Reinforced concrete construction plate face concrete pump pipe supporting frame

A technology for reinforced concrete and concrete pump pipes, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of steel reinforcement disturbance on the plate surface and affect the quality of pouring, so as to save costs, not easy to wear and deform, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

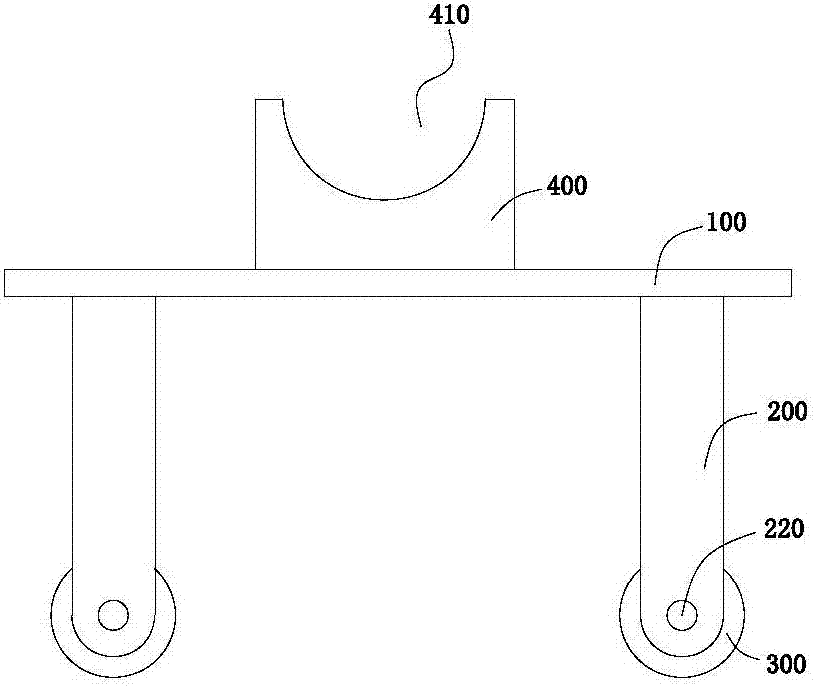

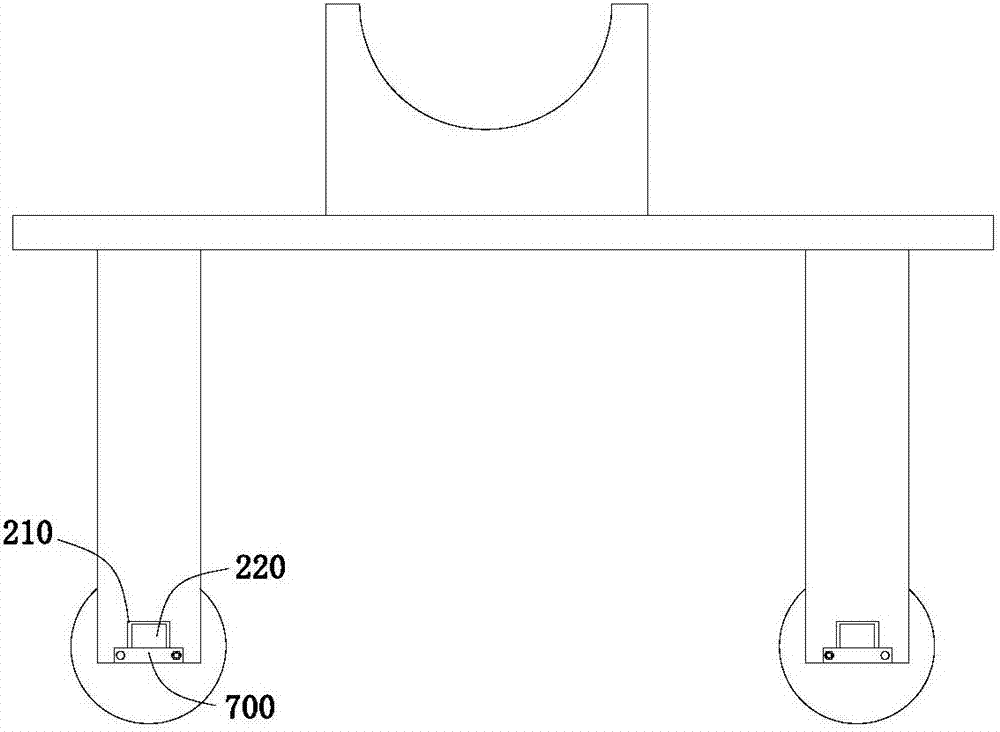

[0042] see figure 1 - Image 6 , This embodiment provides a concrete pump pipe support frame on a reinforced concrete construction slab, which is used for positioning the concrete pump pipe during the construction process of the building, so as to ensure the smooth progress of the construction.

[0043] The reinforced concrete construction slab concrete pump pipe support frame includes a support unit and a positioning unit.

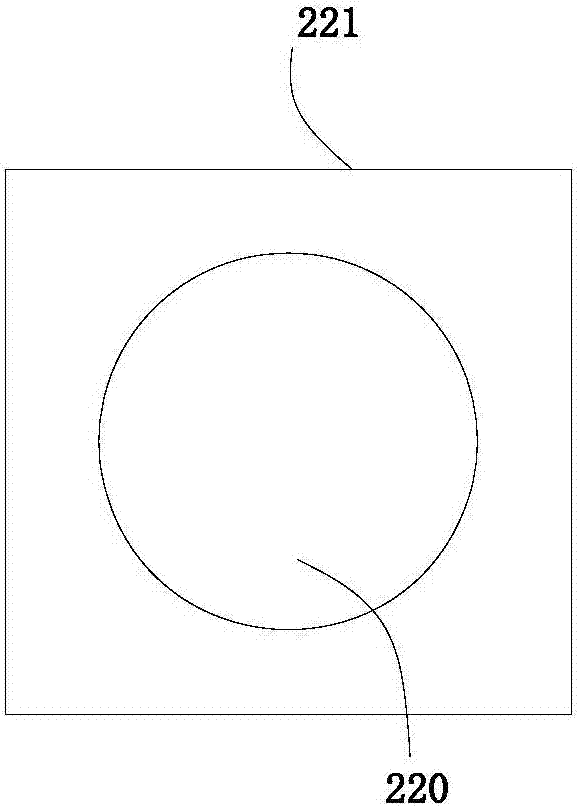

[0044] In this embodiment, the support unit includes a support leg 200 , a support plate 100 and an elastic member 300 . The supporting legs 200 are installed on the supporting board 100 , and the elastic member 300 is installed on the supporting legs 200 . The support leg 200 includes a connection end and a support end. The support leg 200 is installed on the support plate 100 by means of the connection end. The support leg 200 and the support plate 100 are fixedly connected. The overall structure is firm, not easily deformed, and safe to use. The elast...

Embodiment 2

[0052] see figure 1 - Image 6 , This embodiment provides a concrete pump pipe support frame on a reinforced concrete construction slab, which is used for positioning the concrete pump pipe during the construction process of the building, so as to ensure the smooth progress of the construction.

[0053] The reinforced concrete construction slab concrete pump pipe support frame includes a support unit and a positioning unit.

[0054] In this embodiment, the support unit includes a support leg 200 , a support plate 100 and an elastic member 300 . The supporting legs 200 are installed on the supporting board 100 , and the elastic member 300 is installed on the supporting legs 200 . The support leg 200 includes a connection end and a support end. The support leg 200 is installed on the support plate 100 by means of the connection end. The support leg 200 and the support plate 100 are fixedly connected. The overall structure is firm, not easily deformed, and safe to use. The ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com