Patents

Literature

30results about How to "Good shape of graphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium titanium cast iron brake drum and preparation method thereof

The invention relates to a manufacturing technique of an automotive vanadium titanium cast iron brake drum with high strength and high abrasive resistance, and particularly relates to a preparation method of a vanadium titanium cast iron brake drum. The preparation method comprises the following steps: melting base iron, namely b y taking vanadium titanium pig iron, steel scrap, foundry returns, a carburant, ferrosilicon, ferromanganese and ferrochrome as furnace charge, adding the carburant to the furnace bottom; smelting the furnace charges by using a medium-frequency induction furnace to prepare the base iron; heating and purifying molten iron in an overheating manner after the molten iron is molten down, and then carrying out heat preservation at 1520-1530 DEG C; and carrying out drossing, adding a slag conglomeration agent to the surface to carry out heat preservation after drossing, and then adding a little of furnace charge, and adjusting the ingredients and the like of the molten iron. A little of furnace charge is added at the later smelting stage to increase the heterogeneous core technology, so that the chilling tendency of the molten iron is relieved, the graphitization ability of the molten iron is improved, and the inoculation effect is improved. A secondary inoculation treatment process of a launder and a pouring cup is adopted, so that the inoculation effect is improved, the graphite form is improved, carbide and ferrite are removed, and the content of pearlite is improved.

Owner:陈国

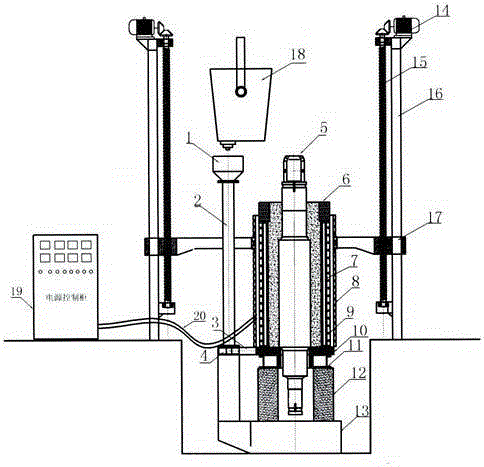

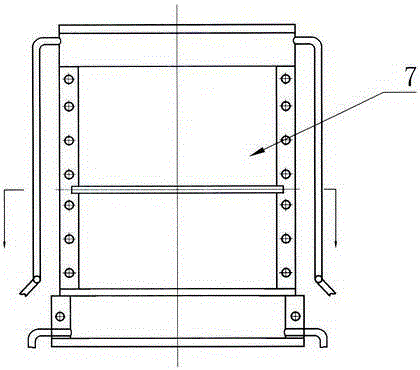

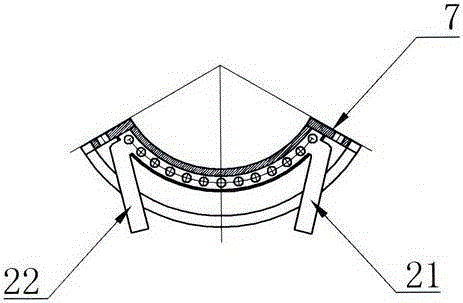

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

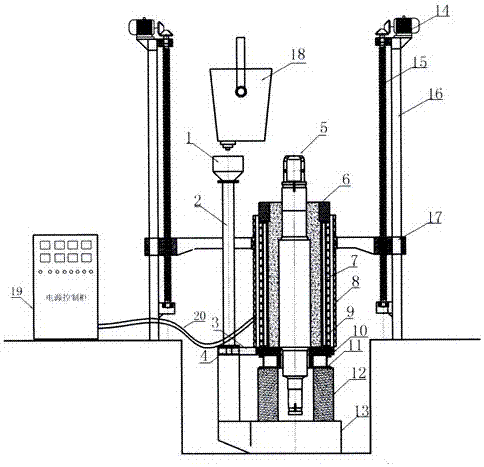

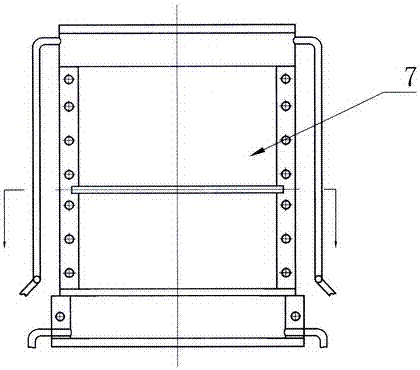

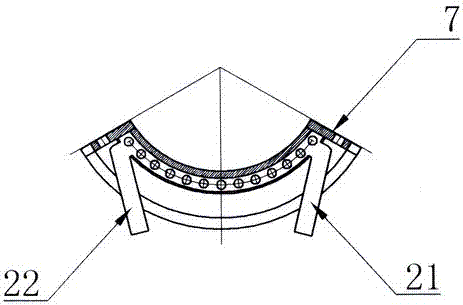

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Manufacturing technique and device for improved bainite nodular cast iron composite roller provided with forged steel roller neck

The invention discloses a manufacturing technique and device for an improved bainite nodular cast iron composite roller provided with a forged steel roller neck. The improved bainite nodular cast iron composite roller provided with the forged steel roller neck is prepared from, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% f Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0-0.05% of P, 0-0.30% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE, and the balance Fe and inevitable trace elements. According to the manufacturing technique and device for the improved bainite nodular cast iron composite roller provided with the forged steel roller neck, yttrium-based rare earth is used for nodularization, Ba, Ca and silicon iron are used for combined inoculation, Nb, Ti, V, B and Sb are added for modification treatment, and thus the mechanical property of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved; integral in-mold heating and casting of a core rod are conducted through an induction heater, and a water-cooling crystallizer is used for formation; the interface of a composite layer can be controlled dynamically, the technique is simple, power consumption is low, the cost is low, composition segregation is avoided, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Method for casting box-type complex water-cooling exhaust pipe by using iron mold coated sand

A method for casting a box-type complex water-cooling exhaust pipe by using an iron mold coated sand is disclosed. By using the water-free coated sand mold, the method helps to realize rapid cooling and mold filling, eliminate the defects of nail-passing-hole structure loosening and casting deformation often happening in the water-cooling exhaust pipe; and the prepared water-cooling exhaust pipe has higher tensile strength, higher hardness, better graphite morphology and better graphite grade, and the amount of stable pearlites is 98% or more. The yield of castings is improved from 54% to 96% or more. The finished product is good in texture compactness, good in texture refining capability, good in surface quality, and stable and reliable in quality. Also, during the production, the method has the advantages of being small in use level of the sand and paints, small in equipment investment, small in equipment occupied area, high in production efficiency, low in manufacture cost, good in environmental protection property, wide in prospect, and applicable to production of various engine exhaust pipes with high quality demands and complex thin-wall double-layer walls.

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

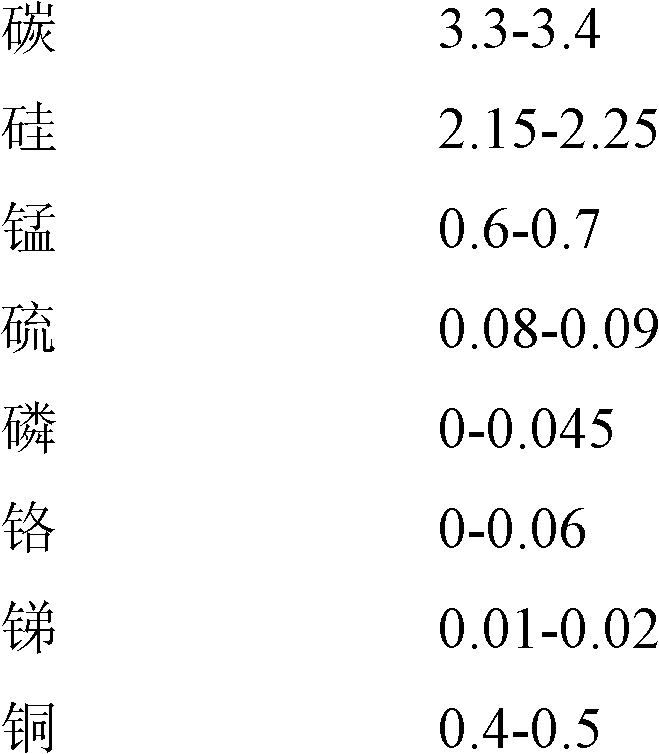

Gray cast iron and preparation method thereof

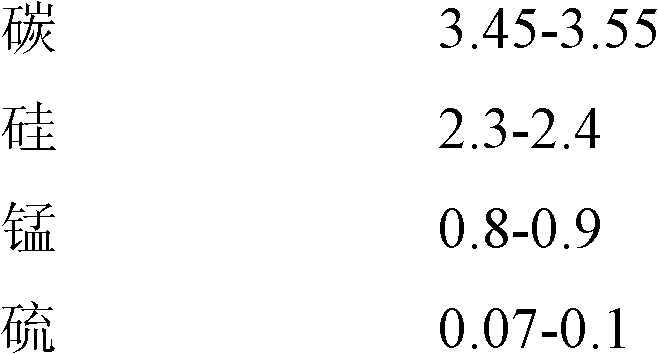

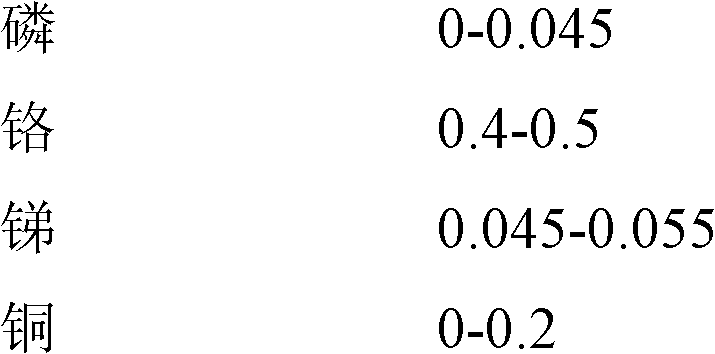

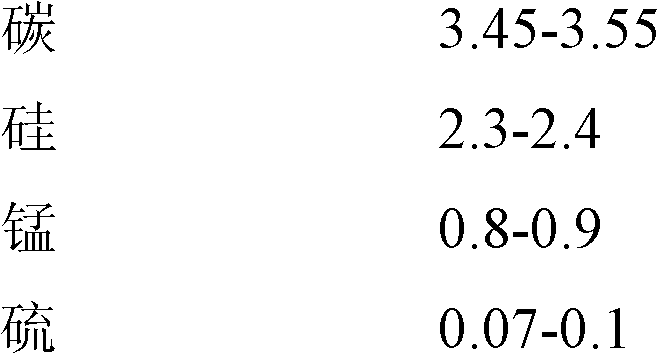

The invention discloses gray cast iron and a preparation method thereof, and belongs to the field of metal casting. The gray cast iron and the preparation method solve the technical problems that existing gray cast iron is high in production cost and insufficient in performance. According to the gray cast iron and the preparation method, precious metal such as copper, molybdenum, nickel and vanadium is not added, strength and hardness of castings are improved through chromium and antimony, the manufacturing cost is reduced, and performance of the gray cast iron can be improved by conducting microalloying on antimony and chromium together.

Owner:浙江杭机铸造有限公司

Preparation method of material suitable for diesel engine cylinder cover

InactiveCN110373601AHigh tensile strengthHigh strengthFoundry mouldsFoundry coresFoundryDiesel engine

The invention relates to a preparation method of a material suitable for a diesel engine cylinder cover. The preparation method of the material suitable for the diesel engine cylinder cover comprisesthe following steps of (1) adopting steel scraps and foundry return as furnace charges, sequentially adding into an intermediate frequency furnace, melting to obtain molten iron, and adding a petroleum coke carburant when the temperature of the molten iron reaches to 1400 DEG C; (2) when the temperature of the molten iron reaches to 1530 to 1560 DEG C, adding ferro manganese nitride, uniformly stirring, and tapping after preserving heat for 8 to 12 minutes; (3) adding an inoculator into a ladle for the first time, starting inoculation treatment for the second time when the molten iron in the ladle accounts for one third of the tapping amount, and adding a metal-stream inoculation agent for the third time in the molten iron pouring process; and (4) adopting a sand-lined metal mold casting mold for pouring to obtain a gray cast iron material suitable for the diesel engine cylinder cover. According to the preparation method of the material suitable for the diesel engine cylinder cover provided by the invention, through adding a nitrogen element, reducing the alloy element content, improving the inoculation times and combining a sand-lined metal mold process for casting, so that the mechanical property and the strength of the gray iron material are remarkably improved, and the cracking problem caused by low material strength and heat fatigue of the diesel engine cylinder cover at present are solved.

Owner:GUANGXI UNIV

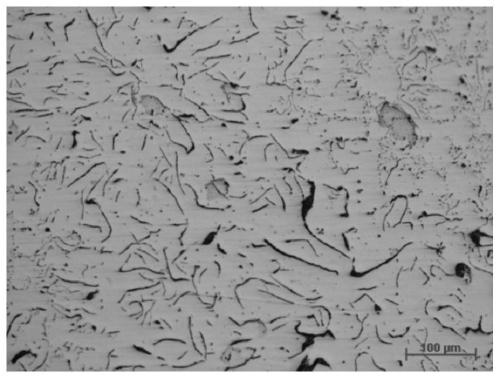

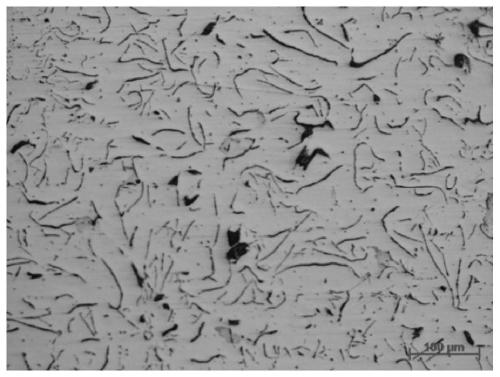

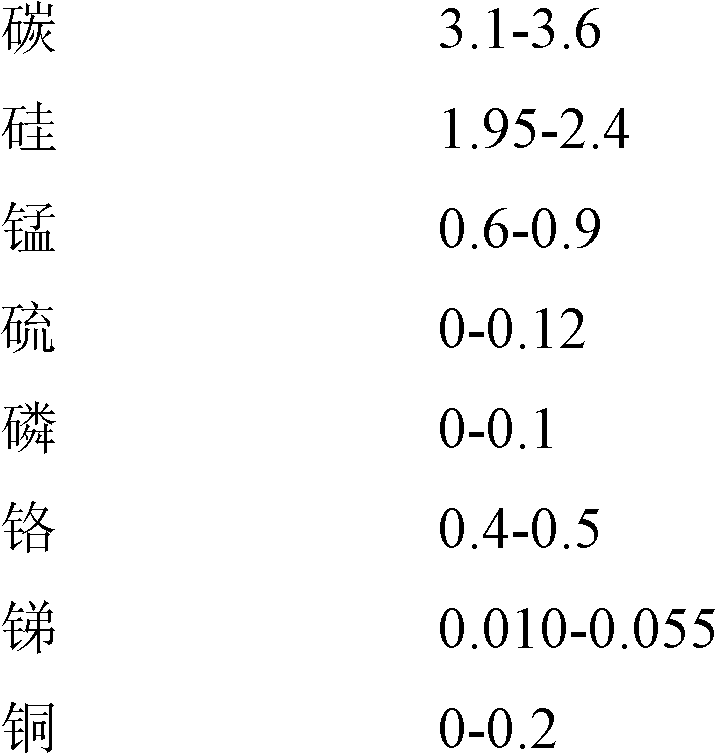

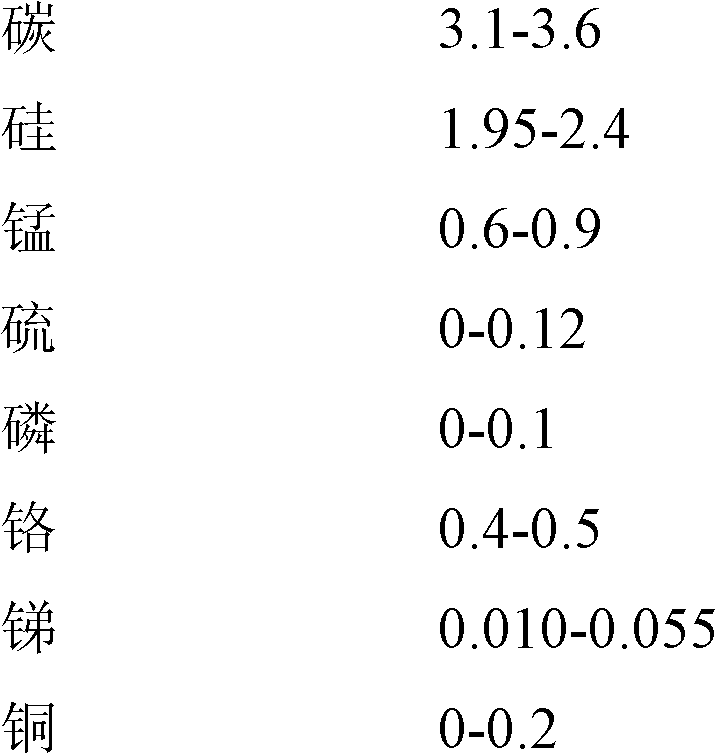

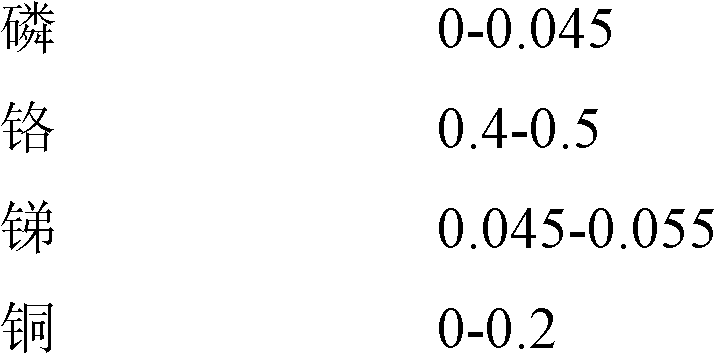

Smelting ingredients of support

The invention provides smelting ingredients of a support, which is mainly used for solving the problem that a support cast by the traditional smelting ingredients of the support comprises the following compositions in percentage by mass: C 3.1-3.6, silicon 1.95-2.4, manganese 0.6-0.9, sulfur 0-0.12, phosphorus 0-0.1, chromium 0.4-0.5, stibium 0.010-0.055, copper 0-0.2 and the balance of ferrum. The finished support casted by the smelting ingredients of the support, provided by the invention, is not easy to crack, high in tensile strength, relatively small in brittleness, high in rigidity, good in graphite pattern, and synchronously relatively low in cost.

Owner:江西德辰科技有限公司

Smelting ingredients of support

The invention provides smelting ingredients of a support, which is mainly used for solving the problem that a support cast by the traditional smelting ingredients of the support comprises the following compositions in percentage by mass: C 3.1-3.6, silicon 1.95-2.4, manganese 0.6-0.9, sulfur 0-0.12, phosphorus 0-0.1, chromium 0.4-0.5, stibium 0.010-0.055, copper 0-0.2 and the balance of ferrum. The finished support casted by the smelting ingredients of the support, provided by the invention, is not easy to crack, high in tensile strength, relatively small in brittleness, high in rigidity, good in graphite pattern, and synchronously relatively low in cost.

Owner:江西德辰科技有限公司

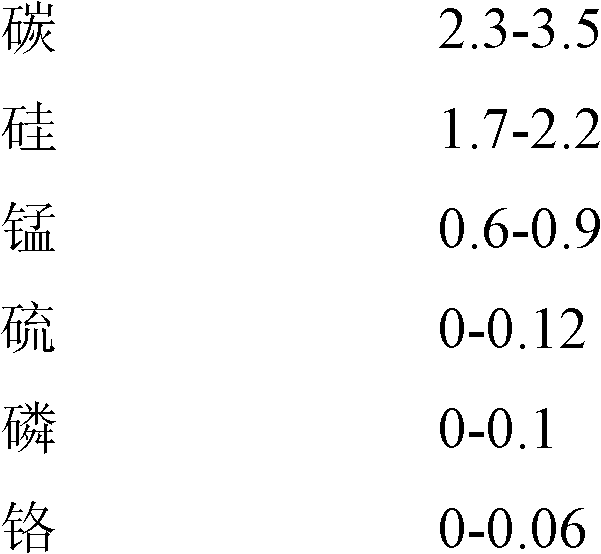

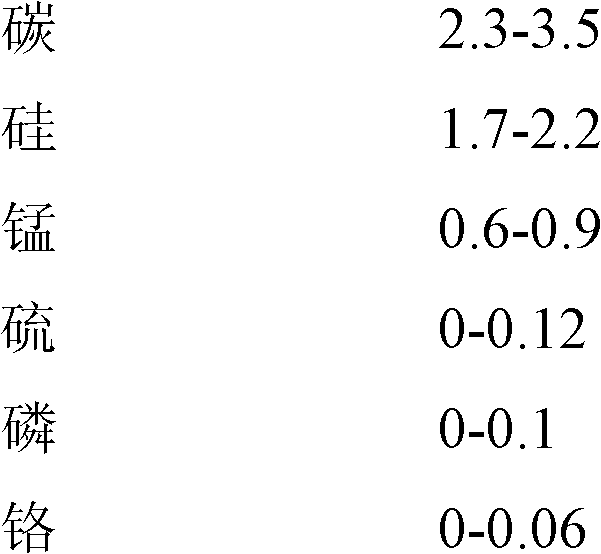

Smelting ingredients for pistons

The invention provides a melting ingredient for a piston, and the melting ingredient is mainly used for solving the problems that the pistons cast and formed from the existing melting ingredient are easy to deform and wear and have lower hardness and larger brittleness. The melting ingredient for the piston comprises the following components in percentage by weight: 2.3-3.5 of carbon, 1.7-2.2 of silicon, 0.6-0.9 of manganese, 0-0.12 of sulfur, 0-0.1 of phosphorus, 0-0.06 of chrome, 0.01-0.02 of antimony, 0.2-0.5 of copper and the balance of iron. The melting ingredient for the piston is molten, casted and formed to obtain a piston finished product; and the obtained piston finished product is not easy to deform and wear and has the advantages of high tensile strength, less brittleness, good graphite morphology and lower cost.

Owner:JIANGSU LEADER PRECISION MACHINERY

Material and casting process of high-strength air cylinder sleeve

InactiveCN102418029ATo meet the needs of improving mechanical propertiesShorten the production cycleChemical compositionAlloy

The invention discloses a material and a casting process of a high-strength air cylinder sleeve, which adopt the technical scheme that the forming of a cast bainite is realized by increasing the content of Cu in chemical components of the air cylinder sleeve to be 1.7 percent and melting Cu instead of part of Ni and Mo alloy at high temperature and the requirement of the air cylinder sleeve on higher mechanical performance is met.

Owner:贾维珍

High-copper low-nickel molybdenum alloy material

InactiveCN102465233ATo meet the needs of improving mechanical propertiesShorten the production cycleChemical compositionCrucible

The invention relates to a high-copper low-nickel molybdenum alloy material, which is prepared by utilizing an intermediate-frequency electric furnace and comprises the following chemical components by weight percent (%): 2.8-3.0% of C, 1.8-2.2% of Si, 0.4-0.6% of Mn, less than 0.1% of P, less than 0.1% of S, 2.0-2.2% of Cu, 0.7% of Mo, 0.2% of Ni, and the balance of Fe. The high-copper low-nickel molybdenum alloy material is prepared according to the following steps of: quickly increasing the temperature of molten iron in the electric furnace to 1,570-1,600 DEG C; starting conventional breeding; after ending breeding, ensuring the temperature in a casting crucible within a scope of 1,440-1,460 DEG C and casting; after cooling the temperature of a casting mould to be 1,150 DEG C, performing water cooling; and not stopping cooling till the temperature of a casting blank is at 700 DEG C. The hardness of the material is 270-310HB and the strength reaches 280Mpa.

Owner:徐金兰

Method for casting box-type complex water-cooling exhaust pipe by using iron mold coated sand

ActiveCN103357821BHigh tensile strengthHigh hardnessFoundry mouldsFoundry coresThermodynamicsMold filling

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

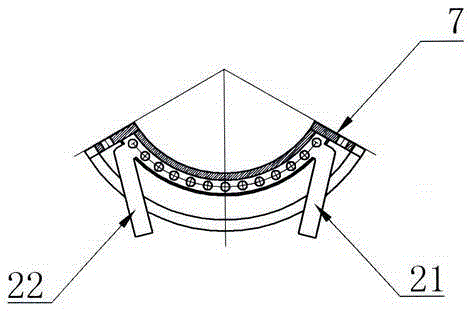

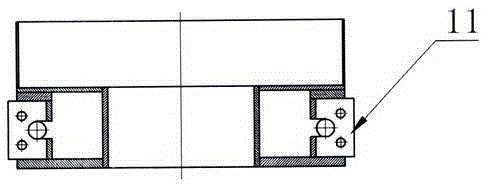

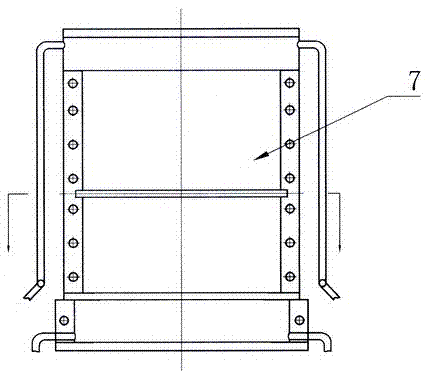

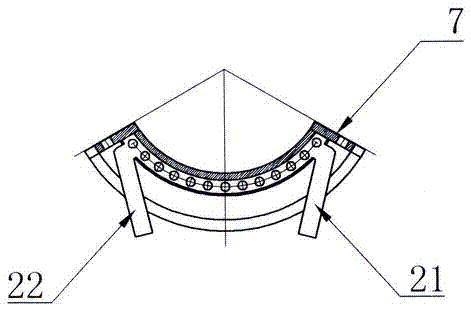

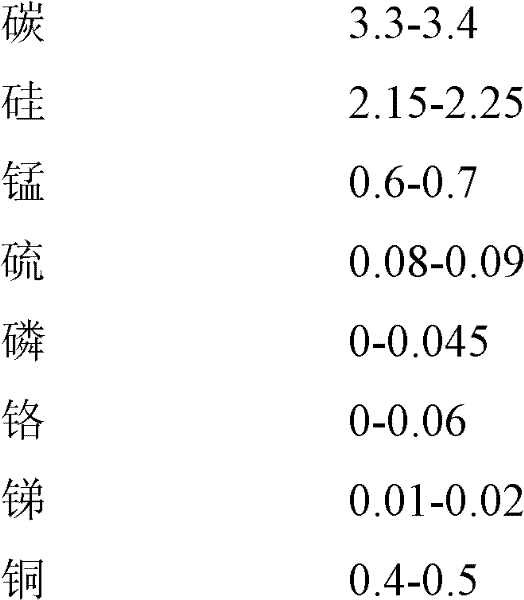

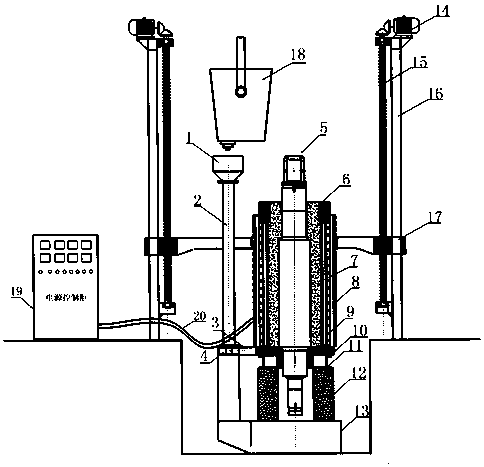

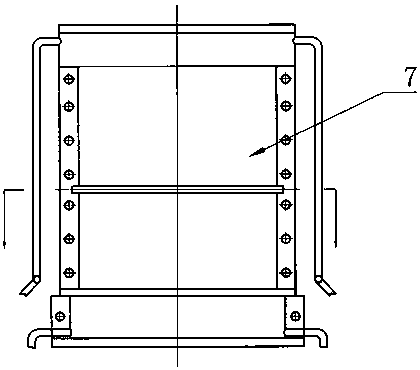

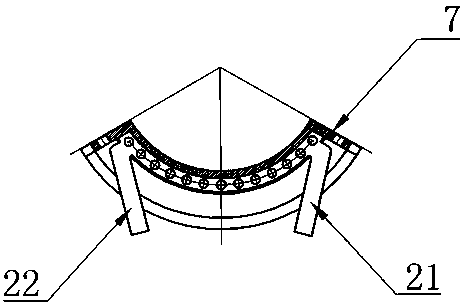

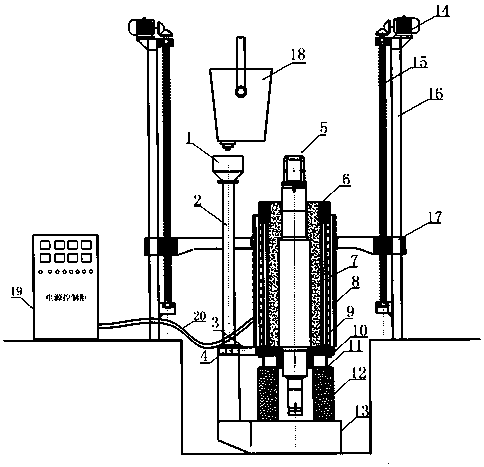

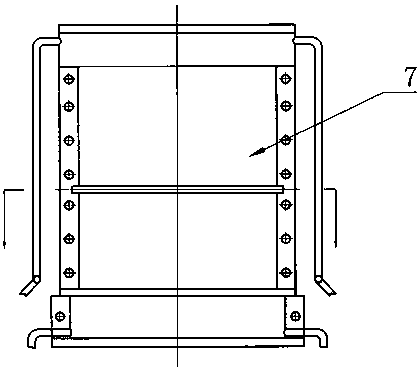

Manufacturing process and equipment for nickel-chromium-molybdenum alloy cast iron composite roller in forged steel roller neck

ActiveCN105328168AEasy feedingOvercome the defect of prone to tissue segregationFerrosiliconDirectional solidification

The invention discloses a manufacturing process and equipment for a nickel-chromium-molybdenum alloy cast iron composite roller in a forged steel roller neck. The nickel-chromium-molybdenum alloy cast iron composite roller is composed of, by mass, 3.3-3.8% of C, 0.6-1.2% of Si, 0.4-1.2% of Mn, 0.6-1.2% of Cr, 0.3-1.0% of Mo, 2.0-3.0% of Ni, 0.6-1.1% of Cu, 0-0.05% of P, 0-0.03% of S, 0.04-0.06% of Mg, 1.5-2.5% of Ba, 1-2% of Ca, 1.0-2.0% of RE and the balance Fe. Rare earth globularization and Ba, Ca and silicon iron composite inoculation are adopted, and the mechanical properties of the roller are improved; the strength of the roller is improved by the adoption of the forged steel roller neck; in-mold integral heating and casting are conducted on a core rod through a sensing heater, forming is conducted through a combined water-cooling crystallizer, a lifting device lifts a heater upwards at a certain speed to form local directional freezing, the interface of a composite layer can be controlled dynamically, the process is simple, the efficiency is high, the electric losses are small, the cost is low, composition segregation of the composite layer is avoided, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

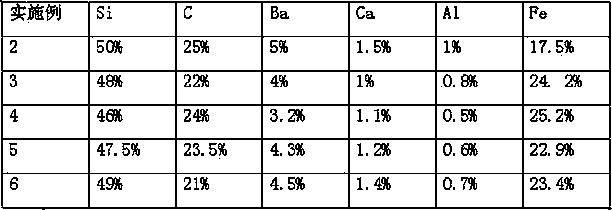

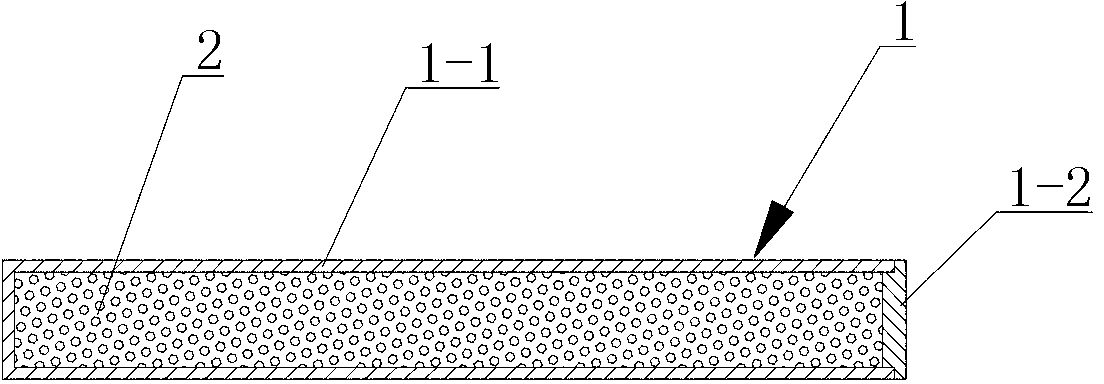

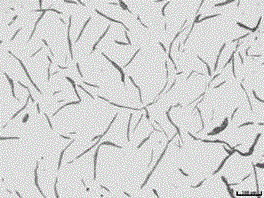

Special inoculant for centrifugally casting thin-wall dry cylinder liner

The invention discloses a special inoculant for centrifugally casting a thin-wall dry cylinder liner, comprising the following chemical constituents by mass ratio: 45-50% of Si, 20-25% of C, 3.5-5% of Ba, 0.8-1.5% of Ca, 0.5-1% of Al, and the balance of Fe, wherein C is high-purity crystal graphite. The thin-wall dry cylinder liner can be centrifugally cast by using the inoculant provided by the invention so as to strongly promote graphitization when the cylinder liner is cast on the basis of uniformity of sections of the cylinder liner, and therefore, graphite form of a cylinder liner cast blank can be improved, graphite form is converted from A+D type into A type, and toughness of the cylinder liner can be greatly improved. At the same time, cylinder liner materials can be configured to increase match-into proportion of melt-down iron, and reduce manufacturing cost of the cylinder liner.

Owner:SHIJIAZHUANG JINGANG KAIYUAN POWER SCI & TECH

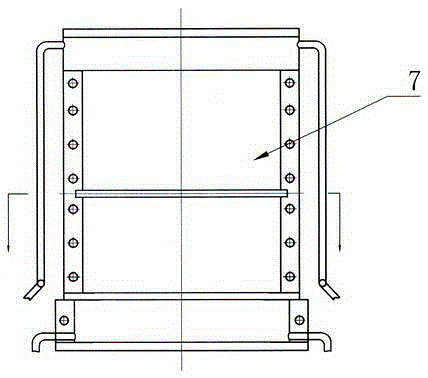

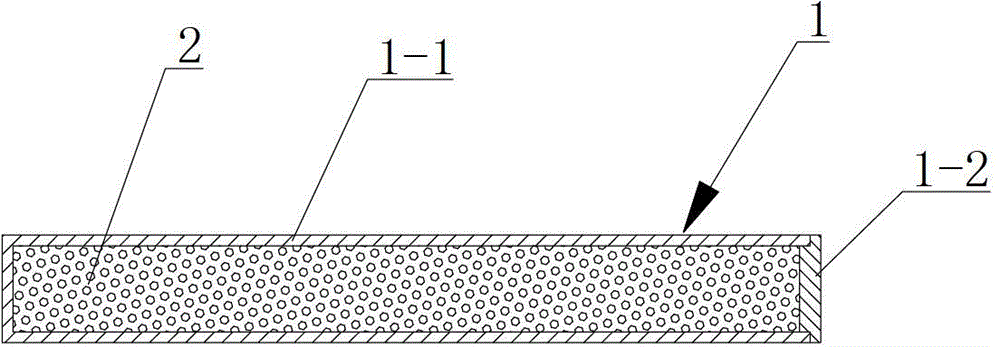

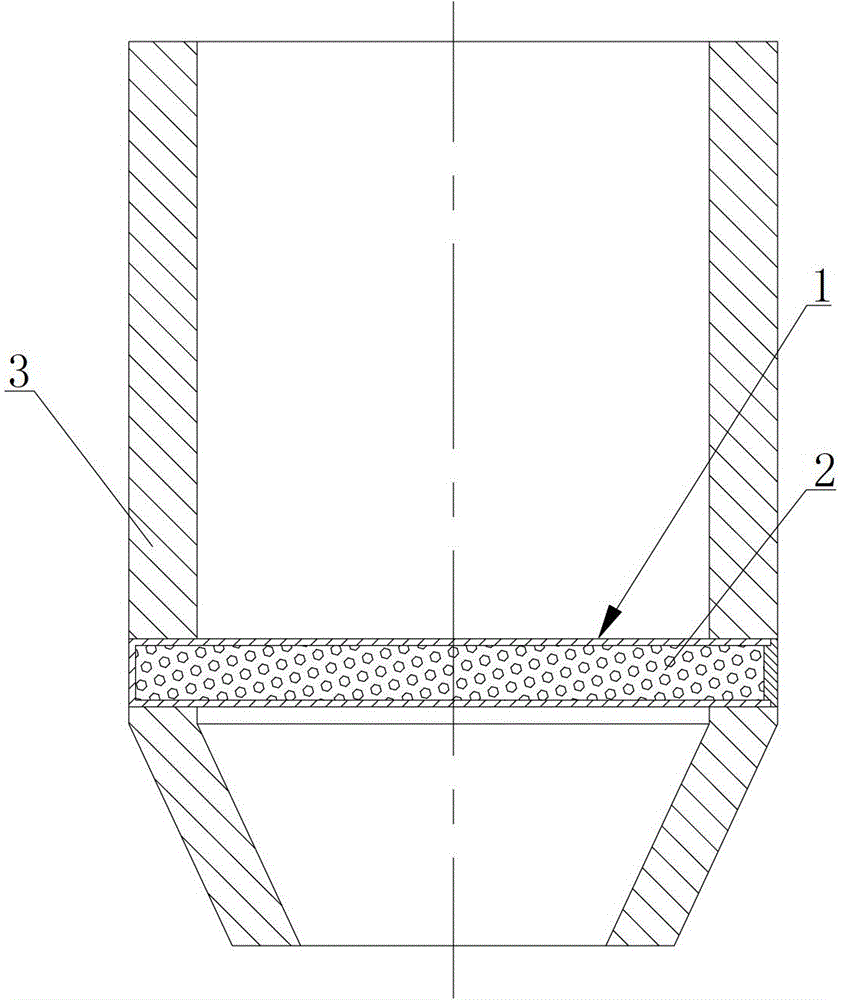

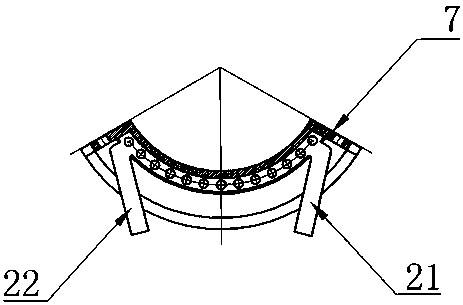

Point inoculation device and point inoculation method

The invention relates to a point inoculation device and a point inoculation method. The point inoculation device is characterized by comprising a package, and inoculation materials consisting of inoculators and nodulizers are filled in the package. The point inoculation method includes proportionally mixing the inoculators with the nodulizers to form the inoculation materials; filling the inoculation materials in an inner cavity of the package; fixing the package filled with the inoculation materials to a specific position of a casting required to be subjected to inoculation before the casting is subjected to pouring; and pouring molten metal into a sand mold and enabling the inoculation materials to perform point inoculation for the specific position of the casting. According to the technical scheme, the point inoculation device and the point inoculation method have the advantages that the package is melted after pouring is completed, and the inoculators and the nodulizers are exposed in the molten metal and are reacted with the molten metal, so that inoculation can be implemented for the specific position of the casting, the specific position of the casting is high in nodularity, the metallographic structure and the graphite morphology of the specific position of the casting are improved, and the machining performance of the specific position of the casting is enhanced.

Owner:天津凯星科技有限公司

A Method for Improving the Microstructure and Properties of Ductile-Grinded Cast Iron

The invention discloses a method for improving the structure and performance of ductile cast iron; it relates to the technical field of cast iron, and introduces graphene composite particles into ductile cast iron to obtain finished ductile iron castings; the introduction is added to molten ductile cast iron after ball milling treatment Graphene composite particles; the ball milling process is mixed ball milling of iron powder and graphene composite particles; the added amount of graphene composite particles in the finished ductile iron casting is 0.25-0.33wt.%; the graphite prepared by the inventive method Graphene composite particles can significantly improve the spheroidization rate of nodular cast iron. By improving the spheroidization rate, the graphite spheres are more rounded. During the solidification process, graphite distortion mainly occurs during the growth of spheroidal graphite in molten iron. Among them, the reduction of growth rate can reduce the probability of distortion. Therefore, by introducing the graphene composite particles prepared by the present invention, the nodularization rate of ductile iron can be greatly increased, and its mechanical properties can be further improved.

Owner:安徽军明机械制造有限公司

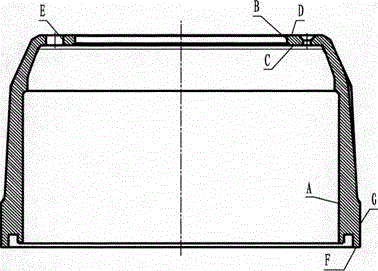

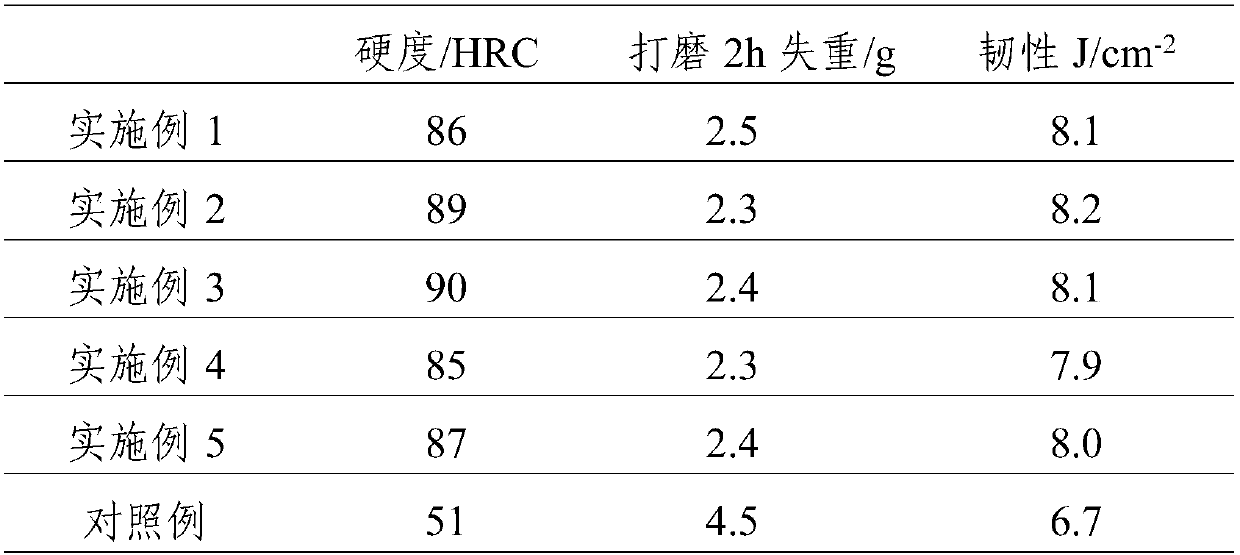

Reinforced chilled roll and preparation method thereof

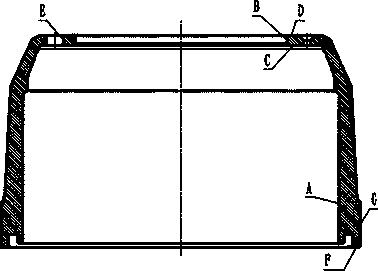

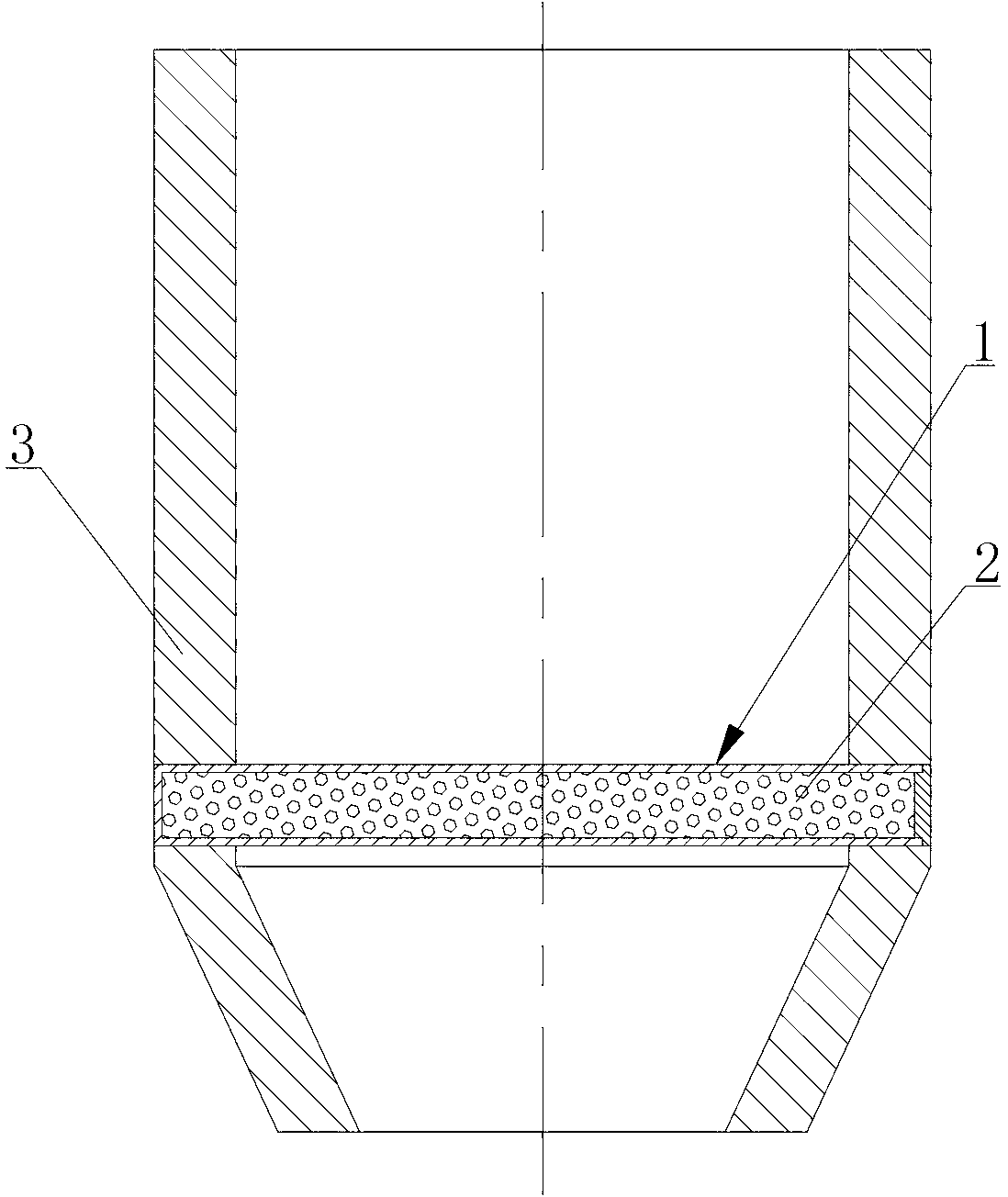

InactiveCN103056164BImprove the situation of unstable combinationGood shape of graphiteRollsMetal rolling arrangementsSlagInstability

The invention discloses a reinforced chilled roll. The reinforced chilled roll comprises an outer alloy layer and a core portion, and a medium layer is arranged between the outer alloy layer and the core portion. By the aid of the medium layer arranged between the outer alloy layer and the core portion, combination instability of an original outer alloy layer and the core portion is improved. In addition, graphite form and number of the alloy outer layer can be obtained and improved in the ideal form by means of adding a preliminary inoculation processing procedure and a microalloying processing procedure to a casting process and controlling nodulizer explosion time. Besides, the performance of the reinforced chilled roll is improved by means of refined crystalline strengthening and strain strengthening of microalloy beneficial elements, quality problems of slag dropping and small spalling are avoided, and steel passing quantity is increased obviously.

Owner:JIANGSU GANGBAO ROLLER

Ferro sulphur and preparation method thereof

The invention relates to ferro sulphur and a preparation method thereof. The ferro sulphur comprises, by weight, 50-70 parts of iron, 15-25 parts of sulphur and 5-35 parts of iron sulfide. The preparation method comprises the steps that the prepared raw materials are smelted, deslagged, molded, smashed, graded, packaged and pressed into balls in sequence. Technology research and development are carried out for a formula and preparation of the ferro sulphur, the raw material utilization rate is improved, and the production cost is reduced. The ferro sulphur has the beneficial effects that the production efficiency is high, materials and cost are reduced, the mold service life is long, no pollution is produced, energy consumption is low, heating is uniform, and the temperature control precision is high.

Owner:LINYING YUZHONG FERROALLOYS

An improved forging steel roller neck Beckle Body Ball Ball -casting Iron Composite Roll Manufacturing Technology and Equipment

ActiveCN105436474BEasy feedingOvercome the defect of prone to tissue segregationTrace elementRare earth

The invention discloses a manufacturing technique and device for an improved bainite nodular cast iron composite roller provided with a forged steel roller neck. The improved bainite nodular cast iron composite roller provided with the forged steel roller neck is prepared from, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% f Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0-0.05% of P, 0-0.30% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE, and the balance Fe and inevitable trace elements. According to the manufacturing technique and device for the improved bainite nodular cast iron composite roller provided with the forged steel roller neck, yttrium-based rare earth is used for nodularization, Ba, Ca and silicon iron are used for combined inoculation, Nb, Ti, V, B and Sb are added for modification treatment, and thus the mechanical property of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved; integral in-mold heating and casting of a core rod are conducted through an induction heater, and a water-cooling crystallizer is used for formation; the interface of a composite layer can be controlled dynamically, the technique is simple, power consumption is low, the cost is low, composition segregation is avoided, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Method for improving structure performance of nodular cast iron

ActiveCN112267060AGrain refinementHigh degree of two-dimensional mismatchCarbon compoundsMolten stateIron powder

The invention discloses a method for improving the structure performance of nodular cast iron, and relates to the technical field of cast iron. The method comprises the following steps: introducing graphene composite particles into the nodular cast iron to obtain a finished nodular iron casting product; according to the introduction step, the graphene composite particles subjected to ball millingtreatment are added to molten-state nodular cast iron; the ball milling treatment is mixing and ball-milling treatment of iron powder and the graphene composite particles; and the addition quantity ofthe graphene composite particles in the finished nodular iron casting product is 0.25wt.%-0.33wt.%. The graphene composite particles prepared with the method can remarkably increase the spheroidization rate of the nodular cast iron, graphite nodules are rounded through improvement of the spheroidization rate, in the solidification process, graphite distortion mainly occurs in the growth process of spherical graphite in molten iron, and the probability of distortion can be reduced through reduction of the growth rate, therefore, through introduction of the graphene composite particles preparedwith the method, the spheroidization rate of nodular cast iron can be greatly increased, and the mechanical property of the nodular cast iron can be further improved.

Owner:安徽军明机械制造有限公司

Castable as well as preparation method and application thereof

PendingCN113881889AIncreased tendency to crackSimple ingredientsFoundry mouldsFurnace typesCrack resistanceChemical composition

The invention relates to a castable as well as a preparation method and application thereof. The castable comprises the following chemical components of, in percentage by mass, 3.0%-3.4% of C, 1.5%-1.8% of Si, 0.3%-0.6% of Mn, less than or equal to 0.04% of P, less than or equal to 0.05% of S, 0.018%-0.025% of Mg, 0.01%-0.03% of Re, 0.1%-0.2% of Ti, and the balance Fe. The invention further discloses a preparation method of a mold. A mold material is low in carbon equivalent and alloy content, the preparation method of the mold is simple, the production cost is low, and the mold has excellent crack resistance and long service life.

Owner:CHANGZHOU INST OF LIGHT IND TECH

Melting ingredient for piston

Owner:JIANGSU LEADER PRECISION MACHINERY

A kind of vanadium-titanium gray cast iron brake drum and preparation method thereof

InactiveCN103993221BEasy to shapeReasonable design of ingredientsManufacturing technologyFerrosilicon

The invention relates to a high-strength and high-wear-resistance vanadium-titanium cast iron brake drum manufacturing technology for automobiles, specifically a method for preparing a vanadium-titanium gray cast iron brake drum. The preparation method includes the following steps: melting the original molten iron: Vanadium-titanium pig iron, scrap steel, furnace charge, recarburizer, ferrosilicon, ferromanganese, and ferrochrome are used as the charge, and the recarburizer is added to the bottom of the furnace, and the charge is smelted in an intermediate frequency induction furnace to obtain the original molten iron. After the molten iron is melted Raise the temperature and overheat to purify the molten iron, then keep it warm at 1520-1530°C; then carry out slag removal, add a slag accumulator on the surface to keep it warm, and then add a small amount of recycled material to adjust the composition of the molten iron. The invention adopts the process of adding a small amount of returned material to increase the heterogeneous core in the later stage of smelting to reduce the tendency of molten iron to be white, improve the graphitization ability of molten iron, and improve the inoculation effect; adopt the secondary inoculation treatment process of the tapping trough and the sprue cup to improve the inoculation effect , Improve graphite morphology, eliminate carbide and ferrite, increase pearlite content.

Owner:陈国

Cylinder sleeve material for abrasion-resistant automobile and blank molding method

InactiveCN103131943ATo meet the needs of improving mechanical propertiesShorten the production cycleCylindersChemical compositionAlloy

Provided are a cylinder sleeve material for an abrasion-resistant automobile and a blank molding method. The technical schemes of the high-performance low-alloy cast-iron cylinder sleeve material and casting process include that the content of copper (Cu) in chemical content of a cylinder sleeve is increased to 1.7%, the Cu replaces partial alloy of nickel (Ni) and molybdenum (Mo) and is melted at a high temperature, a beltian body under a casting state is formed, and requirements of high mechanical performance of the cylinder sleeve are met.

Owner:徐金兰

Manufacturing process and equipment for nickel-chromium-molybdenum alloy cast iron composite roll in forged steel roll neck

ActiveCN105328168BEasy feedingOvercome the defect of prone to tissue segregationFerrosiliconRare earth

The invention discloses a nickel-chromium-molybdenum alloy cast iron composite roll process and equipment in a forged steel roll neck. The material mass percentages are: C: 3.3-3.8%, Si: 0.6-1.2%, Mn: 0.4-1.2%, Cr: 0.6 ~1.2%, Mo: 0.3~1.0%, Ni: 2.0~3.0%, Cu: 0.6~1.1%, P: ≤0.05%, S: ≤0.03%, Mg: 0.04~0.06%, Ba: 1.5~ 2.5%, Ca: 1-2%, RE1.0-2.0%, and the balance is Fe; Rare earth spheroidization and Ba, Ca, and ferrosilicon compound inoculation are used to improve the mechanical properties of the roll, and the forged steel roll neck is used to improve the roll quality. Intensity, using induction heater to heat and cast the mandrel as a whole in the mold, combined water-cooled crystallizer to form, the lifting device lifts the heater up at a certain speed to form a directional solidification in the area, and can dynamically control the interface of the composite layer, the process is simple and the efficiency is high , low power consumption, low cost, no component segregation in the composite layer, and long service life of the roll.

Owner:丹阳恒庆复合材料科技有限公司

point inoculation method

The invention relates to a point inoculation device and a point inoculation method. The point inoculation device is characterized by comprising a package, and inoculation materials consisting of inoculators and nodulizers are filled in the package. The point inoculation method includes proportionally mixing the inoculators with the nodulizers to form the inoculation materials; filling the inoculation materials in an inner cavity of the package; fixing the package filled with the inoculation materials to a specific position of a casting required to be subjected to inoculation before the casting is subjected to pouring; and pouring molten metal into a sand mold and enabling the inoculation materials to perform point inoculation for the specific position of the casting. According to the technical scheme, the point inoculation device and the point inoculation method have the advantages that the package is melted after pouring is completed, and the inoculators and the nodulizers are exposed in the molten metal and are reacted with the molten metal, so that inoculation can be implemented for the specific position of the casting, the specific position of the casting is high in nodularity, the metallographic structure and the graphite morphology of the specific position of the casting are improved, and the machining performance of the specific position of the casting is enhanced.

Owner:天津凯星科技有限公司

Casting technology and application of thick and large ductile cast iron pieces

InactiveCN111230093AGood shape of graphiteImprove qualityCasting plantsFoundry mouldsHardnessDuctile iron

The invention discloses a casting technology and an application of thick and large ductile cast iron pieces. The technology is characterized by including the following steps that (1) castings are designed by the aid of three-dimensional software, and single mode flow analysis is performed on the castings by the aid of mold flow software, so that the non-reducing positions and number are judged; (2) a sand mold is manufactured; (3) a molten iron raw material is prepared; (4) inoculation treatment and spheroidizing treatment technologies are formulated and controlled; (5) the prepared molten iron is heated, and pouring is performed; (6) after pouring is completed, the molten iron is cooled along with the sand mold, off-line separation is performed after cooling, and the castings are obtained; (7) material detection is performed and includes metallographic structure detection, mechanical performance detection, hardness detection and inwards-sinking detection; (8) sand washing, grinding, cleaning and appearance inspection are performed on the castings, and qualified castings are obtained if the castings are qualified. Compared with the prior art, the technology has the advantages thatthe steps are simple, the materials are easy to obtain, the cost is saved, and the technology is wide in applicability.

Owner:苏州勤美达精密机械有限公司

A manufacturing process and equipment for an improved forged steel roll neck high-nickel-chromium-molybdenum alloy cast iron composite roll

ActiveCN105401059BEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyLayer interface

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

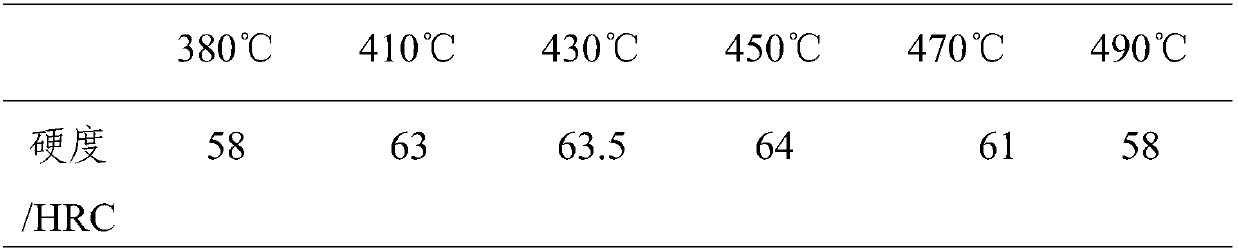

High-strength high-toughness wear-resistant ball and preparation process thereof

InactiveCN107739974AIncreased tendency to disconnectIncrease the expansion forceFurnace typesHeat treatment furnacesWear resistantHardness

The invention relates to the technical field of wear-resistant balls, in particular to a high-strength high-toughness wear-resistant ball and a preparation process thereof. The high-strength high-toughness wear-resistant ball is composed of 1.5%-2.5% of C, 0.3%-0.8% of Si, 0.3%-0.7% of Mn, 1.5%-2.0% of Cr, 0.01%-0.03% of W, 0.01%-0.05% of Mo, less than or equal to 0.05% of P, less than or equal to0.05% of S, 0.05%-0.15% of Sr, 0.05%-0.1% of B, 0.1%-0.4% of Zn, 0.02%-0.04% of Mg and the balance Fe. By means of the wear-resistant ball, the defects that existing wear-resistant balls are low in hardness and impact toughness and poor in wear resistance are effectively made up to a certain extent.

Owner:NINGGUO ZHENGXING WEAR RESISTANT MATERIALS

A kind of gray cast iron and preparation method thereof

The invention discloses gray cast iron and a preparation method thereof, and belongs to the field of metal casting. The gray cast iron and the preparation method solve the technical problems that existing gray cast iron is high in production cost and insufficient in performance. According to the gray cast iron and the preparation method, precious metal such as copper, molybdenum, nickel and vanadium is not added, strength and hardness of castings are improved through chromium and antimony, the manufacturing cost is reduced, and performance of the gray cast iron can be improved by conducting microalloying on antimony and chromium together.

Owner:浙江杭机铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com