Rotary valve with improved structure

A technology of structural improvement and rotary valve, applied in the direction of sliding valve, valve device, engine components, etc., can solve the problems of reduced sealing performance of rotary valve rotary plate and upper reverse hanging plate, environmental pollution, easy wear, etc., to improve the efficiency of exhaust gas treatment and exhaust gas treatment quality, avoid environmental pollution, and ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

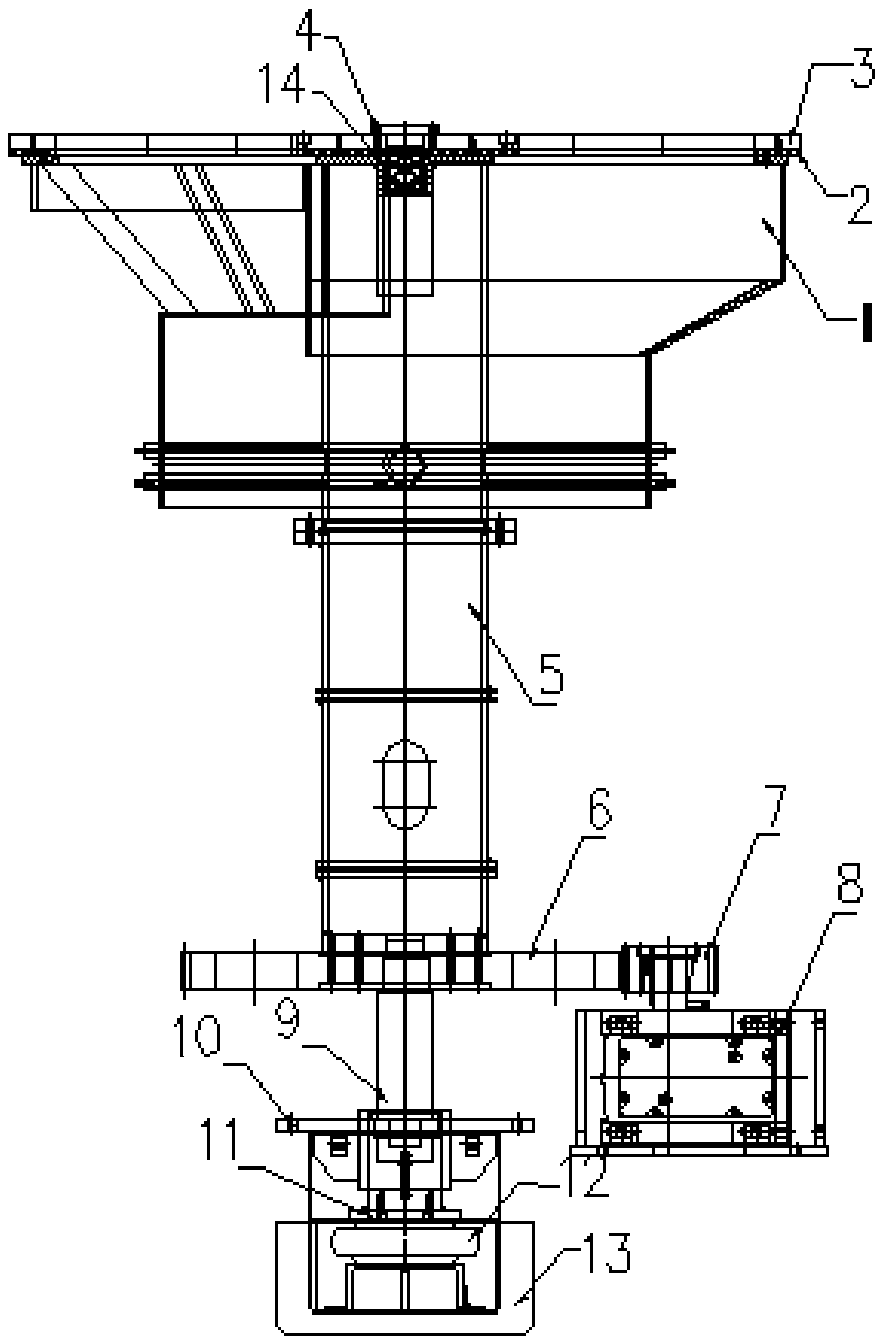

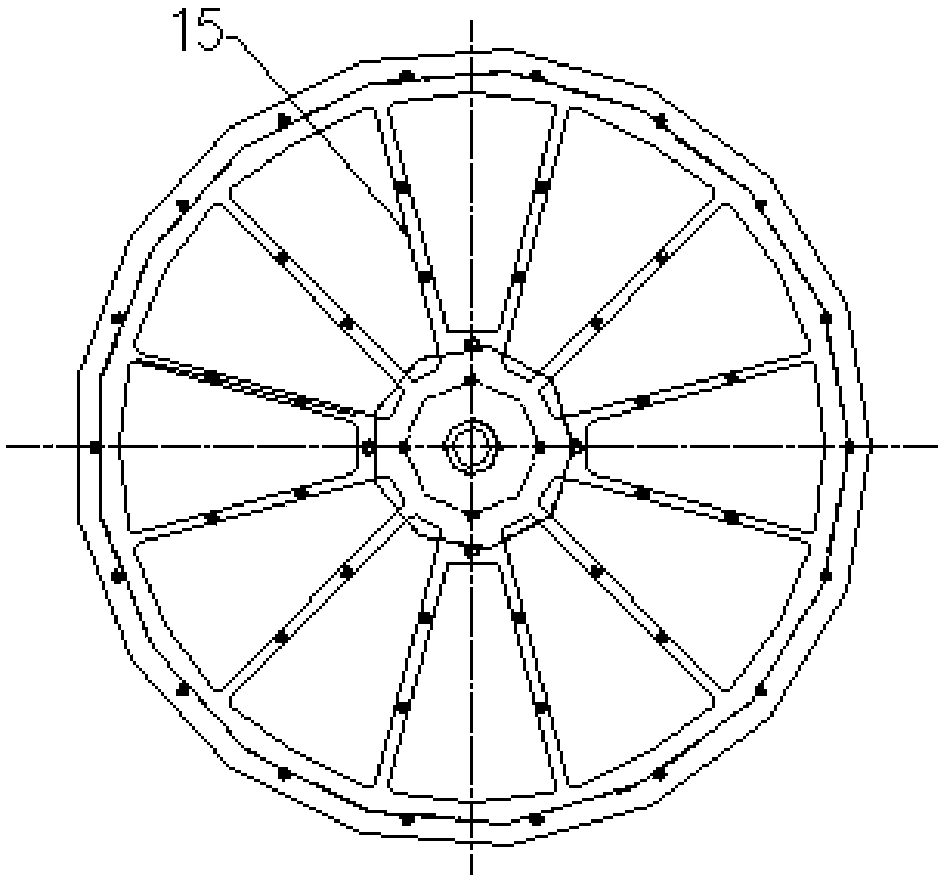

[0016] Embodiment: A rotary valve with improved structure, including rotary valve turntable 1, upper anti-hanging plate 3 and wear-resistant plate 2, the wear-resistant plate 2 made of wear-resistant material can be detachably fixed and installed on the upper anti-hanging On the surface of one end of the disk 3, the surface of the rotary valve turntable 1 can rotate against the surface of the wear-resistant plate 2, and the wear-resistant plate 2 is installed on the lower end of the upper anti-suspension plate 3, and then the rotary valve turntable 1 is pressed against the wear-resistant plate 2 , the rotary valve turntable 1 is in contact with the wear-resistant plate 2 when rotating, and the wear-resistant plate 2 is made of wear-resistant material, which is not easy to wear after long-term use, and can ensure the sealing between the rotary valve turntable 1 and the upper anti-hanging plate 3, When the wear-resistant plate 2 is worn out, it can be quickly replaced with a new ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com