Preparation method of material suitable for diesel engine cylinder cover

A technology for diesel engines and cylinder heads, applied in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of high cost, low performance, and difficulty in improving product market competitiveness, and achieve reduced shrinkage and wear resistance. Excellent, improve the effect of product quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

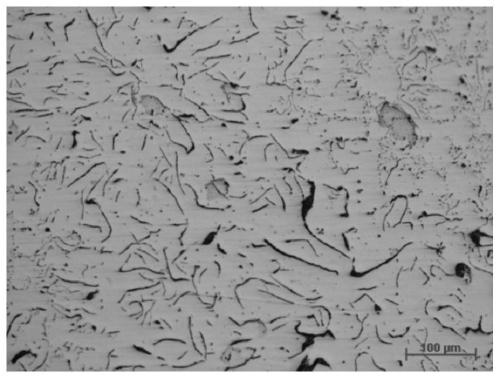

Embodiment 1

[0038] An example of the preparation method of the material that is applicable to diesel engine cylinder head described in the present invention, comprises the steps:

[0039] (1) Furnace charge ratio is 50% by weight of scrap steel and 50% of returned furnace iron. Place the prepared charge in an intermediate frequency furnace for smelting. When the temperature of molten iron in the furnace reaches 1400°C, add it at one time according to the mass percentage of charge as 3 % carburant for carburizing the molten iron, when the charge is completely melted, add copper and ferrosilicon alloy according to the chemical composition requirements of the initial molten iron;

[0040] (2) After the molten iron smelting is completed, control the refining temperature of the molten iron between 1530-1560°C, add ferromanganese nitride to make the nitrogen content in the molten iron reach 0.008%, heat up, stir and keep warm for 8 minutes before tapping;

[0041] (3) Add an inoculant in the mo...

Embodiment 2

[0047] Another example of the preparation method of the material suitable for diesel engine cylinder head described in the present invention, comprises the steps:

[0048](1) The ratio of charge is 70% by weight of scrap steel and 30% of returned iron. Place the prepared charge in an intermediate frequency furnace for smelting. When the temperature of molten iron reaches 1400°C, add 3% of the increase in mass percentage of charge at one time. Carbon agent, when the furnace charge is completely melted, add copper and ferrosilicon alloy according to the chemical composition requirements of the initial molten iron;

[0049] (2) After the molten iron smelting is completed, control the refining temperature of the molten iron between 1530-1560 ° C, add ferromanganese nitride to make the nitrogen content in the molten iron reach 0.018%, heat up and stir and keep warm for 12 minutes before tapping;

[0050] (3) Add inoculants in the molten iron ladle, the inoculant addition is 0.75% o...

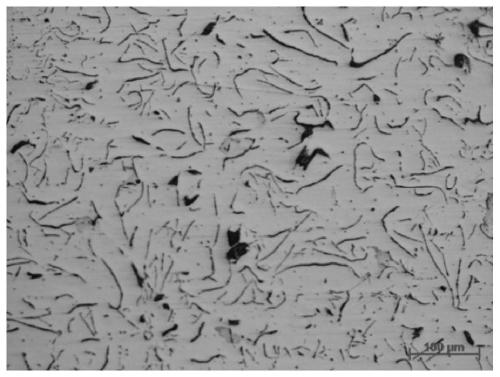

Embodiment 3

[0056] Another example of the preparation method of the material suitable for diesel engine cylinder head described in the present invention, comprises the steps:

[0057] (1) The ratio of charge is 60% by weight of scrap steel and 40% of returned iron. Place the prepared charge in an intermediate frequency furnace for smelting. When the temperature of molten iron reaches 1400°C, add 3% of the increase in mass percentage of charge at one time. Carbon agent, when the furnace charge is completely melted, add copper and ferrosilicon alloy according to the chemical composition requirements of the initial molten iron;

[0058] (2) After the molten iron smelting is completed, control the refining temperature of the molten iron between 1530-1560 ° C, add ferromanganese nitride to make the nitrogen content in the molten iron reach 0.013%, heat up and stir and keep warm for 10 minutes before tapping;

[0059] (3) Add an inoculant in the molten iron ladle, the inoculant addition is 0.60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com