Ultra-supercritical material CB2 steel matched welding rod applicable to long-term high-temperature service and preparation method thereof

An ultra-supercritical, high-temperature service technology, applied in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problem that the welding rod cannot use the ultra-supercritical material CB2 steel, and the welding rod cannot be matched with CB2. Good performance in all positions, good slag removal, and strict control of chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, solder core (wt%): C 0.08-0.10wt%, Mn 0.10-0.30wt%, 0≤Si≤0.10wt%, 0≤S≤0.010wt%, 0≤P≤0.010wt%, Ni 0.10-0.80wt%, Cr 8.50-9.50wt%, Mo1.00-1.40wt%, V 0.10-0.20wt%, Nb 0.001-0.10wt%, N 0.001-0.050wt%, Co 0.90-1.10wt%, 0≤Al≤0.040wt%, B 0.002-0.010wt%, the balance being Fe and impurities.

[0033] In this embodiment, when the welding core is 1000g, the composition and content of the coating are (g): marble: 240, fluorite: 200, rutile: 65, soda ash: 5, zircon sand: 6.5, iron powder: 140 , Electrolytic manganese: 20, silicon micropowder: 65, ice crystal powder: 45, nickel powder: 5, metallic chromium: 6, molybdenum powder: 3, ferrovanadium: 5, niobium powder: 4, ferrochromium nitride: 10, fluoroboric acid Potassium: 6, borax: 3, rare earth silicon magnesium iron alloy: 2.

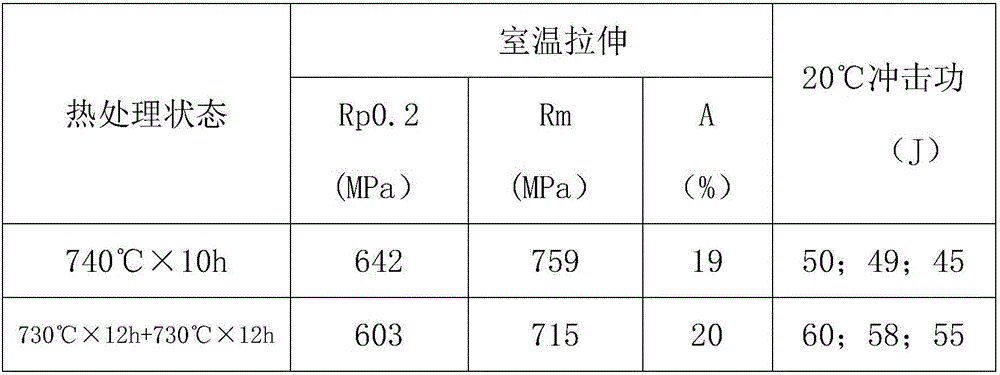

[0034] After the above powder is mixed evenly, add 250g of potassium sodium water glass with a concentration of 43°, stir and mix evenly, send it into the bar press and wrap it on the 4....

Embodiment 2

[0041] The welding core of this experimental embodiment is the same as that of the selected embodiment one.

[0042] In this embodiment, when the welding core is 1000g, the composition and content of the coating are (g): marble: 290, fluorite: 260, rutile: 45, soda ash: 5, zircon sand: 6, iron powder: 115 , Electrolytic manganese: 25, silicon micropowder: 65, ice crystal powder: 45, nickel powder: 6, metallic chromium: 6, molybdenum powder: 3, ferrovanadium: 5.5, niobium powder: 5, ferrochromium nitride: 11, fluoroboric acid Potassium: 5, borax: 6, rare earth silicon magnesium iron alloy: 2.

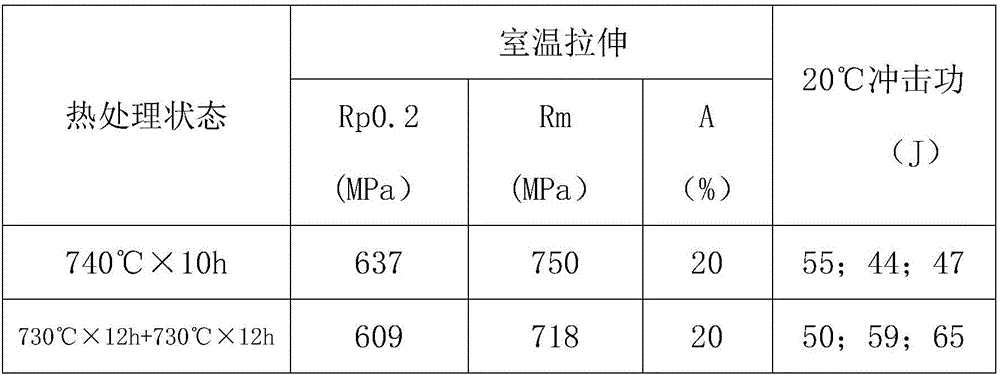

[0043] After the above powder is mixed evenly, add 250g of potassium sodium water glass with a concentration of 43°, stir and mix evenly, send it into the bar press and wrap it on the 3.2mm welding core according to the conventional method, and then bake it at a low temperature of 88°C Baking for 2 hours at a high temperature of 380°C for 1.5 hours to obtain the welding rod.

[0044] T...

Embodiment 3

[0049] The welding core of this experimental embodiment is the same as that of the selected embodiment one.

[0050] In this embodiment, when the welding core is 1000g, the composition and content of the coating are (g): marble: 270, fluorite: 250, rutile: 47, soda ash: 5, zircon sand: 6, iron powder: 120 , Electrolytic manganese: 24, silicon micropowder: 66, ice crystal powder: 48, nickel powder: 6, metal chromium: 6, molybdenum powder: 3, vanadium ferro: 5.5, niobium powder: 5, chromium nitride ferro: 11, fluorine Potassium borate: 3, borax: 7, rare earth silicon magnesium iron alloy: 2.

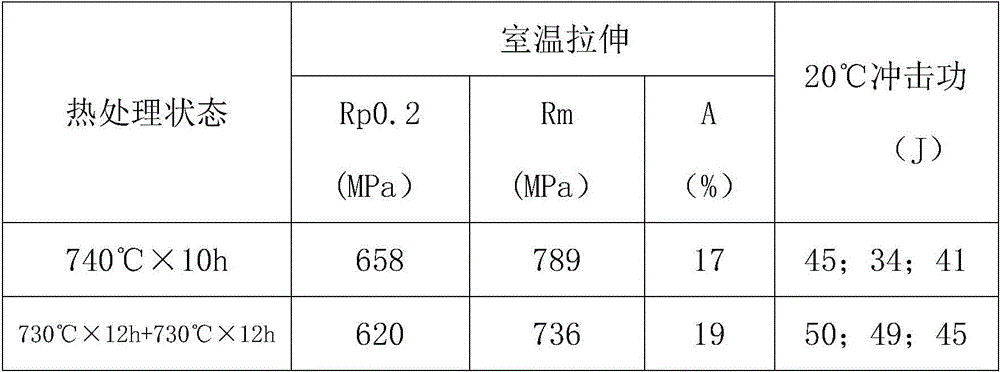

[0051] After the above powder is mixed evenly, add 250g of potassium sodium water glass with a concentration of 43°, stir and mix evenly, send it into the bar press and wrap it on the 5.0mm welding core according to the conventional method, and then bake it at a low temperature of 88°C Baking for 2 hours at a high temperature of 380°C for 1.5 hours to obtain the welding rod.

[0052] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com