A continuous and high-efficiency welding process for the surface of high-precision aluminum substrate and flexible board

A welding process and aluminum substrate technology, applied in the manufacture of printed circuits, electrical components, printed circuits, etc., can solve the problems of many heat points, large heat generated by circuit operation, large resistivity fluctuations, etc., and achieve simple structure and production process Standardization, improvement of welding operation efficiency, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

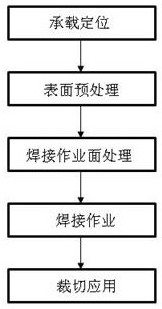

[0024] like figure 1 As shown, a continuous high-efficiency welding process on the surface of a high-precision aluminum substrate and a flexible board includes the following steps:

[0025] S1, bearing positioning, first degreasing, drying and purifying the substrate to be welded, then corona treatment is performed on the back surface of the substrate, and finally the upper and lower surfaces of the corona treated substrate are coated with a thickness of 0.1 millimeter electrostatic film, the next step can be performed after the electrostatic film coating is completed;

[0026] S2, surface pretreatment, first perform corona treatment on the electrostatic film on the upper and lower surfaces of the substrate in step S1, and then print the upper and lower surfaces of the substrate within 3 seconds after the corona treatment according to the needs of the welding operation. The bottom map of the welding work surface is then sintered and cleaned by the laser sintering equipment ac...

Embodiment 2

[0036] A continuous high-efficiency welding process on the surface of a high-precision aluminum substrate and a flexible board, comprising the following steps:

[0037] S1, bearing positioning, first degreasing, drying and purifying the substrate to be welded, then corona treatment is performed on the rear surface of the substrate, and finally the corona-treated upper and lower surfaces of the substrate are coated with a thickness of 1 millimeter electrostatic film, the next step can be performed after the electrostatic film coating is completed;

[0038] S2, surface pretreatment, first perform corona treatment on the electrostatic film on the upper and lower surfaces of the substrate in step S1, and then print the upper and lower surfaces of the substrate according to the needs of the welding operation within 10 seconds after the corona treatment. The bottom map of the welding work surface is then sintered and cleaned by the laser sintering equipment according to the bottom m...

Embodiment 3

[0047] A continuous high-efficiency welding process on the surface of a high-precision aluminum substrate and a flexible board, comprising the following steps:

[0048] S1, bearing positioning, first degreasing, drying and purifying the substrate to be welded, then corona treatment is performed on the back surface of the substrate, and finally the upper and lower surfaces of the corona treated substrate are coated with a thickness of 0.5 millimeter electrostatic film, the next step can be performed after the electrostatic film coating is completed;

[0049] S2, surface pretreatment, first perform corona treatment on the electrostatic film on the upper and lower surfaces of the substrate in step S1, and then print the upper and lower surfaces of the substrate according to the needs of the welding operation within 8 seconds after the corona treatment. The bottom map of the welding work surface is then sintered and cleaned by the laser sintering equipment according to the bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com