Novel water heater bucket

A technology for water heaters and buckets, applied in fluid heaters, heating devices, solar thermal devices, etc., can solve the problems of high cost and easy water leakage of welded joints, and achieve the effects of low cost, extended service life, and easy manufacturing

Inactive Publication Date: 2012-01-11

何淑鹏

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a new type of water heater bucket. This new type of water heater bucket not only has the advantage of lower cost, but also has the joint joints that are not easy to rust and leak, and can effectively overcome the existing water heater tanks. Defects that are relatively high and the weld joints are prone to water leakage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

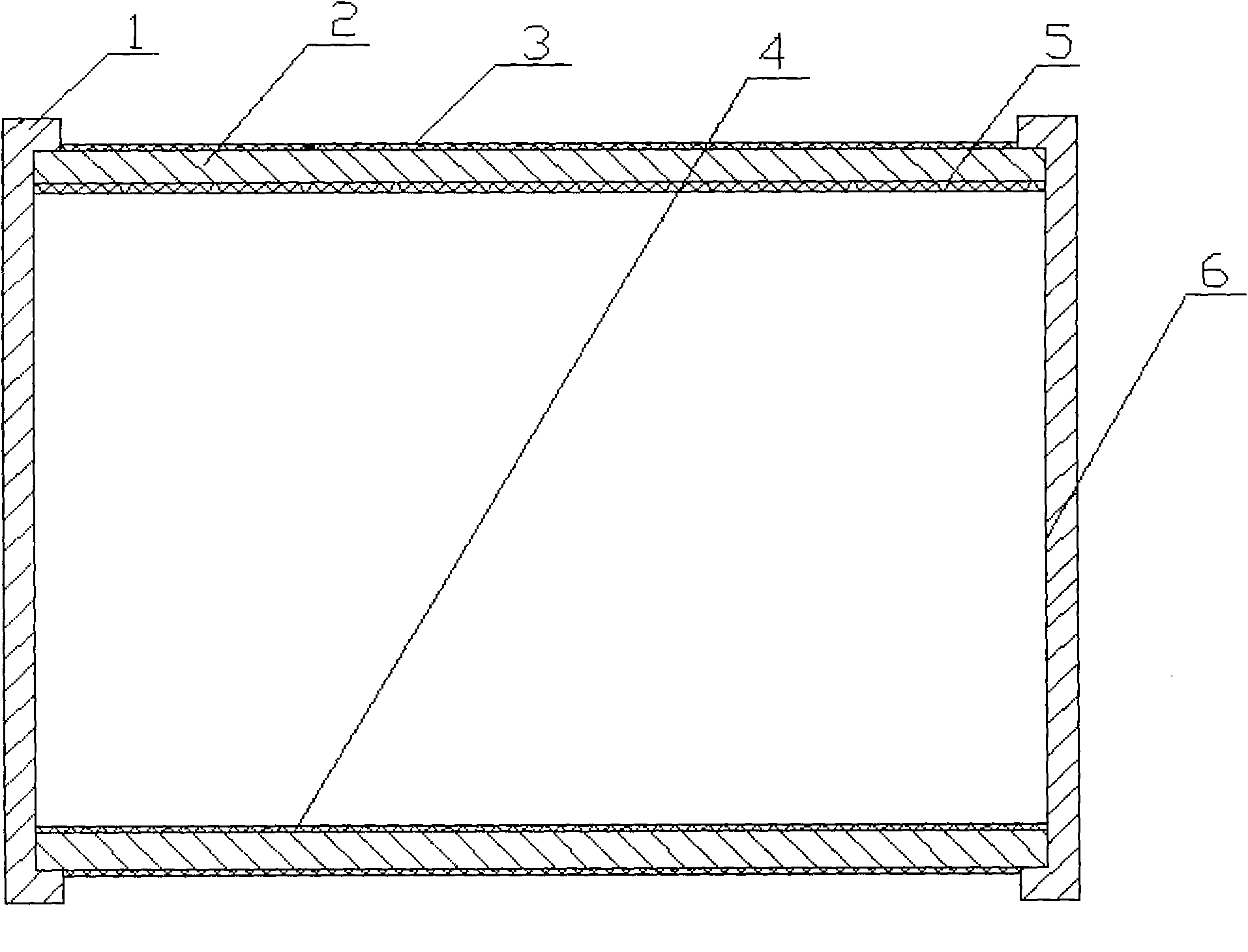

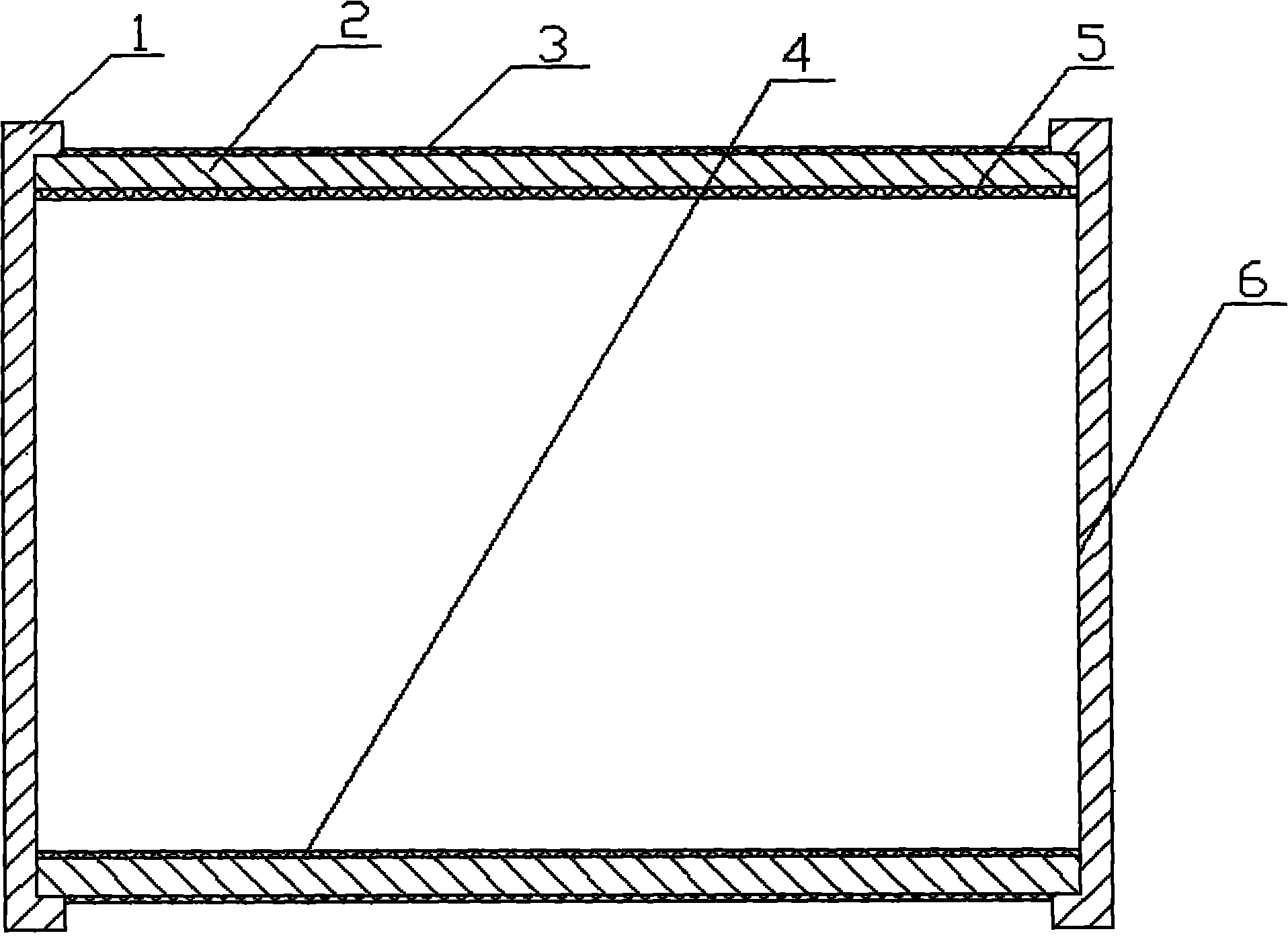

[0009] The water heater bucket has a head (1) and a barrel (2). The head (1) is fixed on both ends of the barrel (2) and the middle bonding layer (5) by welding, and the enamel layer (4) It is sintered on the inner surface of the water bucket (6), and the sprayed layer (3) is covered on the outer surface of the water bucket (6).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a novel water heater bucket which comprises an end closure, a bucket body, a plastic spraying layer, an enamel layer, a meso-position combining layer and a bucket, wherein the water heater bucket is provided with the end closure and the bucket body, the end closure is fixed at two ends of the bucket body and the meso-position combining layer in a welding manner, the enamel layer is sintered on the inner surface of the bucket, and the plastic spraying layer covers the outer surface of the bucket. Because the bucket is made of a common low-carbon steel metal material, thus the novel water heater bucket has the advantages of good processing property and easiness in manufacture, especially lower cost; and because the enamel layer is sintered on the inner surface of the bucket, the plastic spraying layer covers the outer surface of the bucket, the bucket can be effectively protected so that the bucket and welded joints are prevented from being corroded, thus water leakage is avoided and the service life of a water heater is prolonged.

Description

Technical field [0001] The invention relates to a water heater bucket, in particular to a new type water heater bucket, belonging to the technical field of water heaters. Background technique [0002] With the improvement of people’s living standards, solar water heaters and electric water heaters continue to enter people’s lives. People often find in their lives that after the water heater is used for a period of time, the water-containing cylinder will leak. After analysis and It is observed that the water leakage of the bucket is mainly at the weld joint of the cylinder. The main reasons for this phenomenon are: first, there is a problem with the quality of the weld, and the second is the location of the weld during the welding process. The metal structure of the metal has changed and it is prone to rust. After long-term use, it will gradually rust and cause water leakage. Summary of the invention [0003] The purpose of the present invention is to provide a new type of water ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F24J2/46F24H9/00

CPCY02E10/40

Inventor 何淑鹏

Owner 何淑鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com