A solid welding wire for steel castings of 650°C ultra-supercritical thermal power steam turbines

An ultra-supercritical, solid welding wire technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the problem that the deposited metal is difficult to meet the mechanical properties requirements of 650 ℃ ultra-supercritical thermal power steam turbine steel castings , to achieve the effects of good molten iron fluidity, excellent long-term high temperature creep strength, and beautiful weld formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

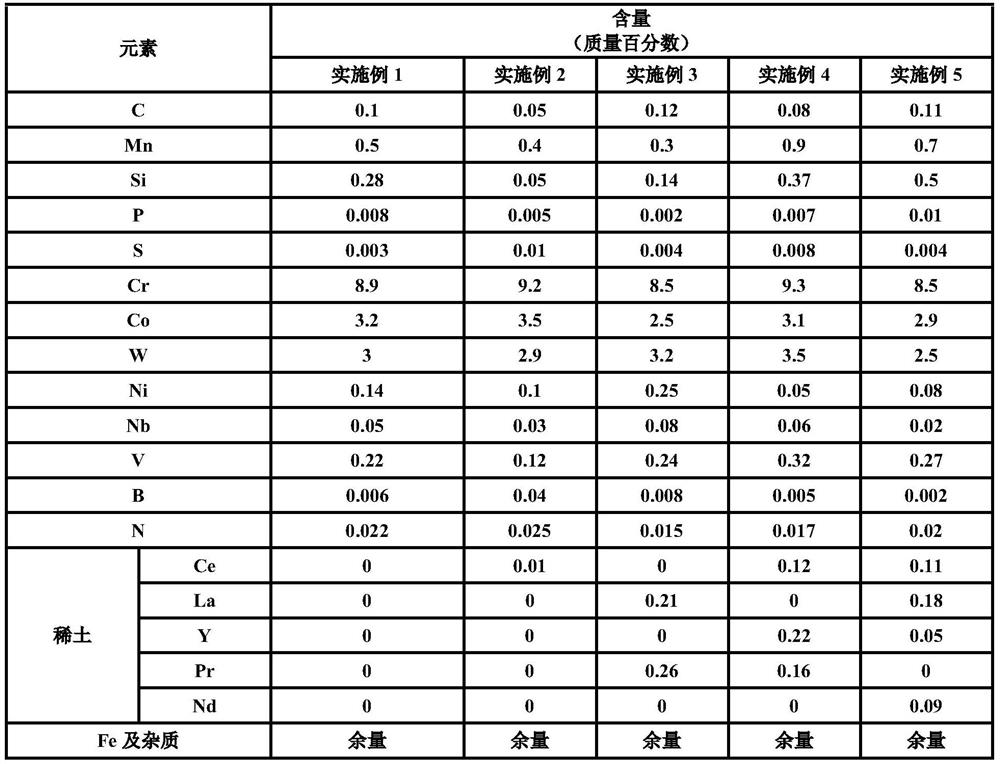

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention are specifically described below, wherein the embodiments of the present invention are used to illustrate the principle of the present invention, but not to limit the scope of the present invention.

[0026] Martensitic heat-resistant steel MARBN is a new type of steel that has emerged in foreign countries in recent years. It has excellent structural stability and durable strength in the temperature range of 620-650 ° C. It has become a key field of research at home and abroad. Correspondingly, G115 steel has also been invented in China. , but G115 steel is difficult to use in the production of steam turbine castings in terms of existing technologies, while MARBN steel can be used to cast steel castings in steam turbines. For example, Goodwin Company has completed the casting of 8 tons of MARBN material valve casing test pieces. However, in the process of developing steel castings for 650°C ultra-supercritical thermal power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com