A magnetic bar self-rotation type permanent magnet filter

A filter device and magnetic rod technology, which is applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of inability to achieve decontamination and filtration effects, deformation or damage of magnetic rods, and affecting filtration efficiency, etc., and achieve the reduction of the overall equipment Dimensions, prevent easy deformation and wear, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

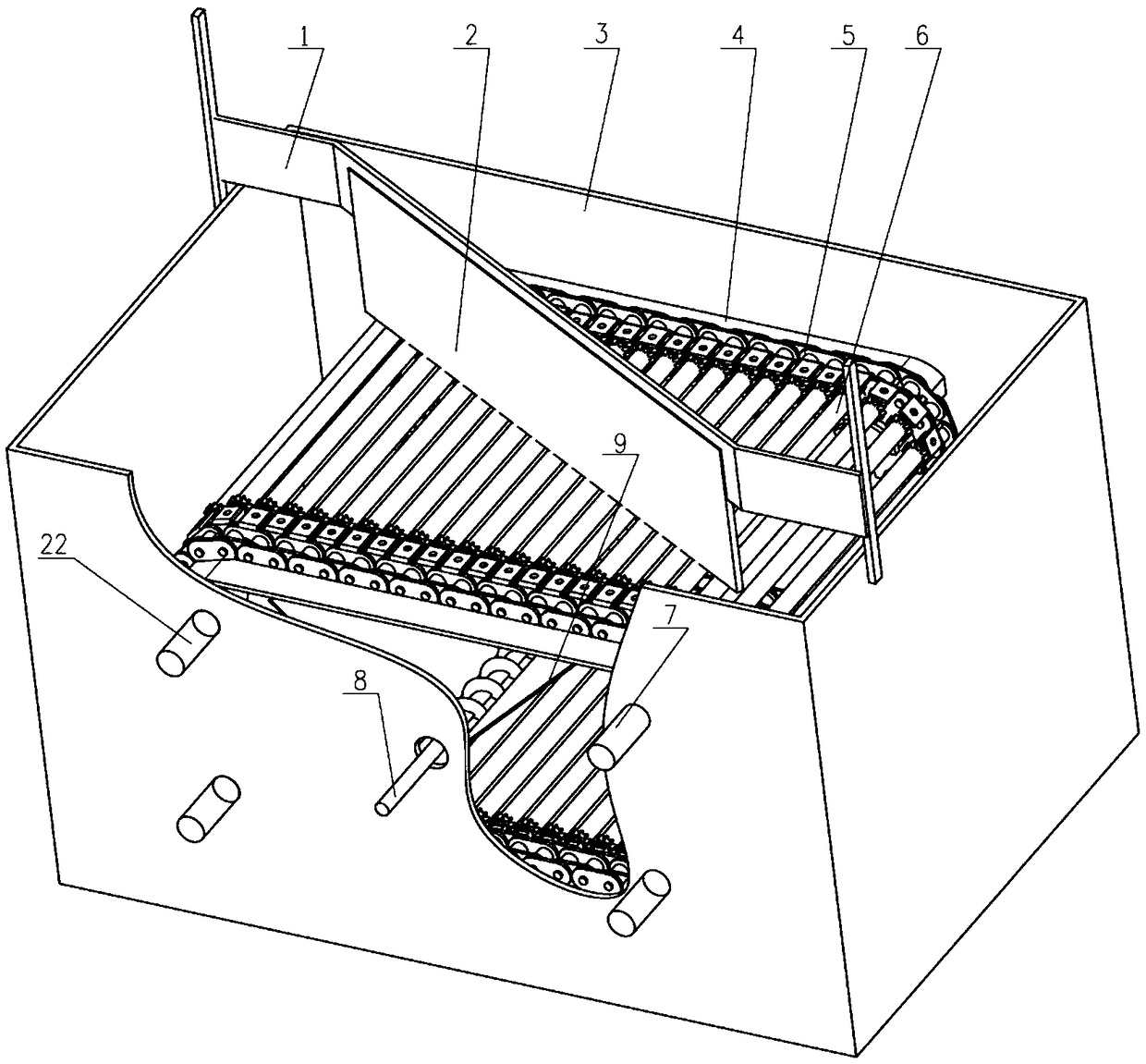

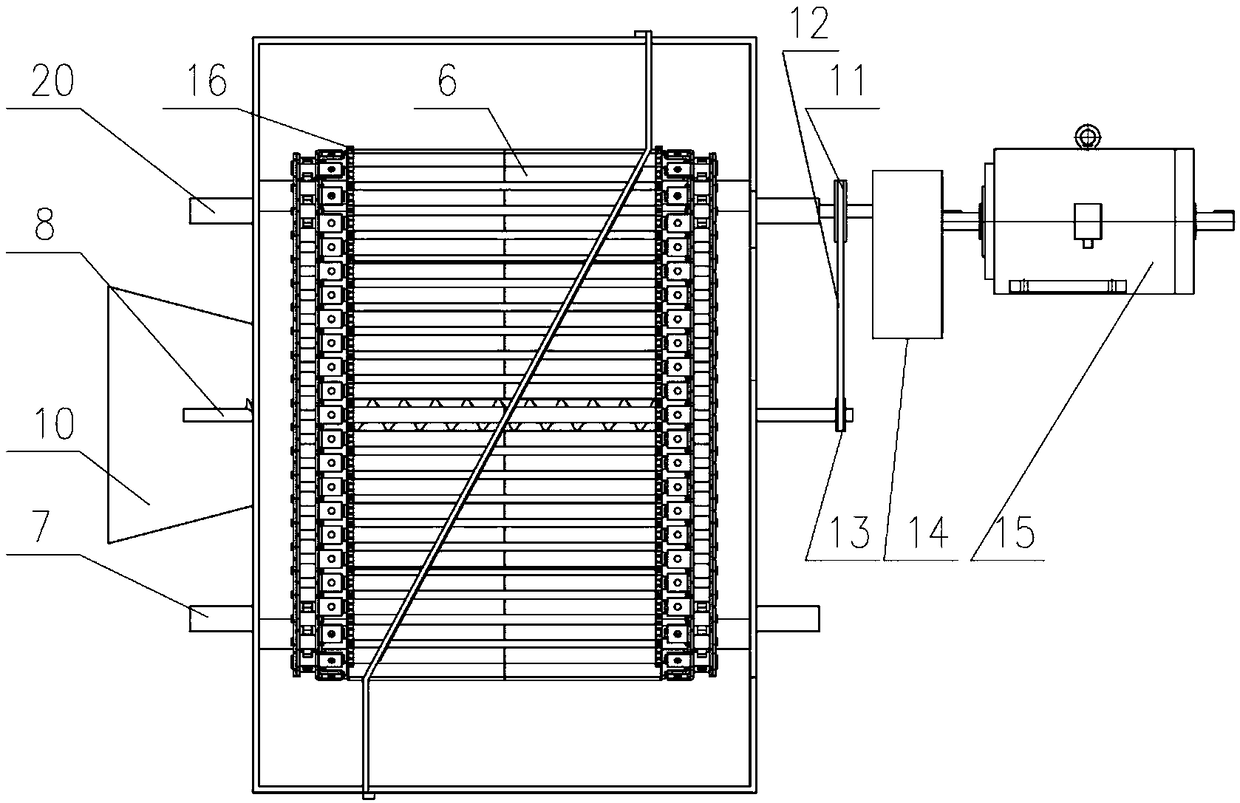

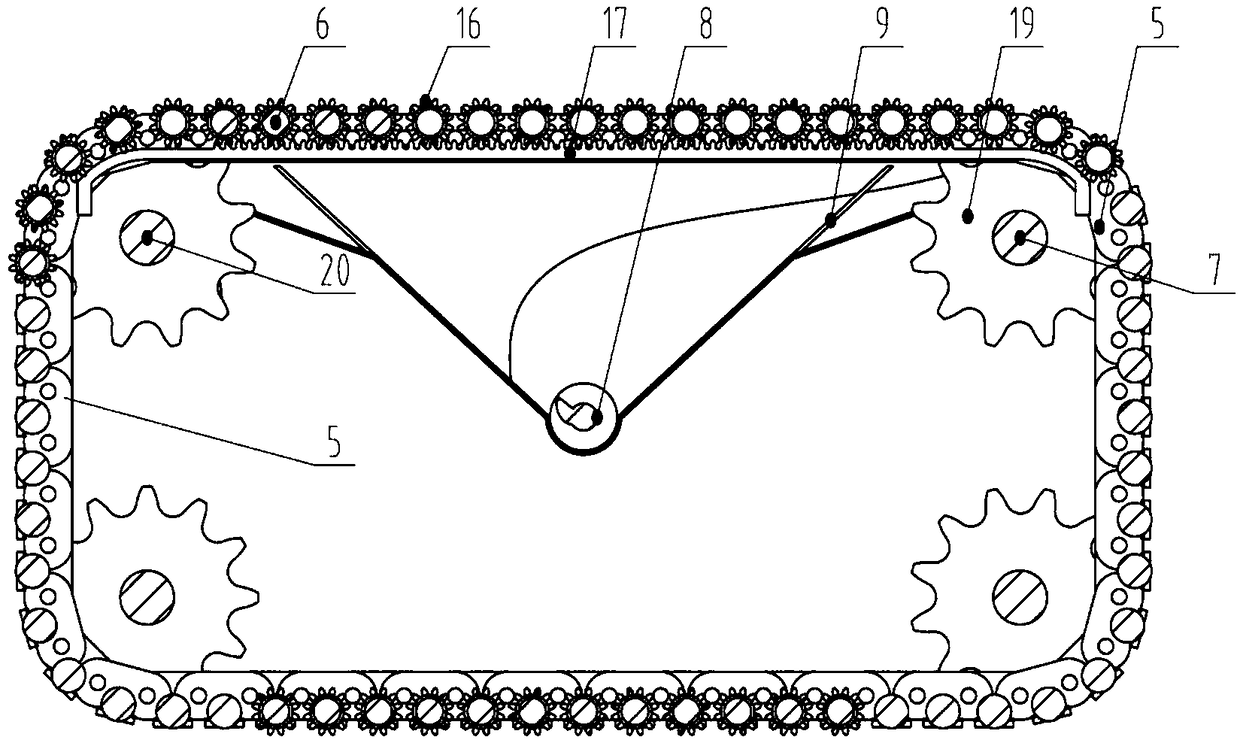

[0033] Such as Figure 1-3 It is one of the specific implementations of the magnet rod self-rotating permanent magnet filter device implemented according to the present invention.

[0034] Such as figure 1 with 2 According to the magnetic bar rotation type permanent magnet filtering device implemented in the present invention, waste water containing iron slag is housed in a water tank 3, and the magnetic chain formed by the chain 5 and the magnetic bar 6 connected in series is supported in the box by the supporting plate 4 and can Go round and round; outside the water tank 3, the motor 15 drives the magnetic chain to rotate through the reduction box 14;

[0035] The slag scraping brush 2 is arranged on the upper part of the magnetic chain through the support 1, and the slag scraping brush 2 is arranged perpendicular to the plane where the magnetic chain is located or at an angle, so that the slag scraping brush 2 can remove the slag body on the magnetic chain at the contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com