Patents

Literature

54results about How to "Improve the efficiency of welding operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding wire of filling flux of gas protection electric arc welding using for high-strength steel

InactiveCN1387975AExcellent welding workabilityImprove the efficiency of welding operationsArc welding apparatusWelding/cutting media/materialsChemical compositionHigh intensity

Disclosed is a flux cored wire for gas shielded arc welding of high tensile strength steel, characterized in that the flux essentially consists of, with respect to the total weight of the wire: metal or ferroalloy containing at least Si, Mg and Al acting as a deoxidizing agent, the sum of the three components, Si, Mg and Al being from 0.5 to 1.5%; from 1.5 to 2.7% Mn, provided that the ratio of Mn to (Mg+Al), i.e., the value of Mn / (Mg+Al) is 3.5-5.0; and two or more components selected from the group consisting of Cr, Ni, Mo and Nb, the sum of the two or more components being 1.0-2.5%. The flux cored wire exhibits good welding workability in all welding positions, ensuring an improvement in the efficiency of welding work, and maintains high tensile strength and impact absorption energy, ensuring stability of welded structures.

Owner:KISWEL LTD

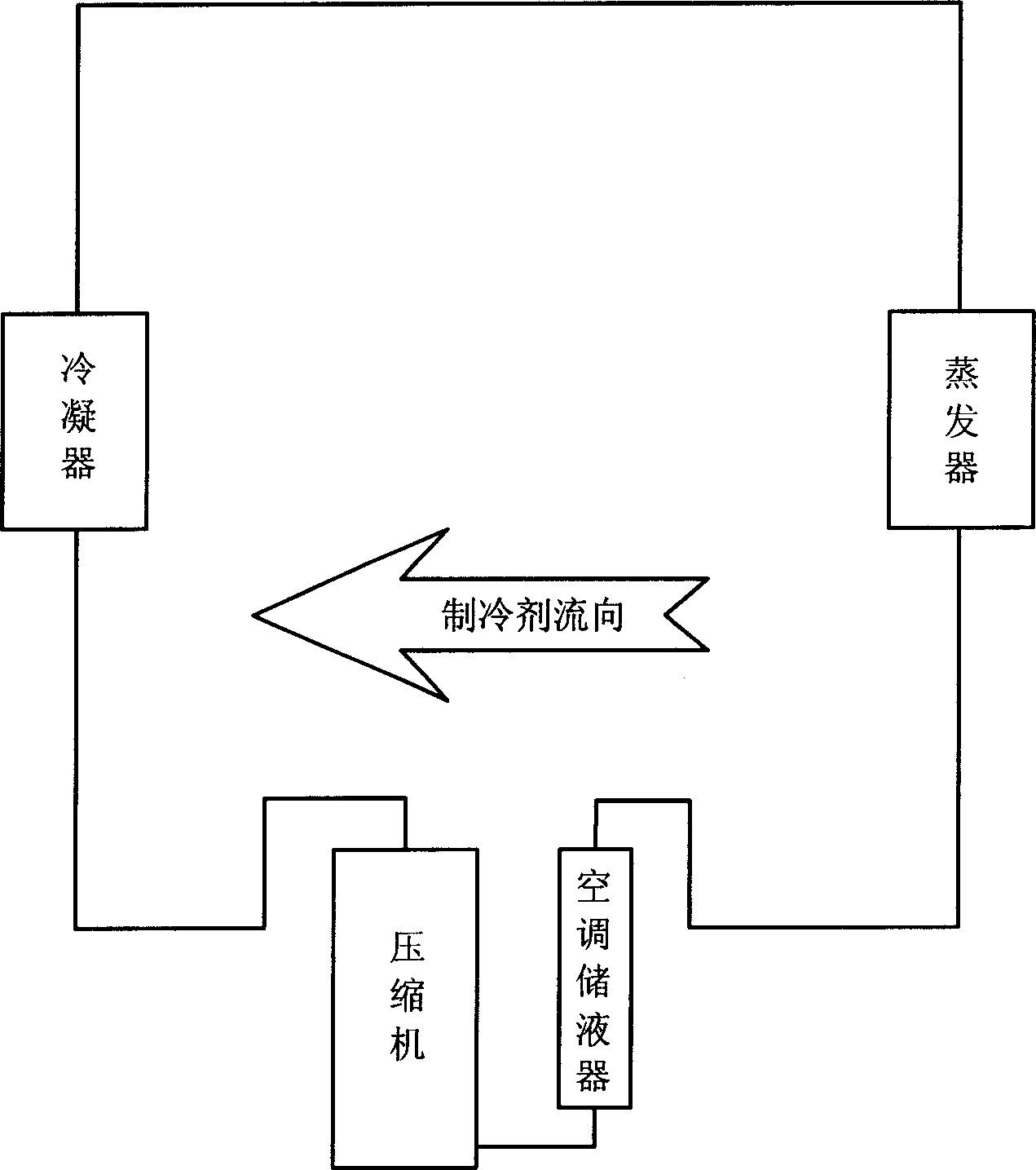

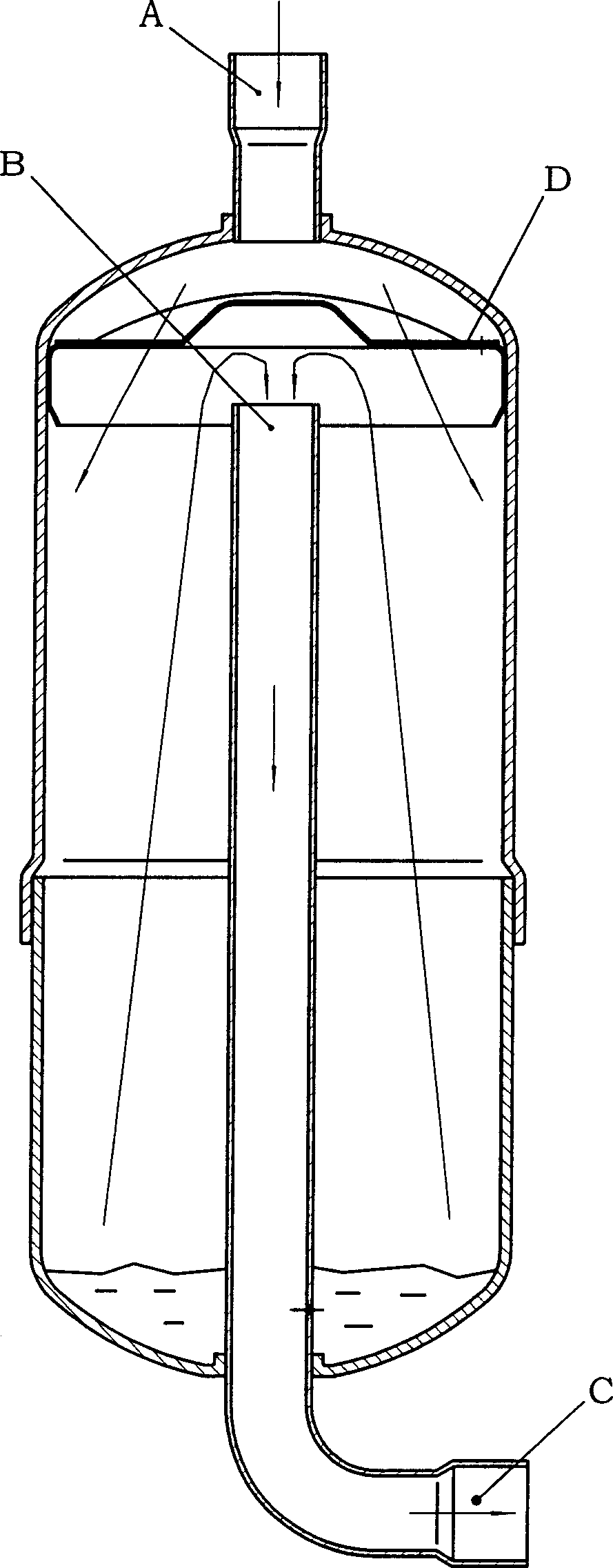

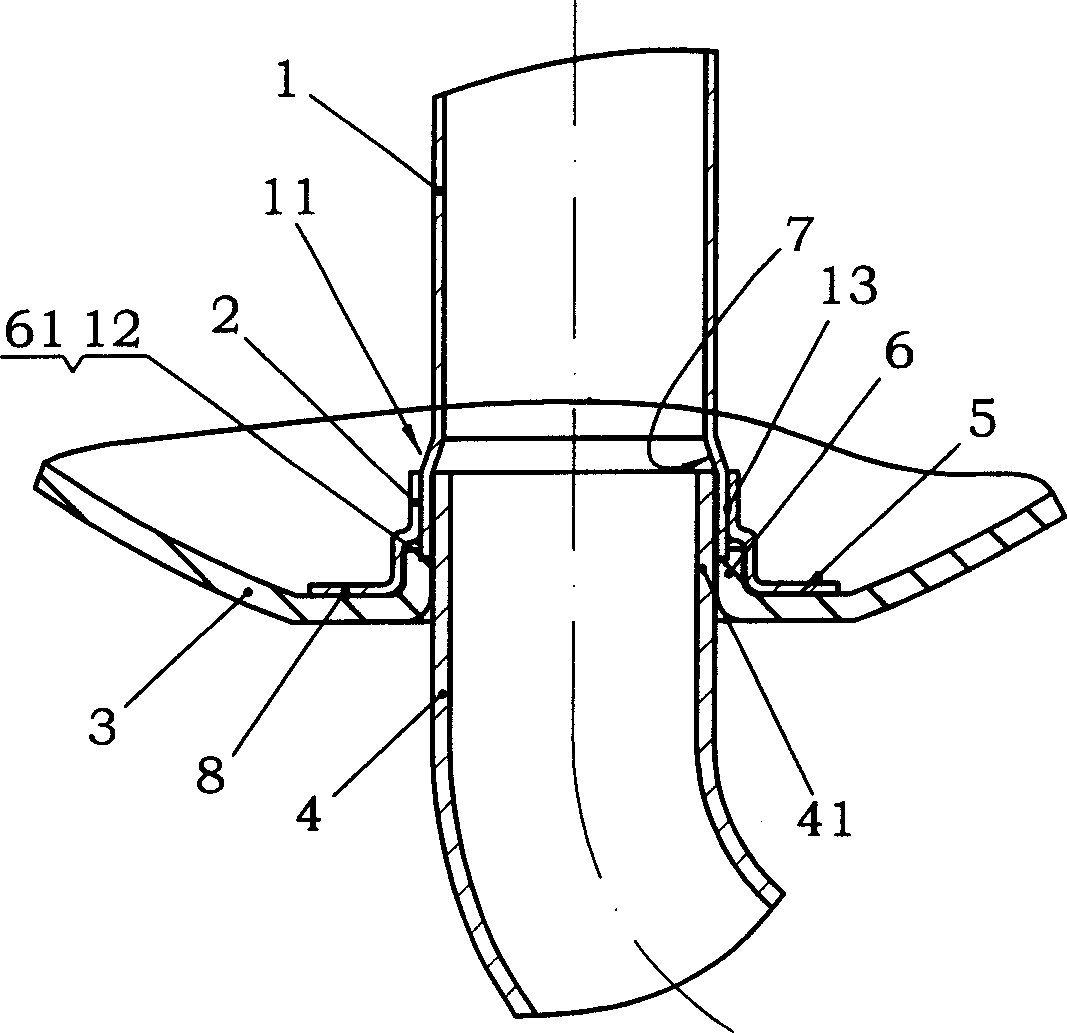

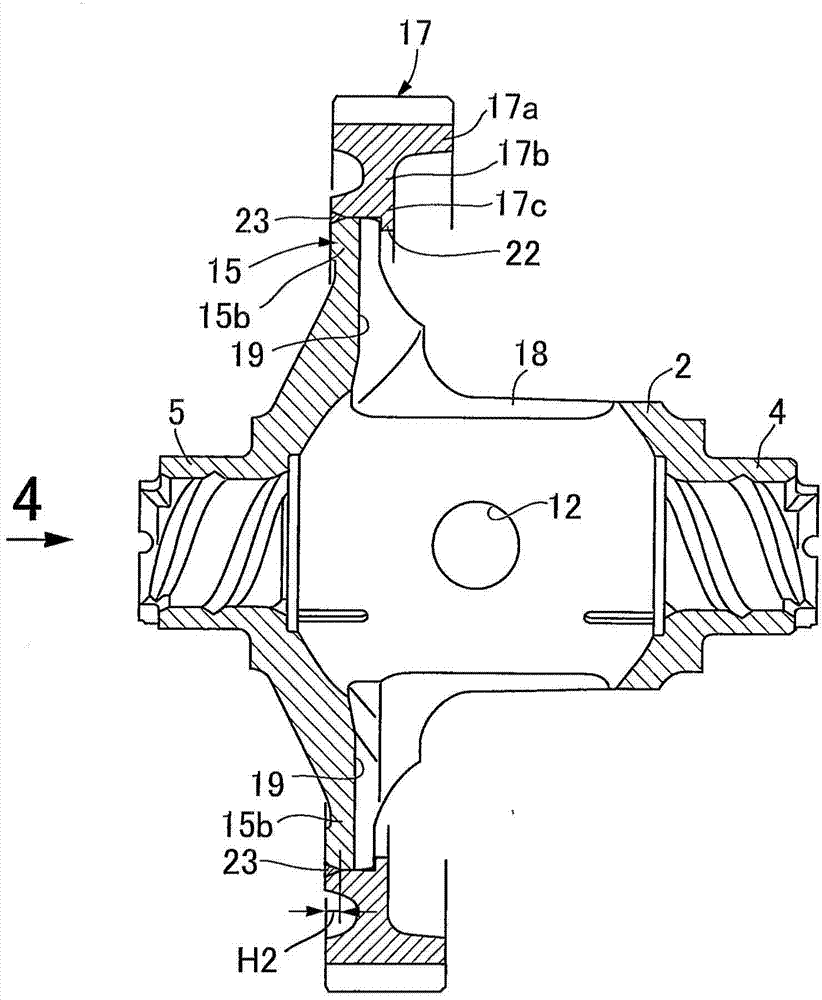

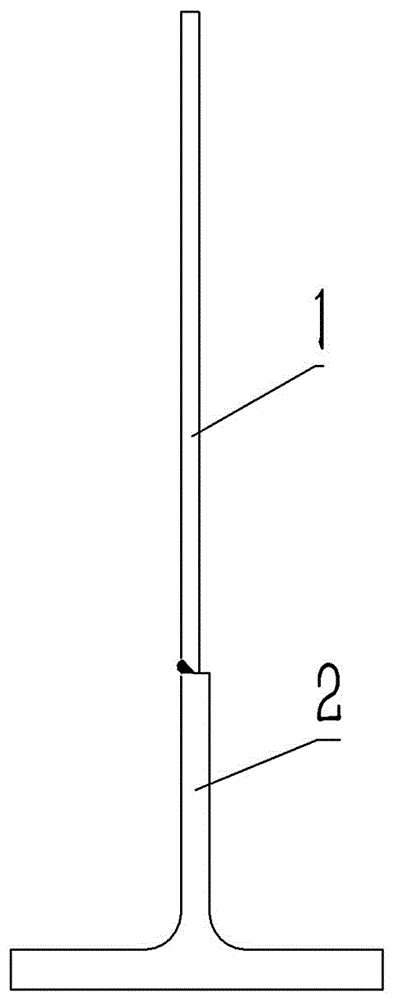

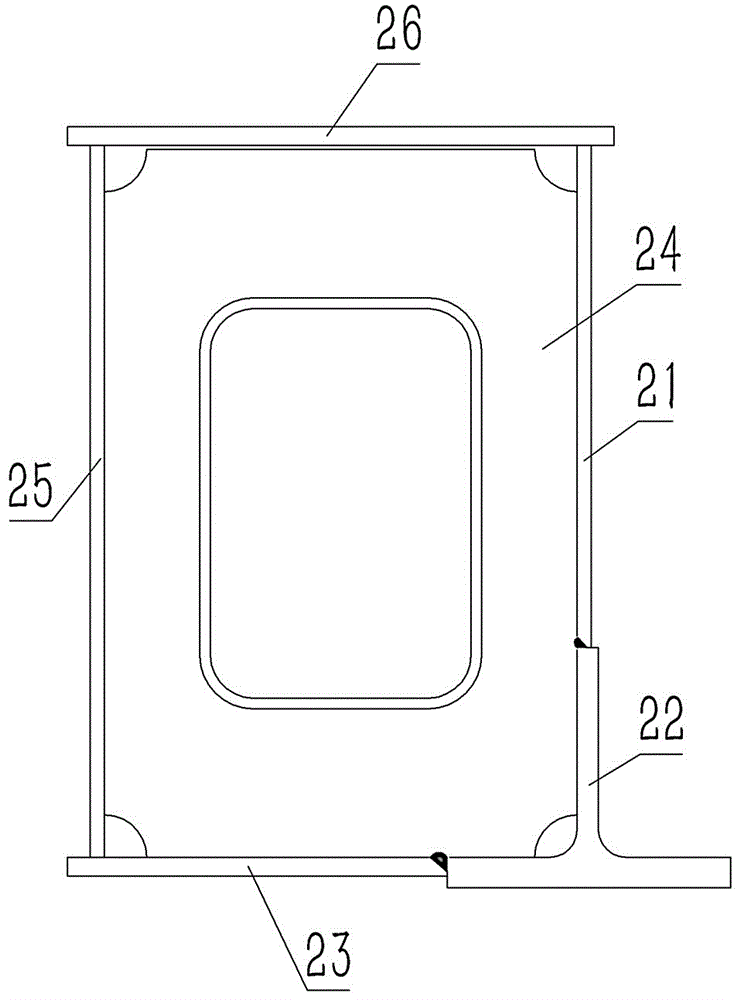

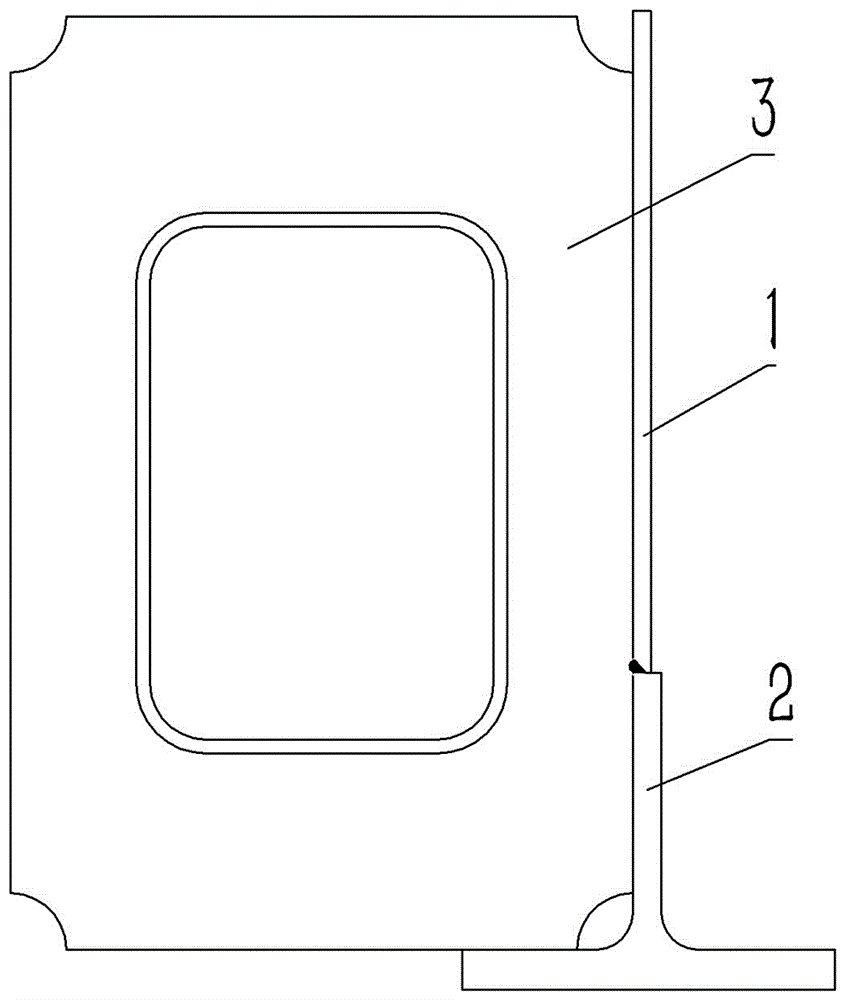

Liquid storing device for storing refrigrant in device

This invention is liquid storage inside of machine that is used for storing refrigerants. The existing liquid discharge wielding structure of liquid storage is: tubular flanging is set at underside of the machine. Inner iron pipe and outer copper pipe are wielded at the tubular flanging. It may cause defects such as cracking before wielding. This invention is to fix the said inner iron pipe on a switching seat. The switching seating is set on the said tubular flanging and wielded with the underside of machine to form step at the position of tubular flanging. The said copper pipe contacts with the said step and is wielded with the underside of machine.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

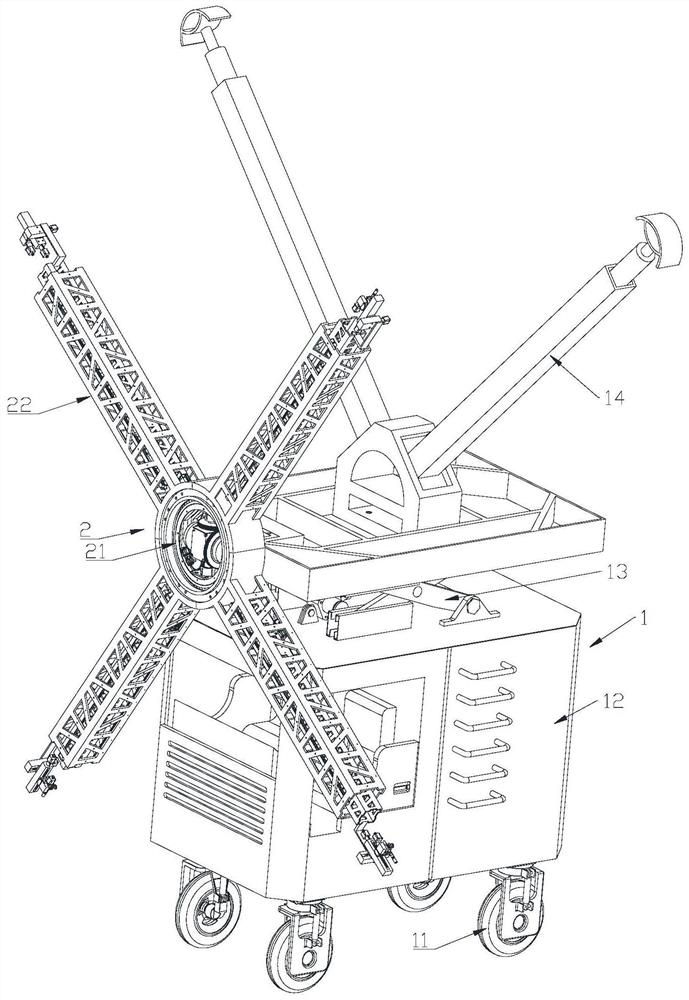

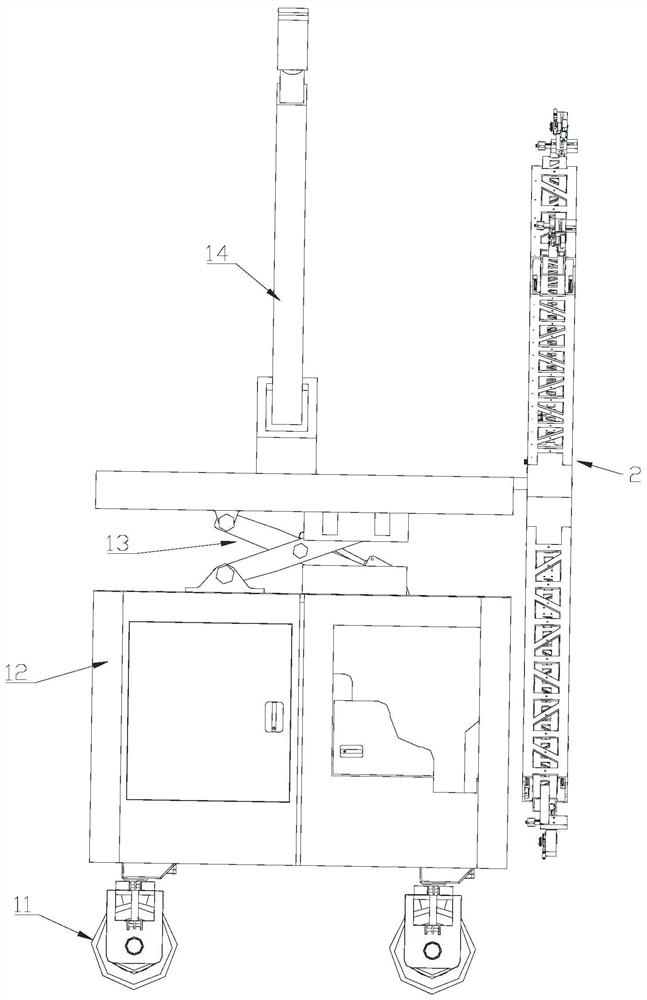

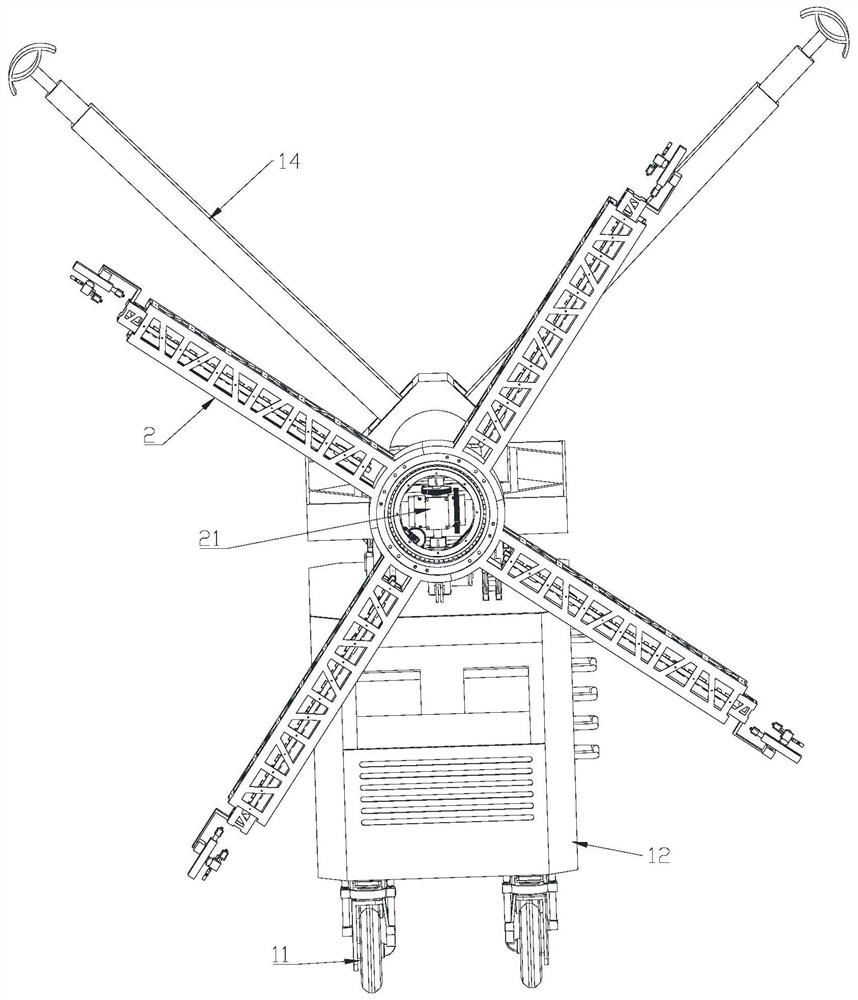

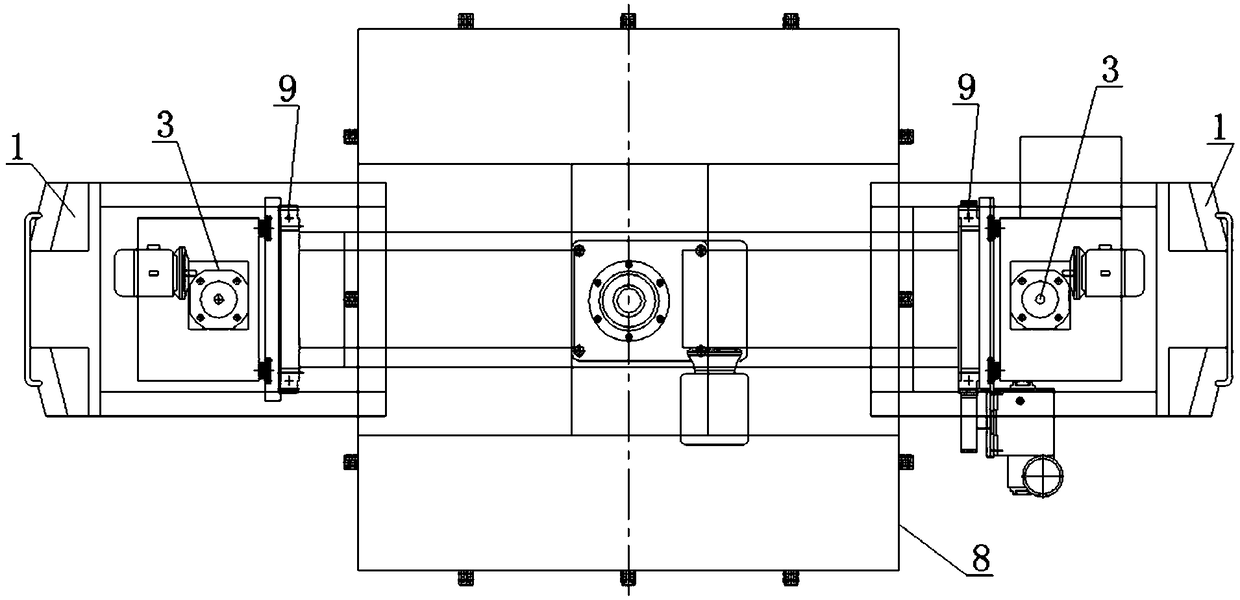

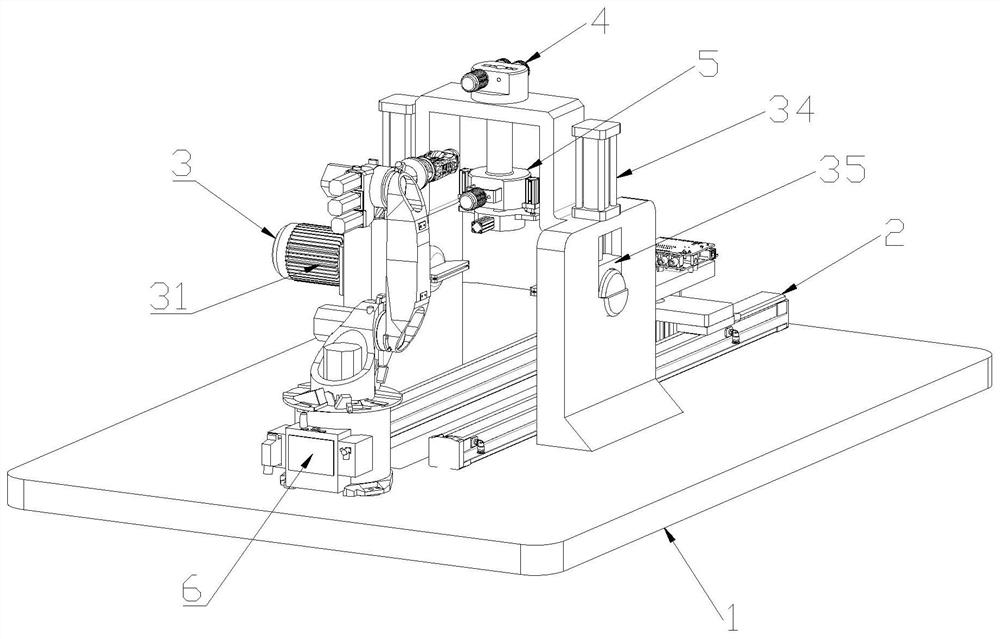

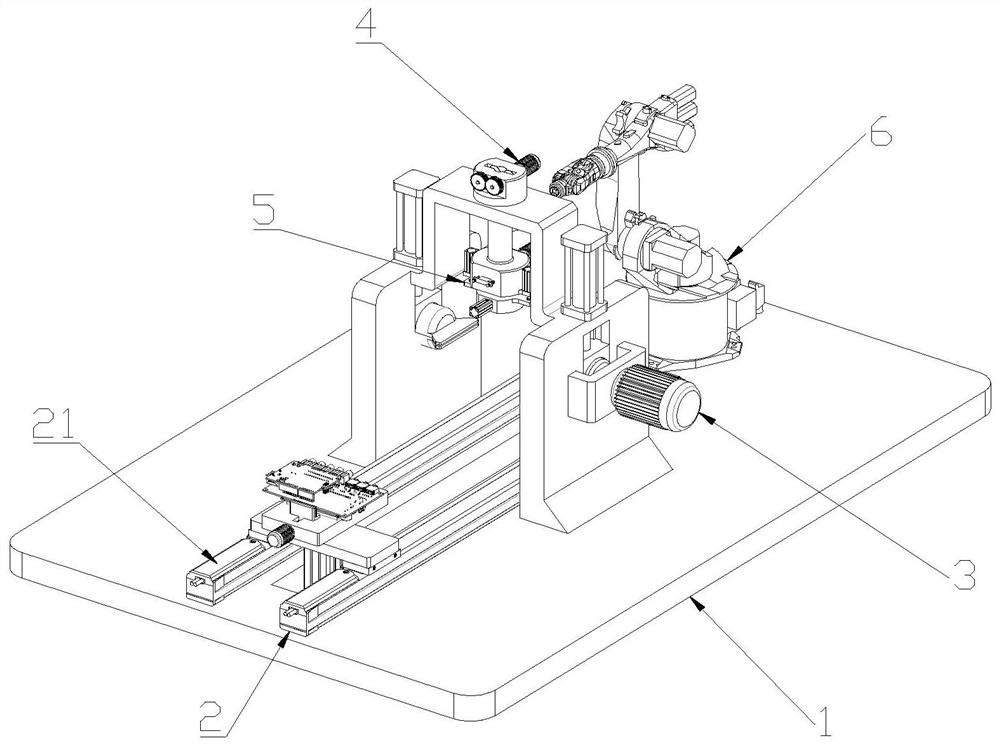

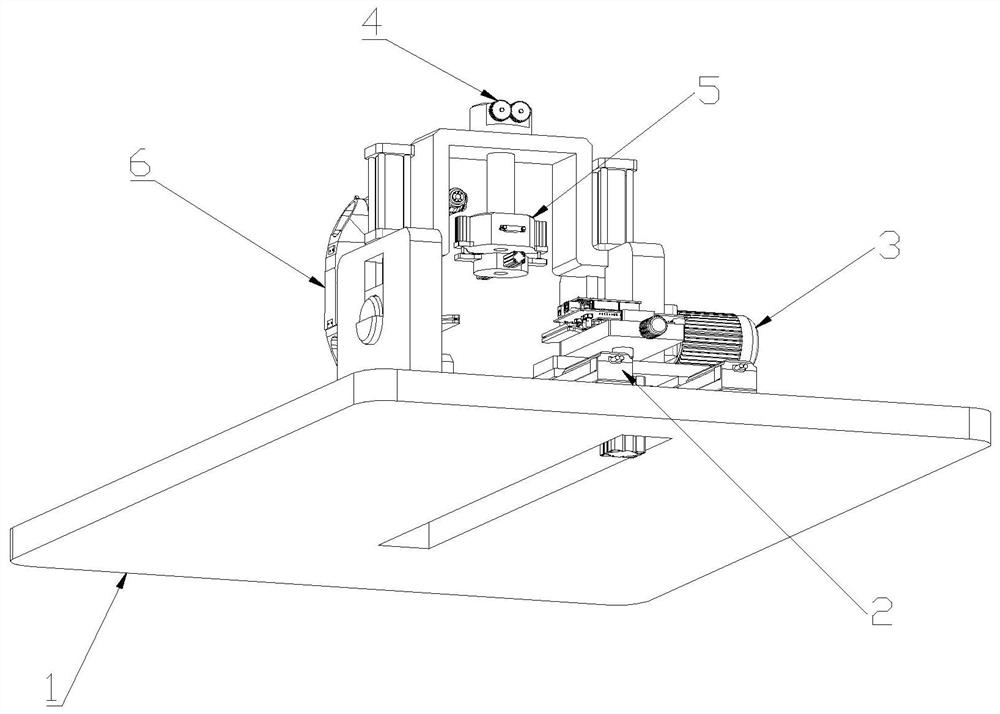

Large pipeline girth welding operation device and welding method

ActiveCN113210921AImprove the efficiency of welding operationsHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesWeld seamSoldering gun

The invention provides a large pipeline girth welding operation device and a welding method, and relates to the technical field of welding equipment. The technical problems that a welding operation device needs to be moved by laying a track, is time-consuming and labor-consuming, and cannot be moved at will are solved. The large pipeline girth welding operation device comprises a movable positioning base, a girth welding operation face non-coupling adjusting device installed on the movable positioning base and a welding gun installed on the girth welding operation face non-coupling adjusting device. Rollers and a positioning control module are arranged on the movable positioning base, and the positioning control module is in signal connection with the rollers so as to control the rollers to advance, retreat and steer. The welding method comprises the steps that the device moves into a pipeline in a linear mode; the device is positioned and fixed; a welding telescopic mechanical arm is adjusted to the welding seam position; welding is carried out; and the device moves forwards for next-time welding. The large pipeline girth welding operation device is used for girth welding of large pipelines and has the advantages of being convenient to move, high in working precision, high in automation degree and wide in application range.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

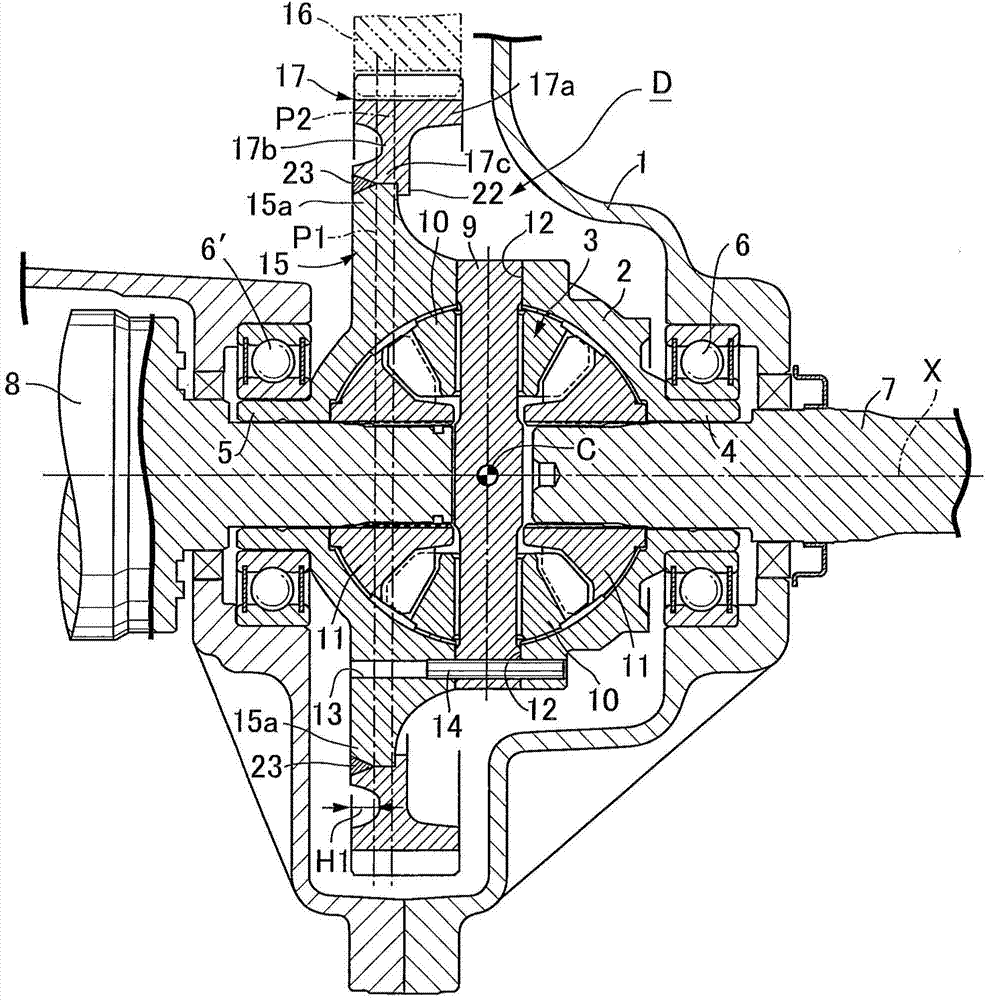

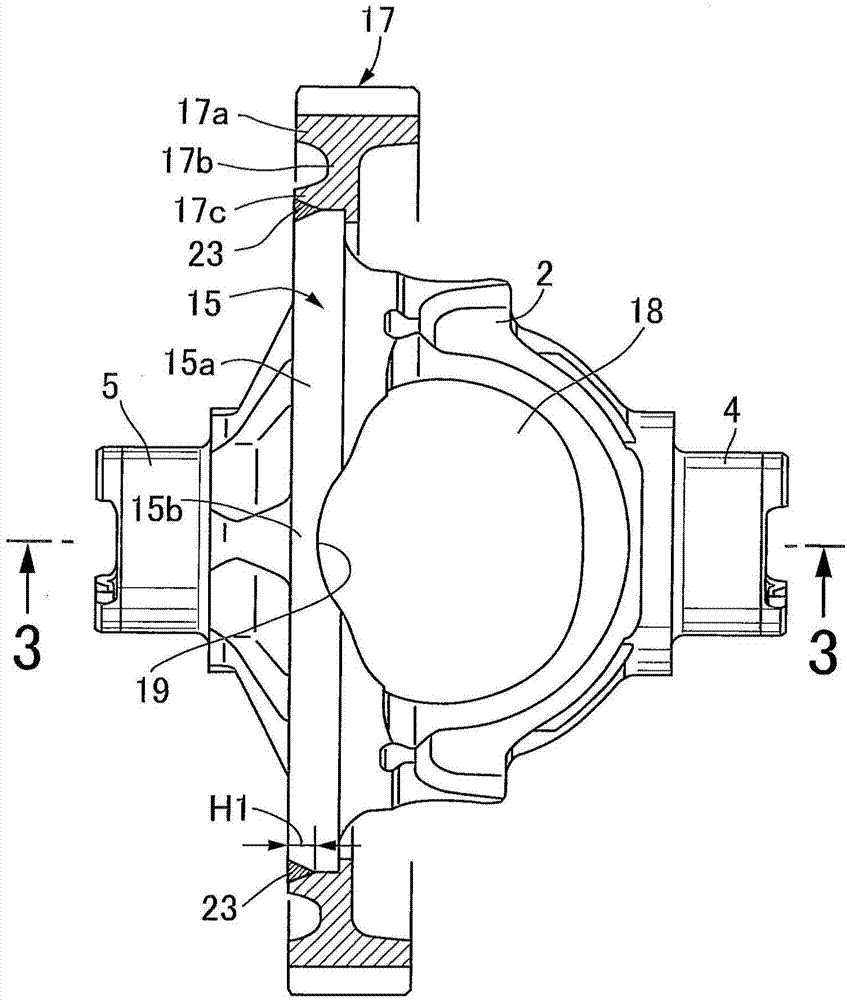

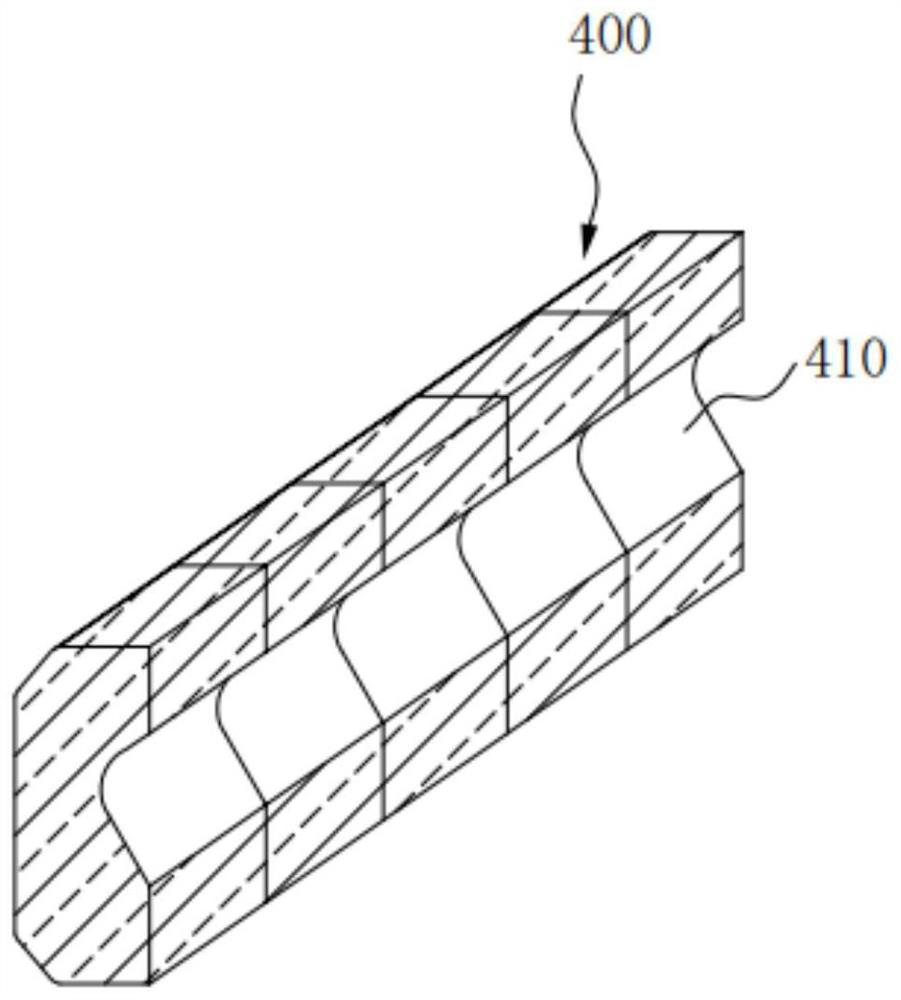

Differential device and method of manufacturing the same

InactiveCN104747681AHigh bonding strengthImprove efficiencyPortable liftingDifferential gearingsFlangeThin walled

In a differential device and a method of manufacturing it, a press-fit regulation device regulating a press fit depth of the flange and the ring gear is provided in a press-fit portion between the flange and the ring gear, the flange includes thin-walled portions with recessed portions and thick-walled portions without the recessed portions, the thick-walled portions and the ring gear are welded from a second bearing boss side to a predetermined weld depth, and the thin-walled portions and the ring gear are welded from the second bearing boss side to a weld depth shallower than the predetermined weld depth or not welded. Accordingly, the press-fit portion between the flange and the ring gear can be efficiently welded even in a case where work windows of a differential case cut into a side surface of the flange on a first bearing boss side to form the recessed portions.

Owner:MUSA PRECISION IND CO LTD

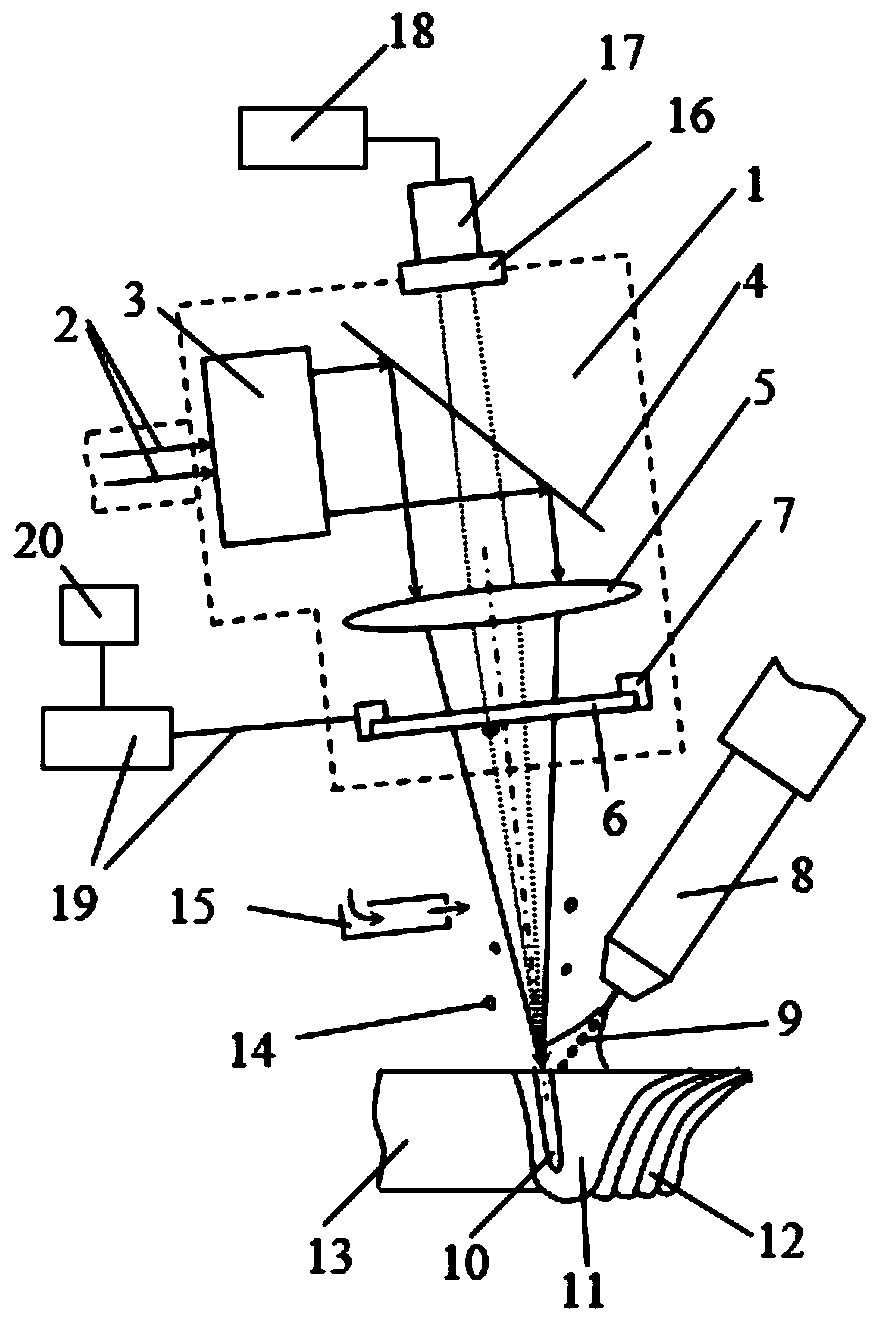

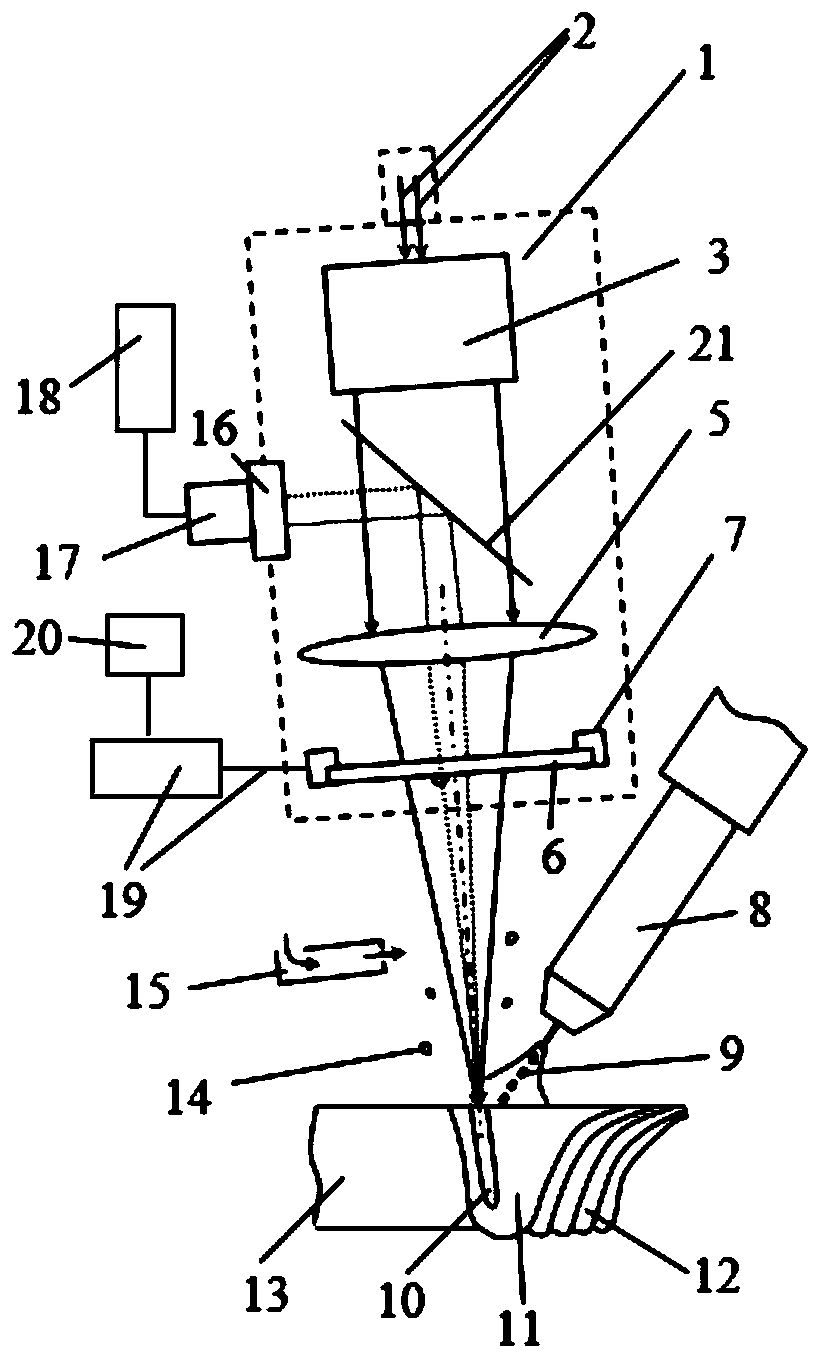

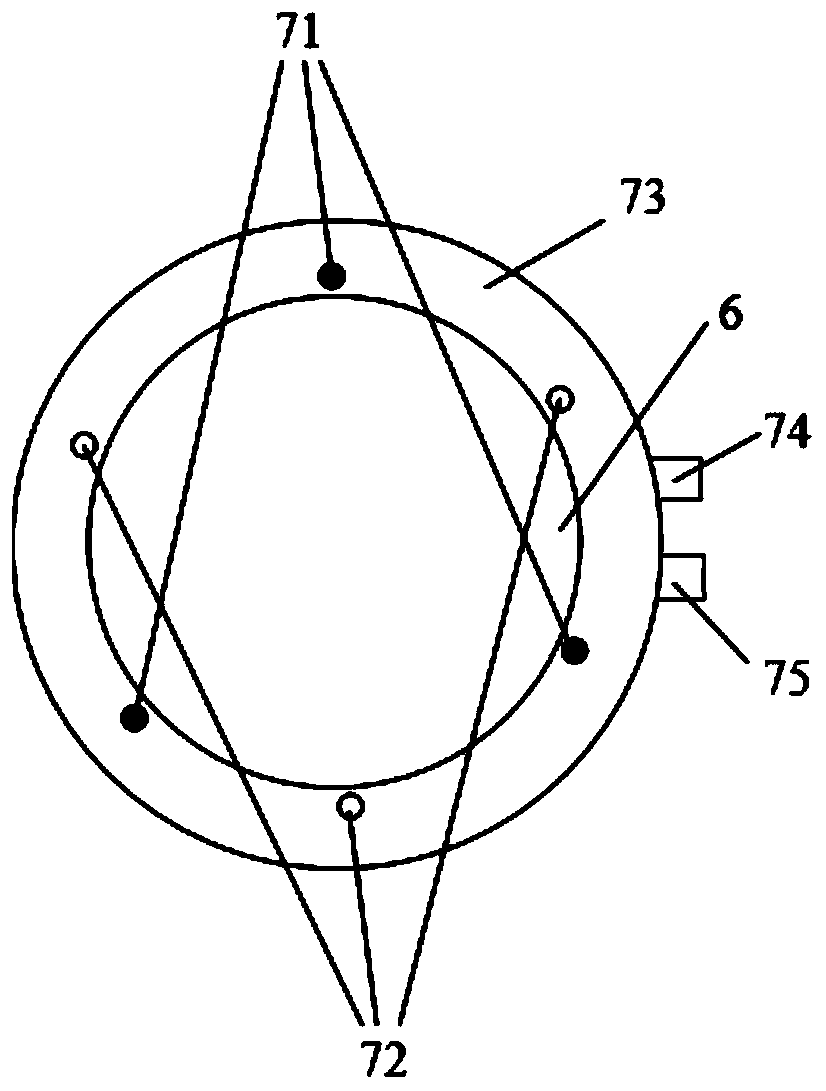

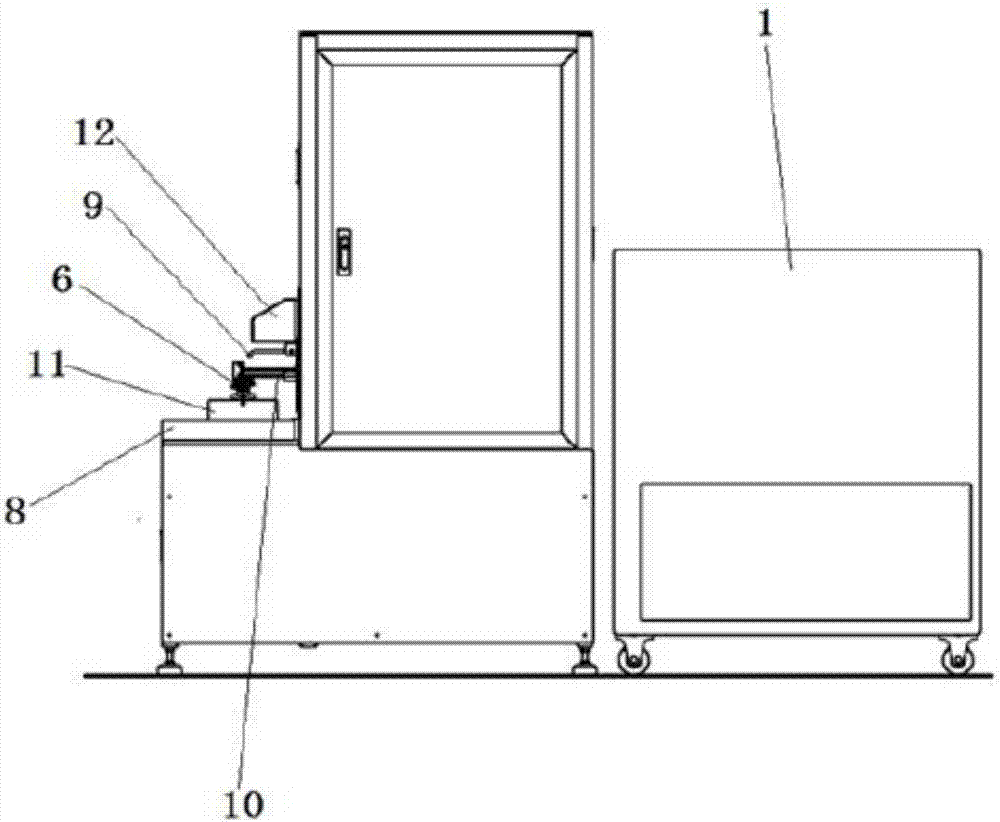

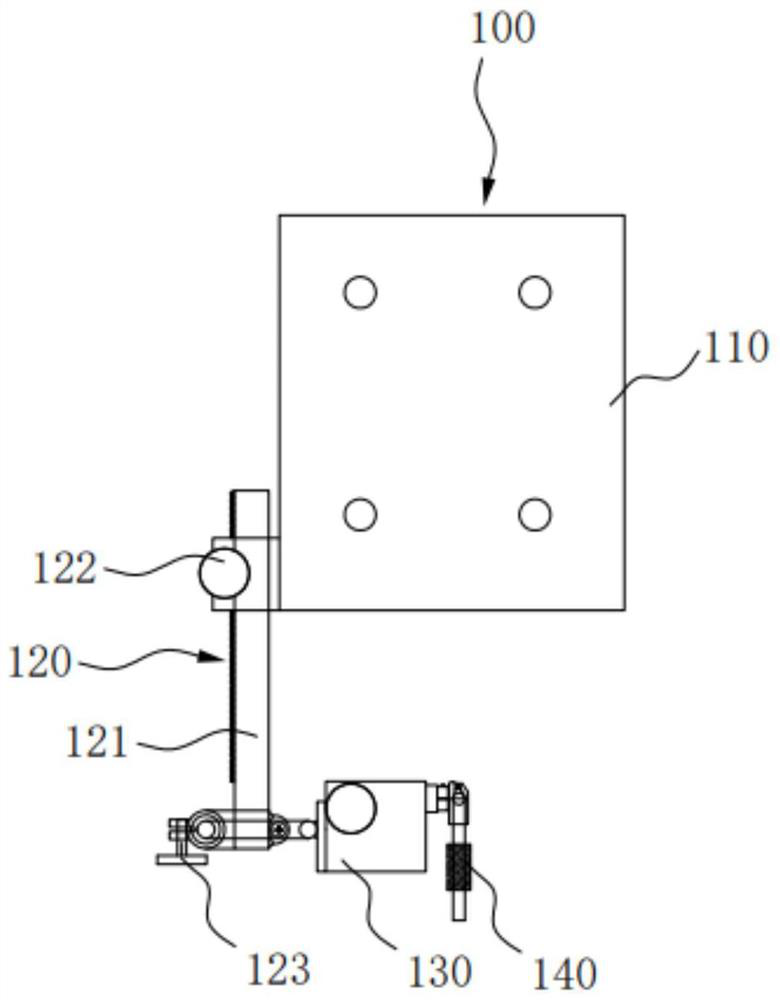

In-situ monitoring device and method for pollution of protective lens for welding laser head

InactiveCN110744213ASolving the conundrum of pollution situationsSolve only before weldingLaser beam welding apparatusEngineeringWelding defect

The invention relates to an in-situ monitoring device and method for pollution of a protective lens for a welding laser head. The in-situ monitoring device comprises the protective lens, a monitoringassembly, a data analysis assembly and an executing terminal; the monitoring assembly is used for monitoring the pollution situation of a laser transmission area on the protective lens; the data analysis assembly is used for calculating the polluted area of the laser transmission area on the protective lens in real time, and the polluted area is compared with a preset threshold value; and when thepolluted area calculated by the data analysis assembly is larger than the preset threshold value, the executing terminal executes a welding interrupt instruction, and the welding laser head stops welding. The welding process of continuous welding defects caused by serious pollution of the protective lens can be stopped in time, subsequent defect elimination and welding continuing are convenient,the obsolescence risk of weldments is lowered to the utmost extent, and the welding pass percentage is further increased.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

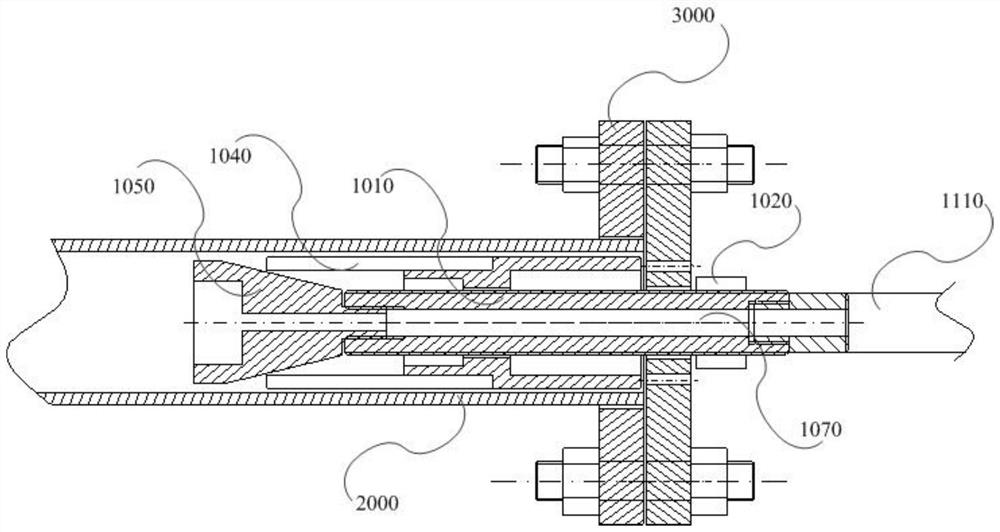

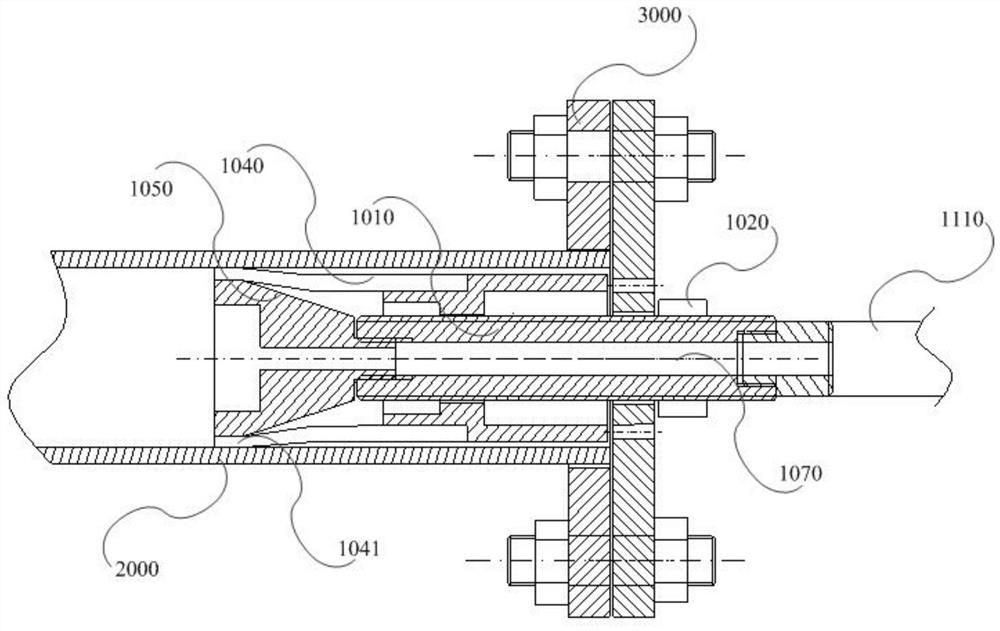

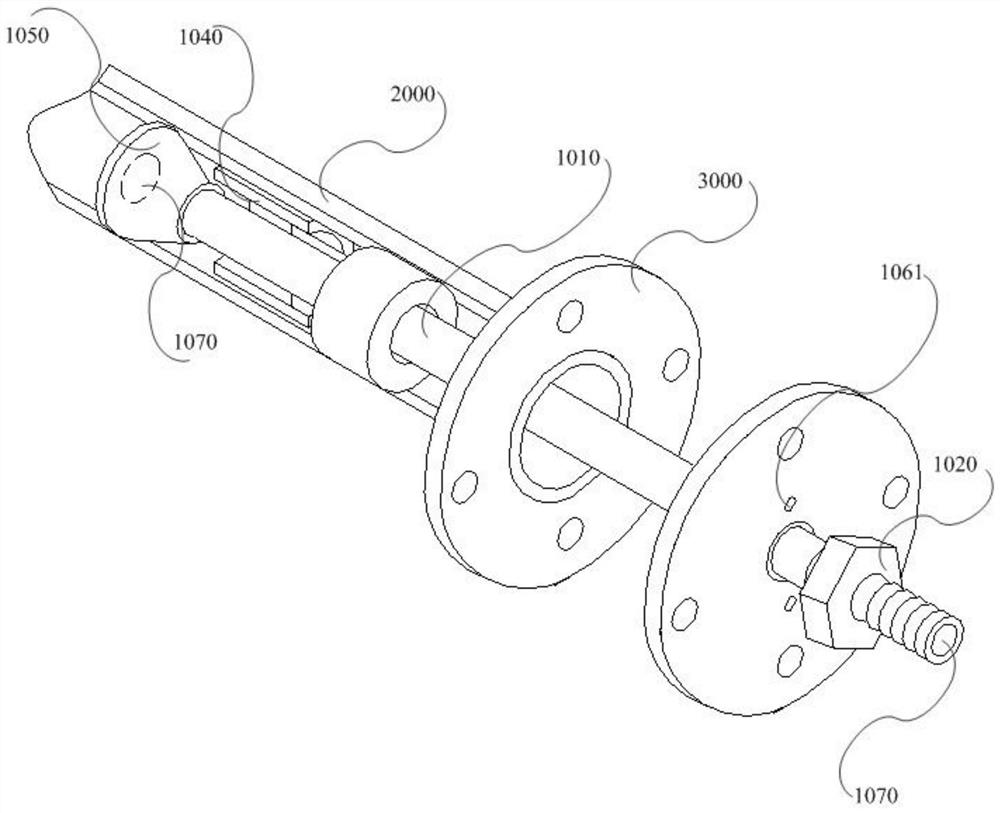

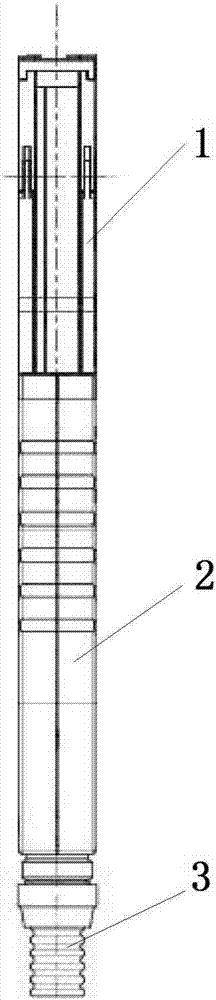

Pipeline welding and plugging device

PendingCN112344126AImprove the efficiency of welding operationsImprove efficiencyFlanged jointsPipe elementsSlag (welding)Mechanical engineering

The invention provides a pipeline welding and plugging device, and relates to the technical field of pipeline welding. The pipeline welding and plugging device provided by the invention is used for plugging a pipeline when a preset flange and the pipeline are welded. The pipeline welding and plugging device comprises a pull rod, wherein an expansion head is connected to the first end of the pull rod, and an air guide hose is connected to the second end; and a screwing nut sleeves the second end of the pull rod, and the pull rod and the expansion head fixed to the pull rod axially move relativeto the pipeline by rotating the screwing nut so as to seal the pipeline. By using the pipeline welding and plugging device, the safety of welding operation is facilitated. Impurities such as high-temperature welding slags can be prevented from entering the to-be-connected pipeline, and the service life of the pipeline can be prolonged.

Owner:PETROCHINA CO LTD

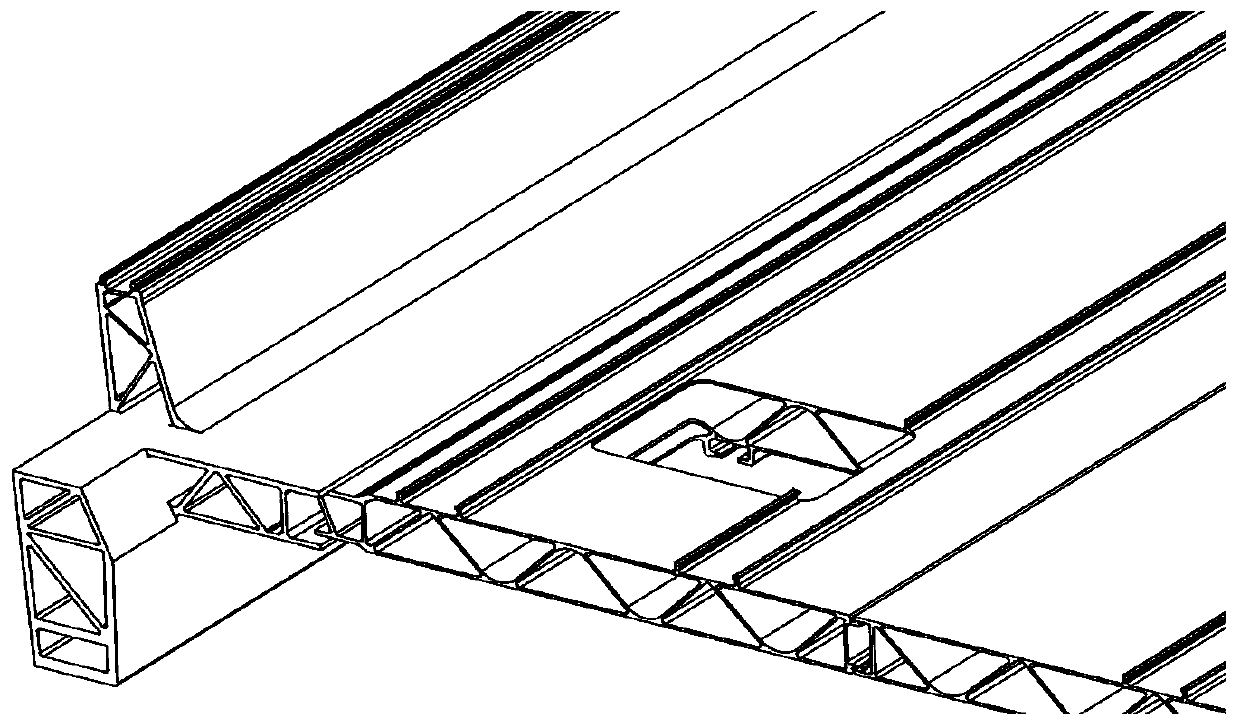

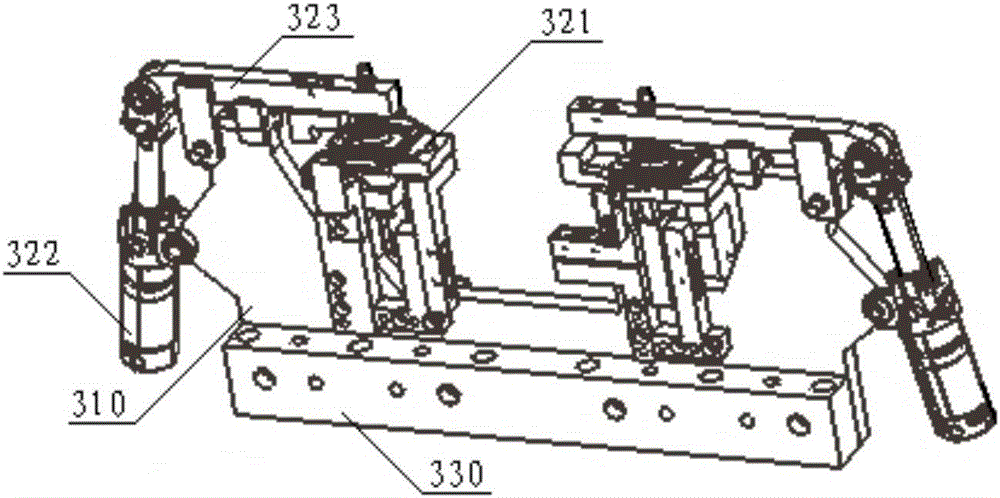

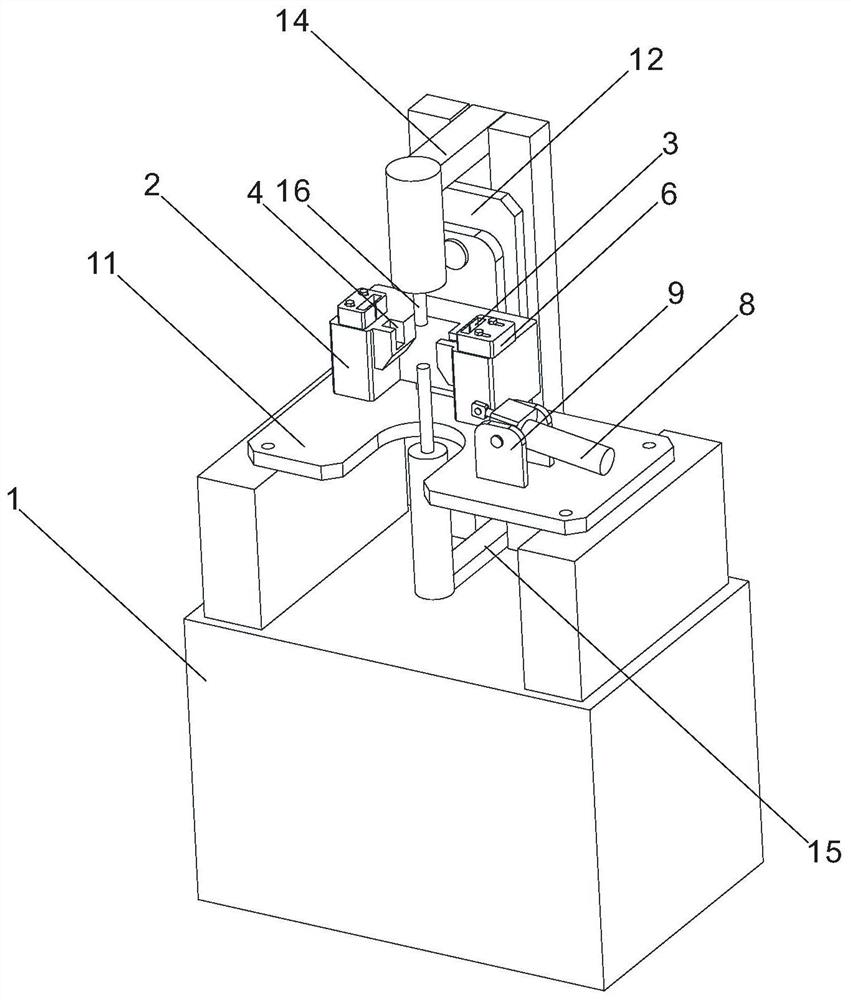

Tool clamp for welding and manufacturing aluminum alloy trapezoid steel structures

InactiveCN111151951ATurn up the economical practicalityEnsure consistencyWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention provides a tool clamp for welding and manufacturing aluminum alloy trapezoid steel structures. The tool clamp comprises a bottom plate mechanism, executing mechanisms and a fastening mechanism. The executing mechanisms are symmetrically installed on the bottom plate mechanism. The fastening mechanism is installed on the bottom plate mechanism. The fastening mechanism is located between the two executing mechanisms. The problems that welding or a flange and screw connecting structure is usually adopted for splicing at present, two welding pieces need to be adjusted to a proper angle and then fixed during welding, then welding is performed, and when the steel structures are welded, since the butt joint between the two steel structures is not stable, the welding effect is not good and the welding position deviates, which quite easily occurs can be solved.

Owner:吴露露

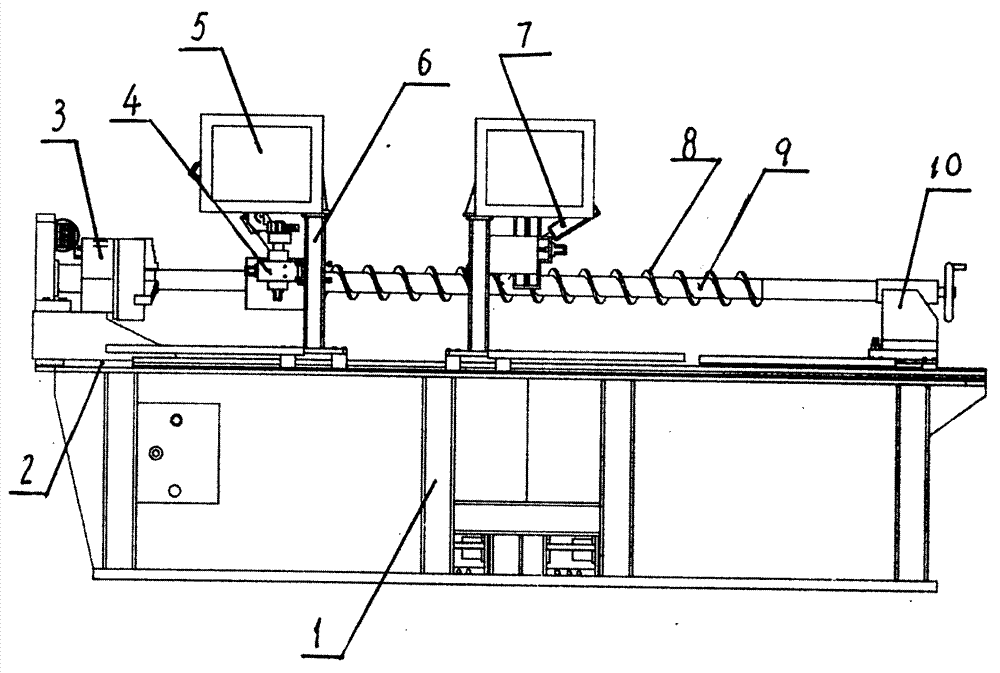

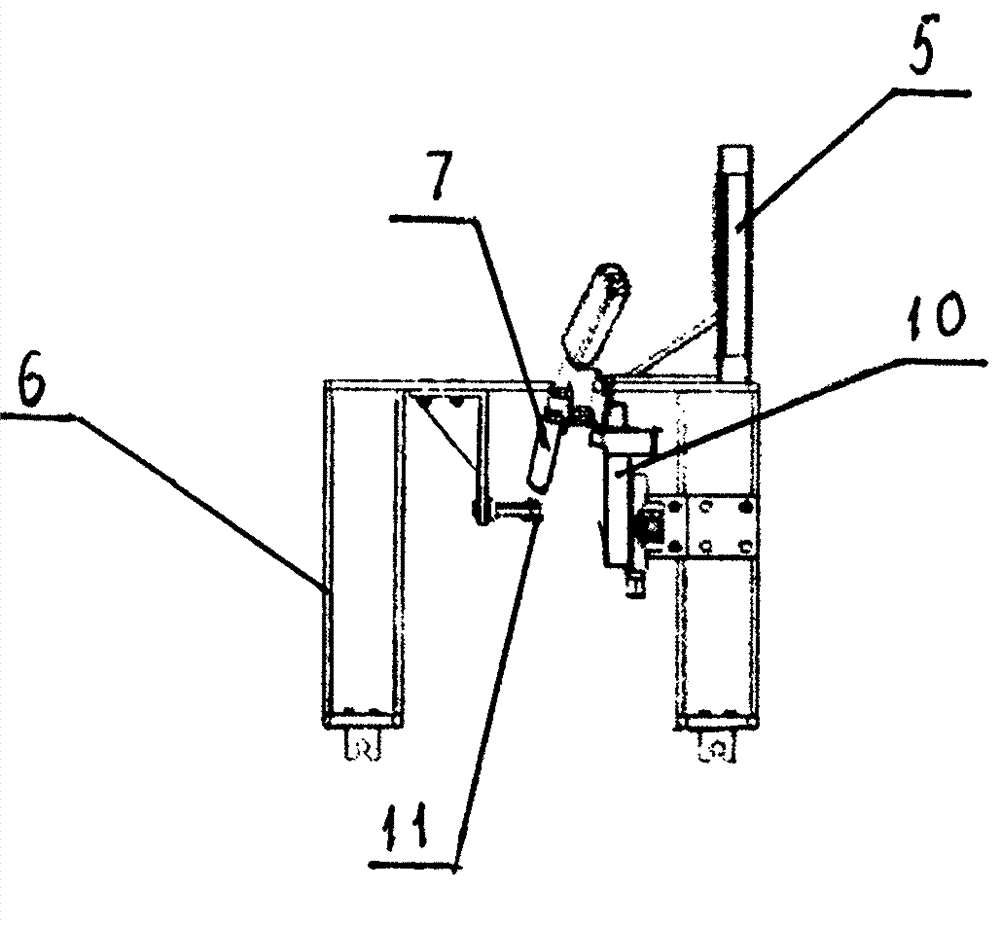

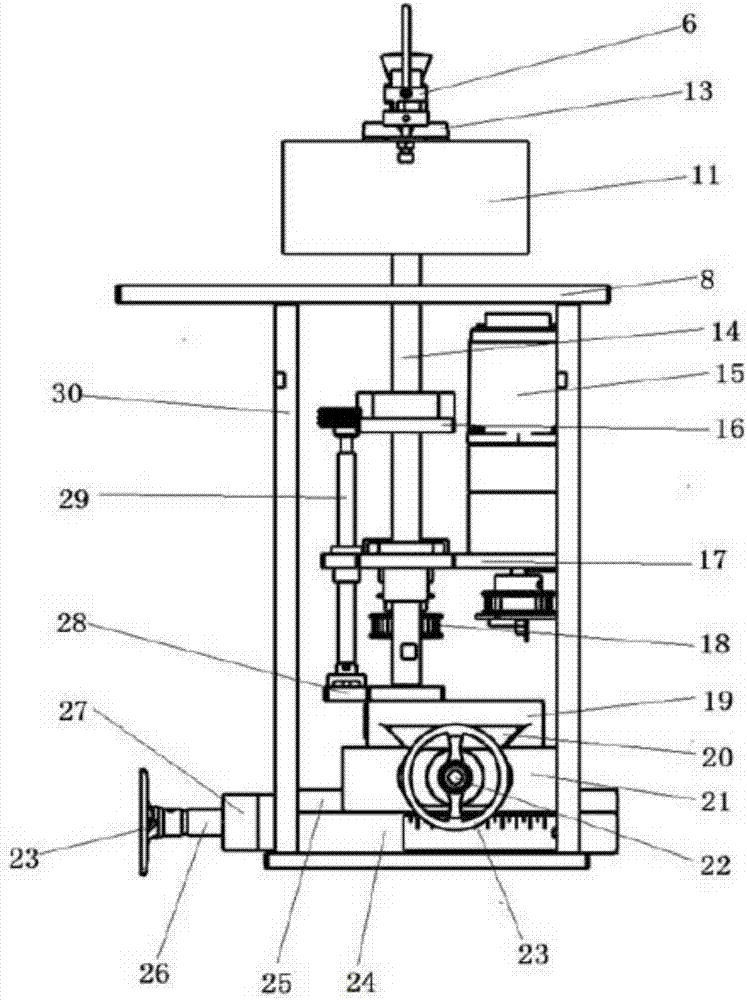

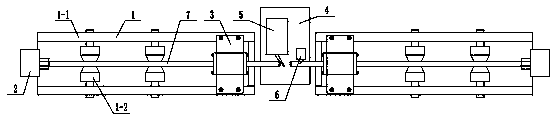

Automatic welding device for auger stem fin

InactiveCN104708246ASimple structureHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention provides an automatic welding device for an auger stem fin, and belongs to welding equipment. The automatic welding device for the auger stem fin comprises a machine body, a guide rail, a headstock box and a tailstock, wherein the guide rail, the headstock box and the tailstock are assembled on the machine body. Two movable frames which are matched with the guide rail and can transversely move are assembled on the machine body. Fine adjustment assemblies, anti-arc light boards and idler wheels are arranged on the movable frames. Welding guns are installed on the fine adjustment assemblies. By the adoption of the automatic welding device, the auger stem fin and a fin shaft are automatically welded in a gas protective welding mode, the structure is simple, the automation degree and welding operation efficiency are high, adjustment is easy and convenient, welding operation quality is good, operation labor intensity is low, and the application range is wide.

Owner:HARBIN LONGFEI WELDING EQUIP

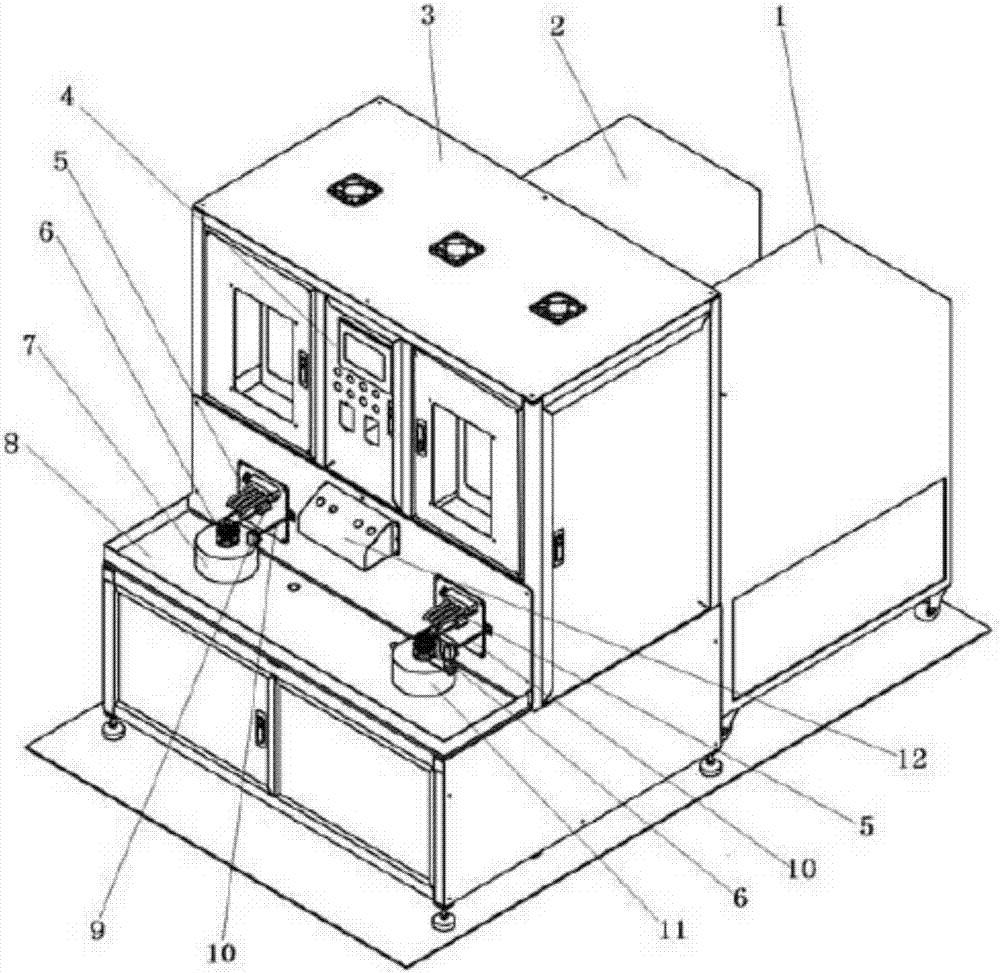

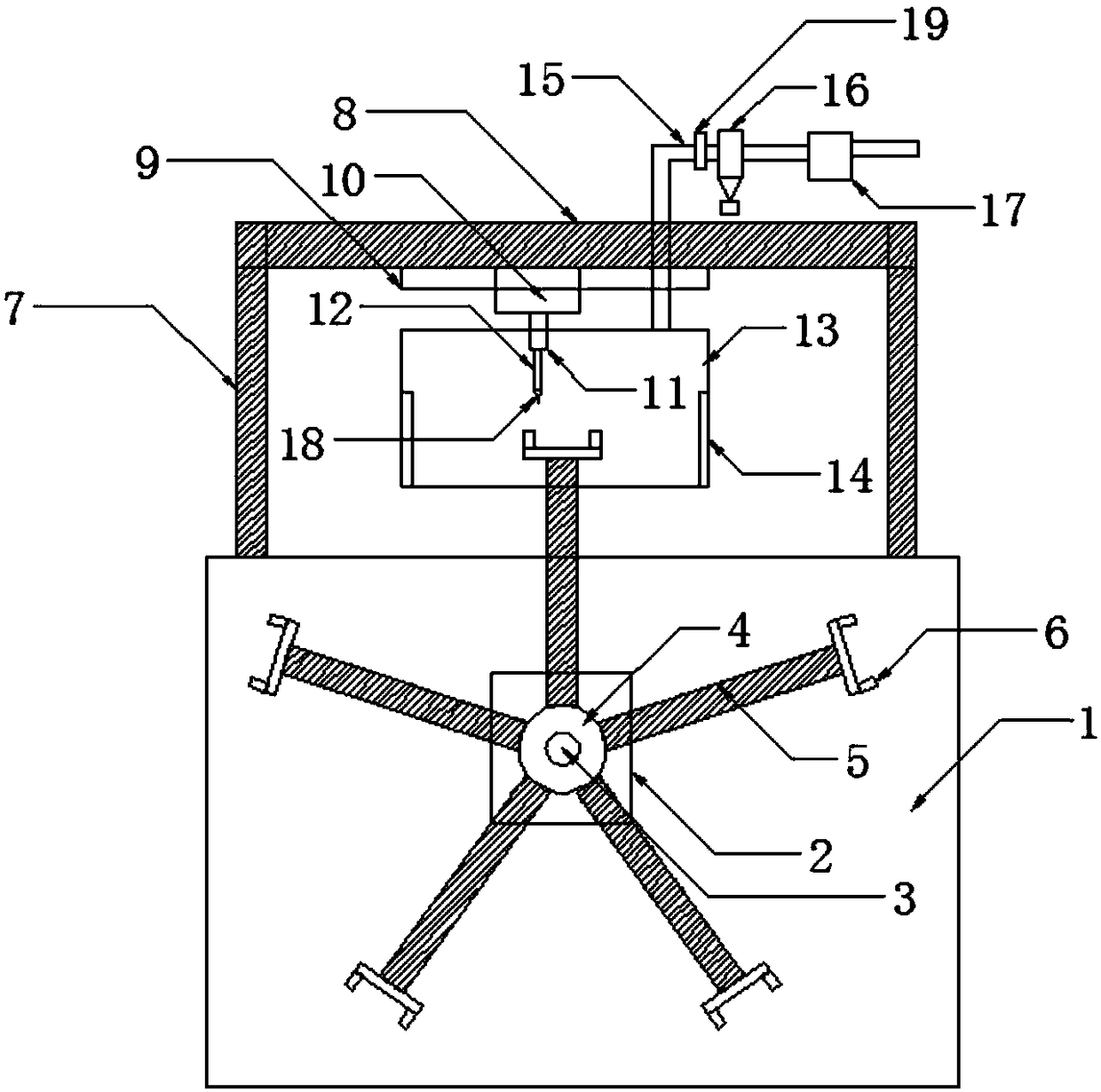

Welding machine for distributor welding

InactiveCN107009056ANo oxidationImprove the efficiency of welding operationsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringNitrogen gas

The invention discloses a welding machine for distributor welding. The welding machine comprises a protection cover in the middle of a rack. A horizontal welding platform is arranged at the position, on the front side of the protection cover, of the rack. A nitrogen cooling head, a brazing head and a water cooling head are arranged at the positions, on the upper side of each work station, of the protection cover. A triaxial adjusting device for adjusting the positions of a carrier and a distributor on the corresponding work station is arranged at the position, below each work station, of the rack. The positions of the carriers and the distributors on the work stations can be prepared and adjusted conveniently and efficiently through the triaxial adjusting devices, and therefore the welding work process is cooperated effectively, welding work efficiency and precision are improved, and product quality is ensured. Meanwhile, a double cooling mode of water cooling and nitrogen cooling is adopted, efficient cooling on the distributors in the welding process is ensured, and the optimum quality of a product is ensured. Nitrogen is adopted as protection gas, it can be ensured that the distributors are not oxidized in the welding process, and the optimum attractiveness effect and quality of the product are guaranteed.

Owner:SUZHOU HONGCHUANG HIGH FREQUENCY HEATING EQUIP CO LTD

Combined type multifunctional welding rotating tire

ActiveCN109014758AAvoid restrictionsMeet welding needsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

Owner:CSR CHENGDU

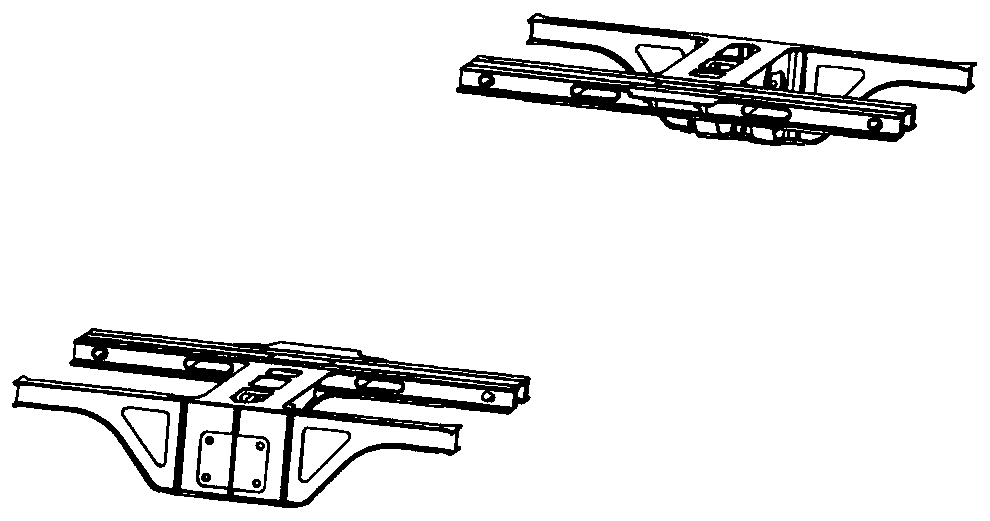

Manufacturing method of subway vehicle chassis

ActiveCN111015036AFast assemblyImprove dimensional accuracy after weldingWelding/cutting auxillary devicesAuxillary welding devicesAutomotive engineeringChassis

The invention discloses a method for manufacturing a subway vehicle chassis, which mainly comprises the following steps of: 1, a chassis boundary beam I, a plurality of floor profiles and a chassis boundary beam II are assembled and welded to obtain a prefabricated chassis; 2, the prefabricated chassis is taken out of a jig to be adjusted and repaired; 3, the adjusted and repaired prefabricated chassis is in a reverse installation state, a traction bolster and a chassis end beam are assembled and welded, and an intermediate chassis is obtained; 4, the welded intermediate chassis is transferredout of the jig, and flame adjustment and repair are conducted; and 5, the adjusted middle chassis is carried out, and accessories are installed to obtain the subway vehicle chassis. Before parts suchas the traction bolster, the end beam and the like are assembled and welded, the chassis boundary beams and the floor profile are assembled; therefore, the assembly of the chassis boundary beams andthe floor profile can meet two different assembly modes of inserting connection and overlapping connection, the problem that the floor cannot be placed into a mould and assembled after the boundary beams are positioned in the connection mode of the chassis boundary beams and the floor of an inserting connection structure is solved, and the manufacturing period of the chassis is effectively shortened.

Owner:河北京车轨道交通车辆装备有限公司

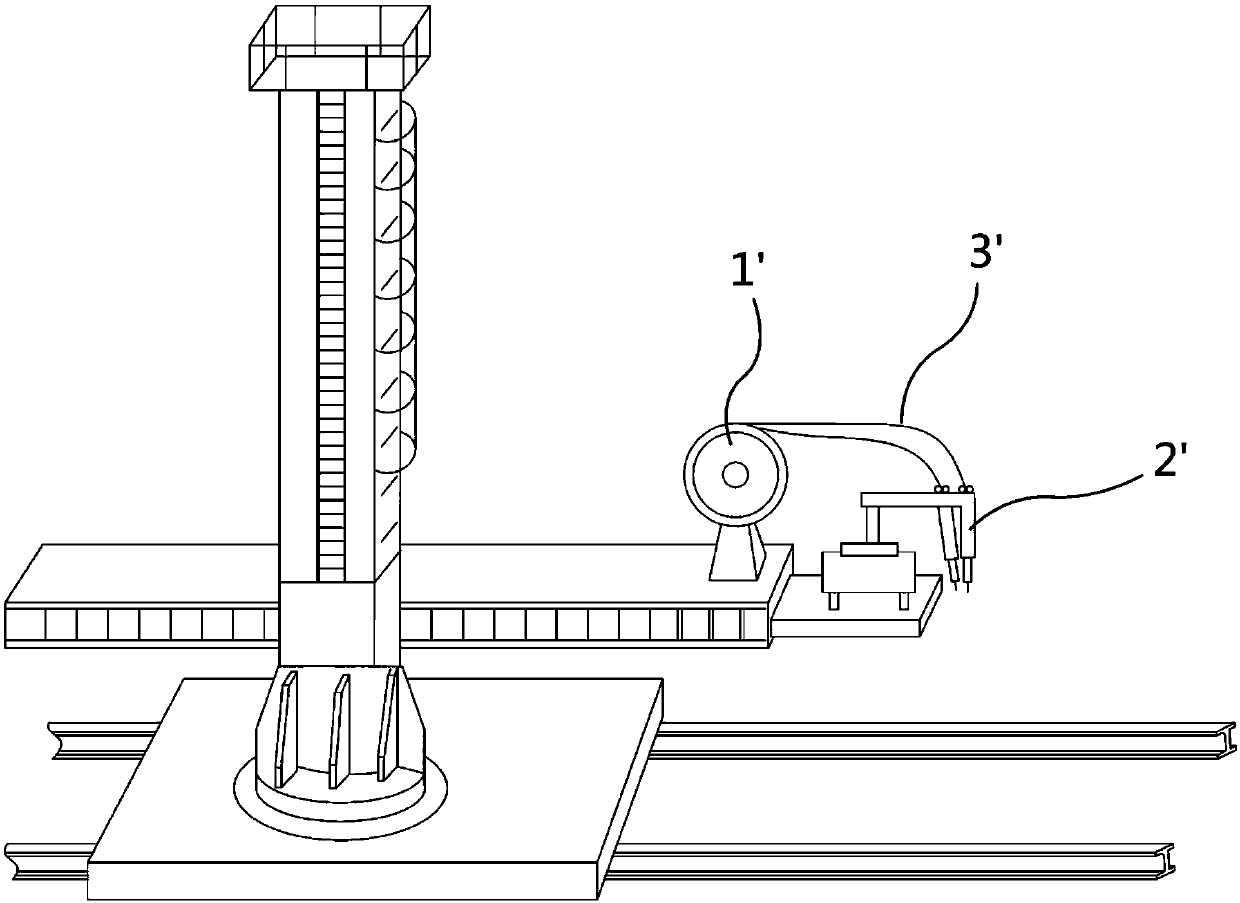

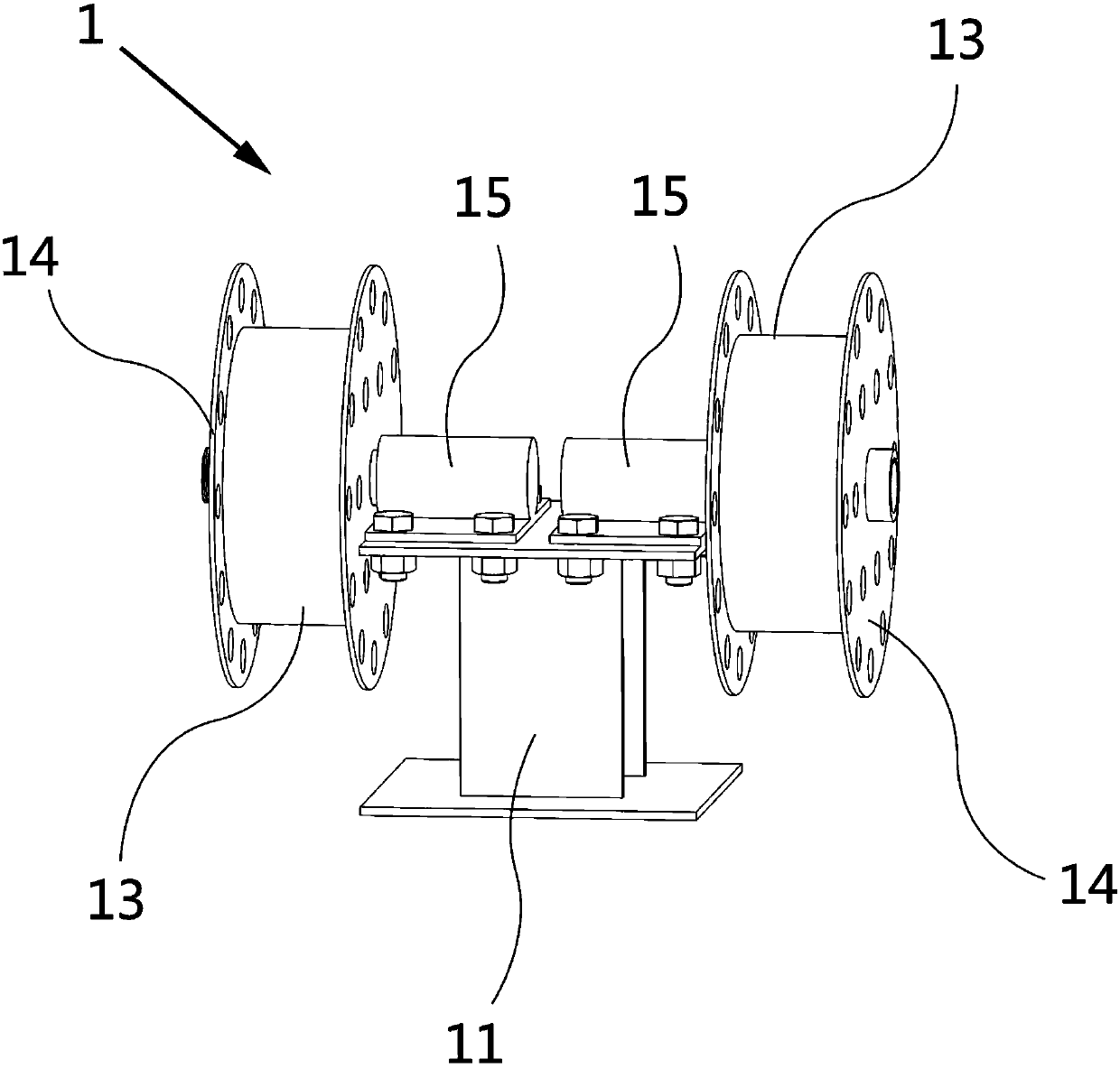

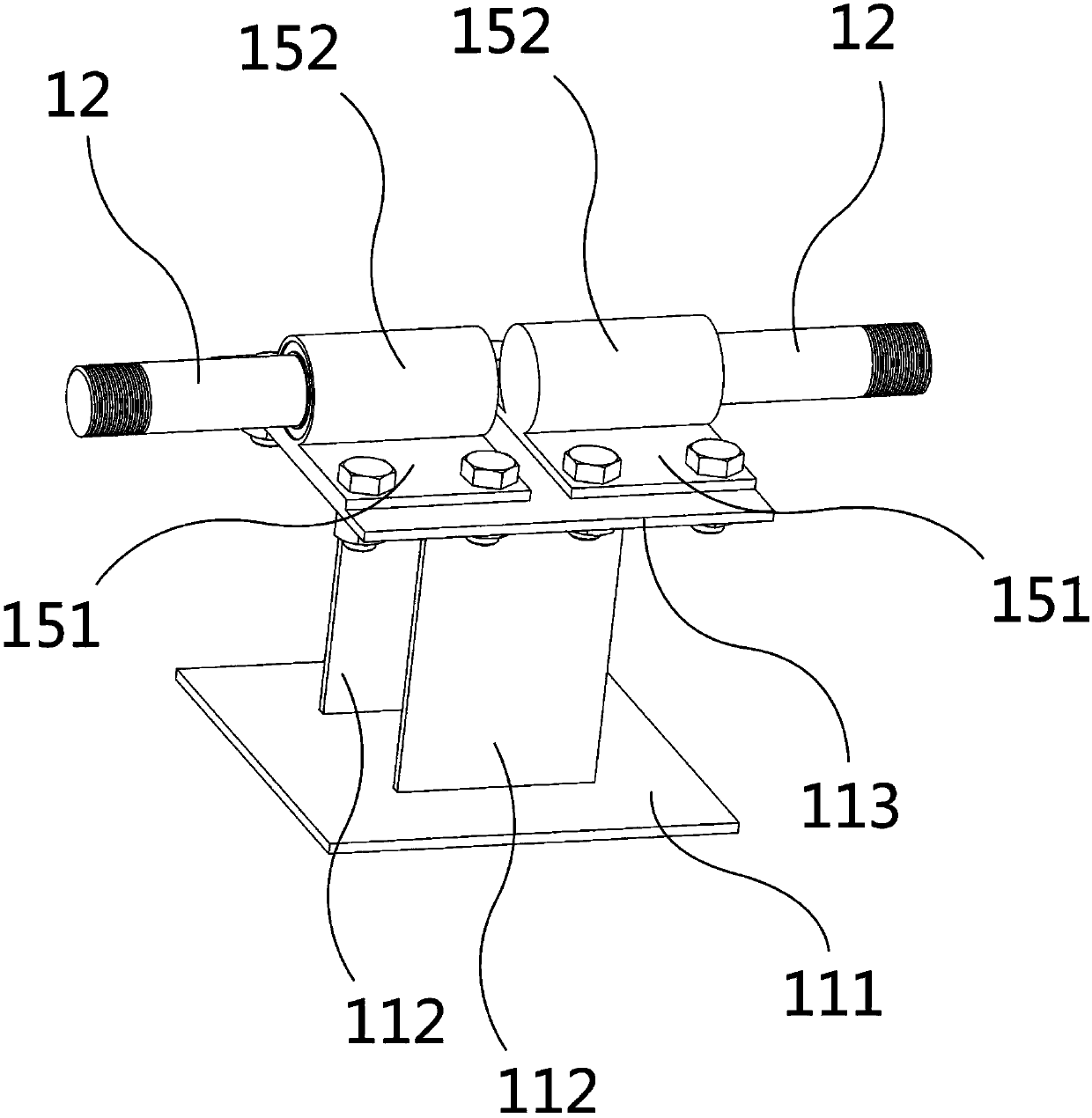

Wire reel and double-wire submerged arc automatic welding equipment with same

InactiveCN109807436AImproved loading capacityReduce replacement frequency and hoisting workloadArc welding apparatusQuenchingEngineering

The invention provides a wire reel and double-wire submerged arc automatic welding equipment with the same. The wire reel comprises a support and at least two rotating shafts, wherein each rotating shaft is connected to the support, rotating parts are arranged on the rotating shafts in a sleeved mode, the rotating parts rotate around the rotating shafts, and welding wires wind around the rotatingparts; an end parts, away from the support, of the rotating shafts are connected with end covers, the end covers are used for limiting the rotation of the rotating parts between the end covers and thesupport; the equipment comprises a guide rail, a sliding platform, a stretchable arm and a welding machine head, wherein the sliding platform is arranged on the guide rail and slides along the guiderail, the stretchable arm is arranged on the sliding platform, a welder head is arranged on the stretchable arm, the wire reel is arranged on the sliding platform, and the welding wires are connectedto the welder head in a welding mode. According to the wire reel, the loading capacity of the wire reel is improved, the loading capacity of the welding wires is improved from the original 25 kg to 350 kg, so that the replacement frequency and the hoisting operation amount of the welding wires are greatly reduced, the arcing and arc quenching times caused by replacement of the welding wires is reduced, and the welding operation efficiency and the safety are improved.

Owner:SHANGHAI TAISHENG WIND POWER EQUIP

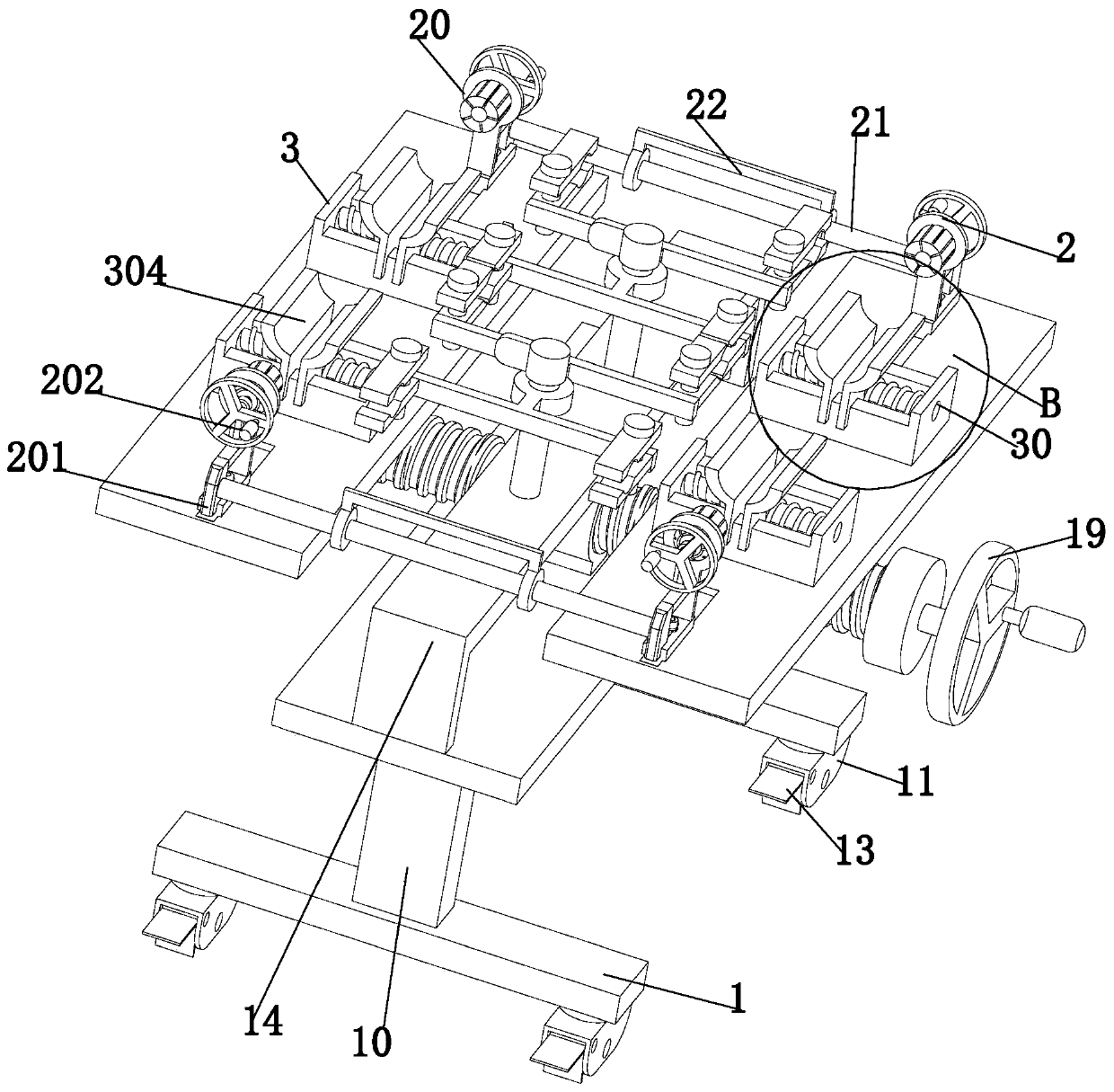

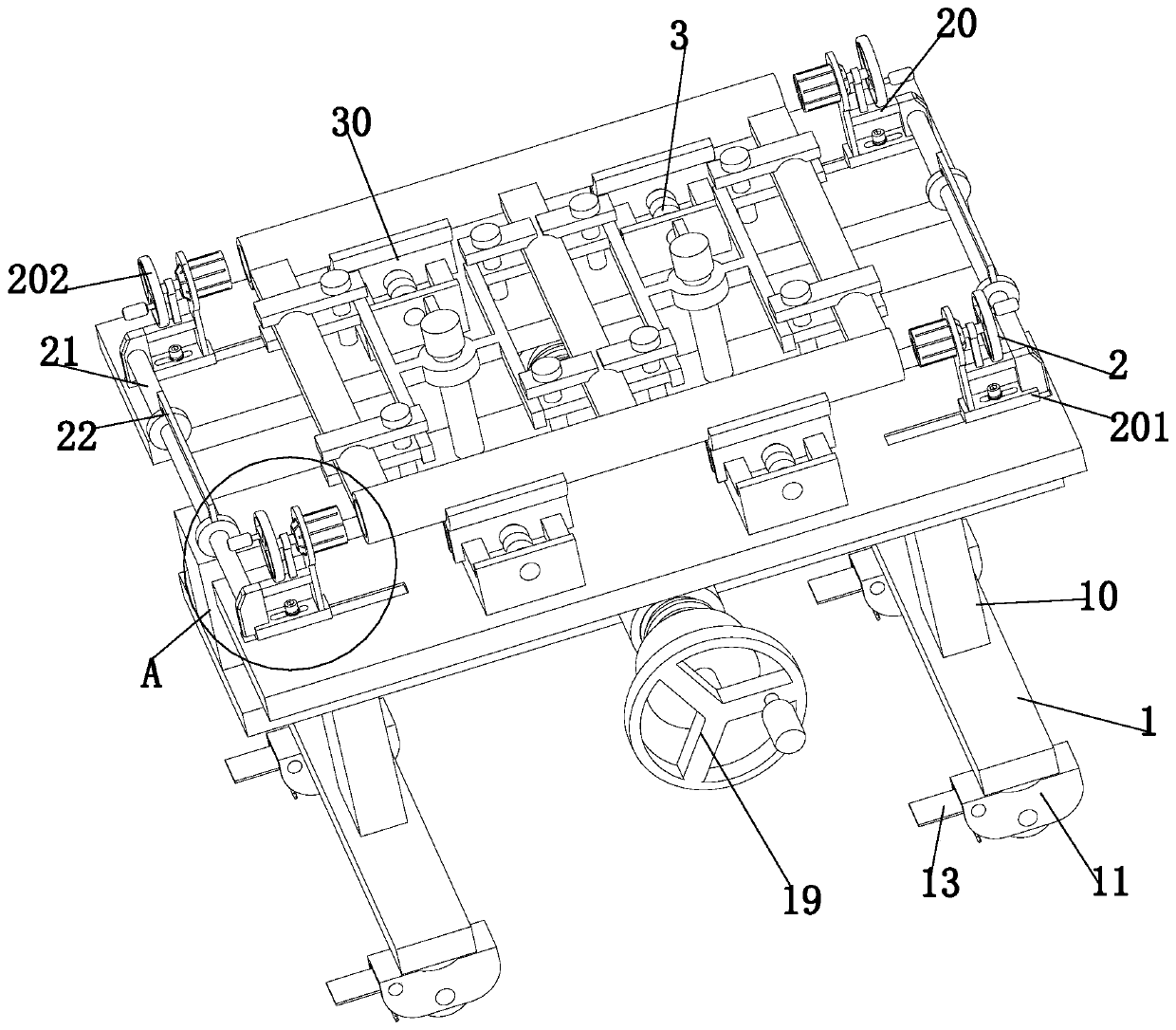

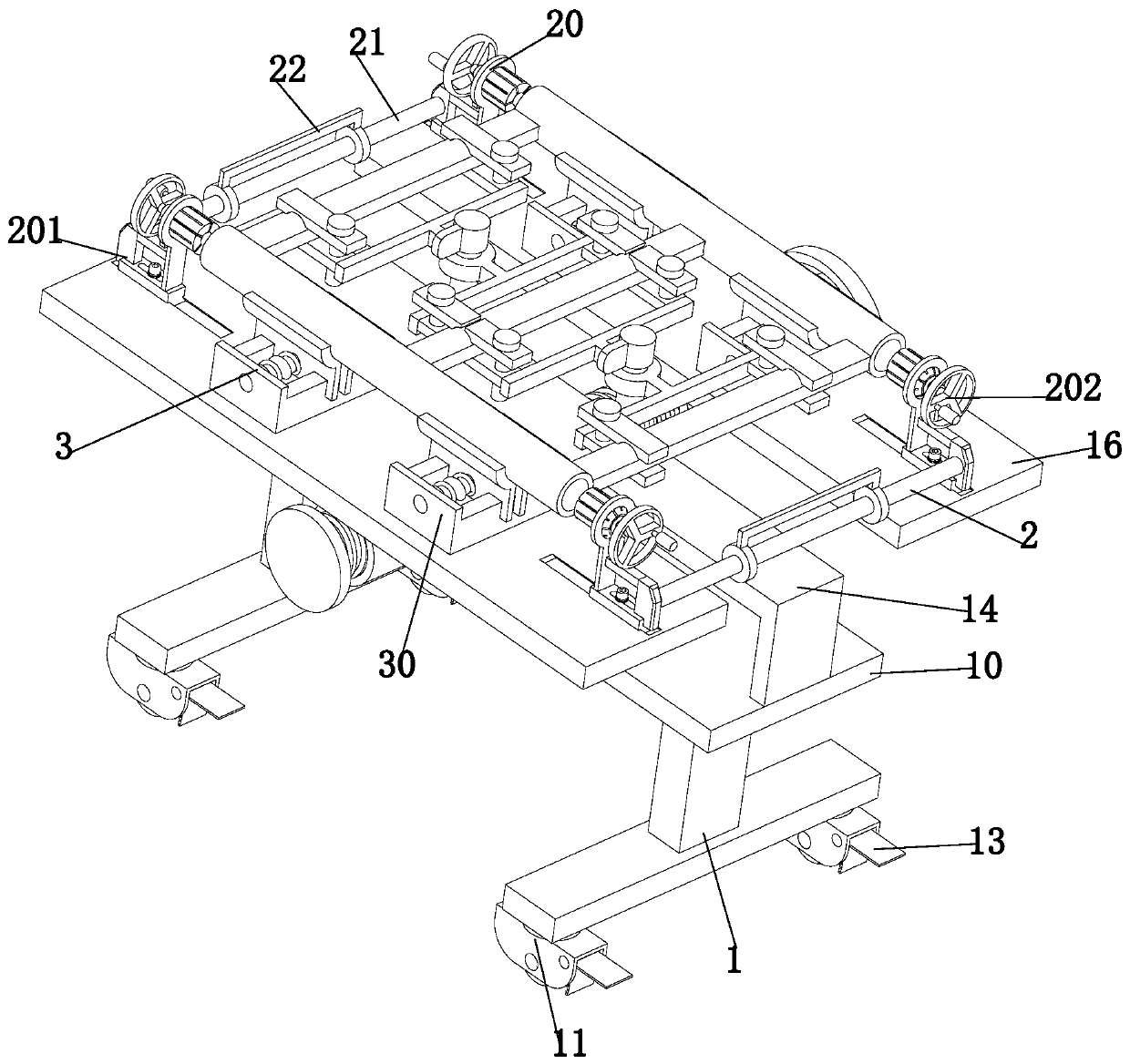

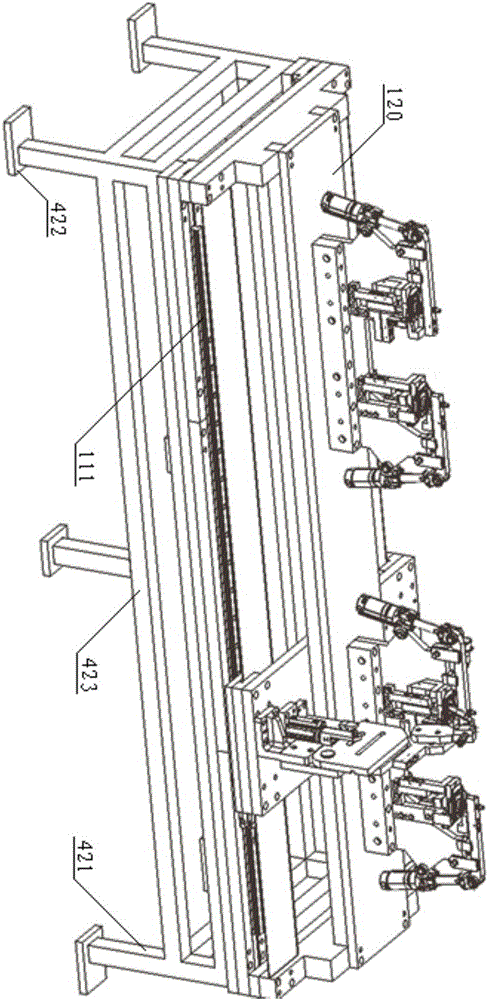

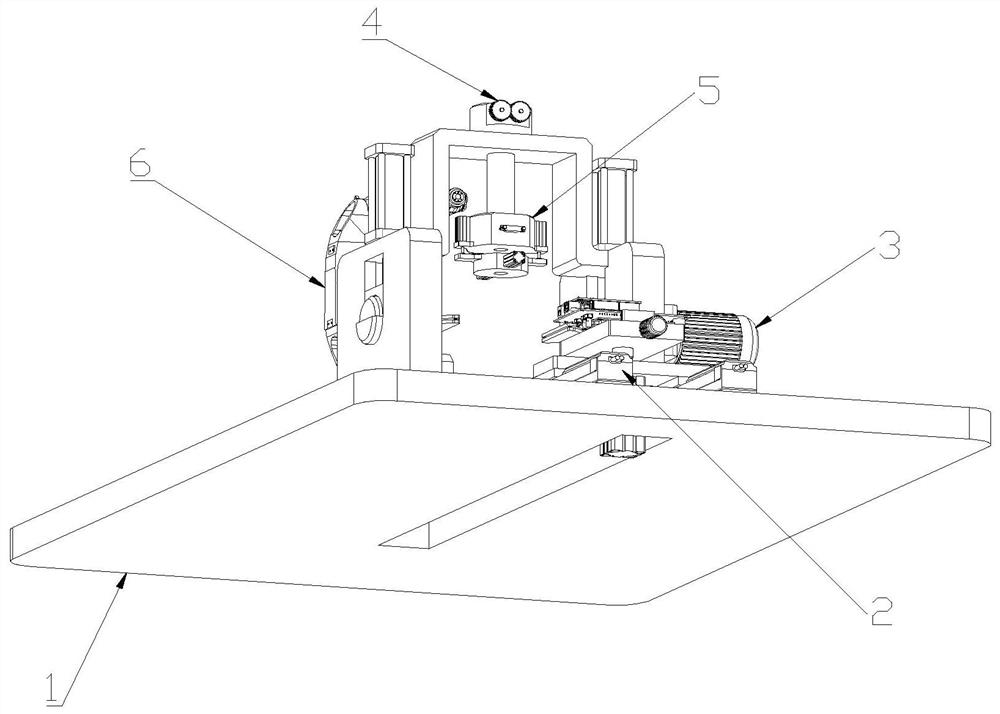

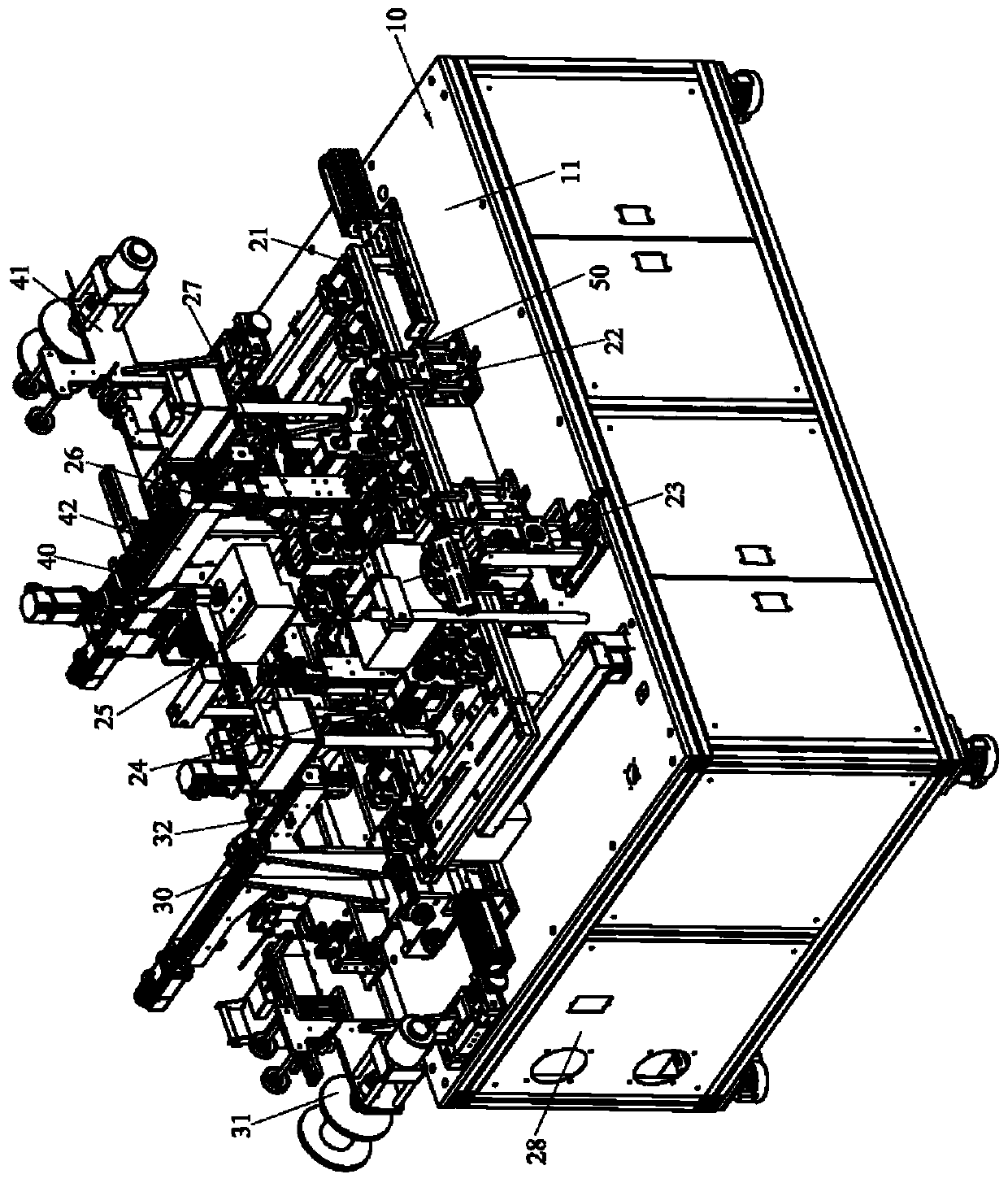

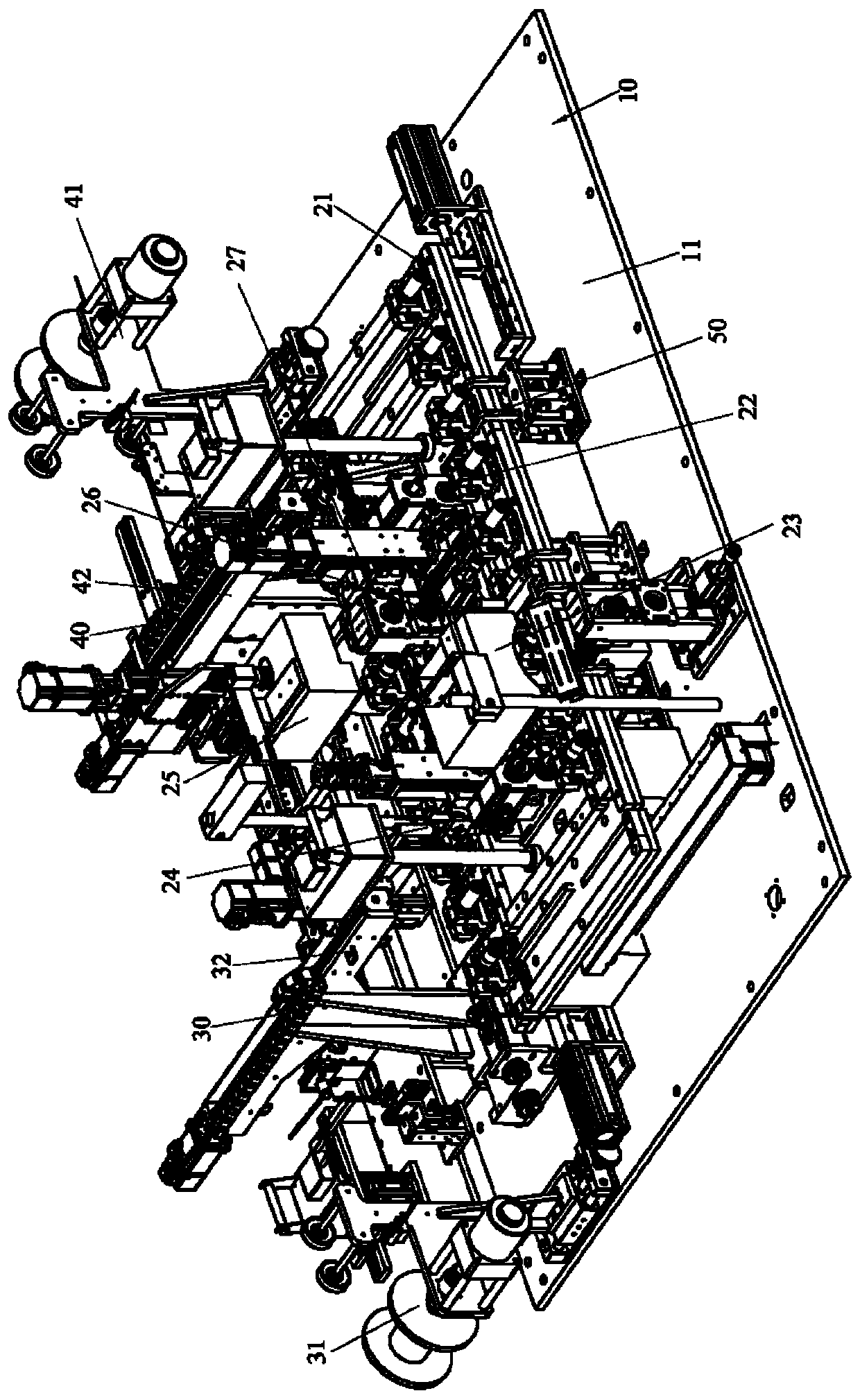

Welding process of rail-mounted automatic welding equipment

ActiveCN106826035AImprove the efficiency of welding operationsSolution efficiency is not highWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention relates to a welding process of rail-mounted automatic welding equipment. The rail-mounted automatic welding equipment comprises an equipment base rack, a double-welding-gun welding device and a to-be-welded part fixing device set, wherein the equipment base rack is provided with welding gun moving rails and a to-be-welded part fixing device set base plate, the double-welding-gun welding device comprises two welding gun devices, the to-be-welded part fixing device set comprises a plurality of to-be-welded part fixing devices, each to-be-welded part fixing device comprises a clamp component plate rack, an air cylinder clamp component is arranged on each of the left end and the right end of each clamp component plate rack, each air cylinder clamp component comprises a to-be-welded part platform and an air cylinder compression arm device, and each air cylinder compression arm device comprises a compression air cylinder and a compression arm. The welding process includes: placing to-be-welded parts, welding from two sides, taking the to-be-welded parts, and the like. The welding process has the advantages that the rail-mounted double-welding-gun welding equipment is used to complete welding operation, and the welding efficiency of same-kind batch welding is high.

Owner:上海众达汽车冲压件有限公司

Enclosed nose for butt welding of high-temperature fused salt collector tubes

InactiveCN107363383ASimple structureReduce volumeMetal working apparatusTubular articlesButt weldingPlate pressure

The invention discloses an enclosed nose for butt welding of high-temperature fused salt collector tubes; the enclosed nose comprises an insulating body, a handle and a harness. The enclosed nose of the invention is simple in structure, small in size and convenient to use and is particularly suitable for welding operations with a gap of less than 36 mm where the nose may enter for welding; a plate pressure spring is arranged on one side of a C-shaped gear of the insulating body, so that good contact is ensured between the C-shaped gear and a copper sleeve, and stable power supply for welding is ensured; a housing of the insulating body includes two parts fastened in closing manner, so that equipment maintenance and detection are facilitated, time wasted for nose maintenance is shortened, and welding efficiency is improved indirectly.

Owner:TIANJIN BINHAI PHOTOTHERMAL TRACKING TECH CO LTD

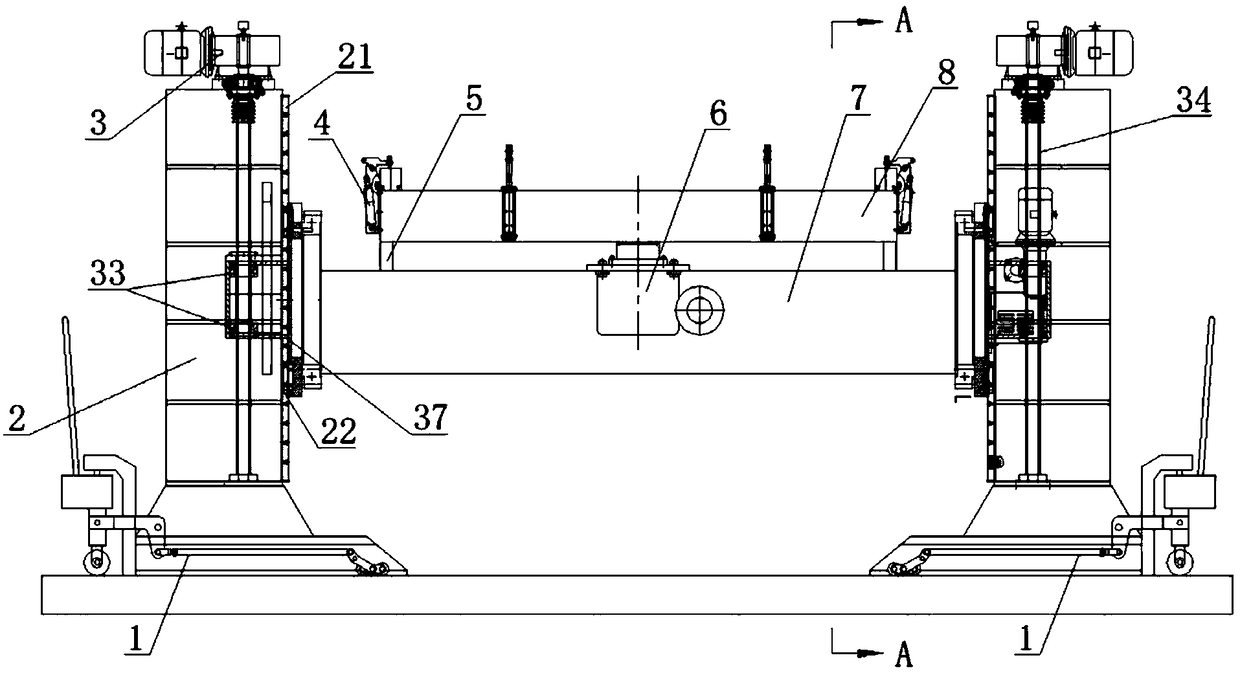

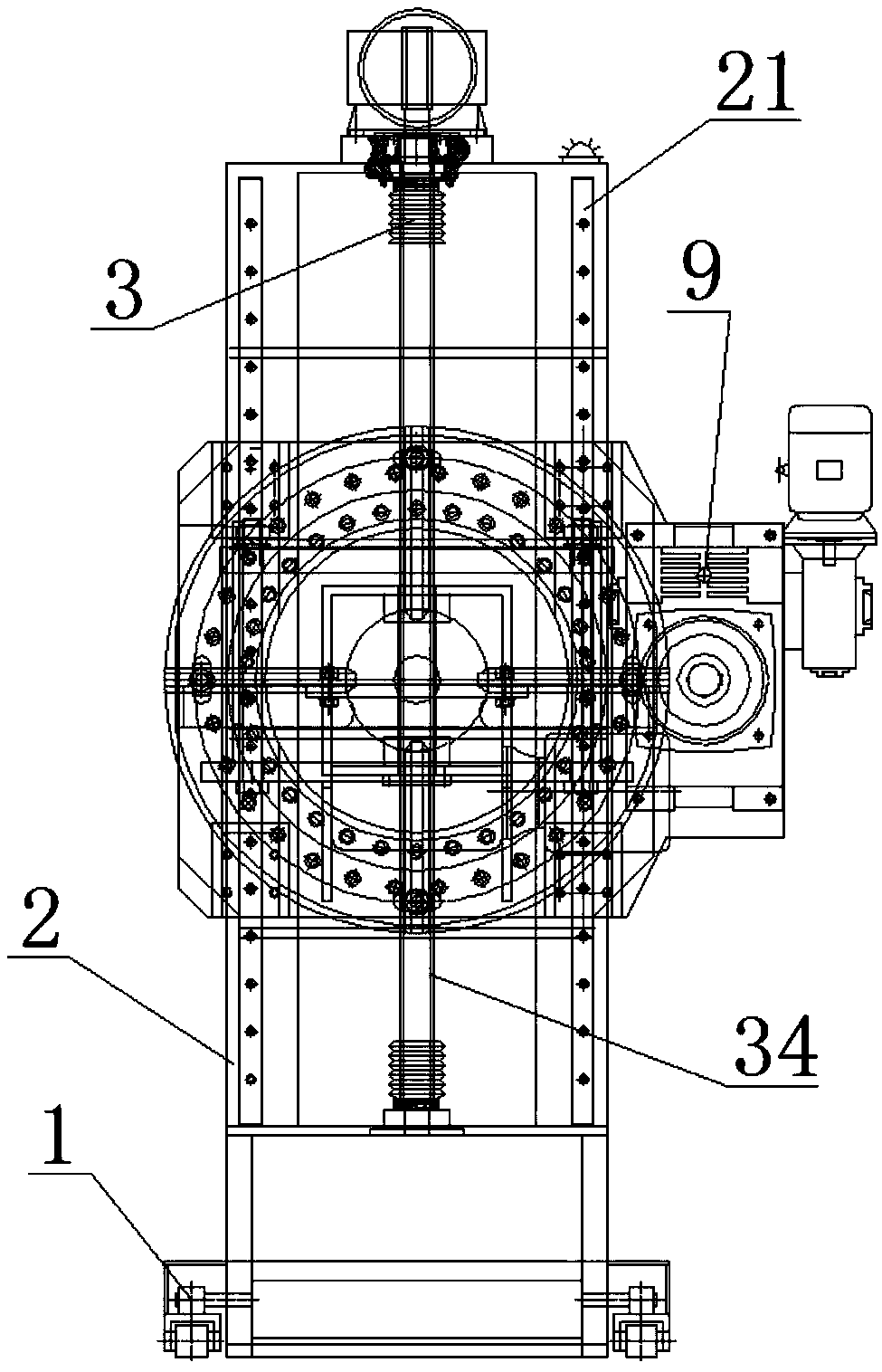

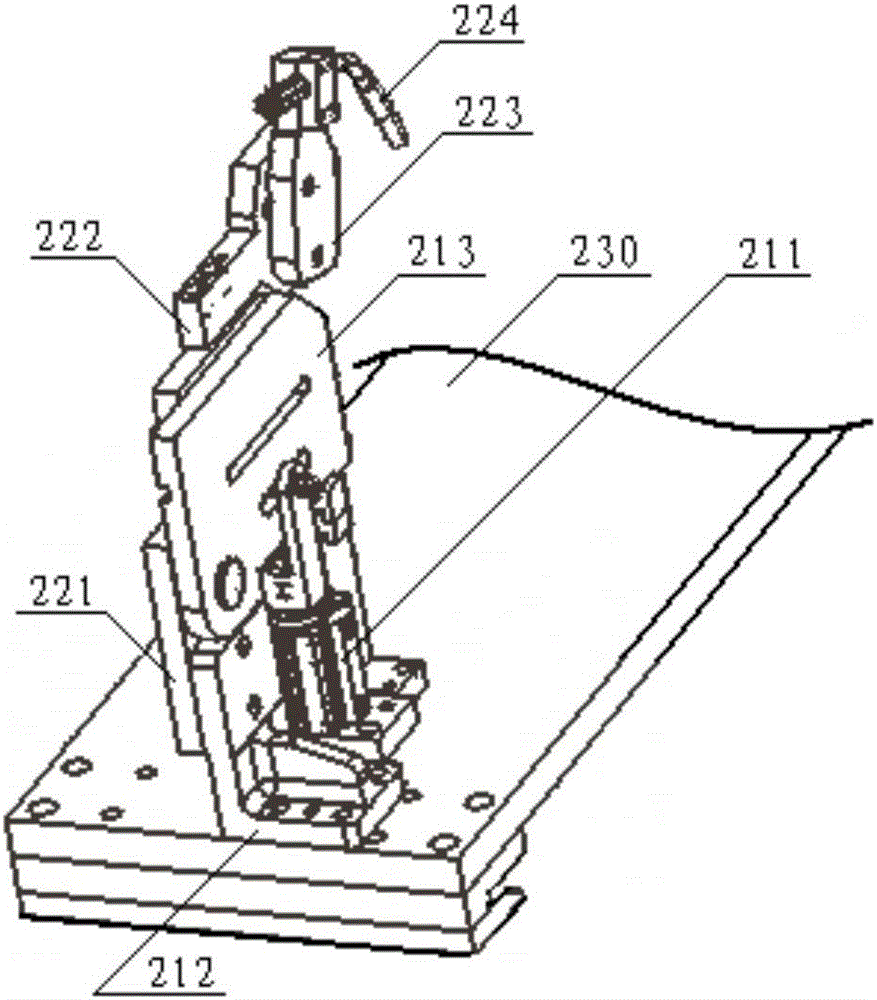

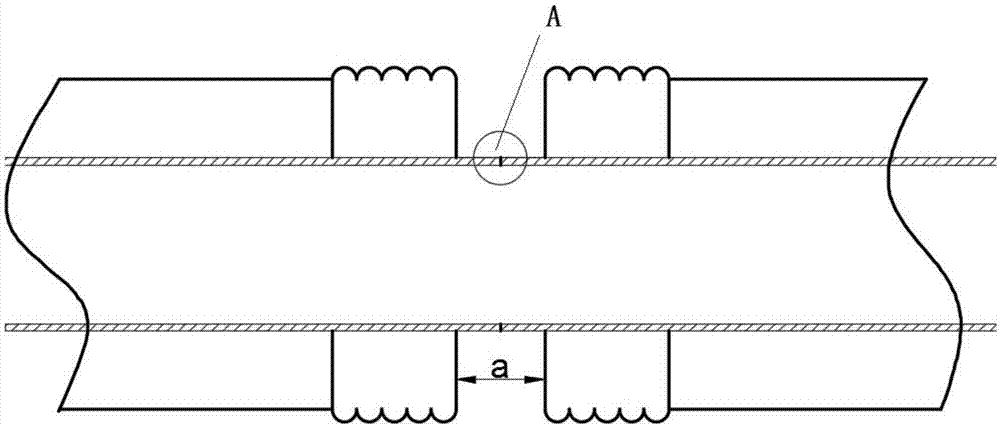

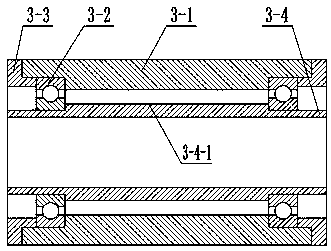

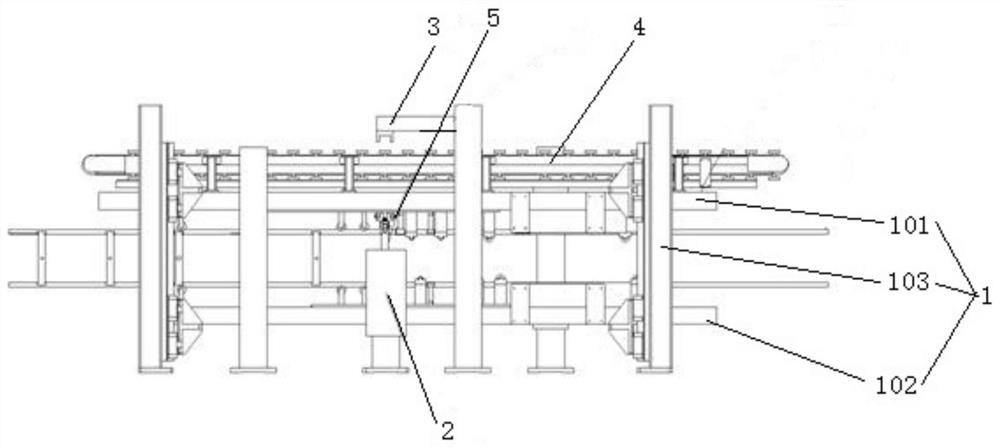

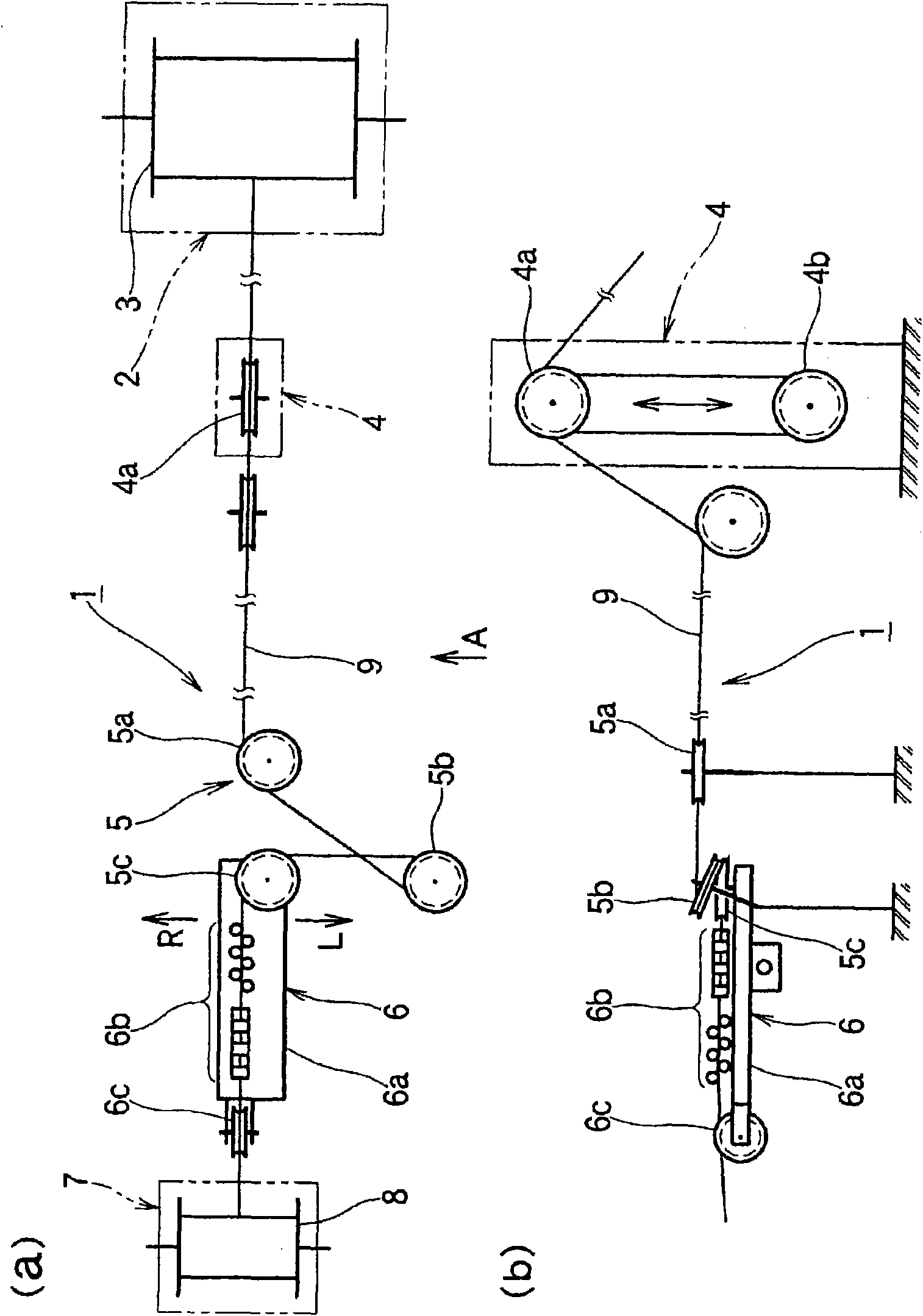

Boiler tube panel butt welding machine

PendingCN110253204AStable circular welding operationsImprove the efficiency of welding operationsWelding/cutting auxillary devicesAuxillary welding devicesButt weldingEngineering

The invention discloses a boiler tube panel butt welding machine. The machine is composed of a conveying mechanism (1), a rotation fixing mechanism (2), a rotation casing tube assembly (3), a welding main support (4), a welding mechanism (5), and a welding height detecting mechanism (6). The conveying mechanism (1) is arranged on the two sides of the welding main support (4) in a bilateral symmetry manner, the rotation fixing mechanism (2) is arranged on the outmost side of the upper portion of the conveying mechanism (1), the rotation casing tube assembly (3) is fixedly arranged above the conveying mechanism (1) and is close to the welding main support (4), the welding mechanism (5) is fixed above the welding main support (4), and the welding height detecting mechanism (6) is fixed to one side of the welding mechanism (5). Through the rotation fixing mechanism and a rotation casing tube, a welding tube can be stably and circumferentially welded, through the welding height detection mechanism, the circumference welding height of the welding point can be detected, and welding work efficiency and the inspection efficiency can be improved.

Owner:江苏汇能锅炉有限公司

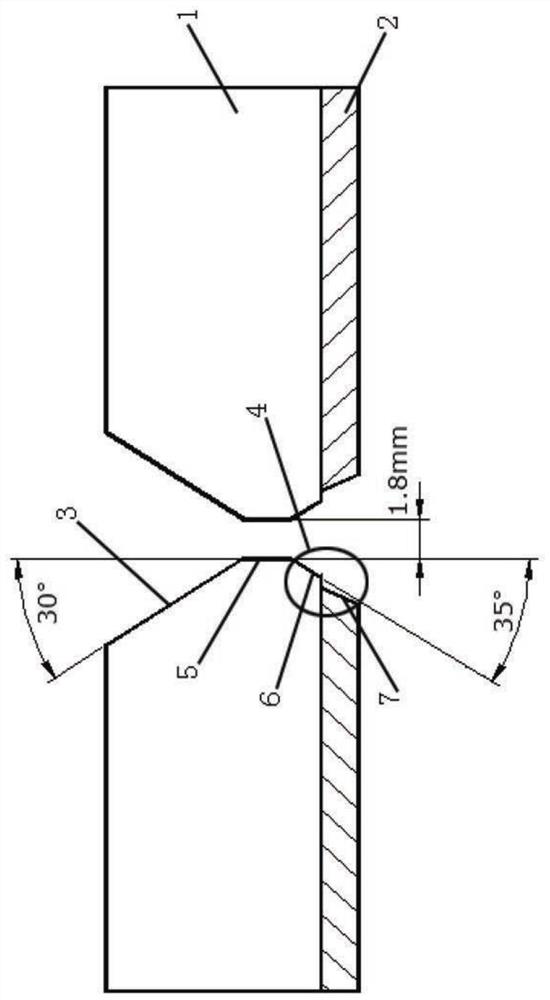

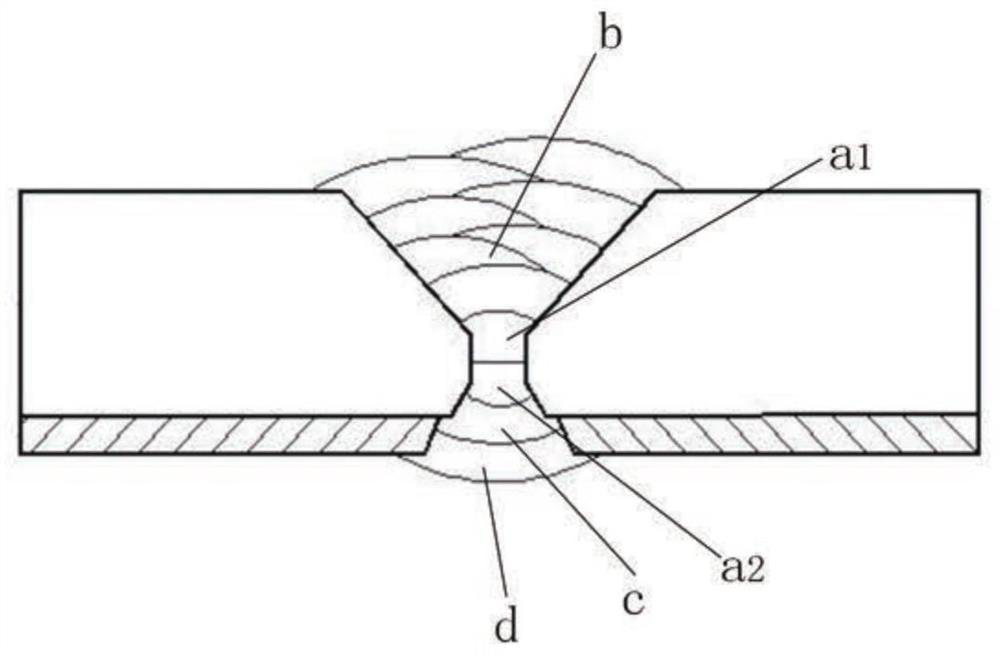

X-shaped groove welding process for corrosion-resistant alloy composite tube

InactiveCN112439982AReduce dosageQuality assuranceArc welding apparatusWorkpiece edge portionsAlloy compositeWelding process

The invention provides an X-shaped groove welding process for a corrosion-resistant alloy composite tube which is provided with a corrosion-resistant alloy layer and a base material layer. The weldingprocess comprises the following steps: processing semi-X-shaped grooves at connecting tubes of two corrosion-resistant alloy composite tubes to be welded to form an X-shaped groove which is formed inthe whole peripheral direction of the corrosion-resistant alloy composite tube, wherein the axial section is provided with a first X-shaped groove and a second X-shaped groove symmetrical with the first X-shaped groove which comprises an upper funnel hole, a lower funnel hole and a transition section, the upper funnel hole being formed on the base material layer in the radial direction, the lowerfunnel hole being reversely formed on the corrosion-resistant alloy layer and one part, close to the corrosion-resistant alloy layer, of the base material layer in the radial direction, and the transition section being used for connecting the upper funnel hole to the lower funnel hole; and introducing protective gas for a certain time before welding, and welding the X-shaped groove. The X-shapedgroove welding process has the advantages of being beneficial for performing the welding process in the corrosion-resistant alloy composite tube and saving use amount of the filling material.

Owner:SICHUAN GASOLINEEUM CONSTR ENG

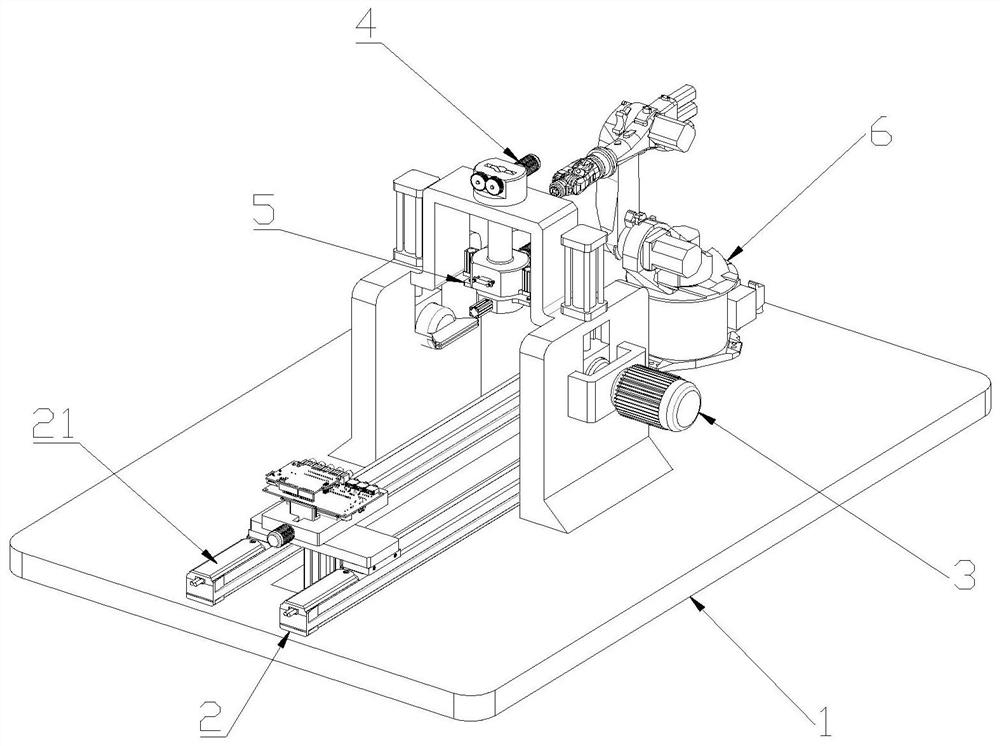

Intelligent electric meter terminal integrated spot welding equipment and using method

ActiveCN113020845AReduce labor intensityImprove the efficiency of welding operationsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses intelligent electric meter terminal integrated spot welding equipment and a using method. The spot welding equipment comprises a supporting frame, wherein the supporting frame is provided with a feeding part used for electric meter part conveying, a rotating part and a transmission part used for terminal transmission, a peeling part used for terminal peeling is arranged below the transmission part, and a mechanical arm used for spot welding is arranged on the supporting frame. The using method comprises the following steps of carrying out terminal feeding, carrying out extruding and cutting, carrying out peeling, carrying out conveying, carrying out clamping, carrying out terminal conveying and carrying out welding. A contact point is welded through the mechanical arm, traditional manual electric welding operation is replaced, the welding operation efficiency is improved, market requirements are met, market changes are coped in time, and the labor intensity of workers is reduced; and the rotation of a circuit board is achieved through a rotating piece, double-face welding operation is achieved, and the process is simplified.

Owner:浙江能兴电气科技有限公司

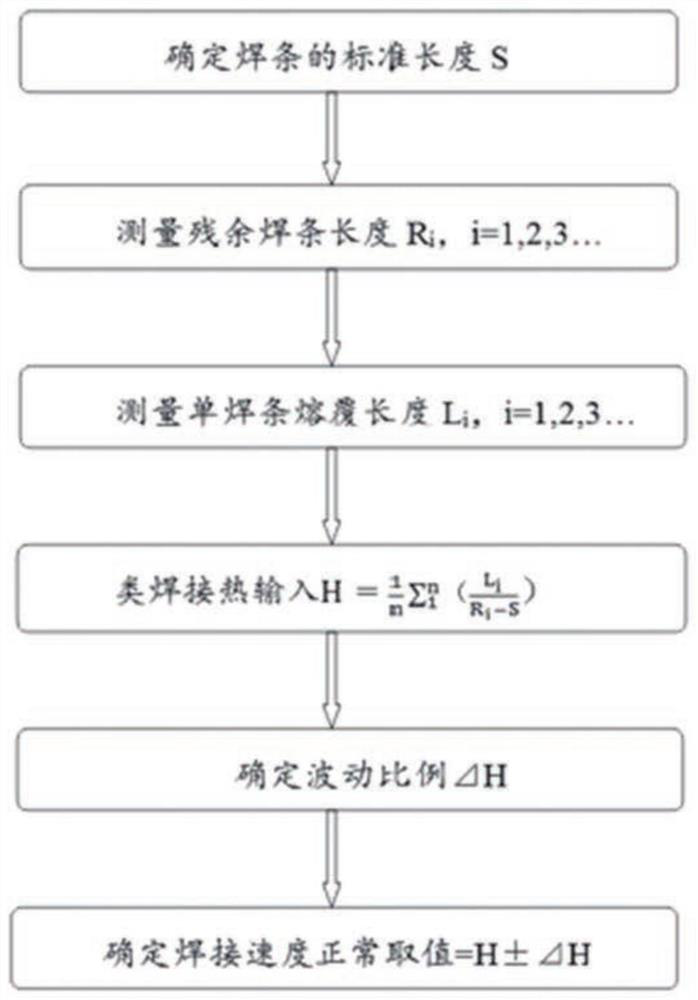

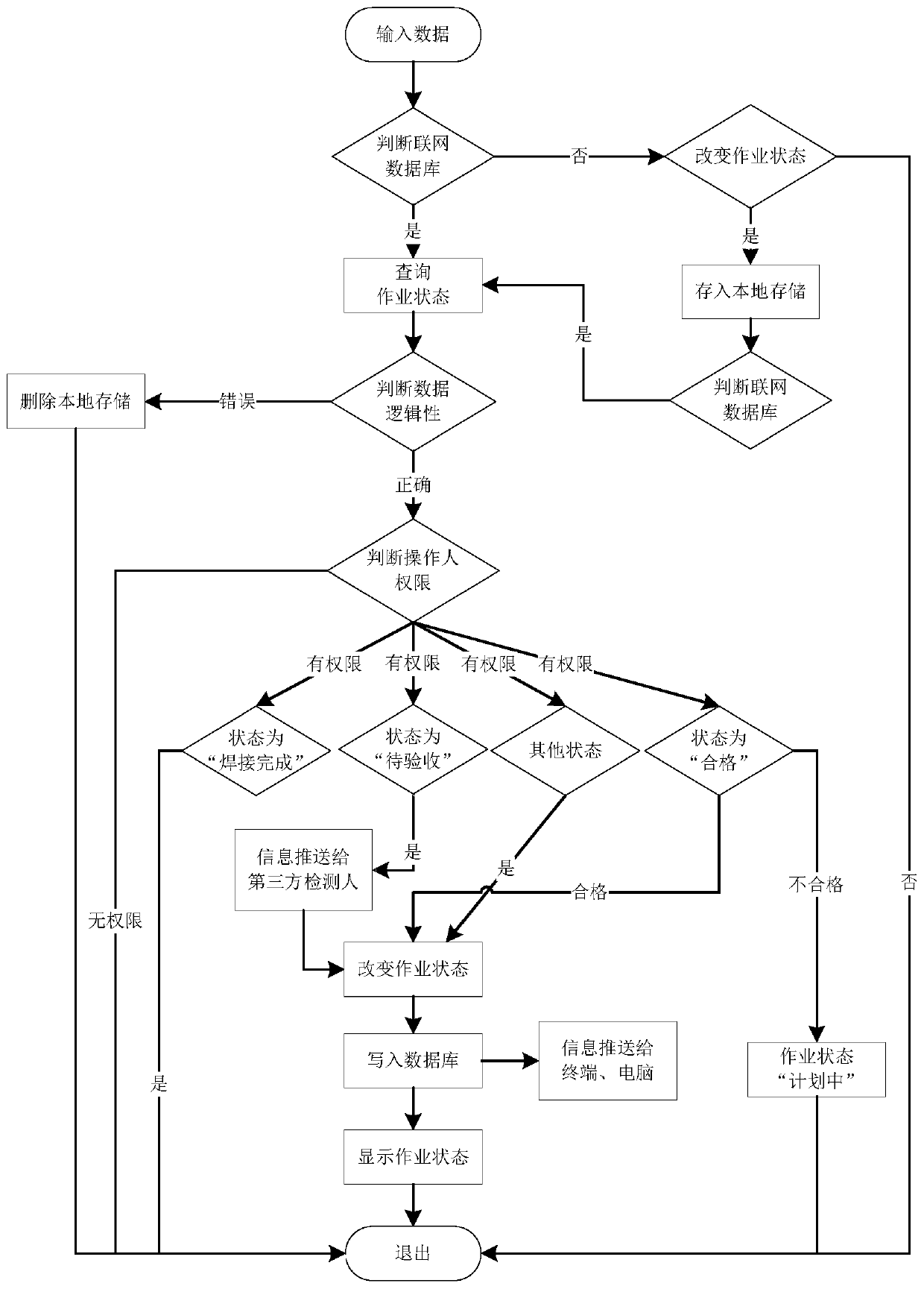

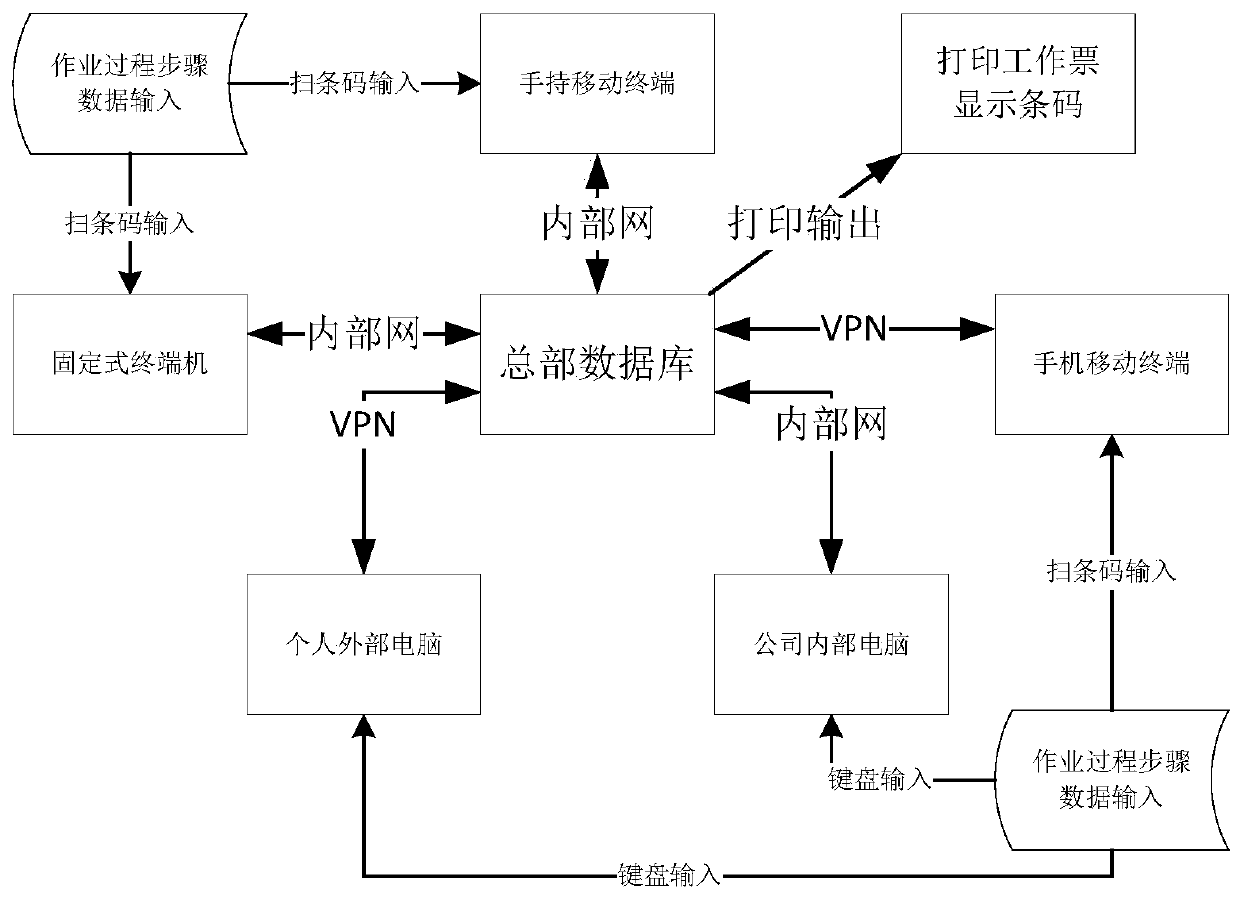

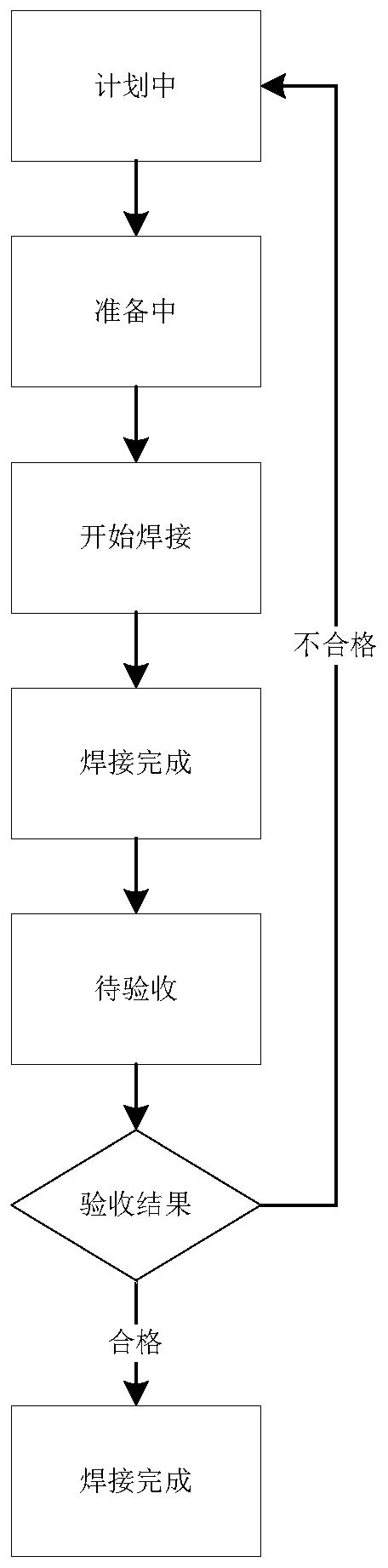

Power station equipment maintenance welding operation process control method

ActiveCN109919517ARealize automatic controlImprove the efficiency of welding operationsResourcesManufacturing computing systemsData informationPower station

The invention belongs to the technical field of power station or factory equipment maintenance, and particularly discloses a power station or factory equipment maintenance welding operation process control method which comprises the following steps: (1) scanning a bar code through a terminal or a computer to obtain power station equipment welding operation state data information, and inputting data; (2) judging whether a headquarter database is networked or not; (3) judging the logicality of the welding operation state data of the power station equipment according to the networking judgment result of the headquarter database in the step (2), judging the authority of an operator of the welding operation of the power station equipment if the logic is correct, and continuously executing the step (4); and (4) judging the authority of the welding operation operator of the power station equipment, writing the welding operation state information of the power station equipment into a headquarter database, displaying the welding operation state of the power station equipment, and pushing the welding operation state information of the power station equipment to a terminal or a computer. By means of the method, effective control over the welding operation process can be achieved, and the welding operation efficiency is improved.

Owner:JIANGSU NUCLEAR POWER CORP

Welding device capable of achieving rotational feeding

InactiveCN108067767AImprove the efficiency of welding operationsSimple structureWelding/cutting auxillary devicesDirt cleaningRotary stageCoupling

The invention provides a welding device capable of achieving rotational feeding. A servo motor is arranged on a workbench. A rotating shaft is fixedly arranged on an output shaft of the servo motor through a coupling. A round rotating table is fixedly arranged at the tail end of the rotating shaft. Multiple connecting arms are uniformly distributed at the rim of the rotating table. A fixing tableis fixedly arranged at the tail end of any connecting arm. Each fixing table is provided with a clamp used for fixing a to-be-welded part. A cross beam is arranged at the top end of the workbench through a support. An electric slide rail is arranged at the bottom end of the cross beam and provided with an electric slide table, wherein the electric slide table is connected with the electric slide rail in a sliding manner. An air cylinder is fixed to the bottom end of the electric slide table. A piston rod is arranged on the air cylinder, wherein the piston rod extends downwards vertically. A welding gun is arranged at the tail end of the piston rod. When the rotating table rotates, the fixing tables can be conveyed to the bottom end of the welding gun. The welding device has the beneficialeffects that ceaseless operation can be achieved, and the operation efficiency is high.

Owner:TIANJIN HAOHANG COMPOSITE PIPE

An integrated spot welding equipment for smart meter terminals and its use method

ActiveCN113020845BReduce labor intensityImprove the efficiency of welding operationsWelding/cutting auxillary devicesAuxillary welding devicesRobotic armEngineering

The invention discloses an intelligent electric meter terminal integrated spot welding device and a using method thereof. The spot welding device includes a support frame, on which a feeding part for electric meter parts transmission is arranged, on the support frame is provided a rotating part, and on the support frame There is a transmission part for terminal transmission on the upper part, a peeling part for terminal peeling is provided under the transmission part, and a mechanical arm for spot welding is provided on the support frame; the method of use includes the following steps: terminal feeding, extrusion cutting, Stripping, transfer, clamping, terminal transfer, soldering. The contact point is welded by the mechanical arm, replacing the traditional manual electric welding operation, which improves the efficiency of the welding operation, meets market demand, responds to market changes in a timely manner, and reduces the labor intensity of the staff; the rotation of the circuit board is realized through the rotating parts. Double-sided welding operation simplifies the process.

Owner:浙江能兴电气科技有限公司

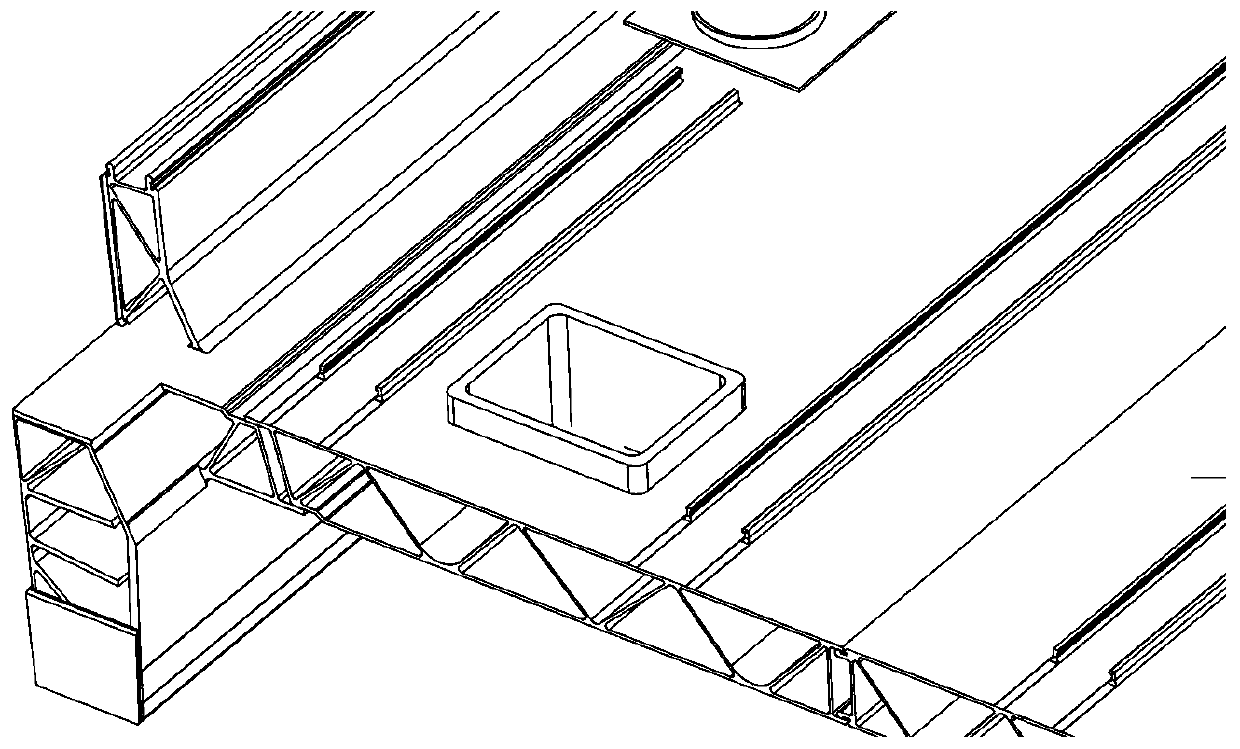

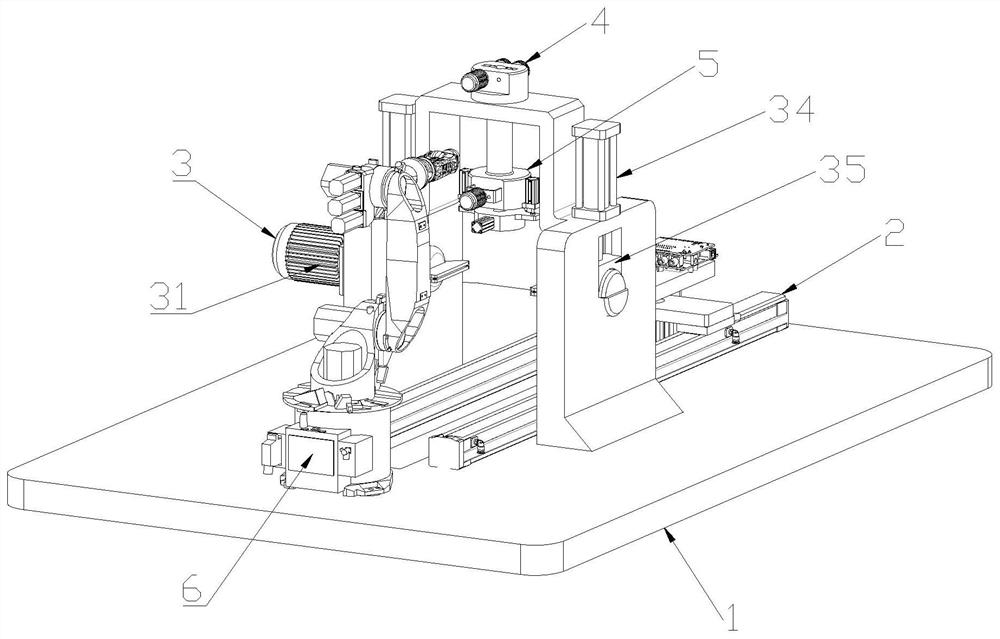

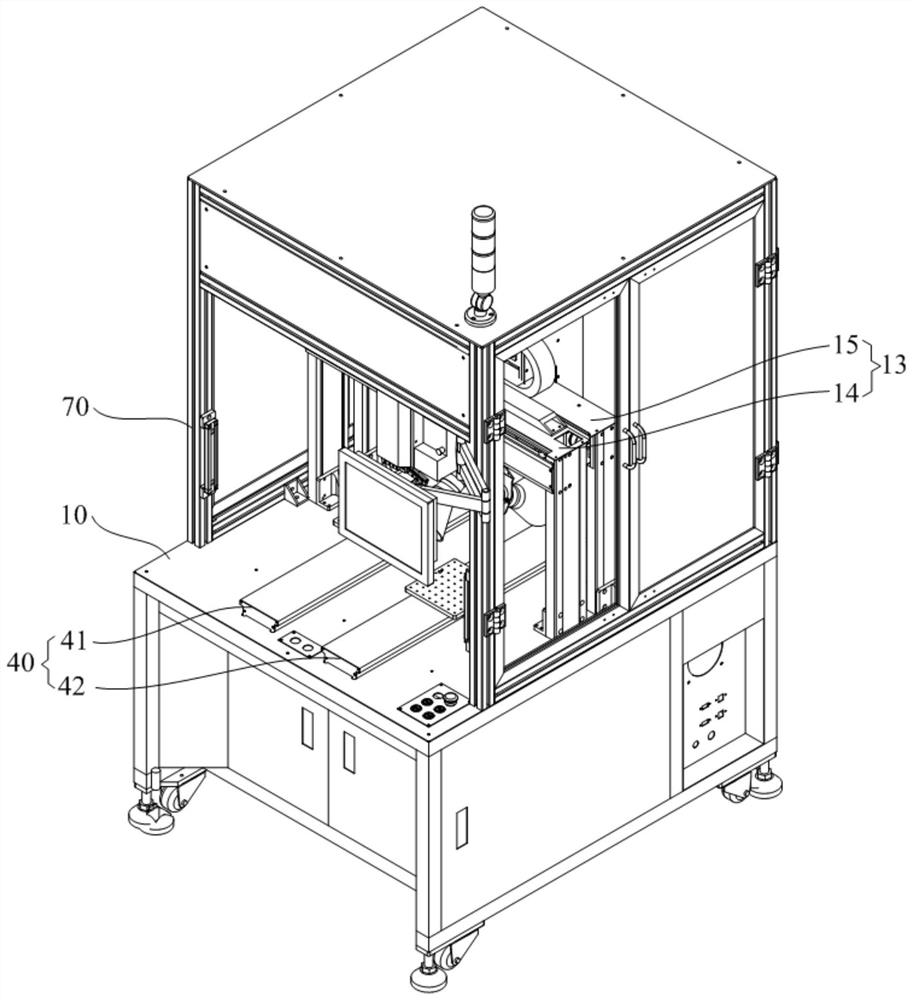

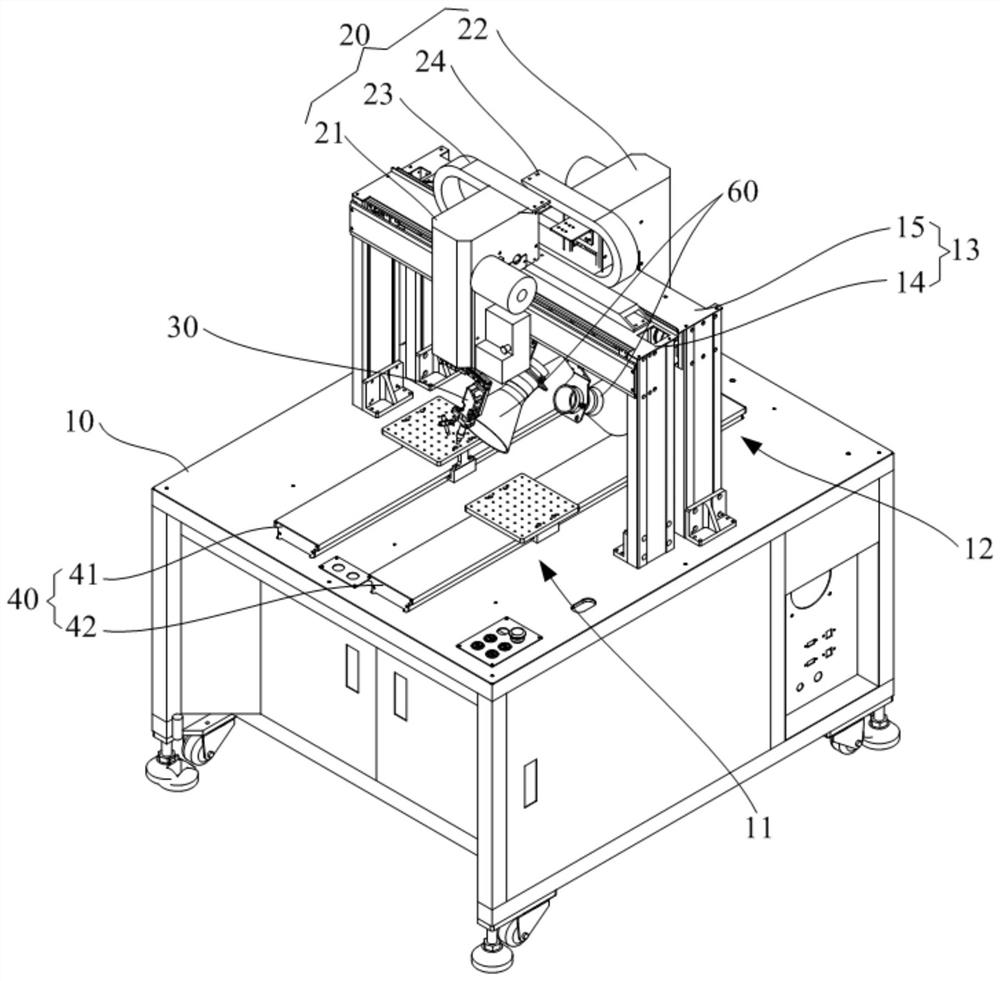

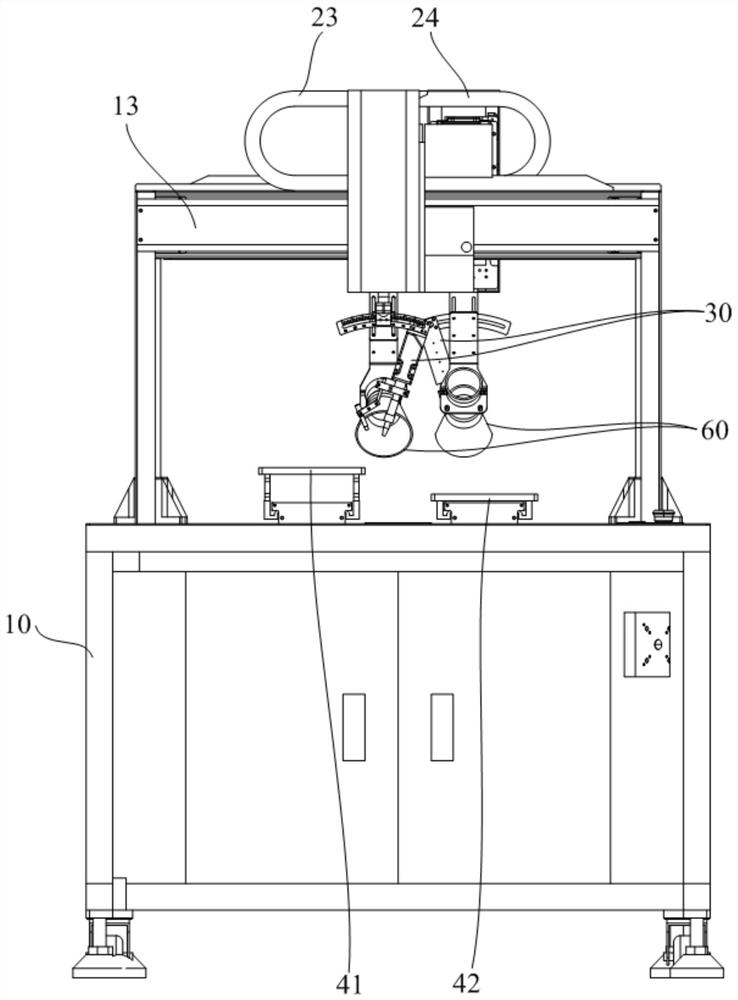

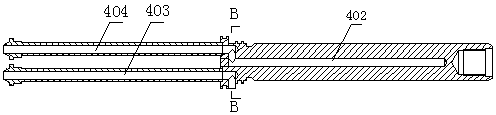

A main keel welding equipment and welding method

ActiveCN110153578BImprove the efficiency of welding operationsEase of large-scale industrializationWelding apparatusKeelIndustrial engineering

The invention discloses a main keel welding equipment and a welding method to improve operation efficiency and realize large-scale production. The main keel welding equipment includes a frame and a welding device, and the welding device is arranged opposite to the frame; when in use, the main keels to be welded are located in the frame and arranged vertically.

Owner:江苏景枫投资控股集团有限公司

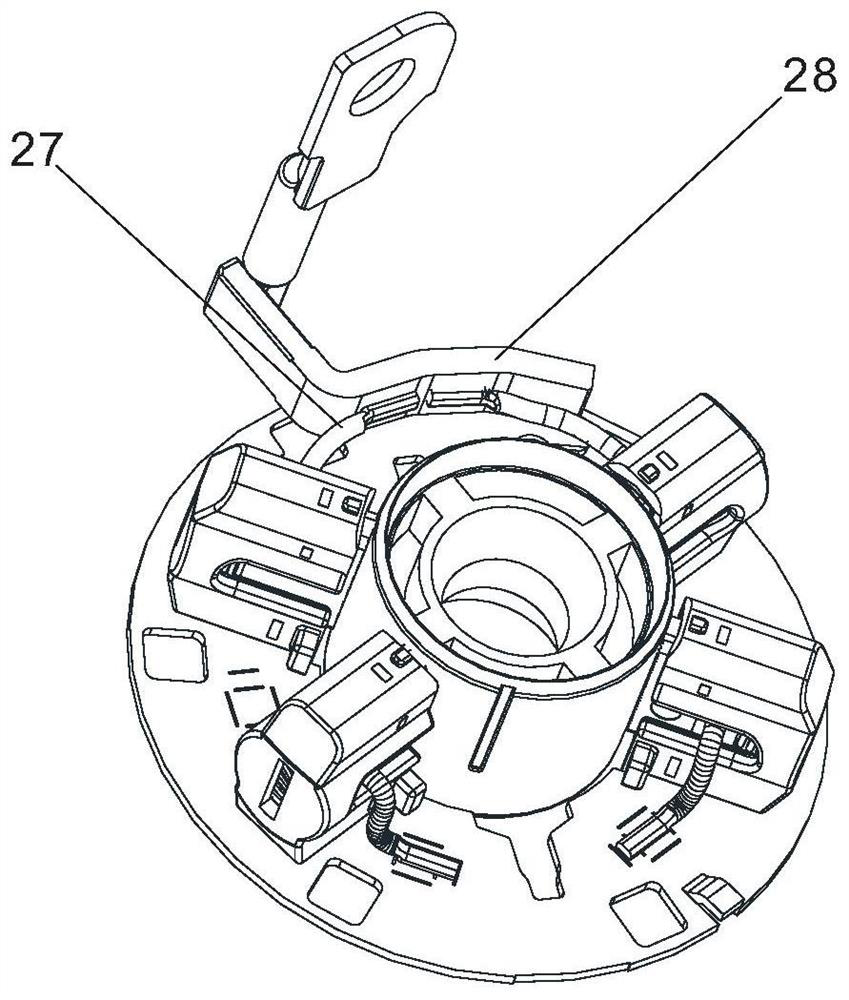

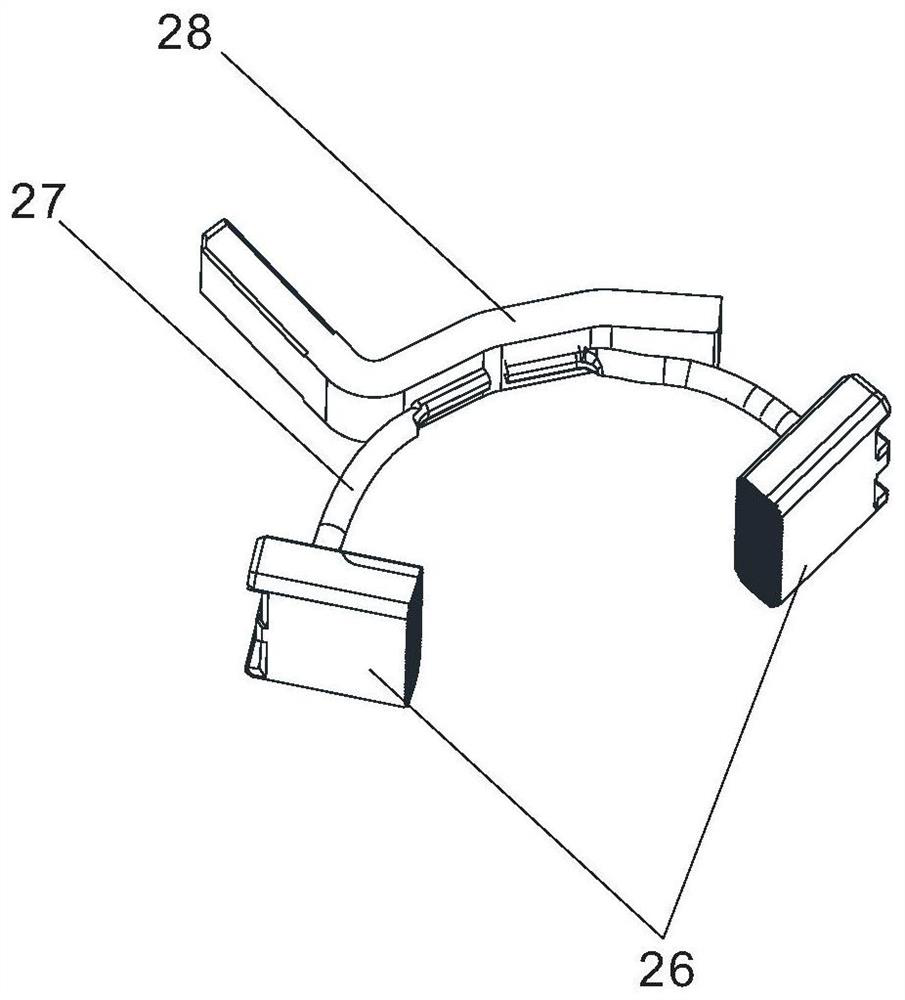

A carbon brush lead wire and connecting bridge welding device

ActiveCN112157333BImprove the efficiency of welding operationsImprove work efficiencySoldering auxillary devicesStructural engineeringTransfer mechanism

The invention provides a carbon brush lead wire and connecting bridge welding device, which includes a machine base, and also includes a welding mechanism, a welding piece positioning mechanism and a welding spot transfer mechanism. The welding mechanism, the welding piece positioning mechanism and the welding spot transfer mechanism are arranged on the base Above, the welding piece positioning mechanism is used to keep the relative position of the carbon brush and the connecting bridge to be welded fixed, and the welding spot transfer mechanism is connected with the welding piece positioning mechanism and can drive the welding piece positioning mechanism to change the position so that the lead wire of the carbon brush and the connecting bridge are connected. Each to-be-welded point corresponds to the welding mechanism respectively. In the present invention, the positioning mechanism of the welding part pre-determines the positions of the carbon brush and the connecting bridge. When welding, the carbon brush and the connecting bridge only need to be placed in place without further adjustment, and the welding can be completed quickly and accurately, so the working efficiency can be greatly improved. And it can improve the welding quality of components inside the carbon brush holder.

Owner:FUYANG DUOBAO ELECTRONICS

Automatic welding machine for braided wire

PendingCN110449719ARealize automatic welding functionImprove the efficiency of welding operationsHigh frequency current welding apparatusEngineeringHigh frequency

The invention discloses an automatic welding machine for a braided wire. The automatic welding machine for the braided wire comprises a rack, a circulation wire, a carrier, a first visual inspection device, a first high-frequency welding device, a second visual inspection device, a rotating device, a second high-frequency welding device, a first braided wire loading device and a second braided wire loading device. The circulation wire is arranged on the rack; the carrier is arranged on the circulation wire and is driven by the circulation wire to move circularly; and the first visual inspection device, the first high-frequency welding device, the second visual inspection device, the rotating device, the second high-frequency welding device, the first braided wire loading device and the second braided wire loading device are arranged on the rack. Through utilizing the circulation wire, the carrier can be recycled; and in addition, by cooperatively arranging the visual inspection devices, the high-frequency welding devices and the braided wire loading devices, an automatic welding function is realized, the welding operation efficiency is effectively improved, and the consistency of welding spots is good.

Owner:DONGGUAN PO YUN ELECTRONICS

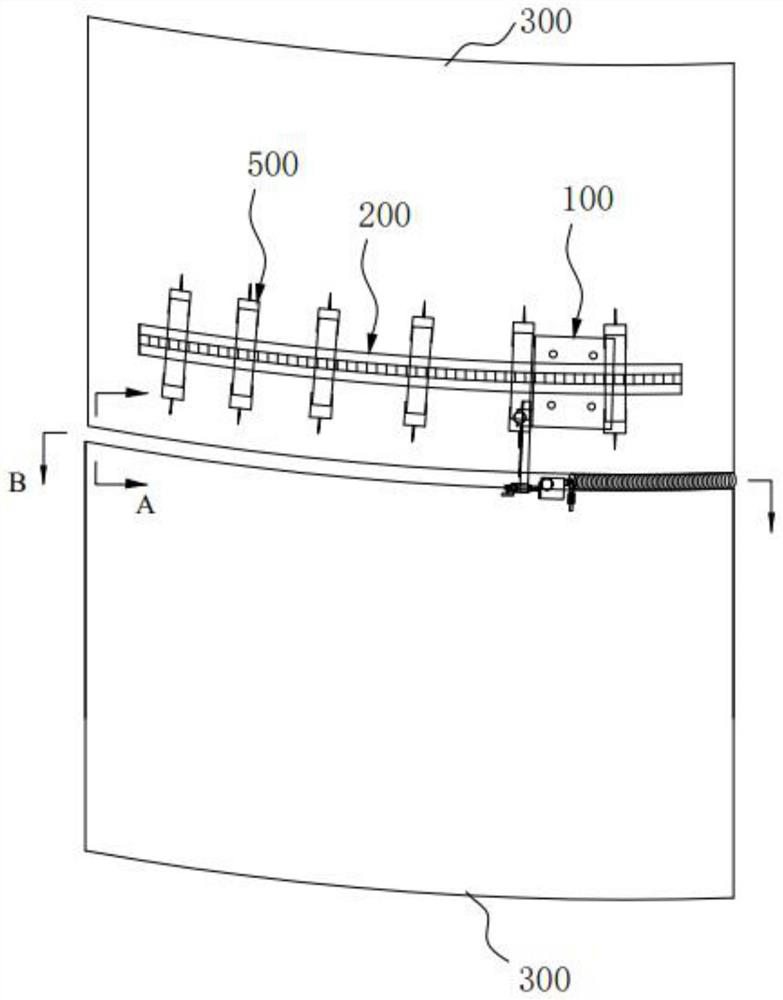

Welding device and welding method

PendingCN114289825AEnsure continuityReduce workloadWelding accessoriesEngineeringWelding deformation

The invention belongs to the technical field of curved surface segmented thin plate welding, and discloses a welding device and a welding method.The welding device comprises a welding trolley, an arc-shaped track and a welding backing; the welding trolley comprises a trolley body, an adjusting mechanism, an oscillator and a welding gun, the adjusting mechanism is installed on the trolley body, the oscillator is installed on the adjusting mechanism, and the welding gun is rotationally connected to the oscillator; the arc-shaped track is made of bendable materials and detachably attached to the curved-surface segmented thin plates, the trolley body is installed on the arc-shaped track and can move along the arc-shaped track, and the welding gun extends into a gap between the two curved-surface segmented thin plates. The welding backing abuts against the two curved segmented thin plates. The welding device can automatically and flexibly adjust the movement direction and control welding deformation in the curved surface segmented thin plate welding procedure, weld joints are formed attractively, the workload of post-welding grinding and beautifying treatment work is reduced, and the welding operation efficiency is improved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

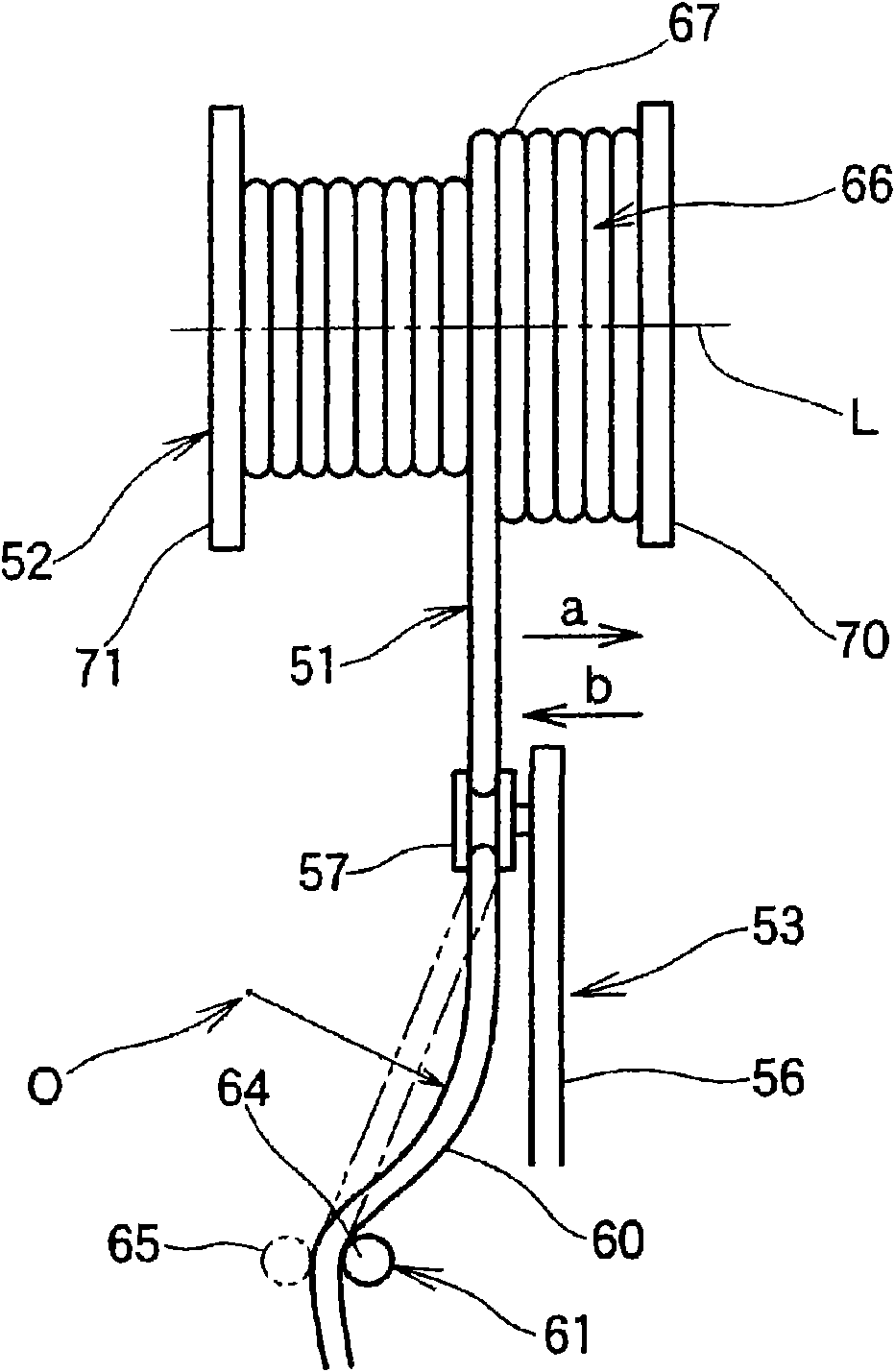

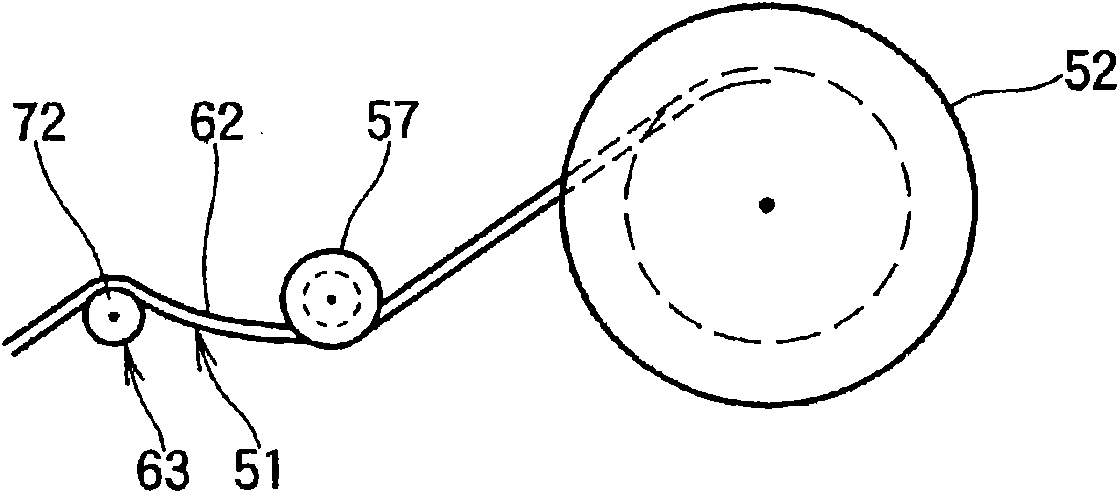

Method for housing solder wire and device thereof

This invention provides a method for housing solder wire and a device thereof, including: a drawing device arranged a tube with big diameter , a tension adjusting roller device that keeps the tention of the solder wires in a certain range where the solder wires are reeled and hanged on the fixed side roller and moving side roller, a idler pulley that temporarily makes the solder wires come from said tension adjusting roller device to form a circular shape, a roller rectifying device which continuously rectifies said circle-shaped solder wires, a moveable workbench that arranges said roller rectifying device and have a reciprocated movement along the direction that orthogonalizes with the travel direction of the solder wires rectified by the roller rectifying device, and a solder wires reeling-replacement device that continuously reels the solder wires drew from said moveable workbench and has a small rolling diameter. By utilizing such a structure, 'bending mark' of solder wires can be rectified effectively, the quality of the solder wires is ensured.

Owner:KOBE STEEL LTD

Manufacturing technology for pile shoe of ocean platform

ActiveCN107503347AGuaranteed construction accuracyEffective segmental deformationBulkheads/pilesManufacturing technologyEngineering

The invention discloses a manufacturing technology for a pile shoe of an ocean platform. The manufacturing technology comprises the steps that lower base plates and an intermediate stand column are spliced and welded, and then inner rib plates, lower base plate inner T row plates and lower base plate outer T row plates are sequentially assembled; secondly, outer upper base plate assemblies are reversely buckled, and the lower base plate outer T row plates are sequentially welded to the outer upper base plate assemblies and the lower base plates; then intermediate partition plates are arranged in an inserted mode; the inner rib plates, the lower base plate T row plates, the intermediate partition plates and the lower base plates are sequentially welded, and then vertical angle welding is carried out on the inner rib plates and the intermediate stand column; then diffusion welding is carried out on upper base plate inner sectional materials; finally three inner upper base plates are sealed; and when three intermediate splicing plates are welded, one side edges of the three intermediate splicing plates are firstly welded to the corresponding edges of three side cover plates, then heating and heat preservation are carried out, the other side edges of two intermediate splicing plates are welded to the corresponding edges of two side cover plates, then heating and heat preservation are carried out, finally, the other side edge of the rest one intermediate splicing plate is welded to the corresponding edge of the rest one side cover plate, and then heating and heat preservation are carried out. According to the manufacturing technology, the staged manufacturing efficiency can be improved.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

A kind of box girder welding method

ActiveCN104607785BImprove welding strengthImprove the efficiency of welding operationsArc welding apparatusWelding/soldering/cutting articlesEngineeringWeld strength

The invention discloses a box beam welding method. The method comprises the steps that a main web and an upper cover plate are fixed to each other in a butt spot welding mode directly or through structural steel indirectly, all ribbed plates are arranged at intervals in the length direction of a semi-beam work piece formed by the welding of the main web and the upper cover plate, and the ribbed plates are fixed to the concave surface of the semi-beam work piece in a butt spot welding mode. Compared with the prior art that the welding of the upper cover plate and the main web is achieved in space in sections formed by the dividing by the ribbed plates, the welding of the upper cover plate and the main web is completed at a time in open space according to the box beam welding method. Accordingly, the welding strength between the main web and the upper cover plate of a box beam and the welding working efficiency are improved, and the problem existing in the prior art that the welding quality and the welding efficiency of the wide flange box beam are low is solved.

Owner:HENAN MINE CRANE +1

Welding equipment

PendingCN113953616AReduce occupancyAvoid inefficiencies in productionSoldering ironSolder feeding devicesEngineeringSoldering iron

The invention discloses welding equipment. The welding equipment comprises a machine base, a moving mechanism, welding assemblies and a Y-axis moving mechanism; the machine base is provided with a first welding station and a second welding station; the moving mechanism is connected to the machine base and comprises a first Z-axis moving mechanism located on the first welding station and a second Z-axis moving mechanism located on the second welding station; the number of the welding assemblies is at least two, the two welding assemblies are connected to the first Z-axis moving mechanism and the second Z-axis moving mechanism correspondingly, and the welding assemblies comprise soldering irons; the Y-axis moving mechanism is arranged on the first welding station and the second welding station in a crossing manner, and the Y-axis moving mechanism can convey products from the first welding station to the second welding station; and the type of at least one in the soldering irons installed on the first Z-axis moving mechanism is set to be different from the types of the soldering irons installed on the second Z-axis moving mechanism. According to the technical scheme, the welding operation efficiency of the welding equipment for products with different welding spot types can be improved.

Owner:苏州市小驰机器人有限公司

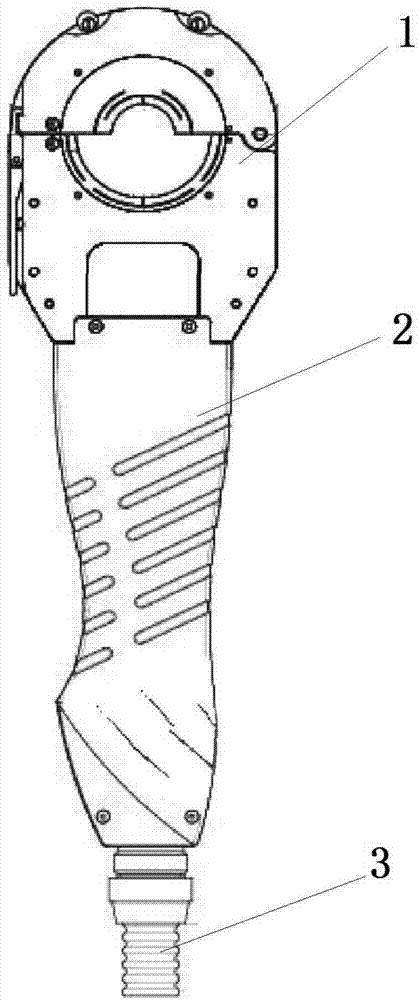

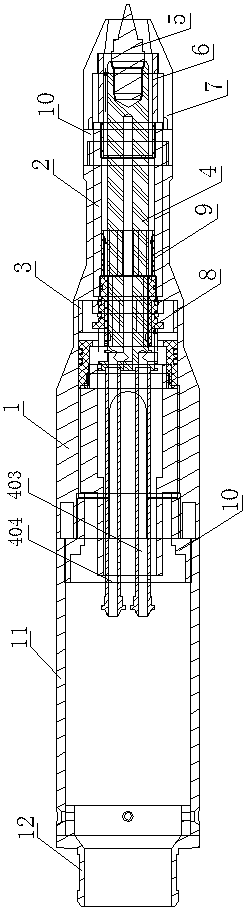

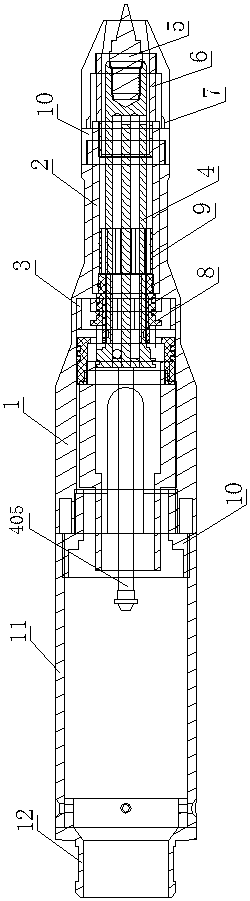

Argon arc welding gun with cooling function and device with argon arc welding gun

ActiveCN107262884AHigh densityStrong penetrating powerCooled electrode holdersElectrode accessoriesEngineeringDistributor

The invention provides an argon arc welding gun with a cooling function and a device with the argon arc welding gun. The argon arc welding gun comprises a gun body shell, an insulator, a first support ring, a sealing body, an electrode connecting body, an electrode, a vortex ring, a ceramic nozzle, a spray nozzle and a gas distributor, wherein the insulator, the first support ring and the sealing body are connected with the gun body shell, and the electrode connecting body is connected with the insulator, the first support ring and the sealing body; the electrode is connected with the electrode connecting body; the vortex ring is connected with the gun body shell; the ceramic nozzle is connected with the insulator; the spray nozzle is connected with the vortex ring; the sealing body is provided with a cooling cavity; and the first end of the electrode connecting body is provided with a first cooling fluid inlet pipe and a first cooling fluid outlet pipe, and the other end of the electrode connecting body is provided with a second cooling fluid inlet pipe and a second cooling fluid outlet pipe. A fluid outlet of the second cooling fluid inlet pipe communicates with a fluid inlet of the cooling cavity. A fluid inlet of the first cooling fluid inlet pipe communicates with a fluid outlet of the cooling cavity. The first cooling fluid inlet pipe and the first cooling fluid outlet pipe extend into the end, close to the electrode, of the electrode connecting body. The electrode connecting body is provided with a protection gas pipe communicating with the gas distributor.

Owner:长沙中创海通智能科技有限公司

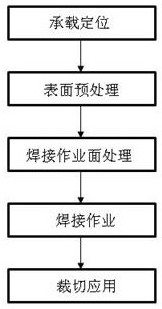

A continuous and high-efficiency welding process for the surface of high-precision aluminum substrate and flexible board

ActiveCN110446370BHigh precisionImprove stabilityPrinted circuit assemblingMetallurgical bondingProcess engineeringAluminum substrate

The invention relates to a high-precision aluminum substrate and a flexible surface continuous high-efficiency welding process, including five steps of bearing positioning, surface pretreatment, welding work surface treatment, welding operation and cutting application. On the one hand, the present invention has a simple and standardized structure and production process, and has good versatility. The use of auxiliary materials such as solder and brazing filler metal is used. While improving the efficiency of welding operations, it also effectively reduces the welding cost and the defects of excessive differences in the resistivity of the circuit system, and also greatly reduces the circuit system after welding operations. The running resistance improves the stability of the circuit operation and reduces the energy consumption and calorific value of the circuit operation.

Owner:河南博美通电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com