Argon arc welding torch and device with the same

A technology of argon arc welding torch and tungsten electrode, which is applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems that the arc energy density cannot be further improved, the arc cannot be accurately controlled, and the influence of welding material adaptability, etc., to achieve reduction Human hazards and damage to equipment, improving welding efficiency, and improving the quality of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

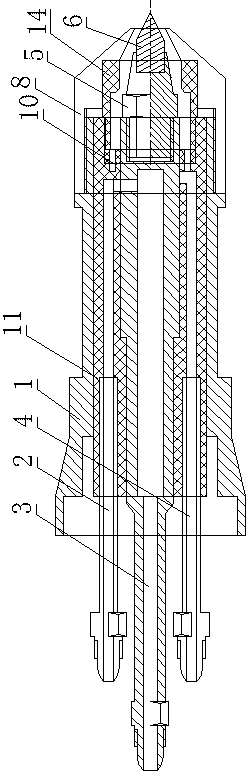

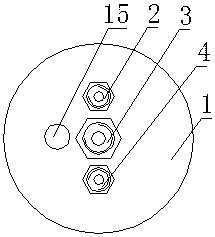

[0023] Embodiment 1: as figure 1 and image 3 The argon arc welding torch shown includes an insulator 11; a torch head body 1 connected to the insulator 11 outside the insulator 11; an eddy current ring 14 connected to the first end of the insulator 11 through threads; and a vortex ring near the torch head body 1 through threads The nozzle 8 that 14 ends are connected; The inlet pipe 4 that is arranged in the insulator 11, the liquid inlet pipe 3 and the liquid outlet pipe 2 that communicates with the liquid inlet pipe 3; The tungsten pole seat 5 that is connected with the near vortex ring 14 ends of the insulator 11; The tungsten pole seat 5 is far away from the tungsten pole 6 connected to the liquid inlet pipe 3; located at the tungsten pole seat 5 away from the tungsten pole 6 end, the outer cylindrical surface is connected with the insulator 11, the inner hole is connected with the tungsten pole seat 5, and the gas diffuser is connected with the air intake pipe 4 Connect...

Embodiment 2

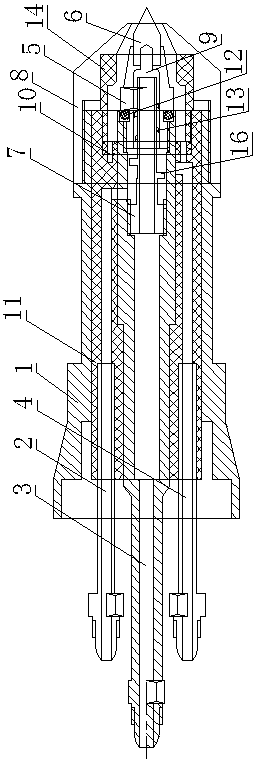

[0024] Embodiment 2: as figure 2 and image 3 The argon arc welding torch shown includes an insulator 11; a torch head body 1 connected to the insulator 11 outside the insulator 11; an eddy current ring 14 connected to the first end of the insulator 11 through threads; and a vortex ring near the torch head body 1 through threads The nozzle 8 connected to the 14 end; the inlet pipe 4, the liquid inlet pipe 3 and the liquid outlet pipe 2 connected with the liquid inlet pipe 3 arranged in the insulator 11; the tungsten pole seat 5 connected with the liquid inlet pipe 3 near the vortex ring 14 end ; The tungsten pole 6 connected with the tungsten pole seat 5 away from the end of the tungsten pole 6; located at the end of the tungsten pole seat 5 away from the tungsten pole 6, the outer cylindrical surface is connected with the insulator 11, the inner hole is connected with the tungsten pole seat 5, and the air outlet is connected with the inlet The gas diffuser network 10 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com