Filling soldering flux wire for titania gas coverage arc welding

A technology of titanium dioxide and shielded arc, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of poor weld bead shape, large amount of spatter, poor peeling of welding slag, etc., and achieve mechanical Excellent performance, less spatter generation, good spatter peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

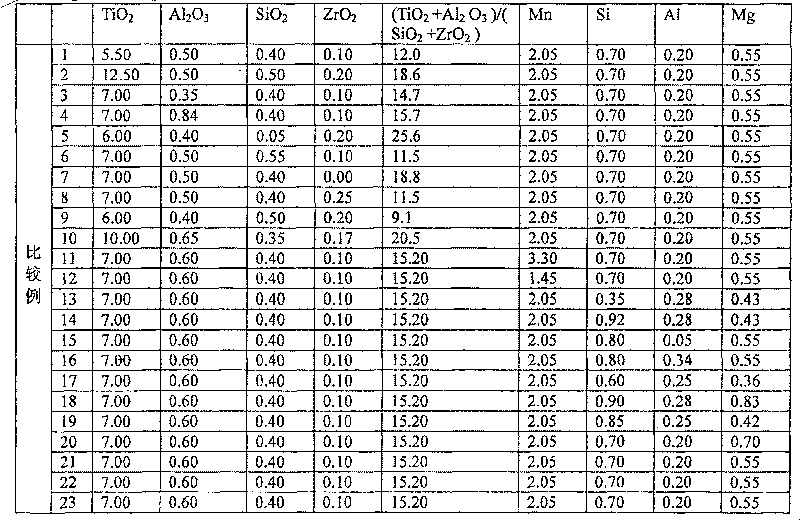

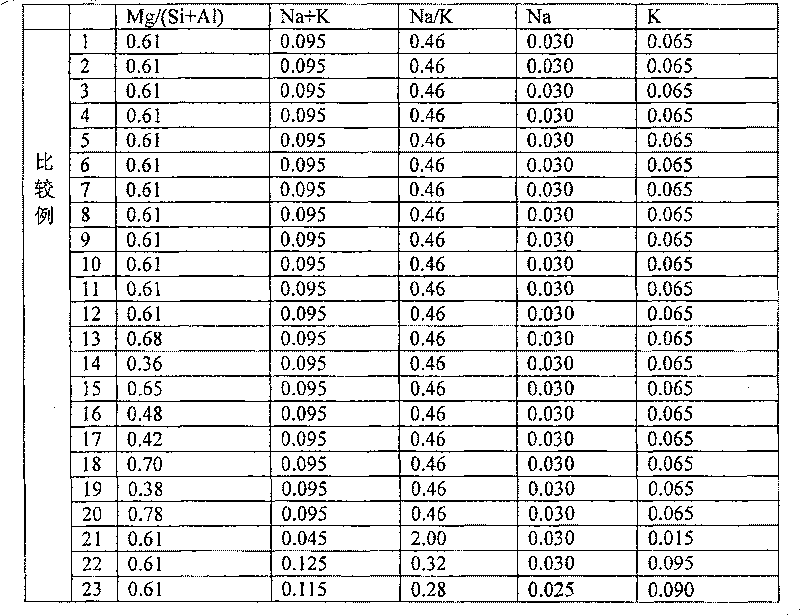

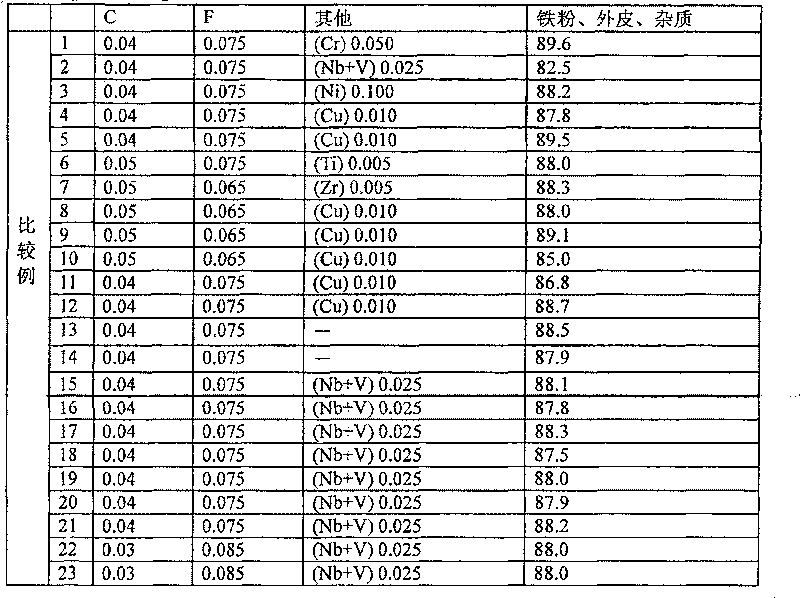

[0074] Next, the effects of the examples of the present invention will be described in comparison with comparative examples that deviate from the scope of the present invention. Table 1 below shows examples of raw materials for each component defined in the present invention. The raw materials shown in Table 1 were properly mixed and filled into a steel (JIS G 23 3141, SPCC) sheath so that the ratio of the flux to the total mass of the wire was 15% by mass to produce a flux-cored wire with a wire diameter of 1.2 mm. . Table 2 and Table 3 show the analysis values of the flux-cored wire component contents of the examples and the comparative examples. The main component of the remainder other than the components in Table 2 and Table 3 is Fe, and P, S, N, Cu, and the like are contained as unavoidable impurities.

[0075] [Table 1]

[0076] TiO 2

Rutile, ルコキシン (mineral name), high titanium slag, etc.

Al 2 o 3

Aluminum oxide, etc.

[0077] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com