Preparation method of flame-retardant high-performance flexible explosion-proof coating

A high-performance, flame-retardant technology, used in coatings, fire-retardant coatings, polyurea/polyurethane coatings, etc., can solve the problems of flame retardancy, physical properties, physical properties, and viscosity of materials. The effect of excellent mechanical properties, improved interface properties, and good process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

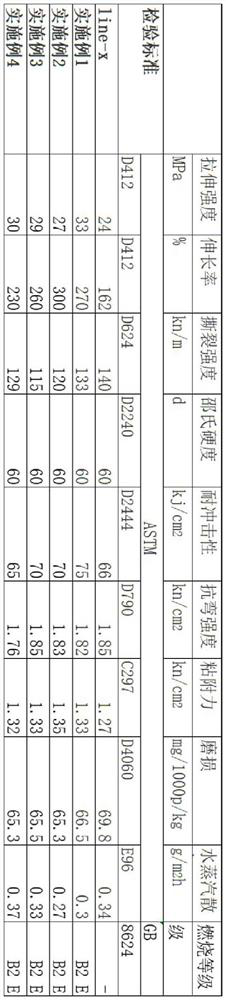

Examples

preparation example Construction

[0043] A method for preparing a flame-retardant high-performance flexible explosion-proof coating, comprising the steps of:

[0044] Step 1: Prepare component A, modify the isocyanate in an inert environment, the method is to heat the polyether resin to 100 ℃ ~ 110 ℃, dehydrate under vacuum -0.1MPa for 2 ~ 3 hours, release the vacuum, and cool down to 60 ℃ Next, add isocyanate and react at 85-95°C for 1.5-2 hours. After the reaction is over, measure the -NCO value and discharge the material, and filter to obtain component A of flame-retardant modified isocyanate; wherein: the mass ratio of isocyanate and polyether resin is 150-250: 50-100.

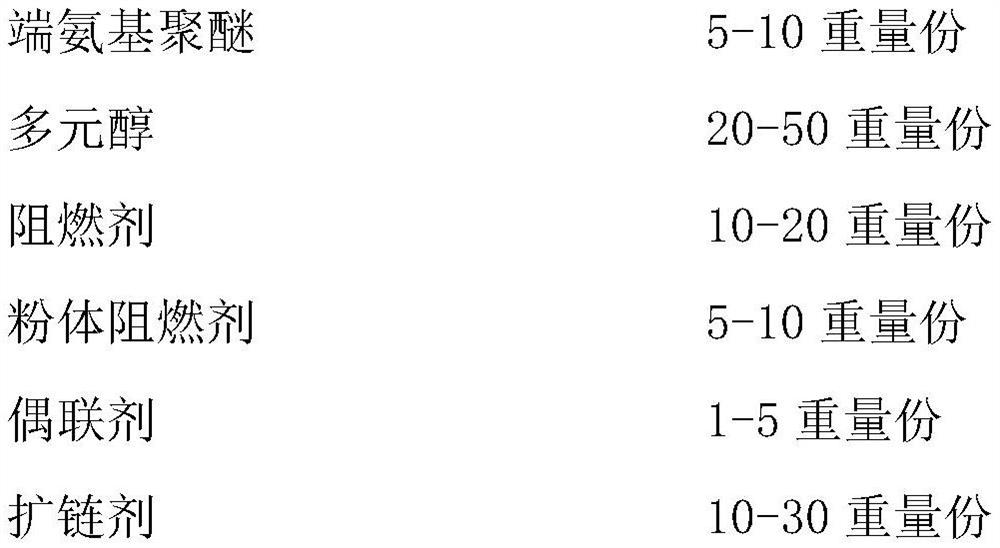

[0045] Step 2: Component B consists of amino-terminated polyether 5-10, polyol 20-50, flame retardant 10-20, powder flame retardant 5-10, coupling agent 1-5, chain extender 10-30 , Catalyst 1-5, water remover 1-5 and color paste 1-5 are stirred and composed, added in sequence, stirred and dispersed evenly, and obtained by filtration.

[...

Embodiment 2

[0059] The preparation process of a flame-retardant high-performance flexible explosion-proof coating in this embodiment is as follows:

[0060] Step 1: Synthesis of component A of flame-retardant high-performance flexible explosion-proof coating material:

[0061] According to the weight ratio, put 100 parts of bisphenol A polyether polyol BEO-10 into a reactor protected by nitrogen, heat it to 105°C under stirring, dehydrate it under vacuum -0.1MPa for 2 hours, release the vacuum, and cool down to Add 100 parts of IPDI below 60°C, and react at 100°C for 2 hours. After the reaction is completed, measure the -NCO value to 21%, discharge, filter and pack.

[0062] Step 1: Preparation of component B:

[0063] Weigh each component according to the order of the formula, 20 parts of amino-terminated polyether D2000, 30 parts of PCL210, 20 parts of FR712, 10 parts of SFR-100, 2 parts of silane coupling agent KH550, 15 parts of chain extender ADR-4368C, 5 parts 1 part of chain ex...

Embodiment 3

[0065] The preparation process of a flame-retardant high-performance flexible explosion-proof coating in this embodiment is as follows:

[0066] Step 1: Synthesis of component A of flame-retardant high-performance flexible explosion-proof coating material:

[0067] According to the weight ratio, put 10 parts of phthalic anhydride polyester polyol PS-3152 and 60 parts of bisphenol A polyether polyol BEO-20 into the reactor with nitrogen protection, heat to 105 ° C under stirring, and vacuum -0.1MPa Dehydrate at low temperature for 2 hours, remove the vacuum, lower the temperature to below 60°C, add 100 parts of TDI, react at 100°C for 2 hours, after the reaction, measure the -NCO value to 21%, discharge, filter and pack.

[0068] Step 2: Preparation of component B:

[0069] Weigh each component according to the order of the formula, 5 parts of amino-terminated polyether T5000, 30 parts of PTMG1000, 20 parts of FR1301, 10 parts of RM4-7081, 2 parts of silane coupling agent KH55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com