Coating transition type heat resistance steel welding rod for 650 DEG C ultra-supercritical thermal power generating unit

A thermal power unit, ultra-supercritical technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

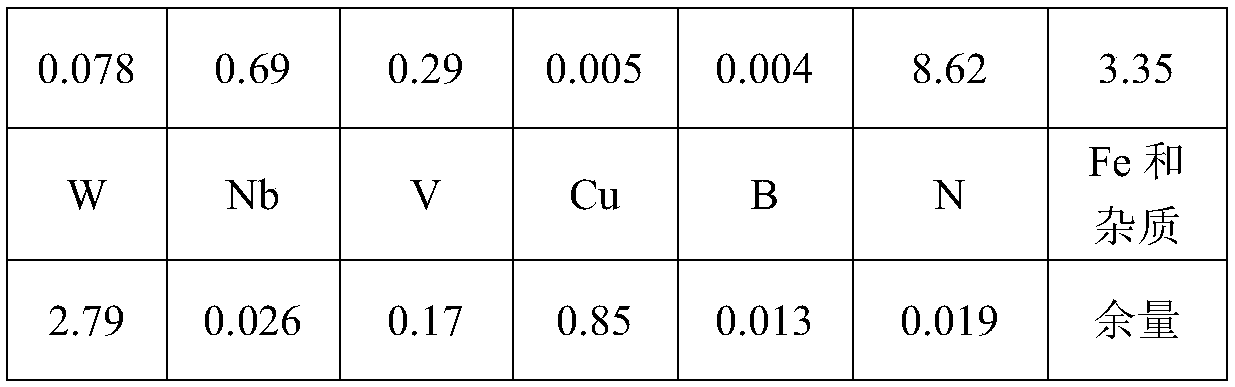

[0031] The technical solutions of the present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these examples.

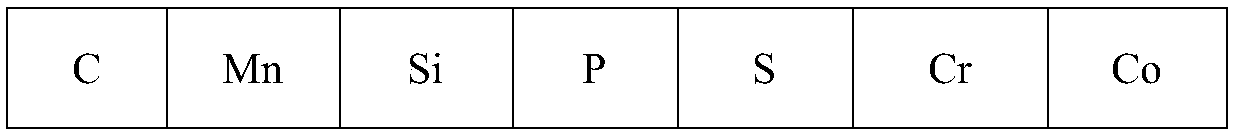

[0032] A 650°C ultra-supercritical thermal power unit coating transition type heat-resistant steel electrode, which is composed of a welding core and a coating, the coating is coated on the outer wall of the welding core, the welding core is made of carbon steel core wire, and the coating is made of CaO-CaF 2 -SiO 2 The slag system, the alloy elements are transitioned by coating; by weight percentage, the main chemical components of the deposited metal of the coating transition type heat-resistant steel electrode of the 650 °C ultra-supercritical thermal power unit are: C 0.06-0.10, Mn 0.30-0.90 , Si≤0.50, P≤0.008, S≤0.008, Cr8.5-9.5, Co 2.5-3.5, W2.5-3.5, Nb 0.02-0.09, V 0.15-0.24, Cu 0.50-1.10, B 0.010-0.024, N 0.005-0.025, the balance is Fe and impurities.

[0033] Preferably, by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com