Submerged arc flux

一种埋弧焊、焊药的技术,应用在电弧焊设备、焊接设备、焊接介质等方向,能够解决高成本等问题,达到降低焊接成本、好熔渣去除性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

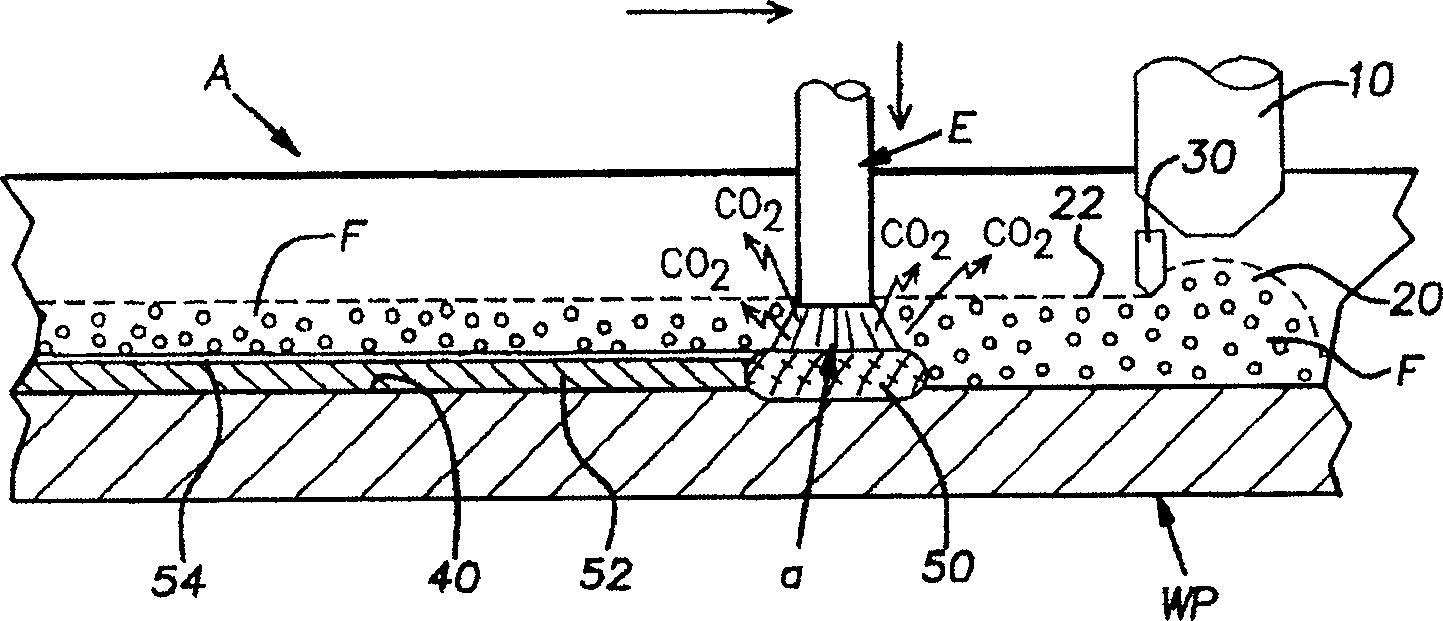

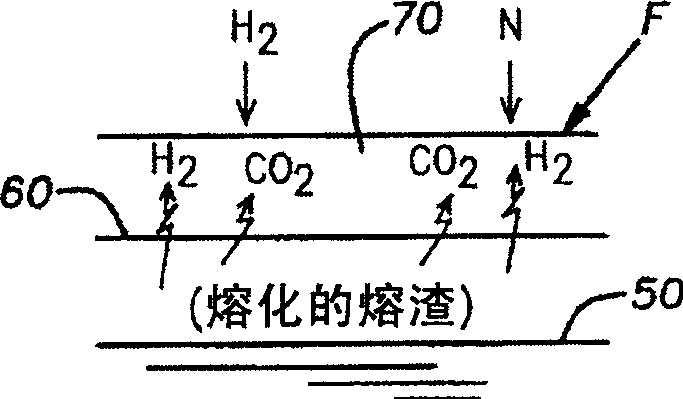

[0024] In submerged arc welding, the arc from the electrode is buried within a particle of flux such as figure 1 As shown, the electrode moves through the particulate flux in a plowing motion. The present invention provides a new type of flux F, which can be used in standard submerged arc welding process, especially process A for welding in deep and narrow grooves. In process A, an electrode E having any chemical composition required for the welding process forms an arc between the advancing electrode E and the workpiece WP. The electrode extends downwards into granulated flux F supplied by a standard flux feeder 10 . A starting flux pile 20 of particle flux F is brought along with electrode E and feeder 10 in zone 22 figure 1 The middle arrow indicates the directional movement of the dam 30 leveling out. The horizontal flux area 22 is the operating area of particle flux, through which the electrode E passes when melted by the arc a to deposit molten metal puddle 50 in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com