Graphitized fiber, carbon fiber, ceramic fiber brake disc and manufacturing process

A ceramic fiber and graphitization technology, applied in the field of brake discs, can solve the problems of increasing the body weight, strong vibration, and high rejection rate, and achieve the effects of improving driving comfort, reducing overall weight, and being less prone to deformation and wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

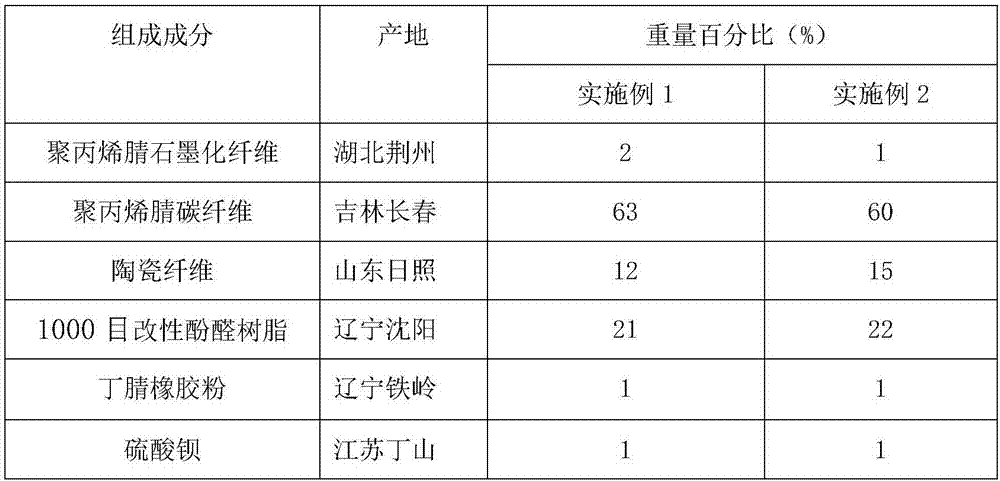

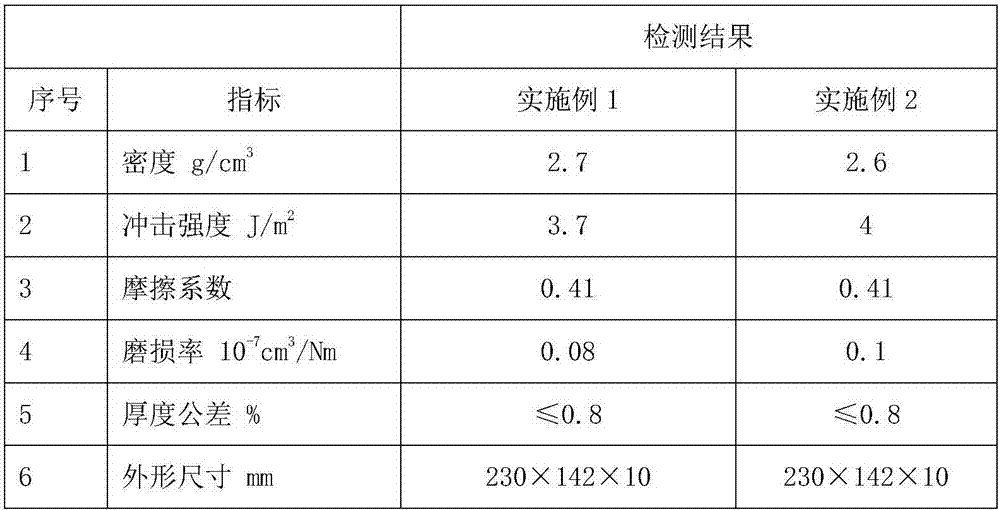

[0027] The graphitized fiber of the present invention, carbon fiber, ceramic fiber brake disk, take polyacrylonitrile graphitized fiber, polyacrylonitrile carbon fiber, ceramic fiber as skeleton material, nitrile rubber powder and barium sulfate are filler, modified phenolic resin is The binder is mixed to make the brake disc raw material, and then the brake disc is made into the brake disc through hot pressing, heat treatment, surface polishing and drilling; the weight percentage content of each component in the brake disc raw material is:

[0028] Polyacrylonitrile graphitized fiber 0.5%~5%:

[0029] Polyacrylonitrile carbon fiber 45% ~ 65%:

[0030] Ceramic fiber 10% to 25%;

[0031] Modified phenolic resin, with a particle size of 15% to 25% above 1000 mesh;

[0032] Nitrile rubber powder 0.5% to 2%;

[0033] Barium sulfate 0.5% to 2%;

[0034] The manufacturing process of graphitized fiber, carbon fiber and ceramic fiber brake disc is characterized in that it comprise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com