Patents

Literature

69results about How to "The smelting process is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength and high-tenacity gas shielded welding wire

ActiveCN101992365AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaManganeseMixed gas

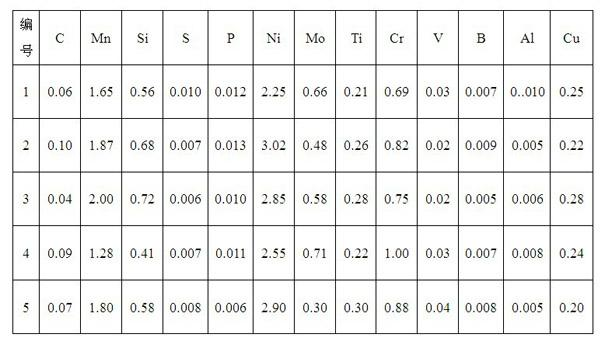

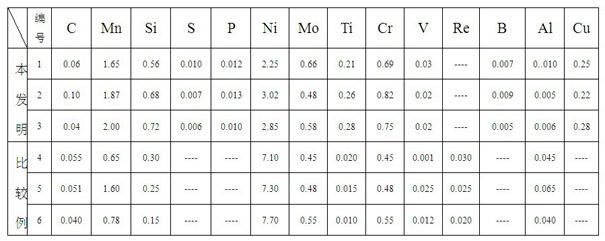

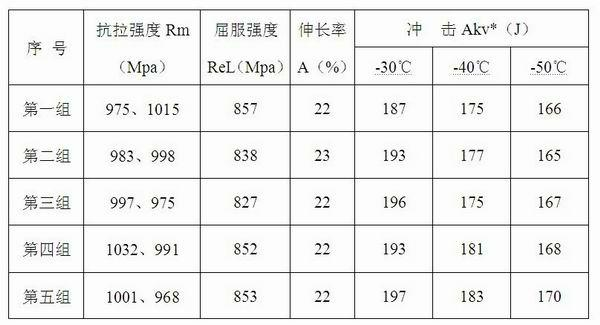

The invention discloses a high-strength and high-tenacity gas shielded welding wire. The welding wire comprises the following chemical composition in percentage by mass: 0.02 to 0.12 percent of carbon (C), 1.20 to 2.10 percent of manganese (Mn), 0.20 to 1.00 percent of silicon (Si), less than or equal to 0.010 percent of sulfur (S), less than or equal to 0.015 percent of phosphorus (P), 2.00 to 3.50 percent of nickel (Ni), 0.20 to 0.80 percent of molybdenum (Mo), 0.20 to 0.30 percent of titanium (Ti), 0.60 to 1.20 percent of chromium (Cr), less than or equal to 0.05 percent of vanadium (V), 0.005 to 0.010 percent of boron (B), less than or equal to 0.015 percent of aluminum (Al), less than or equal to 0.35 percent of copper (Cu) and the balance of iron (Fe). The welding wire is used for welding steels of a strength grade of between 850 and 950MPa; and under the protection of a mixed gas (80 percent of argon (Ar) and 20 percent of carbon dioxide (CO2)), the weld metal tensile strength of the welding wire is more than or equal to 850MPa, the yield strength is more than or equal to 720MPa, the elongation is more than or equal to 22 percent, and the low-temperature impact toughness Akv is more than or equal to 181J at the temperature of -30 DEG C, or more than or equal to 175J at the temperature of -40 DEG C, or more than or equal to 162J at the temperature of -50 DEG C.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

Welding wire prepared from aluminum alloy in use for welding

InactiveCN101092007AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaUltimate tensile strengthImpurity

The invention relates to welding using aluminum alloy welding wire that includes Mg 4.0-6.0wt%, Mn 0.03-0.20wt%, Cr 0.05-0.10wt%, Si less than or equal to 0.25wt%, Fe is less than or equal to 0.40wt%, Cu is less than or equal to 0.20wt%, Zn is less than or equal to 0.20wt%, Be is less than or equal to 0.0003wt%, Ti 0.10-0.15wt%, and the rest is Al and other impurities. The advantages of the invention are stable technology, good extending capacity of welding wire, good welding technology, high intension, and good corrosion resistance.

Owner:哈焊所华通(常州)焊业股份有限公司

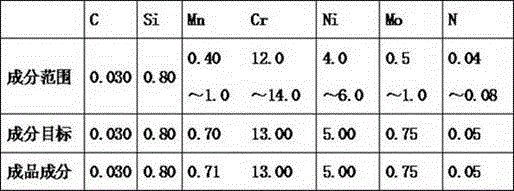

Austenitic stainless steel gas shield welding wire for vehicle

ActiveCN101100021AExcellent rolling and wire drawing propertiesGood welding performanceWelding/cutting media/materialsSoldering mediaIn vehicleWeld seam

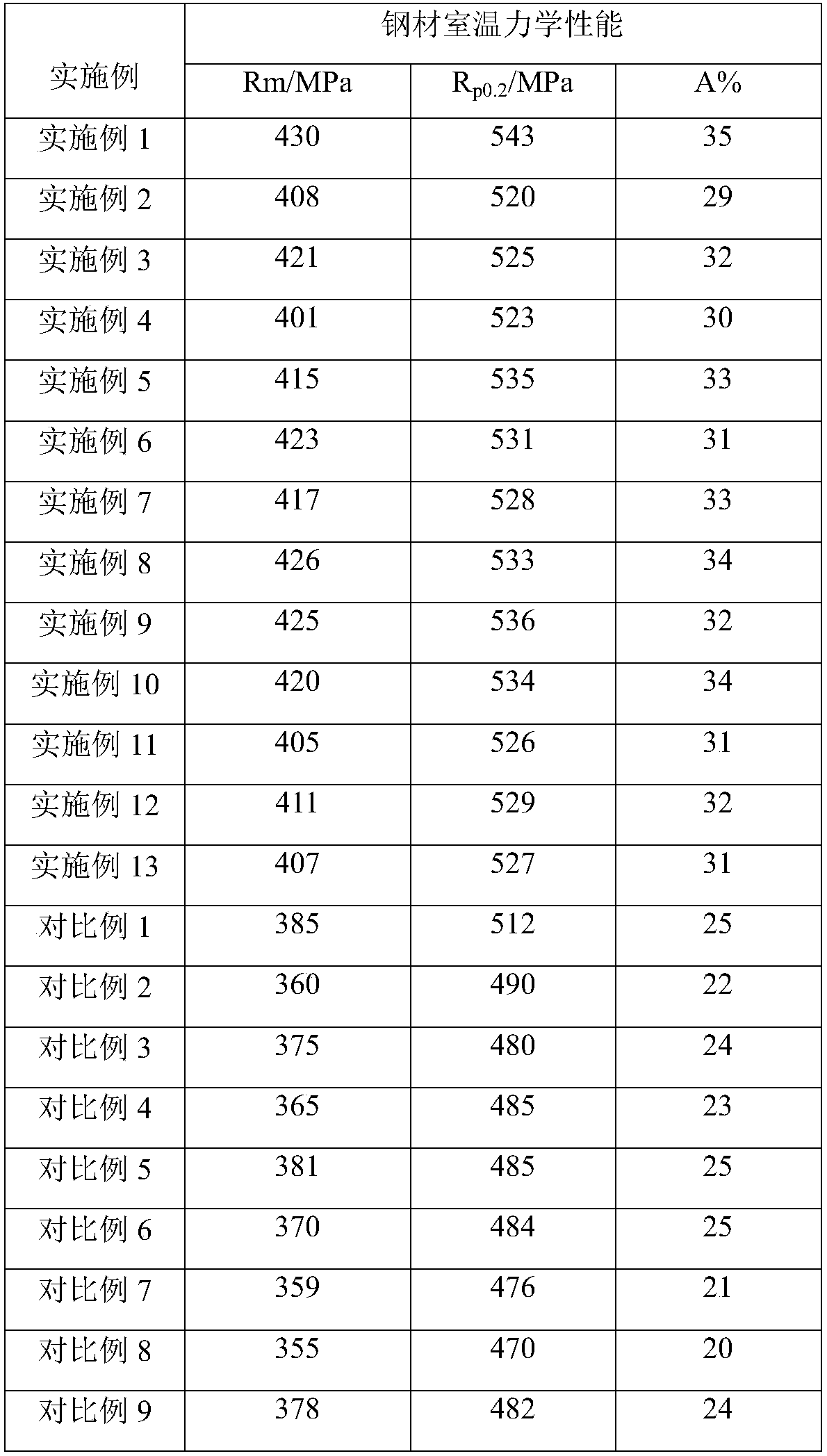

The present invention relates to austenitic stainless steel welding wire for gas protected welding in vehicle. The austenitic stainless steel welding wire has the chemical composition comprising C not more than 0.03 wt%, Si 0.50-0.90 wt%, Mn 1.00-2.50 wt%, P not more than 0.025 wt%, S not more than 0.015 wt%, Ni 9.0-14.0 wt%, Cr 19.5-24.5 wt%, and Fe and inevitable impurity for the rest. The austenitic stainless steel welding wire produced through smelting, rolling, drawing and other steps has excellent performance, including excellent welding performance, is applied for welding steel of 500-700 MPa strength to form weld seam with high strength, high toughness and high corrosion resistance.

Owner:哈焊所华通(常州)焊业股份有限公司

High-strength and high-toughness automatic submerged arc welding wire with weathering resistance

InactiveCN101537549AGood atmospheric corrosion resistanceGood joint performanceWelding/cutting media/materialsSoldering mediaWeather resistanceChemical composition

The invention relates to a high-strength and high-toughness automatic submerged arc welding wire with weathering resistance and mainly aims at overcoming disadvantages of poor atmospheric corrosion resistance, high production cost and the like of the existing submerged arc welding materials. In term of technical measures, the welding wire is made from the following chemical components by weight percent: C: 0.05-0.12, Si: 0.01-0.10, Mn: 1.50-2.1. S: not more than 0.015, P: not more than 0.020, Ni: 0.20-0.60, Cr: 0.20-0.50, Cu: 0.25-0.50, Ti: 0.05-0.16, B: 0.002-0.010, Als: 0.001-0.015, Fe and other unavoidable impurities. The welding wire is matched with a basic sintered flux for welding, a weld joint has excellent atmospheric corrosion resistance and comprehensive mechanical properties, and a deposited metal at a weld seam has tensile strength up to 560MPa and ballistic work up to 107J at -40 DEG C and up to 87J at -50 DEG C.

Owner:武钢集团有限公司

Method for precisely controlling nitrogen content in nitrogen-containing steel smelting in vacuum induction furnace

ActiveCN105779688AStable nitriding rateIncrease nitrogen pressureElectric furnaceAlloy elementNitrogen atmosphere

The invention discloses a method for precisely controlling the nitrogen content in nitrogen-containing steel smelting in a vacuum induction furnace. The method comprises the following steps that an iron and steel stock of which the surface is clean is placed into a crucible of the vacuum induction furnace, and power is supplied for heating when the vacuum induction furnace is vacuumized to be below 10 Pa; after the iron and steel stock is molten down completely, the temperature is raised to 1550-1650 DEG C, and then heat preservation is performed; vacuumizing is stopped, and then argon is introduced in for alloying; after contents of other alloy elements except nitrogen reach target values, and the vacuum degree is smaller than or equal to 100Pa, nitrogen is introduced into the furnace; after the pressure of nitrogen in the furnace reaches a preset value, inflation is stopped, and nitrogen alloying is performed in a nitrogen atmosphere in the furnace by maintaining a certain gas nitriding time period; after nitrogen alloying is finished, the temperature of molten steel is adjusted; and nitrogen is introduced in the furnace again, and after the pressure in the furnace is increased to 10000-20000 Pa, pouring is performed, so that an ingot casting which is precise in content and compact and uniform in inner part is obtained. The method is applicable to smelting of steel types of which the nitrogen content is 0.005%-0.05%; by utilizing the method, the nitrogen content in steel can be precisely controlled in a range of a target value + / -5PPm; and the molten steel is high in cleanness, and the ingot casting is compact and uniform.

Owner:HEBEI IRON AND STEEL

Method for smelting high-titanium liquid iron by utilizing converter

ActiveCN103614508AThe smelting process is stableGuaranteed dephosphorization rateManufacturing convertersAlkalinitySmelting process

The invention discloses a method for smelting high-titanium liquid iron by utilizing a converter. The method is mainly used for smelting the high-titanium liquid iron with the titanium mass percentage of 0.3 to 0.5 percent by utilizing the converter. By adopting a double-slag process, the binary basicity of the furnace slag on the preliminary smelting stage of the converter is 0.8 to 1.2, the mass fraction of TFe is 15 to 25 percent, the temperature of a smelting pool is 1370 to 1420 DEG C, and the slagging quantity can reach 50 to 60 percent, so that the problem that the melting point of the furnace slag is increased because the titanium in the liquid iron is oxidized and enters the furnace slag can be maximally reduced; the decarbonization is carried out according to the conventional converter smelting process. By adopting the production process, the melting point of the furnace slag on the preliminary smelting stage can be lowered, the mobility of the furnace slag is good, the overall phosphorus removal rate can reach more than 85 percent, and the splashing can be avoided.

Owner:SHOUGANG CORPORATION

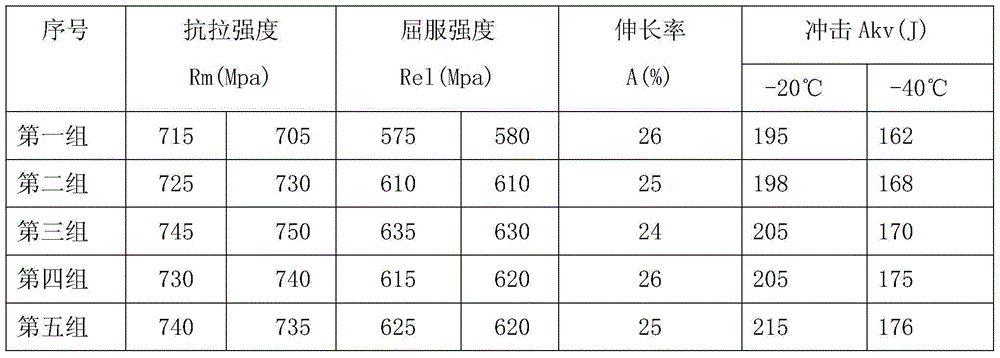

High-strength solid wire made of weathering resistant steel through gas shielded welding

ActiveCN103600178AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaChemical compositionWeather resistance

The invention discloses a high-strength solid wire made of weathering resistant steel through gas shielded welding. Chemical compositions of the solid wire include, by weight percentage, 0.05 to 0.15 of C, 1.65 to 2.10 of Mn, 0.40 to 0.80 of Si, smaller than or equal to 0.010 of S, smaller than or equal to 0.015 of P, 0.25 to 0.55 of Cu, 0.90 to 1.25 of Cr, 0.65 to 0.95 of Ni, 0.12 to 0.18 of Ti, 0.02 to 0.10 of Nb and the balance iron and other impurities. Deposited metal and welding connectors obtained through the solid wire have good atmospheric corrosion resistance. The solid wire has the advantages of being high in strength, high in weathering resistance and the like. Meanwhile, the solid wire has good comprehensive performance, the extension strength of the solid wire is larger than or equal to 680MPa, the yield strength of the solid wire is larger than or equal to 550MPa, the elongation of the solid wire is larger than or equal to 22%, and low-temperature impact Akv at 40 DEG C below zero is larger than or equal to 148J.

Owner:CRRC MEISHAN

A production process for carbon electrode containing scale graphite

InactiveCN1571593AReduce consumptionIncrease productionElectric discharge heatingGraphite carbonAnthracite

The invention discloses a producing technics of squama graphite carbon electrode, its material use following powder gravity percentage: 0.075-0.15mm petroleum coke powder after calcining 23-28%, 0.075-0.15mm squama graphite powder 2-8%, 0.5-4mm petroleum coke after calcining 18-23%, 4-10mm petroleum coke after calcining 11-19%, 4-10mm electric calcining anthracite 6-14%, 10-16mm petroleum coke after calcining 2-10%, warm pitch of binder 16-20%, pugging, forming, baking the above material, then machining, the carbon electrode smelt industry silicon which is produced by the invention, the yield can be improved greatly, the consuming of electrode and electric energy can be reduced, so does the producing cost.

Owner:河北顺天电极有限公司

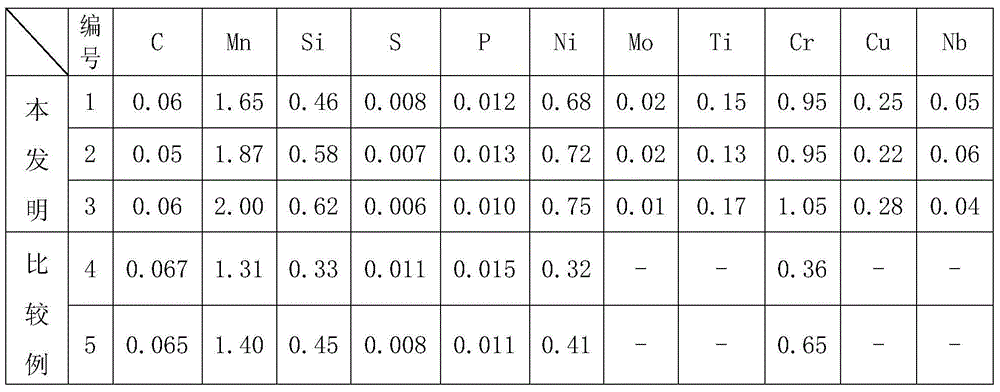

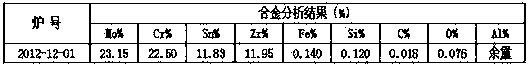

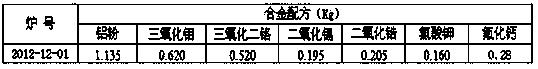

Intermediate alloy for preparation of titanium alloy and preparation method thereof

The invention discloses an intermediate alloy for preparation of titanium alloy and a preparation method thereof, relating to aluminum-molybdenum-tin (aluminum-molybdenum-tin-based) intermediate alloys for preparation of the titanium alloy and preparation methods thereof. The alloy is characterized by containing the following alloy compositions in percentage by weight: 20.0-25.0% of Mo, 20.0-25.0% of Cr, 10-15% of Sn, 10-15% of Zr and the balance of Al. According to the aluminum-molybdenum-tin-chromium-zirconium alloy disclosed by the invention, metallic compounds, which take molybdenum, tin, chromium, zirconium and the like as main ingredients, have the characteristics of good brittleness and easiness in fracture, and a titanium alloy production process is shortened and is easier in operation. According to the preparation method, oxides are taken as raw materials, so that the cost is low, the smelting process is stable, and the state of alloy forming is good; the alloying is uniform, and elemental metals are added to titanium sponge and aluminum beans in the form of intermediate alloy, so that the degree of segregation of the titanium alloy is lowered.

Owner:CHENGDE TIANDA VANADIUM IND

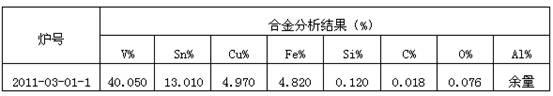

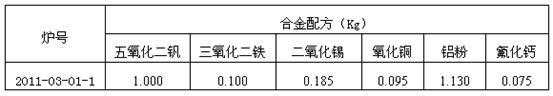

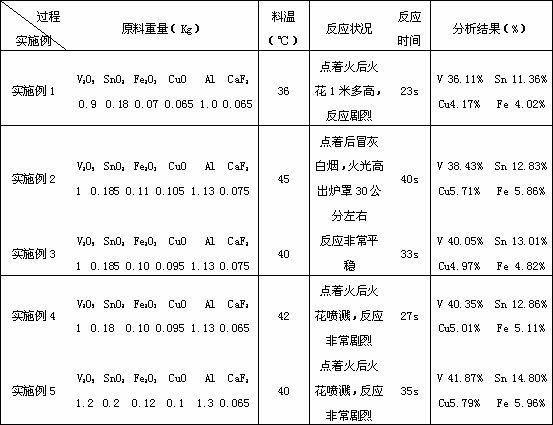

Aluminium-vanadium-tin-copper-iron intermediate alloy and preparation method thereof

The invention relates to an aluminium-vanadium-tin-copper-iron intermediate alloy and a preparation method thereof, and relates to an aluminium-vanadium-tin (aluminium-vanadium-tin-based) intermediate alloy for the preparation of the titanium alloy and a preparation method thereof. The intermediate alloy is characterized in that the alloy comprises the following components by weight percent: 36.0%-42.0% of V, 11.0%-15.0% of Sn, 4.0%-6.0% of Fe, 4.0%-6.0% of Cu and the balance Al. The preparation process adopts the metallothermics. The aluminium-vanadium-tin-copper-iron alloy is a metal compound using vanadium, tin, copper, iron and the like as main components and has the characteristics of high brittleness and easiness in breakage, thus the production process of the titanium alloy can be shortened and the operations of the production process of the titanium alloy are easier. The aluminium-vanadium-tin-copper-iron alloy uses oxides as raw materials and has low cost, the smelting process is stable, the formed state of the alloy is good; and alloying is uniform, the alloy is added in spongy titanium and aluminium shot in an intermediate alloy manner, and the degree of the segregationof the titanium alloy is reduced.

Owner:CHENGDE TIANDA VANADIUM IND

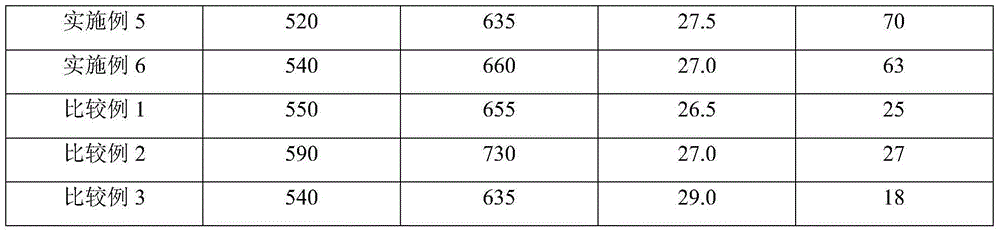

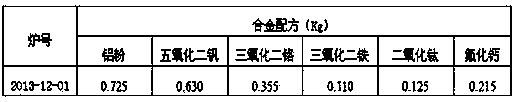

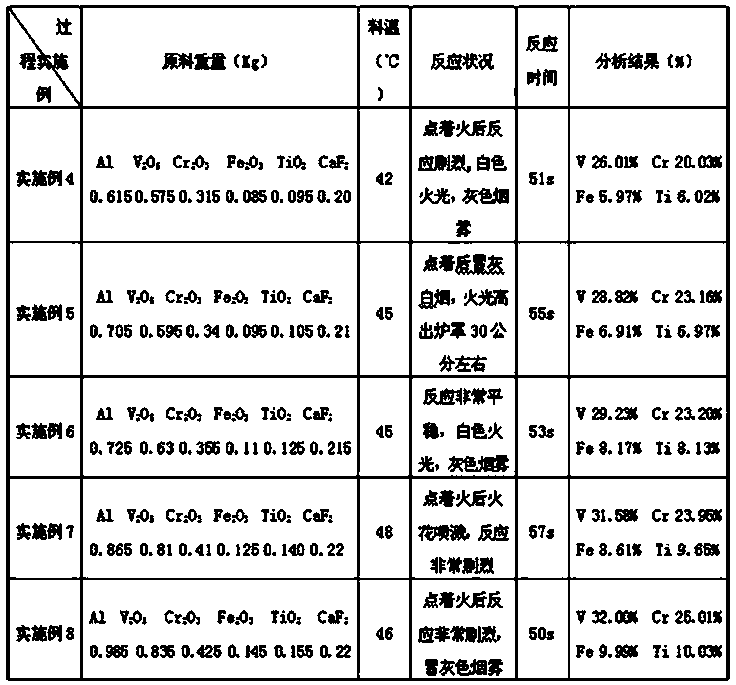

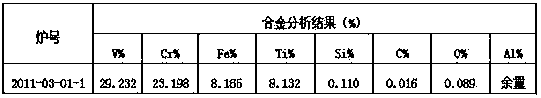

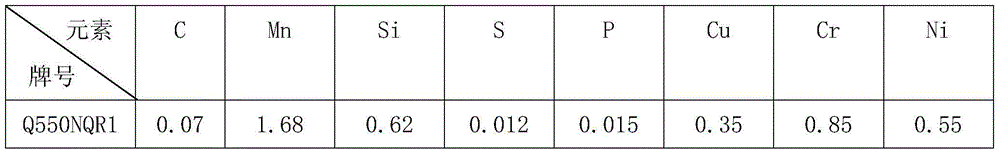

Converter steelmaking method for molten iron [Si] (0.50%)

InactiveCN108893574ANo splashingThe smelting process is stableManufacturing convertersLime productionSteelmakingPhosphor

The invention discloses a converter steelmaking method for molten iron [Si] (0.50%). The converter steelmaking method comprises the following steps: confirming objective temperature, objective carbon,final phosphor, dephosphorizing rate and alkalinity of final residue according to different types of steel; calculating lime addition amount, dolomite addition amount, sinter addition amount and oxygen addition amount during a blowing process according to oxygen balance and heat balance; performing circular smelting in the smelting sequence of leaving residue in the converter, protecting the converter by splashing residue, adding waste steel and mixing with iron, blowing and then tapping. According to the invention, the slag amount and the process splashing phenomenon can be reduced and the consumption of lime and dolomite can be reduced without influence on the dephosphorizing rate.

Owner:SHANDONG IRON & STEEL CO LTD

Full-quantity molten iron converter smelting control method

ActiveCN109423533APrevent splashAvoid pollutionManufacturing convertersProcess efficiency improvementTemperature controlSteelmaking

The invention relates to the technical field of converter steelmaking, in particular to a full-quantity molten iron converter smelting control method. The method specifically comprises the following steps of carrying out deslagging operation, carrying out calculation of the total amount of ore and the total amount of molten iron, carrying out iron converting control, carrying out oxygen supply control, carrying out slagging control, carrying out temperature control and carrying out end point control. According to the control method, splashing in the whole-iron smelting process is avoided, thenvarious defects such as environmental pollution and metal material loss caused by splashing can be avoided, and the smooth smelting process is realized; and the end point carbon temperature hit rateof whole-iron smelting is improved, various hazards caused by end point high-temperature overoxidation are avoided, the quality is ensured, and the important significance in an iron and steel plant isachieved.

Owner:ANGANG STEEL CO LTD

High strength high tenacity high weather resistant gas protecting welding wire

InactiveCN1290661CThe smelting process is stableEasy to implementArc welding apparatusWelding/cutting media/materialsLine tubingChemical composition

Owner:武钢集团有限公司

Outside-furnace welding device and method for auxiliary electrodes of vacuum arc furnace

ActiveCN106312265ACentering accuracy is easy to controlGuaranteed coaxiality accuracyWelding/cutting auxillary devicesAuxillary welding devicesElectric arc furnaceAuxiliary electrode

The invention provides an outside-furnace welding device and method for auxiliary electrodes of a vacuum arc furnace. The outside-furnace welding device and method are used for welding between the auxiliary electrodes of the vacuum arc furnace and consumable electrodes. A consumable electrode positioning device comprises a first center frame regulation device, a second center frame regulation device and a third center frame regulation device, wherein the first center frame regulation device, the second center frame regulation device and the third center frame regulation device are arranged in a manner of spacing a certain interval and are of the same structure. An auxiliary electrode positioning device comprises a fixed shear type regulation device, a movable shear type regulation device, a guide rail, a sighting device positioning mechanism and a scale mechanism. An electrode lifting and rotating drive device comprises a first lifting type rotation device, a second lifting type rotation device and a third lifting type rotation device. The second lifting type rotation device actively rotates (is provided with a drive mechanism), and the first lifting type rotation device and the third lifting type rotation device passively rotate (are not provided with drive mechanisms except a drive roller). By means of the outside-furnace welding device and method, the cylindrical auxiliary electrodes of different specifications and cylindrical consumable electrodes of different specifications can be welded outside the vacuum arc furnace according to a certain coaxiality requirement so that the original manner for conducting welding inside the vacuum arc furnace can be replaced.

Owner:宝武特种冶金有限公司

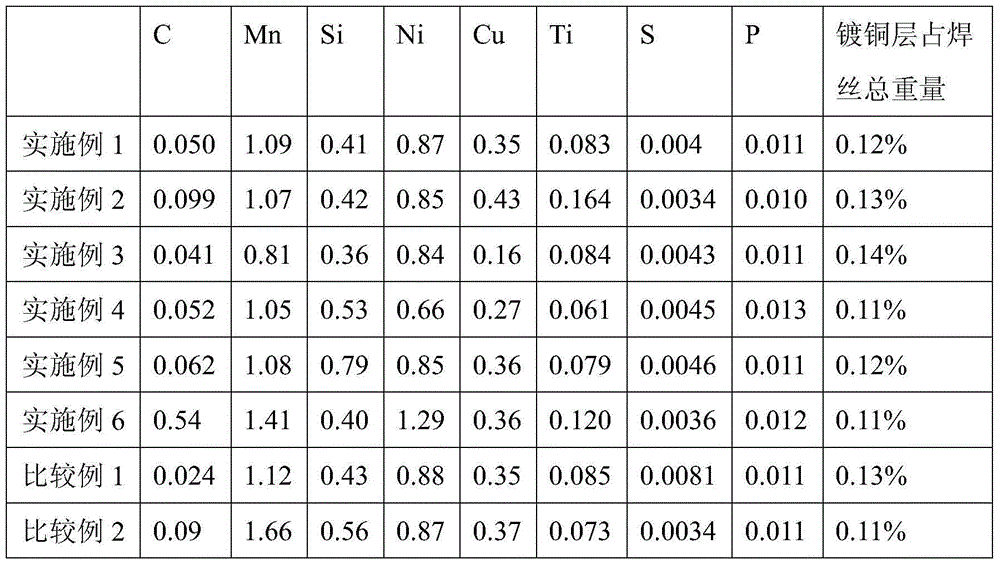

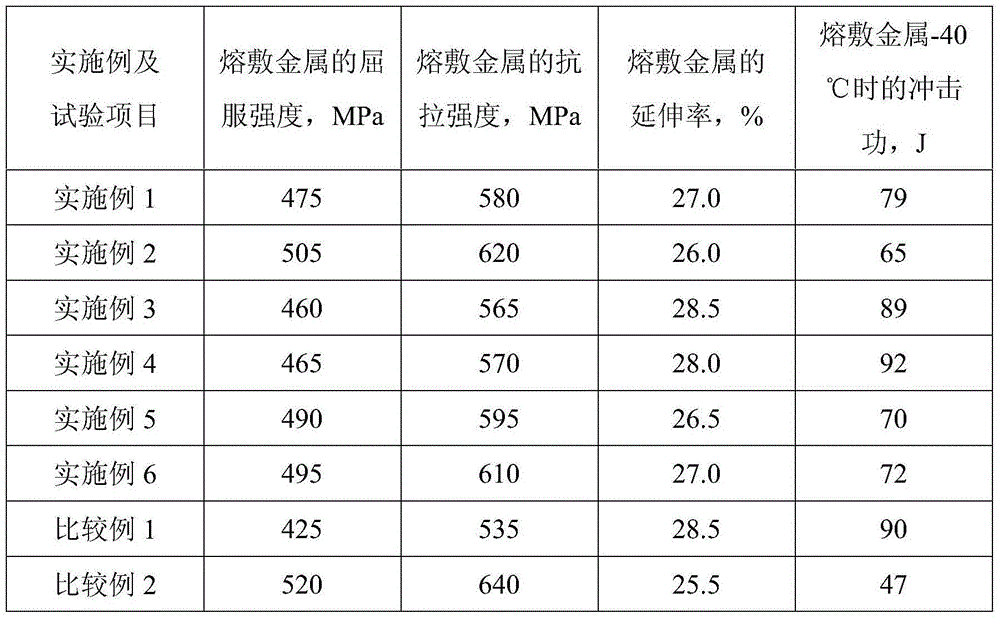

Gas protection welding wire for high-strength weathering steel and steel for gas protection welding wire

InactiveCN105195919AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaCopper platingWeathering steel

The invention provides a gas protection welding wire for high-strength weathering steel and steel for the gas protection welding wire. The steel for the gas protection welding wire comprises 0.015-0.08% of C, 0.70-1.50% of Mn, 0.20-0.80% of Si, 0.50-1.30% of Ni, 0.1-0.4% of Cu, 0.03-0.10% of Nb, 0.20% or less of Cr, 0.015% or less of S and 0.020% or less of P. The welding wire comprises 0.015-0.08% of C, 0.70-1.50% of Mn, 0.20-0.80% of Si, 0.50-1.30% of Ni, 0.15-0.50% of Cu, 0.03-0.10% of Nb, 0.20% or less of Cr, 0.015% or less of S and 0.020% or less of P. A copper plating layer is arranged on the surface of the welding wire, and the content of Cu accounts for 0.05-0.25% of the total weight of the welding wire. The welding wire is used for welding of steel of 600 MPa; when 80% Ar and 20% CO2 protection is adopted, deposited metal ReL is larger than or equal to 500 MPa, Rm is larger than or equal to 600 MPa, A is larger than or equal to 25%, and AKv at the temperature below -40 DEG C is larger than or equal to 40 J. The welding wire has the excellent welding technological performance, and is stable in welding arc, small in splashing, free of air hole, attractive in appearance and applicable to all-position welding.

Owner:ANGANG STEEL CO LTD

Electric furnace steel-making method utilizing like graphite to replace pig iron to match with carbon

InactiveCN101717840AReduce usageLow costElectric furnaceProcess efficiency improvementElectric arc furnaceGraphite

The invention discloses an electric furnace steel-making method utilizing like graphite to replace pig iron to match with carbon. The like graphite with a certain shape is used for partly or entirely replacing raw steel, and the like graphite is added by a material basket or directly added into the furnace by an overhead bunker to perform steel-making production. The invention can reduce the cost of the electric furnace steel making, and is suitable for an electric furnace steel making process.

Owner:ANYANG IRON & STEEL

Method of smelting low-phosphorus steel

ActiveCN109593907AThe smelting process is stableGuaranteed Composition IndexManufacturing convertersProcess efficiency improvementTemperature controlSteelmaking

The invention belongs to the technical field of steelmaking, and discloses a method of smelting low-phosphorus steel. The method comprises the following steps of a reladling station molten iron silicon proportioning control step, a waste steel selection and waste steel ratio control step, a converter loading amount control step, a converter blowing gun position, an oxygen supply strength and a bottom blowing flow comprehensive control step; a carbon content and a temperature control step in a smelting process, a semi-steel slag and final slag R and MgO% control step, an steel tapping slag discharging control step, as well as a steel ladle selecting and slag sticking quantity control step. According to the method of smelting the low-phosphorus steel has the advantages that parameters and procedures are optimized, under the condition that the molten iron and steel scrap are given, a qualified cast blank of a finished product which P is less than or equal to 0.005 percent can be producedfinally.

Owner:BEIJING SHOUGANG CO LTD

Al-V-Cr-Fe-Ti intermediate alloy and preparation method thereof

The invention provides an Al-V-Cr-Fe-Ti intermediate alloy and a preparation method thereof, relating to an Al-V (Al-V-based) intermediate alloy for preparing titanium alloy and a preparation method of the Al-V (Al-V-based) intermediate alloy. The Al-V-Cr-Fe-Ti intermediate alloy is characterized by being prepared from the following components in percentage by weight: 26.0-32.0% of V, 20.0-25.0% of Cr, 6-10% of Fe, 6-10% of Ti and the balance of Al. A metallothermic reduction method is adopted in the preparation process. The Al-V-Cr-Fe-Ti intermediate alloy as a metallic compound with vanadium, chromium, titanium, ferrum and the like as main components has the characteristics of good brittleness and breakability and can be used for shortening the production process of titanium alloy and ensuring that the production process of the titanium alloy is easier to operate. Oxides are used as raw materials, so that the Al-V-Cr-Fe-Ti intermediate alloy is low in cost, stable in smelting process and good in alloy formation state; in addition, the Al-V-Cr-Fe-Ti intermediate alloy is uniform in alloying and is added into titanium sponge and aluminum shots in an intermediate alloy form, so that the segregation degree of the titanium alloy is reduced.

Owner:CHENGDE TIANDA VANADIUM IND

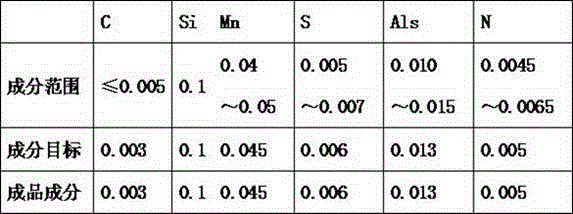

Method for smelting ultra-low carbon steel with carbon lower than or equal to 20 PPm

ActiveCN104988271AGuaranteed mechanical propertiesLow costManufacturing convertersHigh carbonMechanical property

The invention discloses a method for smelting ultra-low carbon steel with carbon lower than or equal to 20 PPm. The method comprises the steps that molten iron desulphurization is conducted through pure magnesium and slaked lime, smelting in another furnace is conducted, high carbon ferromanganese is added according to high oxygen content; argon blowing is conducted; vacuum treatment is carried out inside a RH furnace; vacuum decarburization is conducted, a low-carbon refining agent is added to carry out desulfuration and slugging, and when the vacuum treatment is conducted for 15 min, aluminum balls are added; after recycling is conducted for 3 min, silicon iron, ferromanganese, a low-carbon desulfurizing agent are added immediately, and after the recycling is conducted for 5 min, the vacuum treatment is finished; the aluminum balls are sprinkled on the surface of steel slag, and after the total content of iron oxide and MnO in the slag is lower than 5.5 wt%, a later procedure is conducted. On the premise that the mechanical property of the ultra-low carbon steel is guaranteed, the carbon can be lower than or equal to 20 PPm, parts of low-carbon ferromanganese is replaced with parts of the high carbon ferromanganese, the carbon content is lower than 0.15 wt%, parts of slugging materials and parts of a deoxidizing agent are replaced with the low-carbon refining agent and the low-carbon desulfurizing agent, the cost can be lowered by at least 30 yuan per ton of steel, the smelting process is stable, and slagging is good in the refining process.

Owner:武汉钢铁有限公司

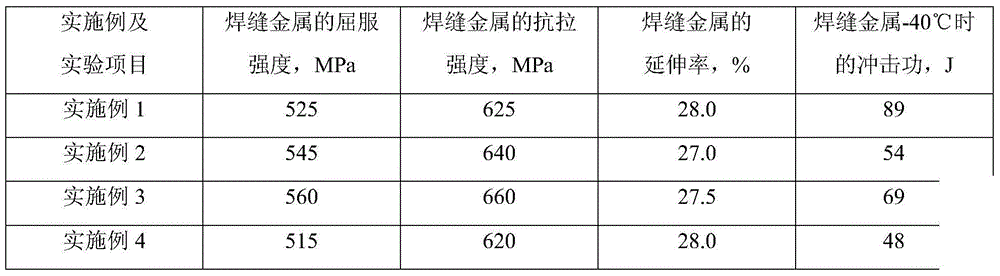

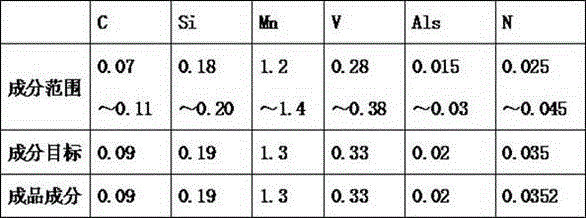

A high-strength high-toughness weather-resistant gas protection welding wire for steel

InactiveCN106312365AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaWeather resistanceSmelting process

The invention provides a high-strength high-toughness weather-resistant gas protection welding wire for steel. The welding wire steel comprises, in weight percentage, 0.03%-0.11% of C, 0.70%-1.50% of Mn, 0.25%-0.90% of Si, 0.55%-1.40% of Ni, 0.15%-0.45% of Cu, 0.05%-0.18% of Ti, not more than 0.015% of S, and not more than 0.020% of P, the balance being iron and inevitable impurities. The welding wire is used for the welding of steel of the 550 MPa strength grade; the welding wire steel smelting process is stable and easy to implement, and the technical requirements for welding high-strength, high-toughness and high-weather resistance steel are met. The gas protection welding wire has excellent welding process properties, has the advantages of stable welding arcs, less splatter, zero gas pores and artistic formation and is suitable for all-position welding.

Owner:ANGANG STEEL CO LTD

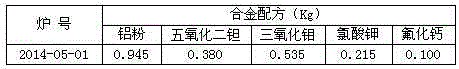

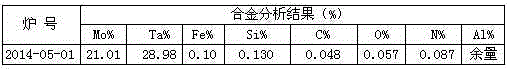

Aluminum-tantalum-molybdenum intermediate alloy and preparing method thereof

The invention relates to an aluminum-tantalum-molybdenum intermediate alloy and a preparing method thereof, in particular to an intermediate alloy for titanium alloy production and a preparing method thereof. The intermediate alloy is characterized by comprising, by weight, 27.0% to 32.0% of Ta, 18.0% to 23.0% of Mo, and the balance of Al; metallothermic reduction is adopted in preparation. The intermediate alloy is a metallic compound comprising mainly tantalum, molybdenum and aluminum and features crispiness and breakage proneness; the production process of the titanium alloys is shortened; the production of the titanium alloys is easier to operate. By the use of oxides as raw material, the cost is low, the smelting process is stable, and the alloy is in good formation state; alloying is uniform; by adding the intermediate alloy into titanium sponge and aluminum shots, segregation degree of the titanium alloys is lowered.

Owner:CHENGDE TIANDA VANADIUM IND

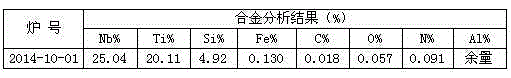

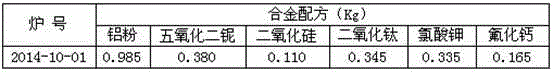

Al-Nb-Si-Ti intermediate alloy and preparation method thereof

The invention relates to an intermediate alloy for producing titanium alloy and a production method thereof, in particular to an Al-Nb-Si-Ti intermediate alloy and a preparation method thereof. The Al-Nb-Si-Ti intermediate alloy is characterized by comprising, by weight, 22.0% to 28.0% of niobium, 4.0% to 6.0% of silicon, 18.0% to 22.0% of titanium and the balance of aluminum. The preparation method is characterized in that metal thermo-reduction is used during the preparation process. The Al-Nb-Si-Ti intermediate alloy, a metallic compound mainly composed of niobium, silicon, titanium and aluminum, has the advantages that the brittleness is good, the breaking is easy, the production process of the titanium alloy is shortened, and the production process of the titanium alloy is easier to operate; oxide serves as raw material, the cost is low, the smelting process is stable and the forming state of the alloy is good; the alloy in the intermediate alloy form is added into sponge titanium and aluminum shot, and the segregation degree of the titanium alloy is reduced.

Owner:CHENGDE TIANDA VANADIUM IND

Sintering method for silicon manganese alloy dust

The invention provides a sintering method for silicon manganese alloy dust. According to the method, high temperature resistant coke powder used as a sintering adhesive of manganese mineral powder and dust and a plant fiber serving as combustion improver are sintered at the temperature of 800-1,200 DEG C to obtain massive porous sintered products. The finished product has high mechanical strength, the situations of dusting in the sintering process and massive dust generation in the melting process can be avoided. The sintering method is a good method for treating dust and fine mineral powder in manganese plants, and is low in production cost and high in treatment quality.

Owner:广西敏诚矿业股份有限公司

Molten steel deoxidizing and microalloying method

PendingCN109680115AUniform composition and temperature of molten ironStable blowingManufacturing convertersElectric furnaceChemical compositionSmelting

The invention provides a molten steel deoxidizing and microalloying method. The molten steel deoxidizing and microalloying method comprises the following steps of blowing oxygen to the top of a top-bottom combined blowing converter, blowing inert gas to the bottom of the top-bottom combined blowing converter for smelting, or blowing inert gas to the bottom of molten steel in an electric furnace for smelting; after main chemical components are qualified, blowing a deoxidizing agent to the bottom with inert gas as a carrier for refining; and when the oxygen content in the molten steel is less than or equal to 200 ppm, blowing alloyed powder into the molten steel with inert gas as a carrier for microalloying treatment, wherein the blowing amount of the alloyed powder is less than or equal to10 kg / t of the molten steel.According to the molten steel deoxidizing and microalloying method, the inert gas is blown to the bottom, and after the deoxidizing agent is blown into the molten steel todeoxidize the molten steel, the alloyed powder is blown for direct microalloying, so that components of the molten steel can be more uniform; a brand new concept is provided for directly microalloyingmicroalloy elements in the steel material production process; the microalloy elements existing in the form of solid solution can be effectively obtained out of a steel material, and thus, the steel performance is improved.

Owner:WUHAN UNIV OF SCI & TECH

Method for producing calcium ferrite from iron oxide

The invention discloses a method for producing calcium ferrite from iron oxide. The method utilizes an iron electrode to realize electric smelting, utilizes the iron electrode to produce calcium ferrite, prevents an additional component from entering into calcium ferrite, improves calcium ferrite purity and realizes better calcium ferrite actual use effects. In steel-making, through use of the calcium ferrite obtained by the method, a slagging rate is fast, dephosphorization efficiency is high, a lime use amount is reduced, fluorine-free steel-making is realized and environmental pollution is reduced.

Owner:ZHENGZHOU WHALE SPECIAL MATERIALS

Vacuum medium-frequency induction furnace smelting method for high-purity low-carbon steel

InactiveCN112375868AThe smelting process is stableImprove purityElectric furnaceShielding gasMolten steel

The invention discloses a vacuum medium-frequency induction furnace smelting method for high-purity low-carbon steel. Pure iron is adopted as a smelting raw material, shot blasting treatment is carried out on the pure iron to remove oxidized scales on the surface of the pure iron and improve the purity of the smelting raw material; vacuumizing is started before the raw material is heated, the rawmaterial is in a vacuumizing state all the time before being heated and melted, and the gas content of the smelting raw material and the gas content of the furnace body environment are reduced; and after the raw material begins to melt, vacuumizing is stopped, and argon is introduced to serve as protective gas till smelting and pouring are finished. According to the vacuum medium-frequency induction furnace smelting method for the high-purity low-carbon steel, the problem that molten steel is oxidized insufficiently due to non-vacuum smelting of a low-carbon steel medium-frequency induction furnace is solved.

Owner:BAOTOU IRON & STEEL GRP

High-strength and high-toughness automatic submerged arc welding wire with weathering resistance

InactiveCN101537549BGood atmospheric corrosion resistanceImprove joint performanceWelding/cutting media/materialsSoldering mediaWeather resistanceWeld seam

The invention relates to a high-strength and high-toughness automatic submerged arc welding wire with weathering resistance and mainly aims at overcoming disadvantages of poor atmospheric corrosion resistance, high production cost and the like of the existing submerged arc welding materials. In term of technical measures, the welding wire is made from the following chemical components by weight percent: C: 0.05-0.12, Si: 0.01-0.10, Mn: 1.50-2.1. S: not more than 0.015, P: not more than 0.020, Ni: 0.20-0.60, Cr: 0.20-0.50, Cu: 0.25-0.50, Ti: 0.05-0.16, B: 0.002-0.010, Als: 0.001-0.015, Fe and other unavoidable impurities. The welding wire is matched with a basic sintered flux for welding, a weld joint has excellent atmospheric corrosion resistance and comprehensive mechanical properties, and a deposited metal at a weld seam has tensile strength up to 560MPa and ballistic work up to 107J at -40 DEG C and up to 87J at -50 DEG C.

Owner:武钢集团有限公司

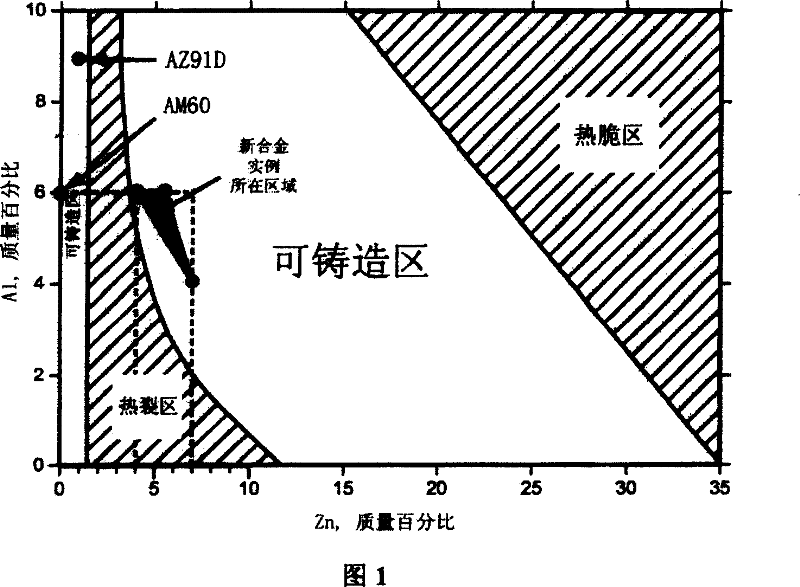

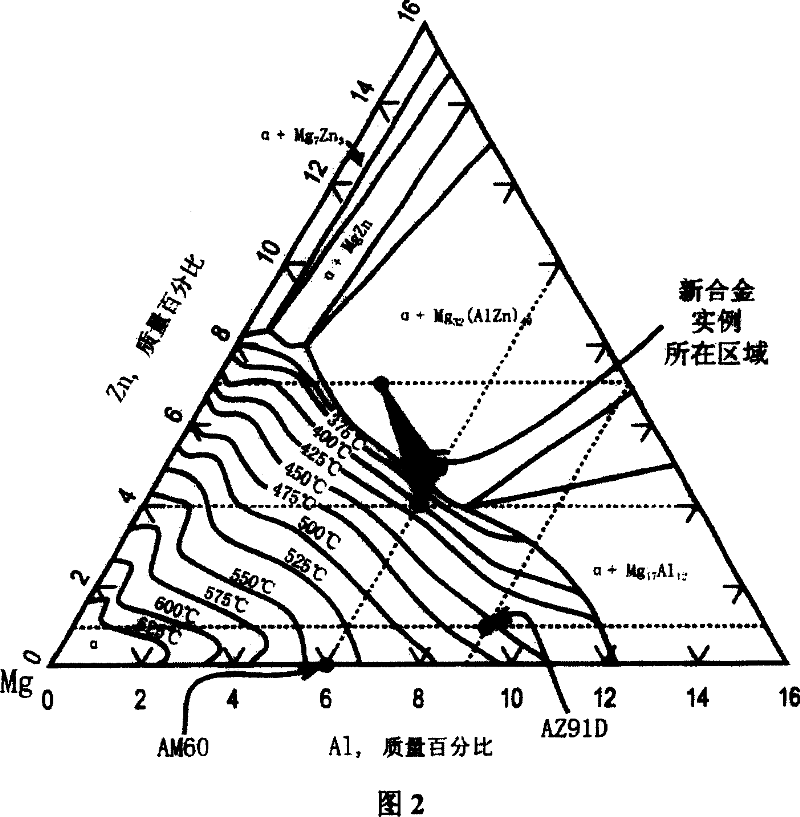

High strength and high toughness cast magnesium alloy and preparing process thereof

The present invention relates to a high strength and high toughness cast magnesium alloy and its preparation process. The compositions (wt%) are as follows:: Al3-9,Zn 3.5-9.Mn 0.15-1.0, Sb 0-2, Re 0-2. The various raw materials, covering reagent and mould are preheated first. The temperature of crucible is setup beforehand, and the preheated pure Magnesium is charged in the crucible, and then pure aluminum, Al-Mn interalloy, Mg-Re interalloy and pure zinc are also added in turn under the protection of mixed gas of CO2 + SF6, and finally Sb powder wrapped with Al foil is added. After stirring, slag removing, casting and forming, the product alloy ingot is obtained. The tensile strength sigma b reaches 260-280MPa, yielding strength sigma 0.2 >=140MPa, elongation delta 5 >= 6%, impingement work alpha k >= 14 J and Brinel hardness HB >= 70 after treatment of solid solution and aging(T6).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

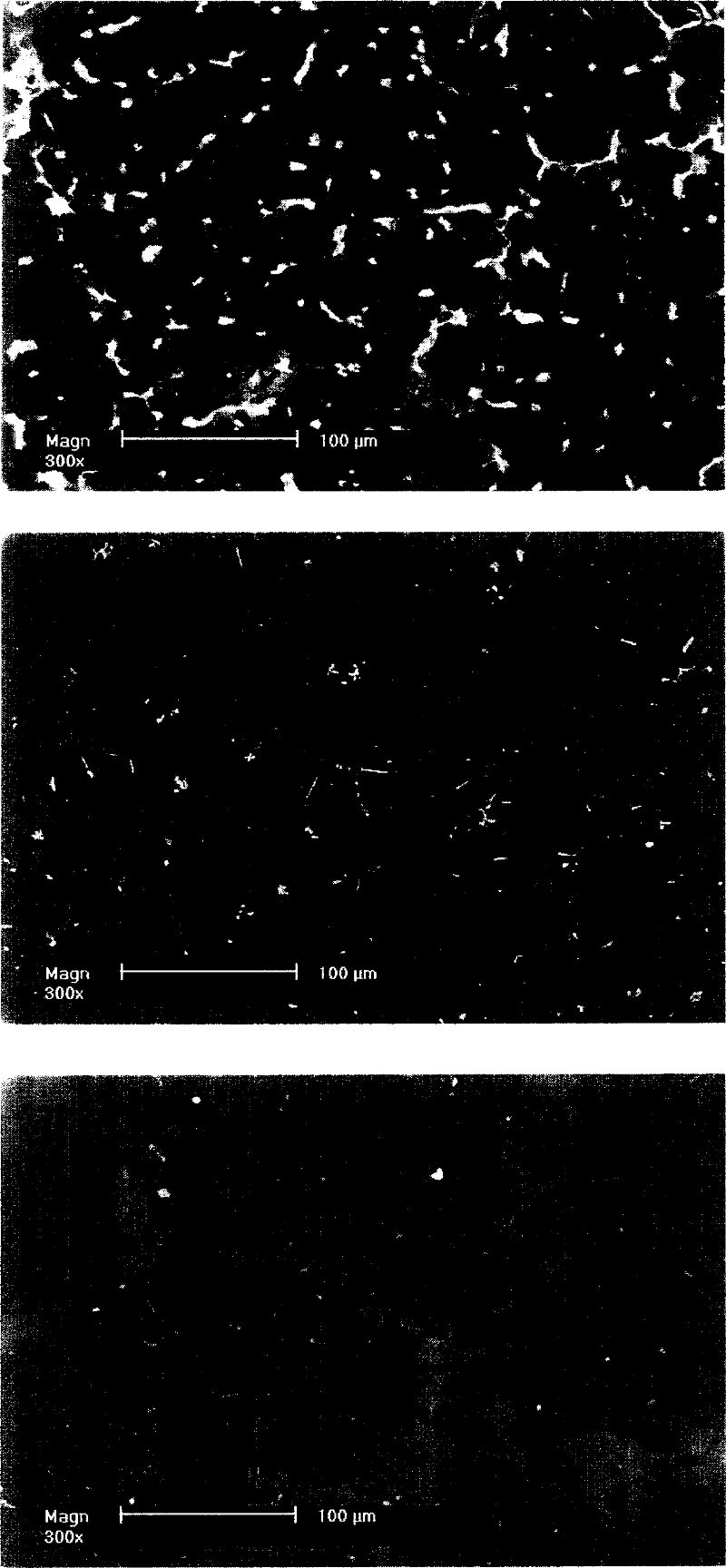

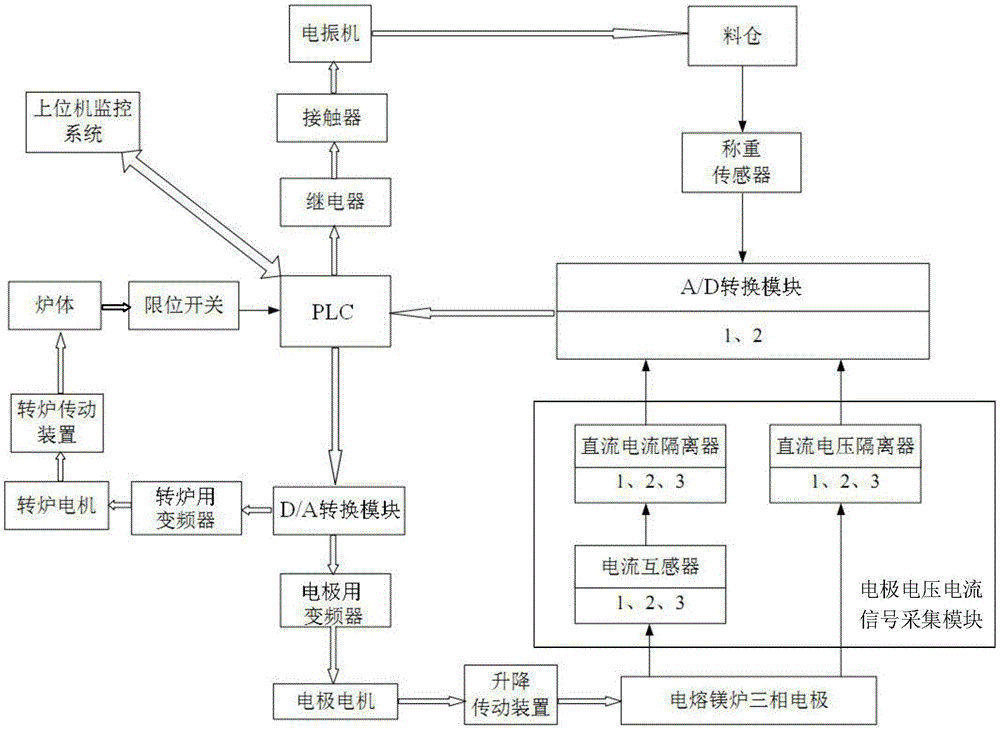

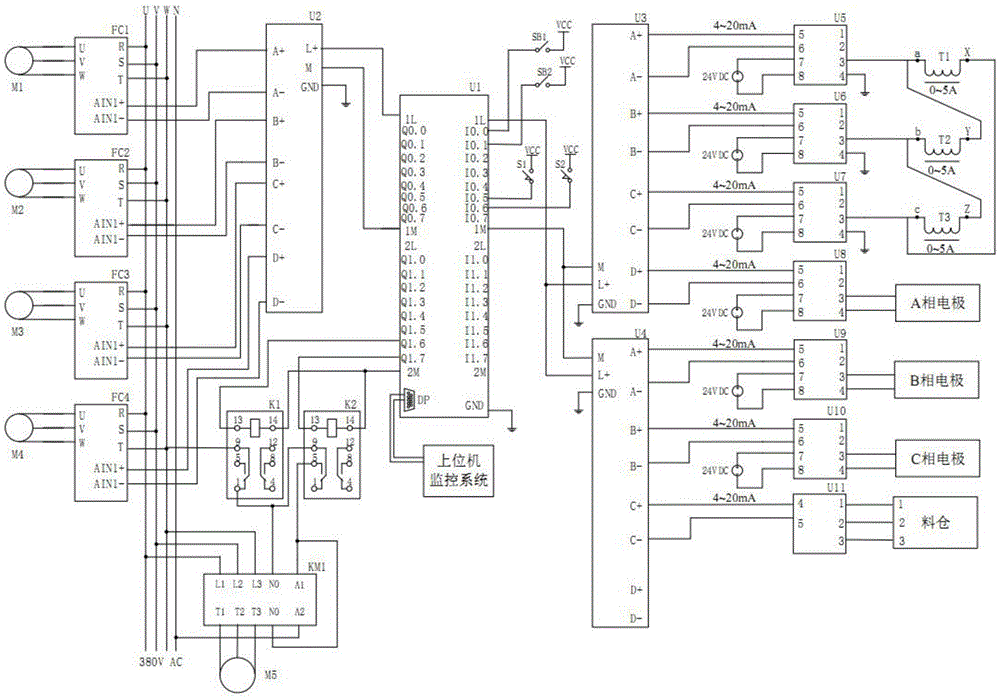

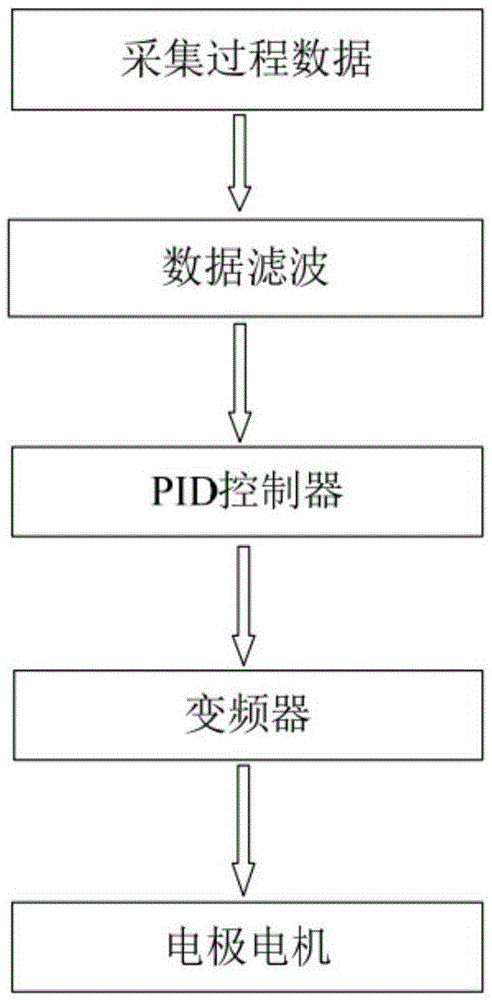

Automatic control device of rotation type electric smelting magnesium furnace and electrode current control method

ActiveCN105571340ARealize the rotation functionReduce work intensityControl devices for furnacesFrequency changerAutomatic control

The invention discloses an automatic control device of a rotation type electric smelting magnesium furnace and an electrode current control method, and belongs to the technical field of electric smelting magnesium furnace process control. The device comprises a PLC (Programmable Logic Controller), an electric vibrator, a converter motor, a converter rotating and positioning limiting switch, a converter frequency changer, an electrode motor, an electrode frequency changer, a D / A conversion module, a weighing sensor, an electrode voltage and current signal collecting module an A / D conversion module and an upper computer monitoring system. The method comprises the steps that the three-phase current and the three-phase voltage flowing through a three-phase electrode of the electric smelting magnesium furnace are collected and converted into standard analog quantity current signals; the standard analog quantity current signals are converted into corresponding digital signals to be output to the PLC; and the current control over the electrode of the rotation type electric smelting magnesium furnace is finished in the PLC. According to the method, the functions of current collecting, controlling and the like of the three-phase electrode of the rotation type electric smelting magnesium furnace can be achieved, the error between the current of the three-phase electrode and the current set value is stabilized within the allowable error range, and electric energy consumption is reduced while the product quality is guaranteed.

Owner:NORTHEASTERN UNIV LIAONING +1

Gas-shielded welding wire for welding high-strength steel

InactiveCN100423880CThe smelting process is stableEasy to implementArc welding apparatusWelding/cutting media/materialsChemical compositionHigh intensity

The invention relates to a solder which is protected by the gas for soldering high intensity and high toughness steel. The main aim solutes the question that the intensity and the toughness of the welding line of the jointing material which is protected by the gas that the high intensity and the high toughness of the new steel used doesn't match at the present. Its technique measure is that its chemic component weight percent of the solder is C 0.04~0.12,Mn 1.50~2.10,Si 0.50~1.0,Ni 0.9~2.0,Ti 0.09~0.25,B 0.002~0.010,Cu 0.10~0.55,Cr 0.20~0.60,S <=0.015,P <=0.020 and Als <=0.015,and the leavingses are Fe and other inevitable impurity substances. The solder in the present invention adopts the mixed gas (80% Ar + 20% CO2) to protect. The metal resisted drawing intensity of the welding line of the invention reaches to 805MPa and the -30 Deg. C impact power is Akv >= 127J.

Owner:武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Converter steelmaking method for molten iron [Si] (0.50%) Converter steelmaking method for molten iron [Si] (0.50%)](https://images-eureka.patsnap.com/patent_img/b91bb63e-6f3d-4dcb-be2c-2c0d3c4466dc/BDA0001701172290000041.png)

![Converter steelmaking method for molten iron [Si] (0.50%) Converter steelmaking method for molten iron [Si] (0.50%)](https://images-eureka.patsnap.com/patent_img/b91bb63e-6f3d-4dcb-be2c-2c0d3c4466dc/BDA0001701172290000042.png)

![Converter steelmaking method for molten iron [Si] (0.50%) Converter steelmaking method for molten iron [Si] (0.50%)](https://images-eureka.patsnap.com/patent_img/b91bb63e-6f3d-4dcb-be2c-2c0d3c4466dc/BDA0001701172290000051.png)