Gas shielded solid welding wire used for steel with yield strength being 460 MPa and manufacturing method

A yield strength, solid wire technology, used in welding media, manufacturing tools, welding equipment, etc., to achieve the effect of improving low temperature toughness, excellent operating performance, and good weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in combination with specific embodiments.

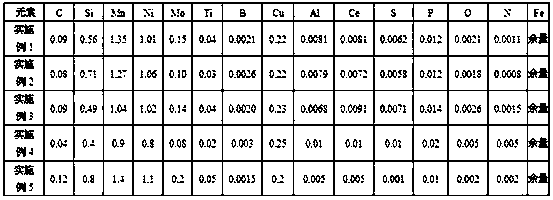

[0025] A gas-shielded solid welding wire for steel with a yield strength of 460MPa, comprising the following components: by mass percentage, C: 0.04%-0.12%, Mn: 0.9%-1.4%, Si: 0.4%-0.8%, Ni: 0.8%-1.1%, Mo: 0.08%-0.2%, Ti: 0.02%-0.05%, B: 0.0015%-0.0030%, Cu: 0.20%-0.25%, Al≤0.01%, S≤0.010%, P≤ 0.020%, O≤0.005%, N≤0.005%, Ce: 0.0050%-0.010%, the balance is iron powder and unavoidable impurities.

[0026] A method for preparing a gas-shielded solid welding wire for steel with a yield strength of 460MPa as described above: take each component according to the mass percentage, smelt the steel ingot, roll the wire rod, anneal the wire rod, draw and reduce the diameter, finish drawing and The copper plating process finally obtains ΦY1.2mm finished welding wire.

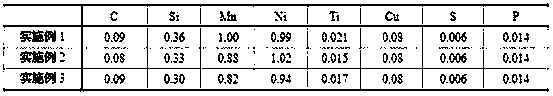

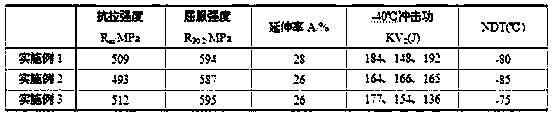

[0027] Examples 1-5 are all high-toughness gas-shielded solid welding wires suitable for 460MPa steel. The composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com