Fragmented graphite prevention large-section nodular cast iron sectional material and process

A technology of nodular cast iron and block graphite, applied in the field of cast iron materials and foundry metallurgy, can solve the problems of fragmented block graphite, long eutectic solidification time, affecting the roundness of profiles and section compactness, etc. Small, good graphite nodularization grade, good graphite morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A large-section ductile iron profile that prevents the formation of fragmented graphite. The mass percentage ranges of carbon, silicon, manganese, bismuth and antimony in the large-section ductile iron profile are: carbon: 3.40%-3.50%, silicon: 2.45%- 2.55%, manganese: 0.35%-0.40%, bismuth: 0.010%-0.014%, antimony: 0.015%-0.025%, and the rest is iron. The mass percentages of carbon, silicon, manganese, bismuth and antimony in large-section ductile iron profiles are: carbon: 3.48%, silicon: 2.50%, manganese: 0.37%, bismuth: 0.012%, antimony: 0.020%, and the rest is iron . The graphite shape of the large-section ductile iron profile is good, the graphite spheroidization grade is good, the graphite spheres are complete and small, and the metallographic structure has no fragmented graphite. And the cross-section is uniform and dense, and the mechanical comprehensive performance is high.

Embodiment 2

[0056] A technology for large-section ductile iron profiles to prevent the formation of fragmented graphite, selected to produce QT500-10 materials The profile has a larger cross-section, and the liquid center will still exist far away from the drawing outlet. During production, the drawing speed is too fast and the liquid level is too low, which will affect the quality of the cross-section structure. Therefore, the production line of Hebei Henggong Machinery Equipment Technology Co., Ltd. Adding alloy bismuth and antimony in the post-inoculation stage, the process specifically includes the following steps:

[0057] (1) For the smelting of molten iron, two 10-ton medium-frequency induction furnaces are used to smelt molten iron. Each package of molten iron is 1.2-1.3 tons. The ratio of pig iron: scrap steel: scrap rod or iron filings is 50:35:15 The post-furnace batching is weighed, and the post-furnace batching described in the post-furnace batching is high-quality pig iron...

Embodiment 3

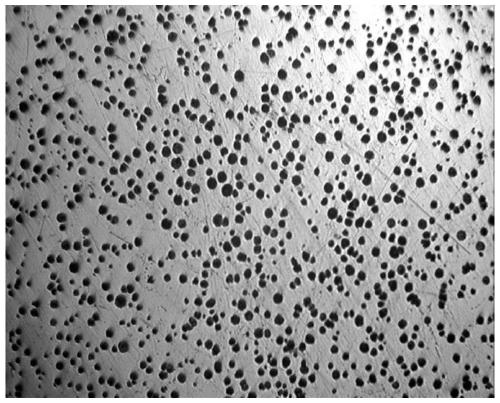

[0066] Get common graphite cast iron profile and the QT500-10 material that adopts embodiment 2 to produce respectively The section of the profile, observe the metallographic image under the metallographic microscope, and get the metallographic structure diagram, such as figure 1 , figure 2 , image 3 as well as Figure 4 shown.

[0067] Will figure 1 and figure 2 To observe and compare, figure 2 The ratio of the number of graphite balls figure 1 The increase in , indicating that the spheroidization rate of the core of the profile has been improved, and the overall quality of the profile has been improved. figure 2 The roundness ratio of the edge of the graphite ball figure 1 The roundness of the edge of the medium graphite ball is high. image 3 More fragmented graphite with irregular edges was formed in the Figure 4 Spherical graphite with relatively rounded edges is distributed in the middle. It can be concluded from the above that the graphite cast iron pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com