Patents

Literature

43results about How to "Suitable for all position welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength and high-tenacity gas shielded welding wire

ActiveCN101992365AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaManganeseMixed gas

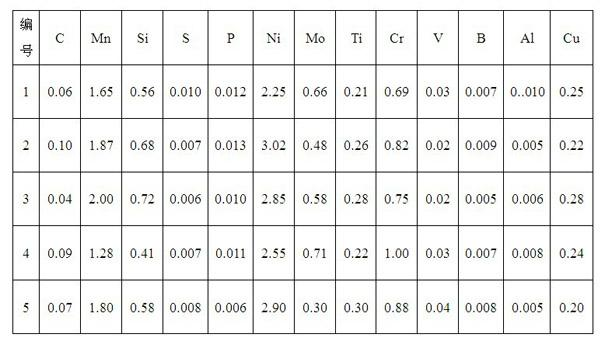

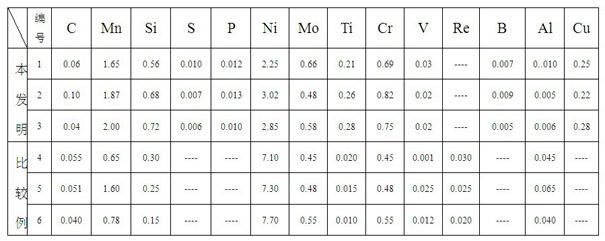

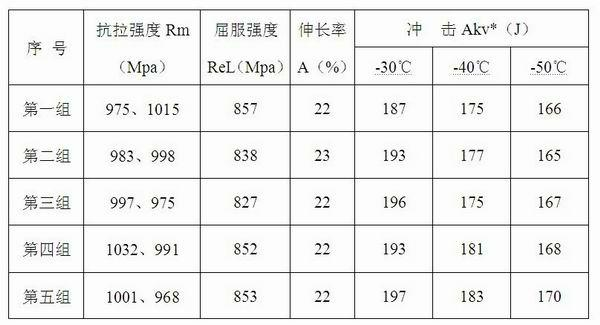

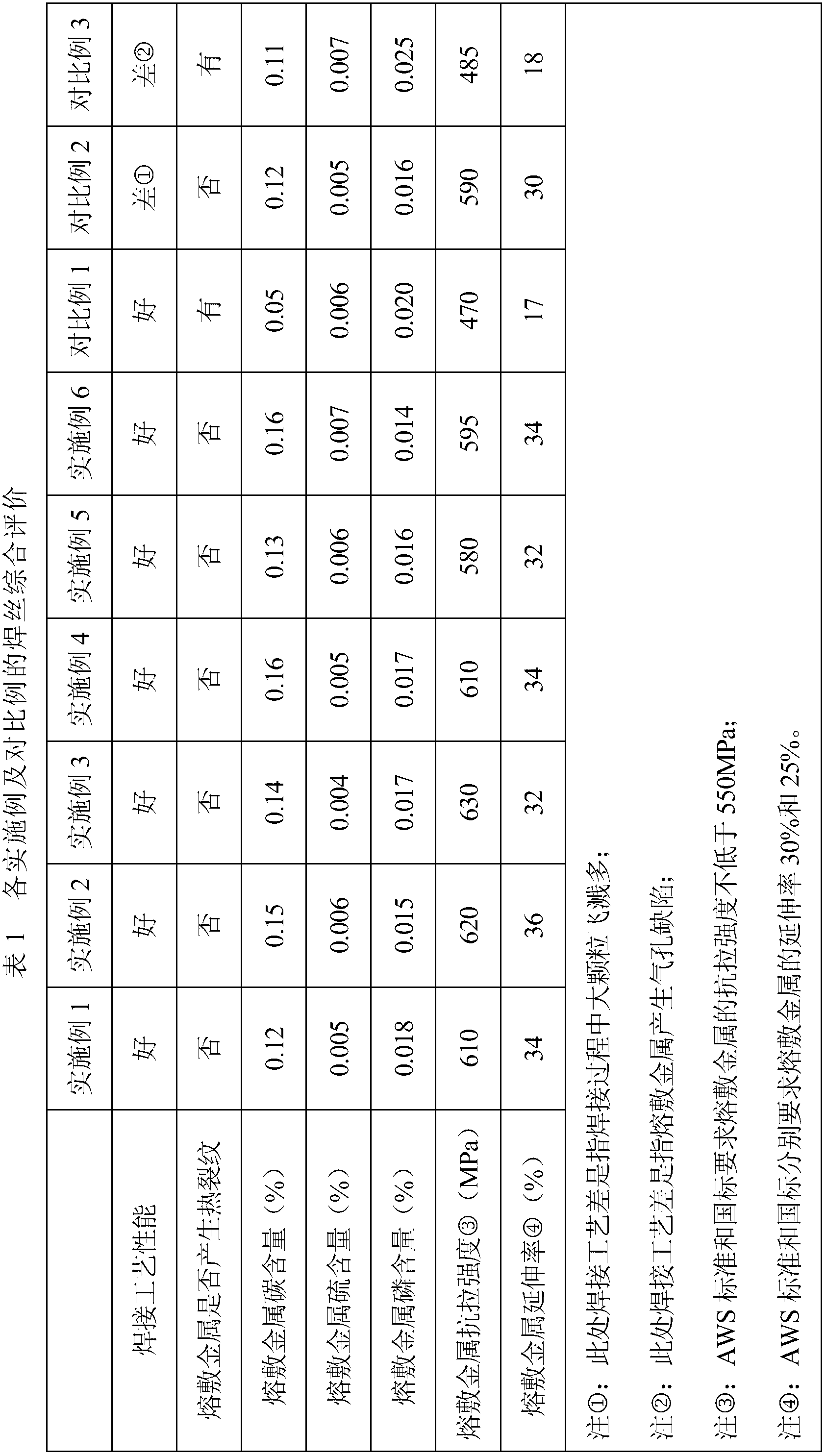

The invention discloses a high-strength and high-tenacity gas shielded welding wire. The welding wire comprises the following chemical composition in percentage by mass: 0.02 to 0.12 percent of carbon (C), 1.20 to 2.10 percent of manganese (Mn), 0.20 to 1.00 percent of silicon (Si), less than or equal to 0.010 percent of sulfur (S), less than or equal to 0.015 percent of phosphorus (P), 2.00 to 3.50 percent of nickel (Ni), 0.20 to 0.80 percent of molybdenum (Mo), 0.20 to 0.30 percent of titanium (Ti), 0.60 to 1.20 percent of chromium (Cr), less than or equal to 0.05 percent of vanadium (V), 0.005 to 0.010 percent of boron (B), less than or equal to 0.015 percent of aluminum (Al), less than or equal to 0.35 percent of copper (Cu) and the balance of iron (Fe). The welding wire is used for welding steels of a strength grade of between 850 and 950MPa; and under the protection of a mixed gas (80 percent of argon (Ar) and 20 percent of carbon dioxide (CO2)), the weld metal tensile strength of the welding wire is more than or equal to 850MPa, the yield strength is more than or equal to 720MPa, the elongation is more than or equal to 22 percent, and the low-temperature impact toughness Akv is more than or equal to 181J at the temperature of -30 DEG C, or more than or equal to 175J at the temperature of -40 DEG C, or more than or equal to 162J at the temperature of -50 DEG C.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

Weather-proof flux core wire used for coating-free bridge steel and preparing method of weather-proof flux core wire

ActiveCN106475706AImprove mechanical propertiesStable welding arcWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a weather-proof flux core wire used for coating-free bridge steel and a preparing method of the weather-proof flux core wire. The weather-proof flux core wire is composed of a steel skin and a powder core. The powder core comprises, by weight percent, 2%-8% of ferro-boron, 0.01%-2% of ferromolybdenum, 1%-6% of fluoride, 1.5%-8% of zircon sand, 2%-7% of magnesium powder, 2%-5% of quartz sand, 2%-8% of silicon iron, 5%-19% of electrolytic manganese, 1%-5% of ferromanganese, 1%-6% of nickel powder, 1%-8% of chromium metal, 1%-8% of copper powder, 2%-9% of ferrotitanium, 0.1%-5% of feldspar, 2%-8% of sodium titanate, 20%-40% of rutile and the balance iron powder. Compared with the prior art, the weather-proof flux core wire is stable in welding arc and little in splashing, slag removing is easy, a welding joint is formed attractively, the weather-proof flux core wire is suitable for all-position welding, the mechanical performance of the welding joint is good, the impact toughness at the temperature of minus 40 DEG C is larger than 80 J, and very high corrosion resistance is achieved.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Flux-cored wire for gas-shielded welding of high-chromium-nickel all-austenitic stainless steel

InactiveCN102699579AGuaranteed processing effectIncrease widthWelding/cutting media/materialsSoldering mediaChromium nickelManganese

The invention provides a flux-cored wire for the all-position welding of an austenitic stainless steel, comprising flux powder and a stainless steel band for external use, wherein the weight of a flux core accounts for 28.0-30.0 percent of the total weight of the flux-cored wire, the flux core contains the following components accounting for the flux core in percentage by weight: 25.0%-28.0% of metallic chromium powder, 29.0%-32.0% of metallic nickel powder, 4.0%-5.0% of electrolytic metallic manganese, 2.0%-4.0% of high carbon ferro-chrome, 18.0%-20.0% of rutiles, 1.0%-2.0% of quartz, 1.0%-2.0% of zircon sands, 1.0%-3.0% of feldspars, 0.5%-1.0% of fluorspars, 0.5%-1.5% of calcium carbonate, 0.5%-1.5% of barium carbonate, and the balance of ferrous powder. The flux-cored wire has good welding process property and is suitable for the all-position gas-shielded welding of a high-chromium-nickel all-austenitic stainless steel.

Owner:CHINA JINGYE ENG +1

Special flux-cored wire for hot-working die repairing surfacing

ActiveCN105057926AGood workmanshipSuitable for automatic weldingArc welding apparatusWelding/cutting media/materialsSlagGas metal arc welding

The invention provides a special flux-cored wire for hot-working die repairing surfacing. The special flux-cored wire comprises the wire tube wall and powder covered by the wire tube wall, wherein the powder comprises a deoxidation alloying agent and a slag former; by adding nanometer chromium nitride powder into iron-base alloy powder, a thin nitride interstitial phase is formed in the deposited metal, so that the deposited metal has good tenacity and anti-cracking capacity; meanwhile, yttria is added into the alloy powder, so that the deposited metal is purified, the occluded foreign substances are nodulized, the nitride strengthening phase is formed, and the anti-fatigue performance of the deposited metal is improved; by adopting the gas metal arc welding technology combining flux-cored wire and argon-rich gas protection to repair the hot-working die, the obtained deposited metal has excellent high-temperature oxidation resistance, excellent abrasive resistance, excellent cleanliness and good anti-fatigue performance.

Owner:SHANDONG UNIV

Alkaline CO2 gas protection dilute alloy heat resistant steel flux-cored wire

InactiveCN103056549AGood welding performanceGood slag coverageWelding/cutting media/materialsSoldering mediaWelding jointFeldspar

The invention provides an alkaline CO2 gas protection dilute alloy heat resistant steel flux-cored wire which is composed of a flux core and a steel skin, wherein the flux core occupies 14-16% of the total weight of the wire. Weight percentages occupied by all components of the flux core are that TiO2 occupies 25-40%, MgO occupies 1-4%, CaCO3 occupies 0.4-0.8%, NaF occupies 1-3%, Na2SiF6 occupies 1-3%, silicomanganese occupies 4.5-20%, cryolite occupies 2-4%, feldspar occupies 4-10%, Teflon occupies 0.2-0.6%, iron alloy occupies 20-35%, and pure metal powder occupies 12-20%. The alkaline CO2 gas protection dilute alloy heat resistant steel flux-cored wire has excellent welding process performance due to the fact that pure CO2 serves as protection gases, and is applicable to all-position welding. In addition, the alkaline CO2 gas protection dilute alloy heat resistant steel flux-cored wire is good in weld joint molten slag coverage, easy to deslug, high in deposition efficiency, good in rust resistance and attractive in formed weld joints.

Owner:CHINA JINGYE ENG +1

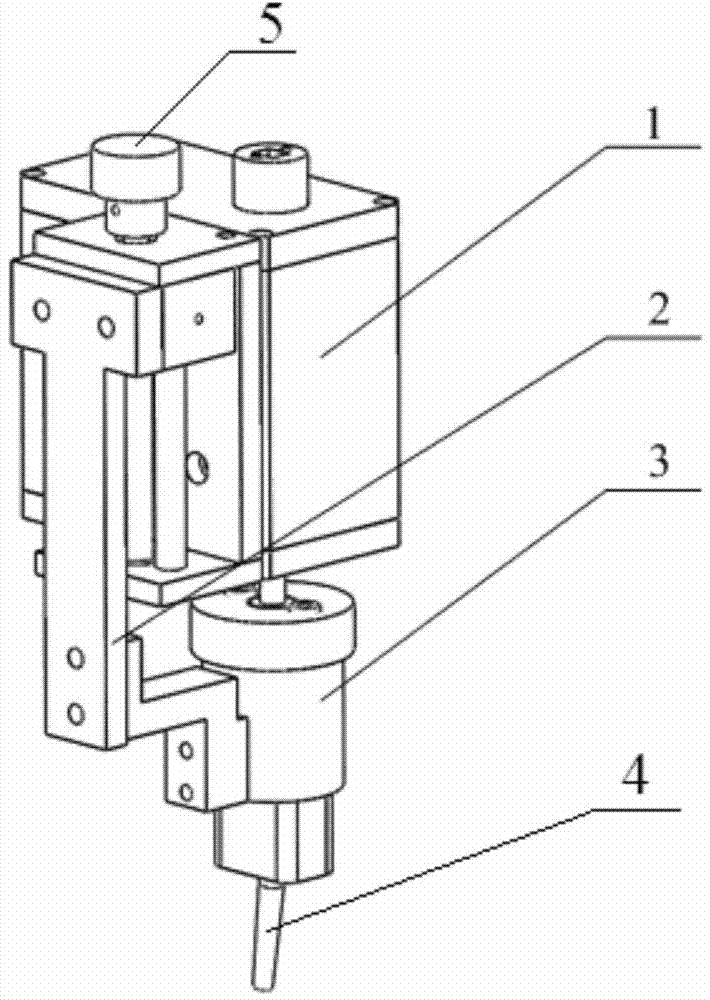

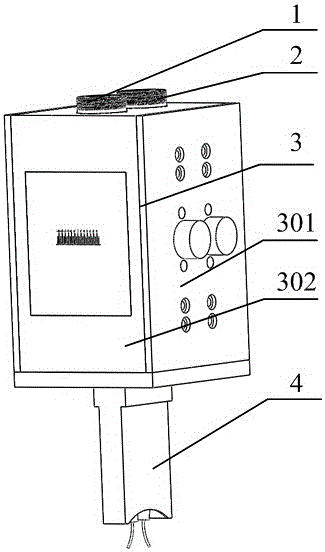

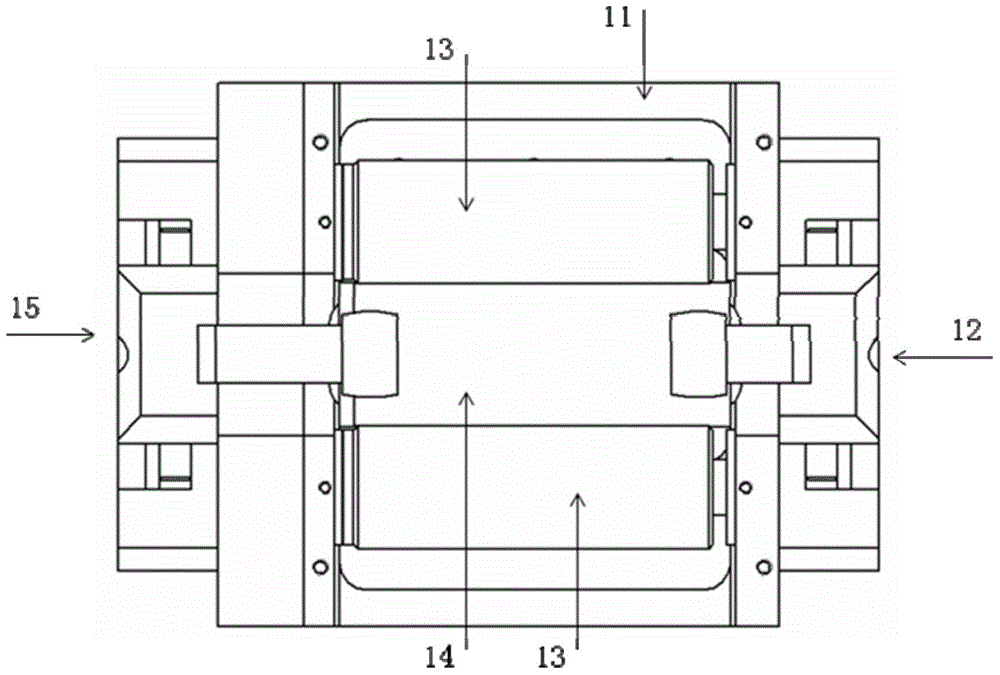

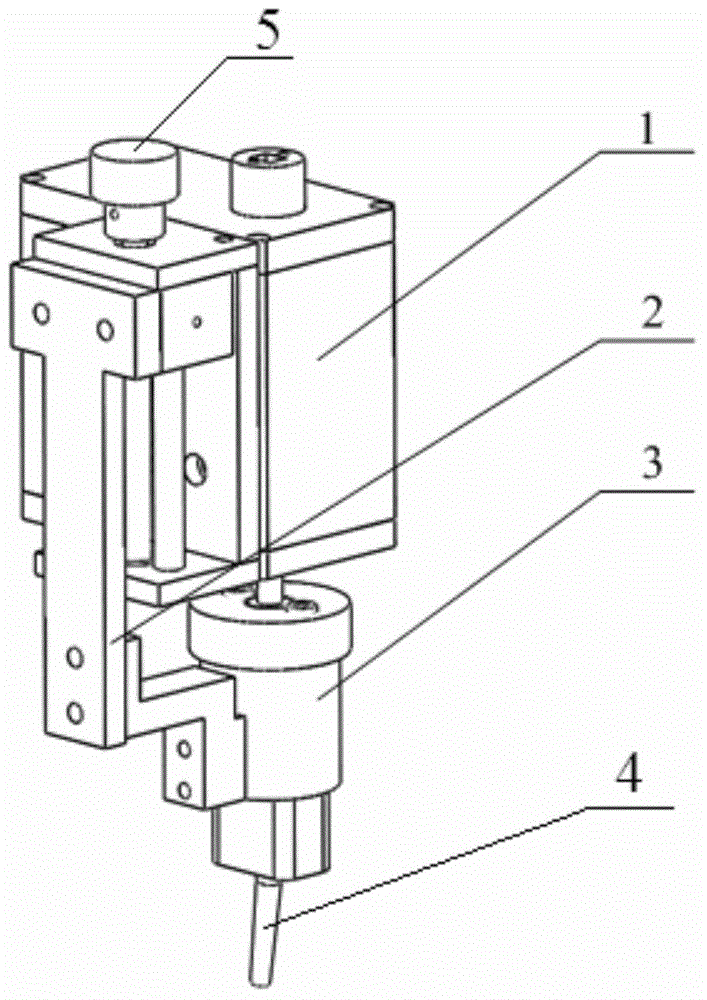

Oscillating-arc narrow-gap MIG/MAG (Metal Inert Gas/Metal Active Gas) welding torch

ActiveCN103658942AImprove the heating effectSolve non-fusion problemsCooled electrode holdersElectrode accessoriesSpray nozzleEngineering

The invention relates to an oscillating-arc narrow-gap MIG / MAG (Metal Inert Gas / Metal Active Gas) welding torch to solve the problem that side walls are not fused during narrow-gap welding. A motor gear is fixedly arranged on an output shaft of a motor. A transition gear is synchronously engaged with the motor gear and an oscillating gear. Two ends of a conductive plate are respectively connected with a welding gun connector and a conductive shaft. The conductive shaft is arranged in a center hole of the oscillating gear and is fixedly connected with the oscillating gear. A conductive shaft sleeve and the conductive shaft form a cavity. The cavity is communicated with two water holes formed in the conductive shaft. Two water pipes respectively communicate a water inlet and a water outlet with the two water holes in the conductive shaft. The upper end of a bent conductive rod is connected onto the conductive shaft through a thread and the lower end of the bent conductive rod penetrates through an external narrow-gap spray nozzle. The axis of a bending head at the lower part of the bent conductive rod and the axis of the conductive shaft form an included angle of 5-15 degrees. A contact tip is connected onto the bending head through a thread. A spray nozzle height adjusting part is installed on the shell of the welding gun. The external narrow-gap spray nozzle is fixedly arranged below the spray height adjusting part. The oscillating-arc narrow-gap MIG / MAG welding torch is used for narrow-gap welding.

Owner:HARBIN INST OF TECH

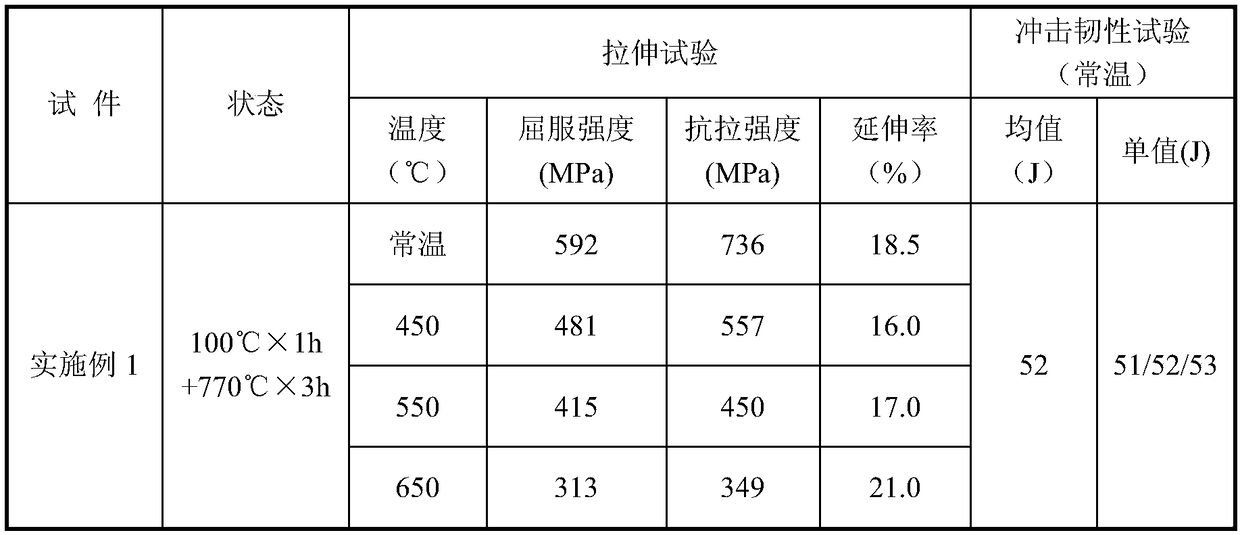

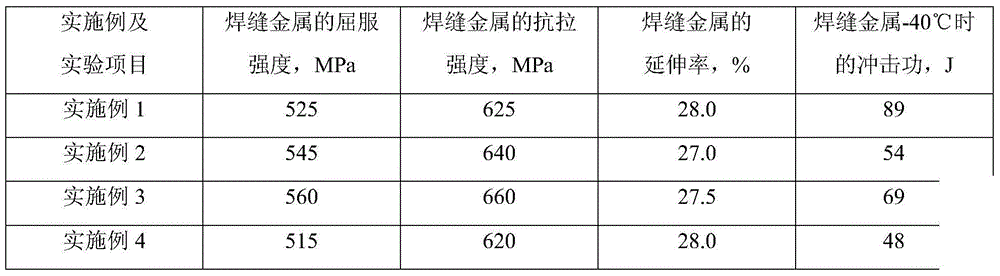

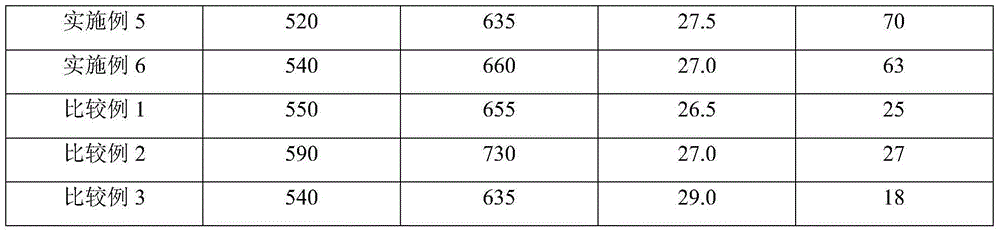

Coating transition type heat resistance steel welding rod for 650 DEG C ultra-supercritical thermal power generating unit

InactiveCN108188614AGood workmanshipStable arc burningWelding/cutting media/materialsSoldering mediaSlagHeat resistance

The invention provides a coating transition type heat resistance steel welding rod for a 650 DEG C ultra-supercritical thermal power generating unit. A CaO-CaF2-SiO2 slag system formula is adopted, atrace of alloy elements are added, the main components of deposited metal are 9%Cr-3%W-3%Co, and the welding technology performance is good. Under the heat treatment condition of 100 DEG C x 1h+780 DEG C x 3h, the tensile strength Rm of the deposited metal is larger than or equal to 680 MPa, and the normal temperature KV2 is larger than or equal to 50 J; and the tensile strength Rm of a welding connector of the deposited metal is larger than or equal to 680 MPa, the normal temperature KV2 is larger than or equal to 50 J, and the low-alloy steel electric welding rod is suitable for the 650 DEGC steam temperature ultra-supercritical thermal power generating unit.

Owner:KUSN GINTUNE WELDING

Gas protection welding wire for high-strength weathering steel and steel for gas protection welding wire

InactiveCN105195919AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaCopper platingWeathering steel

The invention provides a gas protection welding wire for high-strength weathering steel and steel for the gas protection welding wire. The steel for the gas protection welding wire comprises 0.015-0.08% of C, 0.70-1.50% of Mn, 0.20-0.80% of Si, 0.50-1.30% of Ni, 0.1-0.4% of Cu, 0.03-0.10% of Nb, 0.20% or less of Cr, 0.015% or less of S and 0.020% or less of P. The welding wire comprises 0.015-0.08% of C, 0.70-1.50% of Mn, 0.20-0.80% of Si, 0.50-1.30% of Ni, 0.15-0.50% of Cu, 0.03-0.10% of Nb, 0.20% or less of Cr, 0.015% or less of S and 0.020% or less of P. A copper plating layer is arranged on the surface of the welding wire, and the content of Cu accounts for 0.05-0.25% of the total weight of the welding wire. The welding wire is used for welding of steel of 600 MPa; when 80% Ar and 20% CO2 protection is adopted, deposited metal ReL is larger than or equal to 500 MPa, Rm is larger than or equal to 600 MPa, A is larger than or equal to 25%, and AKv at the temperature below -40 DEG C is larger than or equal to 40 J. The welding wire has the excellent welding technological performance, and is stable in welding arc, small in splashing, free of air hole, attractive in appearance and applicable to all-position welding.

Owner:ANGANG STEEL CO LTD

Flux core powder for manufacturing seamless self-shielded welding wire

ActiveCN103949795AArc stabilizationArc blowing force is largeWelding/cutting media/materialsSoldering mediaCopper platingRare earth

The invention relates to flux core powder for manufacturing a seamless self-shielded welding wire. The skin of the seamless self-shielded welding wire adopts a mild steel strip, and the flux core powder is synchronously added to the mild steel strip on line. 100 parts of flux core powder comprises the ingredients: 35-50 parts of barium lithium fluoride, 3-5 parts of magnesium fluoride, 0-4 parts of sodium fluoride, 1-3 parts of calcium fluoride, 4-12 parts of iron oxide red, 1-3 parts of rare earth fluoride, 4-8 parts of metal manganese, 10-18 parts of aluminium magnesium alloy, 6-10 parts of metal nickel, 0.5-2 parts of metal zirconium, and the balance of iron powder. All the materials are mixed and stirred uniformly according to a customary method, so that the flux core powder is obtained; the mild steel strip is curled to form a linear seamed cylinder by roller molding, and the linear seamed cylinder wraps the flux core powder; the linear seamed cylinder is manufactured into a semi-finished product seamless self-shielded welding wire by using high-frequency induction or contact bond; the semi-finished product seamless self-shielded welding wire is subjected to annealing and reducing, and is subjected to copper plating, and then the seamless self-shielded welding wire is prepared. In order to prevent the flux core power from absorbing moisture, the skin can be subjected to copper plating, and thus, the rust resistance of the seamless self-shielded welding wire is improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

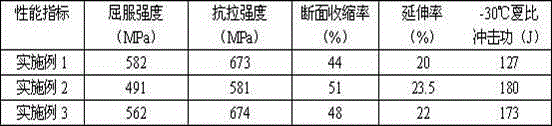

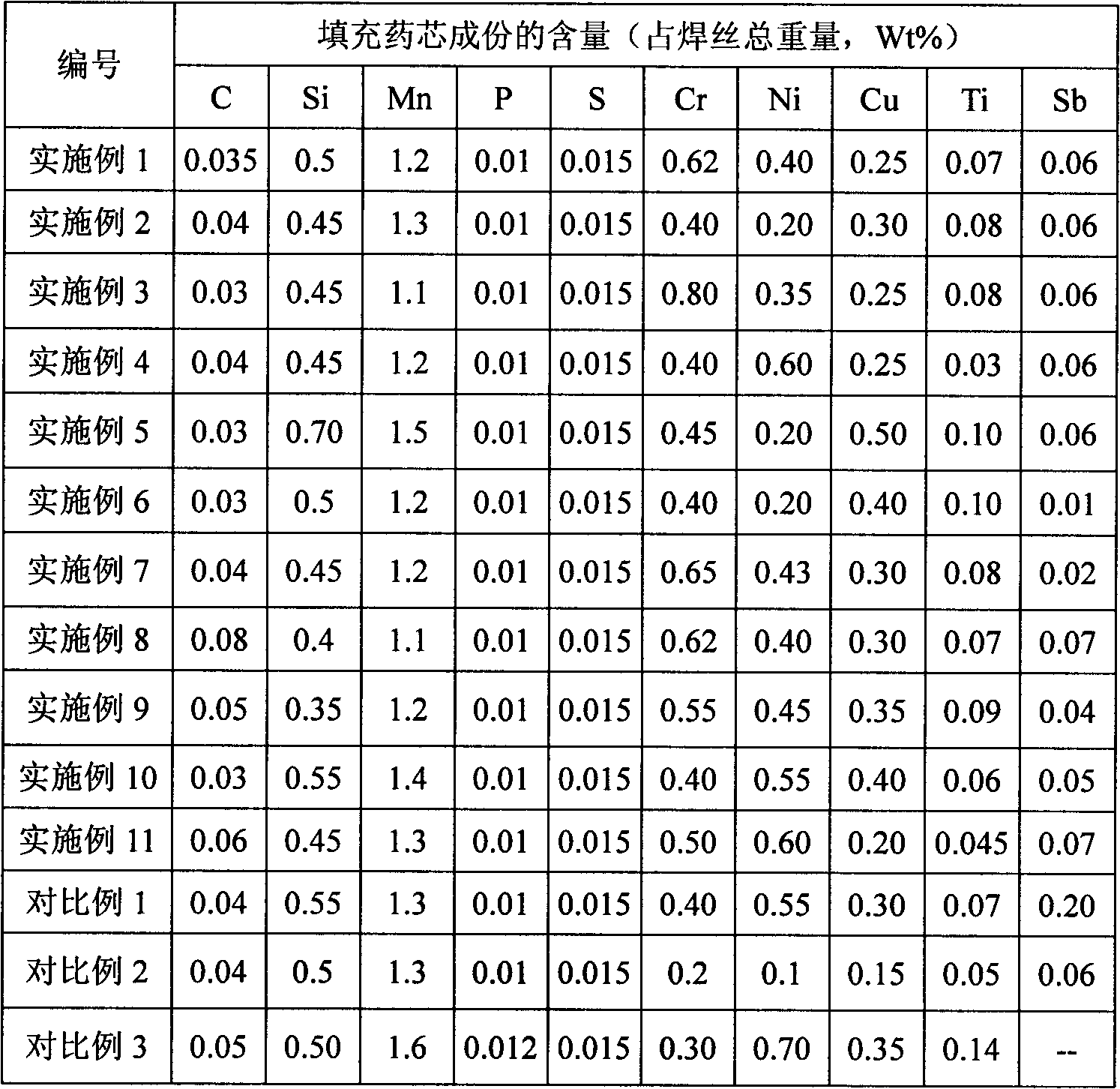

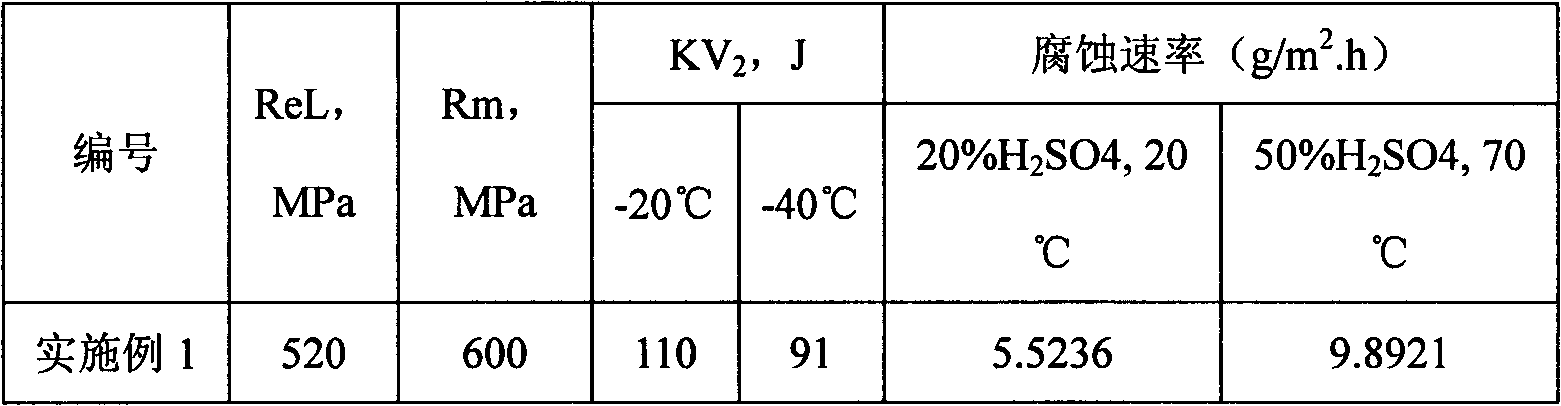

Corrosion-resistant flux-cored welding wire used for gas shielded welding

InactiveCN102825401AGood mechanical propertiesCorrosiveArc welding apparatusWelding/cutting media/materialsAlloyMechanical property

The invention discloses a corrosion-resistant flux-cored welding wire used for gas shielded welding; the flux-cored welding wire is characterized in that the chemical components and content of the alloy powder in percentage by total weight of the wire are as follows: 0.03%-0.08% of C, 0.3%-0.7% of Si, 1.1%-1.5% of Mn, less than or equal to 0.015% of S, less than or equal to 0.02% of P, 0.2%-0.5% of Cu, 0.4%-0.8% of Cr, 0.2%-0.6% of Ni, 0.03%-0.1% of Ti, 0.02%-0.10% of Sb, and the balance of iron and unavoidable impurity; and meanwhile, the ratio of Cu and Sb elements is controlled to be within the range of 4.0-8.0. The wire deposited metal and the welded have excellent mechanical property, the deposited metal has the tensile strength of more than 550MPa and has the impact toughness of more than 60J at (-40) DEG C. The gas shielded welding wire has the combination property of air-corrosion resistance and sulphuric acid dew point corrosion resistance, and meanwhile, the wire is wide in welding parameter adjustment range, stable in welding process and attractive in the formed welding line, so that the wire is beneficial to the all-position welding.

Owner:ANGANG STEEL CO LTD

High-strength steel electrode used for minus 50 DEG C low temperature spherical tank

InactiveCN106425164AGood process performanceStable arc burningWelding/cutting media/materialsSoldering mediaSlagMetal

The invention provides a high-strength steel electrode used for a minus 50 DEG C low temperature spherical tank. According to the high-strength steel electrode, a CaO-TiO2-CaF2 slag system formula is adopted, and microcrystalline alloying elements are added into a deposited metal on the basis of 2.5% Ni, so that the welding technology property of the electrode is good, when welded under a heat input of 30-40 KJ / cm and under a heat treatment condition of 580 DEG C*4 h, the deposited metal has tensile strength Rm of 630 MPA or above, minus 60 DEG C KV2 is 60 J or above, and the welded joint of the deposited metal has the tensile strength Rm of 610 MPa or above, minus 50 DEG C KV2 is 70 J or above, therefore, the high-strength steel electrode is very applicable to weld and construction of the minus 50 DEG C low temperature ethylene / propylene spherical tank.

Owner:KUSN GINTUNE WELDING

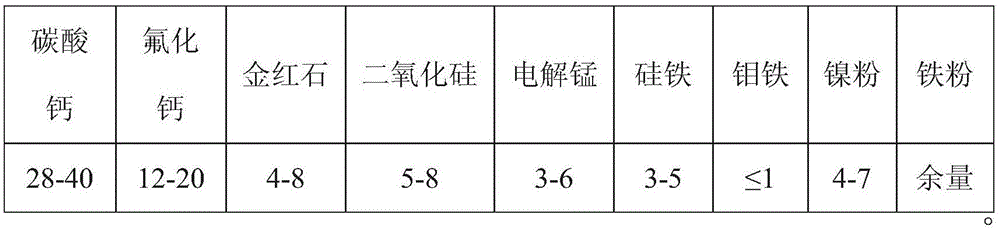

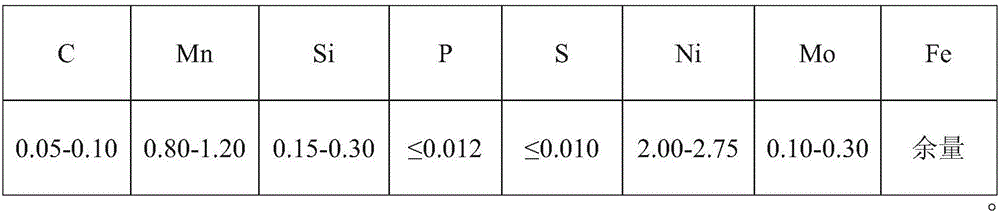

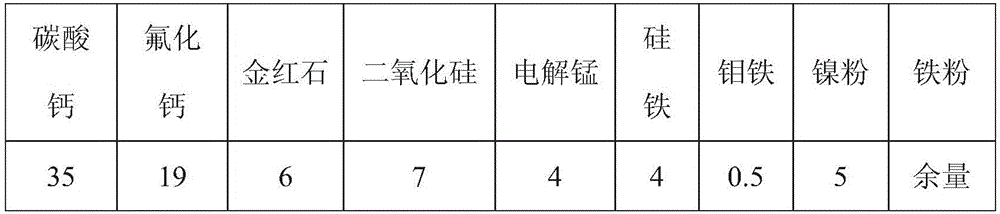

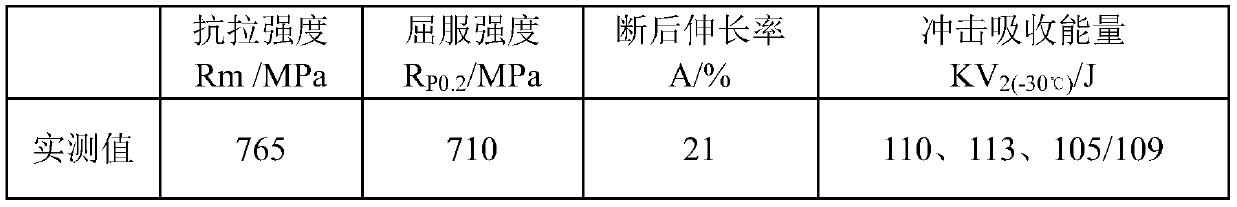

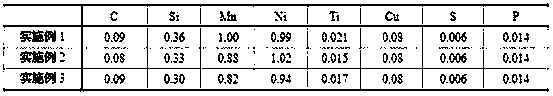

All position welding low hydrogen type electrode excellent in low temperature impact toughness and for SA-508Gr.4N steel

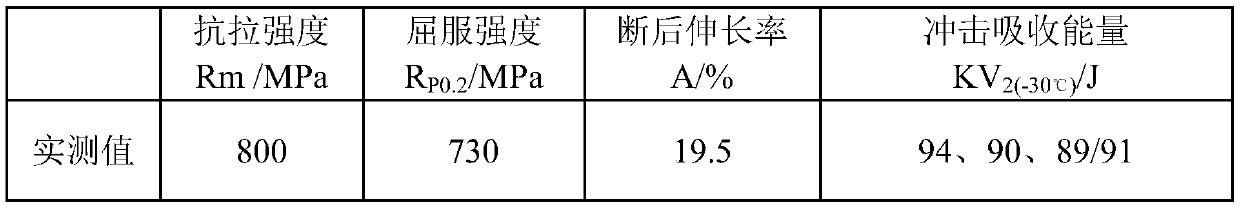

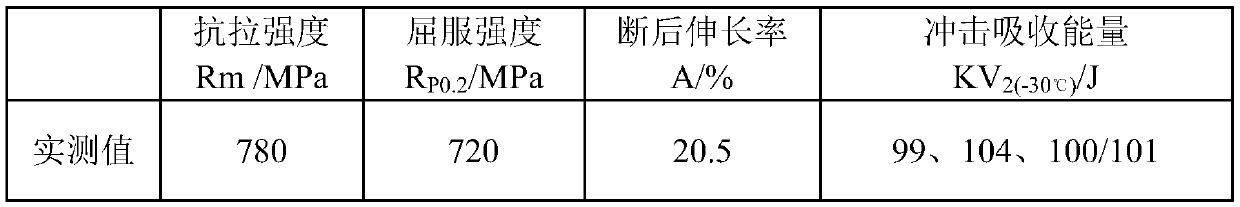

InactiveCN110369908AExcellent all-position welding process performanceEvenly meltedWelding/cutting media/materialsSoldering mediaOperabilityYttrium

The invention discloses an all position welding low hydrogen type electrode excellent in low temperature impact toughness and for SA-508Gr.4N steel, and relates to the weld material technology field.The all position welding low hydrogen type electrode excellent in low temperature impact toughness and for the SA-508Gr.4N steel solves the problems that an existing low hydrogen type electrode for the SA-508Gr.4N steel is poor in low temperature impact toughness and unsuitable for all position welding. The all position welding low hydrogen type electrode excellent in low temperature impact toughness and for the SA-508Gr.4N steel comprises a core wire and a coating, wherein the core wire consists of C, Si, Mn, S, P and the balance Fe, the coating consists of a powder material and a binding agent, and the power material consists of marble, fluorite, strontium carbonate, titanium dioxide, quartz, yttrium-based silicon iron, ferrotitanium, electrolytic manganese, mid-carbon ferromanganese, nickel powder, sodium carbonate and potassium alginate. The all position welding low hydrogen type electrode excellent in low temperature impact toughness and for the SA-508Gr.4N steel has excellent allposition welding technology performance, and is stable in electric arc, small in splashing amount and moderate in sleeving especially in vertical welding and overhead welding, melts the coating evenly, enables a weld pass to be beautiful in shaping, achieves good operability for welding operators, and has ideal mechanical performance. The all position welding low hydrogen type electrode excellentin low temperature impact toughness and for the SA-508Gr.4N steel is suitable for the all position welding of the SA-508Gr.4N steel.

Owner:HARBIN WELL WELDING CO LTD +1

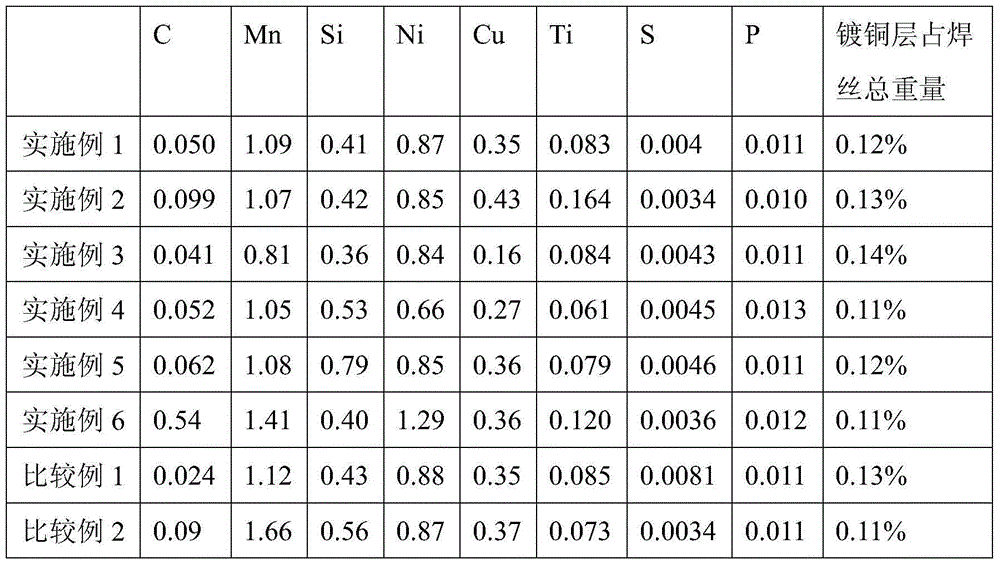

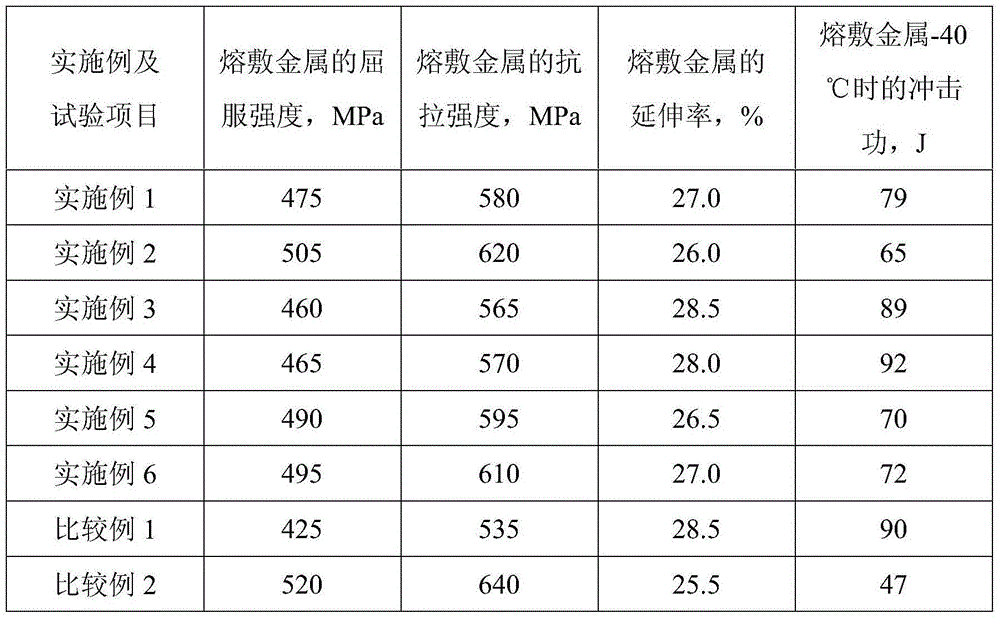

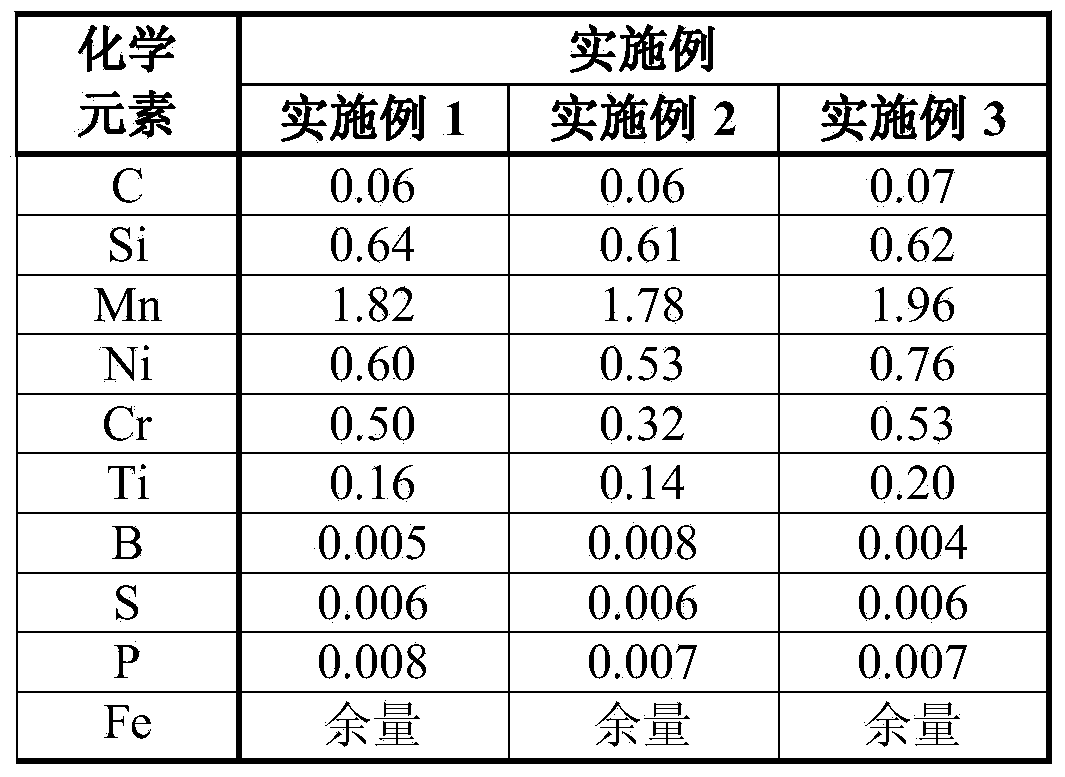

A high-strength high-toughness weather-resistant gas protection welding wire for steel

InactiveCN106312365AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaWeather resistanceSmelting process

The invention provides a high-strength high-toughness weather-resistant gas protection welding wire for steel. The welding wire steel comprises, in weight percentage, 0.03%-0.11% of C, 0.70%-1.50% of Mn, 0.25%-0.90% of Si, 0.55%-1.40% of Ni, 0.15%-0.45% of Cu, 0.05%-0.18% of Ti, not more than 0.015% of S, and not more than 0.020% of P, the balance being iron and inevitable impurities. The welding wire is used for the welding of steel of the 550 MPa strength grade; the welding wire steel smelting process is stable and easy to implement, and the technical requirements for welding high-strength, high-toughness and high-weather resistance steel are met. The gas protection welding wire has excellent welding process properties, has the advantages of stable welding arcs, less splatter, zero gas pores and artistic formation and is suitable for all-position welding.

Owner:ANGANG STEEL CO LTD

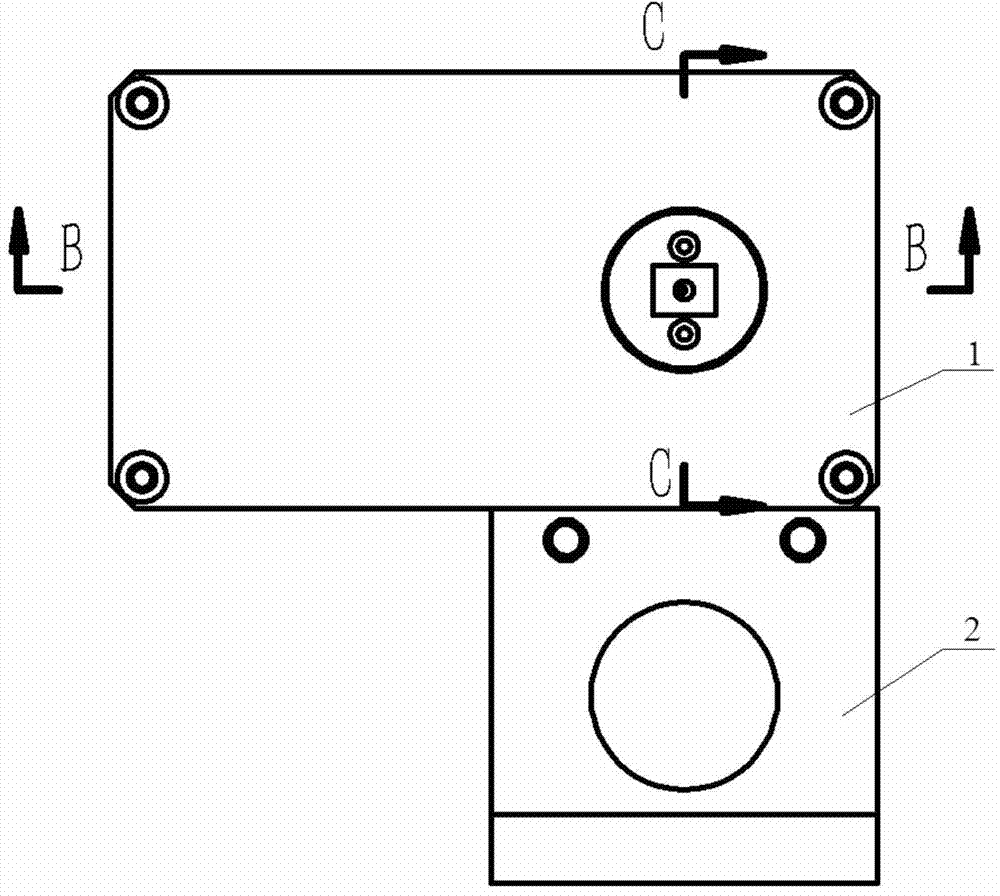

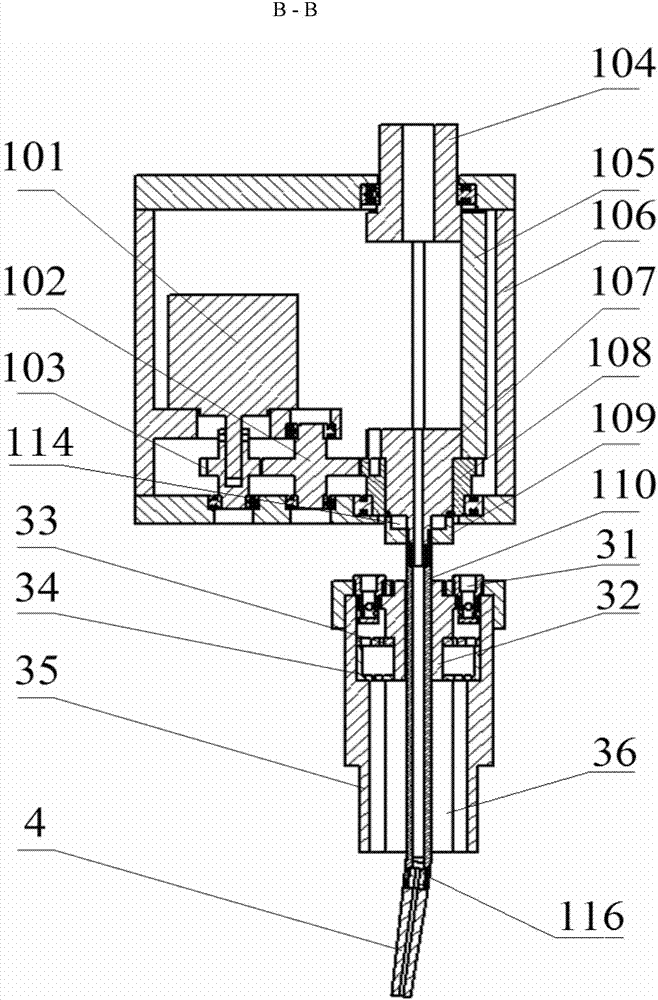

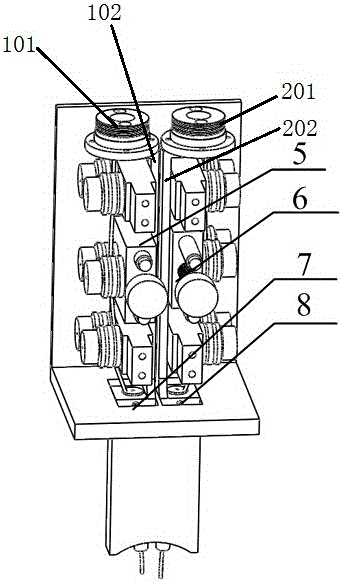

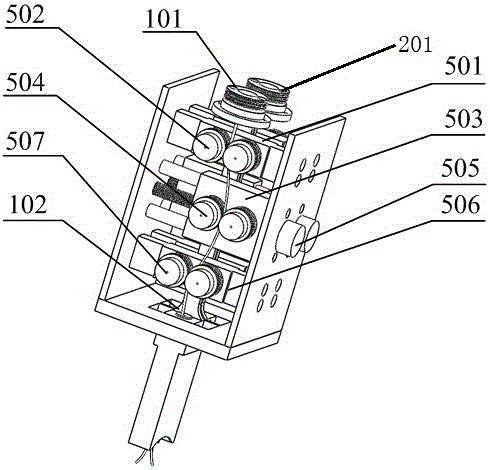

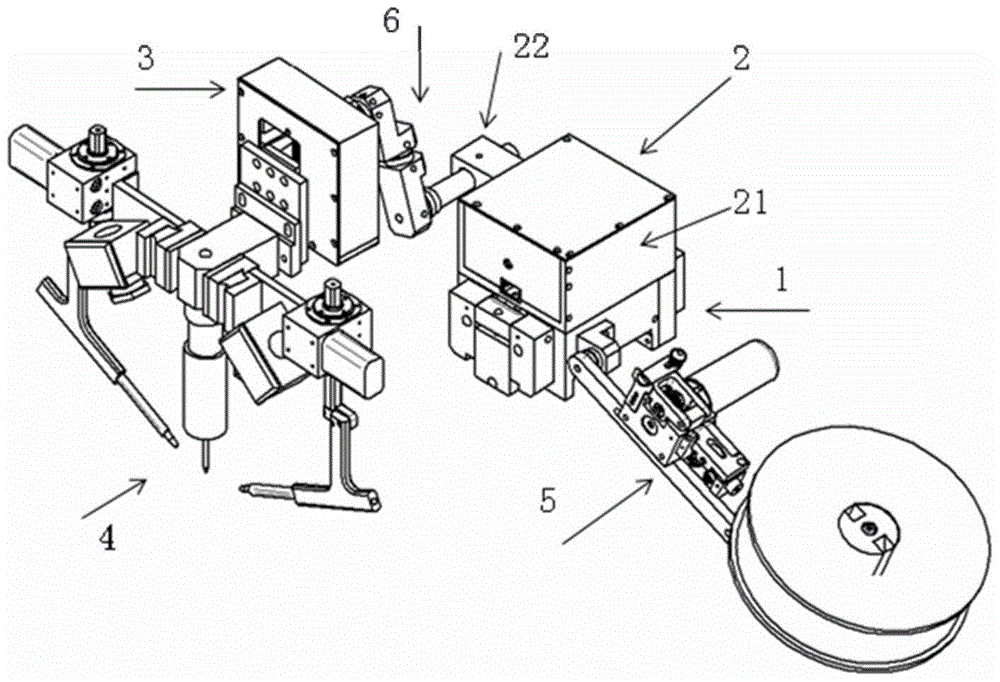

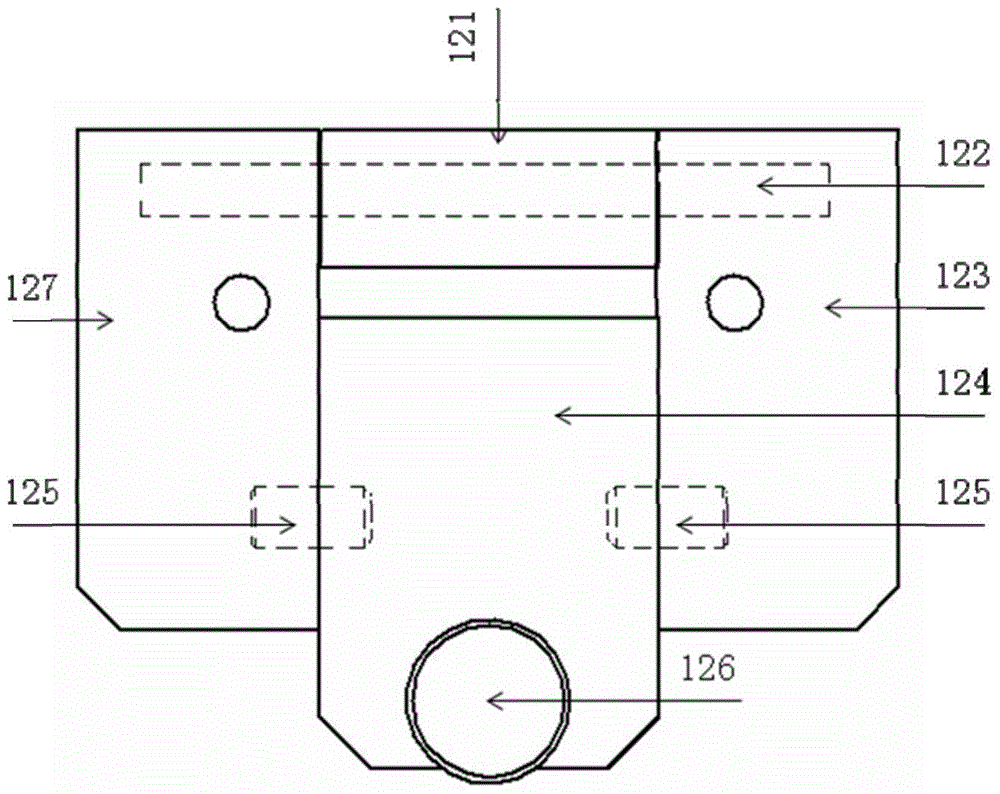

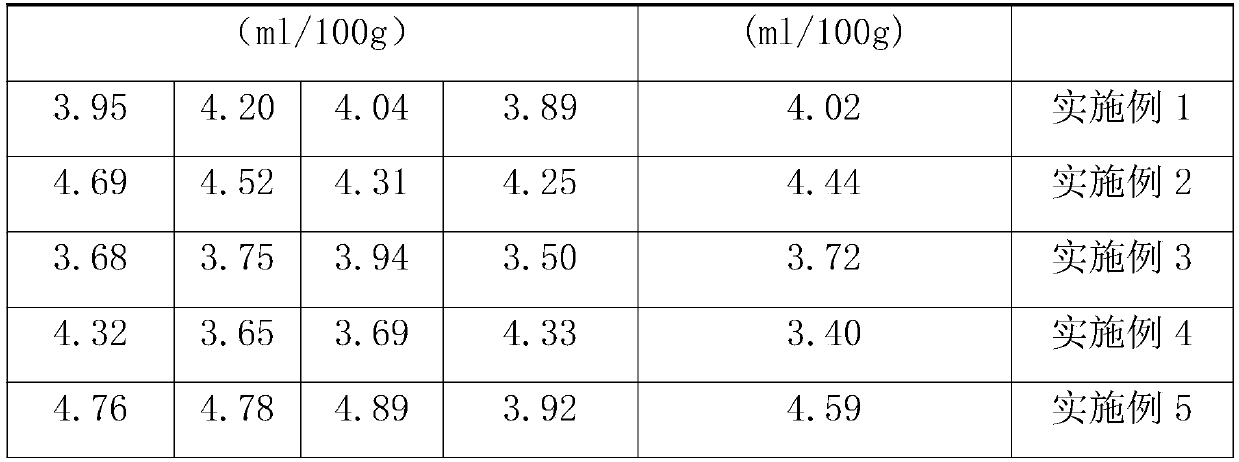

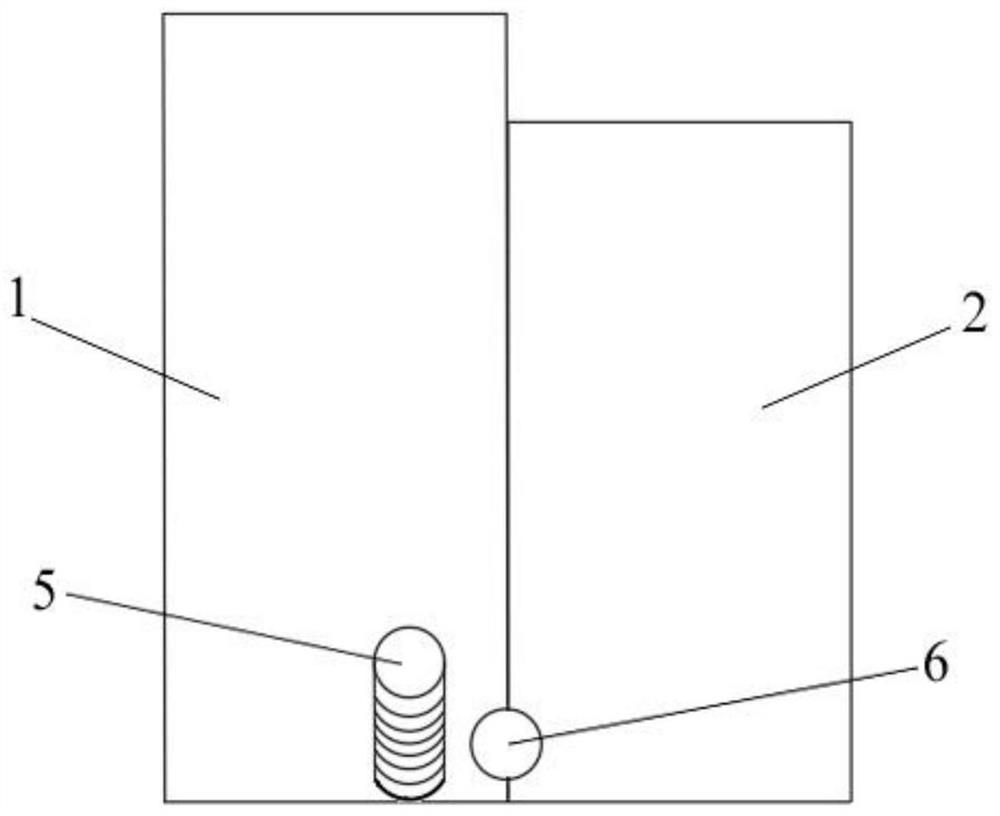

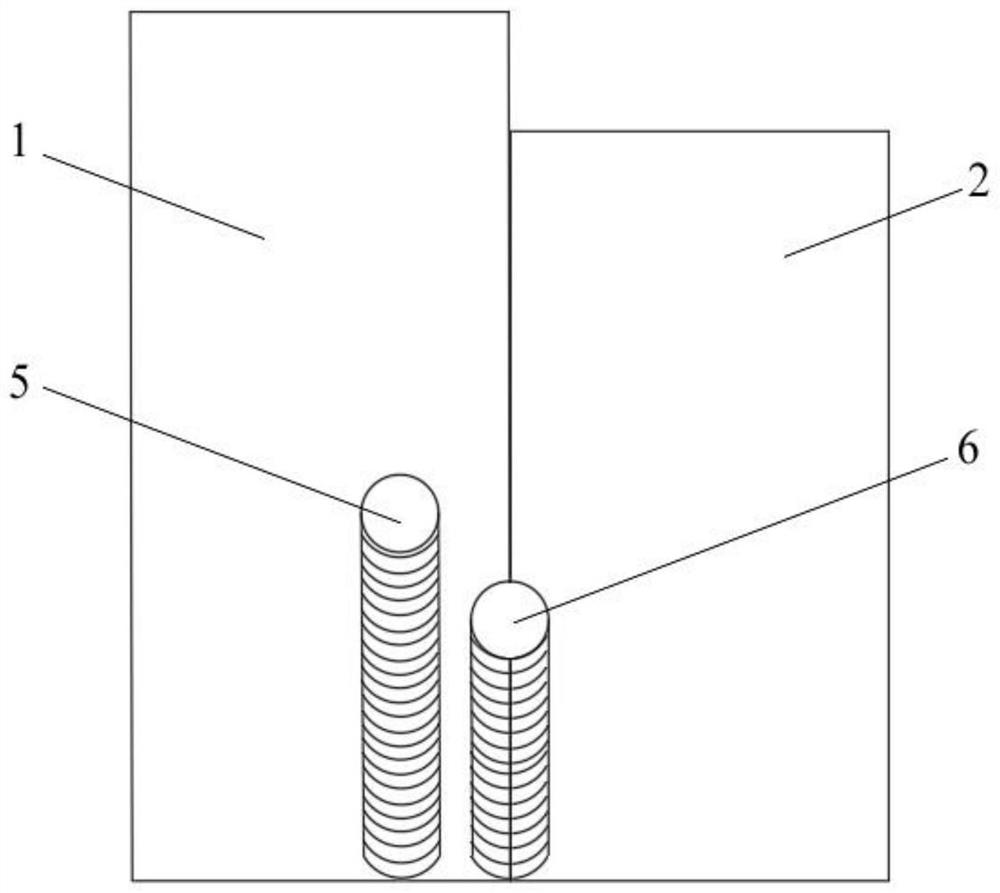

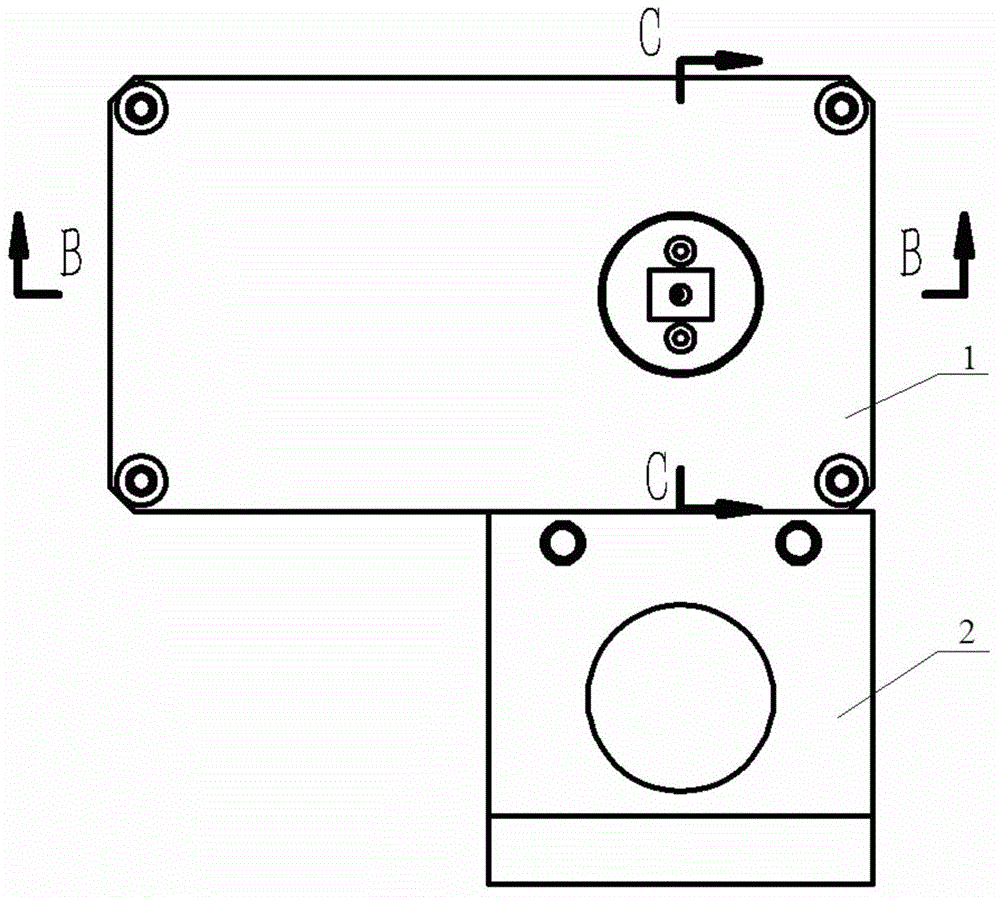

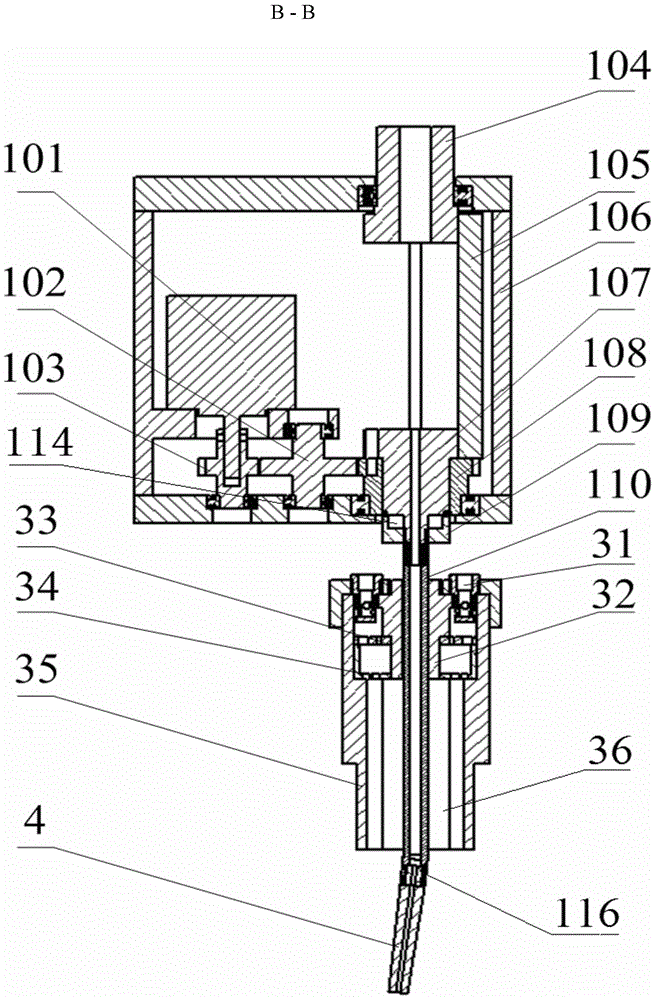

Double-bent-welding-wire narrow-gap gas metal arc welding torch

InactiveCN106475669AImprove the heating effectSolve non-fusion problemsElectrode supporting devicesGas metal arc weldingNarrow gap

The invention relates to a welding technology, in particular to a double-bent-welding-wire narrow-gap gas metal arc welding torch comprising a front electric conduction mechanism 1, a rear electric conduction mechanism 2, a welding torch box 3, an inserted type spray nozzle 4, a front wire bending mechanism 5 and a rear wire bending mechanism 6. The front electric conduction mechanism 1, the rear electric conduction mechanism 2, the front wire bending mechanism 5 and the rear wire bending mechanism 6 are located in the welding torque box 3. The front electric conduction mechanism 1 and the rear electric conduction mechanism 2 are arranged in parallel. The double-bent-welding-wire narrow-gap gas metal arc welding torch is characterized in that the front electric conduction mechanism 1 comprises a front electric conduction connector 101, a front electric conduction plate 102, a front electric conduction rod 103 and a front electric conduction nozzle 104. The upper end of the front electric conduction plate 102 is connected with the front electric conduction connector 101, and the lower end of the front electric conduction plate 102 is connected with the front electric conduction rod 103. The front electric conduction nozzle 104 is connected to the lower end of the front electric conduction rod 103. The rear electric conduction mechanism 2 is similar to the front electric conduction mechanism.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

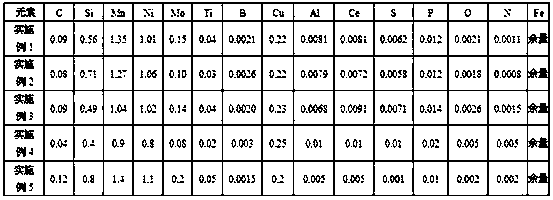

Gas shielded solid welding wire used for steel with yield strength being 460 MPa and manufacturing method

InactiveCN107598409AExcellent welding workabilityWell formed weldWelding/cutting media/materialsSoldering mediaIron powderMechanical property

The invention relates to a gas shielded solid welding wire used for steel with the yield strength being 460 MPa and a manufacturing method. The gas shielded solid welding wire comprises, by mass, 0.04%-0.12% of C, 0.9%-1.4% of Mn, 0.4%-0.8% of Si, 0.8%-1.1% of Ni, 0.08%-0.2% of Mo, 0.02%-0.05% of Ti, 0.0015%-0.0030% of B, 0.20%-0.25% of Cu, less than or equal to 0.01% of Al, less than or equal to0.010% of S, less than or equal to 0.020% of P, less than or equal to 0.005% of O, less than or equal to 0.005% of N, 0.0050%-0.010% of Ce, and the balance iron powder and unavoidable impurities. Whengas shielded welding with 80% of Ar and 20% of CO2 is conducted, the mechanical properties of deposited metal reach welding requirements of steel with the yield strength being 460 MPa and used for marine engineering, impact energy at -40 DEG C is over 120 J, and NDT is below -60 DEG C.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

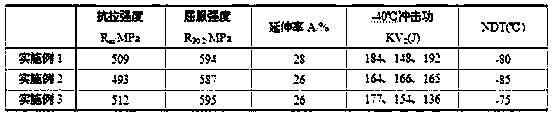

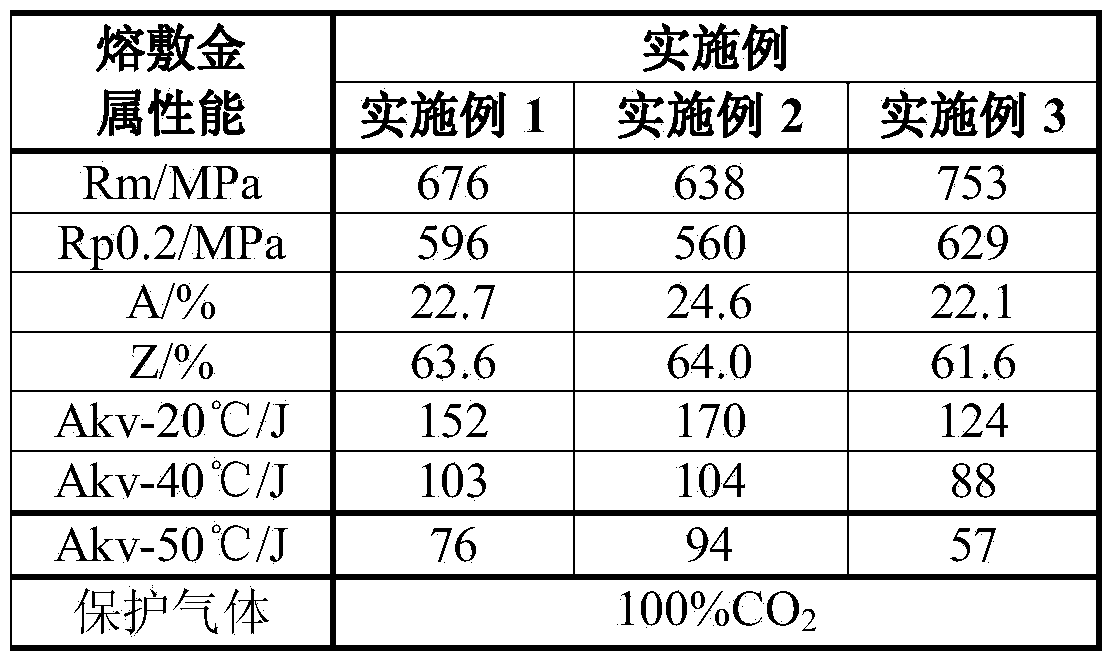

High-toughness CO2 gas protection welding wire and wire rod and application thereof

ActiveCN103464871AControl oxygen contentHigh strengthWelding/cutting auxillary devicesArc welding apparatusElectricityWire rod

The invention relates to a high-toughness CO2 gas protection welding wire and a wire rod and an application thereof. The welding wire and the wire rod both include the following chemical components by weight: 0.05-0.09% of C, 0.40-0.80% of Si, 1.50-2.00% of Mn, less than 0.010% of S, less than 0.015% of P, 0.40-0.80% of Ni, 0.30-0.55% of Cr, 0.10-0.20% of Ti, 0.002-0.010% of B and the balance Fe and inevitable impurities. The welding wire and the wire rod are simple in chemical component design. After CO2 gas protection welding is adopted, the tensile strength of obtained welding gap metal is larger than 620MPa, the yield strength is larger than 540MPa, -50-DEG C impact work is larger than 34J, and the welding wire has good process performance. The welding wire is suitable for welding of low-alloy high-strength steel with the tensile strength equal to or larger than 620MPa and can be used in the manufacture fields of large important structures such as engineering machinery, mine machinery, water and electricity, pressure containers and oil and gas delivery pipelines.

Owner:HAINING RUIAO METAL TECH CO LTD

Seamless flux-cored wire for high-strength steel welding of ocean engineering

ActiveCN111761254AImprove low temperature impact toughnessAvoid growing upWelding/cutting media/materialsSoldering mediaFerrosiliconWeld seam

The invention discloses a seamless flux-cored wire for high-strength steel welding of ocean engineering. The seamless flux-cored wire comprises low-carbon steel strip skin and flux core powder. The mass of the low-carbon steel strip skin accounts for 80% to 90% of the total mass of the seamless flux-cored wire, and the mass of the flux core powder accounts for 10% to 20% of the total mass of the seamless flux-cored wire. The flux core powder comprises the following components of, by mass, 43% to 48% of rutile, 1% to 2% of quartz, 1.2% to 2% of sodium fluoride, 3.5% to 5.5% of potassium titanate, 0.05% to 0.1% of bismuth oxide, 8% to 11% of high-carbon ferromanganese, 5.5% to 8.5% of nickel powder, 3% to 4.8% of rare earth ferrosilicon, 1.5% to 3.5% of magnesium powder, and the balance ironpowder. The seamless flux-cored wire is the seamless flux-cored wire for high-strength steel welding of ocean engineering; and by using the seamless flux-cored wire, a weld joint which is formed after welding with the seamless flux-cored wire is excellent in performance after being subjected to thermal treatment, has the good yield ratio, has higher impact toughness at a low temperature, has thedeposited metal impact energy of no lower than 90 J in the environment of minus 60 DEG C, and can be applied to welding on high-strength thick steel plates of ocean engineering.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Acidic high-strength and high-toughness flux-cored wire

ActiveCN112122820ABeautiful weld shapeImprove welding efficiencyWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention provides an acidic high-strength and high-toughness flux-cored wire. The acidic high-strength and high-toughness flux-cored wire comprises a flux core and a sheath coating the outer sideof the flux core, wherein the flux core is prepared from the following components in parts by weight: 300-430 parts of rutile, 20-40 parts of feldspar, 13-25 parts of quartz, 8-20 parts of zircon sand, 4-14 parts of magnesia, 3-10 parts of sodium fluoride, 3-10 parts of sodium fluosilicate, 3-10 parts of lithium fluoride, 5-13 parts of ferrotitanium, 5-15 parts of magnesium powder, 2-9 parts of silicon-calcium alloy, 3-11 parts of aluminum-magnesium alloy, 22-40 parts of ferrosilicon, 14-25 parts of rare-earth ferrosilicon, 120-170 parts of metal manganese, 110-150 parts of nickel powder, 45-70 parts of ferromolybdenum, 3-12 parts of graphite and the balance of iron powder, wherein the sum of the parts by weight of the medicinal powder components is 1000 parts. The acidic flux-cored wireprovided by the invention still has relatively high low-temperature impact toughness and relatively good cold crack resistance at a relatively high strength.

Owner:TIANJIN YONGCHANG WELDING WIRES

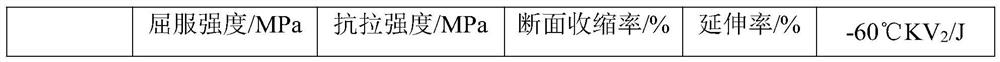

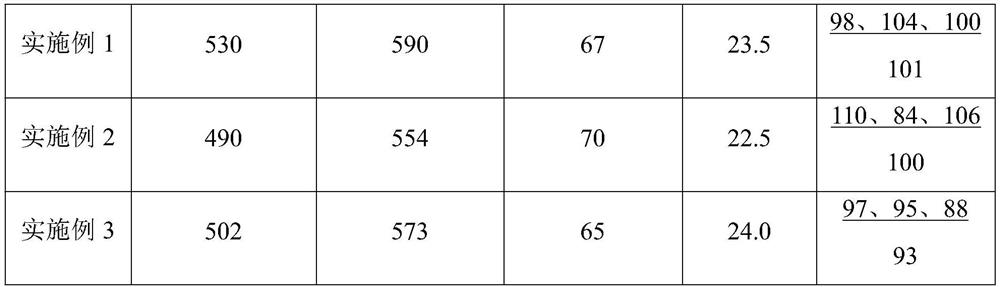

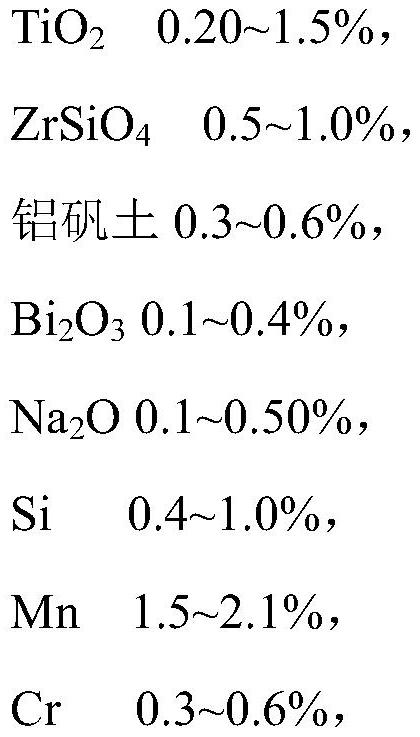

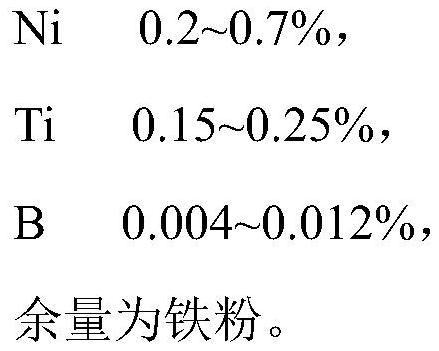

Metal powder core type flux-cored wire

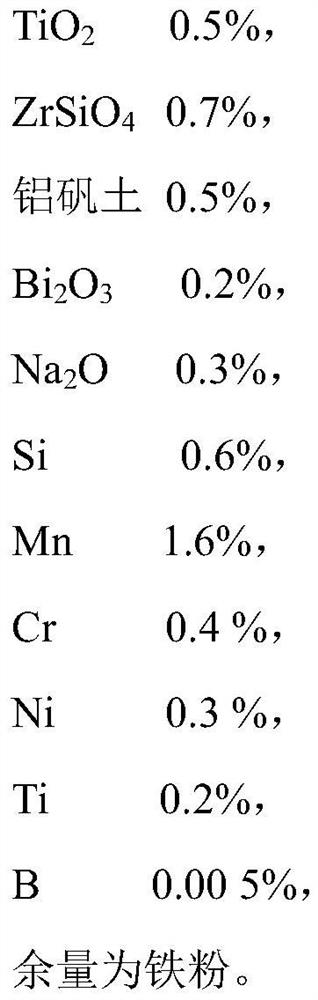

ActiveCN113579549AHigh deposition rateFast welding speedWelding/cutting media/materialsProcess efficiency improvementSlag (welding)Iron powder

The invention discloses a metal powder core type flux-cored wire. The metal powder core type flux-cored wire comprises a carbon steel sheath and powder filled in the carbon steel sheath, wherein the powder comprises the following raw materials in percentage by weight: 0.20-1.5% of TiO2, 0.5-1.0% of ZrSiO4, 0.3-0.6% of bauxite, 0.1-0.4% of Bi2O3, 0.1-0.50% of Na2O, 0.4-1.0% of Si, 1.5-2.1% of Mn, 0.3-0.6% of Cr, 0.2-0.7% of Ni, 0.15-0.25% of Ti, 0.004-0.012% of B, and the balance iron powder. The metal powder core type flux-cored wire can prevent such problems as more splashing and more welding slag in high-speed welding, improves the low-temperature impact performance of weld metal, improves the elongation of the weld metal, reaches the ultralow hydrogen level of the diffusible hydrogen content of the weld metal, and can be suitable for all-position welding.

Owner:山东索力得焊材股份有限公司

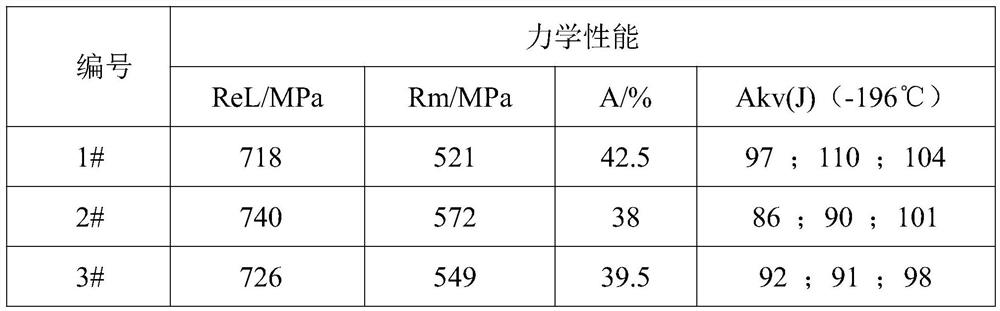

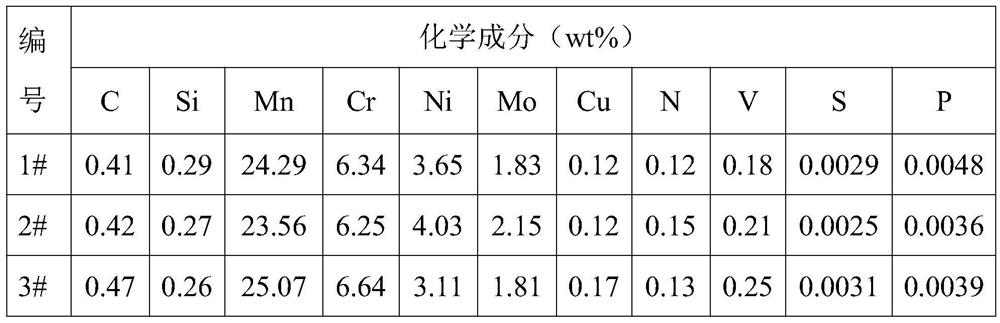

Electric arc welding electrode for ultralow-temperature high manganese steel

ActiveCN113547254AImprove mechanical propertiesReduce Mn contentWelding/cutting media/materialsGas emission reductionMagnetiteChromium nitride

The invention relates to the technical field of welding materials, in particular to an electric arc welding rod for ultralow-temperature high manganese steel. The welding rod comprises a welding rod steel core and a coating wrapping the welding rod steel core, wherein the welding rod steel core comprises, by weight, 0.35%-0.46% of C, 0.06%-0.18% of Si, 22%-30% of Mn, 3.7%-4.6% of Cr, 1.8%-2.5% of Ni, 1.3%-2.1% of Mo, smaller than or equal to 0.015% of S, smaller than or equal to 0.015% of P and the balance Fe and inevitable impurities, water glass serves as a binding agent, the coating accounts for 35%-40% of the total weight of the welding rod, existing welding rod production equipment and an existing welding rod production method are adopted for preparation; the coating comprises, by mass, 20%-30% of marble, 5%-10% of strontium carbonate, 18%-25% of fluorite, 3%-6% of zircon sand, 4%-8% of rutile, 3%-5% of ferrotitanium, 3%-8% of magnetite, 4%-8% of manganese metal, 4%-6% of chromium metal, 6%-10% of nickel metal, 2%-4% of molybdenum metal, 2%-3% of copper powder, 1%-3% of ferrovanadium, 4%-7% of nitrided ferrochromium, 0.5%-1% of graphite, 0.3%-1% of sodium carbonate, and 0.3-1% of seaweed. The welding rod has good ultralow-temperature impact toughness, excellent welding process performance and excellent all-position welding operation performance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Alkaline CO2 gas protection dilute alloy heat resistant steel flux-cored wire

InactiveCN103056549BSimple welding processIncrease coverageWelding/cutting media/materialsSoldering mediaShielding gasAlloy

The invention provides an alkaline CO2 gas protection dilute alloy heat resistant steel flux-cored wire which is composed of a flux core and a steel skin, wherein the flux core occupies 14-16% of the total weight of the wire. Weight percentages occupied by all components of the flux core are that TiO2 occupies 25-40%, MgO occupies 1-4%, CaCO3 occupies 0.4-0.8%, NaF occupies 1-3%, Na2SiF6 occupies 1-3%, silicomanganese occupies 4.5-20%, cryolite occupies 2-4%, feldspar occupies 4-10%, Teflon occupies 0.2-0.6%, iron alloy occupies 20-35%, and pure metal powder occupies 12-20%. The alkaline CO2 gas protection dilute alloy heat resistant steel flux-cored wire has excellent welding process performance due to the fact that pure CO2 serves as protection gases, and is applicable to all-position welding. In addition, the alkaline CO2 gas protection dilute alloy heat resistant steel flux-cored wire is good in weld joint molten slag coverage, easy to deslug, high in deposition efficiency, good in rust resistance and attractive in formed weld joints.

Owner:CHINA JINGYE ENG TECH CO LTD +1

A tig welding machine head with multi-axis servo motion mechanism and welding method

The invention discloses a TIG welding head with a multi-axis servo movement mechanism and a welding method. A walking mechanism is installed on a walking track so that the TIG welding head can move along the walking track. A wire feeding mechanism is installed on one side of the walking mechanism and used for feeding a welding wire when the TIG welding head performs welding. A swinging mechanism is fixed to the upper portion of the walking mechanism and connected with one side of a vertical adjusting mechanism through a welding gun angle adjusting arm, the other side of the vertical adjusting mechanism is connected with a front-end welding mechanism, and therefore a welding gun can swing in a reciprocating mode in the width direction of a welding seam when the TIG welding head performs welding. The vertical adjusting mechanism is used for adjusting the distance between the welding gun and a workpiece. The front-end welding mechanism is used for adjusting the position of the welding wire and the position of a tungsten electrode. The TIG welding head is economical, practical, compact in structure, small, portable, convenient to clamp, convenient to disassemble and maintain due to modularization, high in automation degree and capable of achieving remote monitoring and control in the welding process.

Owner:BEIJING XINGTONG SCI & TECH DEV CO LTD

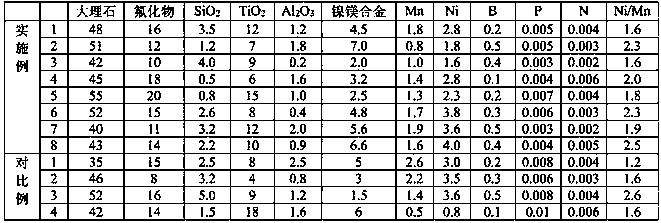

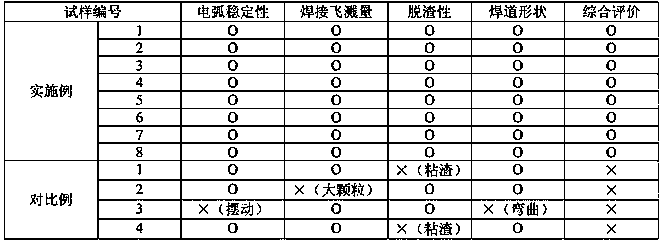

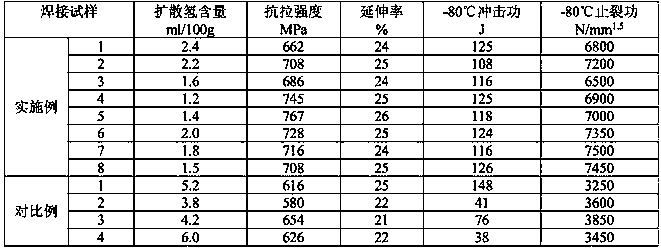

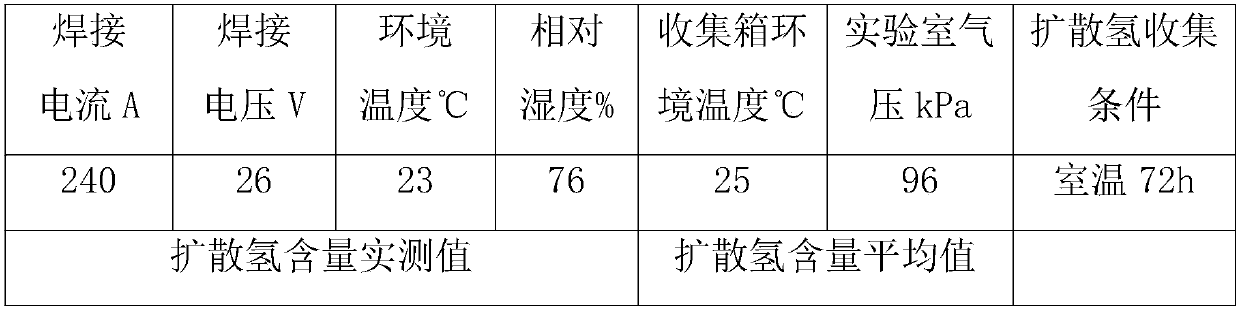

Low-hydrogen high crack prevention welding rod

InactiveCN108393612ALow diffusible hydrogen contentImprove crack arrest performanceWelding/cutting media/materialsSoldering mediaHydrogenPotassium

The invention discloses a low-hydrogen high crack prevention welding rod. The low-hydrogen high crack prevention welding rod comprises, by total weight, 40-55% of marble, 10-20% of fluoride, 0.5-4% ofSiO2, 6-15% of TiO2, 0.1-2% of Al2O3, 2-7% of a nickel-magnesium alloy, 0.8-2.8% of Mn, 1-4% of Ni, 0.1-0.5% of B, smaller than or equal to 0.01% of P, smaller than or equal to 0.01% of N, 2-5% of sodium or potassium oxide, and a proper amount of an adhesion agent and inevitable impurities. The low-hydrogen high crack prevention welding rod can be applied to full-position welding of low temperature spherical tanks and the like.

Owner:张宇

Gas-shielded flux-cored wire for 20 chromium steel for nuclear power and welding method thereof

ActiveCN108044256AImprove corrosion resistanceImprove arc conditionArc welding apparatusWelding/cutting media/materialsElectrolysisSlag

The invention provides a gas-shielded flux-cored wire for 20 chromium steel for nuclear power. The gas-shielded flux-cored wire comprises a carbon steel sheath and a flux core, wherein the carbon steel sheath is 80-84% of the total mass of the flux core, and the flux core is 16-20% of the total mass of the flux-cored wire; the flux core comprises the following components in percentage by total mass: 20-35% of fluorite, 10-20% of rutile, 1-2% of feldspar, 5-7% of 45 silicon iron, 0.5-1% of rare earth fluoride, 1-2% of magnesium powder, 8-15% of electrolytic manganese, 1-1.5% of nickel powder, 1-2% of copper powder, 1-2% of chromium powder and the balance of Fe and unavoidable impurities. The flux-cored wire is matched with CO2 gas shield and has the advantages of stable arc welding, uniformmelting, good fluidity of melting slag and beautiful weld appearance. The 30 DEG C KV2 mean value of deposited metal is larger than 100J, and the content of diffusible hydrogen is less than 5.0mL / 100g. The gas-shielded flux-cored wire meets the performance requirement of the welding process and is suitable for all-position welding.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

A dual-spindle friction stir welding auxiliary heat source welding method

ActiveCN110860781BPlay an auxiliary heating roleHigh speedWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingMetallic materials

A dual-spindle friction stir welding auxiliary heat source welding method belongs to the field of welding technology. The welding steps include: (1) preparing a workpiece to be welded; (2) installing and positioning a stirring head; (3) welding; (4) post-processing. The invention uses the auxiliary heat source stirring head and the welding seam stirring head to cooperate with welding, so that the high-hardness metal material and the low-hardness metal material can reach the plastic state at the same time in the thickness direction, so that the plastic metal flow and the stirring needle during welding are more sufficient. A welded joint with higher strength is obtained, and the operation is simple and feasible, and it is suitable for all-position welding.

Owner:东北大学秦皇岛分校

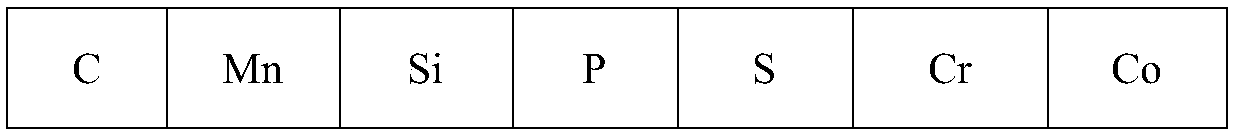

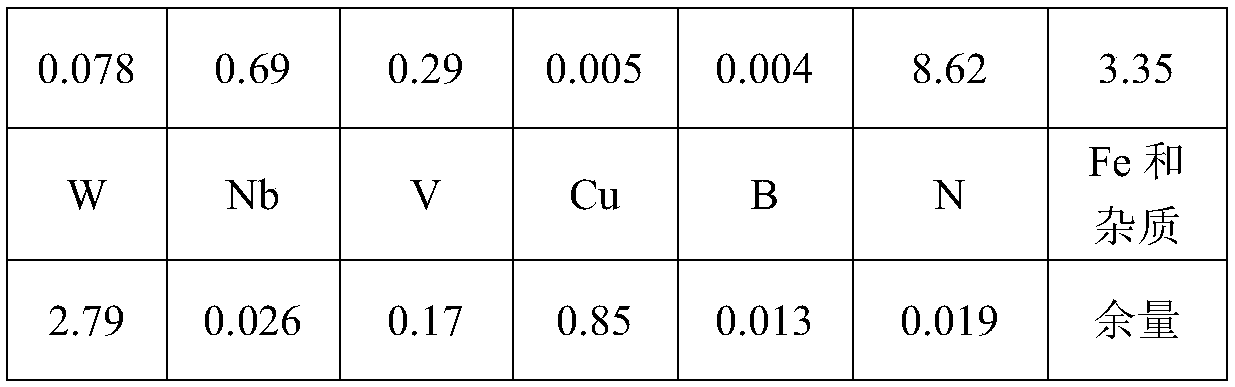

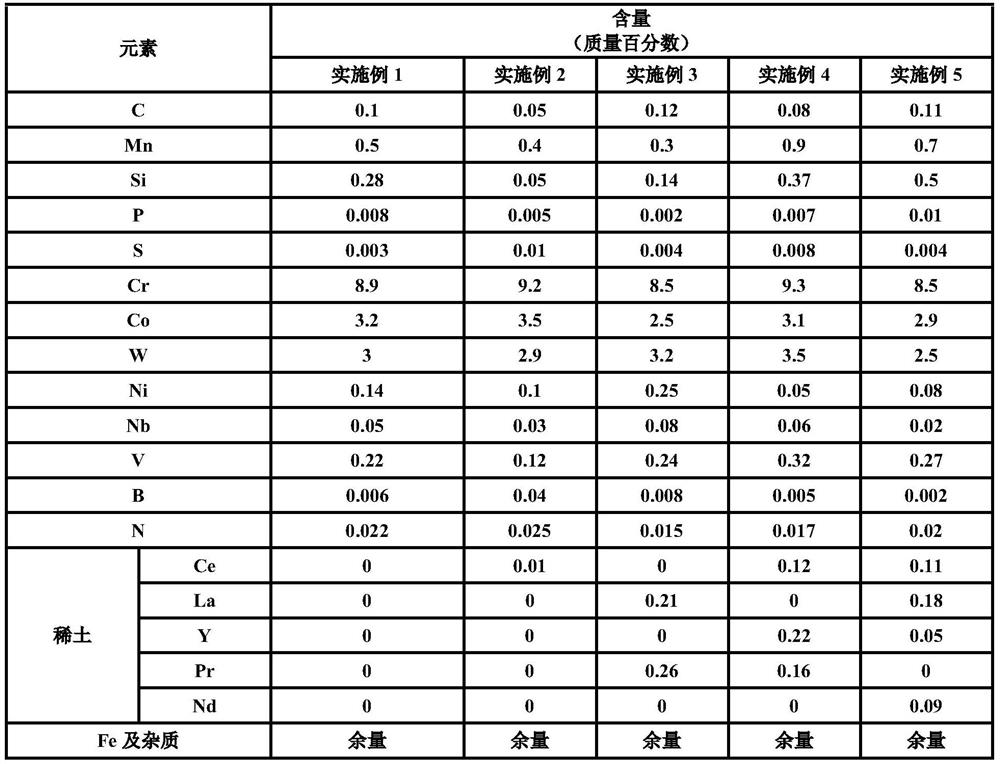

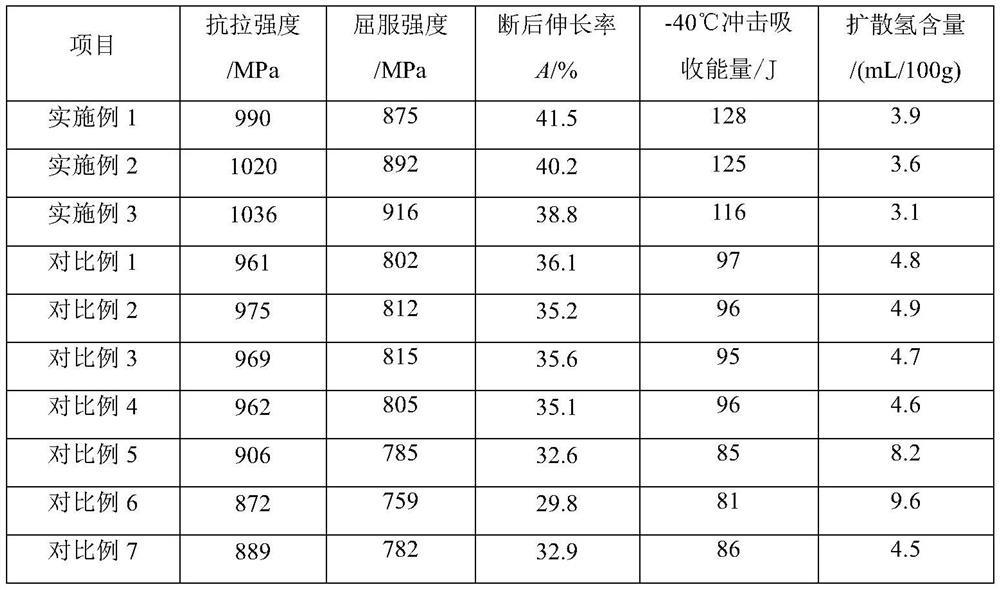

A solid welding wire for steel castings of 650°C ultra-supercritical thermal power steam turbines

ActiveCN109048119BExcellent welding wire manufacturabilityGood fluidity of molten ironWelding/cutting media/materialsSoldering mediaMechanical propertySteel casting

The invention relates to a solid welding wire for steel castings of ultra-supercritical thermal power steam turbines at 650°C, which belongs to the field of welding materials and solves the problem that the deposited metal produced by the existing welding wire cannot meet the mechanical performance requirements of steel castings of ultra-supercritical thermal power steam turbines . The composition of the core wire of the welding wire includes: C: 0.05%‑0.12%, Mn: 0.3%‑0.9%, Si: ≤0.50%, P: ≤0.010%, S: ≤0.01%, Cr: 8.5%‑ 9.3%, Co: 2.5%‑3.5%, W: 2.5%‑3.5%, Ni: 0.05%‑0.25%, Nb: 0.02%‑0.08%, V: 0.12%‑0.32%, B: 0.002%‑0.008% , N: 0.015%‑0.025%. The invention obtains physical and chemical properties similar to the parent metal by adding trace alloy elements and moderately adjusting the content of some elements, and is especially suitable for repair welding and structural welding of ultra-supercritical steam turbine castings, especially for welding of heat-resistant steel MARBN.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

A low-hydrogen easy-welding basic flux-cored welding wire for structural steel prepared from steel slag

ActiveCN112247398BSmall coefficient of linear expansionUniform compositionWelding/cutting media/materialsSoldering mediaSlag (welding)Iron powder

The invention belongs to the technical field of welding materials, in particular to a low-hydrogen easy-to-weld basic flux-cored wire for structural steel prepared from steel slag. It is made of low-carbon cold-rolled steel strip wrapped core powder, which includes steel slag 22%‑28%, Mo40V40Al20 powder 7.5%‑9.0%, FeMn60Si34C0.02 powder 5.6%‑8.2%, FeTi80‑A powder 4.1%‑ 5.0%, CaF plated with Ni on the surface 2 Powder 7.8%‑9.6%, Nano TiO 2 4.2%-6.0%, 200 mesh nitrocellulose powder 3.1%-3.8%, feldspar 2.1%-3.0%, and the balance is FHT100·25 reduced iron powder. The invention has stable arc, small spatter, good post-weld forming, easy slag removal, suitable for all-position welding, low residual hydrogen content in deposited metal, uniform chemical composition and high mechanical properties, and is an innovation in the field of basic flux-cored welding wire. .

Owner:ZHENGZHOU UNIV

Oscillating arc narrow gap mig/mag torches

ActiveCN103658942BImprove the heating effectSolve non-fusion problemsCooled electrode holdersElectrode accessoriesEngineeringWelding torch

The invention relates to an oscillating-arc narrow-gap MIG / MAG (Metal Inert Gas / Metal Active Gas) welding torch to solve the problem that side walls are not fused during narrow-gap welding. A motor gear is fixedly arranged on an output shaft of a motor. A transition gear is synchronously engaged with the motor gear and an oscillating gear. Two ends of a conductive plate are respectively connected with a welding gun connector and a conductive shaft. The conductive shaft is arranged in a center hole of the oscillating gear and is fixedly connected with the oscillating gear. A conductive shaft sleeve and the conductive shaft form a cavity. The cavity is communicated with two water holes formed in the conductive shaft. Two water pipes respectively communicate a water inlet and a water outlet with the two water holes in the conductive shaft. The upper end of a bent conductive rod is connected onto the conductive shaft through a thread and the lower end of the bent conductive rod penetrates through an external narrow-gap spray nozzle. The axis of a bending head at the lower part of the bent conductive rod and the axis of the conductive shaft form an included angle of 5-15 degrees. A contact tip is connected onto the bending head through a thread. A spray nozzle height adjusting part is installed on the shell of the welding gun. The external narrow-gap spray nozzle is fixedly arranged below the spray height adjusting part. The oscillating-arc narrow-gap MIG / MAG welding torch is used for narrow-gap welding.

Owner:HARBIN INST OF TECH

An acidic high-strength and high-toughness flux-cored welding wire

ActiveCN112122820BBeautiful weld shapeImprove welding efficiencyWelding/cutting media/materialsSoldering mediaCrack resistanceFerrosilicon

The invention provides an acidic high-strength and high-toughness flux-cored welding wire, which includes a flux core and a sheath coated on the outside of the flux core; the flux core includes the following components in parts by weight: 300-430 parts of rutile; 20-430 parts of feldspar 40 parts; 13-25 parts of quartz; 8-20 parts of zircon sand; 4-14 parts of magnesia; 3-10 parts of sodium fluoride; 5-13 parts of iron; 5-15 parts of magnesium powder; 2-9 parts of silicon-calcium alloy; 3-11 parts of aluminum-magnesium alloy; 22-40 parts of ferrosilicon; 14-25 parts of rare earth ferrosilicon; 110-150 parts of nickel powder; 45-70 parts of ferromolybdenum; 3-12 parts of graphite, iron powder balance; the sum of the parts by weight of each powder component is 1000 parts. The acidic flux-cored welding wire of the present invention still has relatively high low-temperature impact toughness and good cold cracking resistance at relatively high strength.

Owner:TIANJIN YONGCHANG WELDING WIRES

A thin-diameter flux-cored welding wire specially used for surfacing welding for hot work mold repair

ActiveCN105081611BGood workmanshipLess investmentWelding/cutting media/materialsSoldering mediaCrack resistanceSlag

The invention provides a special fine-diameter flux-cored wire for hot-working die repairing surfacing. The special fine-diameter flux-cored wire comprises a welding stick pipe wall and powder wrapped in the welding stick pipe wall. The powder comprises a deoxygenation alloying agent and a slag former. Nanometer chromium nitride powder is added in iron-based alloy powder, a fine nitride interstitial phase is formed in surfacing metal, and the surfacing metal has good tenacity and good crack resistance. Meanwhile, yttrium oxide is added in alloy powder, the surfacing metal is purified, balling is carried out on inclusions, a nitride strengthening phase is promoted to be formed, and the fatigue resistance of the surfacing metal is improved. A hot-working die is repaired through a gas metal arc welding technology with the cooperation of the flux-cored wire and rich-chlorine gas protection, and the obtained surfacing metal has the superior high-temperature oxidization resistance, the superior abrasion resistance, the superior cleanliness and the good fatigue resistance.

Owner:菏泽广泰耐磨制品股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com