All position welding low hydrogen type electrode excellent in low temperature impact toughness and for SA-508Gr.4N steel

A sa-508gr.4n, low-temperature impact toughness technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of poor low-temperature impact toughness, not suitable for all-position welding, etc., and achieve arc stability, Excellent all-position welding process performance, uniform melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

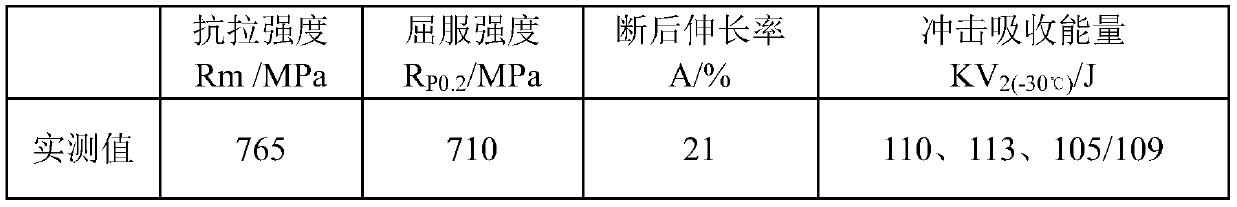

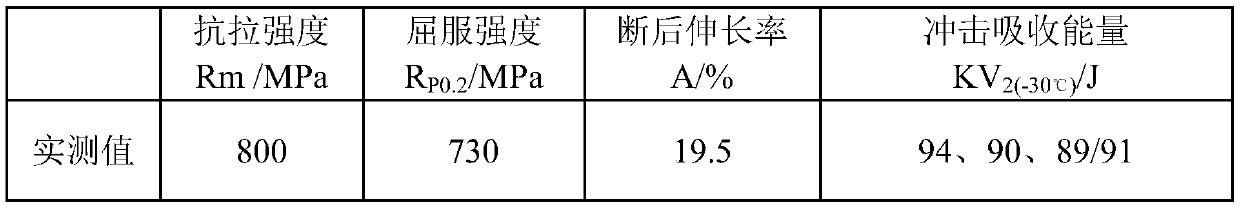

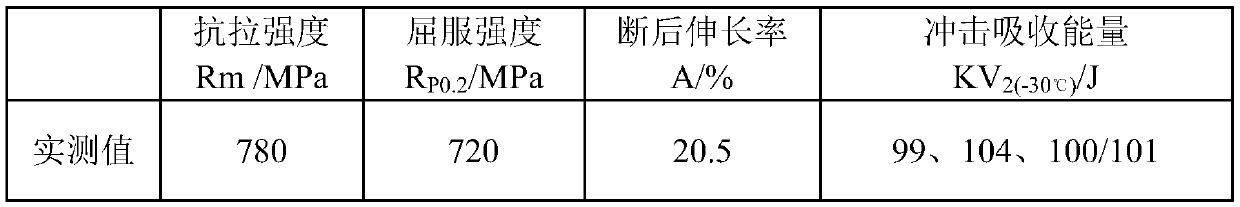

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: The SA-508Gr.4N steel all-position welding low-hydrogen type electrode with excellent low-temperature impact toughness of this embodiment includes a welding core and a coating; the welding core is composed of C≤0.04% by weight. Si≤0.015%, Mn≤0.50%, S≤0.004%, P≤0.008% and the balance Fe; the coating includes powder and binder; the powder is composed of 30% to 42% by weight % Marble, 20% to 30% fluorite, 4% to 10% strontium carbonate, 3% to 8% titanium dioxide, 2% to 7% quartz, 1% to 3% yttrium-based ferrosilicon, 4% to 8% ferro-titanium, 3% to 7% electrolytic manganese, 3% to 6% medium carbon ferromanganese, 3% to 10% nickel powder, 0.5% to 1% soda ash and 0.5% to 1 % Potassium alginate.

[0017] In this embodiment, the sum of the weight percentages of the components in the powder is 100%.

[0018] In this embodiment, the preparation of SA-508Gr.4N steel with excellent low-temperature impact toughness for all-position welding low-hydrogen electrode:...

specific Embodiment approach 2

[0025] Specific embodiment two: This embodiment is different from the specific embodiment one in that the amount of the binder is 25% of the powder weight. Others are the same as the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment three: this embodiment is different from specific embodiment one in that the binder is potassium sodium water glass. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com