Melting ingredient for piston

A piston and smelting technology, applied in the field of casting pistons, can solve the problems of easy deformation and wear of pistons, low hardness, high brittleness, etc., and achieve the effect of good graphite shape, high tensile strength, and low brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1 10

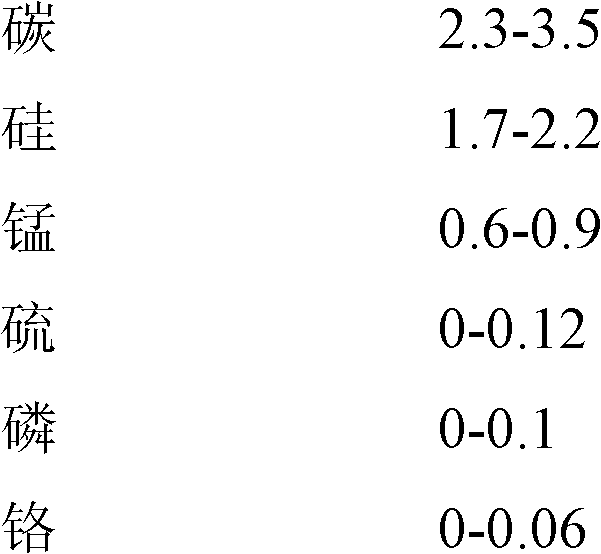

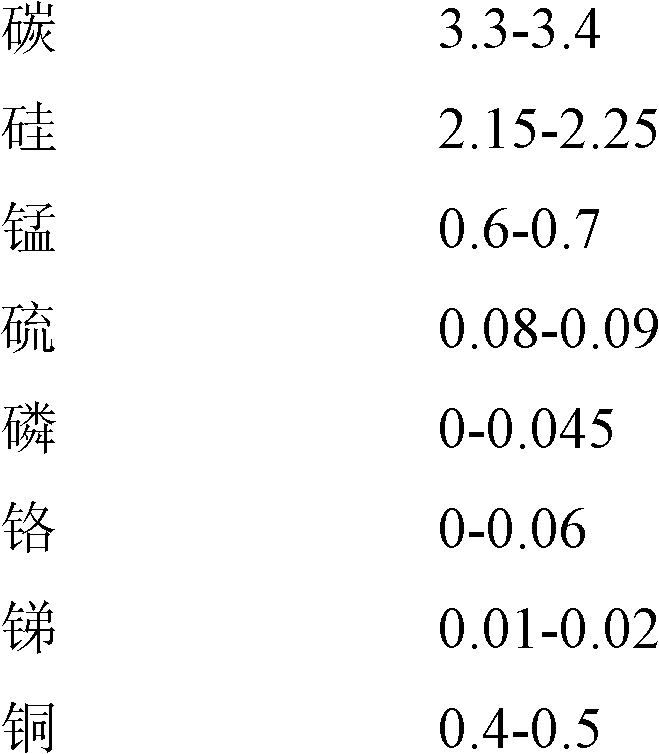

[0022] Specific embodiments of the present invention one to ten, by mass percentage (%) are specifically as follows:

[0023]

[0024] The rest is iron.

[0025] Below in conjunction with the selection of raw materials in the specific preparation process, smelting and final molding process, the above-mentioned embodiment is described in detail:

Embodiment 2

[0027] 1] Raw material selection: take 700kg of pig iron, 2000kg of scrap steel, 2300kg of returned charge, the total weight is 5000kg, and then add 40kg of silicon carbide, 46.5kg of recarburizer, 16.5kg of ferrosilicon, 0.5kg of ferromanganese, and 5.5kg of iron sulfide;

[0028] Among them, the carbon content in pig iron is 4.20%, the silicon content is 1.22%, the manganese content is 0.15%, the sulfur content is 0.021%, the phosphorus content is 0.05%, and the rest is iron; the scrap steel carbon content is 0.33%, The silicon content is 0.23%, the manganese content is 0.64%, the sulfur content is 0.023%, the phosphorus content is 0.04%, the chromium content is 0.04%, and the rest is iron; the carbon content of the returned charge is 3.2%, and the silicon content is 2.3%, 0.75% manganese, 0.085% sulfur, 0.04% phosphorus, 0.4% chromium, 0.025% antimony, 0.45% copper, and the rest is iron;

[0029] 2] After mixing the above raw materials evenly, smelting is carried out, and t...

Embodiment 4

[0035] 1] Raw material selection: take 500kg of pig iron, 2000kg of scrap steel, 2500kg of recycle materials, the total weight is 5000kg, and then add 30kg of silicon carbide, 62.5kg of carburizer, 8.2kg of ferrosilicon, 0.4kg of ferromanganese, and 6.2kg of iron sulfide;

[0036] Among them, the carbon content in pig iron is 4.35%, the silicon content is 1.25%, the manganese content is 0.2%, the sulfur content is 0.03%, the phosphorus content is 0.03%, and the rest is iron; the scrap steel carbon content is 0.3%, The silicon content is 0.25%, the manganese content is 0.55%, the sulfur content is 0.03%, the phosphorus content is 0.02%, the chromium content is 0.04%, and the rest is iron; the carbon content of the returned charge is 3.2%, and the silicon content is 2.3%, 0.75% manganese, 0.085% sulfur, 0.04% phosphorus, 0.4% chromium, 0.155% molybdenum, 0.025% antimony, and 0.45% copper , the rest is iron;

[0037] 2] After mixing the above raw materials evenly, smelting is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com