Metal powder core type flux-cored wire

A technology of flux-cored welding wire and metal powder core, applied in metal processing equipment, welding medium, welding equipment, etc., can solve the problems of excessive welding slag and spatter, achieve no welding slag, good arc stability, and high welding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

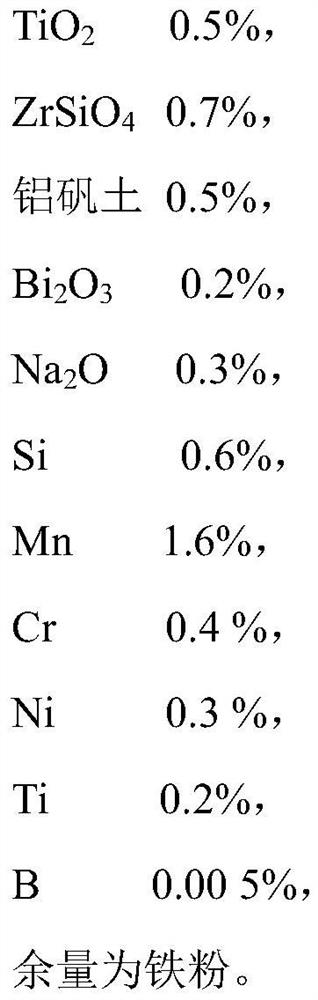

Embodiment 1~5

[0042] Preparation of metal powder new flux cored wire:

[0043] Fill the core powder in the low-carbon steel strip with a filling rate of 14%, and then draw and form it to make a finished welding wire with a diameter of 1.2mm.

[0044] The steel sheath of the flux-cored wire is made of low-carbon steel strip, and its composition is shown in Table 1.

[0045] Chemical composition of table 1 steel strip

[0046] C Si mn P S 0.022 0.003 0.24 ≤0.015 ≤0.015

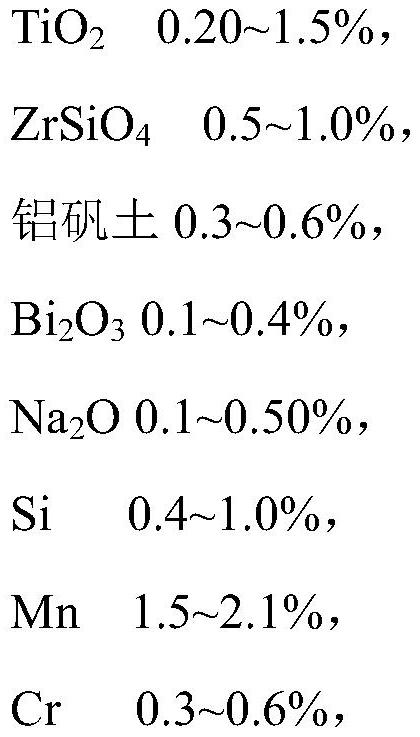

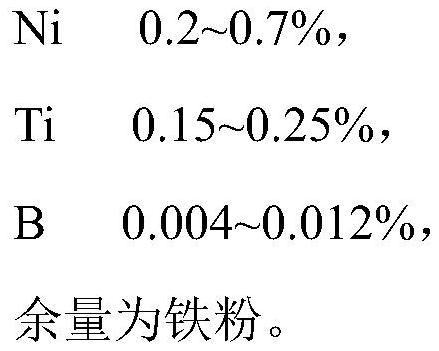

[0047] The composition and dosage of the drug core are shown in Table 2.

[0048] The composition and consumption % of table 2 medicine core

[0049]

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com