Method of controlling graphite shape of core of large-cross-section silicon solid solution strengthening ferritic nodular cast iron

A technology of solid solution strengthening and nodular cast iron, which is applied in the field of cast iron, can solve problems such as the method of guaranteeing the shape and performance of graphite in the center of large-section castings, and the thickness of nodular cast iron.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

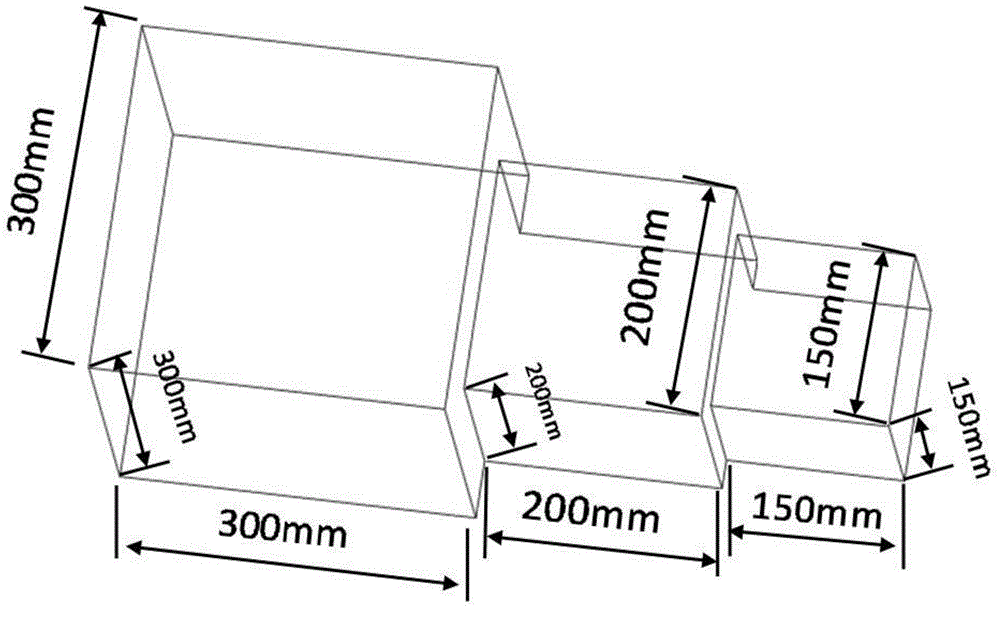

[0036] Example 1: Prepare a stepped ingot of 300mm×300mm×300mm+200mm×200mm×200mm+150mm×150mm×150mm with the material of EN-GJS-450-18. For the structure and size of the stepped ingot, see figure 1 .

[0037] The composition of control elements is: C: 3.4~3.7wt%, Si: 2.8~3.3wt%, Mn≤0.3wt%, P≤0.04wt%, S: 0.01~0.03wt%, Sb: 0.001~0.006wt%, Mg : 0.03~0.06wt%, Re≤0.001wt%, and the rest are Fe and impurities brought in during the preparation process.

[0038] According to the method steps of this invention are as follows:

[0039] A) Material selection and ingredients: pig iron: 60wt%, scrap steel: 20wt%, return material: 20wt%, pig iron selection high-purity pig iron (Mn≤0.15wt%, P≤0.035wt%, S:≤0.03wt%, harmful alloy The sum of elements≤0.08wt%), low-carbon steel is selected for scrap steel (C≤0.03wt%, Mn≤0.15wt%, P≤0.03wt%, S:≤0.03wt%); the nodulizer selects rare earth-free magnesium-silicon-iron alloy balls As the covering agent, choose a low-silicon, high-iron, Ba-containing s...

Embodiment 2

[0048] Example 2: A square ingot of 400mm×400mm×400mm was prepared with the material of EN-GJS-600-10.

[0049] According to the method of the invention, the elemental composition of the ductile iron material:

[0050] C:3.0~3.4wt%, Si:3.1~4.0wt%,, Mn≤0.3wt%, P≤0.04wt%, S:0.01~0.03wt%, Sb: 0.001~0.006wt%, Mg:0.03~0.06 wt%, Re≤0.001wt%, the rest is Fe and impurities brought in during the preparation process;

[0051] The nodular cast iron material of the above formula is smelted first, and the temperature of the molten iron is controlled to be 1420-1460°C for spheroidization treatment. The formula of the nodulizer is Mg5-7wt%, Si40-50wt%, Re≤0.01wt%, and the rest is iron. The addition amount of the nodulizer is 1.2wt%. A covering agent is added on the nodulizer. The covering agent is a low-silicon, high-iron, Ba-containing ferrosilicon covering agent. All the other are with embodiment 1.

[0052] Production shows that the performance of the square ingot of 400mm×400mm×400mm ...

Embodiment 3

[0053] Example 3 Prepare a square ingot of 400mm × 400mm × 400mm with the material of EN-GJS-500-14

[0054] Control of graphite morphology in the core of large-section (wall thickness greater than 60mm) high-strength and high-toughness silicon solid-solution strengthened ferritic nodular cast iron EN-GJS-450-18 wind power castings. The 2.5MW wind power bearing cover plate casting is selected for trial production. The bearing cover plate has a single weight of 0.8 tons and a main wall thickness of 100-220mm. Follow the steps below:

[0055] Control element composition: C: 3.2~3.5wt%, Si: 2.9~3.5wt%, Mn≤0.3wt%, P≤0.04wt%, S: 0.01~0.03wt%, Sb: 0.001~0.006wt%, Mg: 0.03-0.06wt%, Re≤0.001wt%, and the rest are Fe and impurities brought in during the preparation process.

[0056] Select pig iron: 60wt%, steel scrap: 20wt%, recycle materials: 20wt%; first smelt, pig iron, scrap steel, and recycle materials are melted together, and the temperature of molten iron out of the furnace is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com