High-strength steel electrode used for minus 50 DEG C low temperature spherical tank

A high-strength steel and welding rod technology, applied in the direction of welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of unsatisfactory weld metal, unsatisfactory low-temperature impact toughness, and heat input welding, etc., to achieve welding Easy slag removal, good fluidity and guaranteed mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

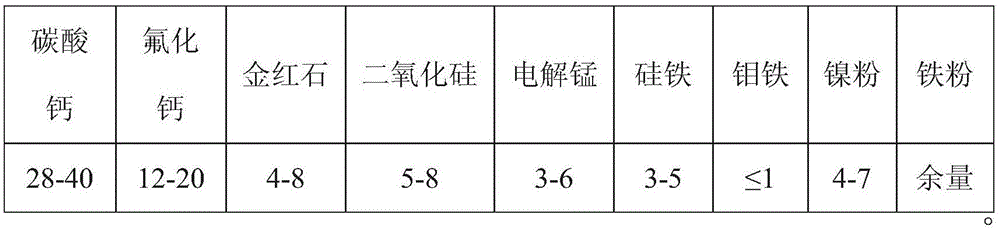

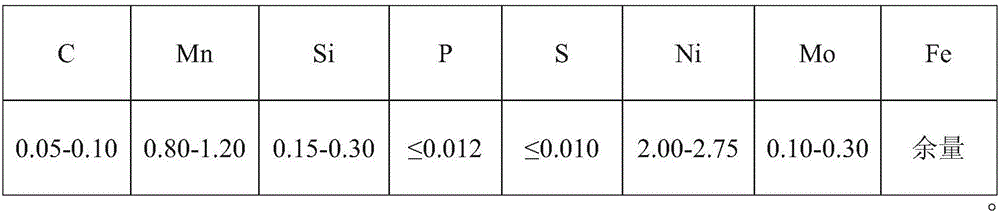

Method used

Image

Examples

Embodiment 1

[0031] The general manufacturing process in the welding rod production industry is adopted, the welding core is selected according to the requirements of the welding core composition, the raw materials of the coating are prepared in proportion, and the welding rod coating is prepared by dry mixing and wet mixing, and the welding rod coating is applied to the welding core. of forming. See Table 1-1 for solder core composition and Table 1-2 for coating composition.

[0032] Table 1-1 Weld core composition (unit: weight percentage)

[0033] C Si mn P S Fe 0.062 0.022 0.477 0.011 0.005 margin

[0034] Table 1-2 drug skin formula (unit: weight percentage)

[0035]

[0036] Test the finished electrode, and bake the electrode at 350-380°C for 1 hour before the welding test. The heat input is 15-20KJ / cm; the welding joint mechanics adopts vertical welding, the path temperature is 150-160°C, and the heat input is 30-35KJ / cm. The chemical properties ...

Embodiment 2

[0047] The general manufacturing process in the welding rod production industry is adopted, the welding core is selected according to the requirements of the welding core composition, the raw materials of the coating are prepared in proportion, and the welding rod coating is prepared by dry mixing and wet mixing, and the welding rod coating is applied to the welding core. of forming. See Table 2-1 for solder core composition and Table 2-2 for coating composition.

[0048] Table 2-1 Weld core composition (unit: weight percentage)

[0049] C Si mn P S Fe 0.058 0.025 0.484 0.010 0.004 margin

[0050] Table 2-2 Drug skin formula (unit: weight percentage)

[0051]

[0052]Test the finished electrode, and bake the electrode at 350-380°C for 1 hour before the welding test. The heat input is 15-20KJ / cm; the welding joint mechanics adopts vertical welding, the path temperature is 150-160°C, and the heat input is 30-35KJ / cm. The chemical properties a...

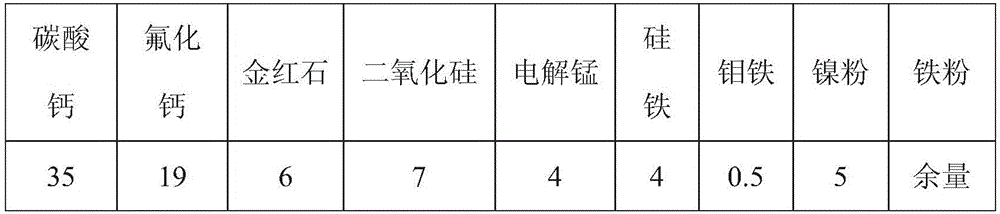

Embodiment 3

[0062] The general manufacturing process in the welding rod production industry is adopted, the welding core is selected according to the requirements of the welding core composition, the raw materials of the coating are prepared in proportion, and the welding rod coating is prepared by dry mixing and wet mixing, and the welding rod coating is applied to the welding core. of forming. See Table 3-1 for solder core composition and Table 3-2 for coating composition.

[0063] Table 3-1 Weld core composition (unit: weight percentage)

[0064] C Si mn P S Fe 0.059 0.023 0.487 0.011 0.003 margin

[0065] Table 3-2 Drug skin formula (unit: weight percentage)

[0066]

[0067] Test the finished electrode, and bake the electrode at 350-380°C for 1 hour before the welding test. The heat input is 15-20KJ / cm; the welding joint mechanics adopts vertical welding, the path temperature is 150-160°C, and the heat input is 30-35KJ / cm. The chemical properties ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com