Low-hydrogen high crack prevention welding rod

A welding rod and anti-crack technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of few reports on low-temperature spherical tank anti-crack electrodes, and achieve the effect of excellent crack arrest performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

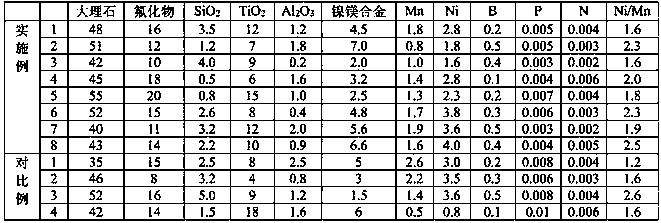

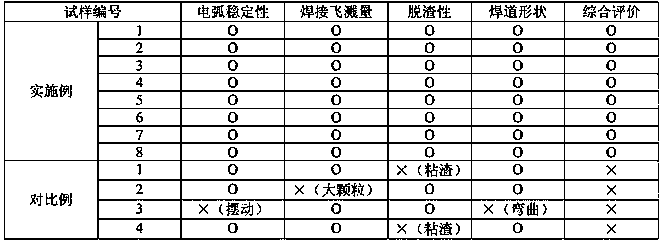

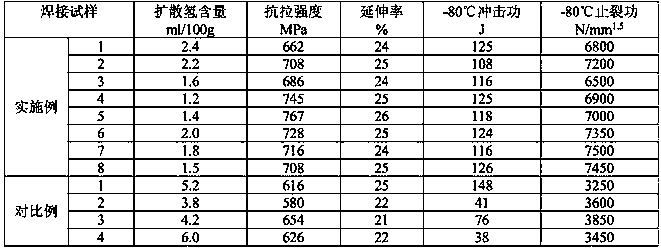

[0039] Steel plate thickness is 5mm, single V-shaped 40° groove, heat input 20kJ / cm, flat welding.

[0040] The electrode specification is 4.0mm, and the composition is shown in Table 1.

[0041] Welding process performance, weld diffusible hydrogen content and crack arrest performance are shown in Table 2-3 respectively.

Embodiment 3-4

[0043] The thickness of the steel plate is 10mm, the single V-shaped 35° groove, the heat input is 25kJ / cm, and it is welded vertically.

[0044] The electrode specification is 4.0mm, and the composition is shown in Table 1.

[0045] Welding process performance, weld diffusible hydrogen content and crack arrest performance are shown in Table 2-3 respectively.

Embodiment 5-6

[0047] The thickness of the steel plate is 10mm, the single V-shaped 40° groove, the heat input is 15kJ / cm, and it is welded vertically downward.

[0048] The electrode specification is 4.0mm, and the composition is shown in Table 1.

[0049] Welding process performance, weld diffusible hydrogen content and crack arrest performance are shown in Table 2-3 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com