form in gray pig iron and a preparing process thereof. The nucleating agent comprises the following raw materials including silicon iron, rare earth ferrosilicon, silicon-calcium-barium and silicozirconium. The raw material of the nucleating agent comprises, by weight percent, 60 to 68% of silicon iron, 15 to 21% of rare earth ferrosilicon, 8 to 13% of silicon-calcium-barium and 3 to 6% of silicozirconium. Through composite of particular elements of barium, calcium, zirconium and the like added in the casting process, the crystallization way during graphite precipitation in the gray pig iron solidifying process can be changed, the compound, formed in molten iron, by the nucleating agent suspends in the molten iron as nonmetallic inclusions, a large amount of outside cores are provided for graphite for promoting graphitization, the number of primary graphite and eutectic graphite crystal nucleuses in the molten iron can be increased, the graphite precipitation is improved, meanwhile, the graphite precipitated form is improved, the tip end of the flake graphite can be passivated, the mechanical property is improved, the casting section sensibility is reduced, and the casting strength and toughness use properties can be improved.

Owner:陕西普德尔新材料科技有限公司

Vermicular graphite cast iron and preparation process and application thereof

ActiveCN109594007AGuaranteed pearlite contentAvoid excessive hardnessRotary piston pumpsRotary piston liquid enginesHardnessUltimate tensile strength

The invention discloses vermicular graphite cast iron and preparation process and application thereof. By mass percentage, 3.6%-4.0% of C, 1.6%-2.0% of Si, 0.4%-0.8% of Mn, 0%-025% of P, 0.01%-0.04% of S, 0.20-0.6% of Cu, 0.04%-0.08% of Sn, 0.10%-0.3% of Cr, and the balance Fe and accompanying impurities are included. In the production process, 0.30%-0.40% of a modification agent is adopted in theproduction process to control the vermicularity of the graphite form to be 20%-60%, the mechanical performance of a material is greatly improved, the strength of extension is larger than or equal to450 N / mm<2>, the yielding strength is larger than or equal to 315 N / mm<2>, the elongation at break is smaller than or equal to 3%, a hardness range is HB200-250, the endurance service life reaches 2600 h according to a test, and the vermicular graphite cast iron can be applied to a compressor core part vortex disk high in mechanical strength requirement.

Owner:苏州勤美达精密机械有限公司

Gray cast iron automobile engine main bearing cover iron mold sand-coating casting method

PendingCN112589054AHigh strengthImprove mechanical propertiesFoundry mouldsFoundry coresMetal moldGraphite morphology

The invention relates to a gray cast iron automobile engine main bearing cover iron mold sand-coating casting method. The method utilizes the characteristics of precoated sand shell mold and metal mold casting of iron mold sand-coating casting, and sets the thickness of a sand-coating layer to be 5-10mm and the thickness of an iron mold to be 20-40mm according to the difference of a casting structure and a mold cavity layout, and the cooling speed of the poured casting is controlled by adopting different sand coating layer thicknesses and iron mold thicknesses in an iron mold cavity; and the alloying elements Mn, Cu and Cr are adopted, the content of Mn is 0.50%-1.10%, the content of Cr is less than or equal to 0.40%, and the content of Cu is 0.40%-1.00%, so that the as-cast high-strengthgray cast iron in an A-type graphite form can be stably obtained at the same time. The cooling speed of the casting is controlled through different sand coating layer thicknesses and iron mold thicknesses of the casting in the cavity, furnace burden is reasonably proportioned, the chemical components of the iron liquid, the in-ladle inoculation amount, the stream inoculation amount, the box opening time and the box opening temperature are controlled to stably reach the as-cast high-gray cast iron engine main bearing cover, and therefore the mechanical property of the casting is improved; and the matrix structure is refined, the A-type graphite in the graphite form is increased and uniform, and the stability and reliability of the gray cast iron material are guaranteed.

Owner:SHIYAN TAIXIANG INDAL

Heat treatment process for eliminating white-mouth defects of spheroidal graphite cast iron

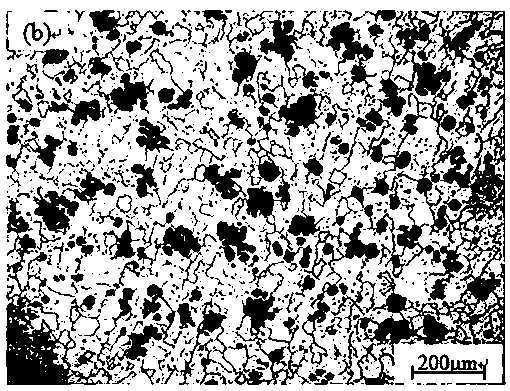

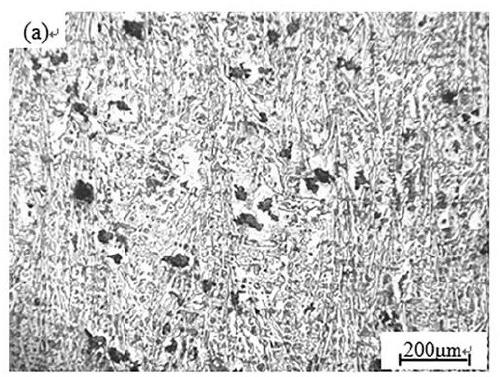

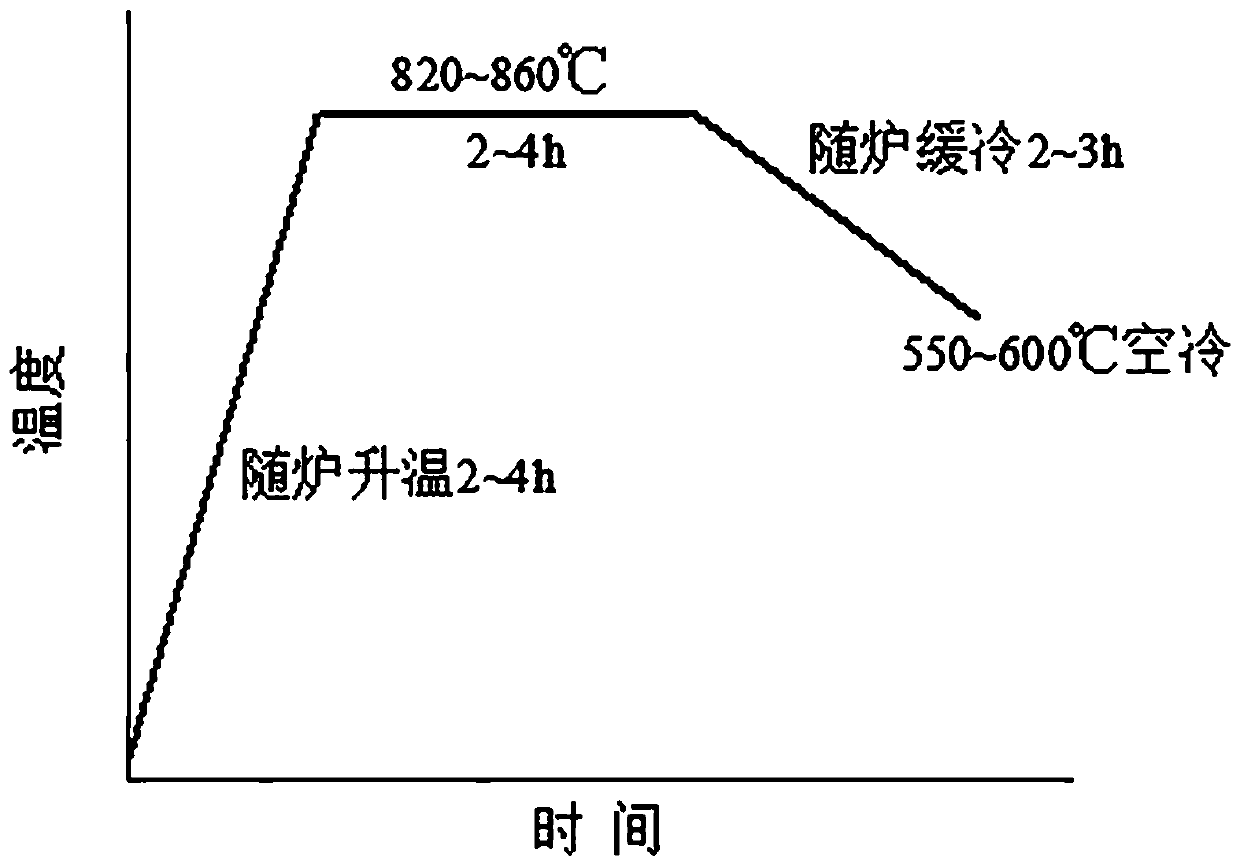

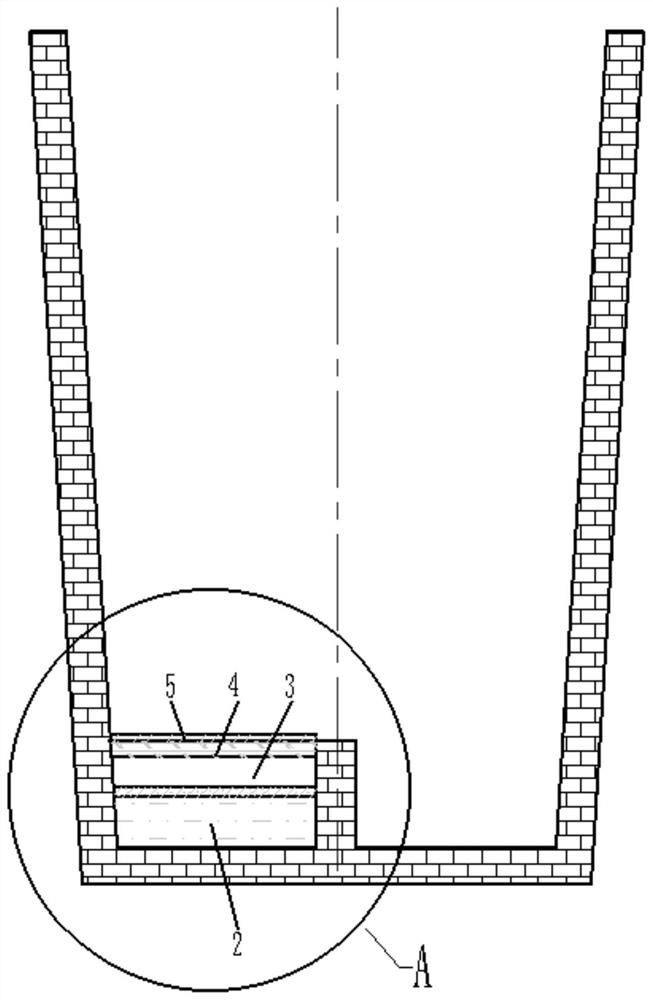

The invention relates to a heat treatment process for eliminating white-mouth defects of spheroidal graphite cast iron, and belongs to the technical field of metal cast iron graphitization treatment.The heat treatment process comprises the following steps of S1, temperature rising, wherein a to-be-treated spheroidal graphite cast iron part is heated to an annealing temperature along with a furnace, the annealing temperature ranges from 820 DEG C to 860 DEG C, and the heating time is controlled to be 2 to 4 hours; S2, heat preservation, wherein the spheroidal graphite cast iron part is kept atthe annealing temperature for 2 to 4 hours; S3, slow cooling and cooling, wherein the spheroidal graphite cast iron part is subjected to slow cooling for 2 to 3 hours along with the furnace; and S4,air-cooling, wherein after slow cooling and cooling is carried out, the spheroidal graphite cast iron part is taken out and air-cooled. The present application is directed to cast defect tissue features that are substantially spherical or partially short worm-like in graphite morphology, the heat treatment process for eliminating defects of the ductile iron white mouth at low temperature and shorttime is proposed, and finally graphite tissue features with globular and small clusters of flocculent are obtained, so that castings meet the application requirements, and the production loss is effectively saved.

Owner:FUJIAN UNIV OF TECH

Production method of high-silicon solid solution ferrite QT500-14 and QT600-10 nodular cast iron

PendingCN113943845ASolve shrinkageSolve the shrinkage cavityProcess efficiency improvementFerrosiliconDuctile iron

The invention provides a production method of high-silicon solid solution ferrite QT500-14 and QT600-10 nodular cast iron, and belongs to the technical field of casting. According to a high-silicon solid solution ferrite theory and mechanical property requirements of tensile strength, yield strength, elongation, hardness, impact property and the like, the silicon content is reasonably formulated, the carbon equivalent and the pouring temperature are reasonably calculated according to different wall thicknesses of castings, a proper high-silicon molten iron spheroidizing inoculation mode is adopted, high-silicon solid solution ferrite QT500-14 and QT600-10 nodular iron castings with the tonnage of 1-30 tons and the main wall thickness of 10-200 mm can be produced in batches, and the problems of casting shrinkage porosity, shrinkage cavity, poor graphite form, graphite floating and the like are solved.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

Method for casting box-type complex water-cooling exhaust pipe by using iron mold coated sand

ActiveCN103357821BHigh tensile strengthHigh hardnessFoundry mouldsFoundry coresThermodynamicsMold filling

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

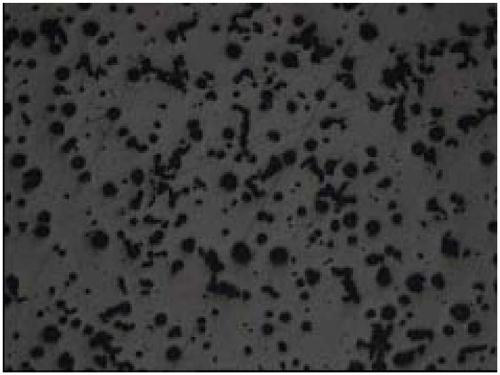

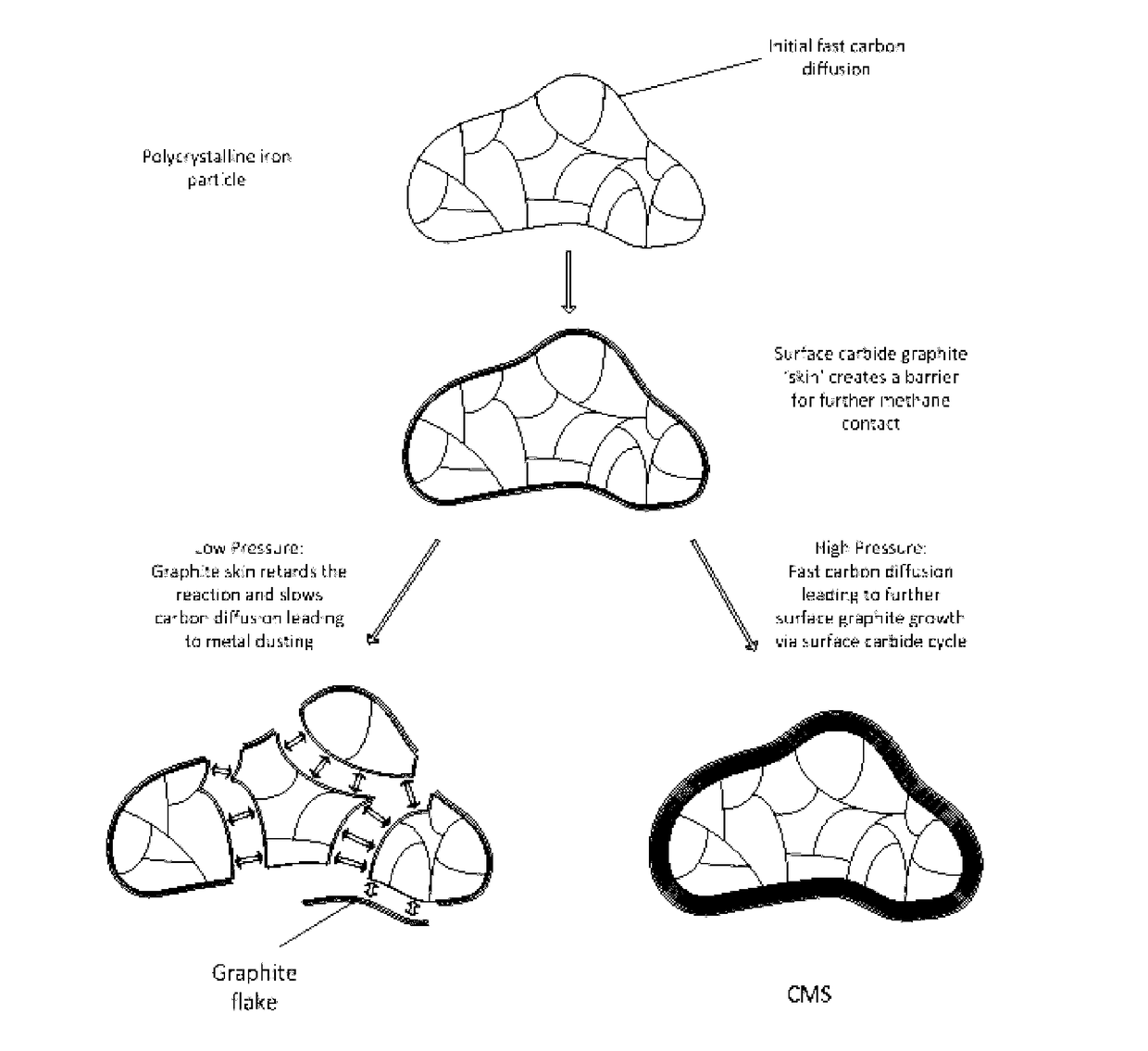

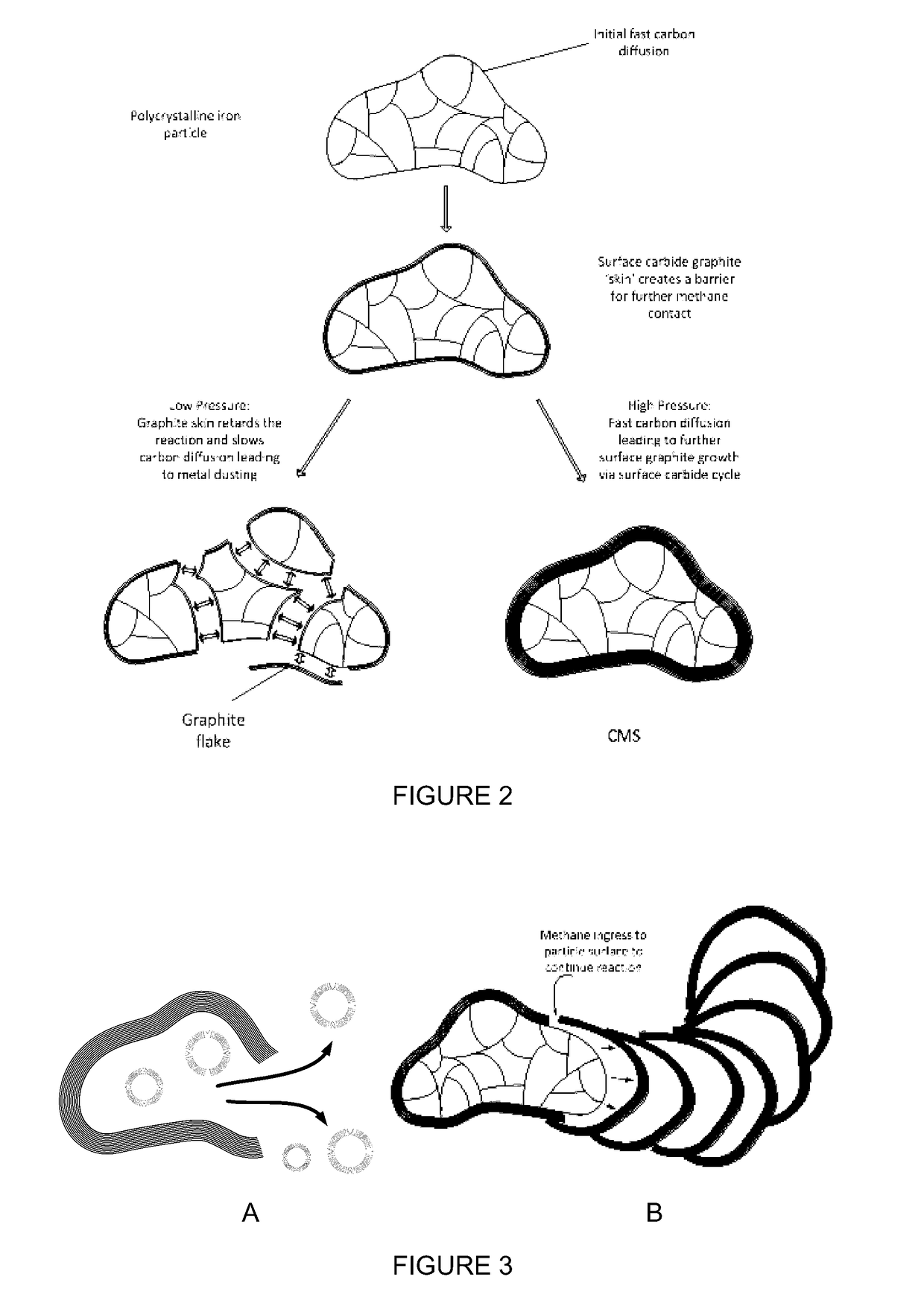

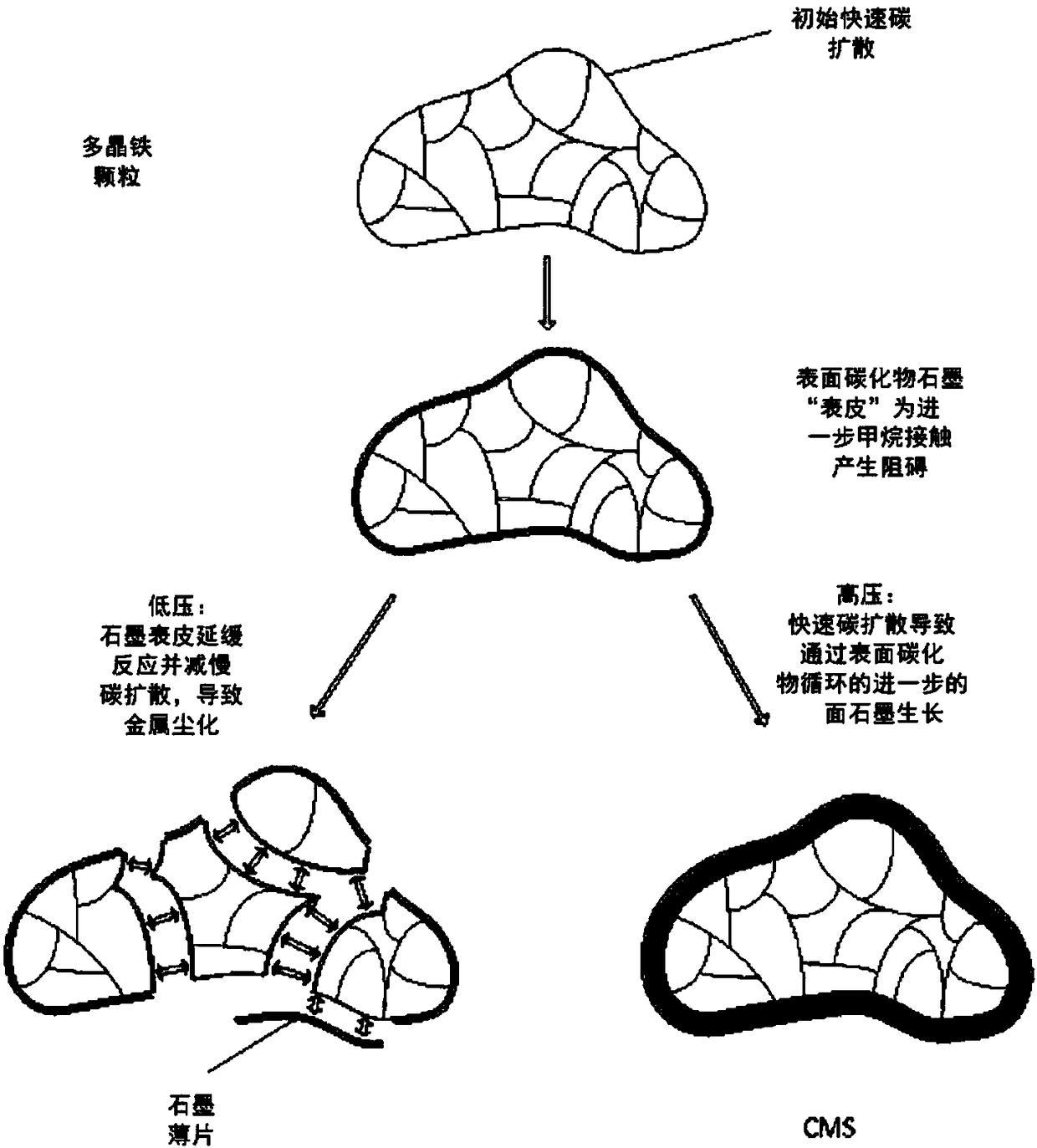

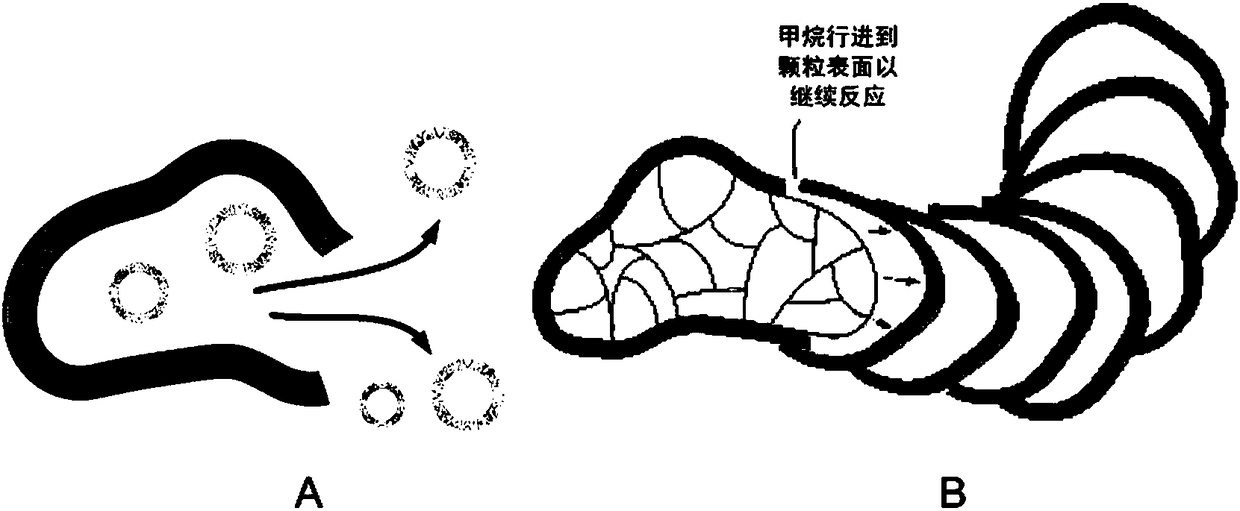

Process of controlling the morphology of graphite

A process of controlling the morphology of graphite in a process for the production of graphite, the process comprising: contacting at elevated temperature, a metal-containing catalyst with a hydrocarbon gas to catalytically convert at least a portion of the hydrocarbon gas to hydrogen and carbon; wherein the temperature is between 600° C. and 1000° C. and a pressure between 0 bar(g) and 100 bar(g), and wherein both the temperature and the pressure are set within predetermined value ranges to selectively synthesise graphitic material with a desired morphology.

Owner:HAZER GRP

A kind of preparation method of high-strength thin-walled gray iron casting

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

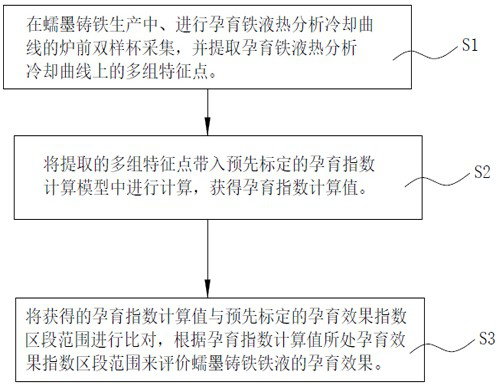

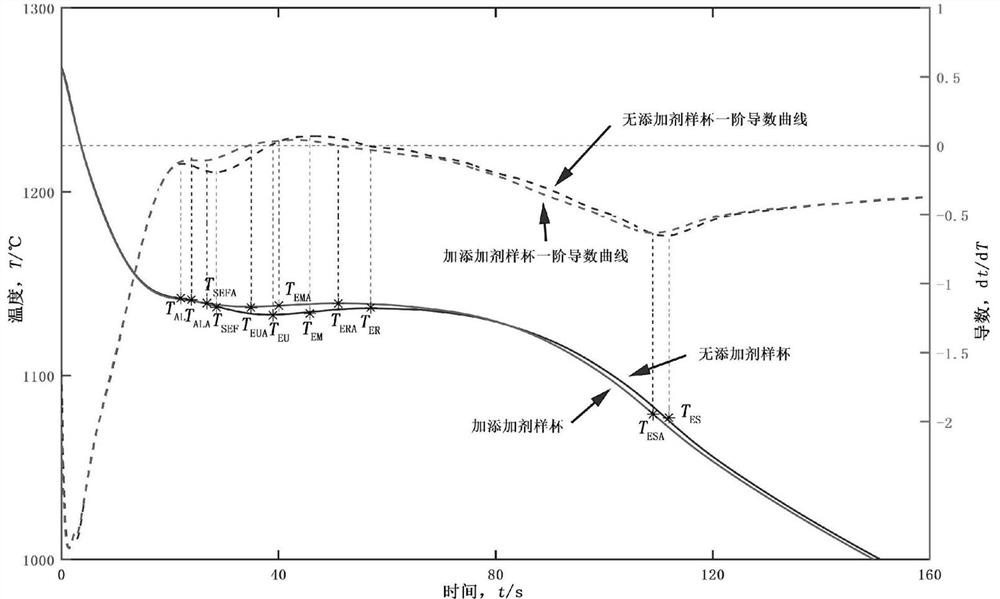

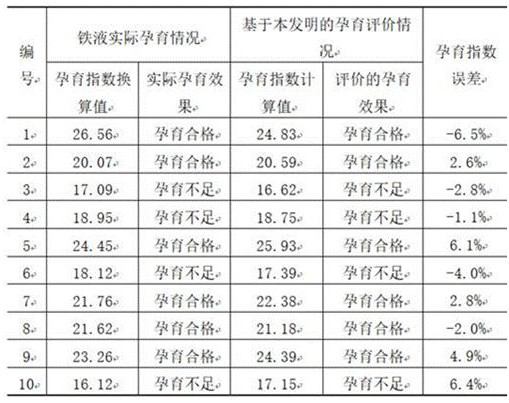

A method for thermal analysis and evaluation of vermicular graphite cast iron molten iron inoculated with multiple feature points and double sample cups

ActiveCN114062418BReasonable evaluation of breeding effectAccurate evaluation of breeding effectMaterial crystallisationDesign optimisation/simulationCooling curveHeat analysis

The invention discloses a method for thermal analysis and evaluation of a multi-feature point double-sample cup for inoculation of molten iron in vermicular graphite cast iron, which includes collecting double-sample cups in front of the furnace for thermal analysis and cooling curves of inoculated molten iron in the production of vermicular graphite cast iron, and extracting the inoculated Multiple groups of feature points on the cooling curve of molten iron thermal analysis; bring the extracted multiple groups of feature points into the pre-calibrated inoculum index calculation model for calculation, and obtain the inoculum index calculation value; combine the obtained inoculation index calculation value with the pre-calibrated The inoculation effect index section range is compared, and the inoculation effect of vermicular graphite cast iron is evaluated according to the inoculation effect index section range of the inoculation index calculation value. The invention can make the evaluation of the inoculation effect of the vermicular graphite cast iron molten iron more reasonable and accurate, provide adjustment basis for the dynamic adjustment of the inoculation state in the production process, achieve a good evaluation effect, and ensure the quality of the cast iron molten iron. It also has a certain evaluation effect on the inoculation effect of cast iron molten iron in other graphite forms.

Owner:WEICHAI POWER CO LTD

A Control Method of Graphite Morphology in the Core of Large-Section Silicon Solid-solution Strengthened Ferritic Nodular Cast Iron

The invention belongs to the technical field of cast iron, and particularly relates to a technological method of ensuring the graphite shape and performances of the core of large-cross section silicon solid solution strengthening ferritic nodular cast iron. The technical scheme of the invention is to provide a method of ensuring the graphite shape of the core of a large-cross section silicon solid solution strengthening ferritic nodular iron casting. The method comprises the following steps of: dissecting the core of an ingot bar with the wall thickness of larger than 300mm and trepanning a large casting body with the wall thickness of larger than 60mm by selecting raw materials, controlling compositions of molten iron, optimizing a nodulizing agent, a covering agent and treatment technologies thereof and determining an inoculant and a treatment technology thereof as well as the addition amount of trace alloying elements and an addition method thereof, so that on the premise of meeting requirements on related properties of materials, chunky graphite does not occur in the core of the ingot bar and the large casting body, a graphite nodule is round and complete, the nodularity is greater than or equal to 80%, the content of ferrite in a matrix structure is greater than 95%, and the content of pearlite in the matrix structure is less than 5%.

Owner:JIANGSU JIXIN WIND ENERGY TECH

A vermicular graphite cast iron scroll and its production process

ActiveCN109536664BSmall sizeAvoid explosionRotary piston pumpsRotary piston liquid enginesUltimate tensile strengthGraphite morphology

The invention discloses a vermicular graphite cast iron scroll plate and a production process thereof. The plate is prepared by casting vermicular graphite cast iron, a raw material for the plate comprises the following components of, by mass: 3.6%-4.0% of C, 1.6%-2.0% of Si, 0.4%-0.8% of Mn, 0%-0.25% of P, 0.01%-0.04% of S, 0.20-0.6% of Cu, 0.04-0.08% of Sn, 0.10%-0.3% of Cr and the balance Fe and accompanying impurities. According to the vermicular graphite cast iron scroll plate, in the raw material production process, 0.30%-0.40% of a modification treating agent is adopted to control the creep rate of the graphite form to be 20%-60%, the mechanical performance of the scroll plate is greatly improved, the tensile strength is larger than or equal to 450N / mm<2>, the yield strength is larger than or equal to 315N / mm<2>, the elongation rate is less than or equal to 3%, and the hardness range is HB200-HB250, and the durability life test is up to 2600 hours.

Owner:苏州勤美达精密机械有限公司

Silicon carbide reinforced synthetic vermicular graphite cast iron material and preparation method thereof

ActiveCN114318118AReduce usageReduce manufacturing costProcess efficiency improvementCarbide siliconMetallic materials

The invention belongs to the technical field of metal material casting, and discloses a silicon carbide reinforced synthetic vermicular graphite cast iron material and a preparation method thereof. The vermicular graphite cast iron comprises the following components in percentage by mass: 3.0-4.0% of C, 1.0-2.0% of Si, 0.0-0.2% of Mn, Plt, 0.1-0.2% of Cr, 0.1-0.2% of Mo, 0.1-0.2% of Mo, 0.1-0.2 0.03%, Slt; the alloy comprises the following components in percentage by weight: 0.03% of Fe, 0.00-0.05% of Ti, 0.0-1.2% of Cu, 0.006-0.03% of Mg and the balance of Fe and inevitable impurities. The preparation method comprises the five steps of silicon carbide pretreatment, burdening, smelting, tapping vermicular inoculation treatment and pouring. According to the method, 3%-9% of pretreated micron-sized silicon carbide and graphite are added for recarburization to control the quality of molten iron of a synthesized vermicular graphite cast iron solution, the molten iron is purified, the graphite form is improved, a matrix structure is refined and strengthened, and on the premise that the comprehensive strength of the vermicular graphite cast iron is improved, the usage amount of raw material pig iron is reduced, the production cost is reduced, and the economic benefit is improved; in addition, the silicon carbide reinforced synthetic vermicular graphite cast iron can be popularized to preparation of all cast parts, and the yield is remarkably improved.

Owner:XIAN TECHNOLOGICAL UNIV

A metal aerosol can

ActiveCN114293103BReduce harmful effectsReduced section sensitivityLiquid dispensingFerrosiliconFerrochrome

The invention discloses a metal aerosol can, which is made of the following components: iron, ferrosilicon, copper block, zinc block, scrap steel, ferromanganese, ferrochromium, ferromolybdenum and ferrozirconium. The metamorphic treatment of molten iron has the function of refining and eliminating the harmful effects of impurity elements, eliminating the D-type graphite and E-type graphite generated by impurity elements on the tendency of molten iron to be supercooled, reducing the section sensitivity of castings with different section thicknesses, and effectively improving the matrix. The mechanical properties of the material, so that the metal aerosol can prepared from the base material has more excellent compression resistance, and the service life is greatly improved. The introduction of zirconium can not only improve the graphite morphology of the matrix material and improve the mechanical properties, but also neutralize the nitrogen content in the molten iron and reduce the probability of crack-like pores in the casting. The addition of chromium can reduce the amount of ferrochromium added in the furnace, change the dissolution and solidification characteristics of chromium in molten iron, and reduce the shrinkage tendency of the matrix material.

Owner:台州绿创包装容器股份有限公司

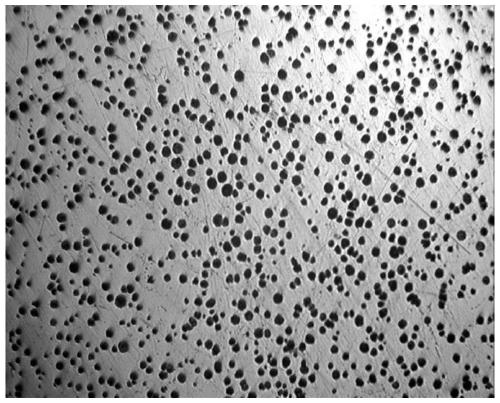

Spheroidal graphite cast iron glass mold inoculating agent

The invention discloses a spheroidal graphite cast iron glass mold inoculating agent. The agent is prepared by the following components including, by weight percent, 2 to 5 percent of Bi, 45 to 50 percent of Si, 0.5 to 3 percent of Ba, 0.1 to 3 percent of La, 2 to 2.2 percent of Al, 0.5 to 1 percent of Ca, 0.5 to 0.8 percent of Sr, and the balance Fe and inevitable trace elements. The inoculating agent provided by the invention promotes the formation of extremely fine spheroidal-graphite cast iron (according to the graphite morphology, 1000 spheroidal-graphite structures are included per square millimeter), promotes the spheroidization rate to be larger than or equal to 90 percent and a spheroidal graphite metallographic structure to be larger than 1000 / mm<2>, and not only can meet the requirements for high temperature resistance, corrosion resistance and dimensional stability of a glass mold, but also can meet the requirement that due to the high inner cavity density, the cavity surface can be subject to mirror polishing, a polishing effect is good due to the density, the service life can be prolonged, the production cost can be reduced, and alloy materials are saved.

Owner:常熟市兄弟玻璃模具有限公司

Fragmented graphite prevention large-section nodular cast iron sectional material and process

The invention discloses a fragmented graphite prevention large-section nodular cast iron sectional material. The large-section nodular cast iron sectional comprises, by mass, 3.40%-3.50% of carbon, 2.45%-2.55% of silicon, 0.35%-0.40% of manganese, 0.010%-0.014% of bismuth, 0.015%-0.025% of antimony, and the balance iron. The obtained large-section nodular cast iron sectional material is good in graphite form and graphite nodulizing grade, graphite nodules are complete and fine, and a metallographic structure is free of fragmented graphite. The invention further discloses a process of the fragmented graphite prevention large-section nodular cast iron sectional material. Alloys bismuth and antimony are added at the inoculation stage after nodulizing treatment so as to obtain the nodular cast iron sectional material with the fine crustal particles. The number of the graphite nodules is increased, a fracture surface is free of fragmented graphite, attenuation of nodulizing and inoculation is delayed, and the nodulizing rate is increased. The roundness of the sectional material is higher, the uniformity, compactness and comprehensive performance of the fracture surface are improved, and the high-quality nodular cast iron sectional material is obtained.

Owner:HANDAN HENGGONG METALLURGICAL MACHINERY CO LTD

A process of controlling the morphology of graphite

A process of controlling the morphology of graphite in a process for the production of graphite, the process comprising: contacting at elevated temperature, a metal-containing catalyst with a hydrocarbon gas to catalytically convert at least a portion of the hydrocarbon gas to hydrogen and carbon; wherein the temperature is between 600 DEG C and 1000 DEG C and a pressure between 0 bar(g) and 100 bar(g), and wherein both the temperature and the pressure are set within predetermined value ranges to selectively synthesise graphitic material with a desired morphology.

Owner:HAZER GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com