Patents

Literature

35results about How to "Not easy to wear and deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

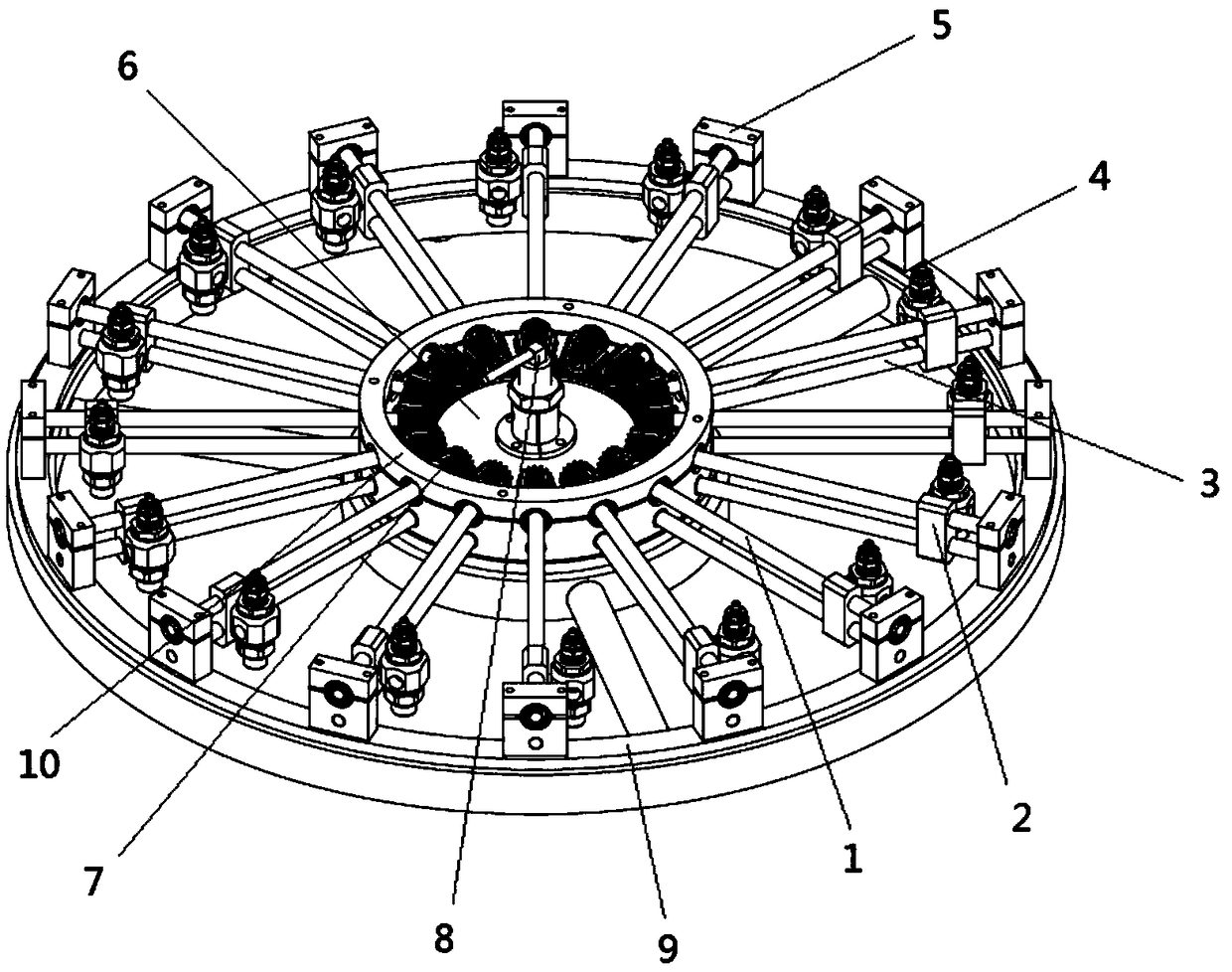

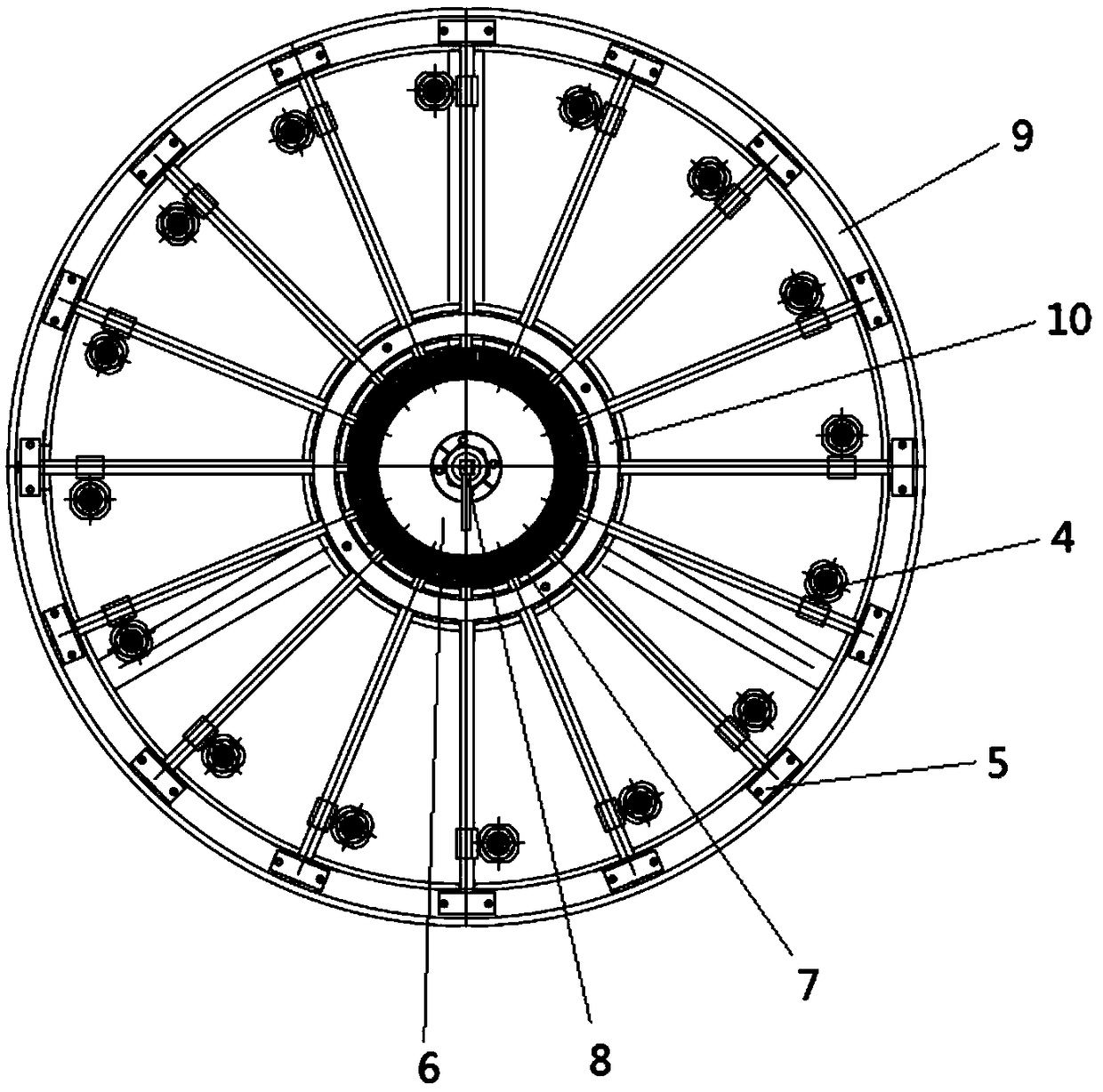

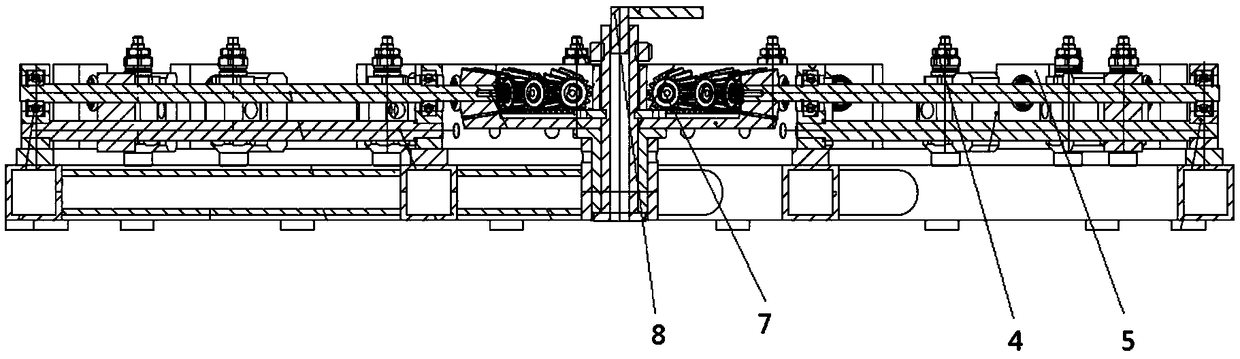

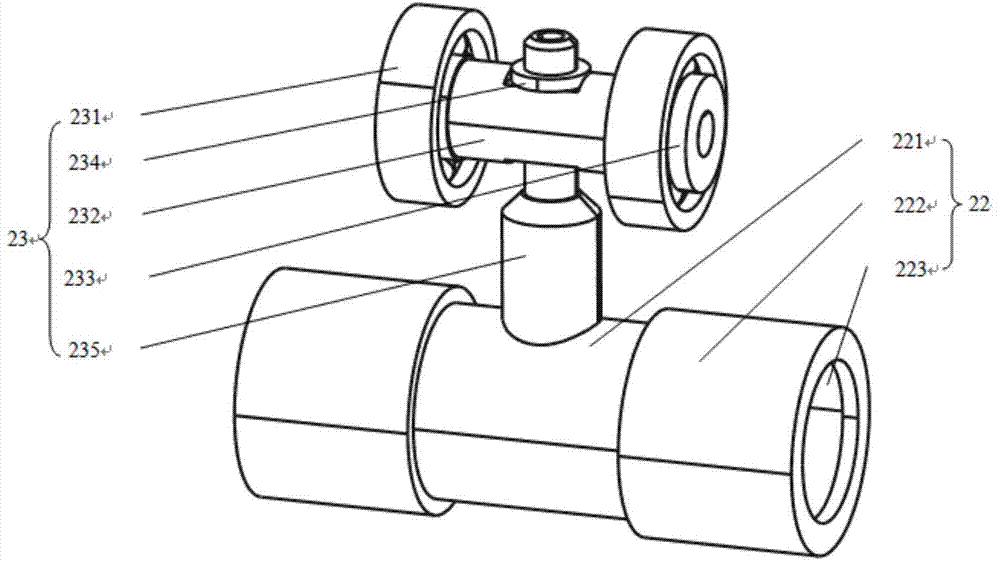

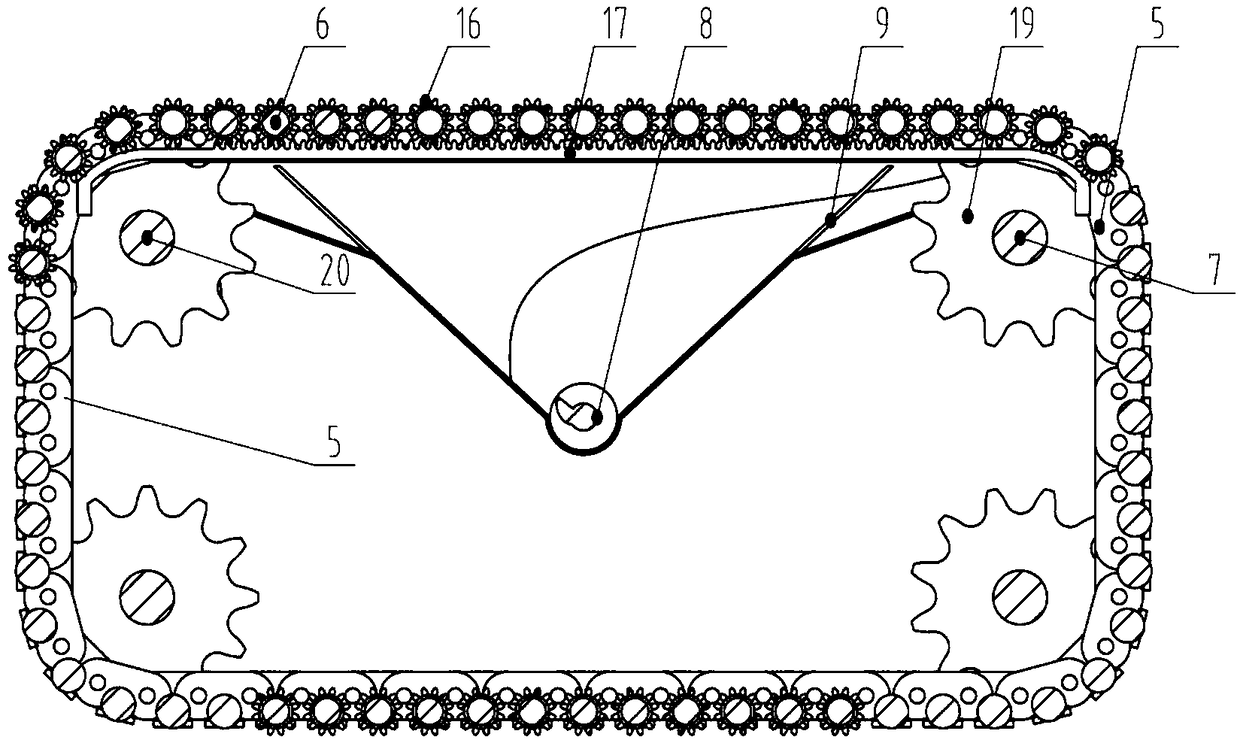

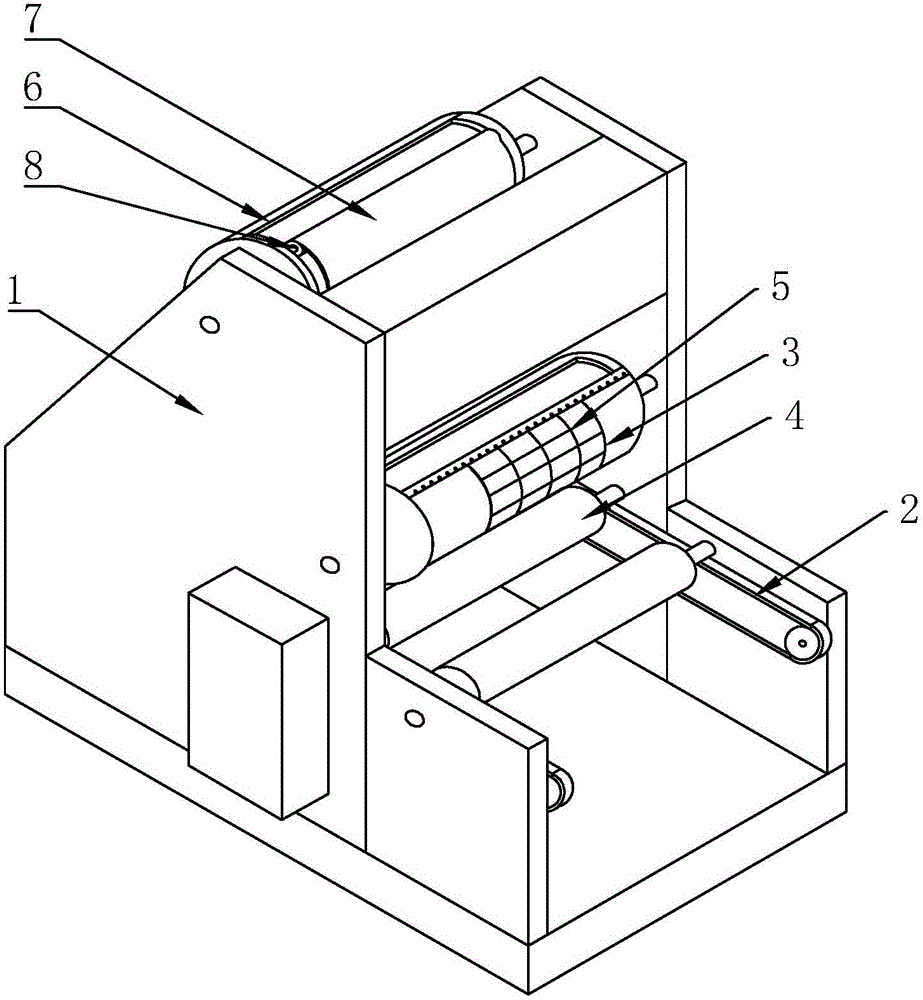

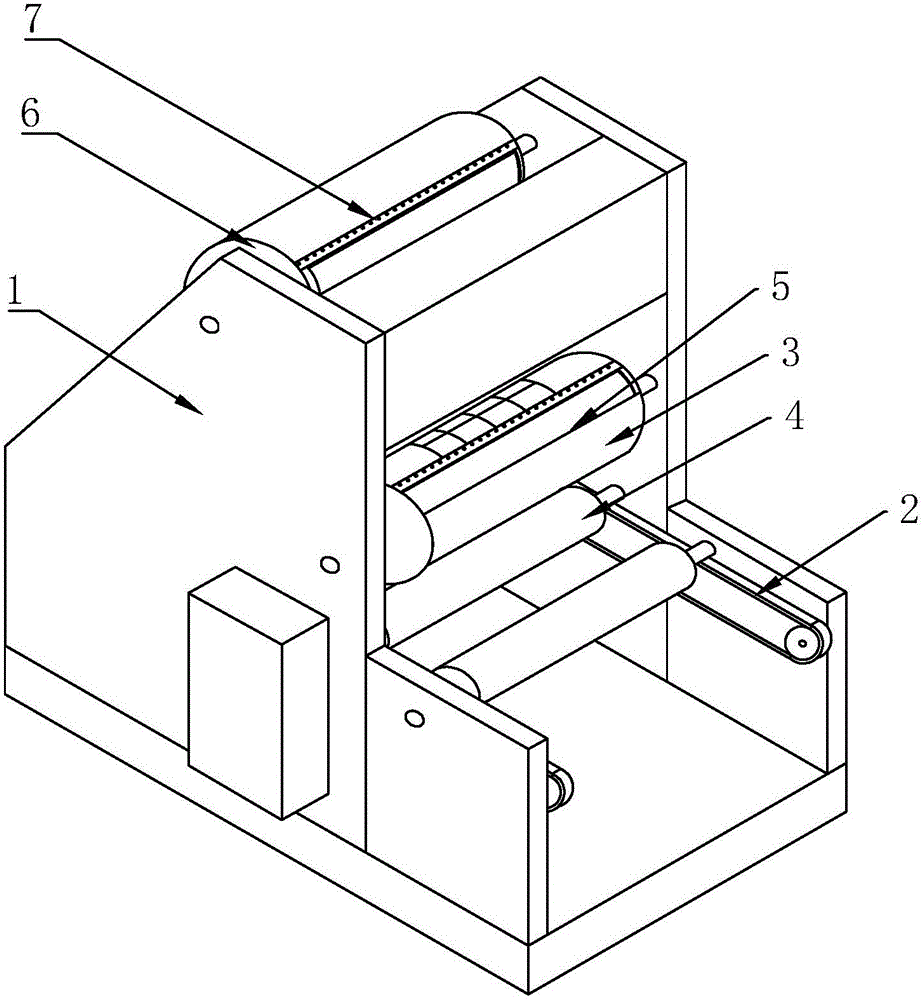

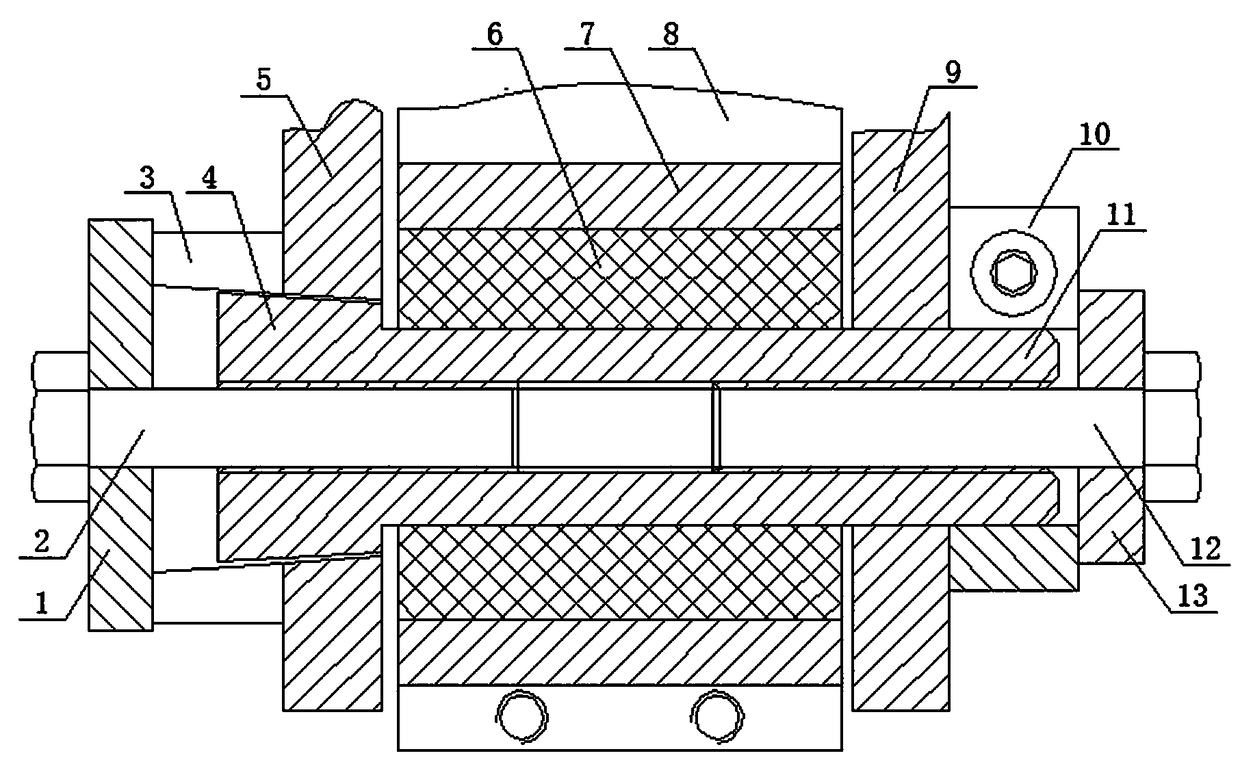

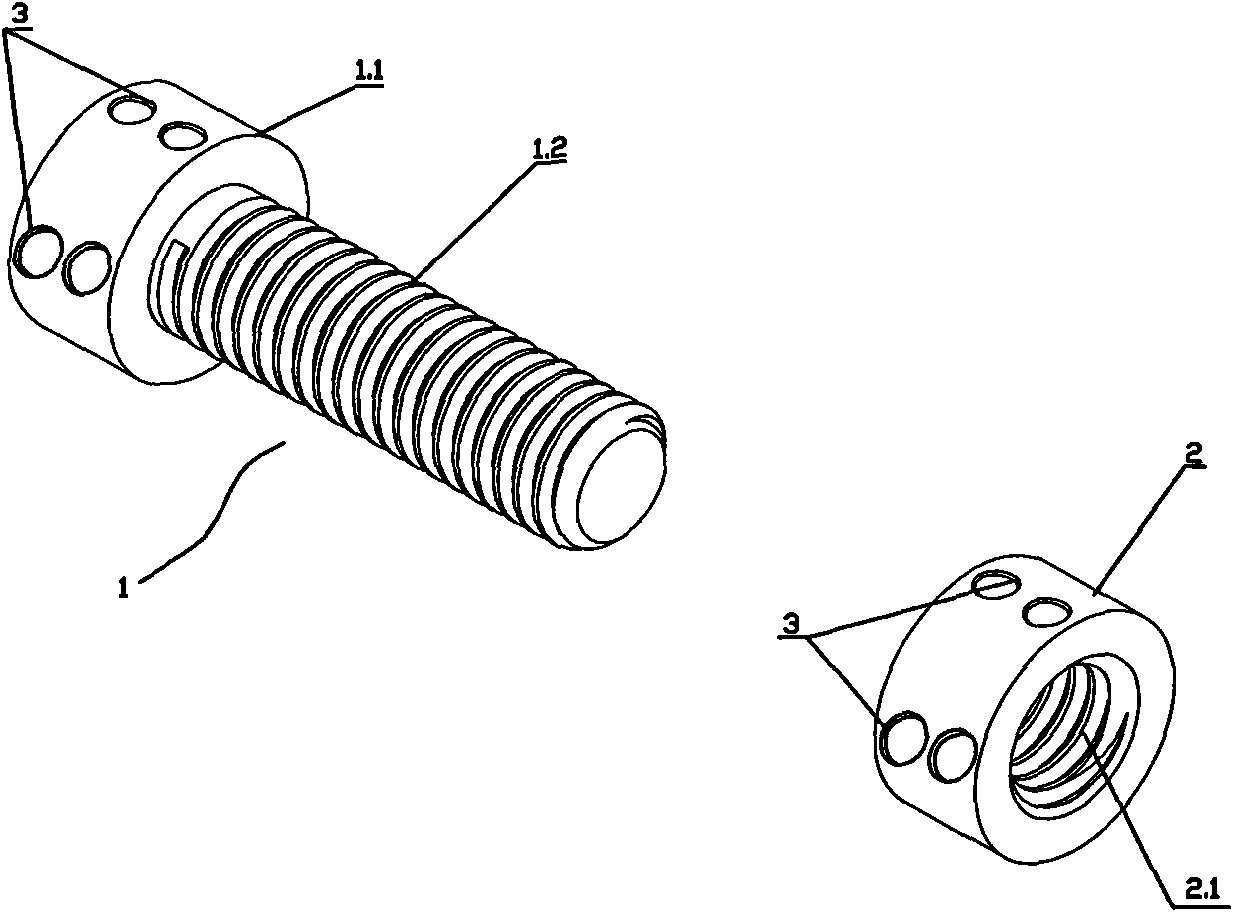

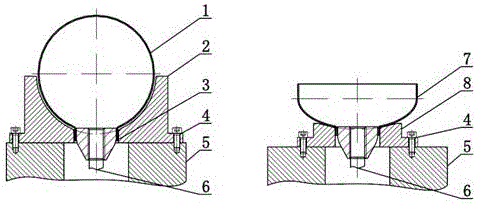

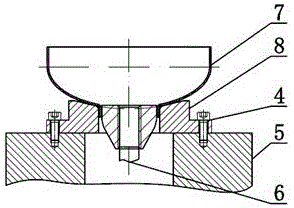

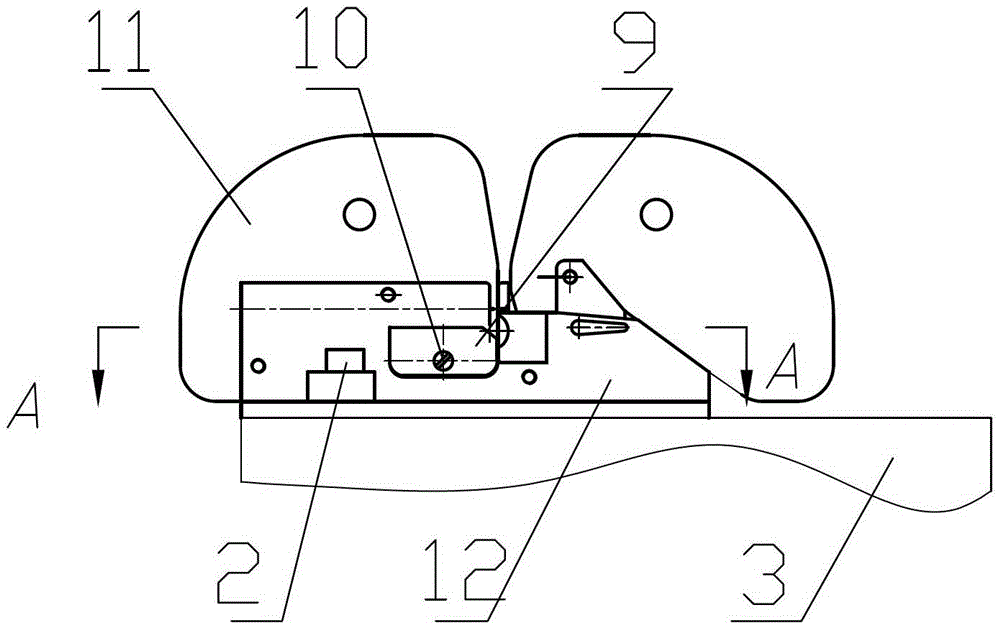

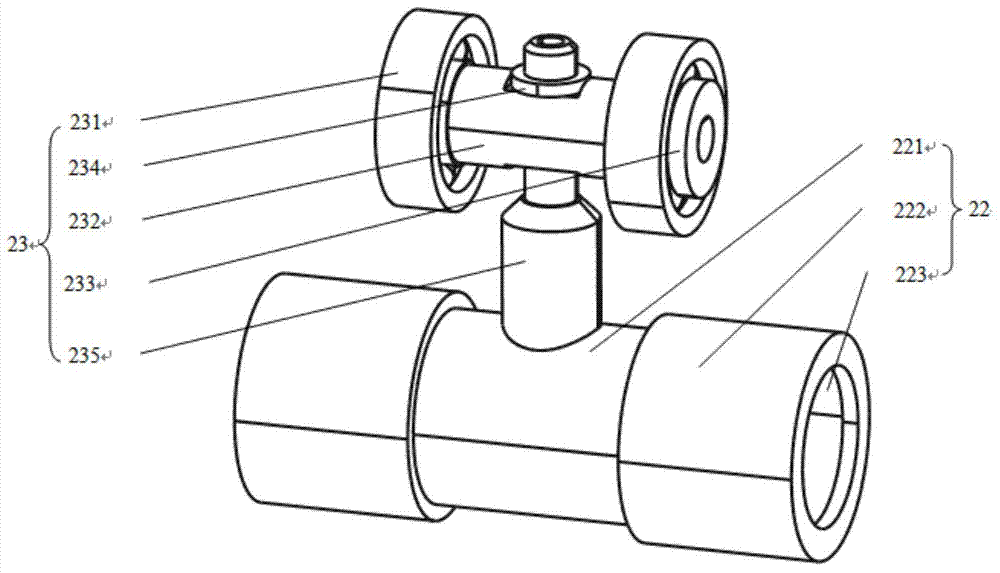

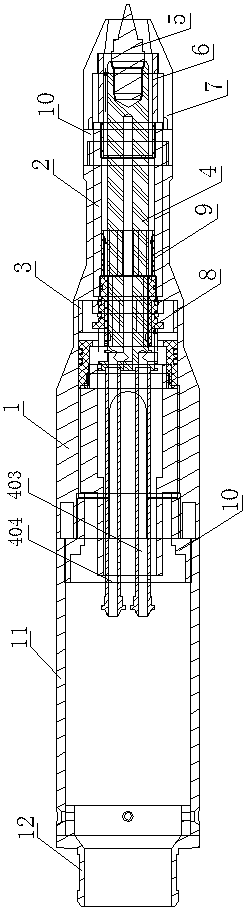

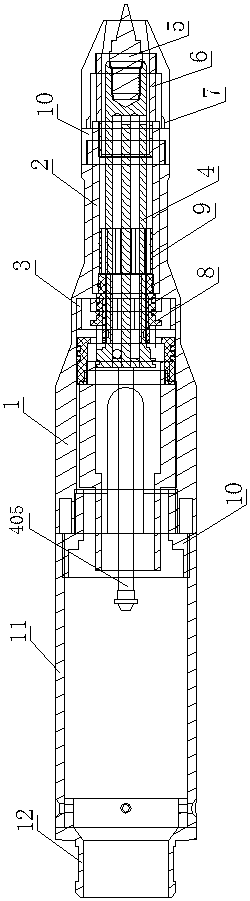

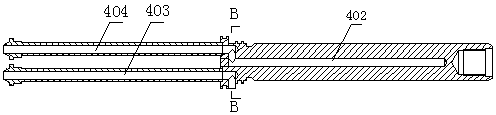

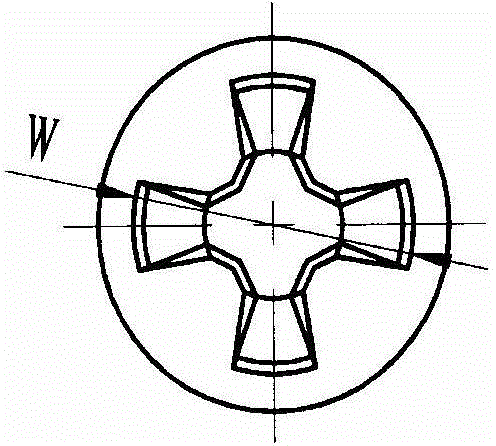

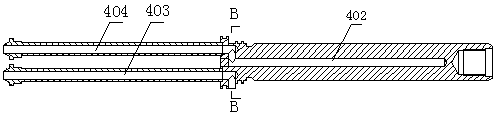

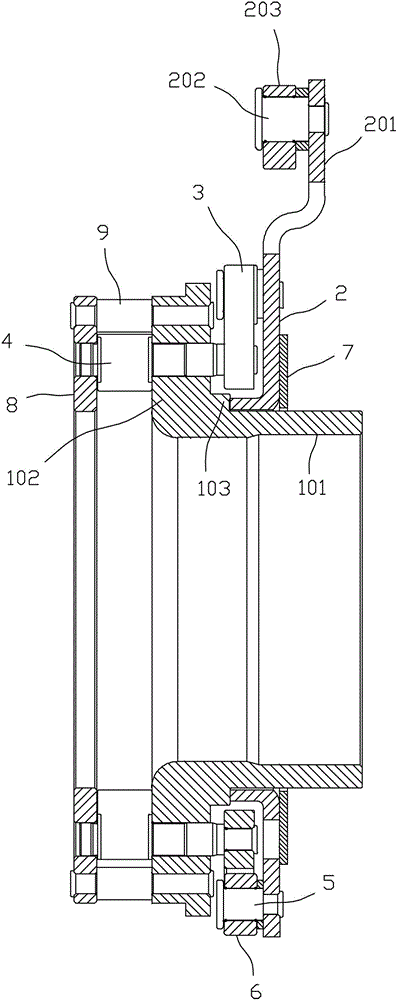

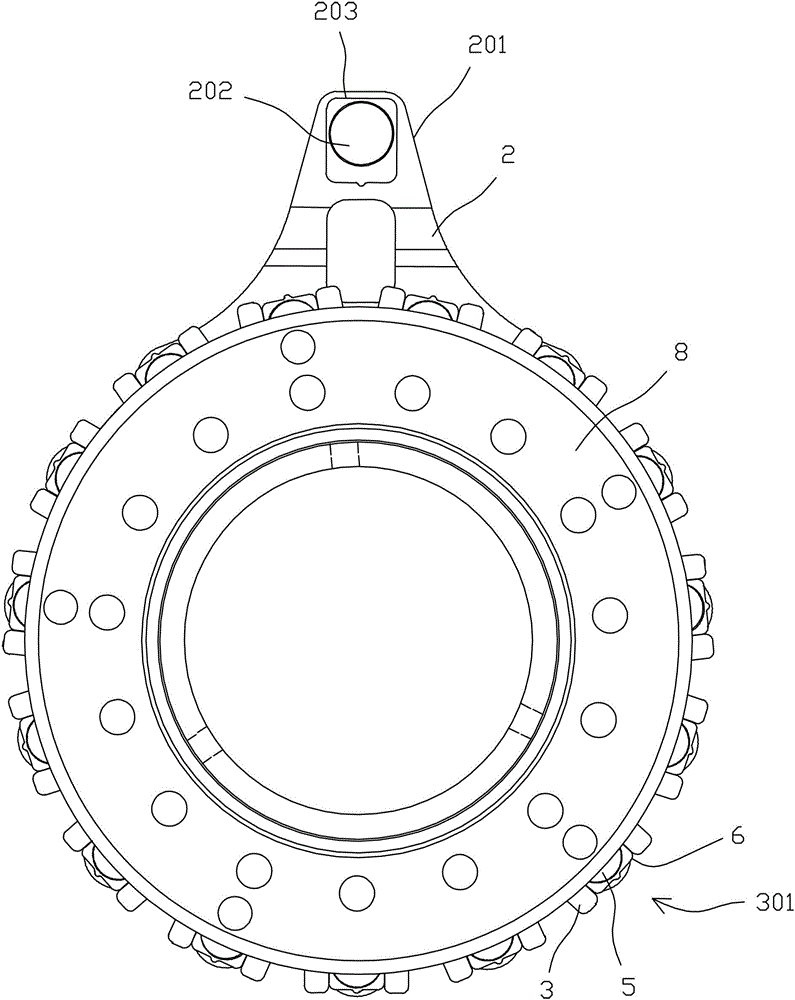

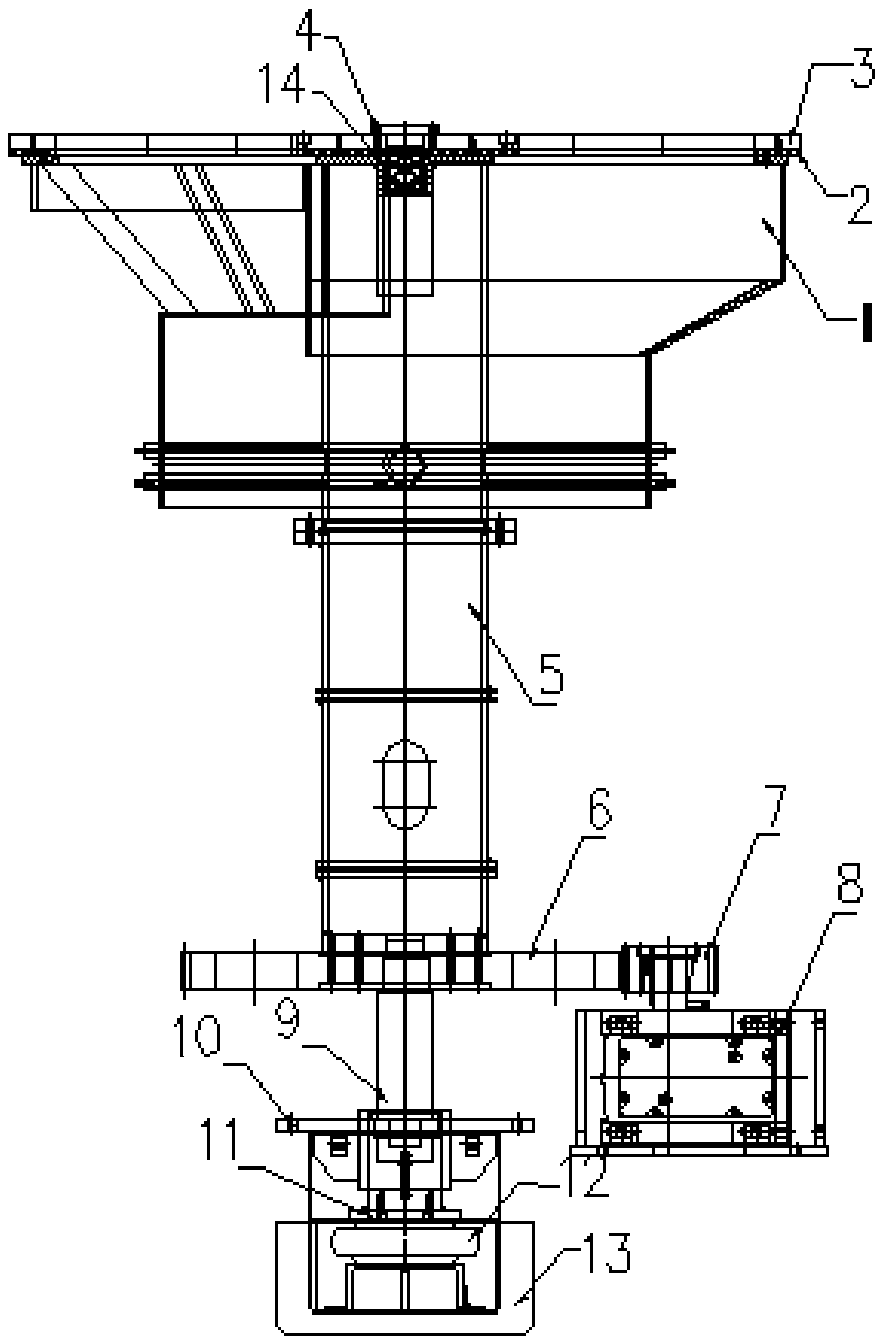

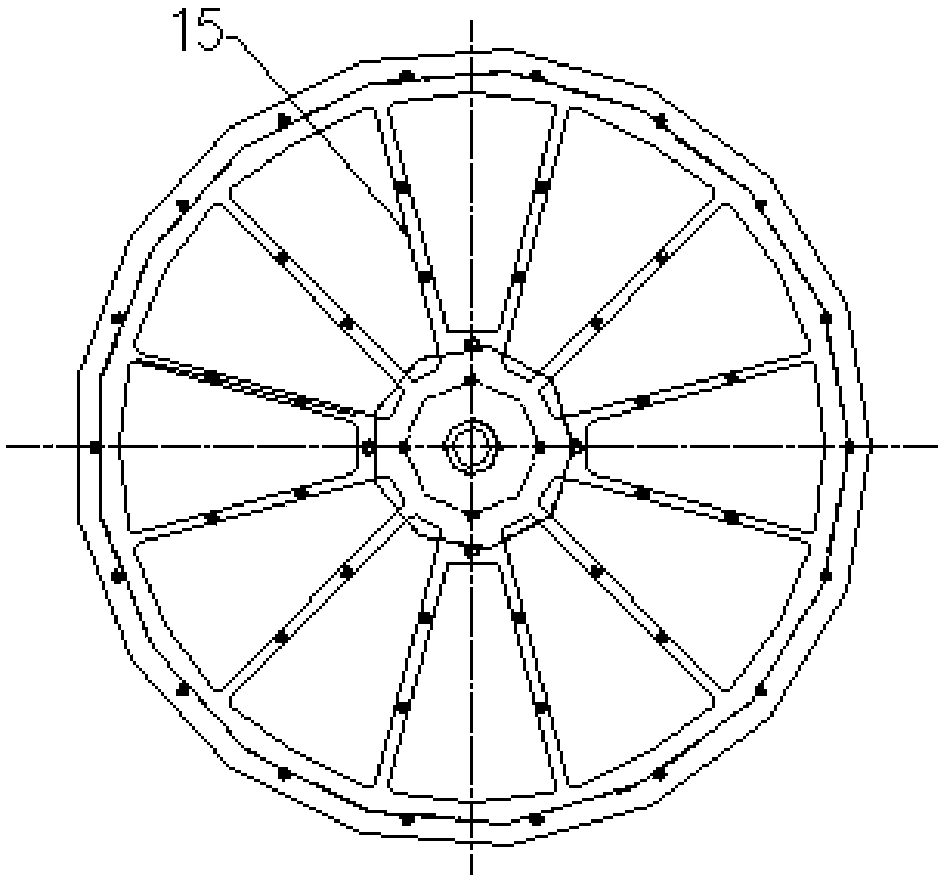

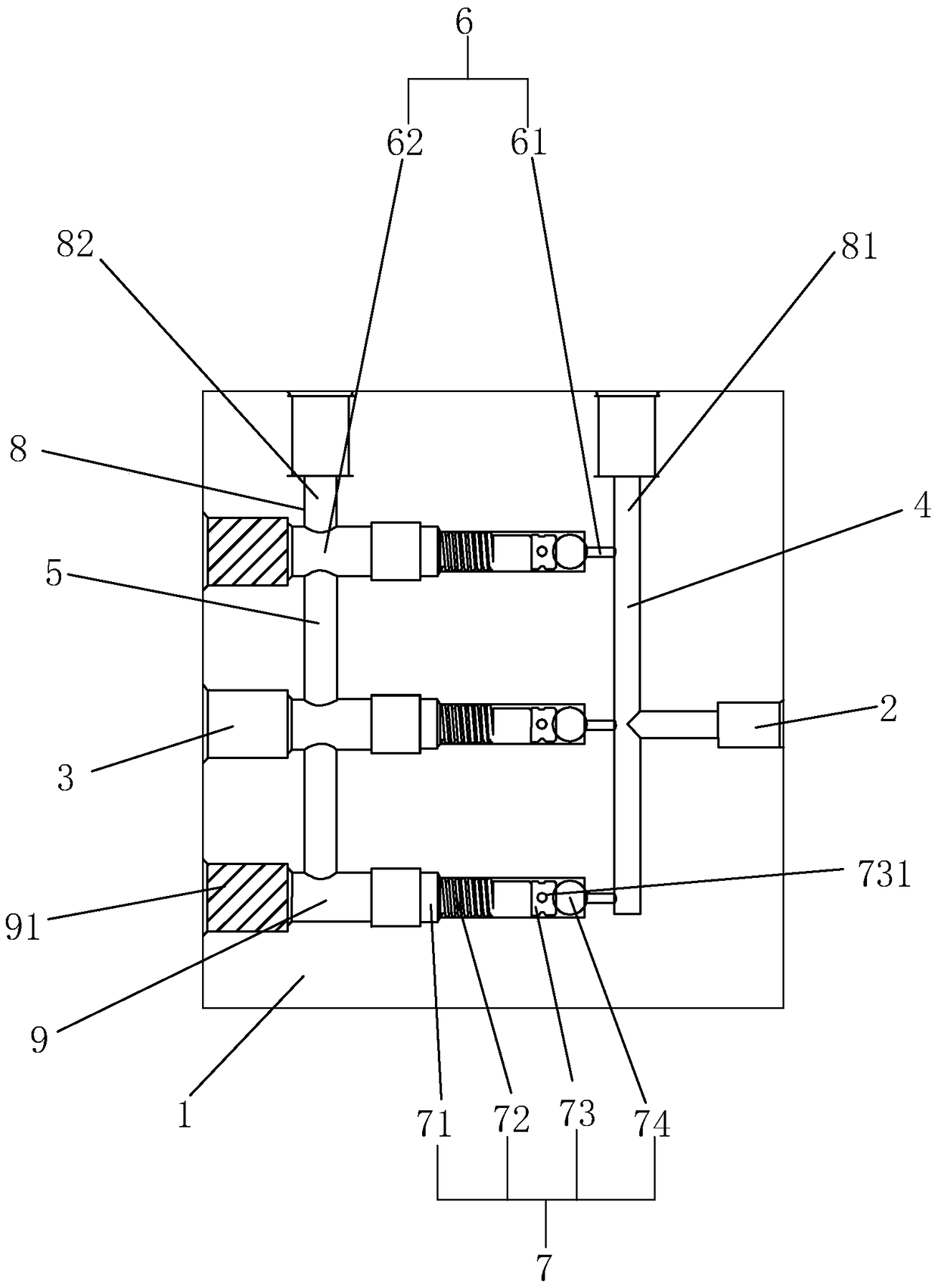

Adjustable spray head

PendingCN108906434AHigh precisionImprove spraying effectSpraying apparatusReciprocating motionEngineering

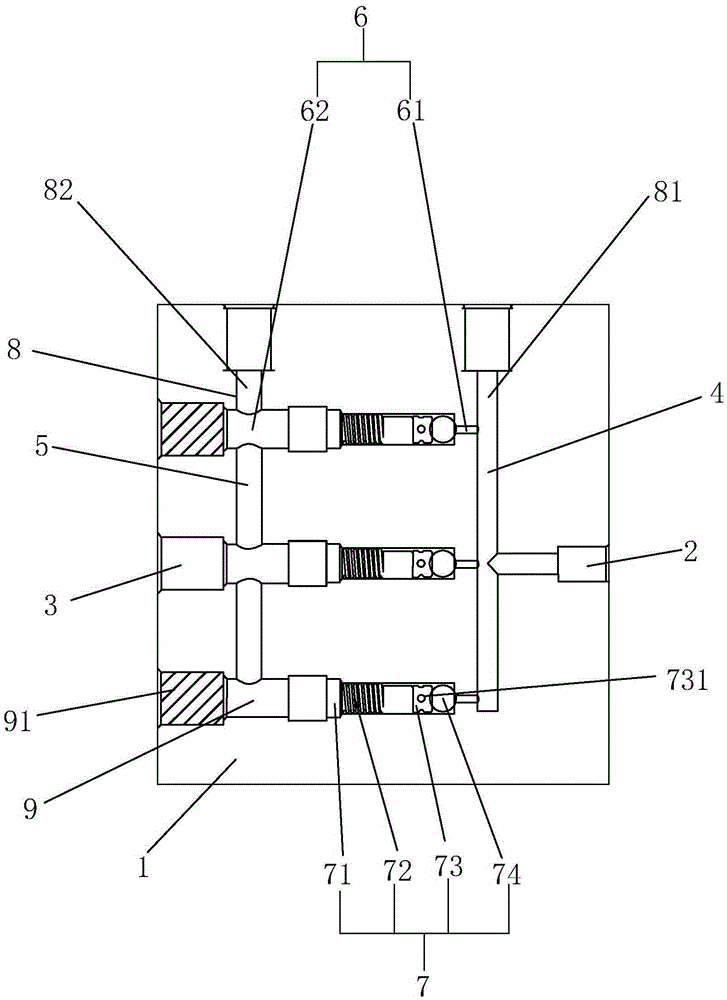

The invention relates to the technical field of spray heads, in particular to an adjustable spray head. The adjustable spray head comprises an inner ring support, an outer ring support, multiple leadscrew assemblies and multiple nozzles, wherein the inner ring support and the outer ring support are arranged concentrically. The multiple lead screw assemblies are arranged between the inner ring support and the outer ring support in a spaced manner in the circumferential direction; each lead screw assembly comprises a lead screw rod and a lead screw nut, wherein each lead screw nut is arranged on the corresponding lead screw rod and performs axial reciprocating motion along the corresponding lead screw rod; the two ends of each lead screw rod are connected with the inner ring support and theouter ring support in a rotary manner correspondingly; and the rotating motion of each lead screw rod is converted into the synchronous axial motion, along the corresponding lead screw rod, of the lead screw nut. The multiple nozzles are arranged on the multiple lead screw nuts correspondingly. The adjustable spray head can adapt to forging molds of different specifications and is suitable for being applied to an aluminum alloy hub forging automated production line so that the production cost can be lowered, the production switch time can be shortened and work efficiency can be improved; andthe adjustable spray head is simple in structure and convenient to operate.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

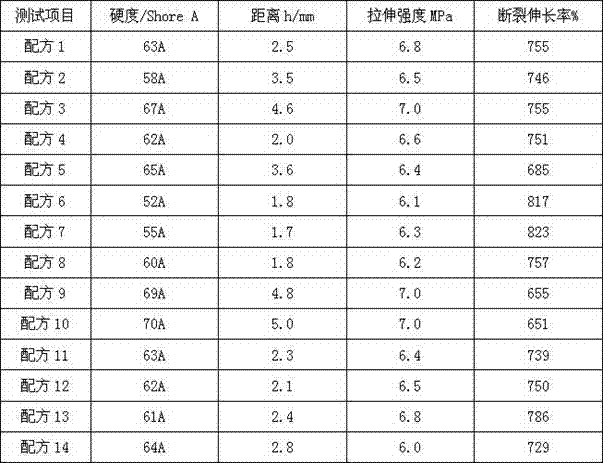

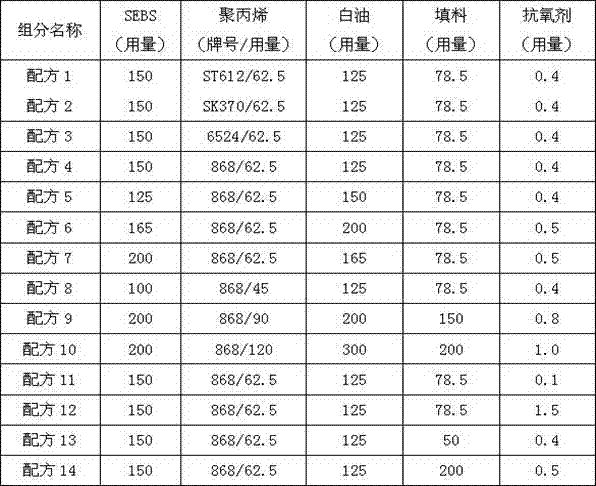

TPE (Thermo Plastic Elastomer) material capable of being recovered after stress and deformation at low temperature, and preparation method and application thereof

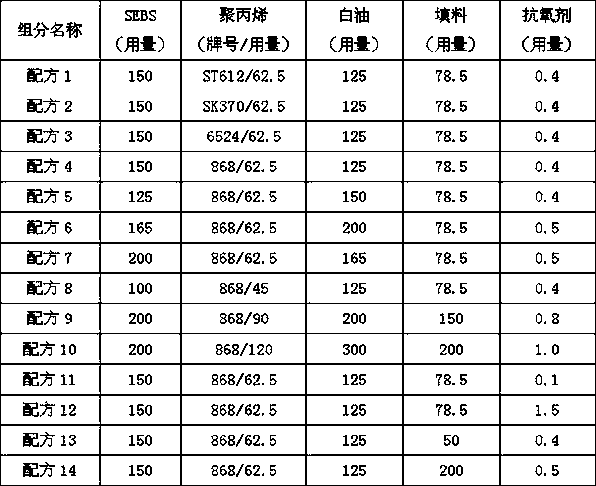

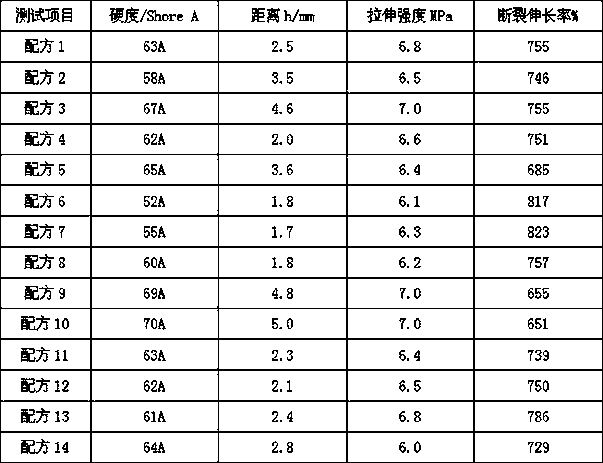

The invention relates to a TPE (Thermo Plastic Elastomer) material capable of being recovered after stress and deformation at low temperature, and a preparation method and application thereof. The TPE material is prepared from the following components in parts by weight: 100 to 200 parts of SEBS, 125 to 300 parts of white oil, 45 to 120 parts of polypropylene, 50 to 200 parts of filler and 0.1 to 1.5 part of antioxygen. In order to prepare the TPE material, the method comprises the steps of screening, weighing and preparing the SEBS, the white oil, the polypropylene, the filler and the antioxygen; adding the prepared SEBS, the prepared polypropylene and the prepared filler into a stirring machine, and stirring at slow speed to 45 DEG C; slowly adding the prepared white oil, and after the white oil is uniformly absorbed, adding the antioxygen; discharging when the temperature is higher than 85 DEG C, and feeding a discharged material into a double-screw extruder for pelleting. The TPE material prepared through the technical scheme can automatically get back into shape after an external force is removed if being stressed to be curled for a long time at low temperature, is excellent in inoxidizability, durable and not easy to abrade and deform, and can be used for manufacturing a foot pad.

Owner:林超

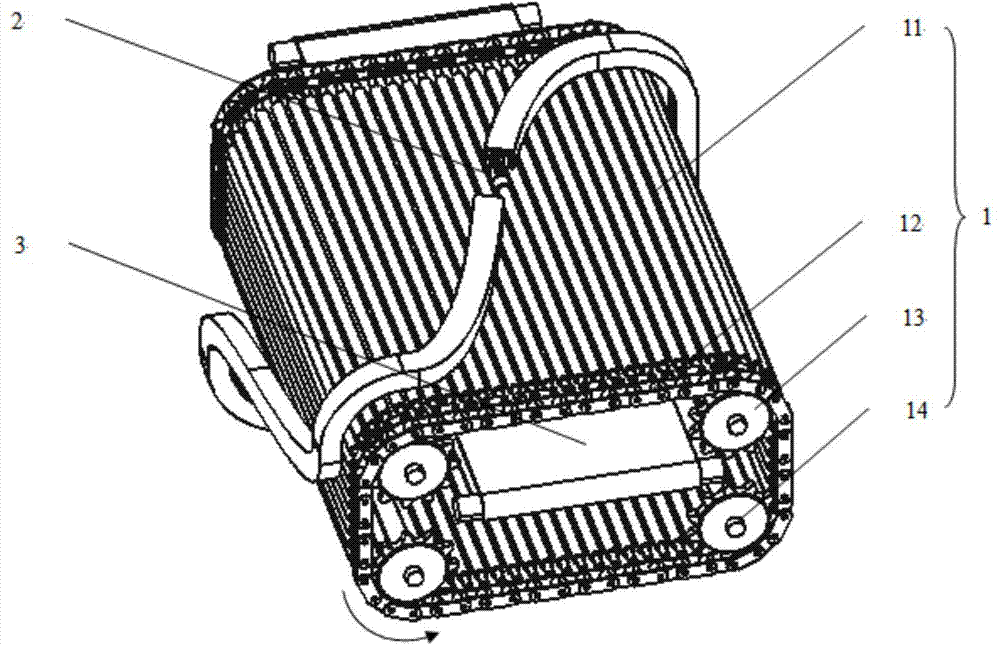

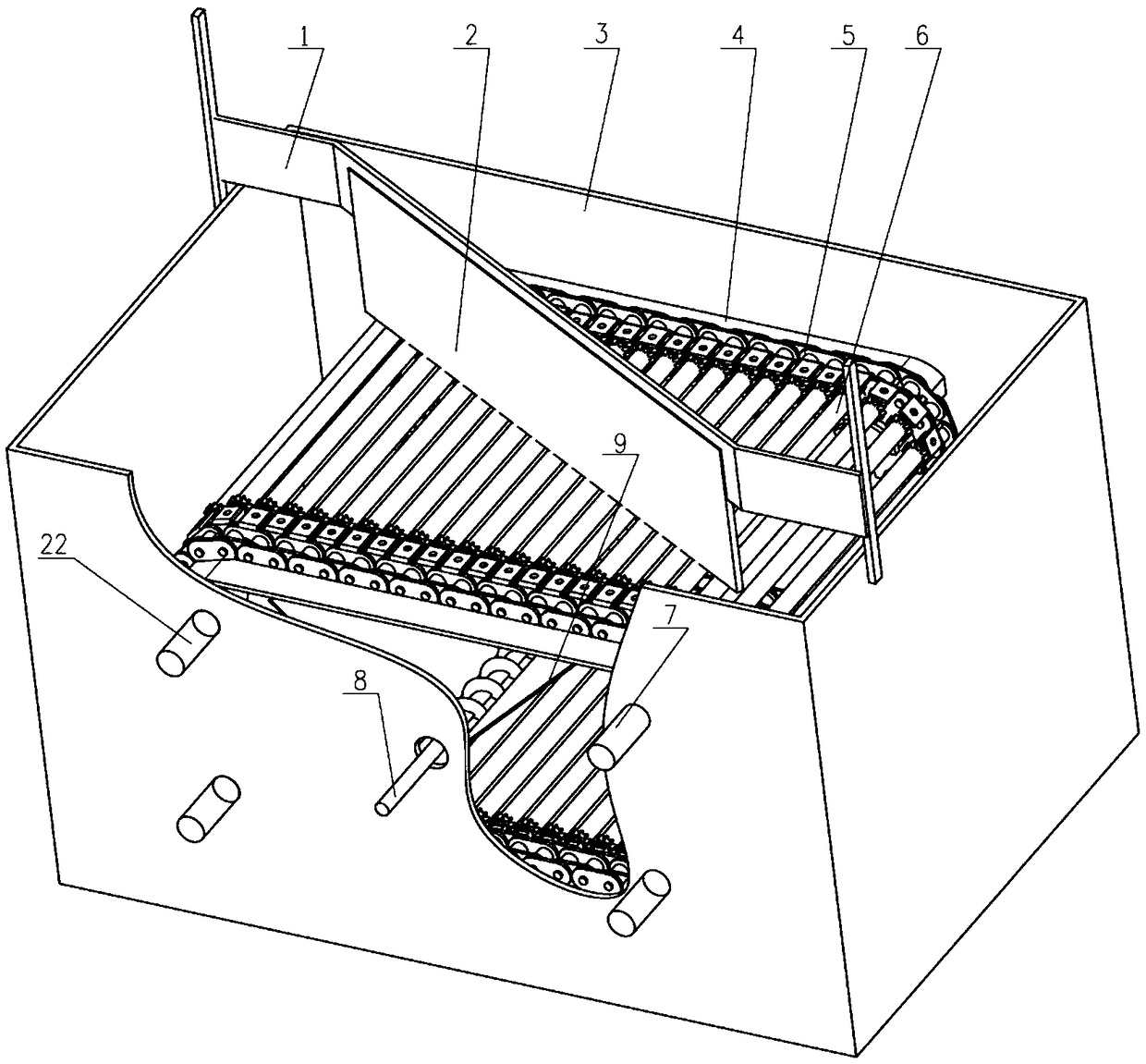

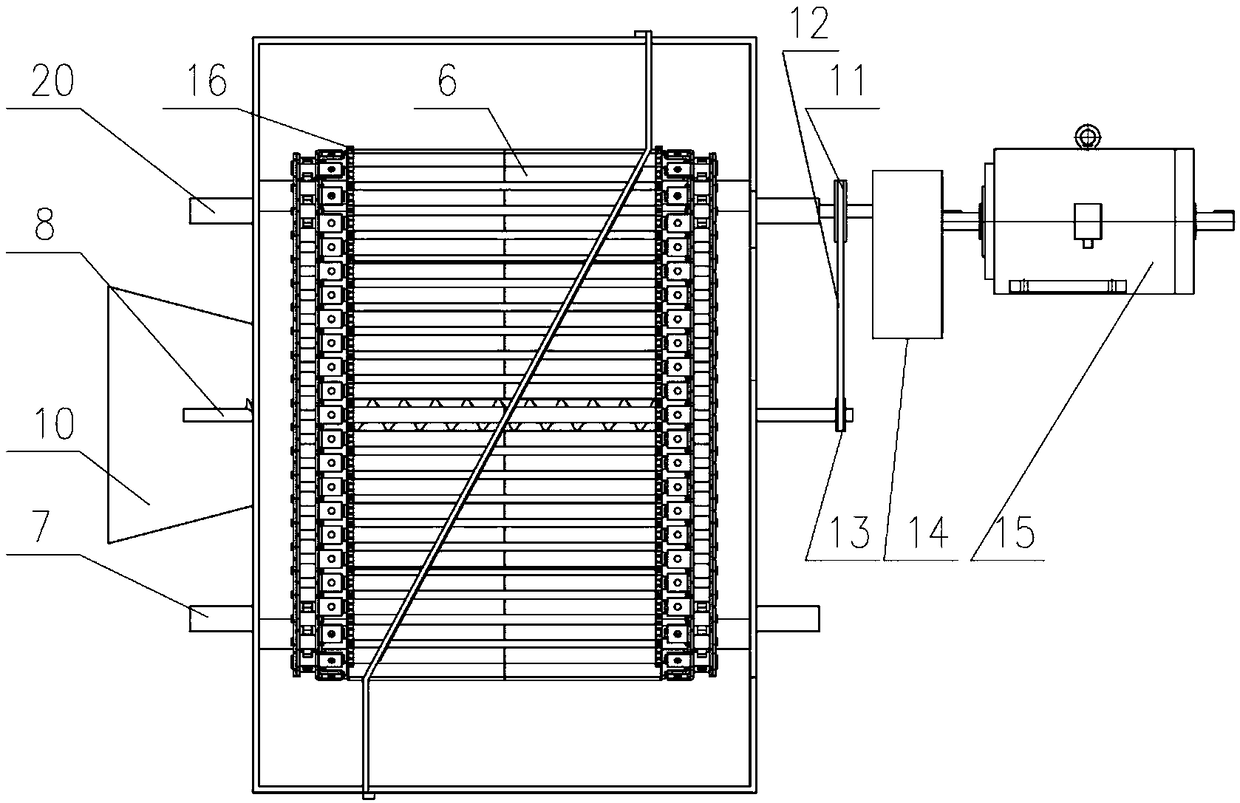

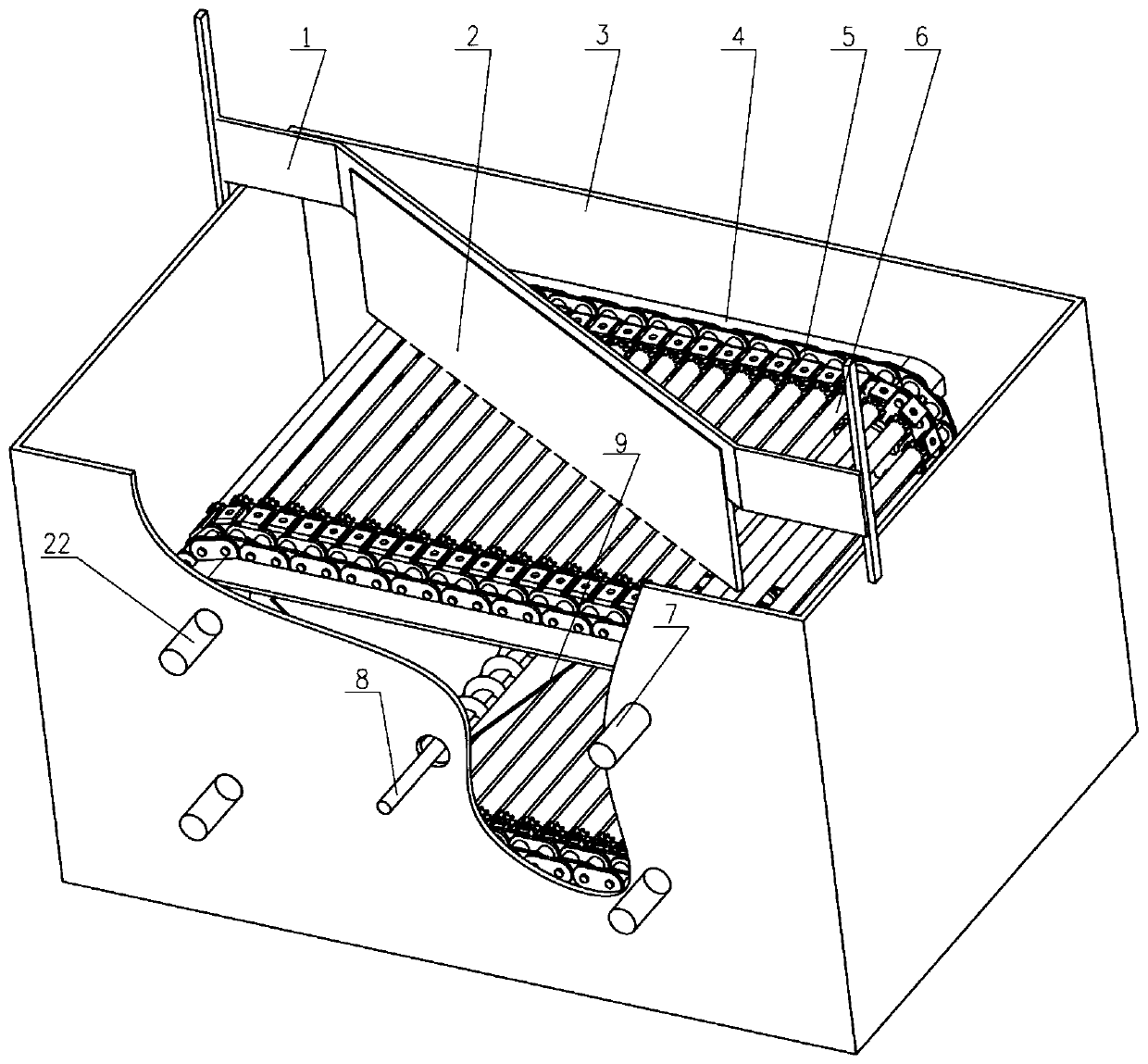

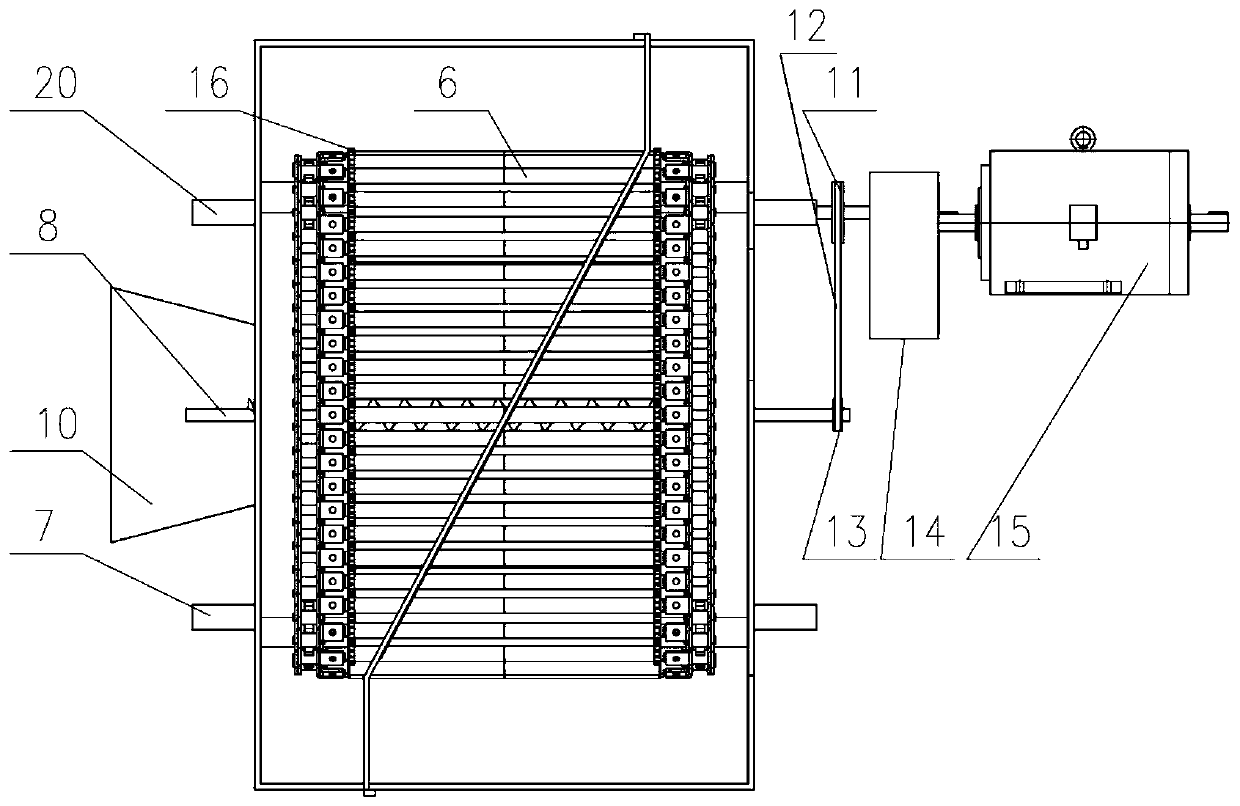

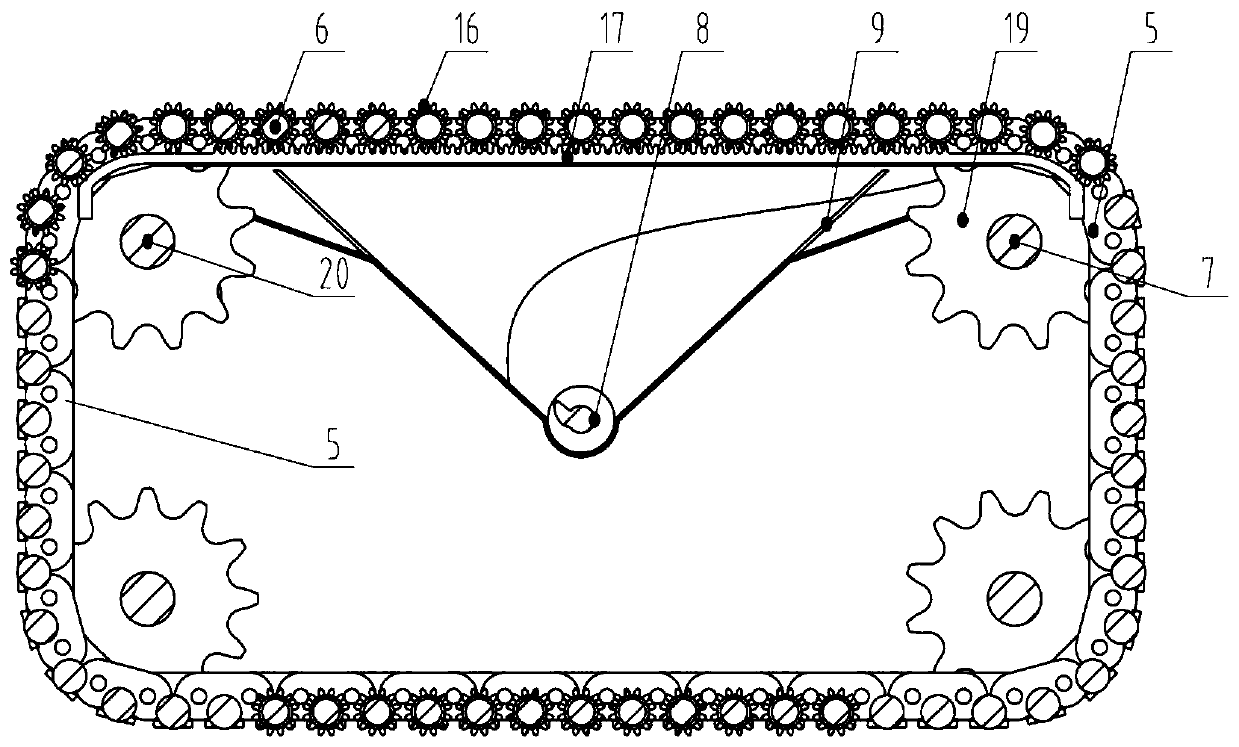

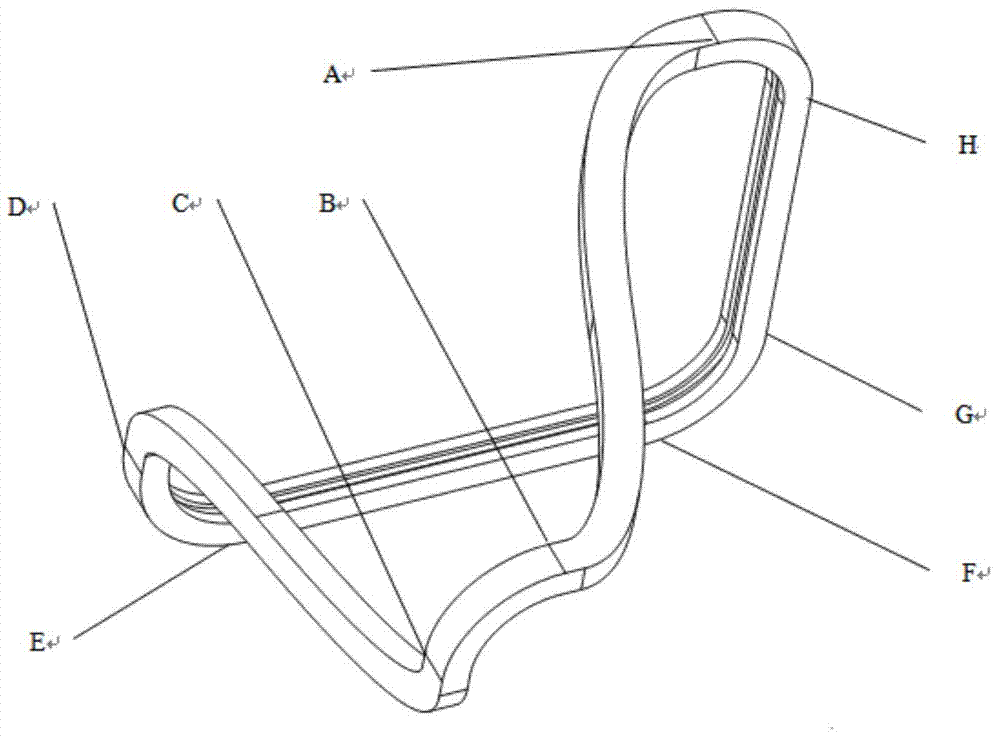

Guide rail type permanent magnet chain filtering system for cold-rolling cooling liquid treatment

The invention discloses a guide rail type permanent magnet chain filtering system for cold-rolling cooling liquid treatment. The guide rail type permanent magnet chain filtering system comprises a magnetic chain mechanism, a pollution cleaning mechanism, a slag recycling mechanism and a motor transmission mechanism, wherein the pollution cleaning mechanism as a key improvement comprises a roller way unit with a space closed-loop structure, sleeve type slag scrapers correspondingly arranged on magnetic sticks in the length direction in a sleeved manner and guide components for connecting the roller way unit with the sleeve type slag scrapers; when the magnetic sticks drive the slag scrapers to do linear motion together along the chain transmission direction, the slag scrapers and the guide components are fixedly connected to do motion and are restrained by a trace of the roller way unit, and therefore, metal dust adsorbed by the magnetic sticks can be scraped off. According to the guide rail type permanent magnet chain filtering system, the phenomenon that a magnetic stick deforms or is damaged due to rigid contact between the pollution cleaning mechanism which moves to an extreme position and the magnetic stick can be effectively avoided; furthermore, the overall size of the system can be greatly reduced, and the running speed and the following efficiency can be obviously improved. The guide rail type permanent magnet chain filtering system can be widely applied to filtering, purifying and magnetic separation of various types of industrial water which contains iron dust and is adhered with dirt.

Owner:WUHAN UNIV OF SCI & TECH

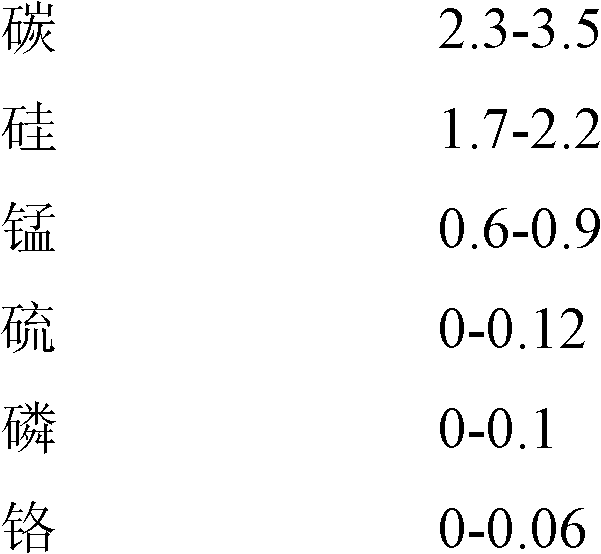

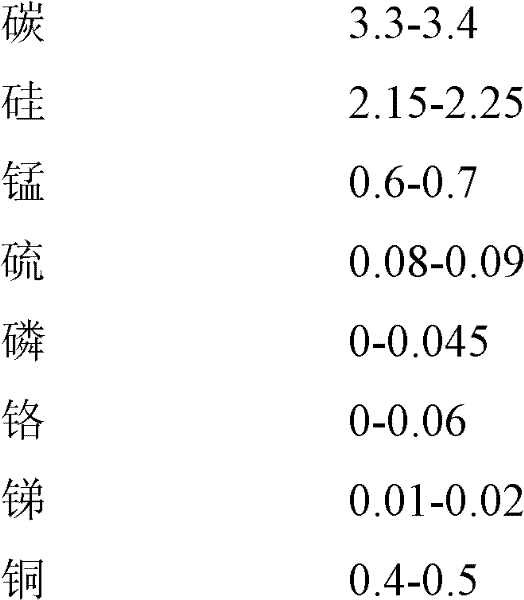

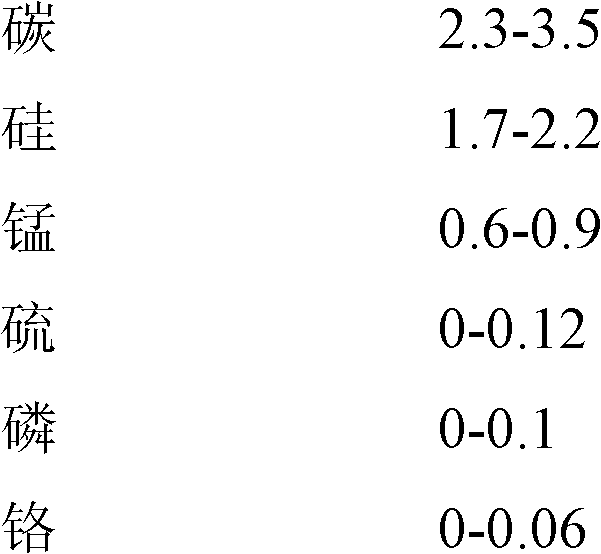

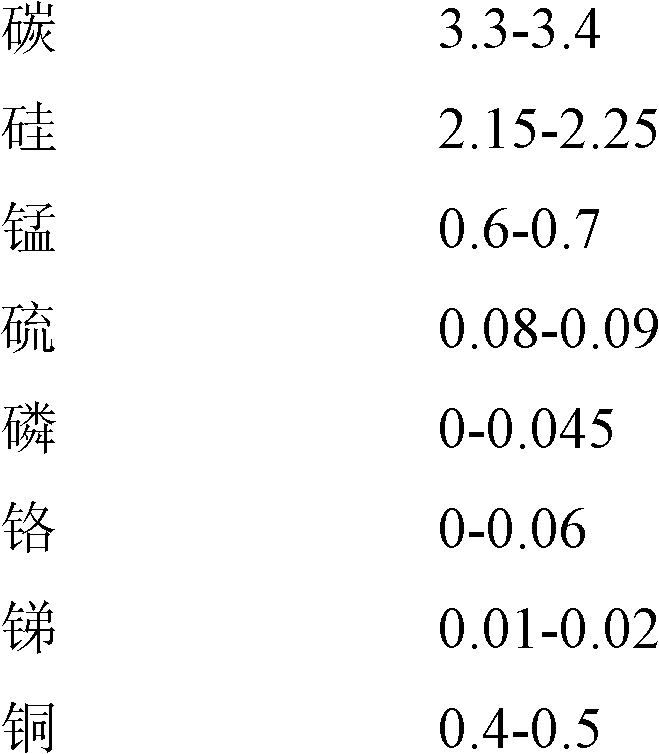

Smelting ingredients for pistons

The invention provides a melting ingredient for a piston, and the melting ingredient is mainly used for solving the problems that the pistons cast and formed from the existing melting ingredient are easy to deform and wear and have lower hardness and larger brittleness. The melting ingredient for the piston comprises the following components in percentage by weight: 2.3-3.5 of carbon, 1.7-2.2 of silicon, 0.6-0.9 of manganese, 0-0.12 of sulfur, 0-0.1 of phosphorus, 0-0.06 of chrome, 0.01-0.02 of antimony, 0.2-0.5 of copper and the balance of iron. The melting ingredient for the piston is molten, casted and formed to obtain a piston finished product; and the obtained piston finished product is not easy to deform and wear and has the advantages of high tensile strength, less brittleness, good graphite morphology and lower cost.

Owner:JIANGSU LEADER PRECISION MACHINERY

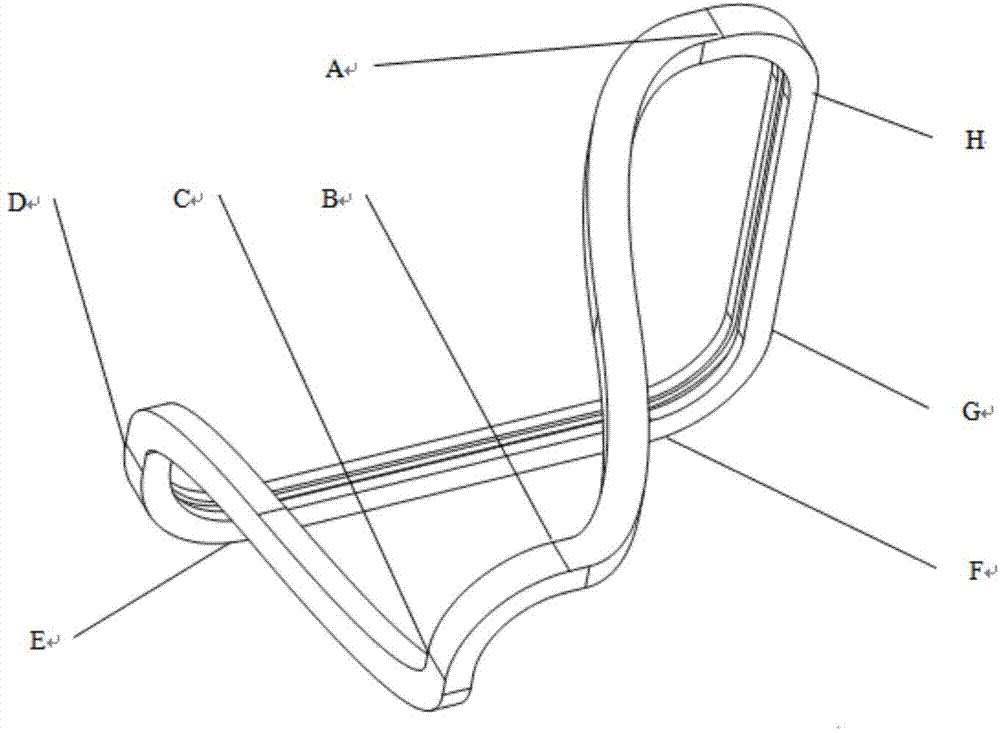

A magnetic bar self-rotation type permanent magnet filter

ActiveCN109201326ANot easy to wear and deformPrevent decontamination from being incompleteCleaning using toolsMagnetic separationMotor driveReciprocating motion

A magnetic bar self-rotation type permanent magnet filter is disclosed. A magnetic chain is driven by a motor drive mechanism to periodically reciprocate and to enter the liquid in a tank body used for storing cold rolling cooling liquid so that metal dust in the cooling liquid is adsorbed. A decontamination mechanism is disposed on the magnetic chain mechanism and is in contact with a decontamination segment, above the liquid level, of the reciprocating magnetic chain in a manner that the decontamination mechanism and the plane where the upper surface of the magnetic chain is are perpendicular to each other or arranged with a certain included angle, and in this process, each magnetic bar moves in a direction perpendicular to the length direction of the magnetic bar and rotates itself at the same time to scrape metal dust off the magnetic bar. Magnetic bar deformation or damage caused by rigid contact with the decontamination mechanism in a magnetic bar movement process, and device failure breakdown caused when the decontamination mechanism is stuck in the magnetic bar transmission chain can be prevented. In addition, the overall size of the device can be greatly reduced, the operation speed and follow-up effect of the magnetic chain mechanism are significantly improved, and the device has wider applicability.

Owner:WUHAN UNIV OF SCI & TECH

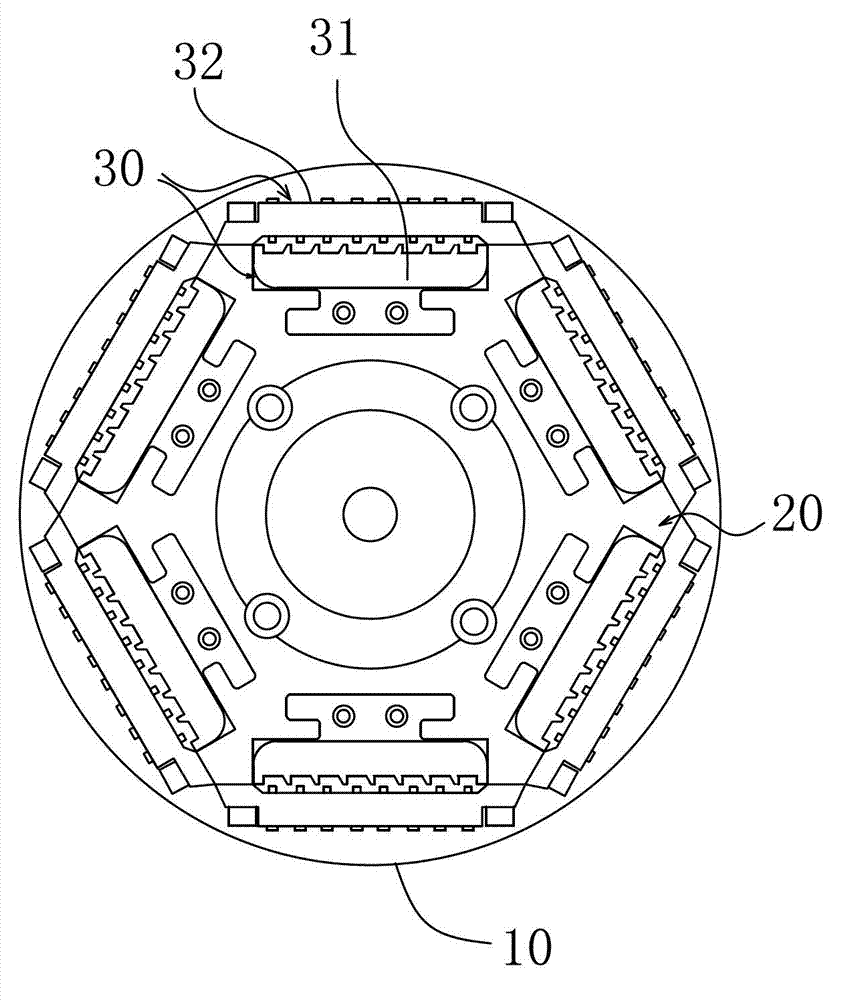

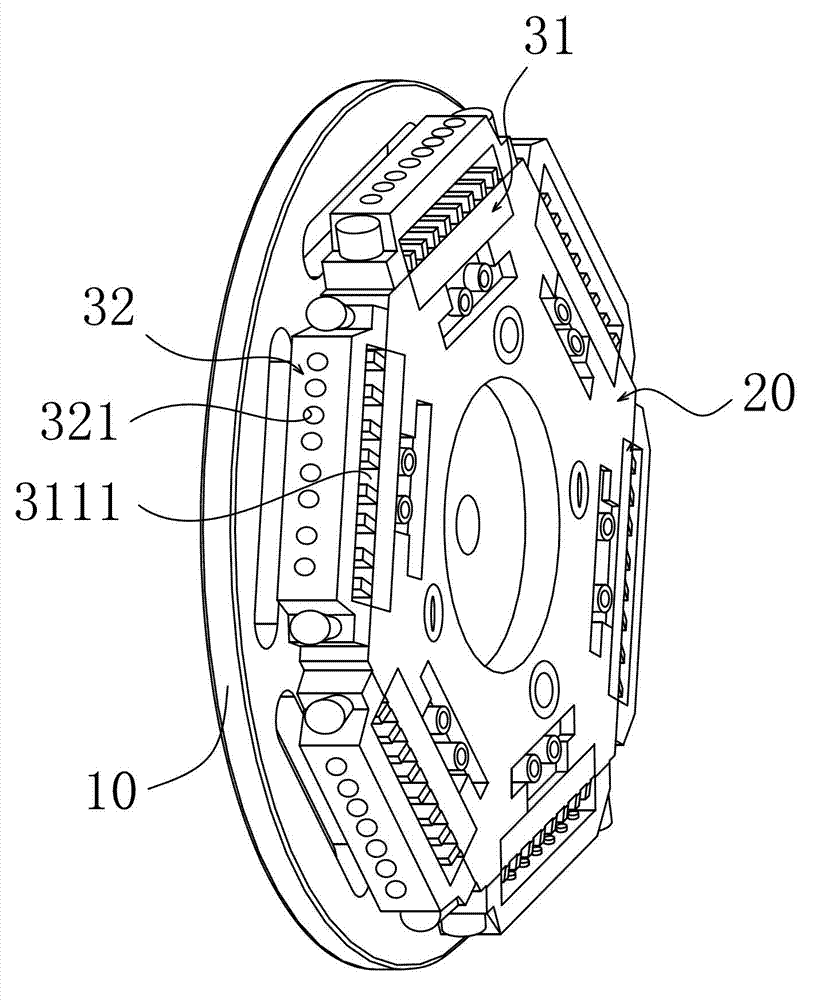

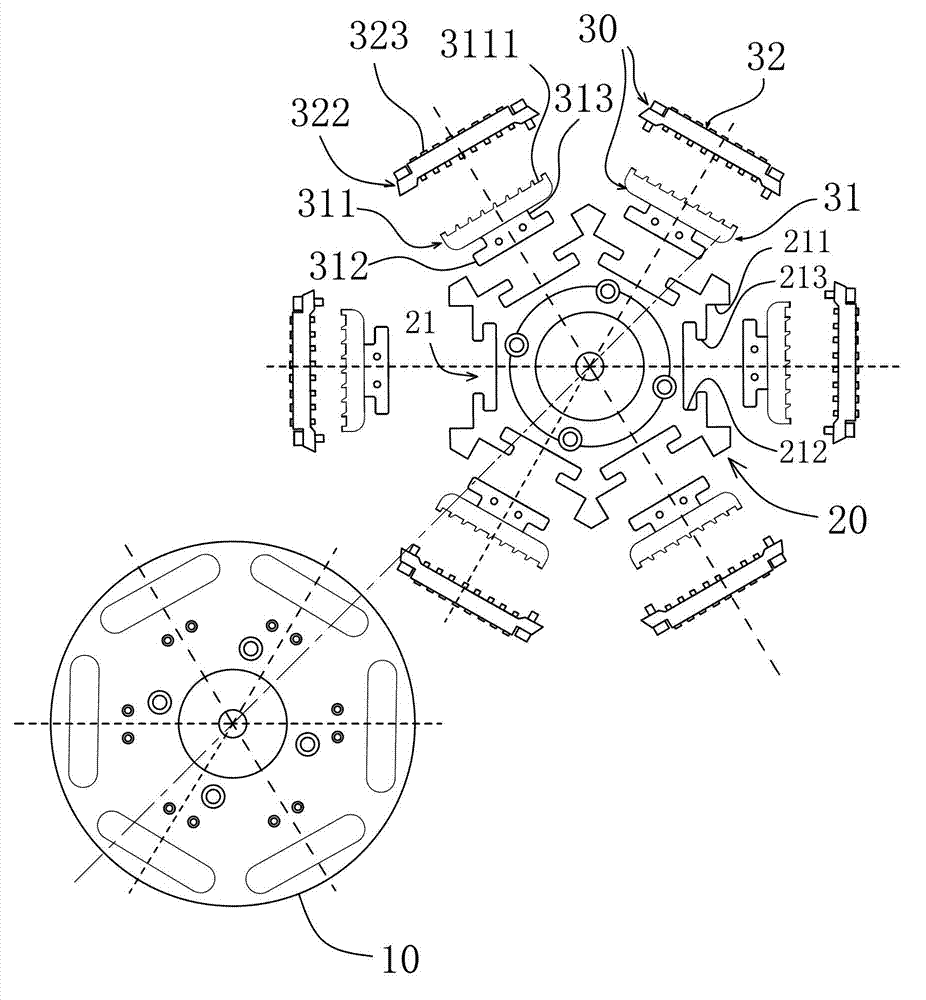

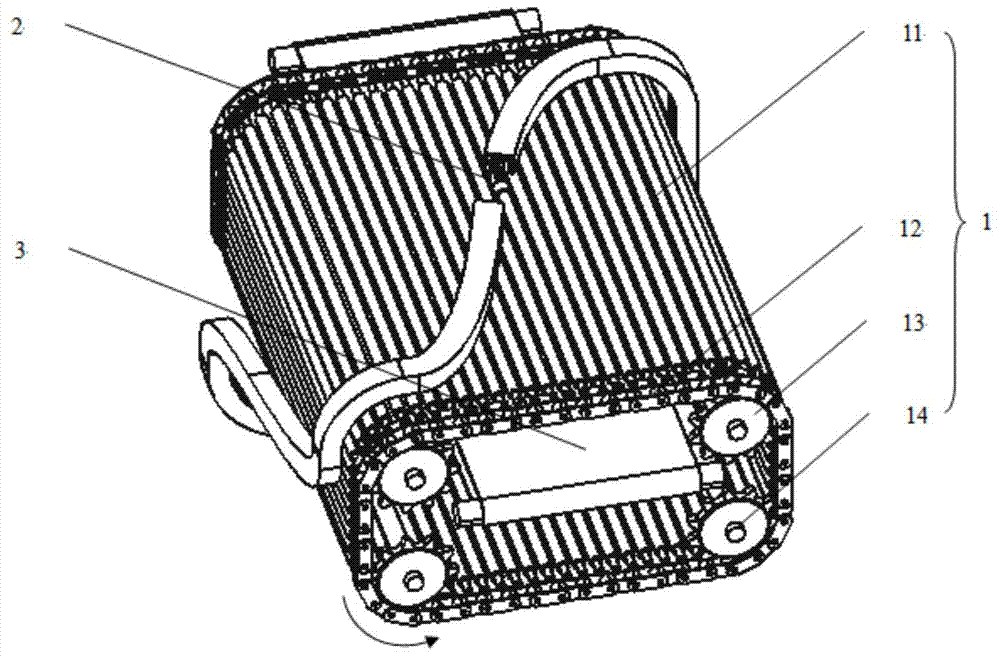

Wear-resistant clamp for grinding optical fiber connector blanks

InactiveCN102896579AImprove work efficiencyNot easy to wear and deformWork carriersOptical fiber connectorTungsten

The invention discloses a wear-resistant clamp for grinding optical fiber connector blanks. The clamp is provided with a circular base (10), wherein the base (10) is provided with a polygonal clamp disk (20); each edge of the polygonal clamp disk (20) is provided with a clamp positioning gap (21) respectively; a group of unit clamps (30) is arranged in each clamp positioning gap respectively; each group of unit clamps (30) comprises a clamp body (31) made of tungsten steel and an adjustable pressure plate (32) which is detachably connected to the outer side of the clamp body (31); and each clamp body (31) is used for clamping a plurality of optical connector blanks to be ground through the adjustable pressure plates (32). Due to the adoption of the clamp, the wear resistance of the clamp is improved effectively, the service life of the clamp is prolonged, the quantity of single-batch grinding is large, the processing efficiency is high, and the product quality can be ensured fully.

Owner:SHENZHEN TYKOFIBER

Preparation method of valve liner material

InactiveCN104277387AIncreased abrasion resistance and hardnessNot easy to wear and deformPolytetrafluoroethyleneMolybdenum disulfide

The invention discloses a preparation method of a valve liner material. The preparation method is characterized by mainly comprising the following steps of firstly, sufficient mixing, namely sufficiently mixing glass fiber, carbon fiber, molybdenum disulfide, polytetrafluoroethylene and stainless steel powder to form a mixture; then, compression molding, namely carrying out compression molding on the sufficiently-mixed mixture at the pressure of 15-20MPa and the temperature of 360-380 DEG C; and finally, cooling to room temperature. The wear strength and hardness of the valve liner material prepared by using the method can be greatly improved, and various products prepared from the valve liner material are not easy to deform and wear and relatively good in sealing performance, so that the service life of each product is prolonged.

Owner:甘燕芬

Embossing relief printing plate, machining process thereof and printing machine with embossing relief printing plate

InactiveCN106079848AHigh in manganeseImprove corrosion resistanceRotary pressesForme preparationPrinting pressMachining process

The invention discloses an embossing relief printing plate, a machining process thereof and a printing machine with the embossing relief printing plate. A main substrate of the relief printing plate is made of high manganese steel, and the relief printing plate is manufactured through a prescribed machining method and applied to the printing machine; the embossing relief printing plate is not prone to being abraded and deformed when used for printing products, and the steel plate is selected as the machining substrate; the embossing relief printing plate can be selected and used for a die cutting machine by people, and the corrosion resistance of the die cutting machine is strengthened; or the embossing relief printing plate is selected and used for the printing machine by the people so that rugged concave and convex embossed patterns can be printed, and the printed embossed patterns are deeper and more three-dimensional; and through the concave and convex property of the embossing relief printing plate, people do not need to use laser paper to conduct embossing, and a laser embossing effect can also be achieved, and the application range is wide. By means of the machining method, the three-dimensional sense of the printed embossed patterns on a printed object can be improved, and the embossing relief printing plate is not prone to being damaged.

Owner:孙红武

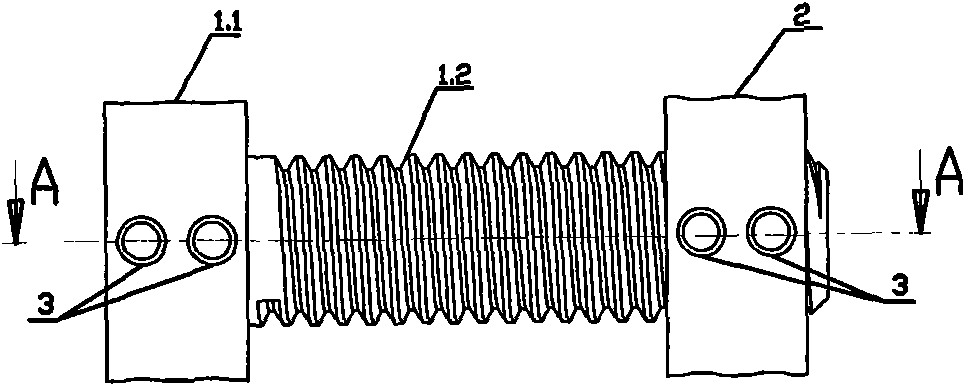

Vibration arm connecting structure

Owner:CHINA TOBACCO HENAN IND

Bolt device and special spanner

Owner:宁波甬嘉变压器有限公司

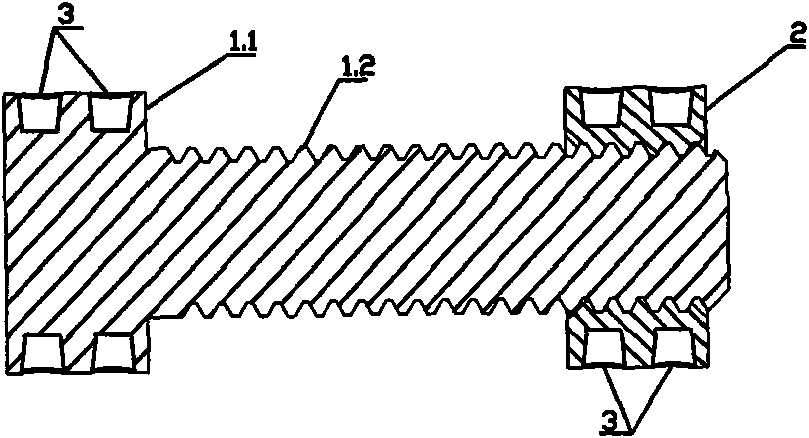

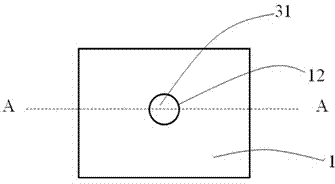

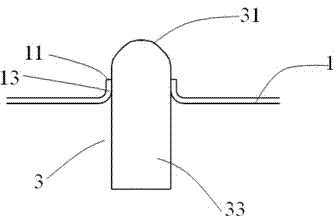

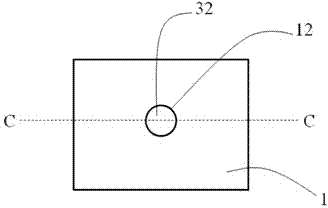

Plate material omnibearing locating structure and method in hot press forming technology

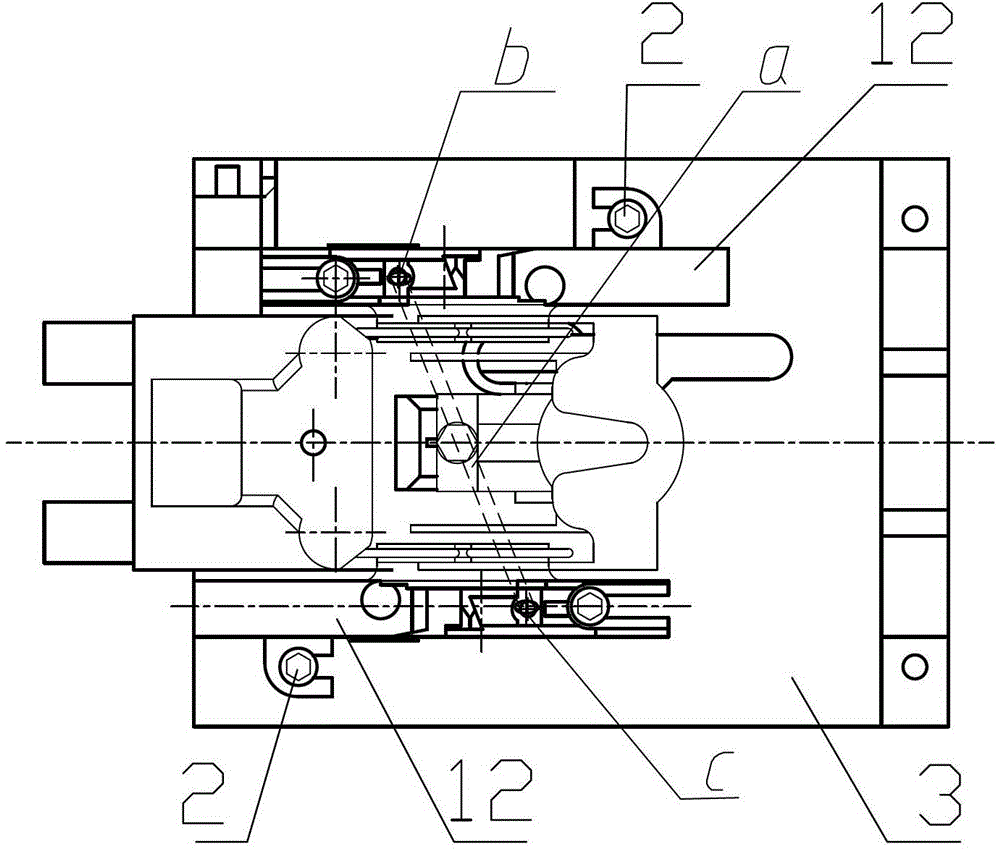

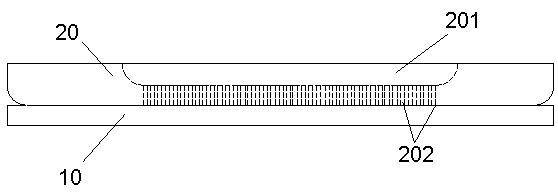

InactiveCN104741472APrecise positioningNot easy to wear and deformMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention relates to the field of hot press forming and discloses a plate material omnibearing locating structure and method in a hot press forming technology. According to the omnibearing locating structure, a circular flanged hole extending out from the surface of a plate material (1) and integrated with the plate material (1), and the edge (11) of the circular flanged hole is higher than the plane where the plate material (1) is placed. When locating is needed, a pre-punched hole (12) is machined in a preset position of the plate material (1), then the pre-punched hole (12) is machined into the circular flanged hole, and then a locating pin (2) is inserted into the circular flanged hole to carry out omnibearing locating on the plate material (1). The circular flanged hole is a protruding hole relative to the plane of the plate material, so that when the plate material is located, only the locating pin with the same size and shape as the hole needs to be used, omnibearing locating can be carried out, the circular flanged hole cannot deform and be abraded easily, and locating is accurate.

Owner:上海凌云汽车模具有限公司

A magnetic rod self-rotating permanent magnet filter device

ActiveCN109201326BNot easy to wear and deformPrevent decontamination from being incompleteCleaning using toolsMagnetic separationMotor driveReciprocating motion

The invention discloses a magnetic bar rotation type permanent magnet filtering device. Driven by a motor transmission mechanism, the magnetic link periodically reciprocates and enters below the liquid level of a box used to store cold rolling coolant, thereby filtering the liquid in the coolant. Metal dust is adsorbed; above the magnetic link mechanism, a decontamination mechanism is also provided. The decontamination mechanism is arranged perpendicularly or at an angle to the plane of the upper surface of the magnetic link to decontaminate the reciprocating magnetic link above the liquid level. During this process, each magnetic rod moves perpendicular to the length of the magnetic rod and rotates to scrape off the metal dust on the magnetic rod. It can effectively avoid the deformation or damage of the magnetic rod caused by the rigid contact with the decontamination device during the movement of the magnetic rod, and prevent the decontamination mechanism from getting stuck, causing equipment shutdown failure caused by the magnetic rod transmission chain; in addition, it can greatly reduce the overall size of the equipment. At the same time, it significantly improves the running speed and following performance of the magnetic link mechanism, and has wider applicability.

Owner:WUHAN UNIV OF SCI & TECH

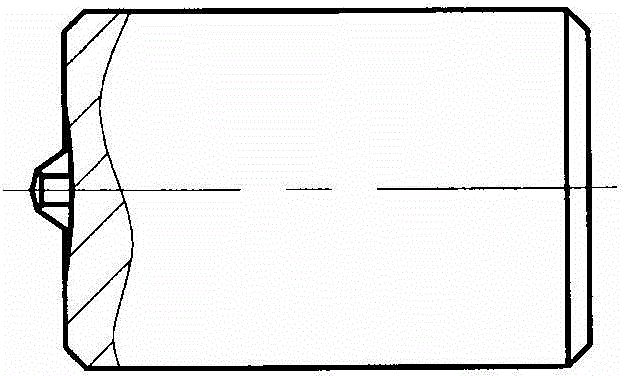

Pipe orifice mould-withdrawing tool for container

InactiveCN106270070ANot easy to wear and deformGuaranteed molding sizeShaping toolsEngineeringMechanical engineering

The invention relates to a pipe orifice mould-withdrawing tool for a container. The tool is composed of a mould-withdrawing barrel, a barrel pipe-withdrawing lower mould, a pipe-withdrawing upper mould, inner hexagonal screws, mould placing platforms, a hydraulic machine connecting screw rod, a mould-withdrawing seal head and a seal head pipe-withdrawing lower mould. The tool is suitable for pipe orifice mould-withdrawing mould forming production of sanitary grade equipment, and belongs to the technical field of an innovative process of manufacturing the sanitary grade equipment. A reasonable mould operating mode is as follows: a mould is driven hydraulically; a workpiece is placed on a hydraulic platform by a worker, upper and lower moulds are assembled, a hydraulic device is started, and a step of withdrawing the mould can be finished only by an operation of a single worker, so that the labor intensity of the worker is alleviated.

Owner:FEATURE-TEC (WUXI) FILTRATION TECH CO LTD

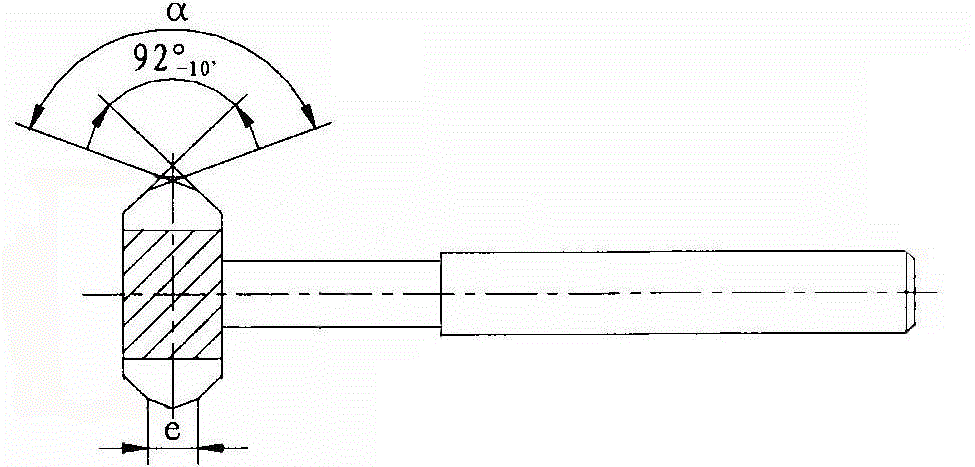

Rotational flow untwisting device used for Z-twist special yarn

InactiveCN102943359AIncreased precision and strengthNot easy to wear and deformTextile treatment untwisting devicesPiercing arrangementsAcute angleYarn

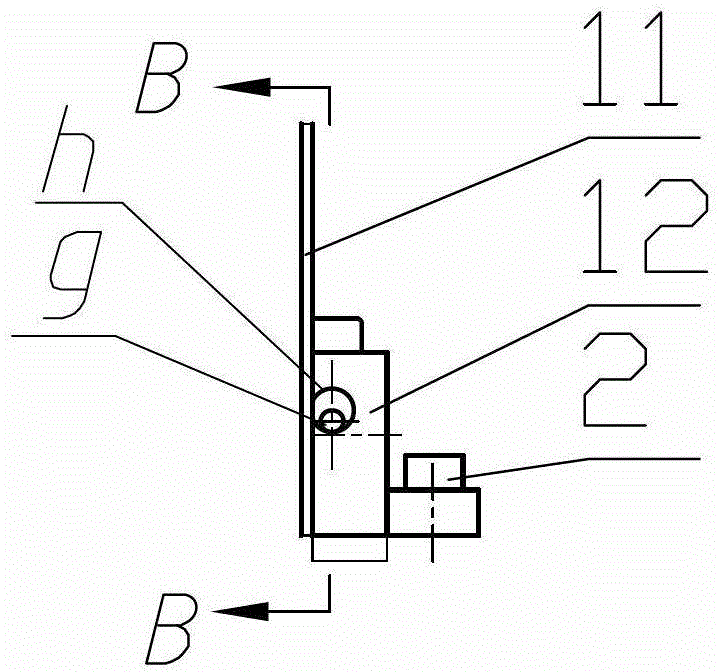

The invention relates to a rotational flow untwisting device used for a Z-twist special yarn. The rotational flow untwisting device comprises a main body, wherein a horizontal untwisting hole h is arranged in the main body; the main body is made of metal material; the main body is provided with a material incoming groove for untwisting fiber, which is intersectant with the inner end of the untwisting hole h; the inside of the main body is provided with a channel e, a channel f and an injection hole g from bottom to top, wherein the channel e, the channel f and the injection hole g are mutually communicated; the injection hole g and the untwisting hole h are respectively distributed in two sides of the material incoming groove; the injection hole g is horizontally arranged; an acute angle alpha is formed between the extending line of the centre line of the injection hole g and the centre line of the untwisting hole h; the diameter of the injection hole g is less than the diameter of the untwisting hole h; and the injection hole g is internally tangent with the bottom of the untwisting hole h. The main body of the untwisting device disclosed by the invention is integrally formed by metal materials, so that the main body has a high strength and precision and is unlikely to deform and abrade, the use stability and reliability of the product can be improved, the service life is prolonged, and the repairing and maintaining cost is lowered.

Owner:WUXI SANDA TEXTILE ACCESSORY

Ultrahigh-pressure pipeline system with combined type check valve

ActiveCN105423035APrevent backflowIncrease wall thicknessBranching pipesUltra high pressureEngineering

The invention discloses an ultrahigh-pressure pipeline system with a combined type check valve. The ultrahigh-pressure pipeline system comprises a base. A liquid inlet main flow channel and a liquid outlet main flow channel are formed in the two sides of the base. A first convergence flow channel, a second convergence channel and a plurality of branches are arranged between the liquid inlet main flow channel and the liquid outlet main flow channel. The branches are provided with liquid inlets and liquid outlets. The liquid inlets are connected with the first convergence flow channel. The liquid outlets are connected with the second convergence channel. The first convergence flow channel is communicated with the liquid inlet main flow channel. The second convergence channel is communicated with the liquid outlet main flow channel, and the drift diameter of each branch is less than the drift diameter of the liquid inlet main flow channel and the drift diameter of the liquid outlet main flow channel. The ultrahigh-pressure pipeline system further comprises the combined type check valve. The combined type check valve comprises independent check valve bodies of which the number is equal to that of the branches, and each branch is internally provided with an independent check valve body. The base is further provided with a detection branch. The detection branch comprises a low-pressure branch and a high-pressure branch.

Owner:ZHEJIANG MOTORBACS TECH

TPE material recoverable under stress and deformation at low temperature, its preparation method and use

The invention relates to a TPE (Thermo Plastic Elastomer) material capable of being recovered after stress and deformation at low temperature, and a preparation method and application thereof. The TPE material is prepared from the following components in parts by weight: 100 to 200 parts of SEBS, 125 to 300 parts of white oil, 45 to 120 parts of polypropylene, 50 to 200 parts of filler and 0.1 to 1.5 part of antioxygen. In order to prepare the TPE material, the method comprises the steps of screening, weighing and preparing the SEBS, the white oil, the polypropylene, the filler and the antioxygen; adding the prepared SEBS, the prepared polypropylene and the prepared filler into a stirring machine, and stirring at slow speed to 45 DEG C; slowly adding the prepared white oil, and after the white oil is uniformly absorbed, adding the antioxygen; discharging when the temperature is higher than 85 DEG C, and feeding a discharged material into a double-screw extruder for pelleting. The TPE material prepared through the technical scheme can automatically get back into shape after an external force is removed if being stressed to be curled for a long time at low temperature, is excellent in inoxidizability, durable and not easy to abrade and deform, and can be used for manufacturing a foot pad.

Owner:林超

A variable width box girder mobile formwork device and construction method

InactiveCN107558374BImprove wear resistanceExtended service lifeLiquid/solution decomposition chemical coatingBridge erection/assemblyHydraulic cylinderWide beam

The invention provides a variable-width box girder mobile formwork device and a construction method. A variable-width box girder mobile formwork device includes a main beam, a temporary main beam, a beam, a corbel beam, a bracket, and a hydraulic pump. Station, motion mechanism and electrical system, the corbel is fixed on the bridge pier through corbel columns, a main girder is arranged on both sides of the top of the corbel, and at least one main girder is arranged between the two main girders. Beam, the main beam and the temporary main beam are all set on the corresponding kinematic mechanism through the corresponding bracket, the kinematic mechanism is set on the corbel beam, the kinematic mechanism and the corbel beam, the kinematic mechanism and the bracket There is a mobile hydraulic cylinder between the bracket and the temporary main beam and between the bracket and the main beam. The mobile hydraulic cylinder is connected with the hydraulic pump station through the oil pipe. The main beam and A crossbeam is arranged on the upper side of the temporary main beam, and an inner mold and an outer mold composed of wear-resistant templates are arranged on the upper side of the crossbeam. The invention also provides a construction method.

Owner:王丽丽

Silk-screen printing method used for panel

InactiveCN110978828AHigh mechanical strengthNot easy to wear and deformScreen printersOther printing apparatusScreen printingWeather resistance

The invention discloses a silk-screen printing method used for a panel. The method comprises the following steps that S1, a printing panel is placed on a carrying table; S2, a metal screen printing plate with corresponding patterns to be printed is placed on the bearing panel, and printing patterns of the metal screening plate right face the to-be-printed position of the printing panel, a clamp isused for clamping and fixing the metal screen printing plate and the printing panel, and the metal screen printing plate is made of hard metal or alloy of the metal; S3, printing ink is poured to thesurface of the metal screen printing plate, a scraping plate is adopted for scraping the ink to the printing patterns of the metal screen printing plate, the scraping plate carries out scraping to enable the ink to form corresponding patterns on the printing panel, and pressure of the scraping plate to the corresponding positions of the printing patterns of the metal screen printing plate is constant; and S4, the printing panel is dried to enable the ink on the surface of the panel to be cured. The metal screen printing plate made of the hard metal or alloy of the metal is adopted, the mechanical strength is high, the metal screen printing plate is not prone to wear and deform, the weather resistance is high, the metal screen printing plate is applied to silk-screen printing, the printingposition of the printing panel do not deviate, and the printing precision is high.

Owner:广东省华锐高新材料股份有限公司

A rail-type permanent magnet flux linkage filter system for cooling liquid treatment in cold rolling

Owner:WUHAN UNIV OF SCI & TECH

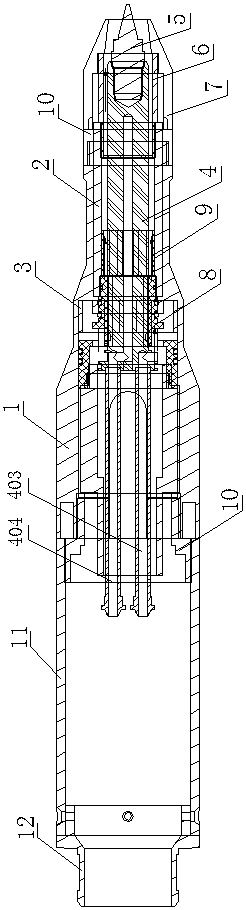

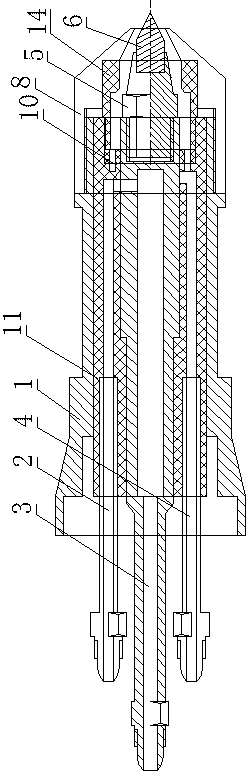

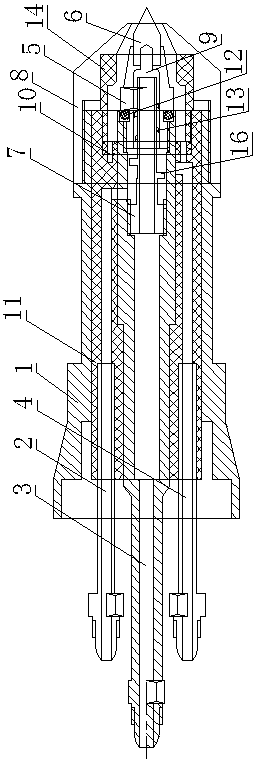

Argon arc welding gun with cooling function and device with argon arc welding gun

ActiveCN107262884AHigh densityStrong penetrating powerCooled electrode holdersElectrode accessoriesEngineeringDistributor

The invention provides an argon arc welding gun with a cooling function and a device with the argon arc welding gun. The argon arc welding gun comprises a gun body shell, an insulator, a first support ring, a sealing body, an electrode connecting body, an electrode, a vortex ring, a ceramic nozzle, a spray nozzle and a gas distributor, wherein the insulator, the first support ring and the sealing body are connected with the gun body shell, and the electrode connecting body is connected with the insulator, the first support ring and the sealing body; the electrode is connected with the electrode connecting body; the vortex ring is connected with the gun body shell; the ceramic nozzle is connected with the insulator; the spray nozzle is connected with the vortex ring; the sealing body is provided with a cooling cavity; and the first end of the electrode connecting body is provided with a first cooling fluid inlet pipe and a first cooling fluid outlet pipe, and the other end of the electrode connecting body is provided with a second cooling fluid inlet pipe and a second cooling fluid outlet pipe. A fluid outlet of the second cooling fluid inlet pipe communicates with a fluid inlet of the cooling cavity. A fluid inlet of the first cooling fluid inlet pipe communicates with a fluid outlet of the cooling cavity. The first cooling fluid inlet pipe and the first cooling fluid outlet pipe extend into the end, close to the electrode, of the electrode connecting body. The electrode connecting body is provided with a protection gas pipe communicating with the gas distributor.

Owner:长沙中创海通智能科技有限公司

Method of Machining Cross Recessed Male Die Using Cold Heading Technology

The invention provides a method for machining a cross groove male die with the cold heading technology. The method includes the following concrete steps: (1) machining and forming milling cutter, (2) after the cross groove profile of a forming punch is milled roughly with the forming milling cutter, performing finish machining with a forming grinding wheel to remove the allowance and meanwhile controlling the size b, the size e and the size f of the forming punch and the compound angle gamma and the compound delta of the forming punch, (3) punching a forming pressing die with the forming punch, and (4) forming the cross groove male die in a pressing mode with the forming pressing die. While the material and the hardness of the male die are kept unchanged, the auxiliary tools including the forming milling cutter, the forming punch and the forming pressing die get involved and the punching process is improved. Thus, not only can the boundary dimensions of the cross groove male die be reflected fairly well, but also the method can be used for machining the cross groove at one time and will not cause the quality problems such as collapse on the periphery of the cross groove and changing of the angle of a countersunk head when the head portion is formed. Anti-fatigue strength of parts is obviously promoted, and while precision requirements are met, the method has the advantages of saving time and material.

Owner:SHENYANG AIRCRAFT CORP

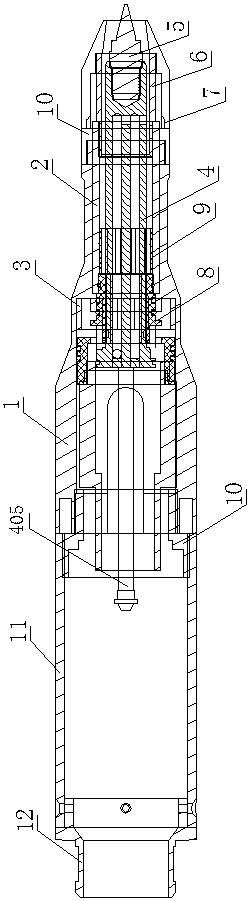

Argon arc welding torch with cooling function and device with the same

ActiveCN107262884BHigh densityStrong penetrating powerCooled electrode holdersElectrode accessoriesCooling chamberEngineering

An argon arc welding torch with cooling function and a device with the argon arc welding torch, comprising a gun body shell; an insulator connected with the gun body shell, a first support ring and a sealing body; connected with the insulator, the first support ring and the sealing body The electrode connecting body; the electrode connected with the electrode connecting body; the swirl ring connected with the gun body shell; the porcelain nozzle connected with the insulator; the nozzle connected with the swirl ring; the gas distributor; the sealing body has a cooling cavity; the electrode connection The first end of the body is provided with a first cooling fluid inlet pipe and a first cooling fluid outlet pipe, the other end is provided with a second cooling fluid inlet pipe and a second cooling fluid outlet pipe, and the second cooling fluid inlet pipe The liquid outlet of the cooling chamber is connected with the liquid inlet of the cooling chamber, the liquid inlet of the first cooling fluid liquid inlet pipe is connected with the liquid outlet of the cooling chamber, and the first cooling fluid liquid inlet pipe and the first cooling fluid liquid outlet pipe extend into the electrode connection The body is close to the end of the electrode; the electrode connecting body is provided with a protective gas pipe which is communicated with the gas distributor.

Owner:长沙中创海通智能科技有限公司

A variable section nozzle ring for a turbocharger

ActiveCN104295325BReduce wearNot easy to wear and deformInternal combustion piston enginesStatorsTurbochargerEngineering

The invention discloses a variable section nozzle ring for a turbocharger. The variable section nozzle ring comprises an installation disk, a shifting disk, a plurality of pin shafts and a plurality of shifting forks. The installation disk comprises a cylindrical portion and an annular portion. The annular portion extends outwards in the radial direction from one end of the cylindrical portion. The shifting disc is rotationally arranged on the cylindrical portion in a sleeving mode. The pin shafts are connected to the shifting disk. One end of each shifting fork and one corresponding blade are connected and rotate synchronously, and the other end of each shifting fork is provided with a gap. A sliding sleeve is rotationally arranged on each pin shaft in a sleeving mode. The sliding sleeves are sleeved with the shifting forks in a one-to-one corresponding mode through the gaps. The sliding sleeves can freely rotate and slide in the gaps in the shifting forks. The sliding sleeves are matched with the gaps in shape. The outer walls of the sliding sleeves are approximately square. The contact surfaces between the outer walls of the sliding sleeves and the two side walls of the gaps in the shifting forks are flat surfaces. Abrasion is reduced in the relative sliding process of the pin shafts and the shifting forks.

Owner:PINGXIANG DEBO TECH CO LTD

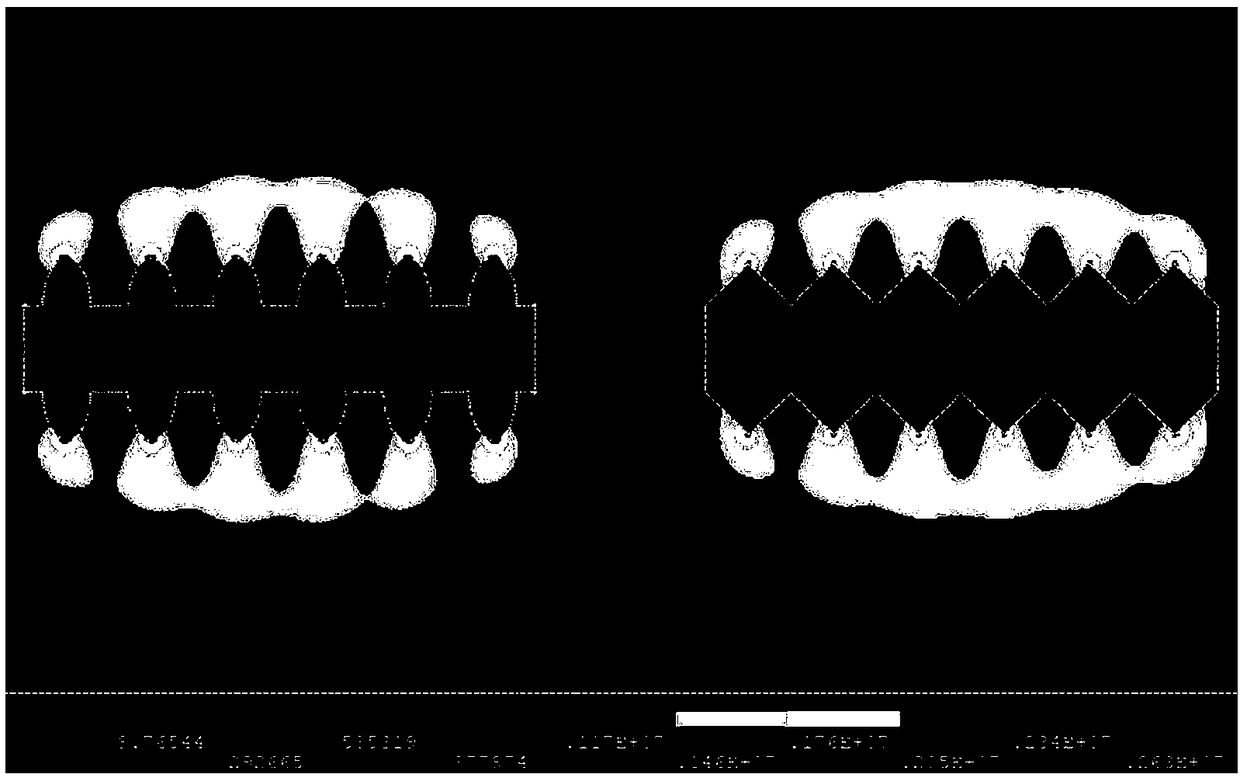

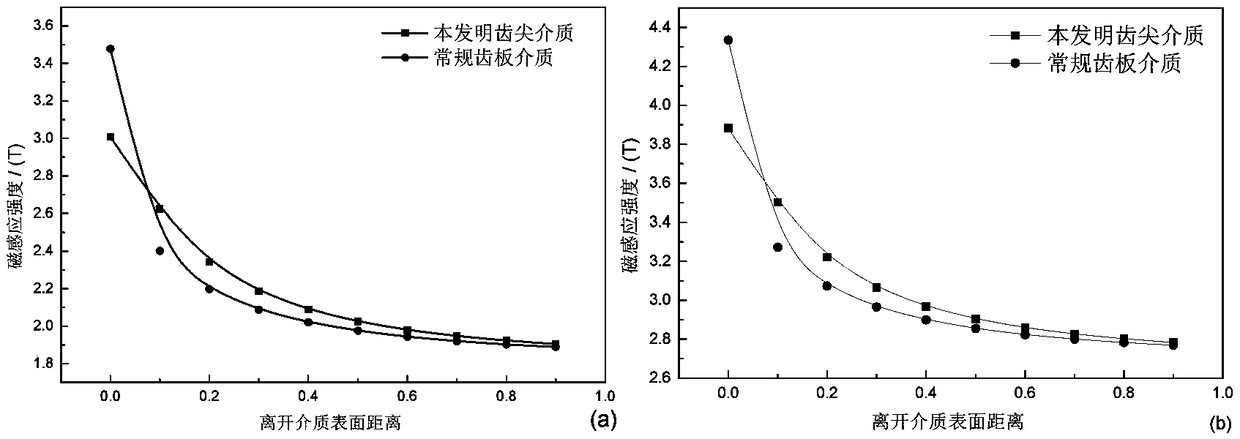

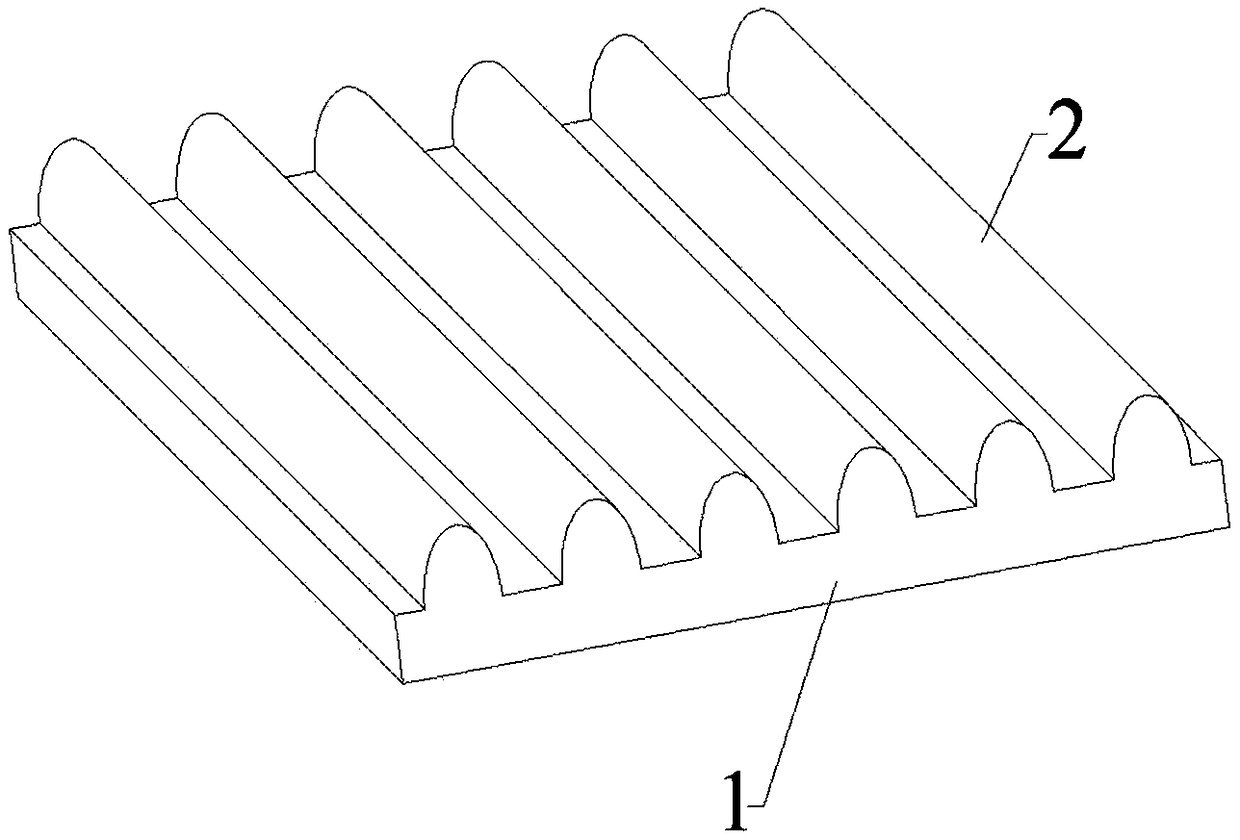

Single-surface tooth plate medium, double-surface tooth plate medium, tooth plate medium box and flat ring high-intensity magnetic separator

PendingCN109331996AStrong magnetic concentrationLess prone to magnetization saturationHigh gradient magnetic separatorsMagnetic tension forceMagnetic effect

The invention discloses a single-surface tooth plate medium. The single-surface tooth plate medium comprises a basal body, and a tooth tip arranged on one side of the basal body; and the tooth tip issemi-elliptical. The invention further discloses a double-surface tooth plate medium; and the double-surface tooth plate medium comprises a basal body, and tooth tips arranged on two sides of the basal body; and the tooth tip on at least one side is semi-elliptical. The invention further correspondingly discloses a tooth plate medium box, and a flat ring high-intensity magnetic separator comprising the tooth plate medium box. The single-surface tooth plate medium and the double-surface tooth plate medium both comprise the semi-elliptical tooth tips; the semi-elliptical tooth tips achieve a high magnetic gathering effect, and have the characteristics of difficult magnetizing saturation, difficult wear and high magnetic effect depth, so that the sorting efficiency of weak-magnetism mineralscan be further improved, and the recovery rate of fine-particle weak-magnetism minerals is increased; and the semi-elliptical tooth tips are difficultly worn and deformed, so that the problem of instable production caused by wear of conventional tooth plate medium sharp angles can be solved.

Owner:CENT SOUTH UNIV

Melting ingredient for piston

Owner:JIANGSU LEADER PRECISION MACHINERY

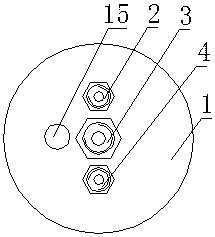

Argon arc welding torch and device with the same

An argon arc welding torch and a device having the same, comprising an insulator (11); a torch head body (1) located outside the insulator (11) and connected to the insulator (11); and a first end connected to the insulator (11) The swirl ring (14); the nozzle (8) connected to the end of the gun head body (1) near the swirl ring (14); the air inlet pipe (4), the liquid inlet pipe (3) and the liquid outlet arranged in the insulator (11) tube (2); the tungsten pole seat (5) connected to the liquid inlet pipe (3) or the insulator (11) near the vortex ring (14); the tungsten pole seat (5) connected to the end far away from the liquid inlet pipe (3) Tungsten pole (6); located at the end of the tungsten pole seat (5) away from the tungsten pole (6), the outer cylindrical surface is connected with the insulator (11), the inner cylindrical surface is connected with the tungsten pole seat (5), and the gas diffuser is connected with the air intake pipe (4 ) communicated air diffuser net (10); there is a gas flow channel for the gas to flow out between the tungsten pole seat (5) and the tungsten pole (6), the vortex ring (14) and the nozzle (8).

Owner:长沙中创海通智能科技有限公司

Rotary valve with improved structure

The invention discloses a rotary valve with an improved structure. The rotary valve comprises a rotary valve rotating disc, an upper reverse-hanging disc and an abrasion-resistant plate. The abrasion-resistant plate made of an abrasion-resistant material is detachably and fixedly mounted on the surface of one end of the upper reverse-hanging disc, and the surface of the rotary valve rotating disccan rotatably and tightly abut against the surface of the abrasion-resistant plate. According to the rotary valve with the improved structure, the abrasion-resistant plate is mounted on the upper reverse-hanging disc, the rotary valve rotating disc and the abrasion-resistant plate make close contact, and relative rotating friction occurs between the rotary valve rotating disc and the abrasion-resistant plate, so that the abrasion-resistant plate is not liable to be abraded and deform after being used for a long term, airtightness in the waste gas circulating process is guaranteed, and environment pollution is avoided; and automatic rotating of the rotary valve rotating disc is further achieved by arranging a motor decelerator and a rotary valve supporting column, the distance between the rotary valve rotating disc and the upper reverse hanging disc is adjusted by arranging an airbag, repair and maintenance are facilitated while the airtightness is further improved, the waste treatmentefficiency and quality are greatly improved, and the service life of the equipment is prolonged.

Owner:KUNSHAN JUHONG MACHINERY TECH

An ultra-high pressure pipeline system with a combined check valve

ActiveCN105423035BIncrease wall thicknessExtended service lifeBranching pipesUltra high pressureEngineering

The invention discloses an ultrahigh-pressure pipeline system with a combined type check valve. The ultrahigh-pressure pipeline system comprises a base. A liquid inlet main flow channel and a liquid outlet main flow channel are formed in the two sides of the base. A first convergence flow channel, a second convergence channel and a plurality of branches are arranged between the liquid inlet main flow channel and the liquid outlet main flow channel. The branches are provided with liquid inlets and liquid outlets. The liquid inlets are connected with the first convergence flow channel. The liquid outlets are connected with the second convergence channel. The first convergence flow channel is communicated with the liquid inlet main flow channel. The second convergence channel is communicated with the liquid outlet main flow channel, and the drift diameter of each branch is less than the drift diameter of the liquid inlet main flow channel and the drift diameter of the liquid outlet main flow channel. The ultrahigh-pressure pipeline system further comprises the combined type check valve. The combined type check valve comprises independent check valve bodies of which the number is equal to that of the branches, and each branch is internally provided with an independent check valve body. The base is further provided with a detection branch. The detection branch comprises a low-pressure branch and a high-pressure branch.

Owner:ZHEJIANG MOTORBACS TECH

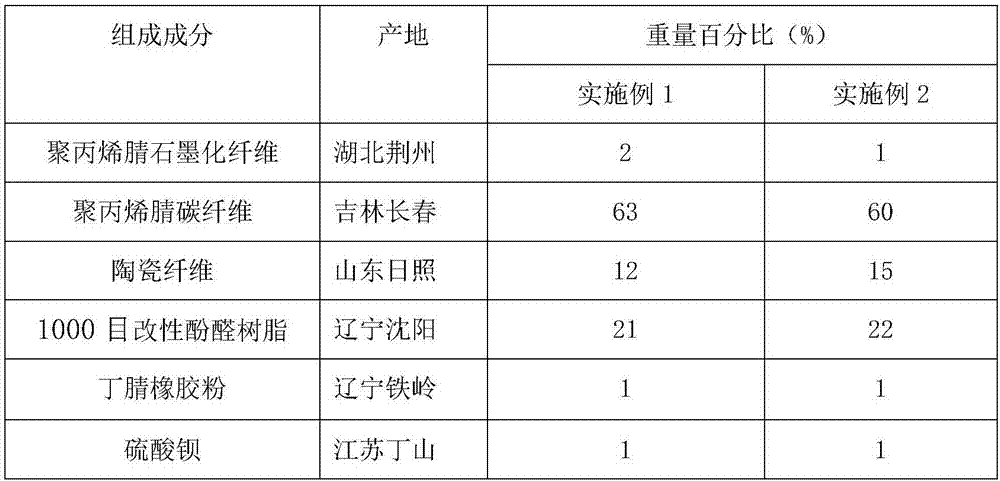

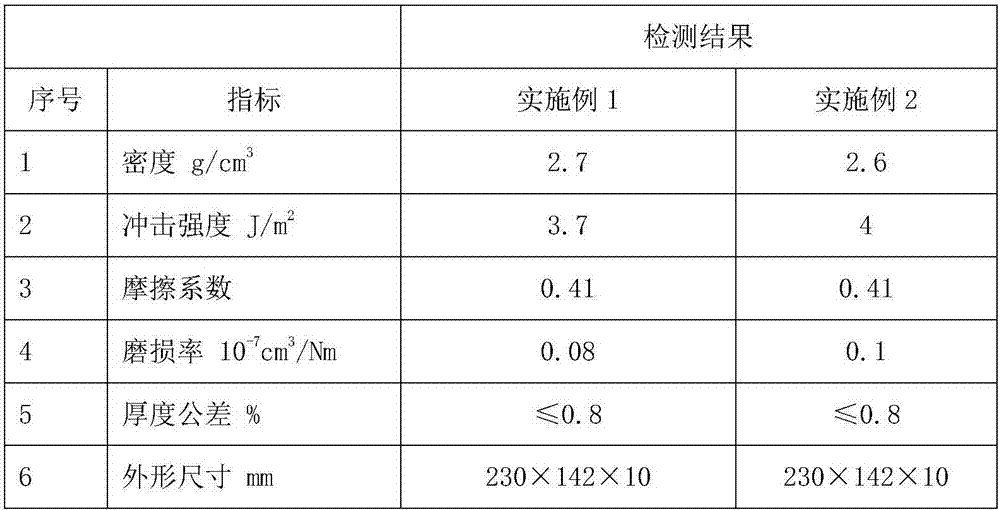

Graphitized fiber, carbon fiber, ceramic fiber brake disc and manufacturing process

The present invention relates to a kind of graphitization fiber, carbon fiber, ceramic fiber brake disc and its manufacturing process, with polyacrylonitrile graphitization fiber, polyacrylonitrile carbon fiber, ceramic fiber as skeleton material, nitrile rubber powder and barium sulfate as filler, The modified phenolic resin is used as a binder to make the brake disc raw material, and then the brake disc is made by hot pressing, heat treatment, surface polishing and drilling; the weight percentage of each component of the brake disc raw material is: polypropylene Nitrile graphitized fiber 0.5%~5%; polyacrylonitrile carbon fiber 45%~65%; ceramic fiber 10%~25%; modified phenolic resin 15%~25%; nitrile rubber powder 0.5%~2%; barium sulfate 0.5% to 2%; the invention uses a new type of brake disc made of non-metallic materials, which has the advantages of light specific gravity, large heat capacity, strong adhesion, high temperature resistance, stable friction coefficient, good wear resistance, and strong mechanical properties. Excellent braking performance, not easy to deform and wear, no noise.

Owner:UNIV OF SCI & TECH LIAONING

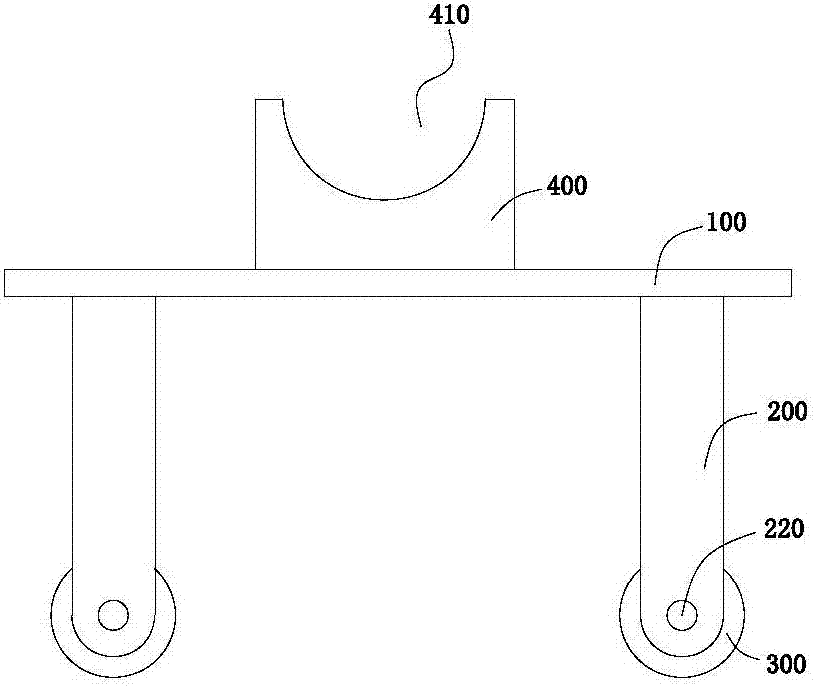

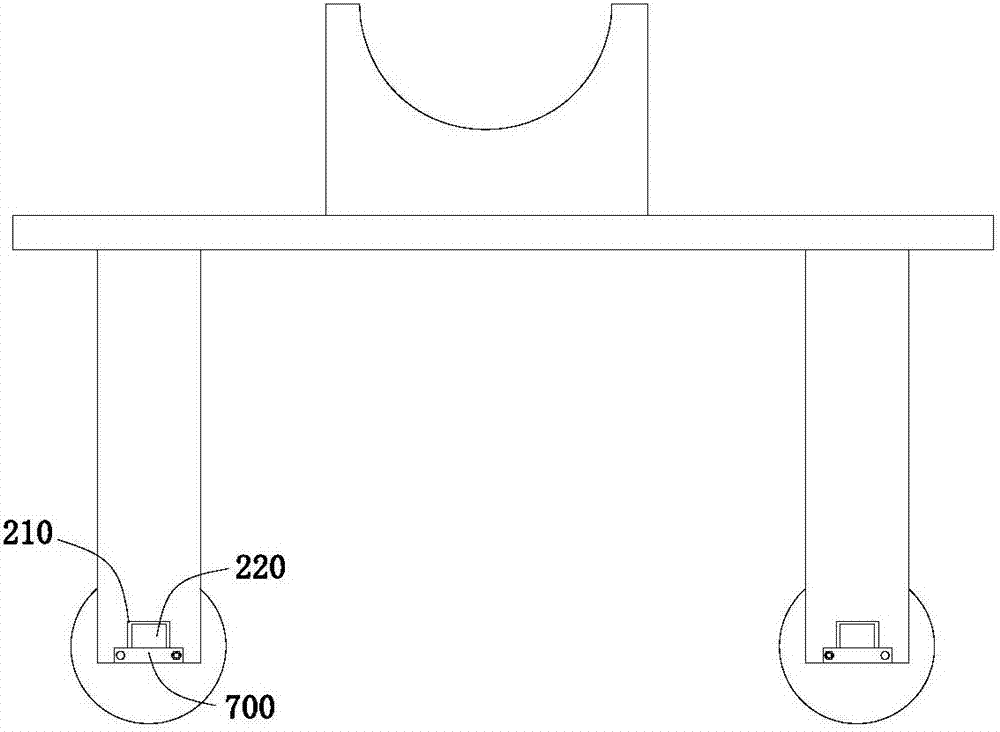

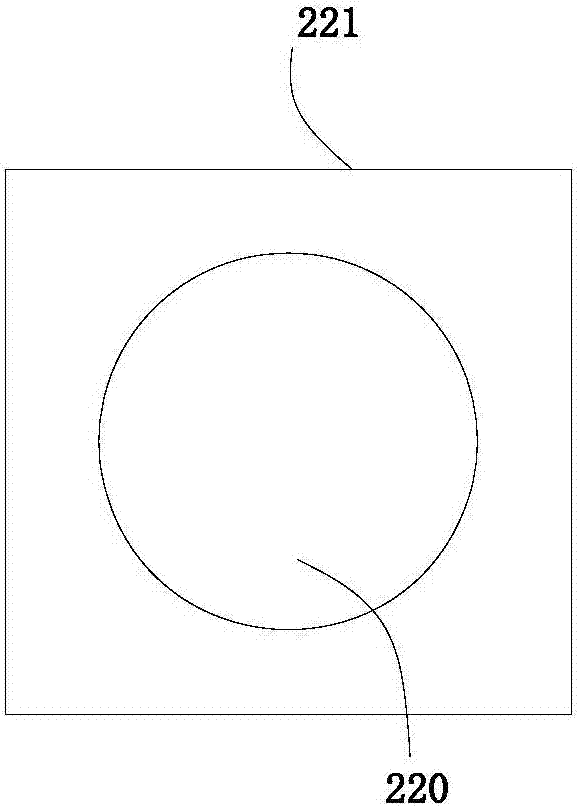

Reinforced concrete construction plate face concrete pump pipe supporting frame

The invention provides a reinforced concrete construction plate face concrete pump pipe supporting frame. The reinforced concrete construction plate face concrete pump pipe supporting frame comprisesa supporting unit and a positioning unit, the supporting unit comprises a supporting plate, a supporting leg and an elastic part, the supporting leg comprises a connecting end and a supporting end, the connecting end is mounted on the supporting plate, the elastic part is arranged on the supporting end, the positioning unit comprises a positioning part which is mounted on the supporting plate, thepositioning part is provided with a sinking part used for containing a pump pipe, in the supporting process of the reinforced concrete construction plate face concrete pump pipe supporting frame, thesupporting frame directly supports the mold plate, and cannot make contact with the reinforced concrete structure on a mold plate body, supporting is stable and reliable, in the concrete pouring process, pump pipe vibration is transmitted to the mold plate through the supporting frame, a reinforced concrete structure cannot be disturbed, and construction quality is ensured.

Owner:CHINA AEROSPACE CONSTR GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com