Film plating device for preparing TCO (Transparent Conductive Oxide) film and film plating method

An oxide thin film, transparent oxide technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low coating quality and high coating cost, achieve high-speed deposition rate and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

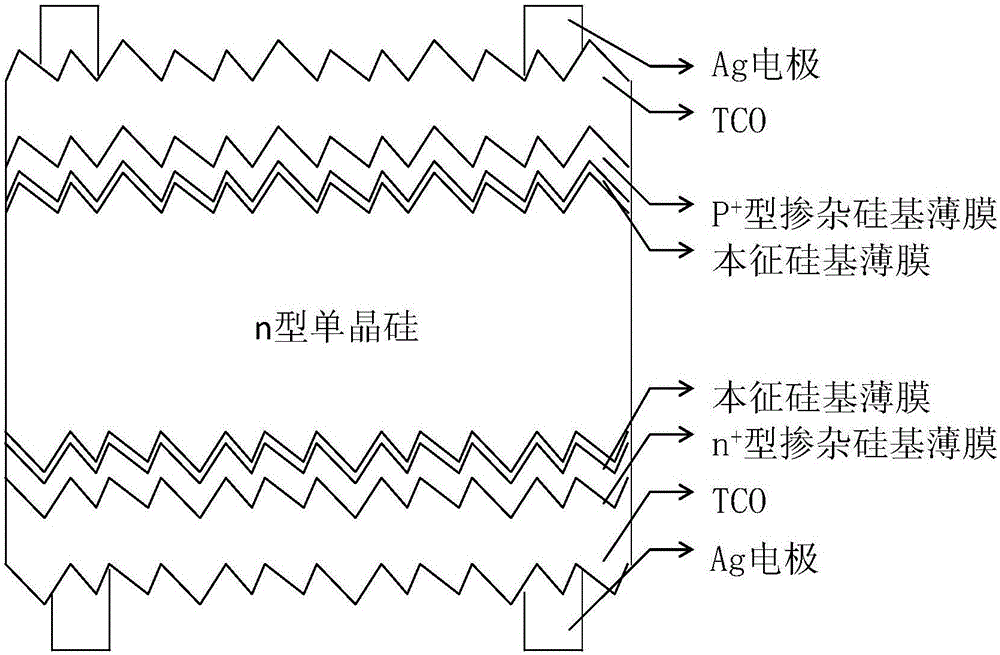

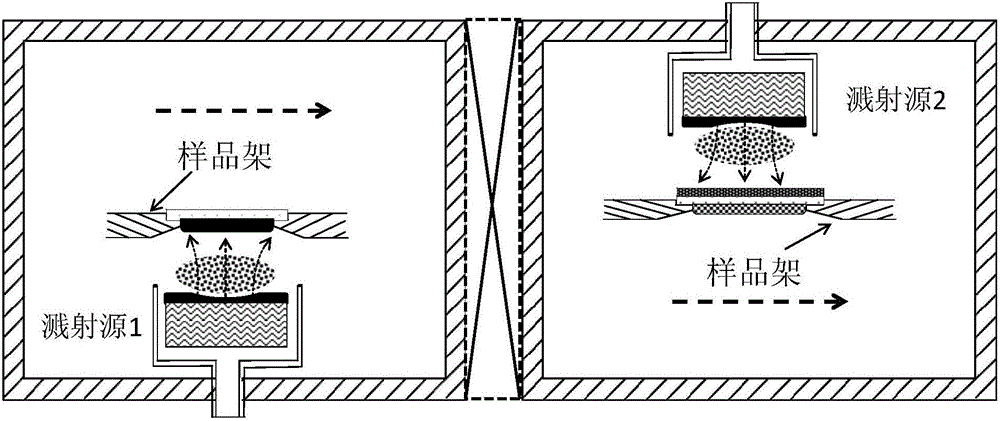

[0044] This embodiment describes the equipment and method for continuously fabricating low-damage, high-quality TCO thin film stacks on the light-receiving front surface of a photoelectric conversion device or solar cell.

[0045] see Figure 6 , which is a schematic structural view of the coating equipment used in this embodiment for producing a transparent conductive oxide thin film. The equipment consists of two parts, the ion coating source and the sputtering coating source, which are respectively installed in two independent vacuum chambers, and the two chambers are separated by a diaphragm valve. The coating direction of the ion coating source and the sputtering coating source are the same, and TCO thin film stacks of different materials or TCO thin film stacks of the same material with different structures can be continuously produced under different vacuum and gas atmosphere conditions by moving the sample holder.

[0046] In one case, the ion-plating source can be us...

Embodiment 2

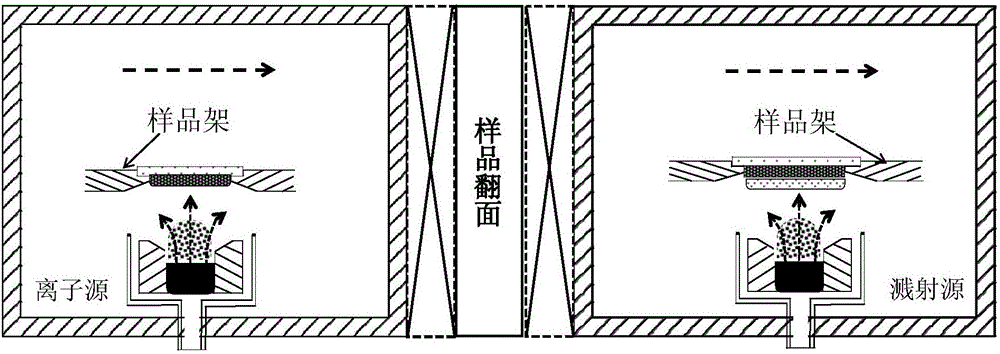

[0056] This embodiment describes the equipment and method for continuously fabricating TCO thin films or thin film stacks on both sides of photoelectric conversion devices or solar cells.

[0057] see Figure 7 , which is a schematic structural view of the coating equipment used in this embodiment for producing a transparent conductive oxide thin film. The equipment consists of two parts, an ion coating source and a sputtering coating source. The coating directions of the ion coating source and the sputtering coating source are opposite, and they are respectively installed in two independent vacuum chambers. The two chambers are separated by a partition The plate valve is separated, and the TCO film can be prepared on the front surface and the back surface of the photoelectric conversion device or solar cell in sequence without exposing the atmosphere, so as to avoid the increase of the device structure caused by the flipping of the device and the impact on the photoelectric c...

Embodiment 3

[0065] The difference between this embodiment and the second embodiment is that the sputtering coating source is combined with a radio frequency sputtering coating source and a direct current sputtering coating source.

[0066] see Figure 8 , which is a schematic structural view of the coating equipment used in this embodiment for producing a transparent conductive oxide thin film. The equipment consists of two parts, the ion coating source and the sputtering coating source, which are respectively installed in two independent vacuum chambers, and the two chambers are separated by a diaphragm valve.

[0067] As an example, the ion coating source is an RPD coating source, the coating direction is from bottom to top, the target material is tungsten-doped indium oxide (IWO), and the doping concentration of tungsten oxide is 3%.

[0068] As an example, the sputtering coating source is combined with a radio frequency sputtering coating source and a DC sputtering coating source, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com