Patents

Literature

108results about How to "Excellent welding workability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flux-cored wire for stainless steel arc welding

ActiveCN102091881AImprove pitting resistanceImprove low temperature toughnessWelding/cutting media/materialsWelding/soldering/cutting articlesRare-earth elementFluoride

A flux-cored wire for stainless steel arc welding including an outer sheath made of stainless steel and flux filled up in the outer sheath contains, as percentage to the total mass of the wire, Cr: 22.0-30.0 mass %, Ni: 6.0-12.0 mass %, Mo: 2.0-5.0 mass %, N: 0.20-0.35 mass %, TiO2: 4.0-9.0 mass %, SiO2: 0.1-2.0 mass %, ZrO2: 0.5-4.0 mass %, total of Li2O, Na2O and K2O: 0.50-1.50 mass %, metal fluoride in terms of fluorine amount: 0.10-0.90 mass %, and rare earth element component: 0.10-1.00 mass %, limits C to 0.04 mass % or below, W to 4.0 mass % or below, Cu to 2.0 mass % or below, Bi2O3 to 0.01 mass % or below, and limits oxides other than the above to 3.0 mass % or below. With such a composition, it is possible to obtain a weld bead which is excellent in the weldability in welding in all attitudes and is more excellent in the low temperature toughness while keeping excellent pitting corrosion resistance in arc welding of duplex stainless steel and the like.

Owner:KOBE STEEL LTD

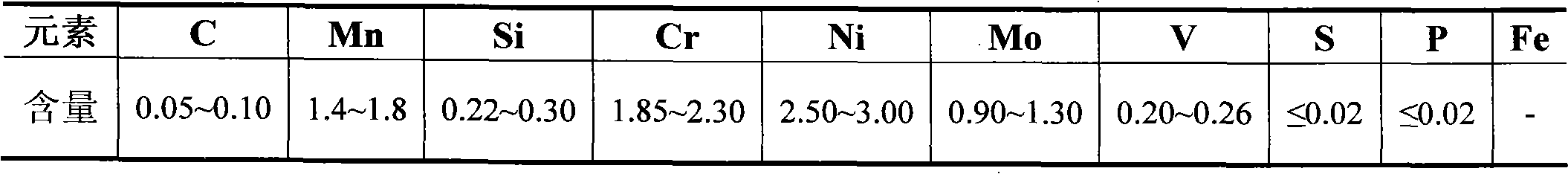

Surfacing electrode for repairing hot forged mould

InactiveCN101898284AExcellent welding performanceImprove yieldWelding/cutting media/materialsSoldering mediaSolid componentSlag

The invention discloses a surfacing electrode for repairing a hot forged mould, which uses a low-carbon steel H08A core wire conforming to the GB / T3429 requirement. The solid component quality content of coating is as follows: 30-40% of marble, 12-20% of fluorite, 1.5-3% of zircon sand, 0-2% of soda ash, 2-5% of silicon epitaxy material, 1-3% of titanium white, 0-3% of flogopite, 1-2% of rare earth fluoride, 3-7% of manganese metal, 2-5% of ferrosilicon, 4-6% of ferrotitanium, 4-8% of chromium metal, 4-8% of ferromolybdenum, 6-12% of metallic nickel and 1-2% of aluminium magnesium alloy. The invention has favorable welding rod performance, smooth welding rod surface, high yield and stable eccentricity; electric arc is easy to ignite and is stable to burn; coating is even to melt, a welding line is attractive in shape, and slag is easy to clean; and a deposition metal weld metal buildup has moderate welding state hardness which reaches the requirements of the hot forged mould, thus improving the service life cycle of the hot forged mould.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

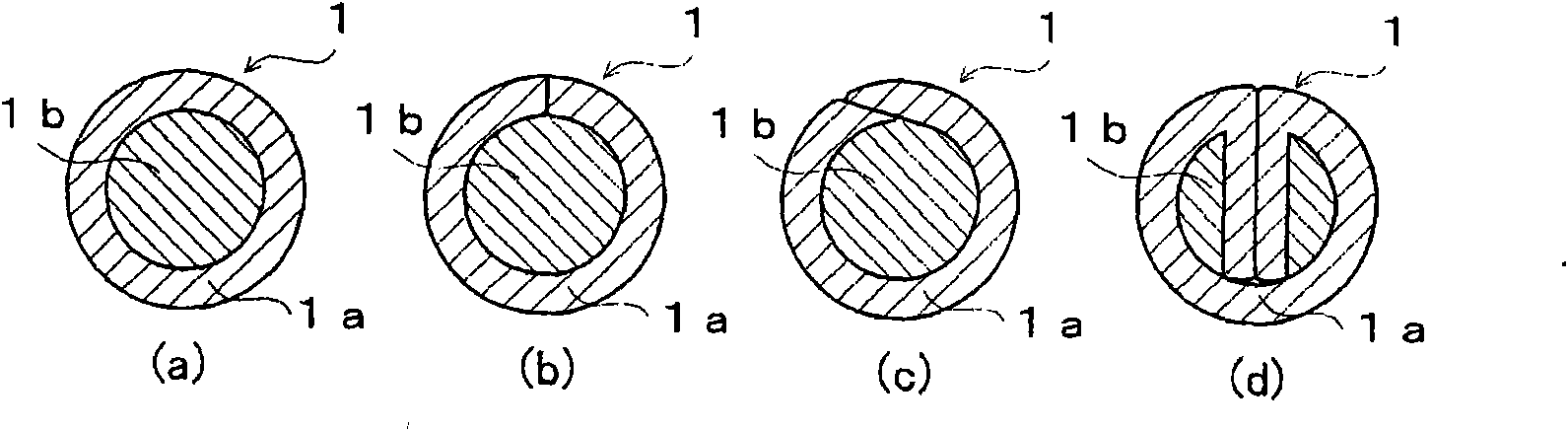

Flux-cored wire for different-material bonding and method of bonding different materials

InactiveCN101378873AImprove joint strengthGood welding efficiencyArc welding apparatusWelding/cutting media/materialsBonding strengthHigh intensity

The present invention provides a flux cored wire which increases bonding strength and is excellent in bonding efficiency in jointing an aluminum-base material with a steel-base material, a method for jointing dissimilar materials and a bonded joint obtained by the method. Specially, the present invention provides the method for jointing dissimilar materials when high-tension steel section and 6000 series aluminum alloy with different strength are executed with welded connection or when steel section is coated with aluminum. In one mode, the flux cored wire which is filled with welding flux in the outer skin of the aluminum product, therefore, the flux is prepared to a fluoride composition containing a certain amount of AlF3 and containing no chloride. The outer aluminum contains 1-13wt% of Si. When the flux cored wire according to the invention is used, a high jointing strength is obtained when high-tension steel section and 6000 series aluminum alloy with different strength are executed with melting welding.

Owner:KOBE STEEL LTD

High-strength low-temperature-resistant TiO2-series CO2 gas-shielded low-hydrogen type flux-cored wire

ActiveCN102528332AIncrease coverageArc stabilizationWelding/cutting media/materialsSoldering mediaHydrogen contentMetal

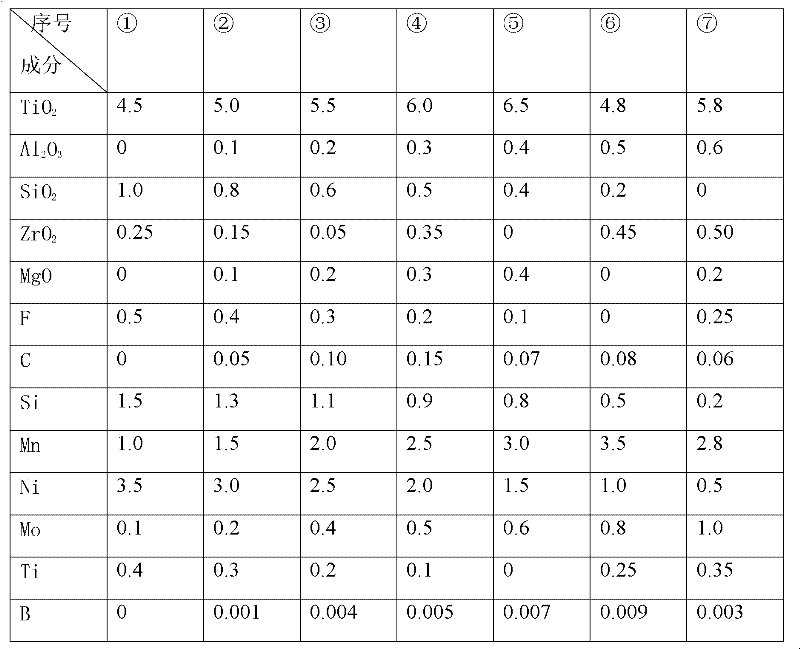

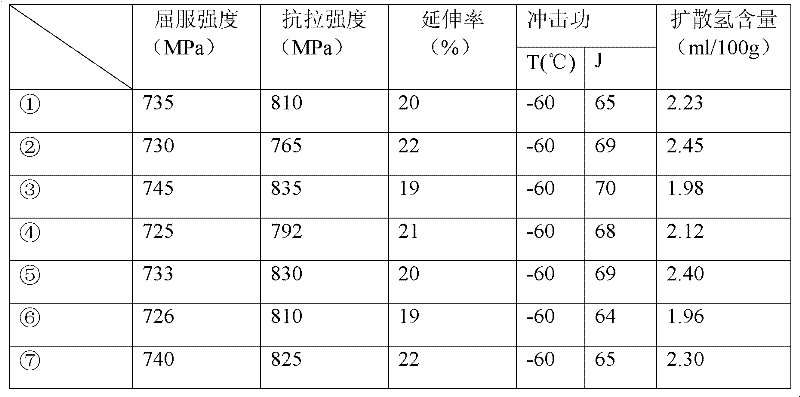

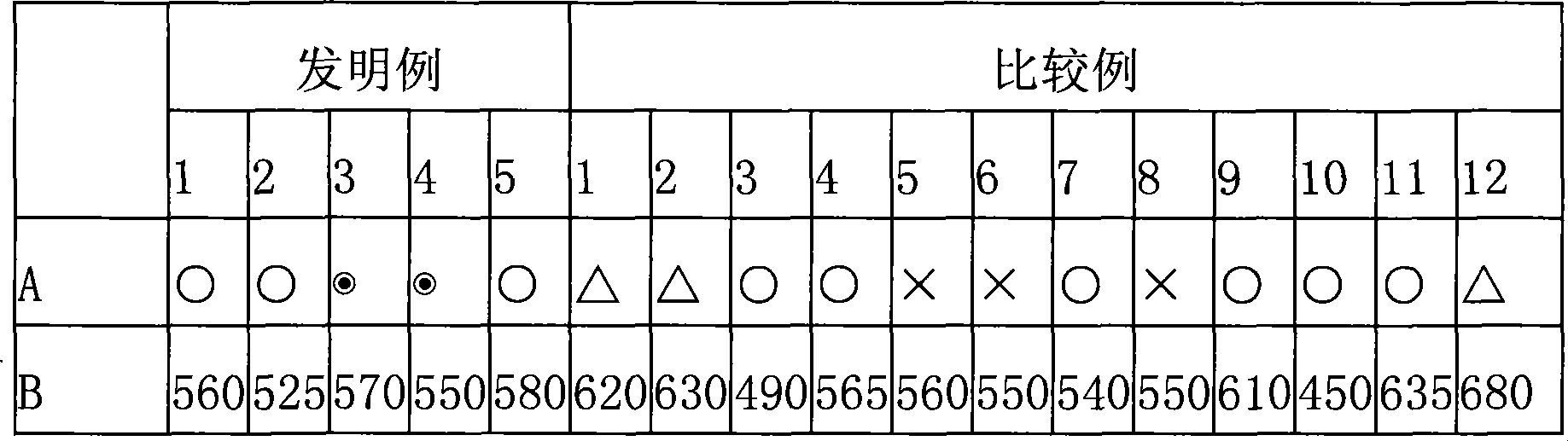

The invention discloses a high-strength low-temperature-resistant TiO2-series CO2 gas-shielded low-hydrogen type flux-cored wire, which comprises the following components in percentage by mass (based on total mass): 4.5-6.5% of TiO2, 0-0.6% of Al2O3, 0-1% of SiO2, 0-0.5% of ZrO2, 0-0.4% of MgO, 0-0.5% of F, 0-0.15% of C, 0.2-1.5% of Si, 1.0-3.5% of Mn, 0.5-3.5% of Ni, 0.1-1.0% of Mo, 0-0.4% of Ti and 0-0.009% of B. The cold-rolled steel strip for preparing the flux-cored wire comprises the following chemical ingredients by weight content: not more than 0.02% of C, not more than 0.010% of P, and not more than 0.008% of S. The tensile strength of the deposited metal can reach more than 760MPa, the low-temperature impact at -60 DEG C achieves more than 47J, and the diffusible hydrogen content is smaller than 4mL / 100g ( mercury method); and the flux-cored wire has excellent welding operational performance, and is suitable for port machines, ocean platforms, bridges and the like.

Owner:KUSN GINTUNE WELDING

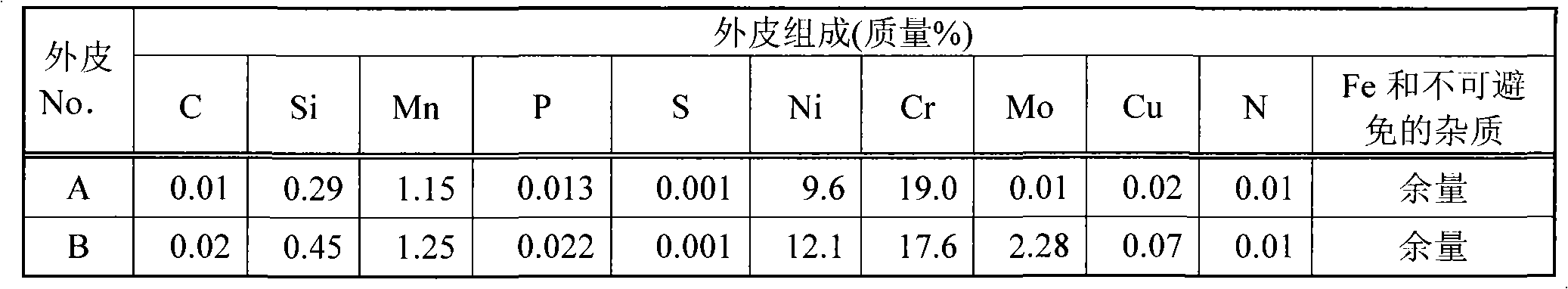

Stainless steel flux-cored wire for welding galvanized steel sheets and arc welding method for galvanized steel sheets using the same

ActiveCN102264505AImprove ductilityExcellent welding workabilityArc welding apparatusWelding/cutting media/materialsSheet steelSlag

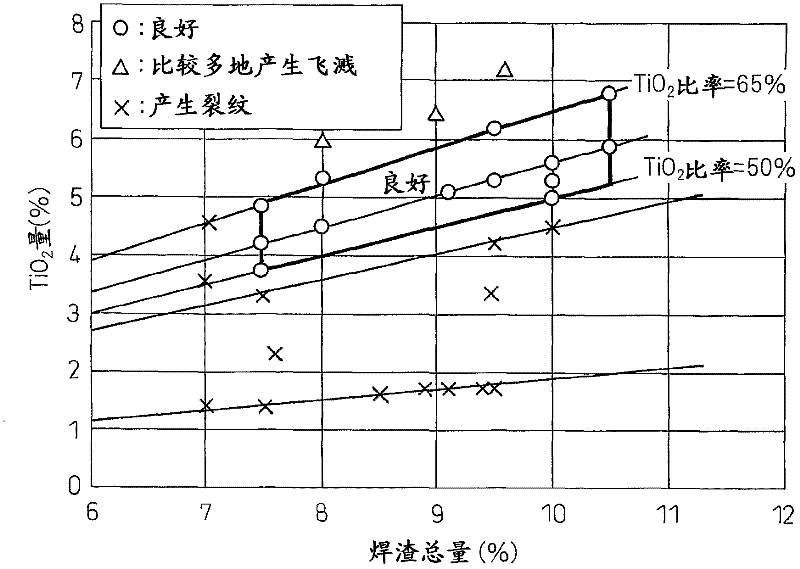

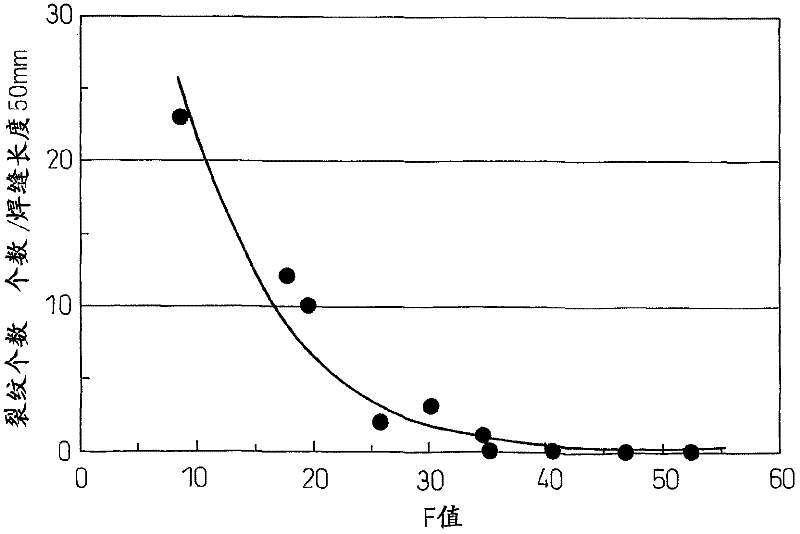

A stainless steel flux-cored welding wire for the welding of galvanized steel sheets, which dose not cause zinc embrittlement cracking, can give welds excellent in corrosion resistance and ductility, and attains excellent workability in welding; and a process for welding with the same. The welding wire is characterized in that the sheath and the flux contain, as metal or alloying components and in a total amount based on the total mass of the wire, C: 0.01 to 0.05%, Si: 0.1 to 1.5%, Mn: 0.5 to 3%, Ni: 7 to 10% and Cr: 26 to 30% with the F value falling within the range of 30 to 50, that the flux contains, as slag formers, TiO2: 3.8 to 6.8%, SiO2: 1.8 to 3.2%, ZrO2: 1.3% or below, and Al2O3: 0.5% or below, that the total amount of these slag formers and the other slag formers is 7.5 to 10.5%, that TiO2 accounts for 50 to 65% of the total amount of all the slag formers, and that the balance of the sheath and the flux consists of Fe and unavoidable impurities.

Owner:NIPPON STEEL CORP

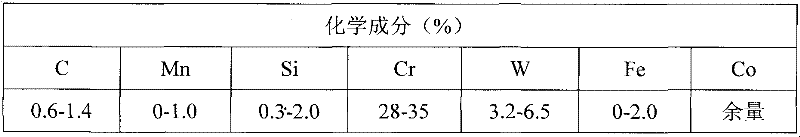

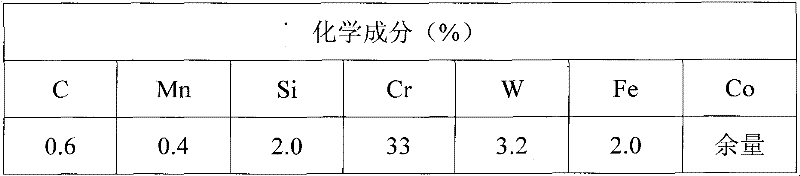

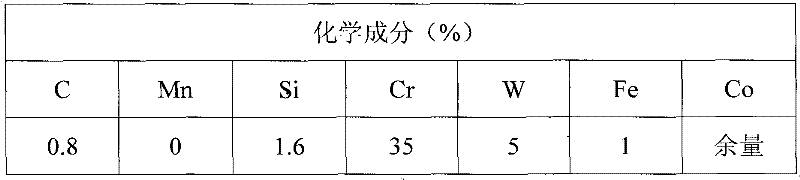

Surfacing welding electrode

ActiveCN102233496AImprove wear resistanceImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaSodium BentoniteSlag

The invention discloses a surfacing welding electrode. The surfacing welding electrode consists of a welding core and a coating, wherein the coating is coated on the outer wall of the welding core; the welding core comprises the following chemical components in percent by weight: 0.6-1.4% of C, 0-1.0% of Mn, 0.3-2.0% of Si, 28-35% of Cr, 3.2-6.5% of W, 0-2.0% of Fe and the balance of Co; and the coating adopts a TiO2-Si02-CaO slag system and comprises a slag making agent, a gas making agent and an alloy agent. All the components are as follows: the slag making agent comprises the following components in percentage by weight: 35-50% of rutile and titanium white (TiO2), 10-20% of mica, feldspar and bentonite (SiO2) and 5-12% of fluoride, wherein the fluoride comprises at least one of NaF and MgF2, CaF2 and BaF2; the gas making agent comprises the following component in percentage by weight: 12-22% of carbonate comprising CaCO3, MgCO3 and BaCO3; and the alloy agent comprises the following component in percentage by weight: 10-18% of manganese, chromium and nickel. In the welding material, a drill is utilized as a base body, so that the surfacing metal can still maintain good wear resistance and corrosion resistance when in working at the temperature of about 650 DEG C, and simultaneously the welding operation is good.

Owner:KUSN GINTUNE WELDING

Filling soldering flux wire for titania gas coverage arc welding

ActiveCN101157169AImprove mechanical propertiesExcellent peelabilityWelding/cutting media/materialsWelding/soldering/cutting articlesSolderingMechanical property

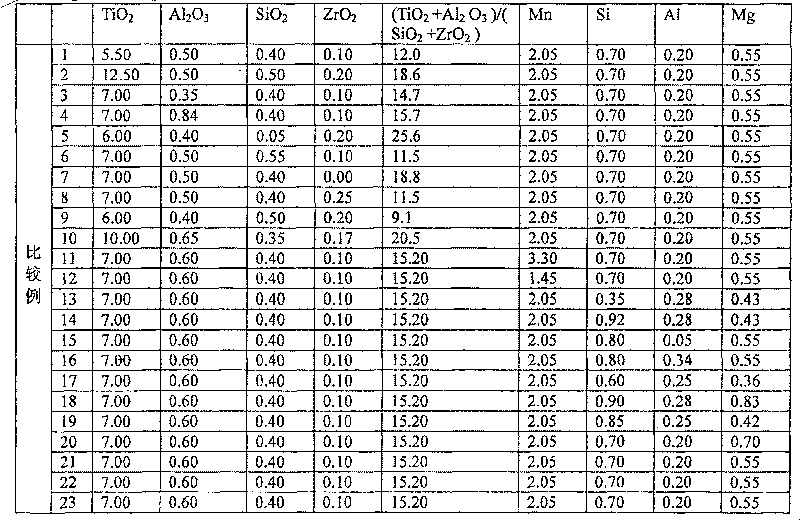

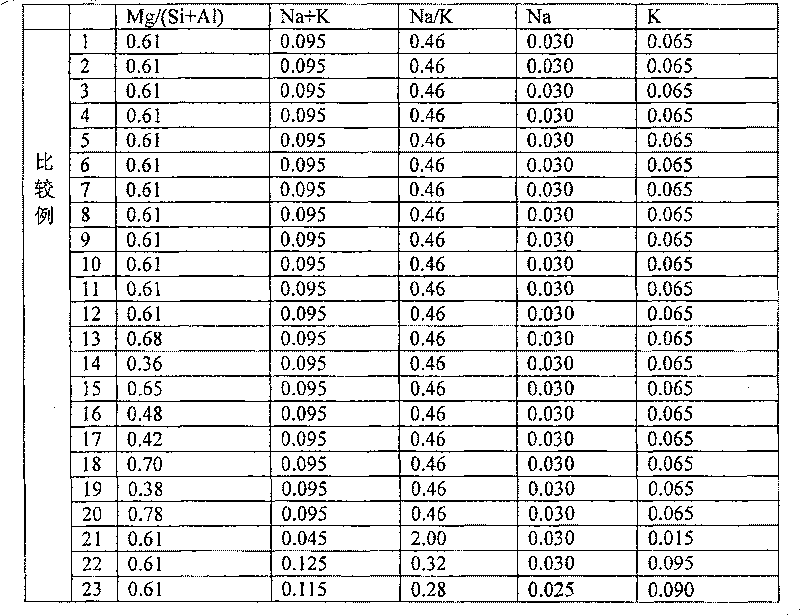

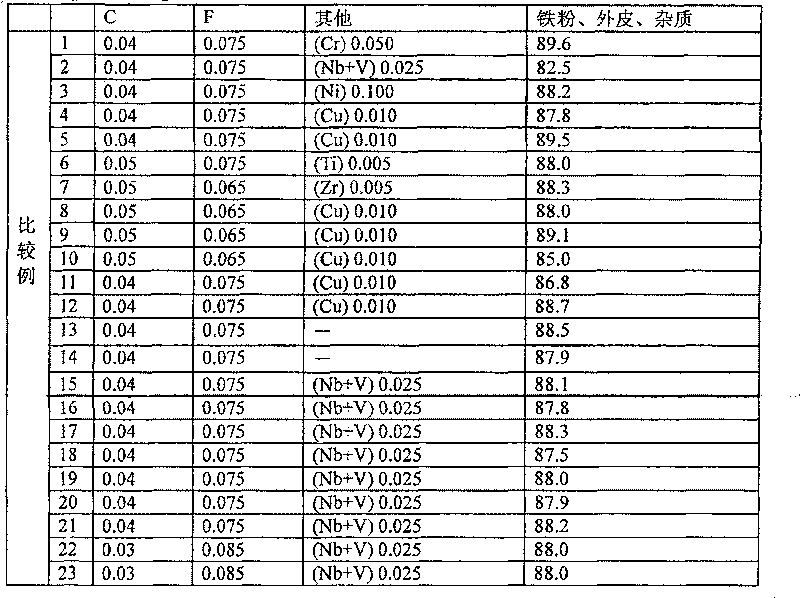

The invention provides a flux-cored wire for gas-shielded arc welding. The total quality of flux-cored wire which contains in its quality percentage TiO2: 6 to 12%, Al2O3: 0.4 to 0.8%, SiO2: 0.1 to 0.5%, ZrO2: 0.05 to 0.2%, Mn: 1.0 to 3.0%, Si: 0.4 to 0.9%, Al: 0.1 to 0.3% and Mg: 0.4 to 0.8%. The invention also comprises C, F, Cr, Cu, Ni, V, Nb, Ti and or Zr. The rest comprises Fe and impurities, wherein, TiO2 and Al2O3: SiO2 and ZrO2 is 10 to 20; Mg: Si and Al is 0.4 to 0.7; Na and K is 0.05 to 0.12%; and Na: K is more than 0.3. The invention has the advantages of having no molten metal falling off even the welding gap root is quite narrow along the vertical direction, having good welding performance and having excellent mechanical capacity of the welded metal.

Owner:KOBE STEEL LTD

Flux-cored wire

InactiveCN101396774AExcellent welding workabilityGood weld metal tensile strength and impact toughnessWelding/cutting media/materialsSoldering mediaDuctilityElectric arc

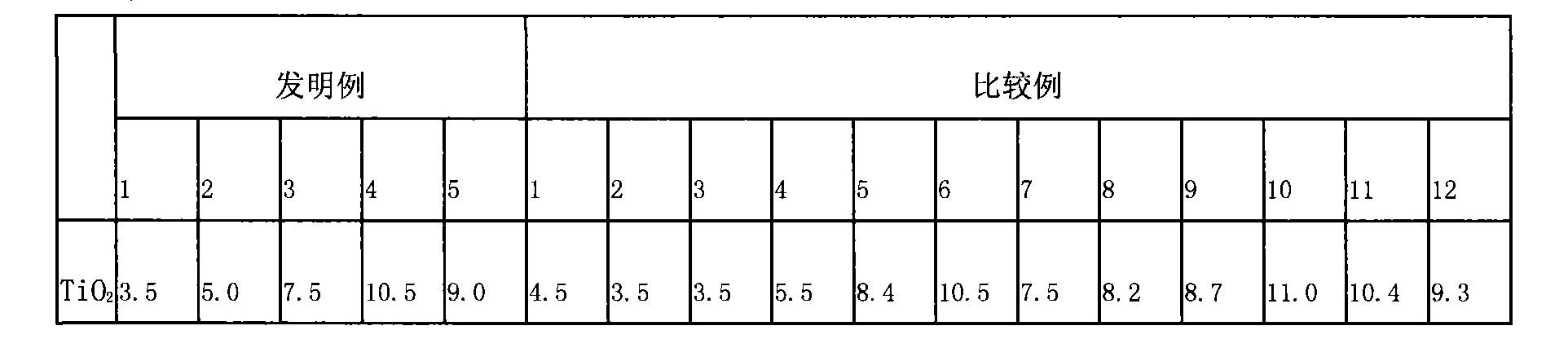

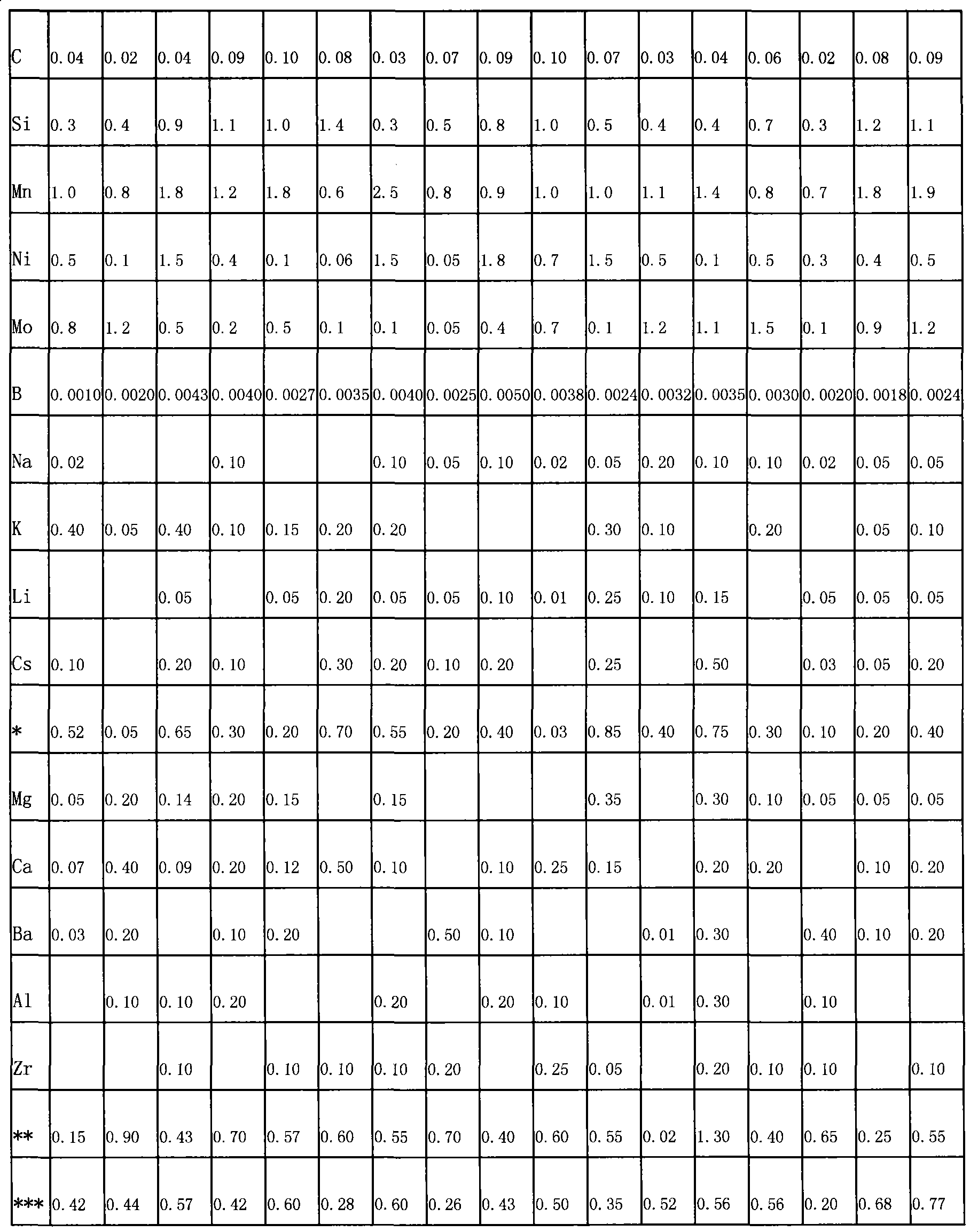

The invention discloses a flux-cored wire, which relates to a flux-cored wire with medicinal powder filled in a soft steel sheath that is specially used for gas shielded arc welding. Each component of the medicinal powder has the following percentages by weight relative to wires: 3.0% to 11.0% of TiO2; 0.02% to 0.10% of C; 0.3% to 1.2% of Si; 0.7% to 2.0% of Mn; 0.1% to 1.5% of Ni; 0.1% to 1.2% of Mo; 0.0010% to 0.0045% of B; 0.05% to 1.00% of the sum of any one or more than two elements of Na, K, Li and Cs; 0.05% to 1.00% of the sum of any one or more than two elements of Mg, Ca, Ba, Al and Zr; balance iron powder and irremovable impurities, and the composition of each element satisfies the conditional expression that C+Si / 25+Mn / 5+Ni / 40+Mo / 5 is greater than or equal to 0.25 and is less than or equal to 0.60; the electric arc welding for gas shielding at the conditions that the maximum welding heat is 60KJ / cm and the maximum interlayer-temperature is 350 DEG C has excellent welding operation, fine welding metal intensity of tension and impact ductility.

Owner:SUPAITE METAL KUSN

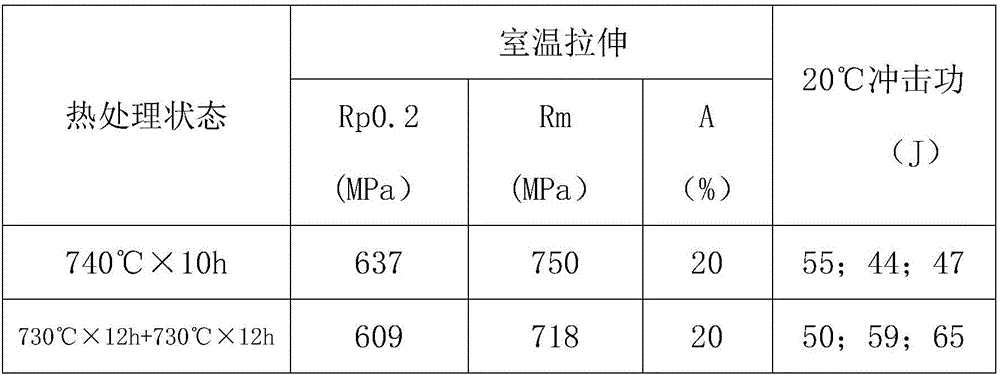

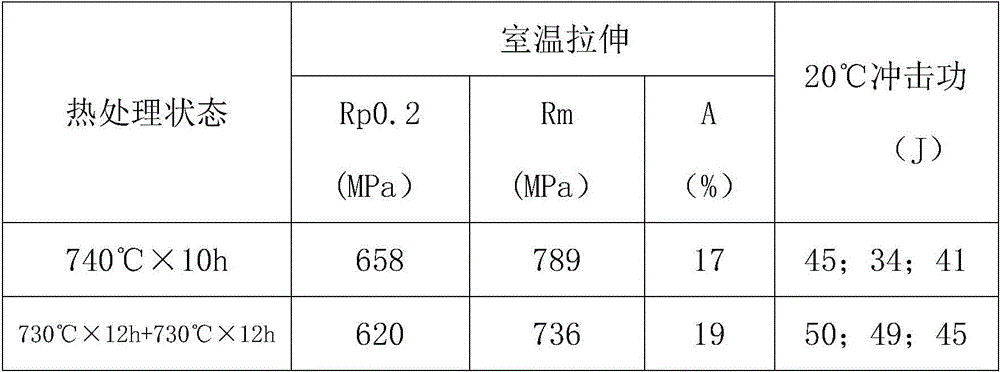

Ultra-supercritical material CB2 steel matched welding rod applicable to long-term high-temperature service and preparation method thereof

ActiveCN106808113AImprove yieldEasy to remove slagWelding/cutting media/materialsSoldering mediaElectrolysisNiobium

The invention discloses an ultra-supercritical material CB2 steel matched welding rod applicable to long-term high-temperature service. A coating is prepared from, by weight, 220-300 parts of marble, 180-300 parts of fluorite, 40-70 parts of rutile, 4.5-7.0 parts of sodium carbonate, 6-8 parts of zircon sand, 100-150 parts of iron powder, 10-30 parts of electrolytic manganese, 40-80 parts of silica powder, 20-60 parts of cryolite powder, 1-15 parts of nickel powder, 1-10 parts of chromium metal, 1-5 parts of molybdenum powder, 1-15 parts of ferrovanadium, 1-15 parts of niobium powder, 1-15 parts of nitrogen-bearing ferrochromium, 1-10 parts of potassium fluoborate, 1-10 parts of borax and 1-5 parts of si-mg-fe alloy. Weld joint molding is attractive, the weld pass height is moderate, the weld joint infiltration angle is moderate, and the deposited metal physical and chemical property is moderate.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

Welding wire of filling flux of gas protection electric arc welding using for high-strength steel

InactiveCN1387975AExcellent welding workabilityImprove the efficiency of welding operationsArc welding apparatusWelding/cutting media/materialsChemical compositionHigh intensity

Disclosed is a flux cored wire for gas shielded arc welding of high tensile strength steel, characterized in that the flux essentially consists of, with respect to the total weight of the wire: metal or ferroalloy containing at least Si, Mg and Al acting as a deoxidizing agent, the sum of the three components, Si, Mg and Al being from 0.5 to 1.5%; from 1.5 to 2.7% Mn, provided that the ratio of Mn to (Mg+Al), i.e., the value of Mn / (Mg+Al) is 3.5-5.0; and two or more components selected from the group consisting of Cr, Ni, Mo and Nb, the sum of the two or more components being 1.0-2.5%. The flux cored wire exhibits good welding workability in all welding positions, ensuring an improvement in the efficiency of welding work, and maintains high tensile strength and impact absorption energy, ensuring stability of welded structures.

Owner:KISWEL LTD

Sintered flux for submerged-arc welding of steel structure U-shaped rib plate

ActiveCN105945453AImprove bindingNo crackArc welding apparatusWelding/cutting media/materialsSubmerged arc weldingMetallurgy

The invention discloses sintered flux for submerged-arc welding of a steel structure U-shaped rib plate. The sintered flux comprises, by mass percent, 15%-25% of MgO, 3%-8% of CaO, 15%-25% of CaF2, 2%-5% of MnO, 25%-35% of Al2O3, 10%-20% of SiO2, 3%-7% of TiO2 and 1%-3% of SiFe. According to the sintered flux, the welding speed can be increased, the stable fusion depth can be provided in the high-speed welding state, and welding forming is attractive.

Owner:武汉天高熔接股份有限公司

Filling flux welding wire

InactiveCN102485409AExcellent high temperature crack resistanceImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaFilling rateHigh intensity

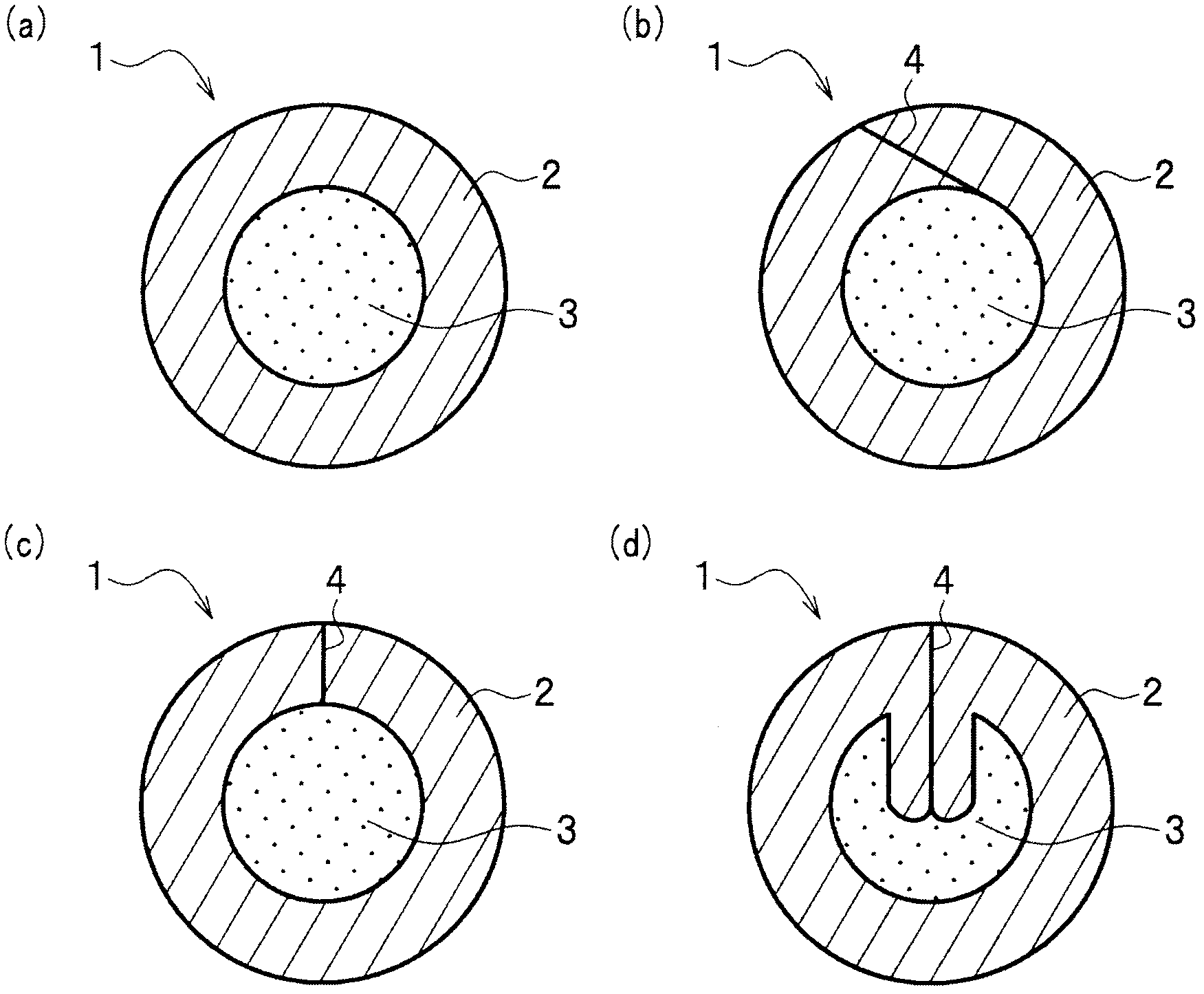

The invention provides a filling flux welding wire, which possesses the advantages of high temperature resistance of the primary layer welding part, which is welded by a single layer joint of the steel plate formed by the soft steel and the high tension steel, and welding operation performance as well as the welding metal machinery performance of the integral gesture welding. The invention is a filing flux welding wire used for the welding of the steel plates formed by the soft steel or the high tension steel and of the filling flux welding wire formed by filling the flux in the steel outer skin. The invention is characterized in that the required volume of the welding flux filling rate is a welding wire integral quality, and compared to the required volume of the welding wire integral quality, the invention comprises C, Si, Mn, Ti, TiO2,A1, A12O3,B,N,Ni(including0%), Cu(including0%), and the invention satisfies the equation that 10 equal to or larger than (Ni+14*C+0.29*Mn+0.30*Cu) / (1.5*Si) larger than or equal to 2.5(symbol of element represents the content of the element (mass percent)).

Owner:KOBE STEEL LTD

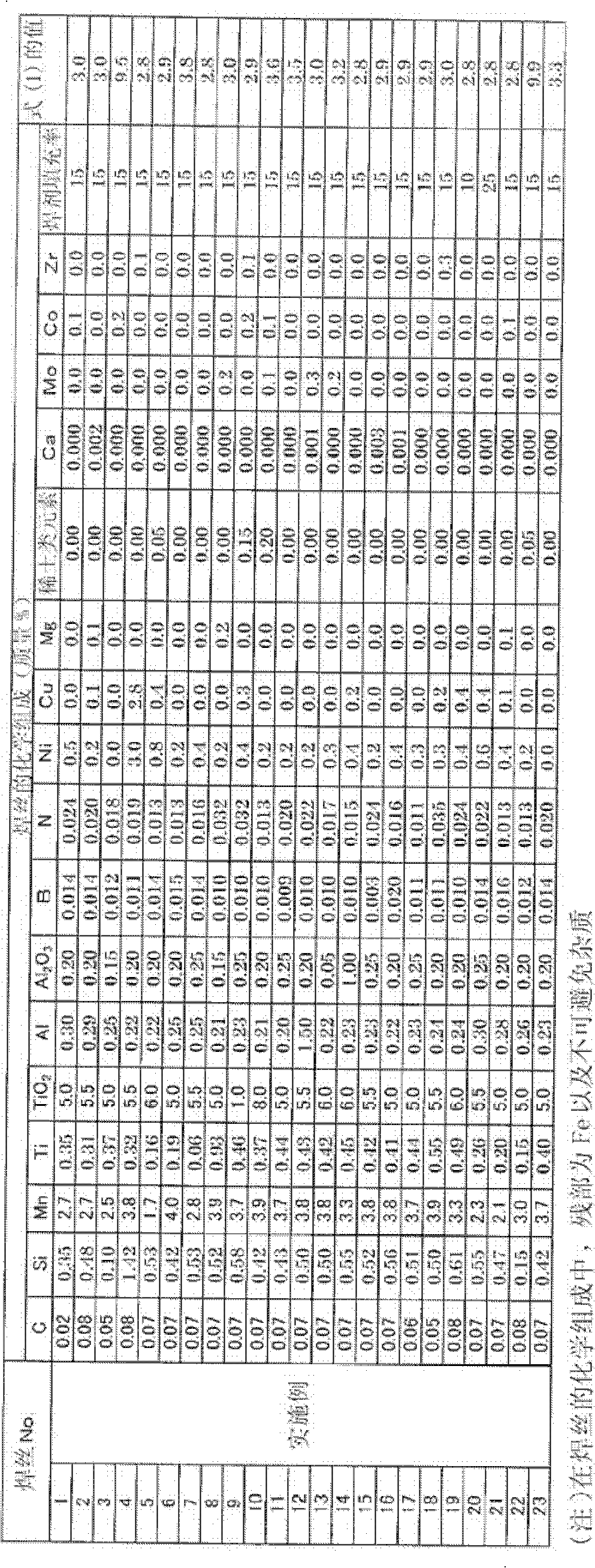

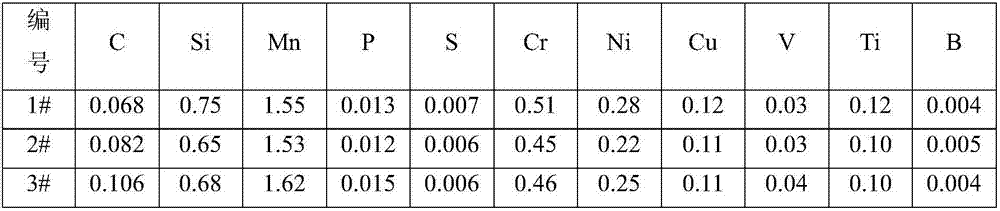

Solid welding wire for gas-shielded electric-arc welding of high-strength steel

InactiveCN107009047AImprove mechanical propertiesImprove impact toughnessWelding/cutting media/materialsSoldering mediaProcess windowMechanical property

The invention discloses a solid welding wire for gas-shielded electric-arc welding of high-strength steel, and belongs to the technical field of welding materials. The solid welding wire consists of the following chemical components in percentage by mass: 0.06-0.15% of C, 0.60-1.00% of Si, 1.50-2.00% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.10-0.60% of Ni, 0.40-0.80% of Cr, less than or equal to 0.25% of Cu, 0.02-0.10% of V, 0.08-0.25% of Ti, 0.002-0.008% of B, less than or equal to 0.0070% of O, less than or equal to 0.0070% of N, and the balance iron and inevitable impurities. The solid welding wire has mechanical property superior to that of a base material, is excellent in welding operation property, is suitable for a relatively wide operation process window, is mature and efficient in industrial production route, and is low in processing manufacturing cost.

Owner:SHOUGANG CORPORATION

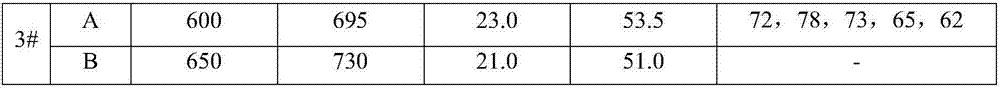

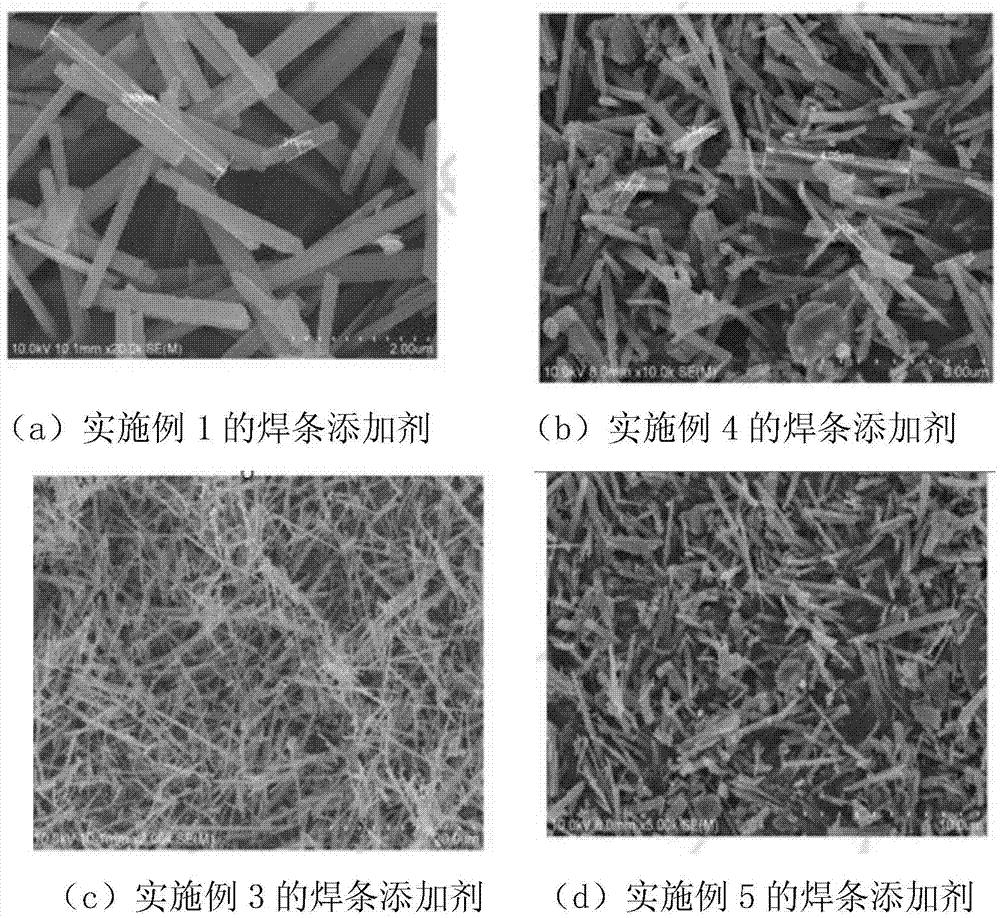

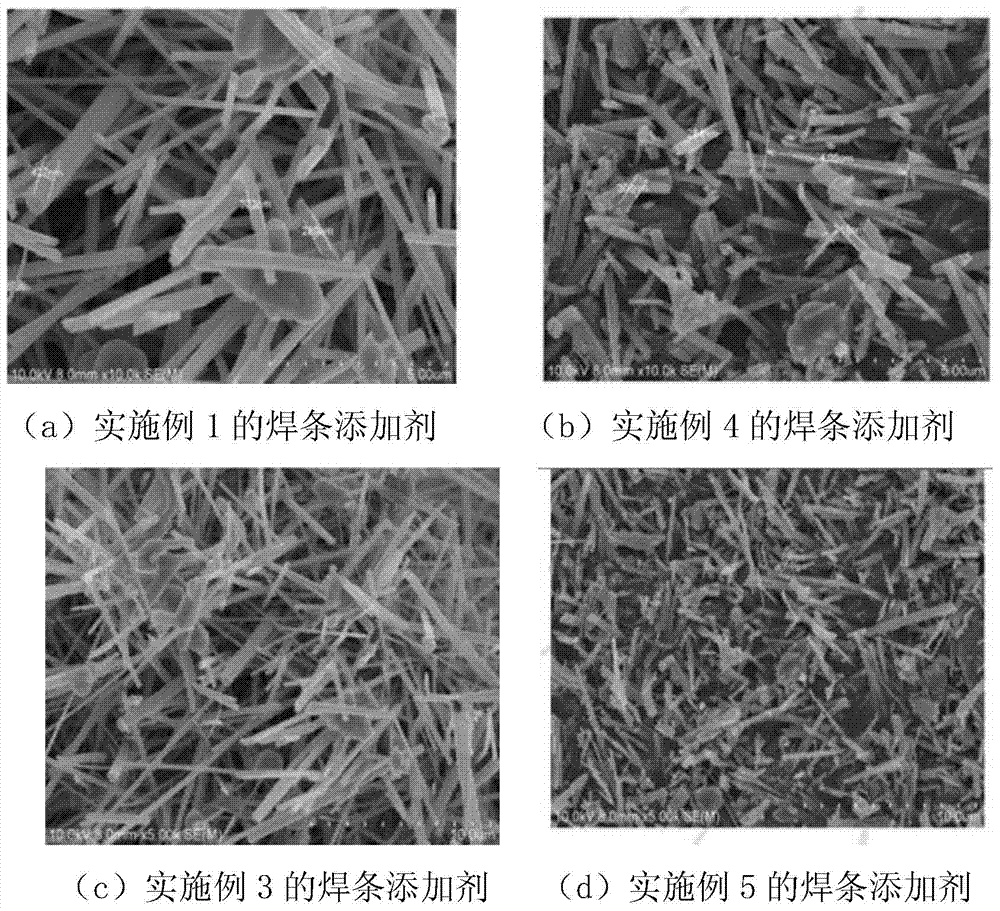

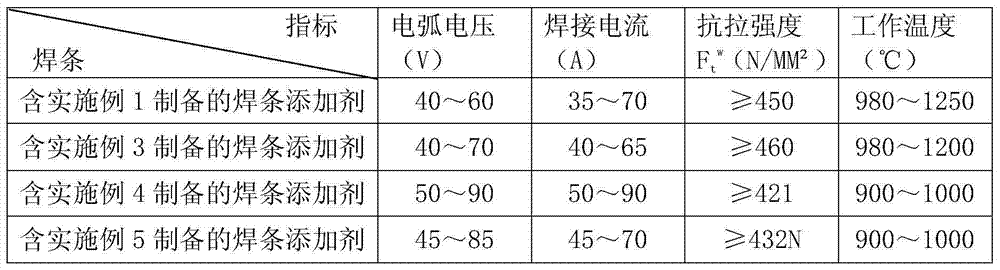

Welding rod additive containing cerium oxide and method for preparing welding rod additive containing cerium oxide

ActiveCN104117784AEasy to useExcellent welding workabilityWelding/cutting media/materialsSoldering mediaPowder mixtureFree cooling

The invention discloses a welding rod additive containing cerium oxide and a method for preparing the welding rod additive containing cerium oxide. The method for preparing the welding rod additive containing cerium oxide comprises the following steps that (a) high-purity titanium dioxide, carbonate and cerium oxide are weighed according to a proportion and then are mixed, so that a mixture is obtained; (b) the mixture is placed into a ball mill for ball milling for three hours to five hours, and a powder mixture is obtained; (c) the powder mixture is contained in a bowl, the bowl containing the powder mixture is pushed into a furnace, the temperature of the furnace is made to rise to 1195 DEG C-1205 DEG C with the temperature rising rate of 240 DEG C / h-260 DEG C / h, the temperature is maintained for 3.5 hours to 4.5 hours, then a temperature rising system of the furnace is stopped, and the bowl is taken out of the furnace after natural cooling is conducted for 7.5 hours to 8.5 hours; (d) after a synthesized lump in the bowl is naturally cooled to be at the normal temperature, the lump is smashed and ground to be particles which at least can pass through a 100-mesh screen, and thus the welding rod additive containing cerium oxide is obtained. When the welding rod additive is added to welding rods, arc voltage can be lowered when the welding rods are used, electric arcs can be stabilized, splashing is reduced, and the welding strength of the welding rods can be greatly improved.

Owner:ANHUI SHENGHONG ELECTRONICS +1

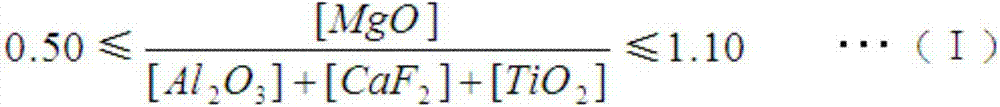

Flux for use in submerged arc welding

ActiveCN107206549AExcellent welding workabilityReduce moisture absorptionArc welding apparatusWelding/cutting media/materialsSubmerged arc weldingWater soluble

Provided is a flux for use in submerged arc welding, capable of reducing the moisture content in the flux and the amount of diffusible hydrogen in the welding metal, and exhibiting favorable welding activity, regardless of whether the welding power source is of the alternating current or the direct current type. The composition of this flux for use in submerged arc welding contains MgO in the amount of 25-35 mass%, F in the amount of 15-35 mass% when calculated as CaF2, Al2O3 in the amount of 10-25 mass%, SiO2 in the amount of 10-20 mass%, one or more of Na when calculated as Na2O, K when calculated as K2O, and Li when calculated as Li2O in the total combined amount of 0.5-6.5 mass%, Fe in the amount of 0.5-5 mass% when calculated as FeO, TiO2 in the amount of 1-5 mass%, CaO in the amount of 6 mass% or less (including 0 mass%), Mn in the amount of less than 2.0 mass% when calculated as MnO (including 0 mass%), water-soluble SiO2 in the amount of 1.0 mass% or less (including 0 mass%), water-soluble Na2O in the amount of 1.0 mass% or less (including 0 mass%), and water-soluble K2O in the amount of 0.8 mass% or less (including 0 mass%). In addition, the C content thereof is 0.2 mass% or less (including 0 mass%). Furthermore, the flux composition satisfies mathematical formula (I), given that the MgO content is [MgO], the Al2O3 content is [Al2O3], the F content when calculated as CaF2 is [CaF2], and the TiO2 content is [TiO2].

Owner:KOBE STEEL LTD

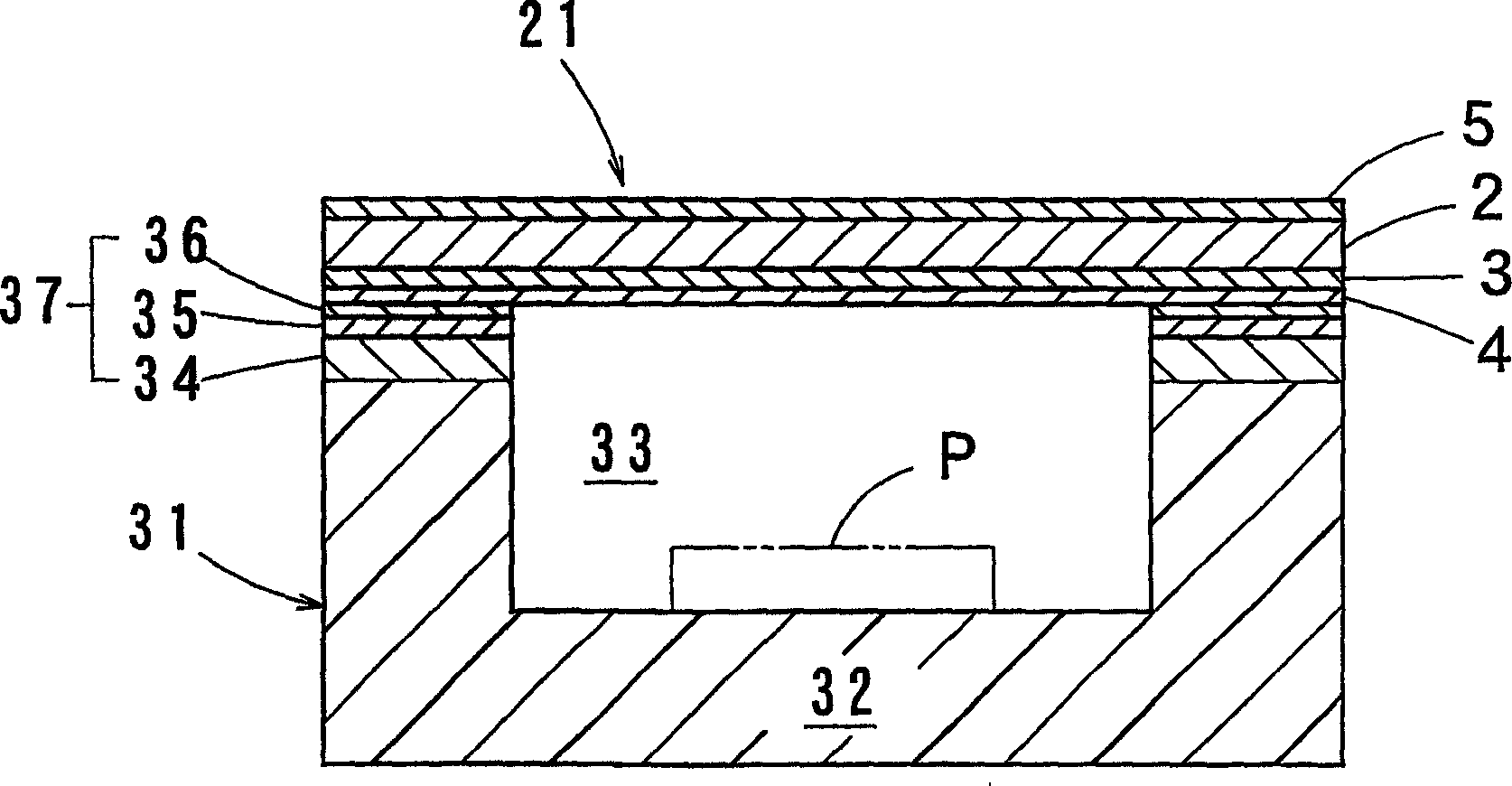

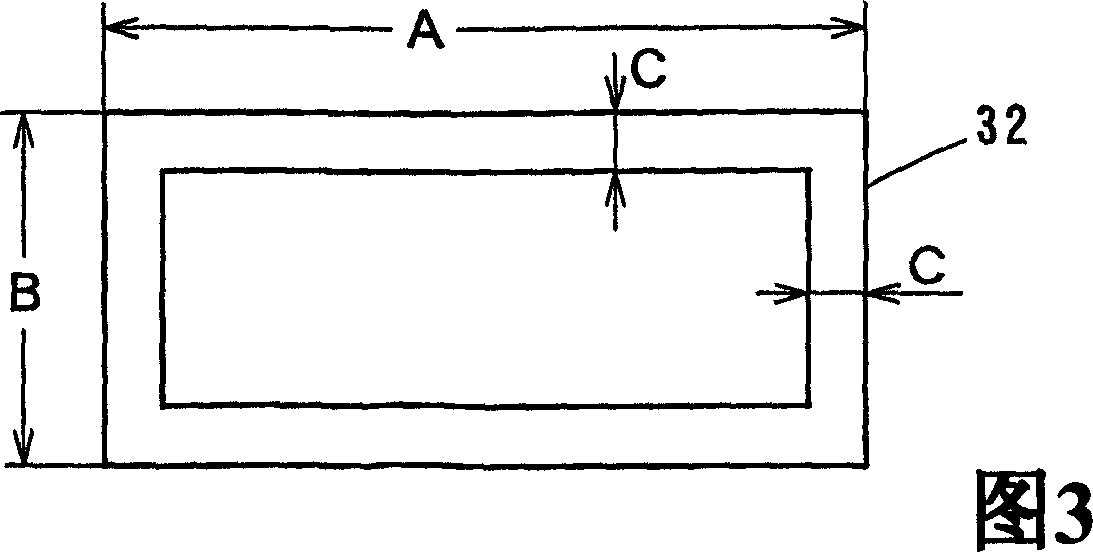

Package for electronic parts, lid thereof, material for the lid and method for producing the lid material

InactiveCN1561542AInhibit thermal stressPrevent poor welding workabilitySemiconductor/solid-state device detailsSolid-state devicesThermal expansionBond properties

Owner:DAISHINKU CORP +1

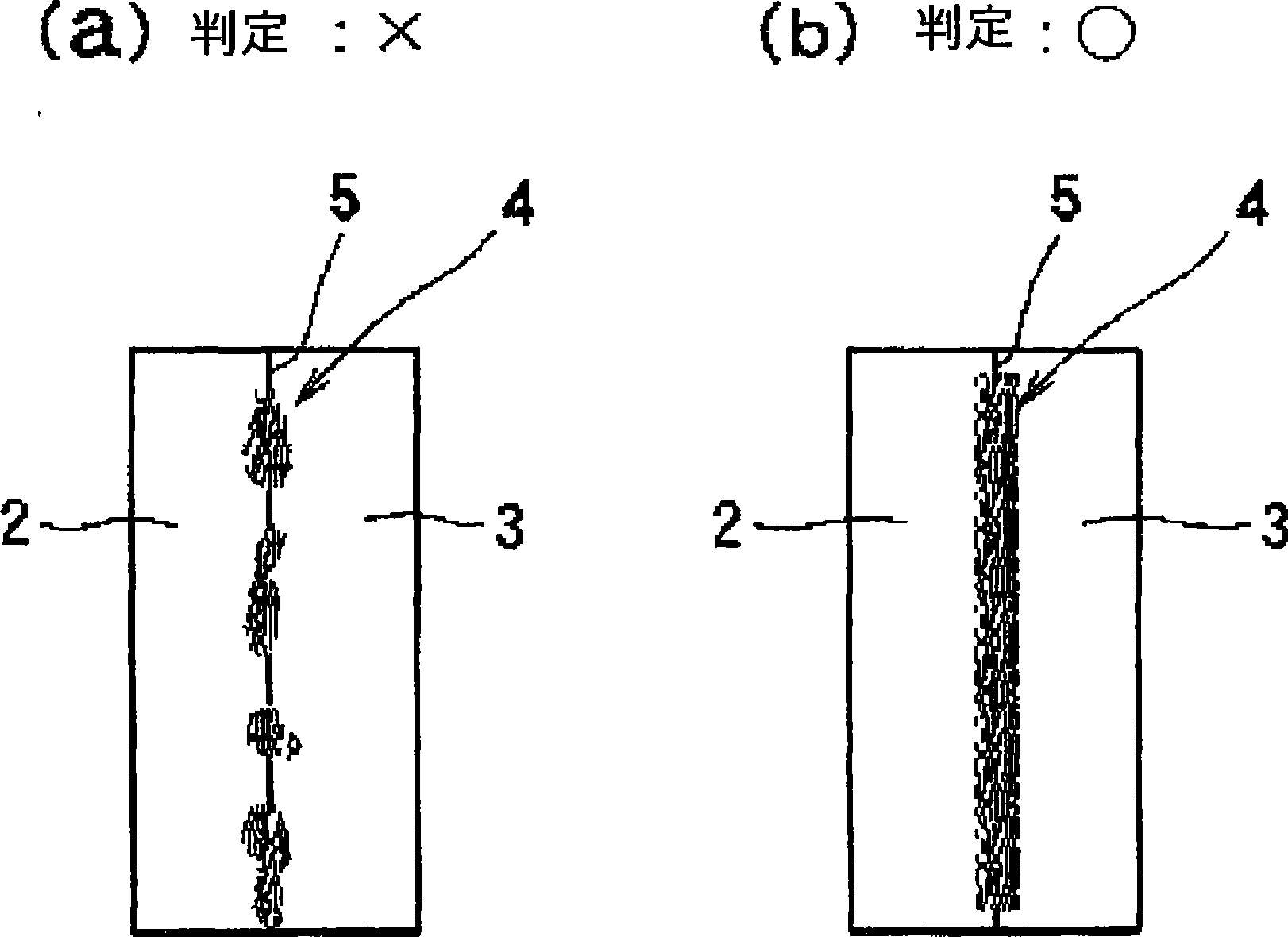

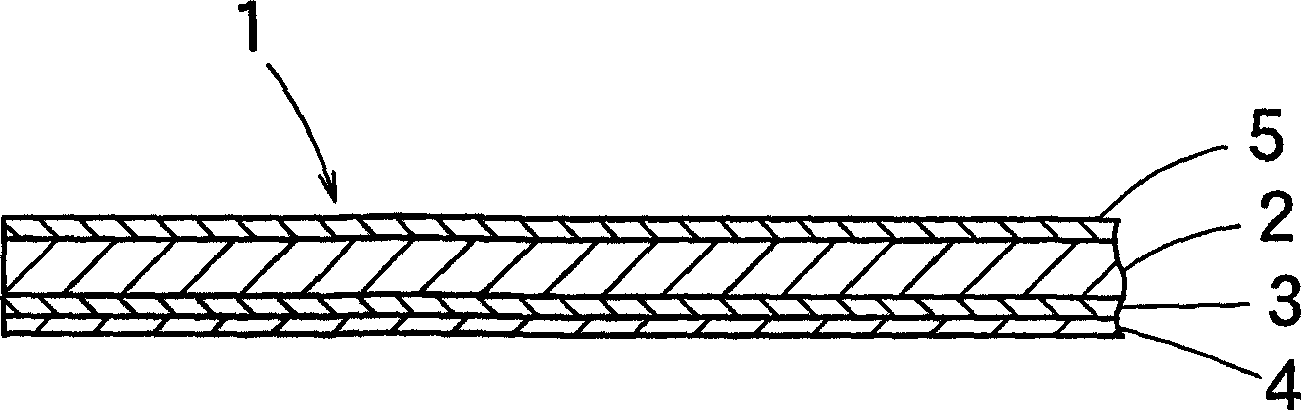

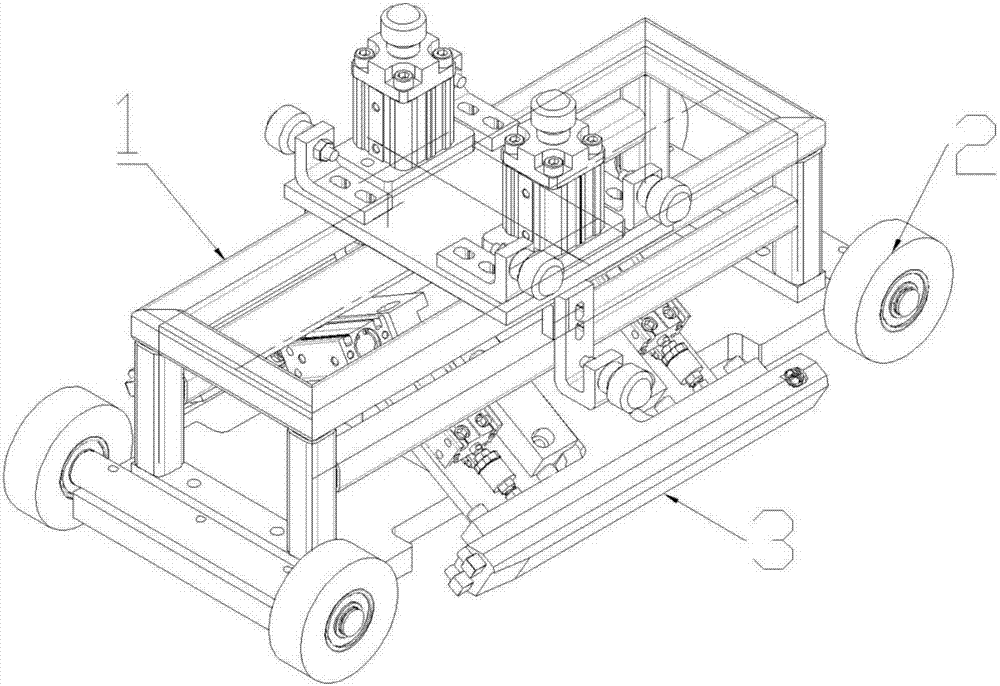

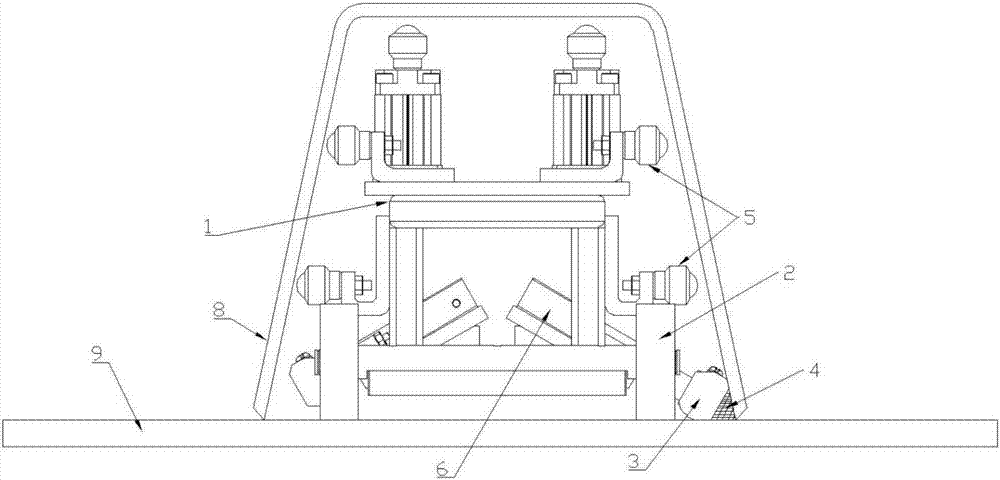

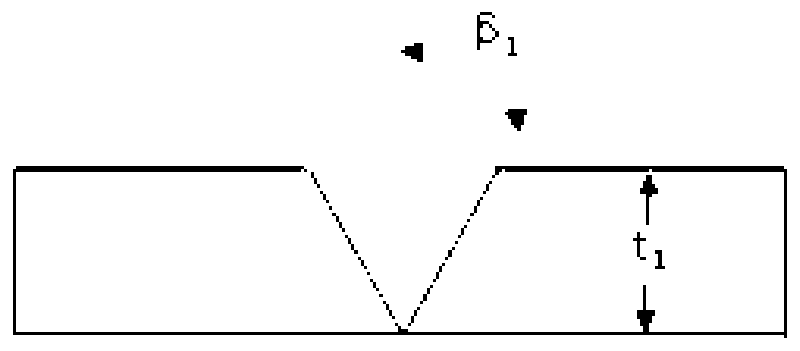

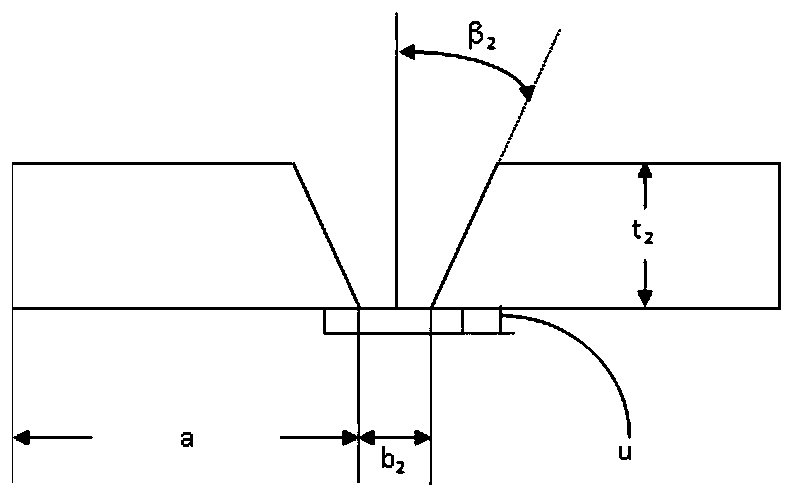

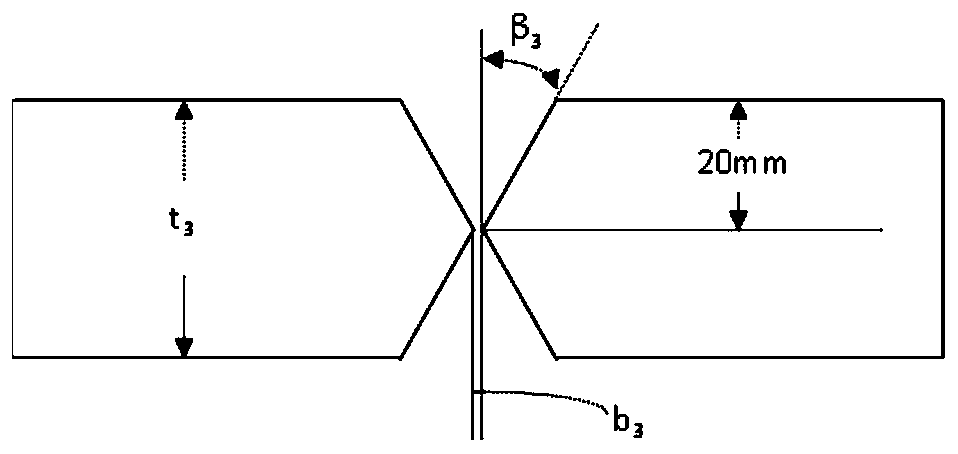

Combined gasket and automatic mounting and pasting jacking mechanism and welding process of combined gasket

ActiveCN107414260ALow costImprove fatigue resistance of weldsWelding/cutting media/materialsSoldering mediaBridge deckEngineering

The invention discloses a combined gasket. The combined gasket is used for forming the back face of a longitudinal seam when the front face of the longitudinal seam of a bridge deck slab and a U-shaped rib is welded, and comprises a soft gasket body used for being attached to the back face of the longitudinal seam tightly, and a hard gasket body used for being attached to the face, away from the longitudinal seam, of the soft gasket body, wherein when the front face of the longitudinal seam is welded, part of the soft gasket body is fused, and the hard gasket body is not fused. The invention further discloses an automatic mounting and pasting jacking mechanism of the combined gasket and a welding process of the combined gasket. Through the combined gasket, the problem of hybrid manufacturing of low-melting-point materials and high-melting-point materials is solved, the gasket cost is reduced, through the automatic mounting and pasting jacking mechanism, the problem that gaskets cannot be mounted in long and narrow U-shaped cavities manually is solved, and through the welding process, the problem that burn through is liable to occur to traditional bridge deck slab U rib welding or the design weld penetration cannot be reached is solved.

Owner:武汉天高熔接股份有限公司 +2

Welding rod additive containing yttrium oxide and method for preparing welding rod additive containing yttrium oxide

ActiveCN104117785AExcellent welding workabilityWeld fineWelding/cutting media/materialsSoldering mediaPowder mixtureWeld strength

The invention discloses a welding rod additive containing yttrium oxide and a method for preparing the welding rod additive containing yttrium oxide. The method for preparing the welding rod additive containing yttrium oxide comprises the following steps that (a) high-purity titanium dioxide, carbonate and yttrium oxide are weighed according to a proportion and are mixed, so that a mixture is obtained; (2) the mixture is placed into a ball mill for ball milling for 3 hours to 5 hours, so that a powder mixture is obtained; (3) the powder mixture is contained in a bowl, the bowl containing the powder mixture is pushed into a furnace, the temperature of the furnace is made to rise to 1195 DEG C-1205 DEG C with the temperature rising rate of 240 DEG C / h-260 DEG C / h, the temperature is maintained for 3.5 hours to 4.5 hours, then a temperature rising system of the furnace is stopped, and the bowl is taken out of the furnace after natural cooling is conducted for 7.5 hours to 8.5 hours; (d) after a synthesized lump in the bowl is naturally cooled to be at the normal temperature, the lump is smashed and ground to be particles which at least can pass through a 100-mesh screen, and thus the welding rod additive containing yttrium oxide is obtained. When welding rods manufactured with the welding rod additive serving as processing raw materials are used practically, the arc voltage during welding can be lowered, electric arcs can be stabilized, splashing is reduced, the welding strength of the welding rods can be effectively improved, and electricity loss can be reduced.

Owner:ANHUI JINSANLONG RENEWABLE RESOURCES +1

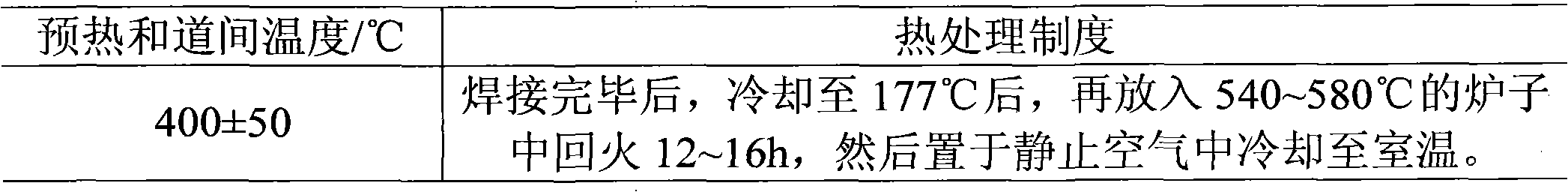

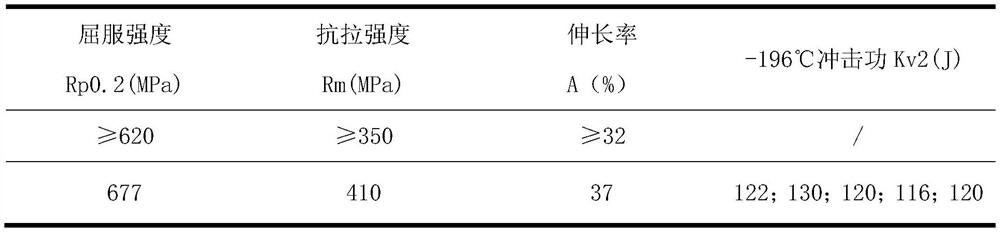

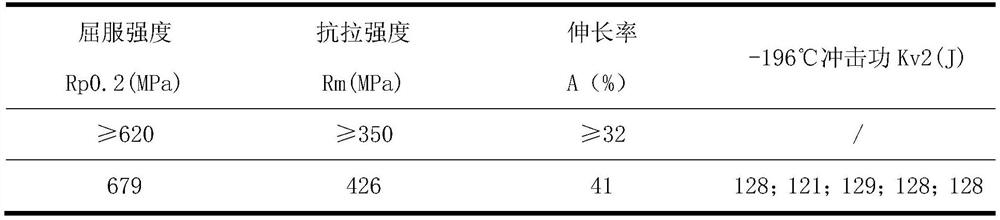

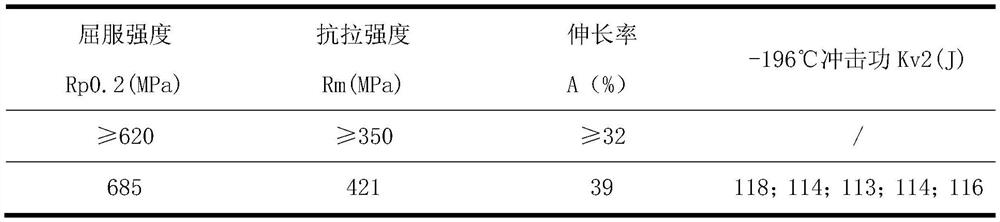

ENi6620 nickel-based welding rod for alternating current and preparation method and welding method thereof

ActiveCN113414519AArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention discloses an ENi6620 nickel-based welding rod for alternating current and a preparation method and a welding method of the ENi6620 nickel-based welding rod for alternating current. The ENi6620 nickel-based welding rod comprises a core wire and a coating wrapping the surface of the core wire. The coating is composed of the following components in parts by weight, 6-10 parts of marble, 3-6 parts of strontium carbonate, 6-9 parts of fluorite, 2-5 parts of potassium ice crystal powder, 0.5-1.5 parts of potassium fluoborate, 2-6 parts of rutile, 5-8 parts of electrolytic manganese, 25-30 parts of chromium metal, 15-22 parts of ferromolybdenum, 2-5 parts of ferrotitanium, 3-6 parts of tungsten powder, 5-9 parts of ferrocolumbium, 1-3 parts of sodium carbonate, 2-6 parts of potassium titanate, 1-4 parts of rare earth fluoride, 0.5-2.5 parts of zirconium dioxide and 0.5-3.5 parts of rare earth ferrosilicon. By the adoption of the scheme, the welding rod meets the GB / T 13814ENi6620 technical index, has good welding process performance and mechanical performance, and particularly has good low-temperature toughness under the condition of minus 196 DEG C.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

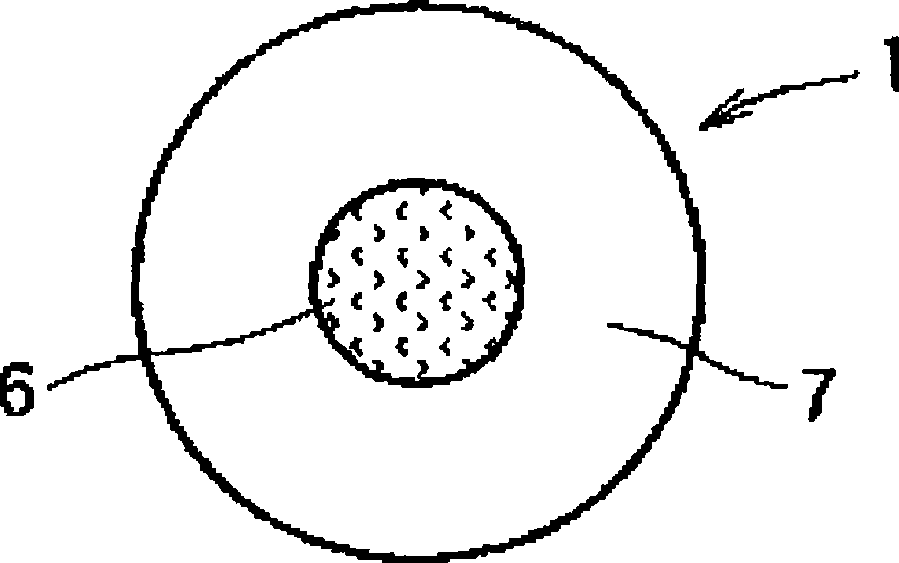

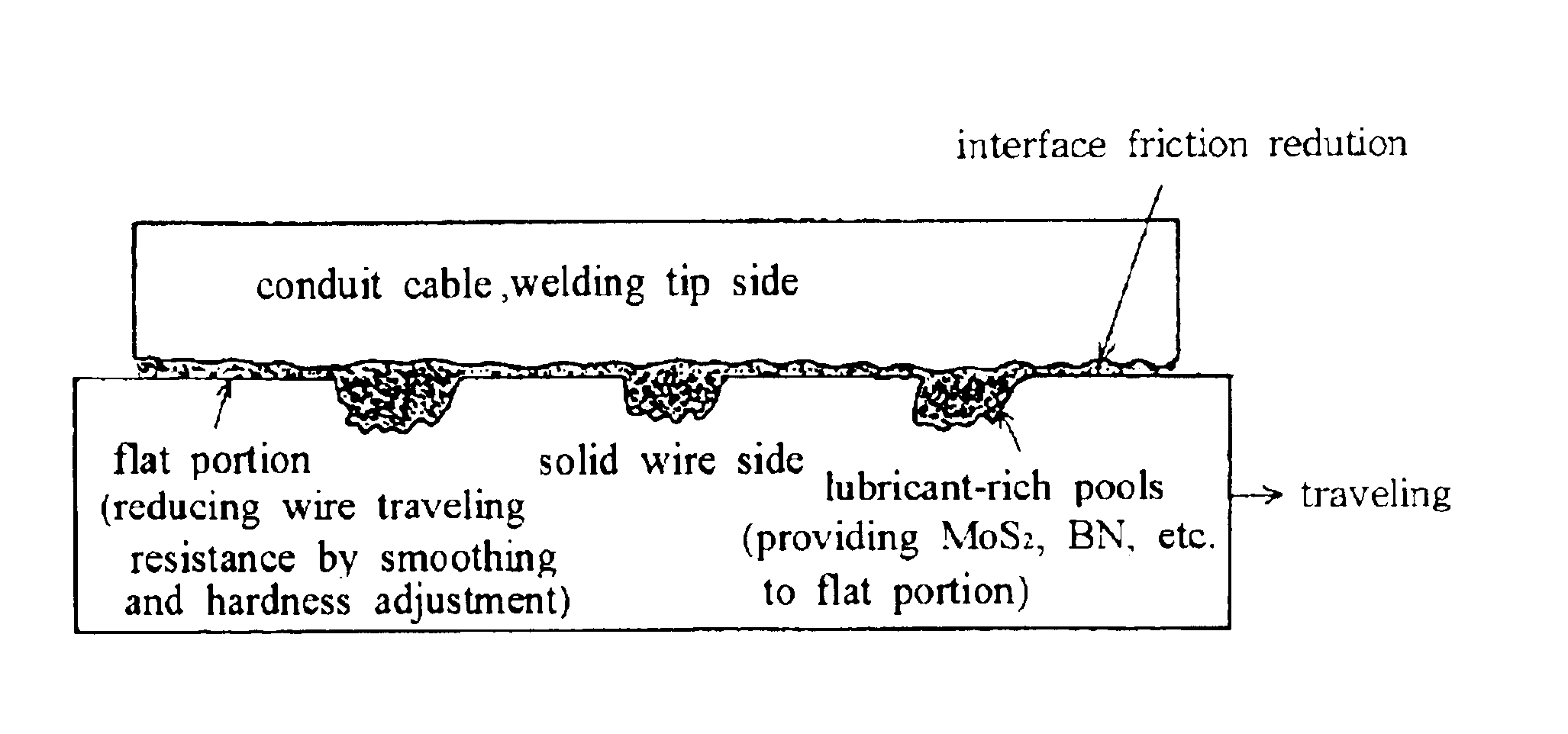

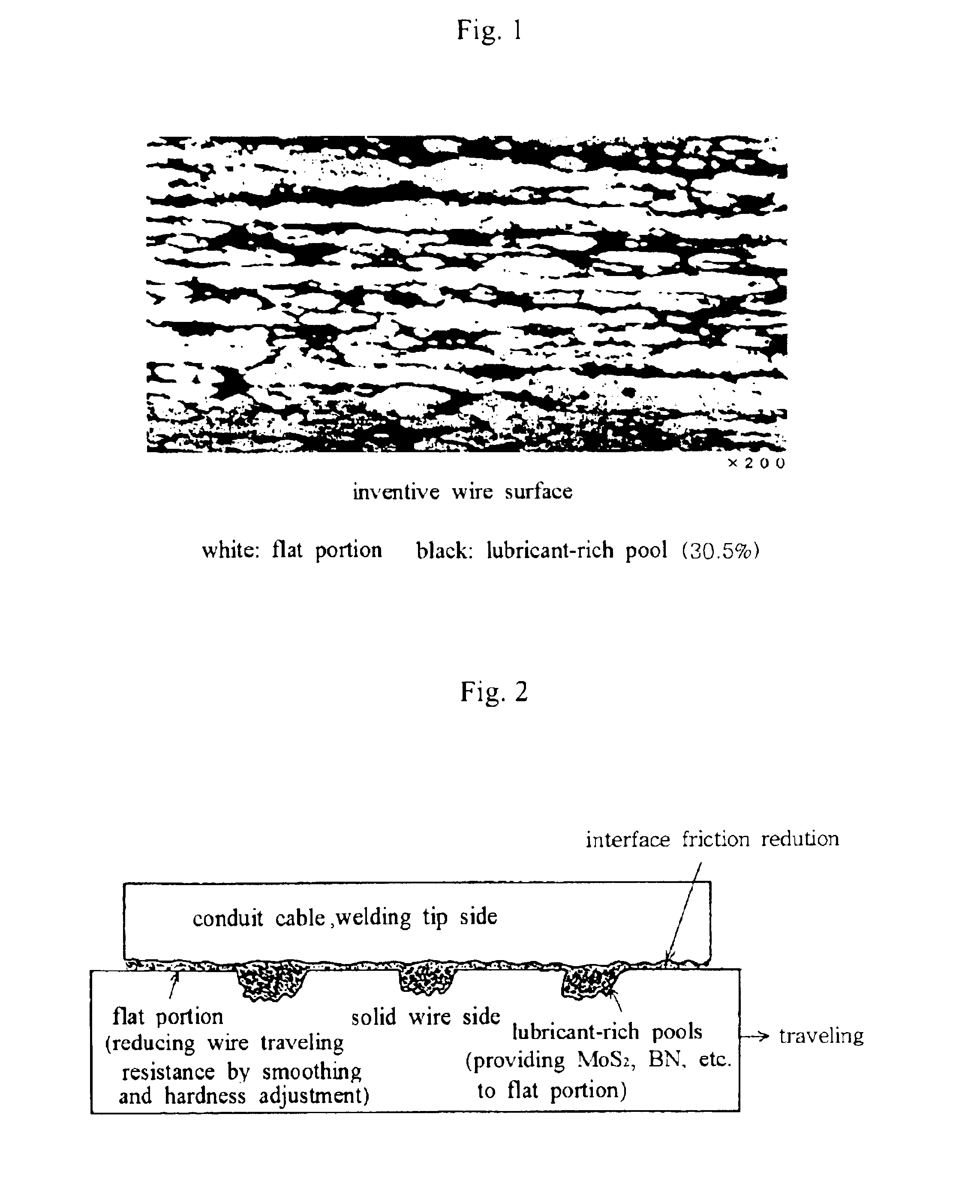

Solid wire for arc welding

ActiveUS6906286B2Improve feeding effectExcellent welding workabilityWelding/cutting media/materialsWelding electrode featuresCopper platingElectric arc

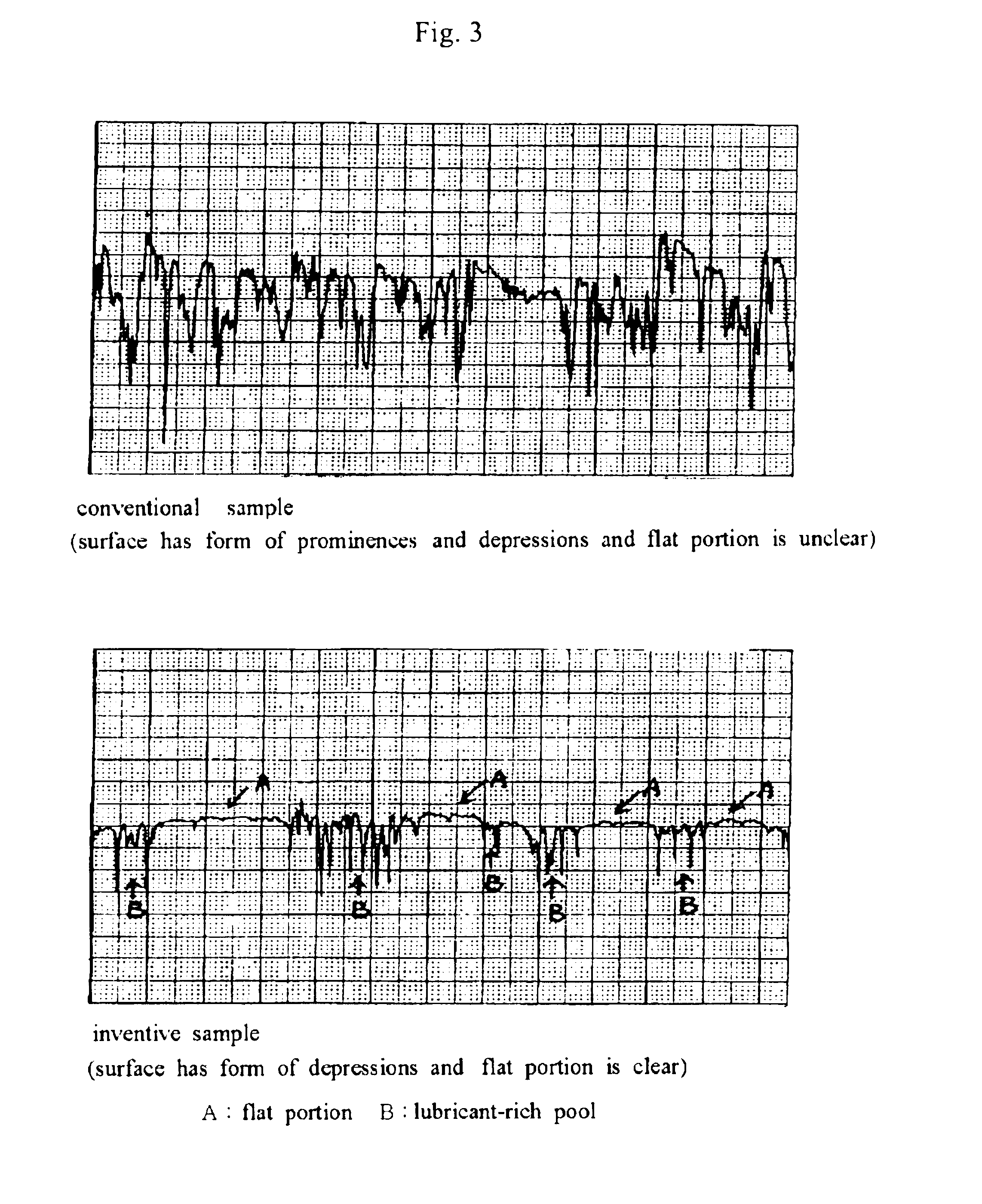

Disclosed is a solid wire for arc welding, including: a flat portion of a wire surface with no copper plating, wherein micro Vickers hardness (Hv) of the flat portion is in the range of 115 to 310 and arithmetical average roughness (Ra) of the flat portion is in the range of 0.01 to 0.30·m. The solid wire is based on a new concept different from a conventional solid wire. The solid wire for arc welding has excellent feedability without copper plating, thereby improving weld workability. Consumption of energy during manufacture of the solid wire can be reduced because the solid wire is manufactured without copper plating, and a weld work environment can be improved because copper fumes are not generated.

Owner:KISWEL LTD

Filling soldering flux wire for titania gas coverage arc welding

ActiveCN101157169BImprove mechanical propertiesExcellent peelabilityWelding/cutting media/materialsWelding/soldering/cutting articlesSolderingMechanical property

Owner:KOBE STEEL LTD

Flux-cored wire

InactiveCN101623802AExcellent welding workabilityExcellent joint strengthWelding/cutting media/materialsWelding/soldering/cutting articlesFilling rateRosin

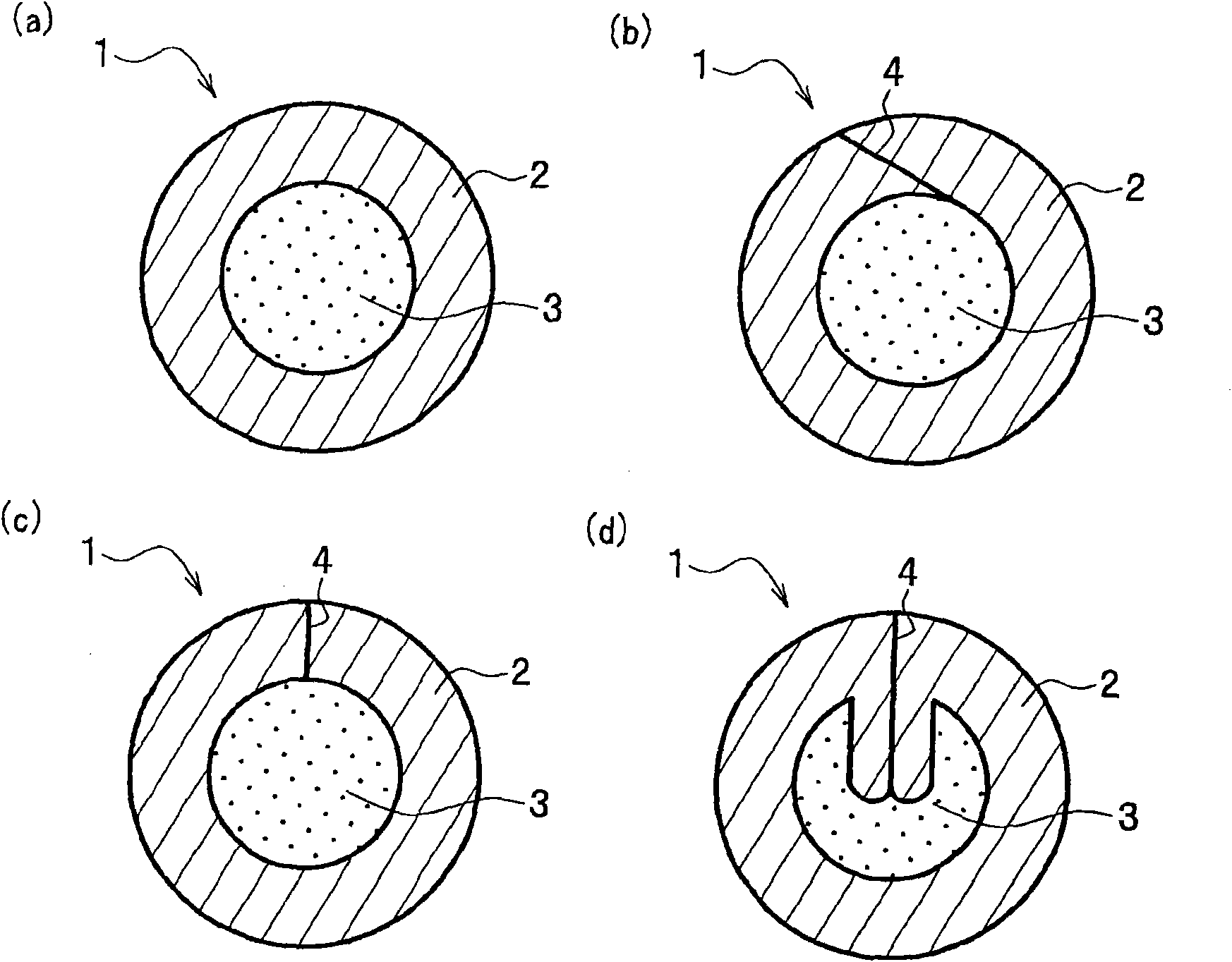

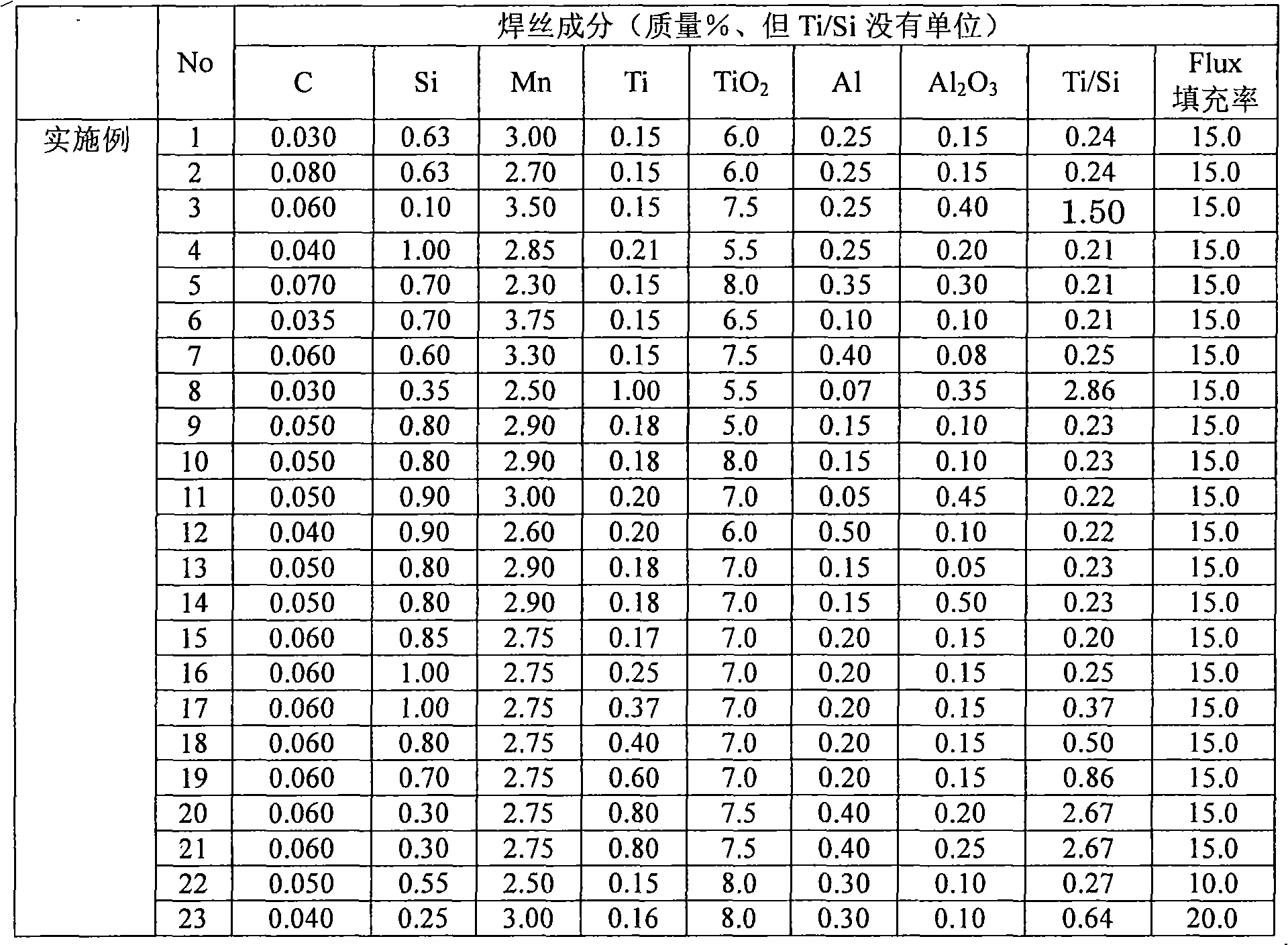

The invention provides a flux-cored wire with excellent high-temperature crackle forming property. Rosin flux filling rate in mass percentages of the flux-cored wire relative to total mass of welding wire is 10-20%, relative to the total mass of the welding wire, the flux-cored wire contains: in weight percentages, C 0.03-0.08%, Si (sum of Si amount calculated from total Si source contained in the welding wire): 0.10-1.00%, Mn (sum of Mn amount calculated from total Mn source contained in the welding wire): 2.30-3.75%, Ti 0.15-1.00%, TiO2: 5.0-8.0%, Al: 0.05-0.50%, Al2O3: 0.05-0.50%, and the rest amount is composed of Fe and unavoidable impurity, and, the Ti amount calculated from the Ti is used as a calculation amount, and the sum of the Si amount calculated from total Si source contained in the welding wire is used as a Si calculation amount, which satisfies the relationship (Ti calculation amount / Si calculation amount)>0.20.

Owner:KOBE STEEL LTD

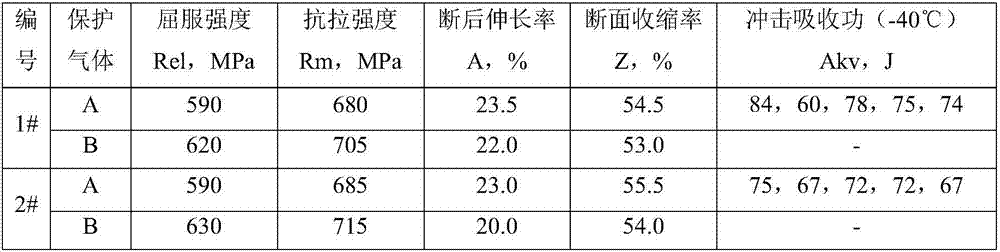

Auxiliary welding rod of Q500QE steel suitable for bridge and preparation method thereof

ActiveCN106624467AImprove performanceImprove yieldWelding/cutting media/materialsSoldering mediaManganesePotassium

The invention discloses an auxiliary welding rod of Q500QE steel suitable for bridge and a preparation method thereof. The auxiliary welding rod is composed of a core wire and a coating wrapped on the surface of the core wire, the compositions and the content of the coating are, by weight, 300-400 parts of marble, 200-320 parts of fluorite, 30-100 parts of rutile, 4-7 parts of sodium carbonate, 1-5 parts of zircon sand, 150-350 parts of iron powder, 10-20 parts of electrolytic manganese, 10-40 parts of silica powder, 10-20 parts of cryolite powder, 5-10 parts of nickel powder, 2-5 parts of molybdenum powder, 5-10 parts of potassium titanate, and 5-10 parts of potassium fluosilicate. Compared with the prior art, the auxiliary welding rod is smooth in surface, high in yield, and stable in eccentricity.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

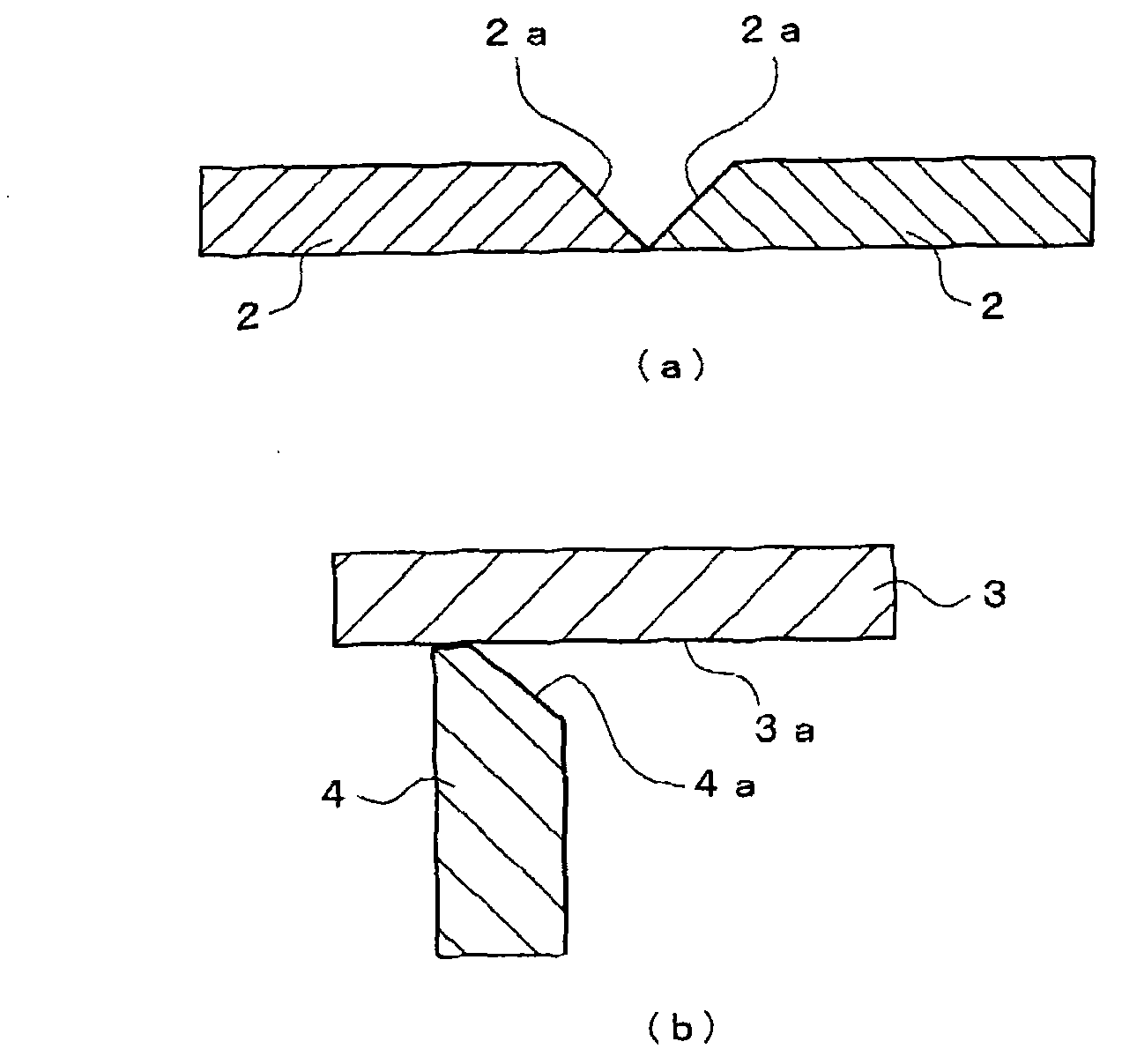

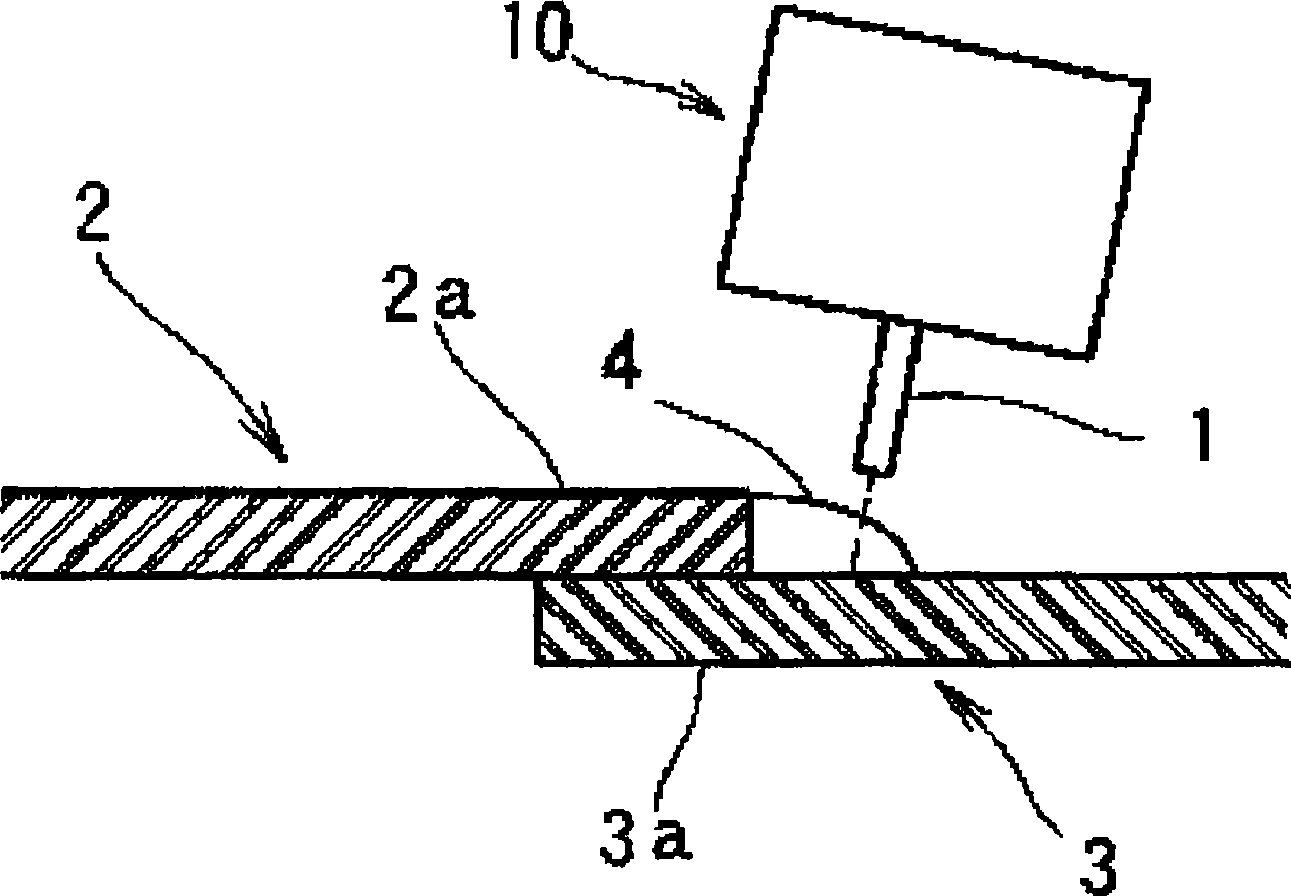

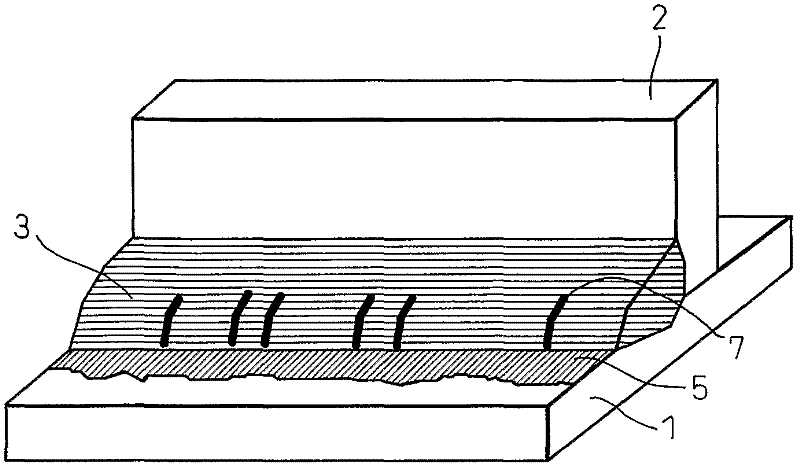

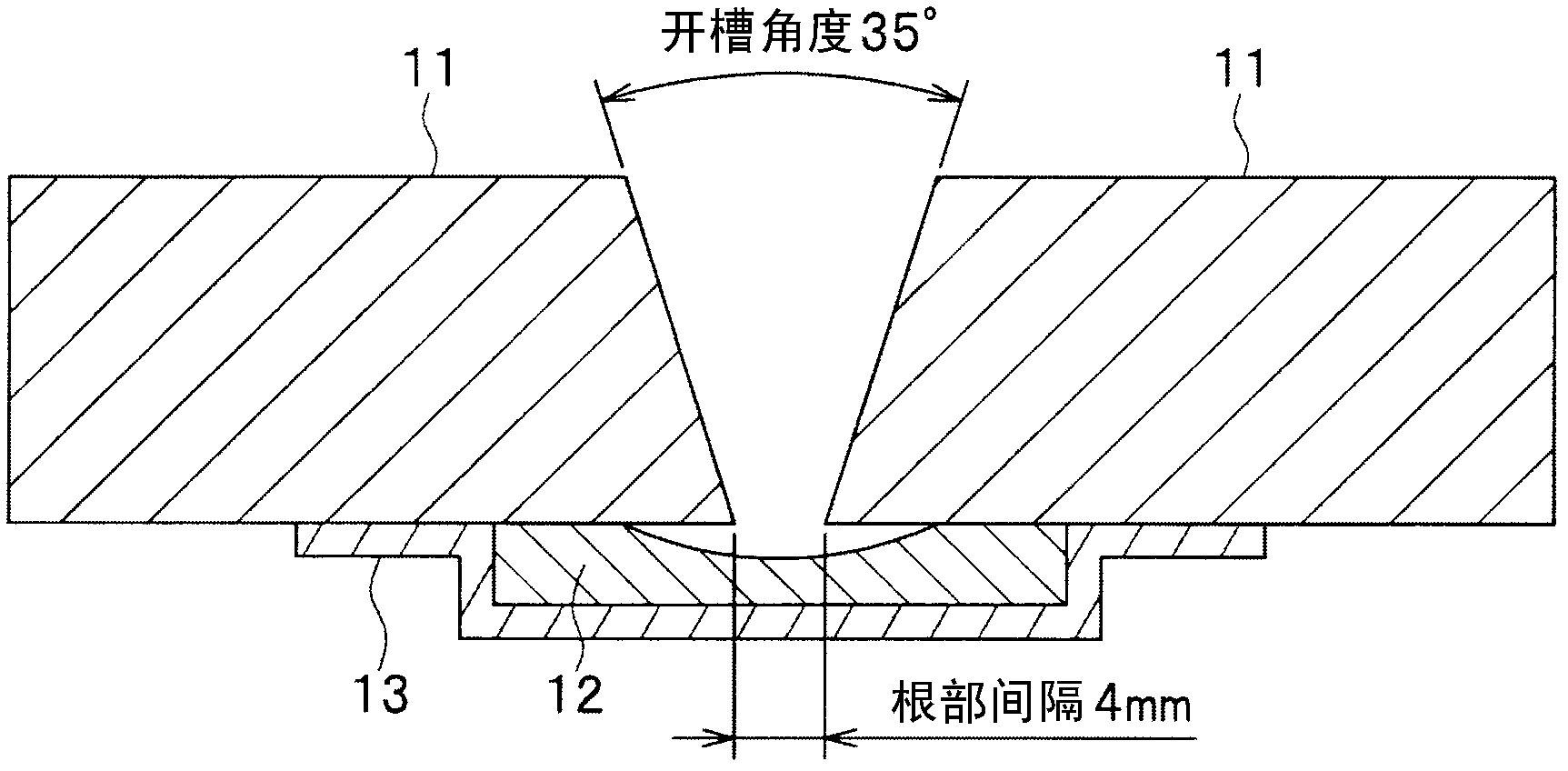

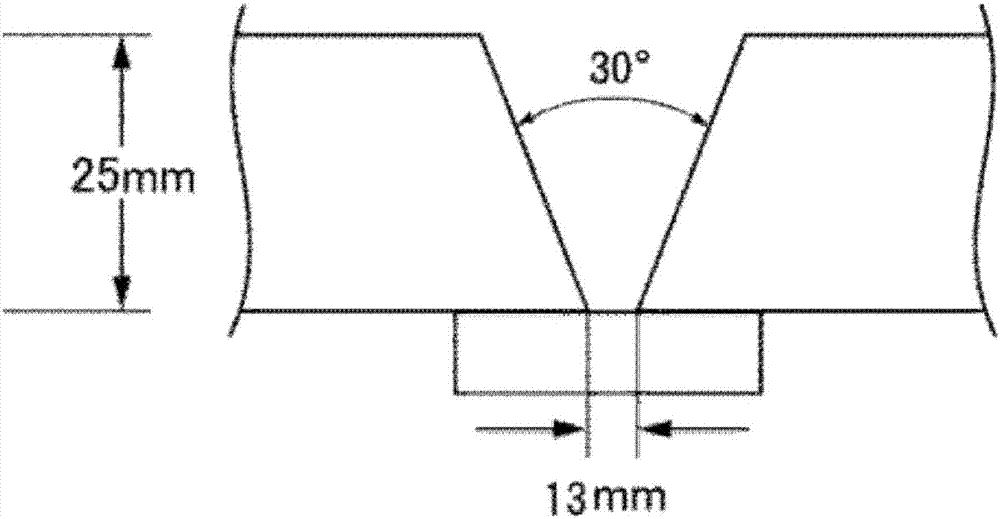

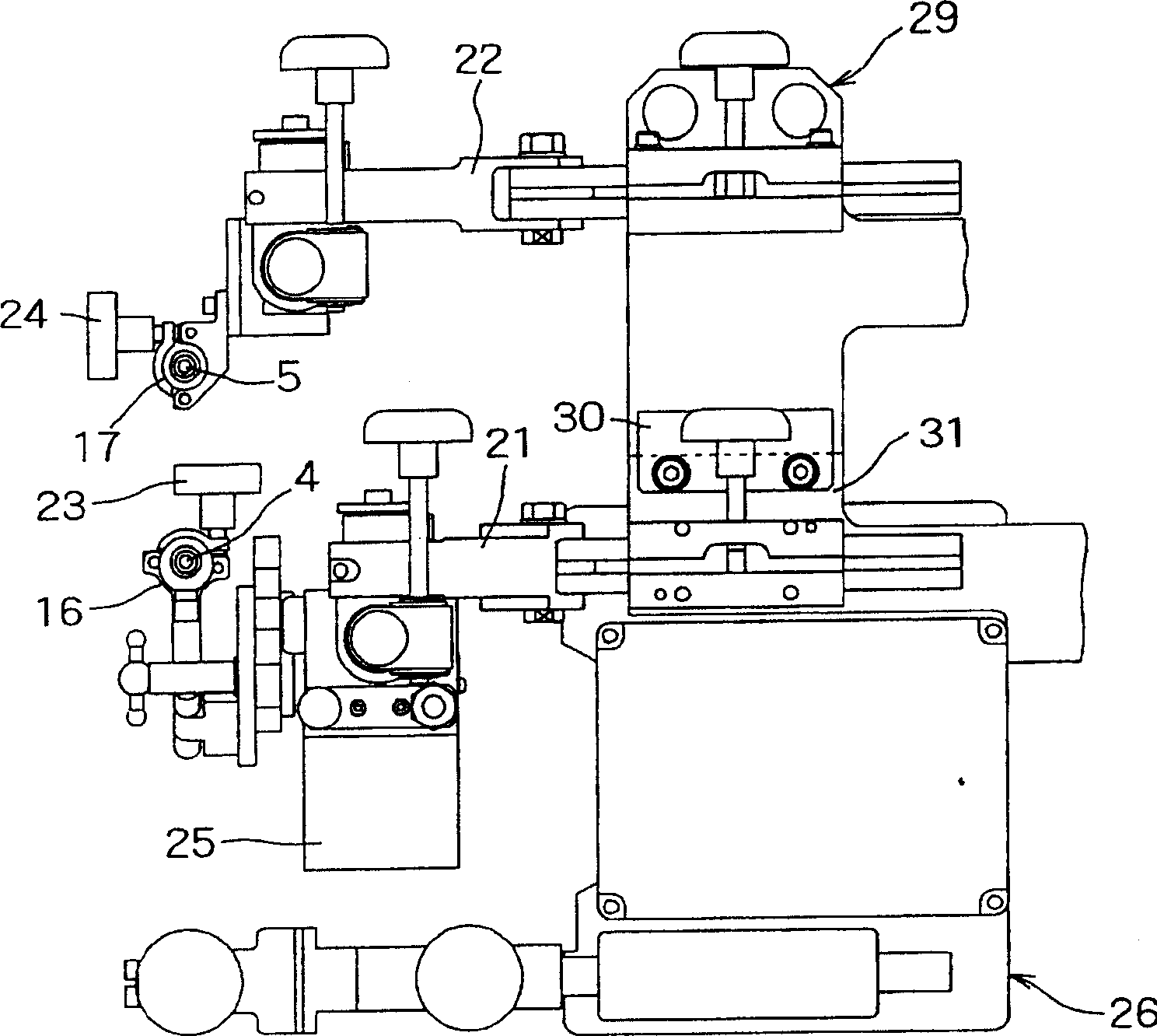

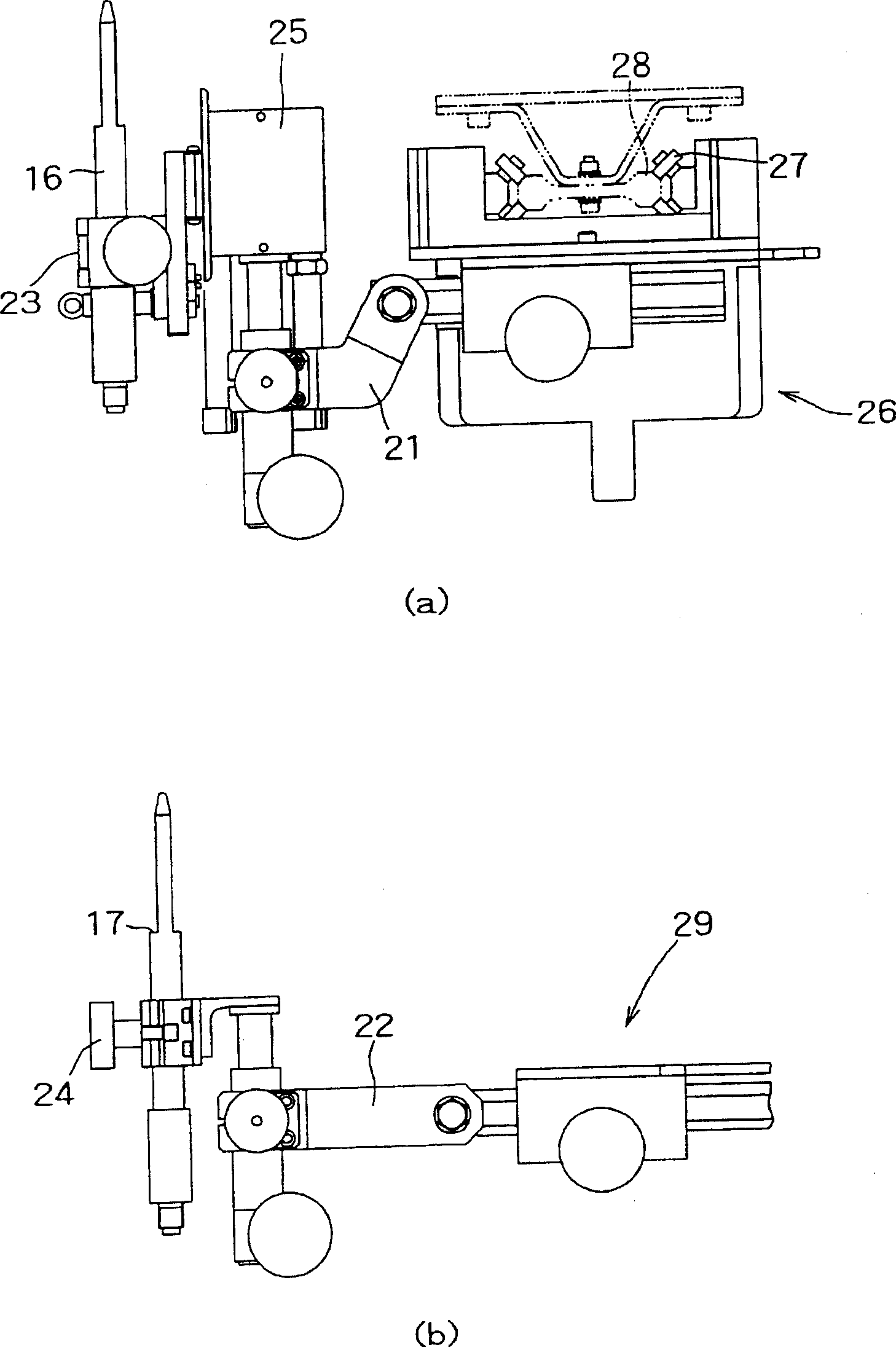

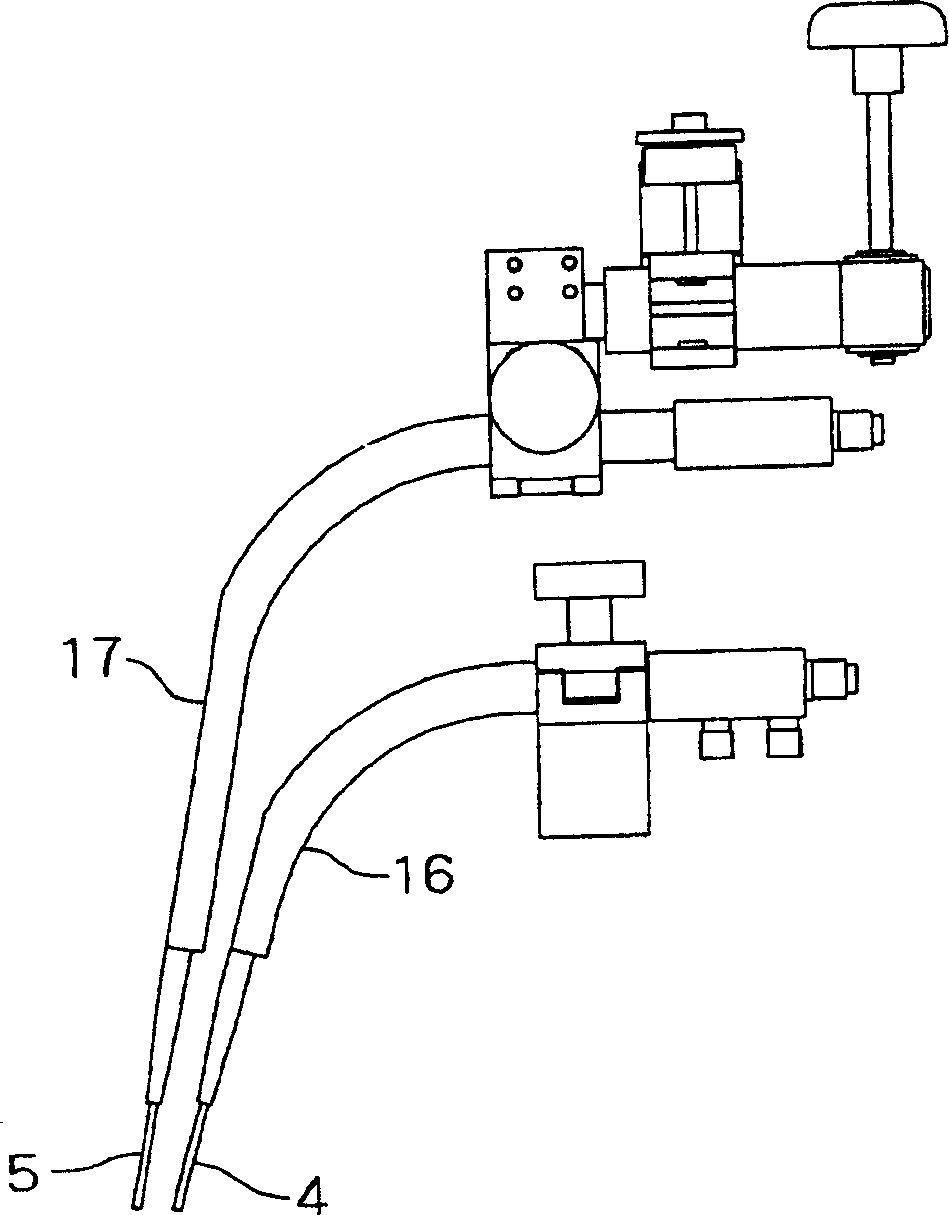

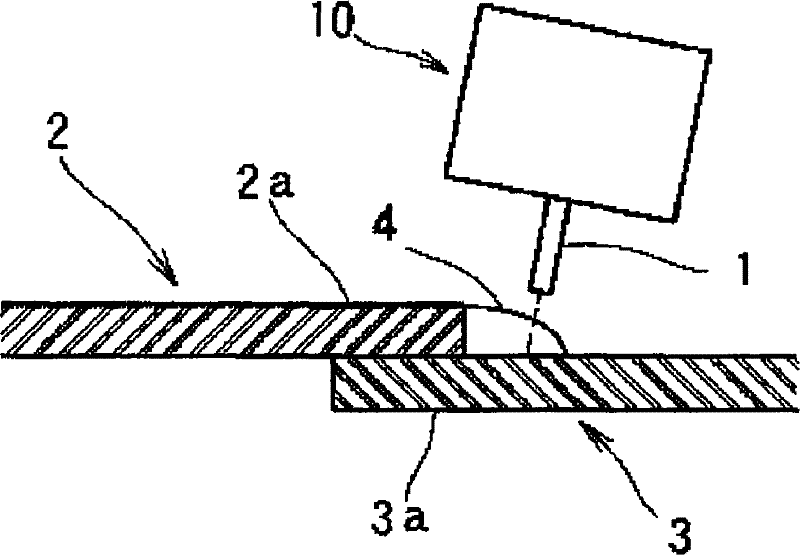

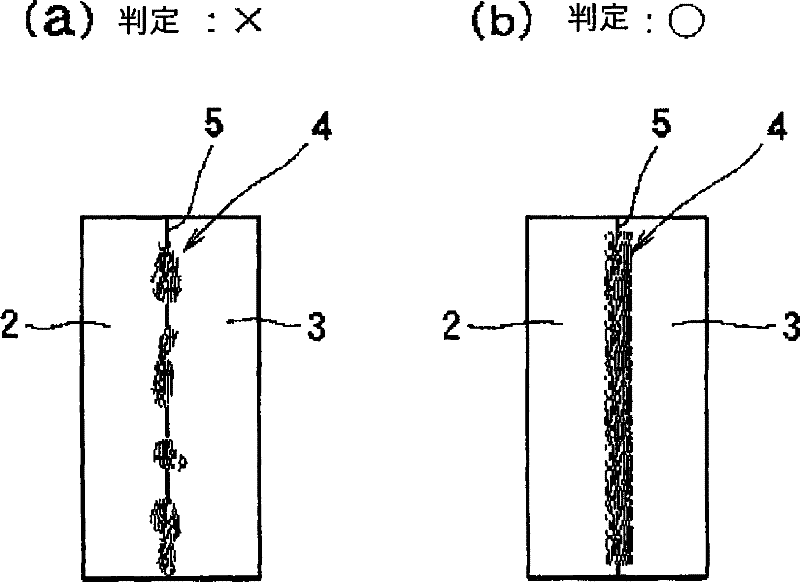

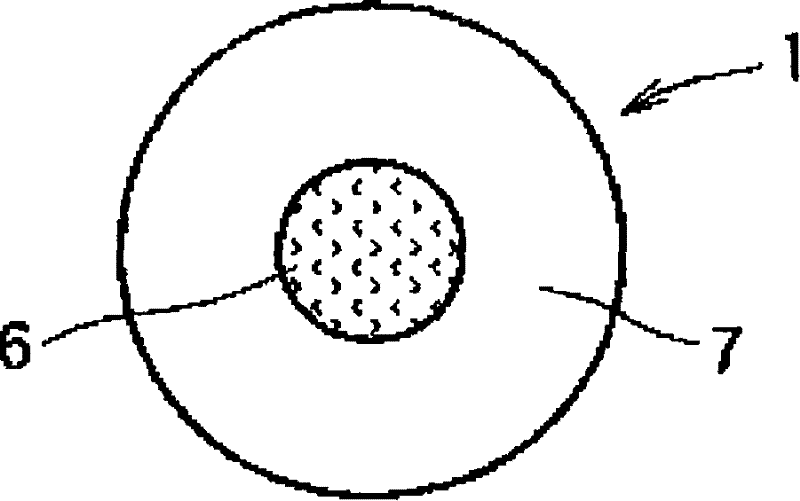

Tubular wire rod for double-electrode gas protective welding, its welding method and appts.

InactiveCN1251832CReduce shockImprove toughnessArc welding apparatusWelding/cutting media/materialsElectricityWire rod

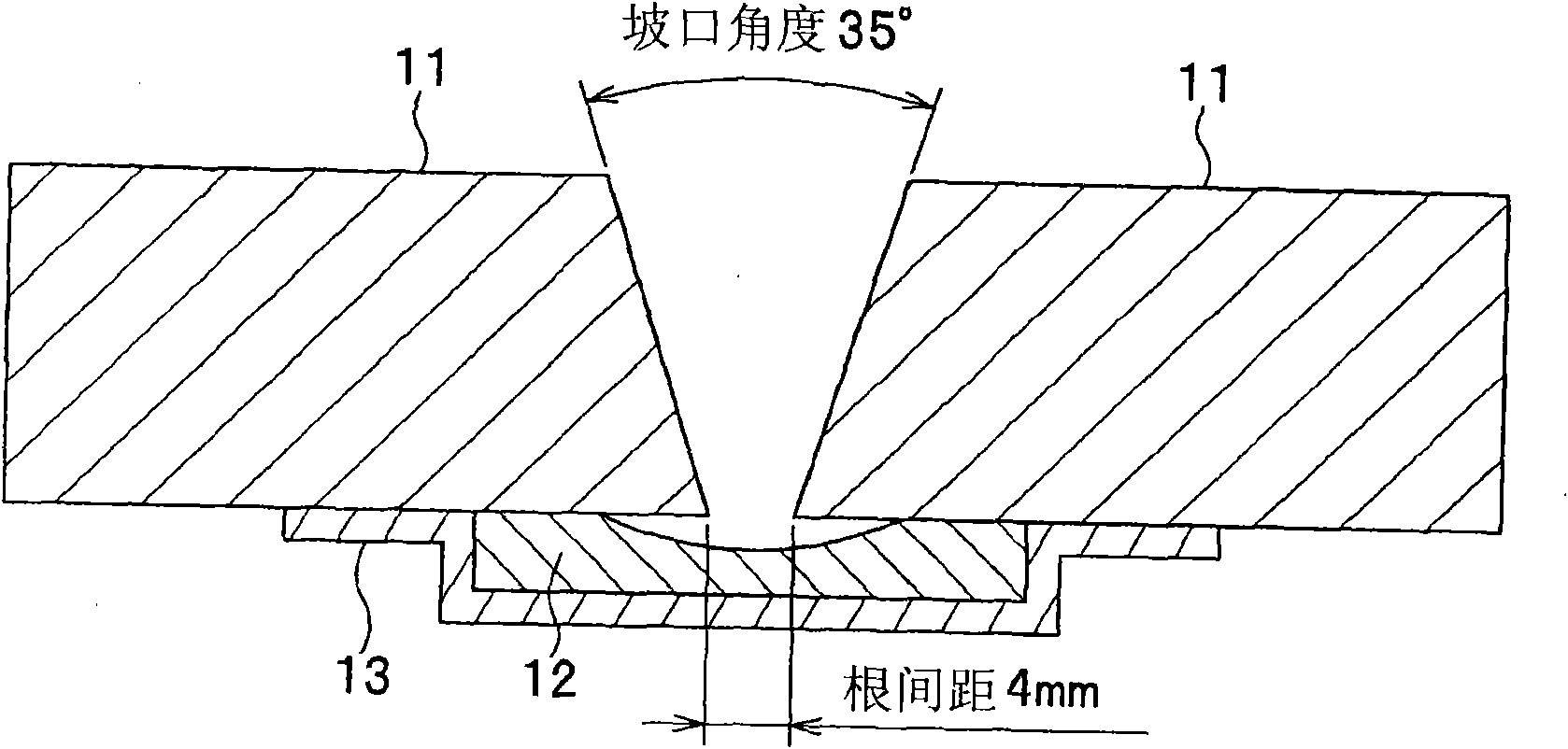

A flux charged wire for two-electrode electro-gas arc welding, a two-electrode electro-gas arc welding method, and a two-electrode electro-gas arc welding device are provided to obtain excellent welding work efficiency and excellent low-temperature toughness. In a two-electrode electro-gas arc welding method, a sliding copper plate(2) sliding upward is put on the surface side of a plate(1) to be welded and a fixed-type backing material is put on the rear side. Two welding wires(4,5) are arranged in a bevel in an isolated state to the surface side and the rear side. The bevel is welded through upright butt welding. The welding wires are flux charged wires. The welding wire of the surface side is vibrated in the plate thickness direction and welding is executed with the polarity of the welding wires reversed. A two-electrode electro-gas arc welding device has a welding trolley supplying the surface-side welding wire in the bevel and moving along the bevel, and a supply member supplying the rear-side welding wire to the position of the backing member side.

Owner:KOBE STEEL LTD

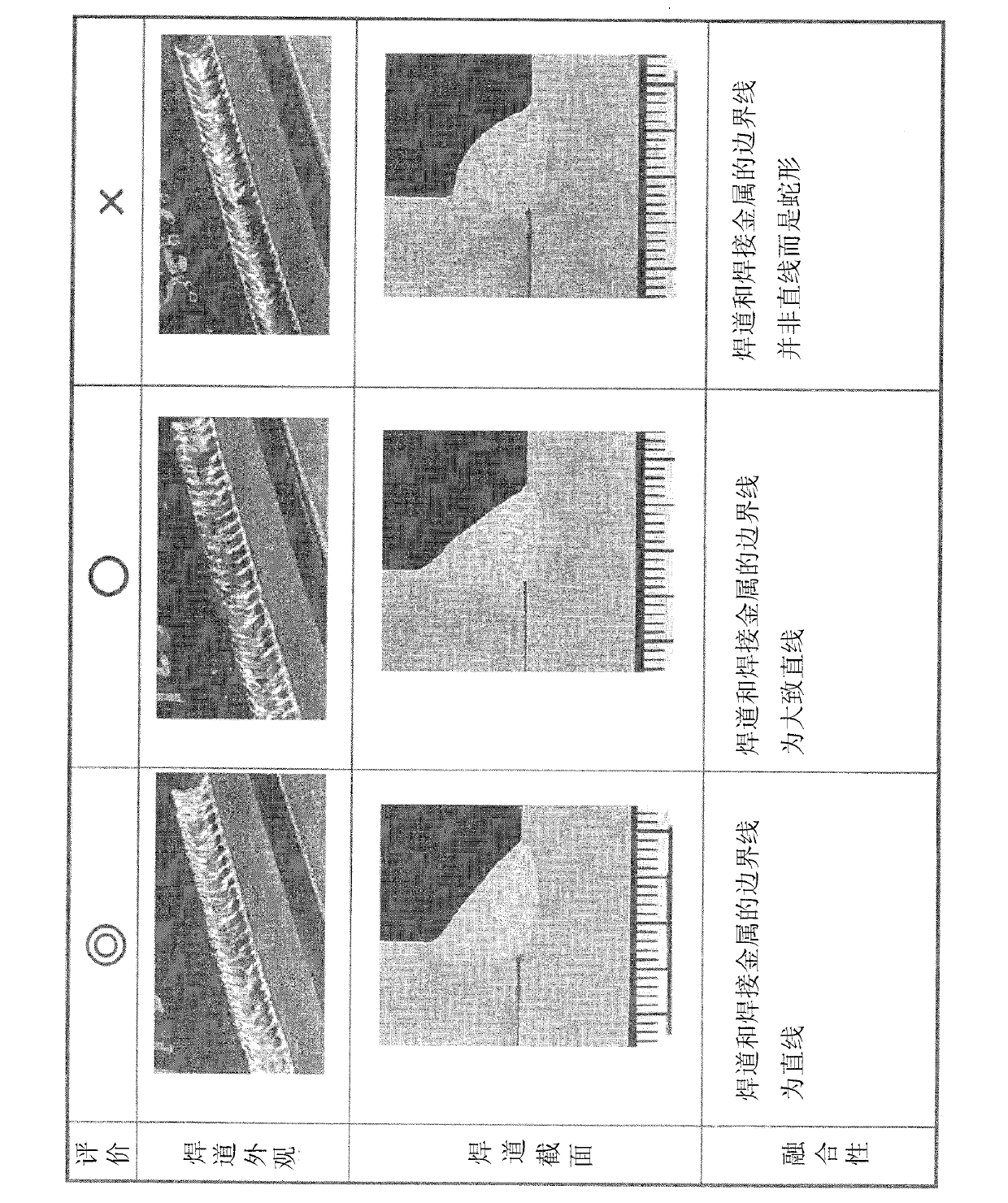

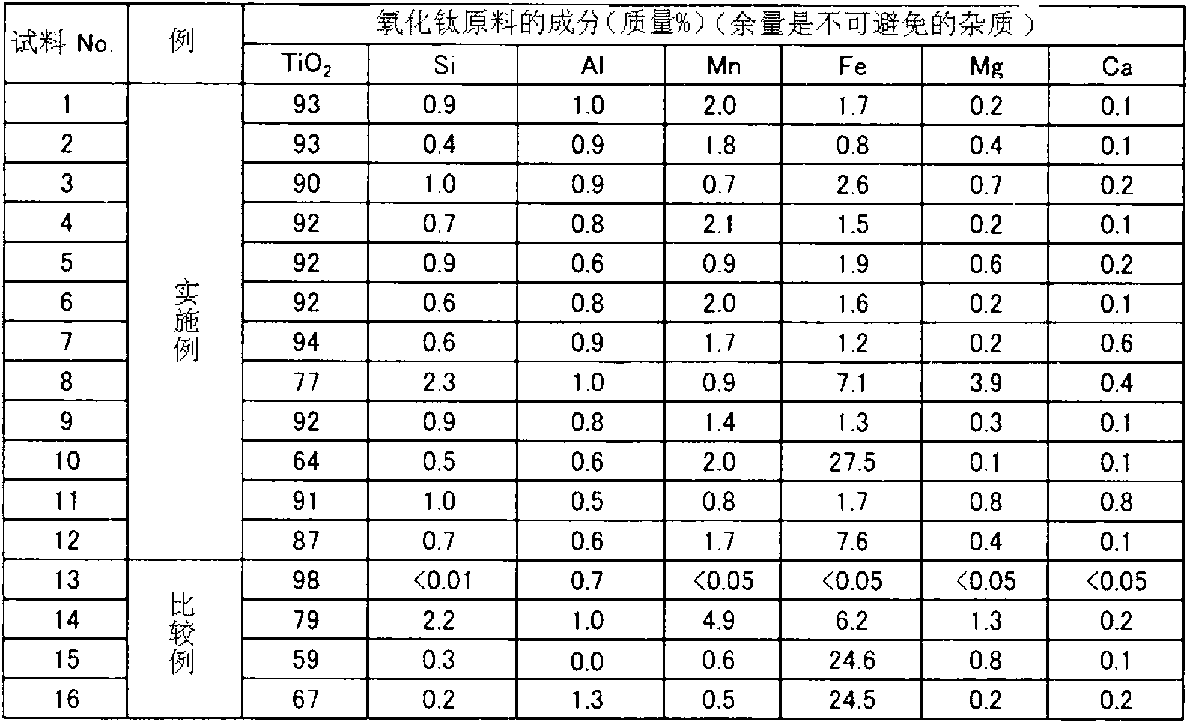

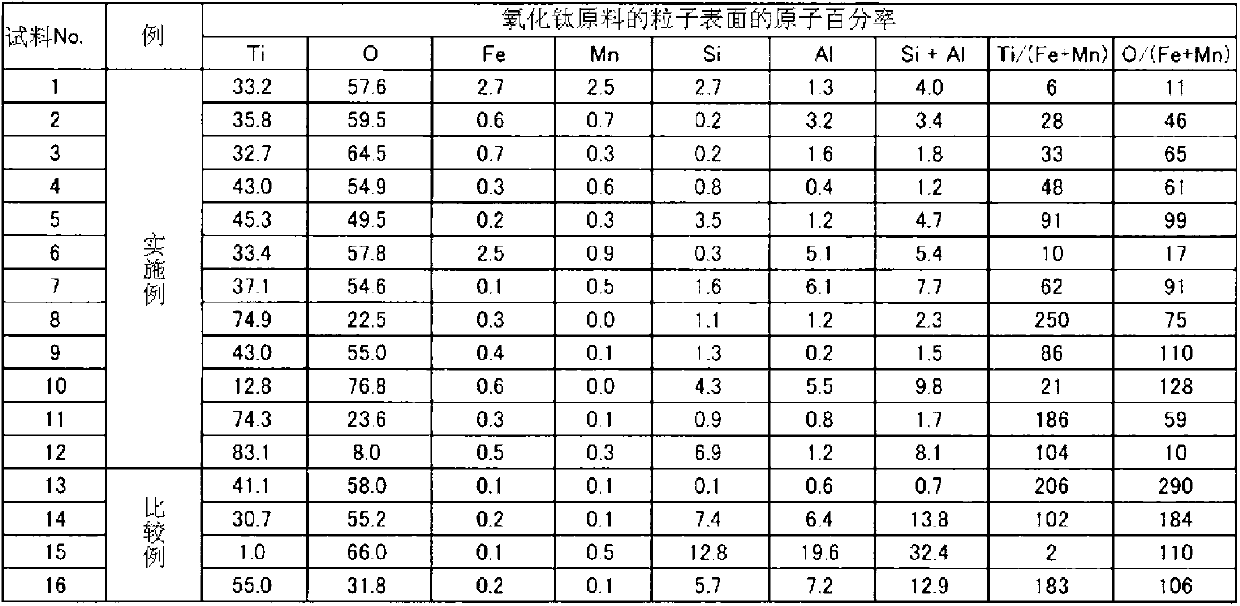

Flux-cored wire for gas protection of arc welding

ActiveCN103302416AEnsure stabilizationHigh strengthArc welding apparatusWelding/cutting media/materialsMagnesiumElectric arc

The present invention provides a flux-cored wire for gas protection of arc welding which guarantees normal welding work at high current and form a good weld bead when the welding is performed vertically. The flux-cored wire for gas protection of arc welding contains prescribed quantity of titanium oxide, C, the combination of silicon convertion amount of metal silicon and silicon conversion amount of silicon oxide, silicon conversion amount of metal silicon, combination of aluminum conversion amount and magnesium, combination of sodium conversion amount of sodium compound and kalium conversion quantity of kalium compound, and fluorine conversion amount of fluorine compound. Filling ratio of flux is limited. Titanium oxide comprises prescribed amounts of titanium dioxide, silicon, aluminum, iron, magnesium and calcium, and a compound formed by more than one of the titanium, the iron, the magnesium, aluminum and silicon exists on the surface of a particle. Furthermore, in the oxide, the percent of the atoms of the aluminum and the silicon meets the formulation of 1<=Al+Si<=10.

Owner:KOBE STEEL LTD

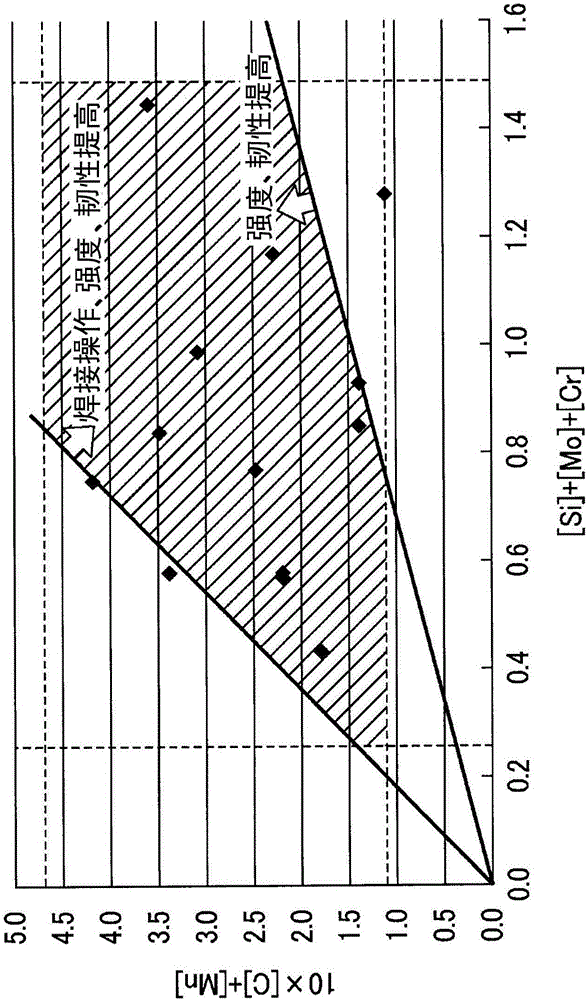

Flux cored wire for gas-shielded arc welding

ActiveCN106794558AExcellent welding workabilityImprove low temperature toughnessArc welding apparatusWelding/cutting media/materialsArc weldingMetallurgy

A flux cored wire, which is obtained by filling the inside of a steel outer skin with a flux, is configured to have a composition that contains, in mass% relative to the total mass of the wire, 0.01-0.12% of C, 0.05% or more but less than 0.30% of Si, 1.0-3.5% of Mn, 0.1% or more but less than 1.0% of Ni, 0.10-0.30% of Mo, 0.1-0.9% of Cr, 4.5-8.5% of TiO2, 0.10-0.40% of SiO2, 0.03-0.23% of Al2O3 and 80% or more of Fe.

Owner:KOBE STEEL LTD

Wear-resistant manual surfacing electrode

InactiveCN103659048AImprove wear resistanceImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaCelluloseWear resistant

The invention discloses a wear-resistant manual surfacing electrode. The wear-resistant manual surfacing electrode is composed of, by weight, 10-20 parts of ferroboron, 3-8 parts of silicon, 2-6 parts of barium carbonate, 5-12 parts of carbon, 4-9 parts of high carbon ferro-chrome, 2-5 parts of nickel powder, 3-8 parts of ferrotitanium, 5-14 parts of cellulose, 6-8 parts of amorphous graphite and 10-12 parts of rutile. Because a substrate of the surfacing electrode is made of cobalt, good wear resistance and good corrosion resistance can stilled be kept when the surfacing electrode works under the temperature of about 650DEG C; meanwhile, the surfacing electrode is good in welding operation performance and has the advantages that electric arcs are stable, arc light is soft, spatter is small, slag detachability is good, the appearance of weld joints is attractive and welding performance is good.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

Flux-cored wire for different-material bonding and method of bonding different materials

InactiveCN101378873BImprove joint strengthImprove welding efficiencyArc welding apparatusWelding/cutting media/materialsAluminum fluorideHigh intensity

The invention provides a flux cored wire for joining dissimilar materials with each other, capable of enhancing a bonding strength upon joining an aluminum-base material with a steel-base material, and excellent in bonding efficiency, which is obtained by filling a bonded joint wherein a steel based member is joined with an aluminum based member for joining dissimilar materials together in the interior an aluminum alloy envelope, so that the bonded joint is formed into a fluorid containing 0.1-15 mass% of aluminum fluoride of the total mass of the flux cored wire and no chloride, and 0.3-20 mass% of the bonded joint of the total mass of the flux cored wire is filled. If such a flux cored wire is use, it is possible to obtain a high bonding strength in the case of melt weld-bonding of high-strength dissimilar materials with each other, that is, the high-strength steel member with the high-strength 6000 series aluminum alloy member.

Owner:KOBE STEEL LTD

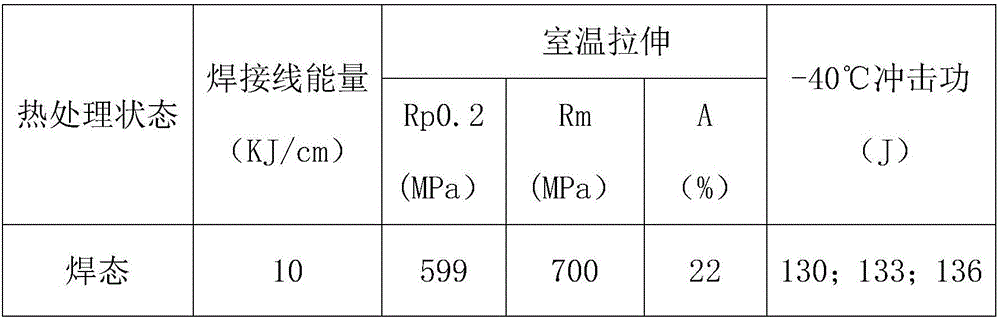

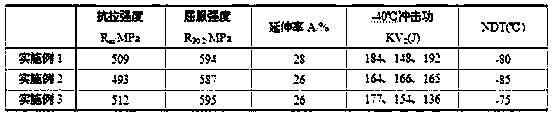

Gas shielded solid welding wire used for steel with yield strength being 460 MPa and manufacturing method

InactiveCN107598409AExcellent welding workabilityWell formed weldWelding/cutting media/materialsSoldering mediaIron powderMechanical property

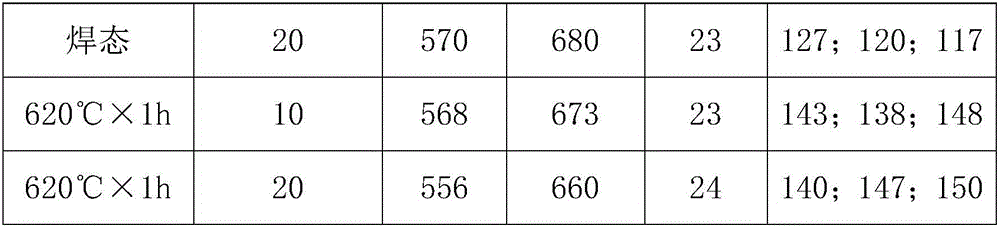

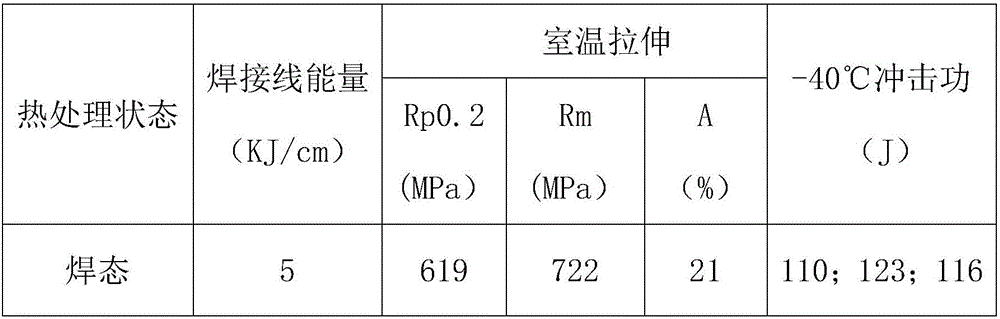

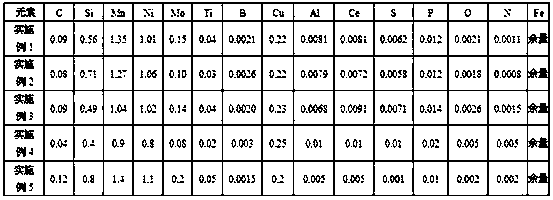

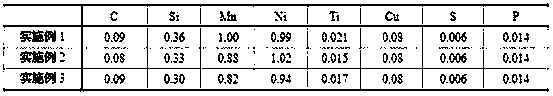

The invention relates to a gas shielded solid welding wire used for steel with the yield strength being 460 MPa and a manufacturing method. The gas shielded solid welding wire comprises, by mass, 0.04%-0.12% of C, 0.9%-1.4% of Mn, 0.4%-0.8% of Si, 0.8%-1.1% of Ni, 0.08%-0.2% of Mo, 0.02%-0.05% of Ti, 0.0015%-0.0030% of B, 0.20%-0.25% of Cu, less than or equal to 0.01% of Al, less than or equal to0.010% of S, less than or equal to 0.020% of P, less than or equal to 0.005% of O, less than or equal to 0.005% of N, 0.0050%-0.010% of Ce, and the balance iron powder and unavoidable impurities. Whengas shielded welding with 80% of Ar and 20% of CO2 is conducted, the mechanical properties of deposited metal reach welding requirements of steel with the yield strength being 460 MPa and used for marine engineering, impact energy at -40 DEG C is over 120 J, and NDT is below -60 DEG C.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Austenitic stainless steel submerged-arc welding agent

InactiveCN111185652AImprove purityExcellent welding workabilityArc welding apparatusWelding/cutting media/materialsRare-earth elementSS - Stainless steel

The invention discloses an austenitic stainless steel submerged-arc welding agent. The austenitic stainless steel submerged-arc welding agent is prepared from the following components in percentage byweight: 10-35% of a fluoride of an F equivalent value, 10-35% of MgO, 7-17% of Al2O3, 10-25% of SiO2, less than 0.05% of P2O5, less than 0.05% of SO3, 15-30% of CaO, 0.5-10% of ZrO2, 0.2-3% of BaO, 0.015-0.40% of rare earth elements, and the balance of inevitable impurities. The austenitic stainless steel submerged-arc welding agent has the excellent welding operation performance, meanwhile, theaustenitic stainless steel submerged-arc welding agent can further reduce welding defects and improve the degree of purity of high-welding metal, and the welding metal obtained by the welding agent still has excellent extremely low temperature impact toughness and anti-cracking ability after being treated at 400-600 DEG C.

Owner:KUSN GINTUNE WELDING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com